One-way bearing assembly and mechanism, armrest box and cup holder with the one-way bearing assembly

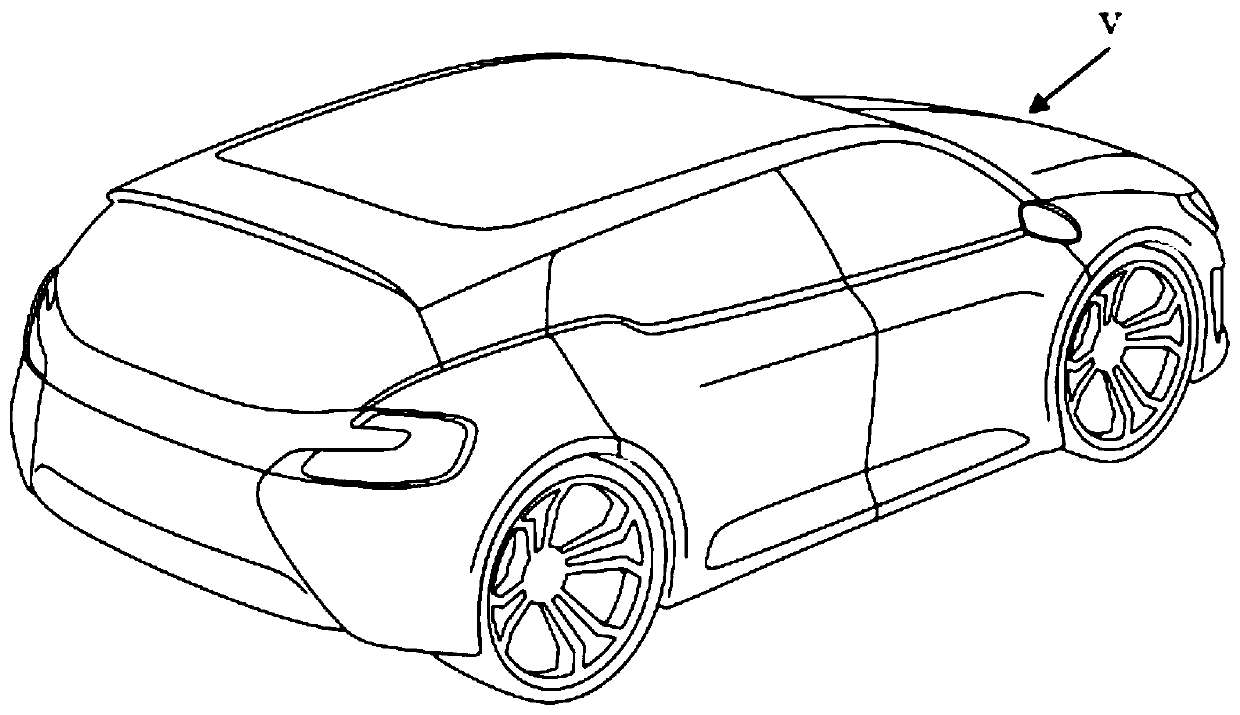

A technology of one-way bearings and armrest boxes, which is applied in the direction of armrests, transportation and packaging, and special positions of vehicles, etc. It can solve the problems of users who cannot operate freely and cannot satisfy users in time, and achieve the effect of eliminating abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

