Middle insert part and glass window comprising same

An intermediate insert, glass window technology, applied in the direction of windshield, transportation and packaging, window glass installation, etc., can solve the problems of easy sliding, easy to produce abnormal noise, complex structure of the intermediate insert, etc., to reduce the price, The effect of eliminating abnormal noise and ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

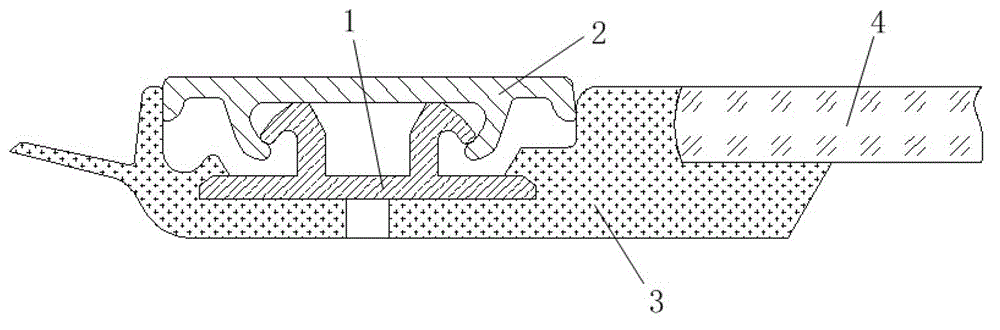

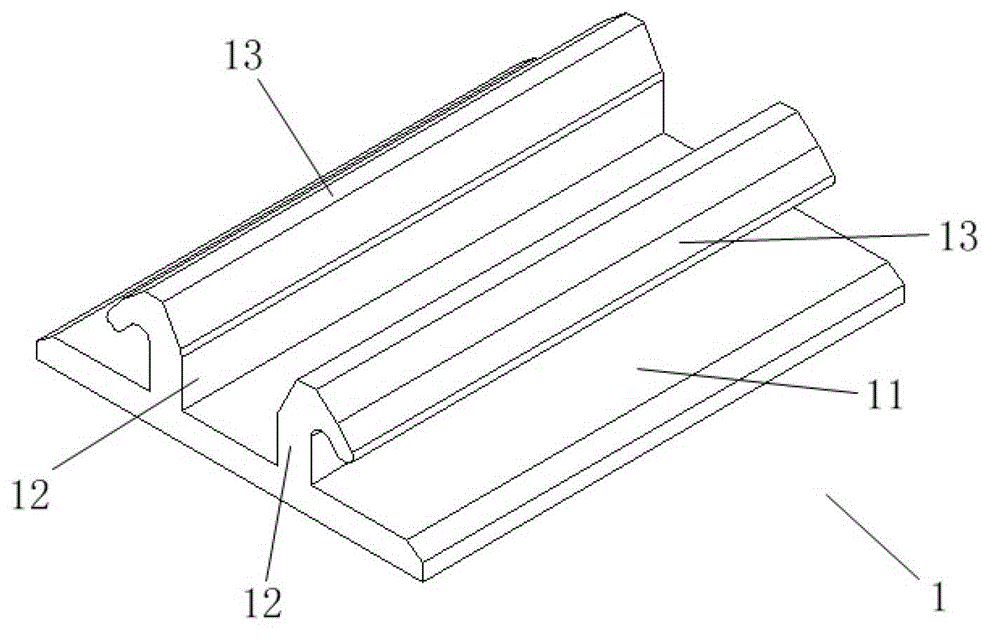

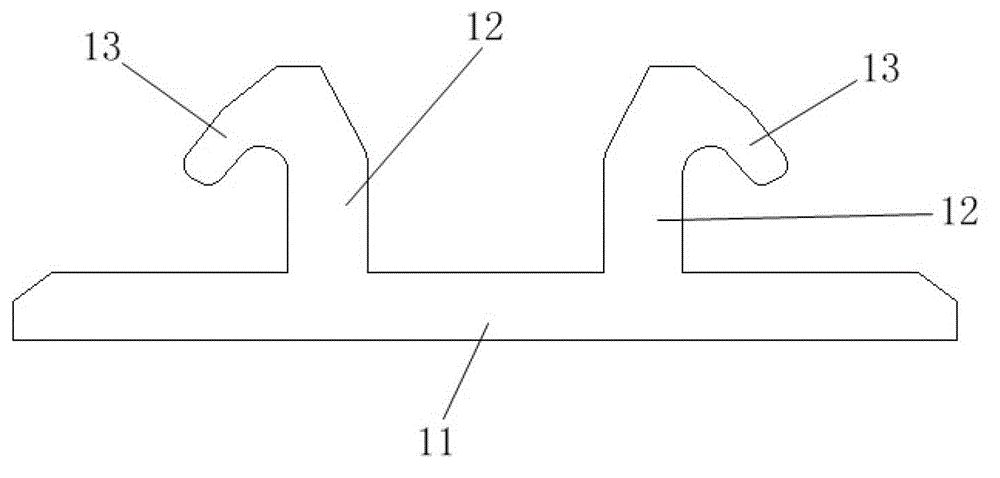

[0047] Such as Figure 7 Shown is a cross-sectional view of the first embodiment of the present invention, the intermediate insert 1 in this embodiment is used to install the bright trim 2 on the automotive glass surround 3, and the intermediate insert 1 includes a base 11 and The two fixed plates 12 arranged on the base 11 are parallel to each other. The tops of the two fixed plates 12 are provided with inclined parts 13 respectively. The outer side is inclined, and the two fixing plates 12 can be approached by two external forces in opposite directions, so that the two inclined parts 13 are inserted into the matching groove 21 of the bright trim strip 2 and locked with the matching groove 21 .

[0048] Wherein, the middle insert 1 in this embodiment is made of POM, and the adhesive block 14 arranged between the two fixing plates 11 is used to prevent the bright trim 2, especially the straight bright trim The fixed part that is freely slidable on the bounding edge 3 matched ...

Embodiment 2

