Patents

Literature

33results about How to "No dust pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

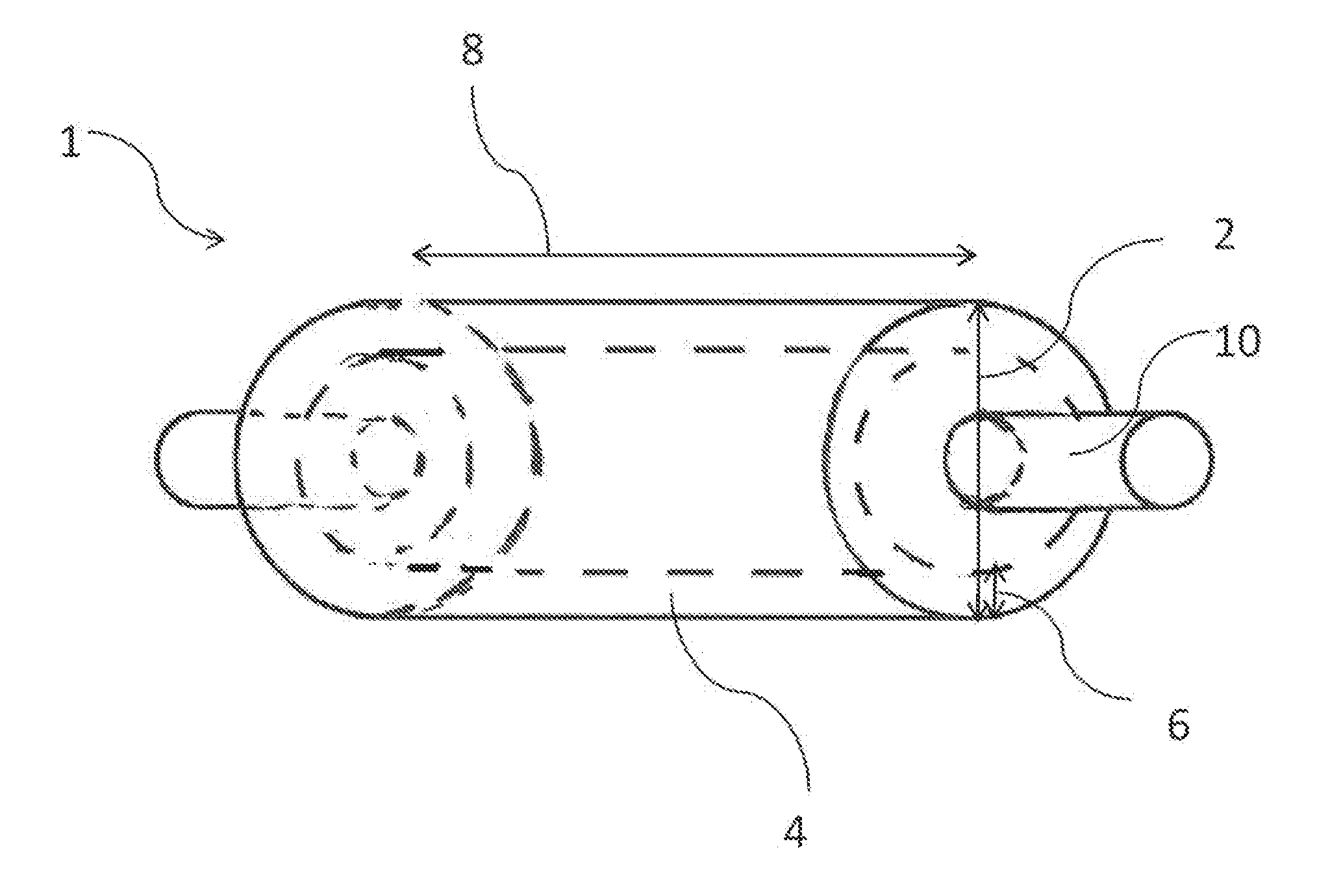

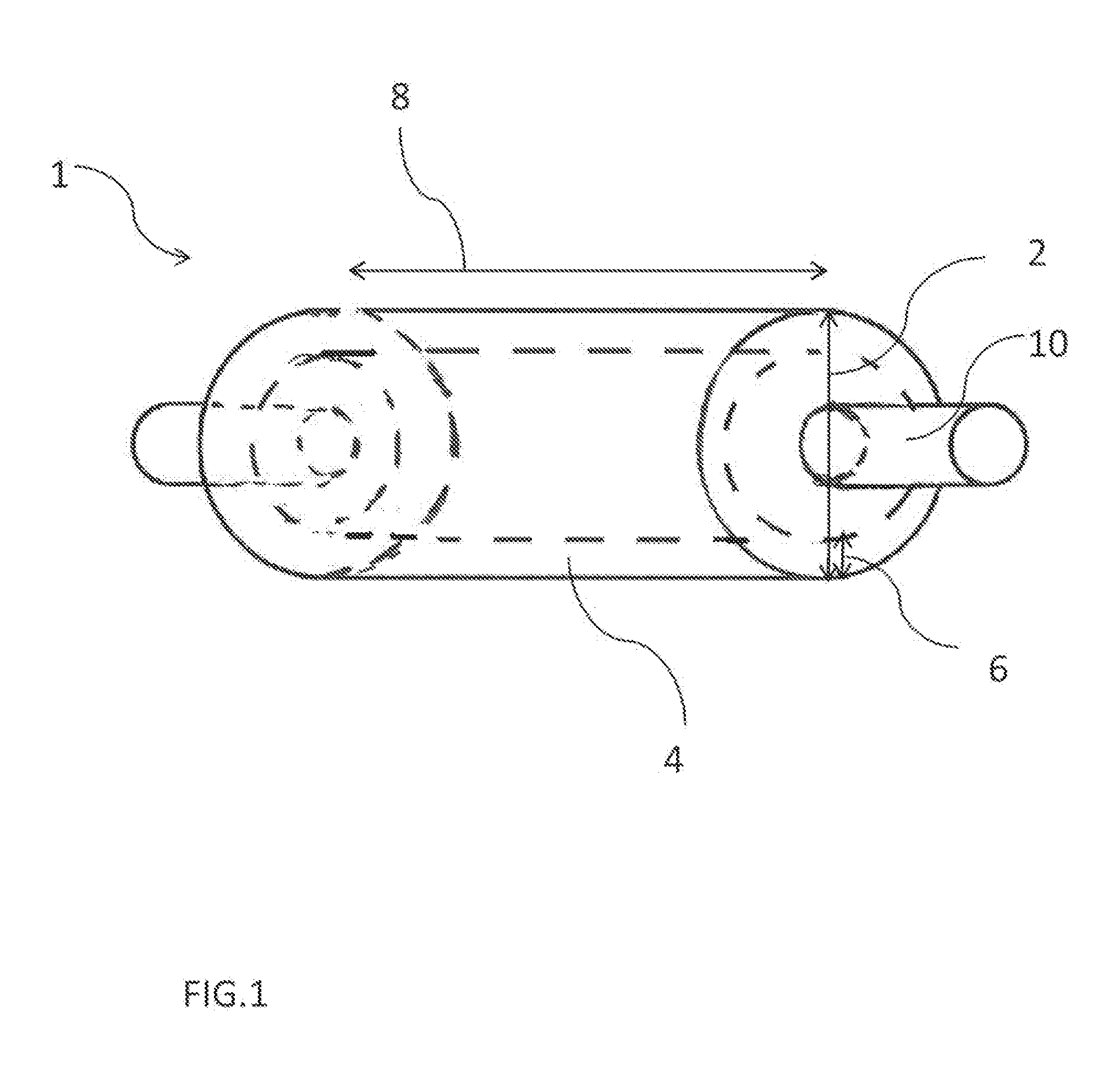

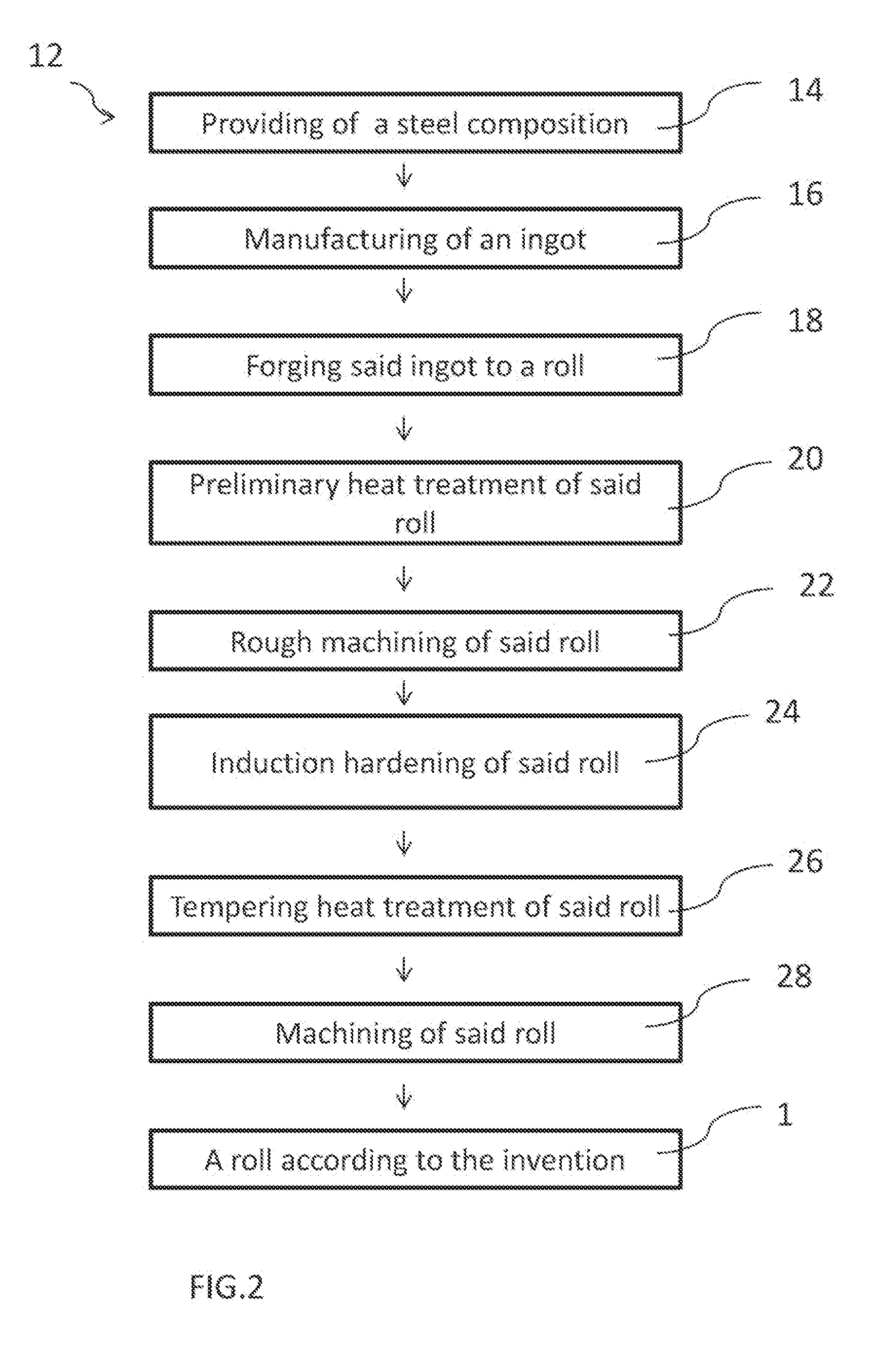

Forged roll meeting the requirements of the cold rolling industry and a method for production of such a roll

ActiveUS20120225761A1Improve milling resultsReduce coefficient of frictionFurnace typesIncreasing energy efficiencyCarbideHardness

A forged roll for use, inter alia, in the cold rolling industry and a method of producing a forged roll as described. The roll has a steel composition, by weight, with 0.8 to less than 1% C, 0.2 to 0.5% Mn, 0.2 to 2.0% Si, 7.0 to 13.0% Cr, 0.6 to 1.6% Mo, more than 1.0 to 3.0% V, the remainder being Fe and impurities. The steel is tempered martensite with retained austenite at less than 5% per volume with eutectic carbides of less than 5% by volume, a hardness between 780-840 HV, and internal compressive stresses of between −300 to −500 MPa.