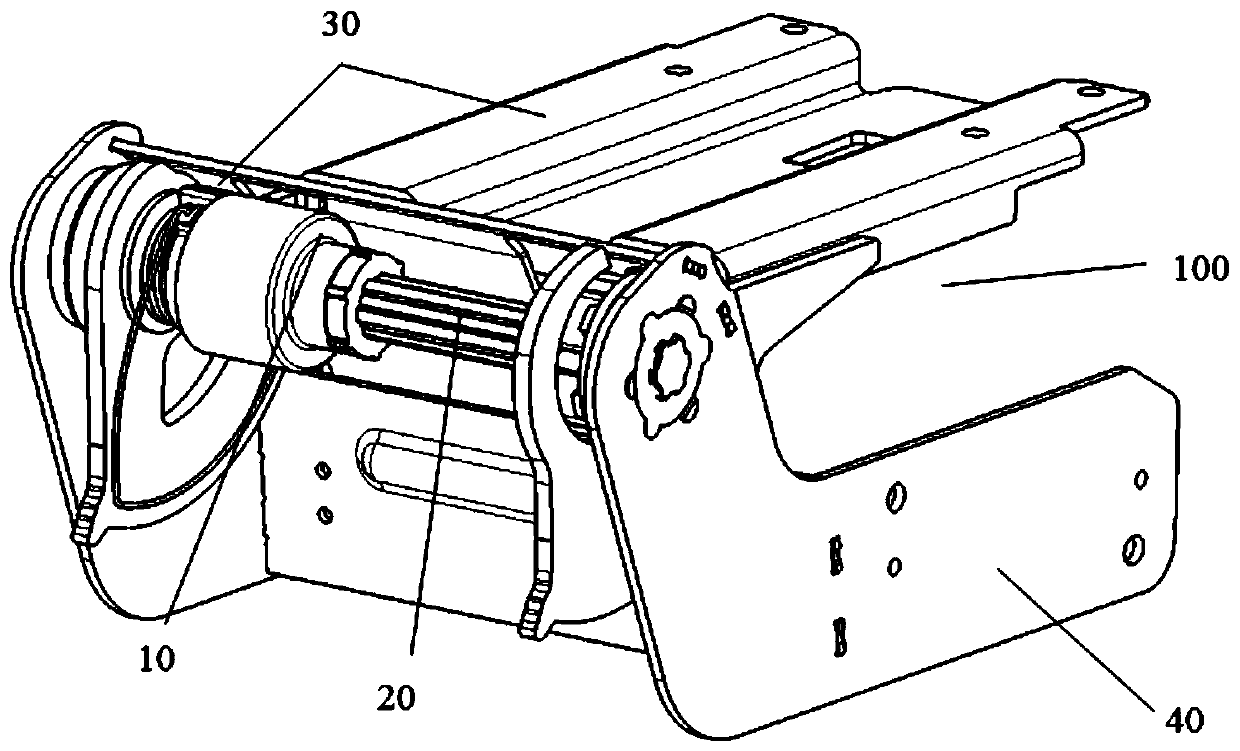

[0078] Embodiment 1: Shaft Mechanism

[0079] The rotating shaft mechanism including the one-way bearing assembly according to a preferred embodiment of the present invention will be firstly introduced below.

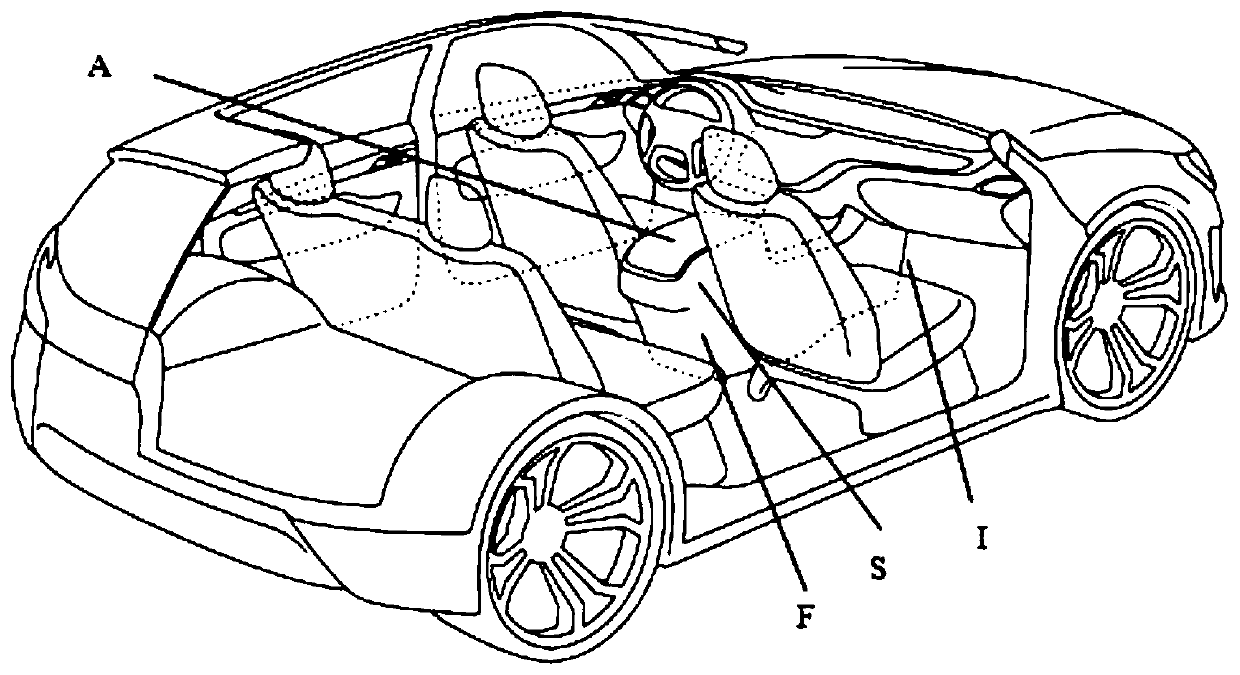

[0080] (organization composition)

[0081] Such as figure 2 As shown, the shaft mechanism 100 with a one-way bearing assembly includes: Figure 1B The fixed bracket 40 connected to the shown storage box S, and the Figure 1B The armrest body A shown is connected and relative to the fixed bracket 40 in the initial position (corresponding to the closed position where the armrest body A covers the storage compartment) and the maximum rotation angle position (corresponding to the maximum opening position where the armrest body A exposes the storage compartment The rotating bracket 30 that rotates between positions). In this embodiment, the rotating shaft is set as a spline shaft 20 . The one-way bearing assembly 10 is fixed on the spline shaft 20, and is used to realize...

Embodiment 2

[0105] Embodiment 2: slide rail mechanism

[0106] A slide rail mechanism including a one-way bearing assembly 10' according to another preferred embodiment of the present invention will be described below.

[0107] (organization composition)

[0108] Such as Figure 21 , 22 As shown, the slide rail mechanism 200 includes: with Figure 1B The sliding support 70 that shown armrest body A is connected, and Figure 1B The fixed bracket 80 connected to the shown storage box S and the one-way bearing assembly 10' installed on the fixed bracket 80. Wherein, the sliding bracket 70 includes a sliding rail 71, and the sliding rail 71 is designed with axially arranged teeth 711 that cooperate with the one-way bearing assembly 10'. In this embodiment, the sliding bracket 70 includes two sliding rails 71, and correspondingly, two one-way bearing assemblies 10' are mirror-image mounted on the fixed bracket 80, and the sliding bracket 70 connects with the one-way bearing assembly 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com