[0050] Such as Figure 8 Shown is a cross-sectional view of the second embodiment of the present invention, the intermediate insert 1 in this embodiment is used to install the bright trim 2 on the automotive glass surround 3, and the intermediate insert 1 includes a base 11 and The two fixed plates 12 arranged on the base 11 are parallel to each other. The tops of the two fixed plates 12 are provided with inclined parts 13 respectively. The outer side is inclined, and the two fixing plates 12 can be approached by two external forces in opposite directions, so that the two inclined parts 13 are inserted into the matching groove 21 of the bright trim strip 2 and locked with the matching groove 21 .

[0051] Wherein, the middle insert 1 in this embodiment is made of PP, and the protrusion 15 provided on the inclined part 13 is used to prevent the bright trim 2, especially the straight bright trim The fixed part that slides freely on the side 3, a groove 22 is set in the matching...

Embodiment 3

[0053] Such as Figure 9 Shown is a sectional view of the third embodiment of the present invention, the intermediate insert 1 in this embodiment is used to install the bright trim strip 2 on the automotive glass surround 3, and the intermediate insert 1 includes a base 11 and The two fixed plates 12 arranged on the base 11 are parallel to each other. The tops of the two fixed plates 12 are provided with inclined parts 13 respectively. The outer side is inclined, and the two fixing plates 12 can be approached by two external forces in opposite directions, so that the two inclined parts 13 are inserted into the matching groove 21 of the bright trim strip 2 and locked with the matching groove 21 .

[0054] Wherein, the middle insert 1 in this embodiment is made of stainless steel, and the adhesive block 14 arranged between the two fixing plates 11 is used to prevent the bright trim 2, especially the straight bright trim The fixed part that is freely slidable on the bounding edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com