Buffer piston energy accumulator

A buffer piston and accumulator technology, applied in mechanical equipment and other directions, can solve the problems of high pressure, high heat, and shorten the service life of the accumulator, and achieve the effects of prolonging the service life, low manufacturing cost, and adjustable buffer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

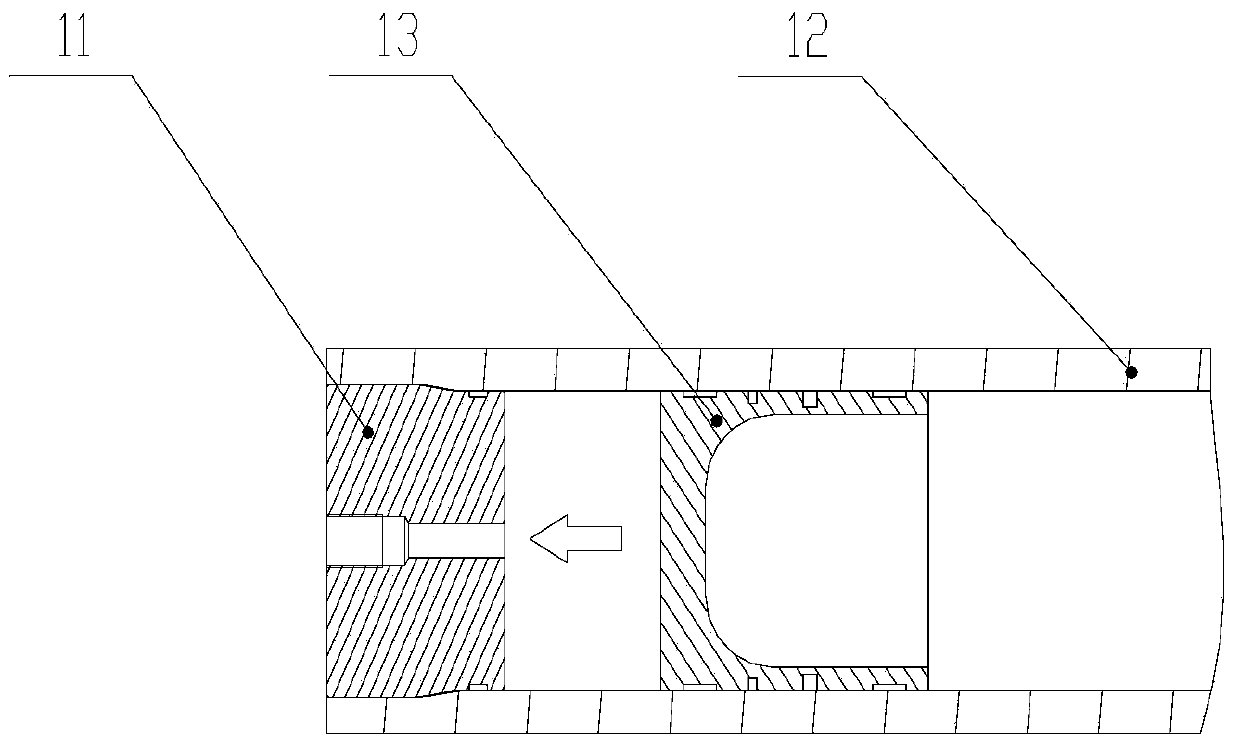

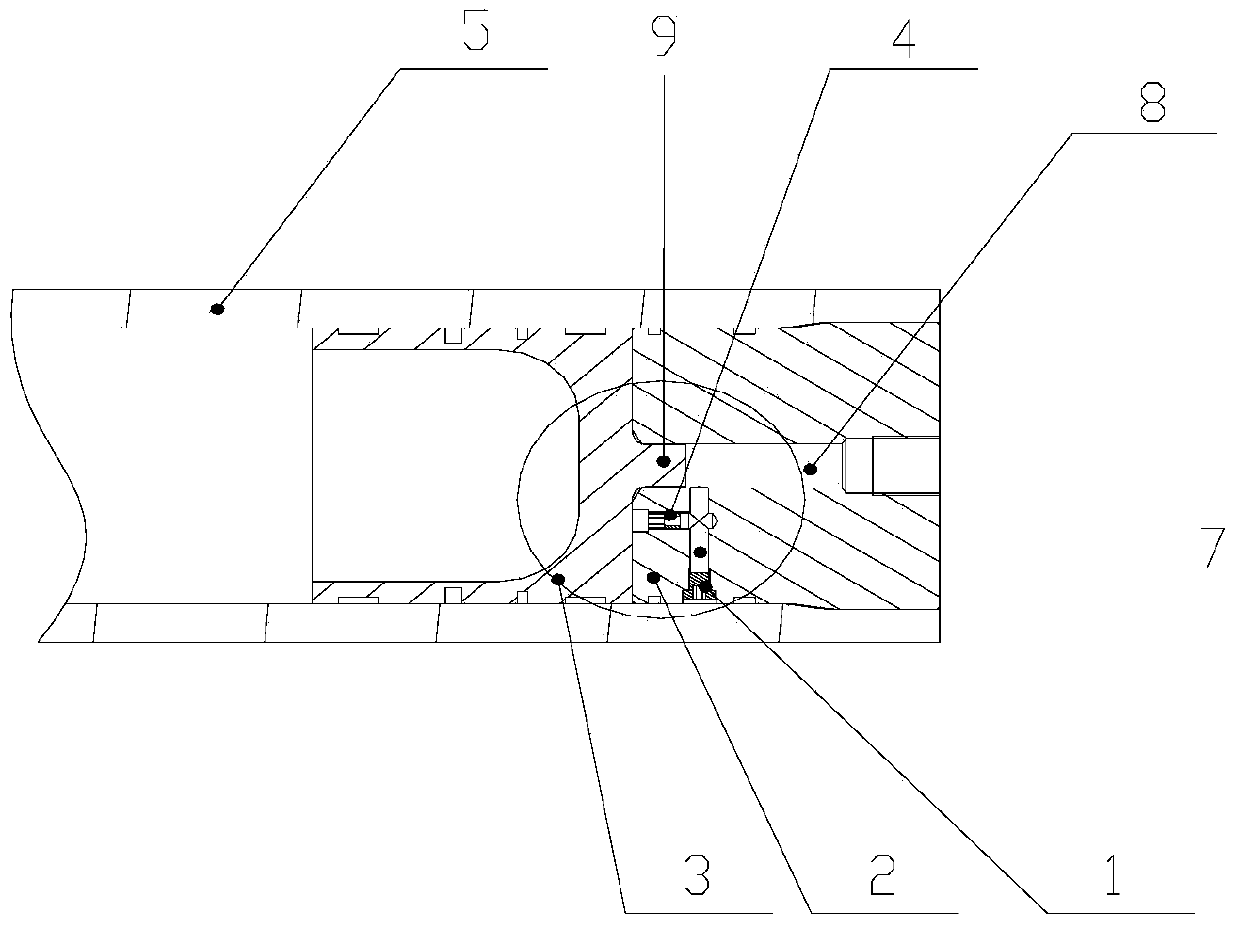

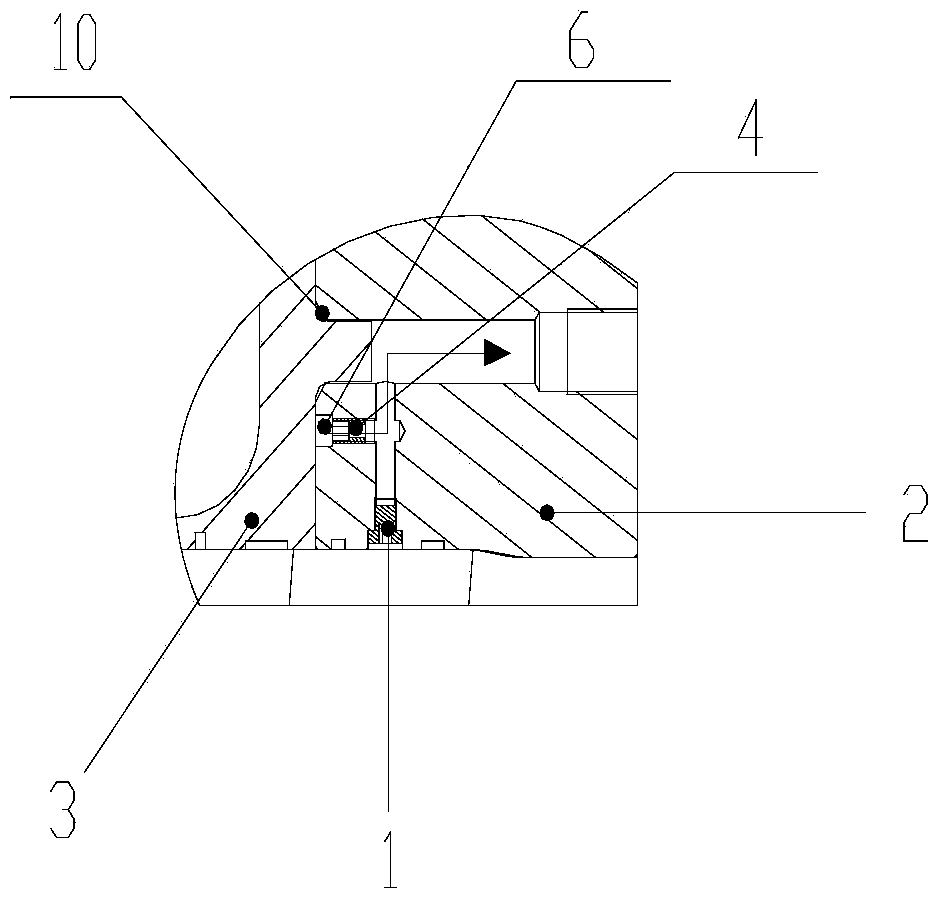

[0020] See figure 2 and image 3 As shown, a buffer piston accumulator of the present invention, the buffer piston accumulator is composed of a cylinder 5, a cylinder end cover 2 and a piston 3, the cylinder end cover 2 is arranged at one end of the cylinder 5, and the piston 3 is arranged In the cylinder body 5 and on one side of the cylinder end cover 2, an oil discharge port 8 is provided at the center of the cylinder end cover 2, and the oil discharge port 8 runs through the cylinder end cover 2. It is characterized in that the piston 3 is relatively One side of the cylinder end cover 2 is provided with a protrusion 9, the cylinder end cover 2 is provided with a buffer hole 6 relative to the surface of the piston 3, a throttling plug 4 is installed in the buffer hole 6, and the side of the cylinder end cover 2 is opened There is a process hole 7, and a process plug 1 is installed in the process hole 7. When the piston 3 moves to the cylinder end cover 2, the protrusion 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com