Owner:AKERS INT AB

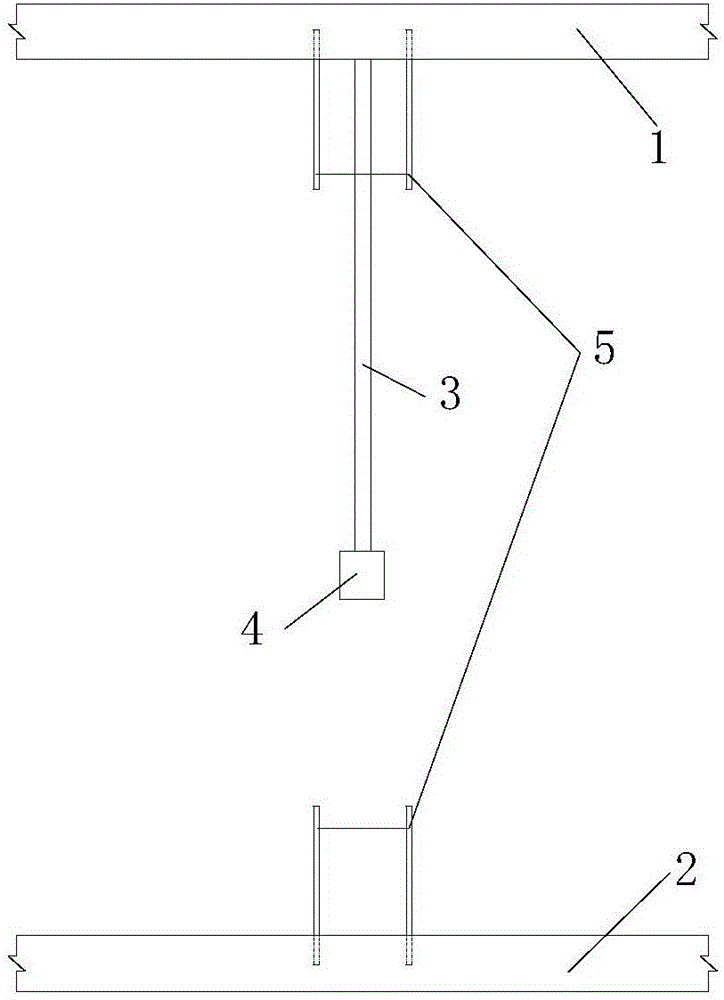

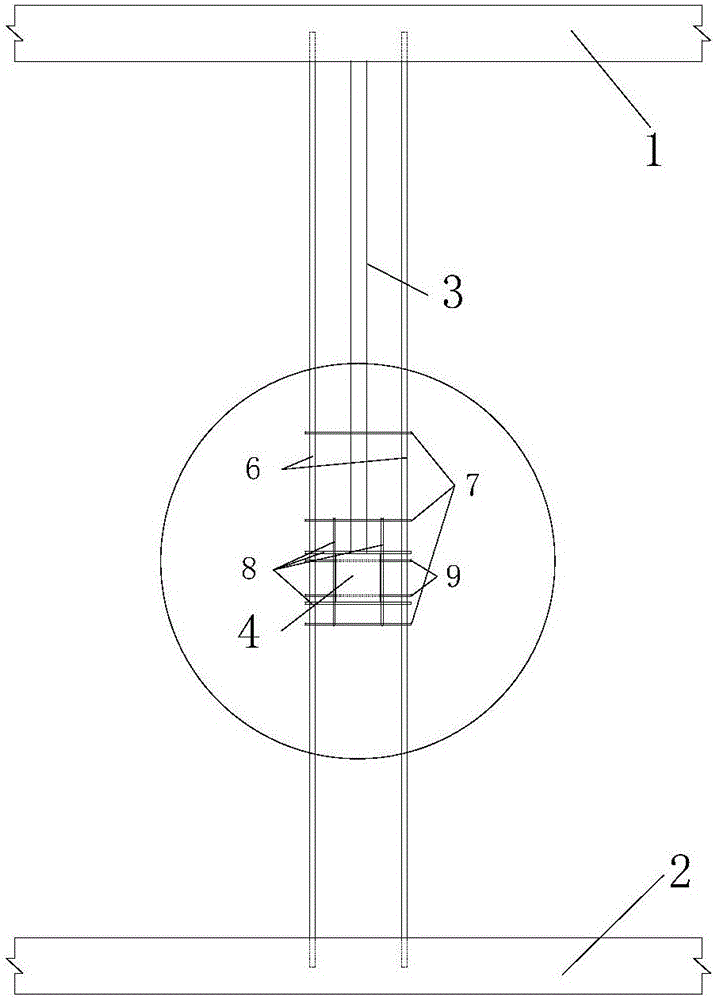

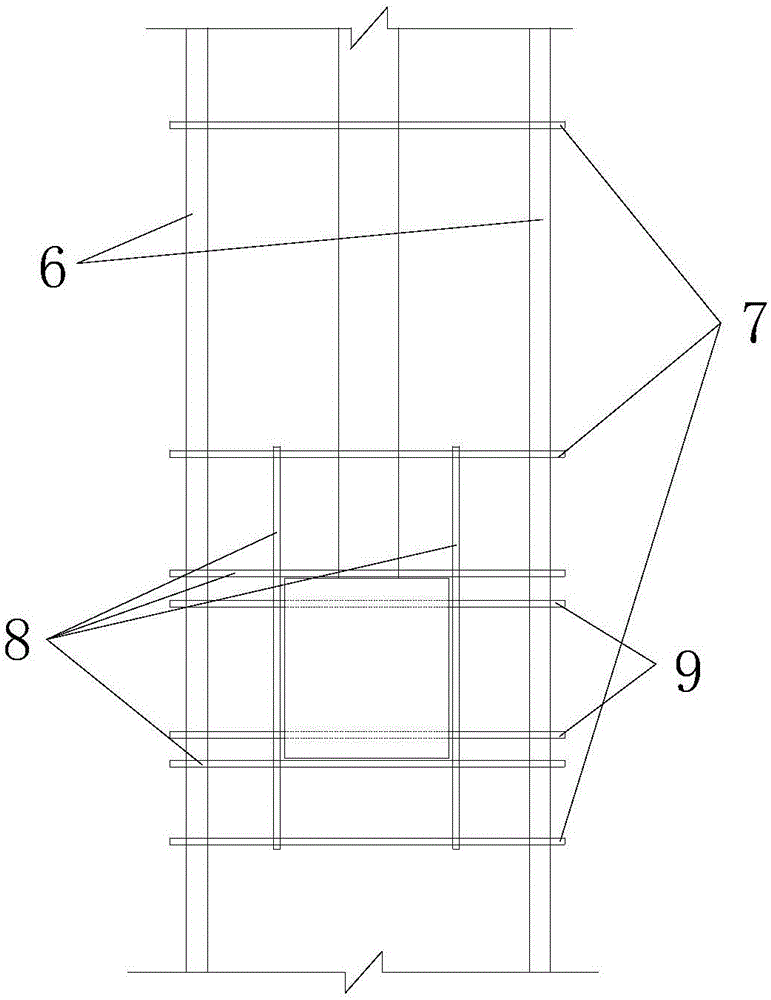

Masonry-wall line-pipe, line-groove and line-box burying construction method

InactiveCN106320706APrevent the occurrenceProduced noBuilding material handlingCable installation apparatusArchitectural engineeringRebar

The invention discloses a masonry-wall line-pipe, line-groove and line-box burying construction method. The construction method includes the steps that in the pre-construction method, reinforcing steel bars are pre-buried or post-implanted into a top plate and a bottom plate on the peripheries of a line pipe and a line groove buried in a masonry wall, the line pipe, the line groove and a line box are completely arranged, then the corresponding pre-buried reinforcing steel bars of the bottom plate and the top plate are bound and woven into a whole in a concrete-constructional-column mode, the line pipe, the line groove and the line box are fixed, a formwork is installed, and concrete pouring is carried out; in the post-construction method, reinforcing steel bars are pre-buried or post-implanted into a top plate and a bottom plate on the peripheries of a line pipe and a line groove buried in a masonry wall, the portion is reserved when wall masonry is carried out, and after masonry construction is completed, the line pipe, the line groove and a line box are installed, then the corresponding pre-buried reinforcing steel bars of the bottom plate and the top plate are bound and woven into a whole in a concrete-constructional-column mode, the line pipe, the line groove and the line box are fixed, a formwork is installed, and concrete pouring is carried out. According to the construction method, the wall does not need to be slotted, cracks or fractures of the wall can be avoided, environment pollution is reduced, labor strength is reduced, construction is simple, construction time is short, the cost is low, and the installing quality is reliable.

