Automotive trim clip

A technology for automotive interior parts and buckles, which is applied to vehicle parts, connecting components, mechanical equipment, etc., can solve the problems of difficult maintenance of connecting parts, increased production costs, and large welding energy consumption, and achieves elimination of poor welding and easy replacement. , the effect of reducing assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

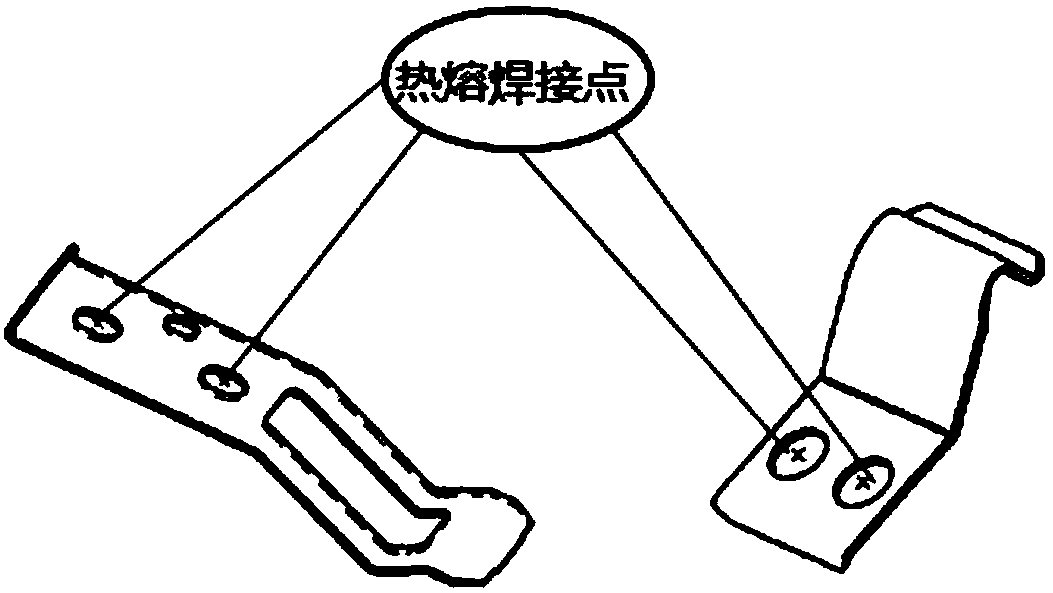

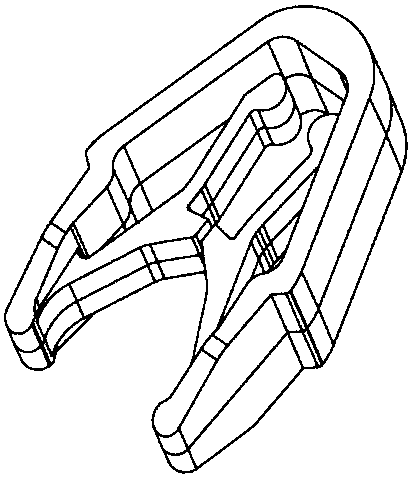

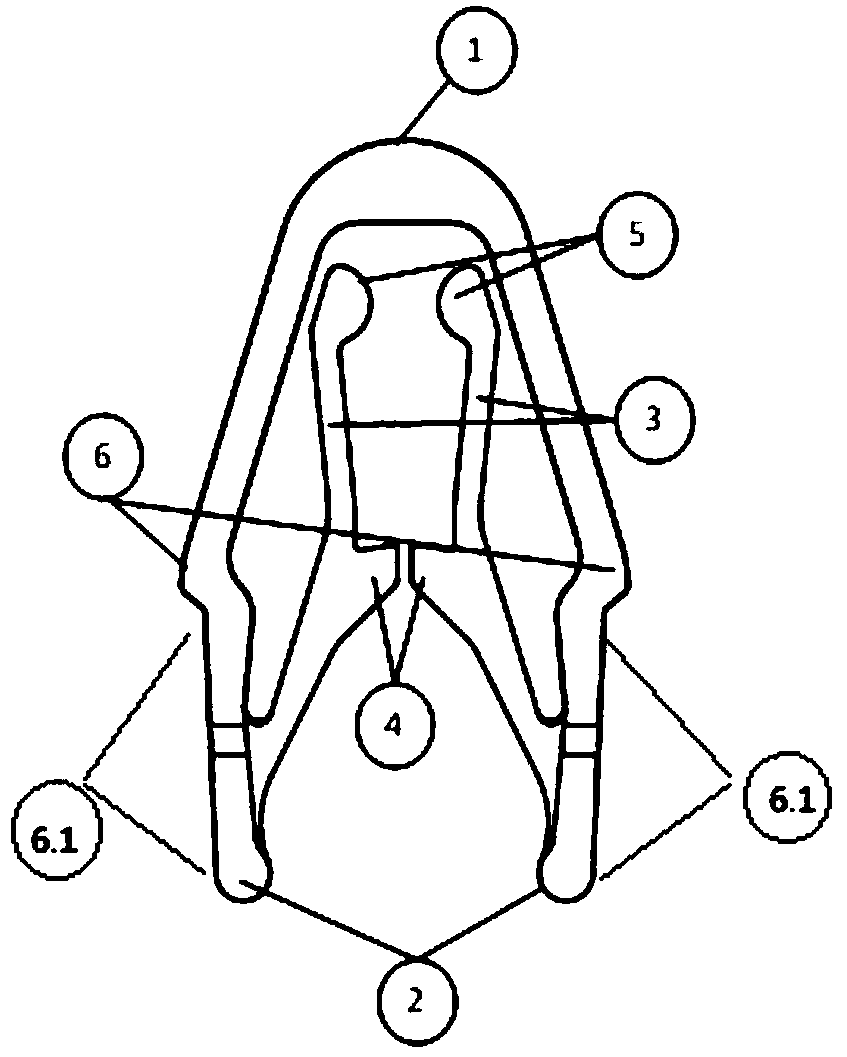

[0025] like figure 2 and 3 Shown is a schematic diagram of the buckle structure, including the buckle body, and the outer sides of the buckle body are respectively provided with anti-falling undercut protrusions 6, and the lower part of the anti-falling underturn protrusions 6 is an outer clamping part 6.1, and the buckle body A pair of elastic rib positions 3 are provided on the inner side, and the elastic rib positions 3 are provided with anti-falling barbs 4, and the elastic rib positions 3 are provided with clamping bosses 5, and the anti-falling barbs 4 are connected by being fixed on the target The fixing part 8 on the piece fixes the target connecting piece to prevent falling off, and the snap buckle has certain elasticity through injection molding. like Figure 8 As shown, the clamping boss can also be provided on the inner side of the buckle body for clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com