Owner:CHINA FIRST METALLURGICAL GROUP

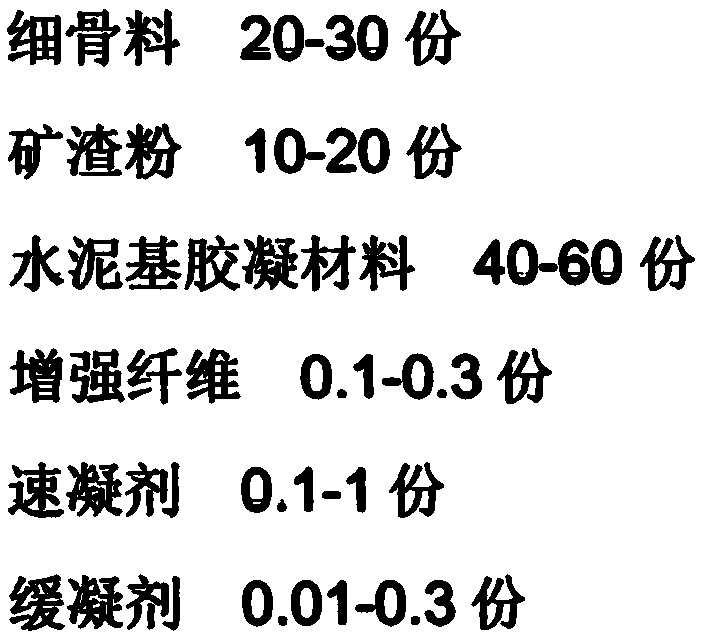

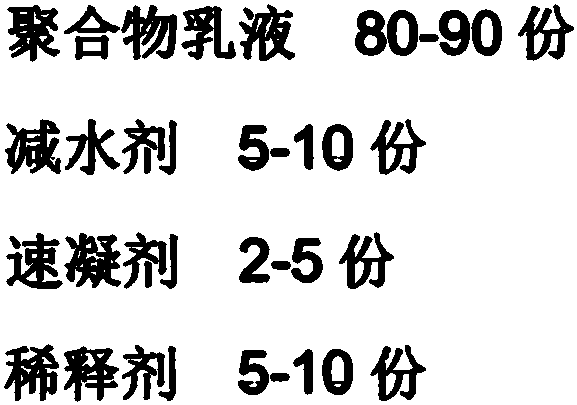

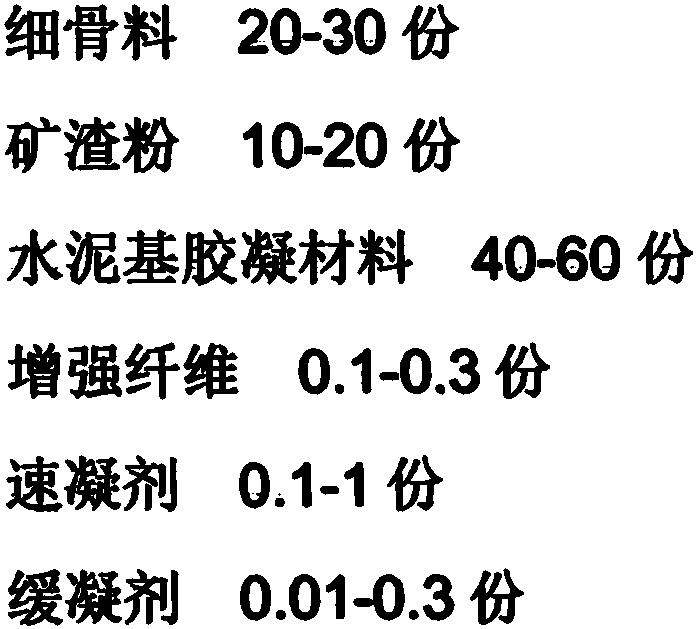

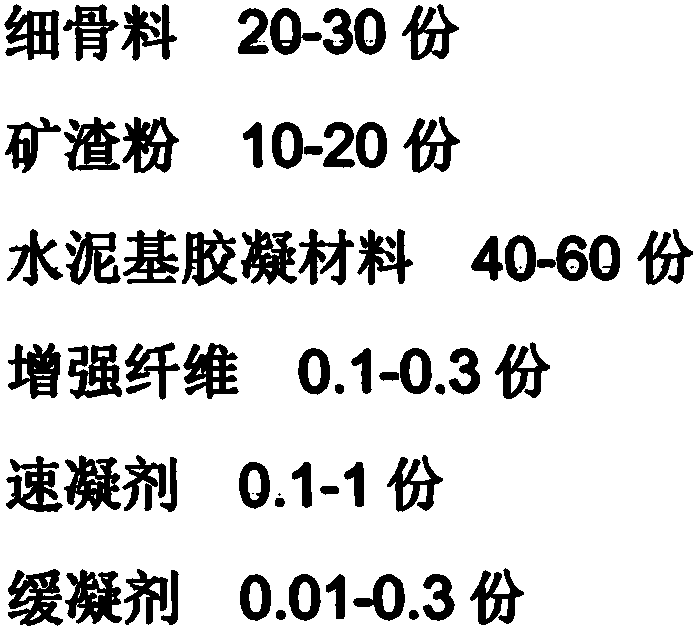

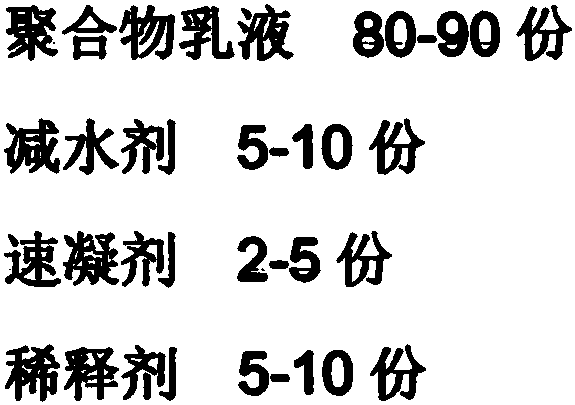

Flexible spraying material for mine laneway supporting and preparation method and application of flexible spraying material

ActiveCN111533518ANon-volatileEfficient use ofUnderground chambersTunnel liningSlagHazardous substance

The invention relates to a flexible spraying material for mine roadway support and a preparation method and application of the flexible spraying material, and belongs to the technical field of mine roadway supporting. The slag-based anchoring and shotcreting support guniting material prepared by the method is an organic-inorganic hybrid material and does not volatilize harmful substances and is safe and environment-friendly; a slag doped guniting material is adopted so that effective utilization of slag is developed, secondary pollution is relieved, and the cost is reduced; vertical face and top face spraying construction does not flow, the construction environment is friendly, and any springback and dust pollution problems are avoided; the curing temperature is low, and the flame-retardant property is realized.

Owner:赣州创可通科技有限公司

Waste packaging iron drum disposal and recovery method

InactiveCN108722631AAvoid dustNo dust pollutionSolid waste disposalDispersed particle separationMagnetic separatorRecovery method

The invention discloses a waste packaging iron drum disposal and recovery method. The method comprises the following steps of (1) cleaning residual liquid in a waste packaging iron drum; (2) shreddingthe waste packaging iron drum through a double-shaft shredding machine; (3) conducting alkali liquid cleaning through a cleaning machine; (4) conducting ball grinding through a ball grinding machine;(5) conducting screening through a magnetic separator; (6) conducting cleaning through a cleaning machine; (7) conducting drying through a drying machine. Through the method, the waste packaging irondrum is subjected to shredding, cleaning, ball grinding, magnetic separation and recleaning, and a large quantity of iron balls are recovered. Meanwhile, produced cleaning wastewater, waste gas and waste residues are reasonably disposed, and resource cyclic regeneration is achieved.

Owner:无锡添源环保科技有限公司

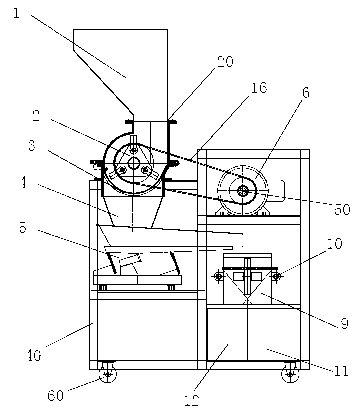

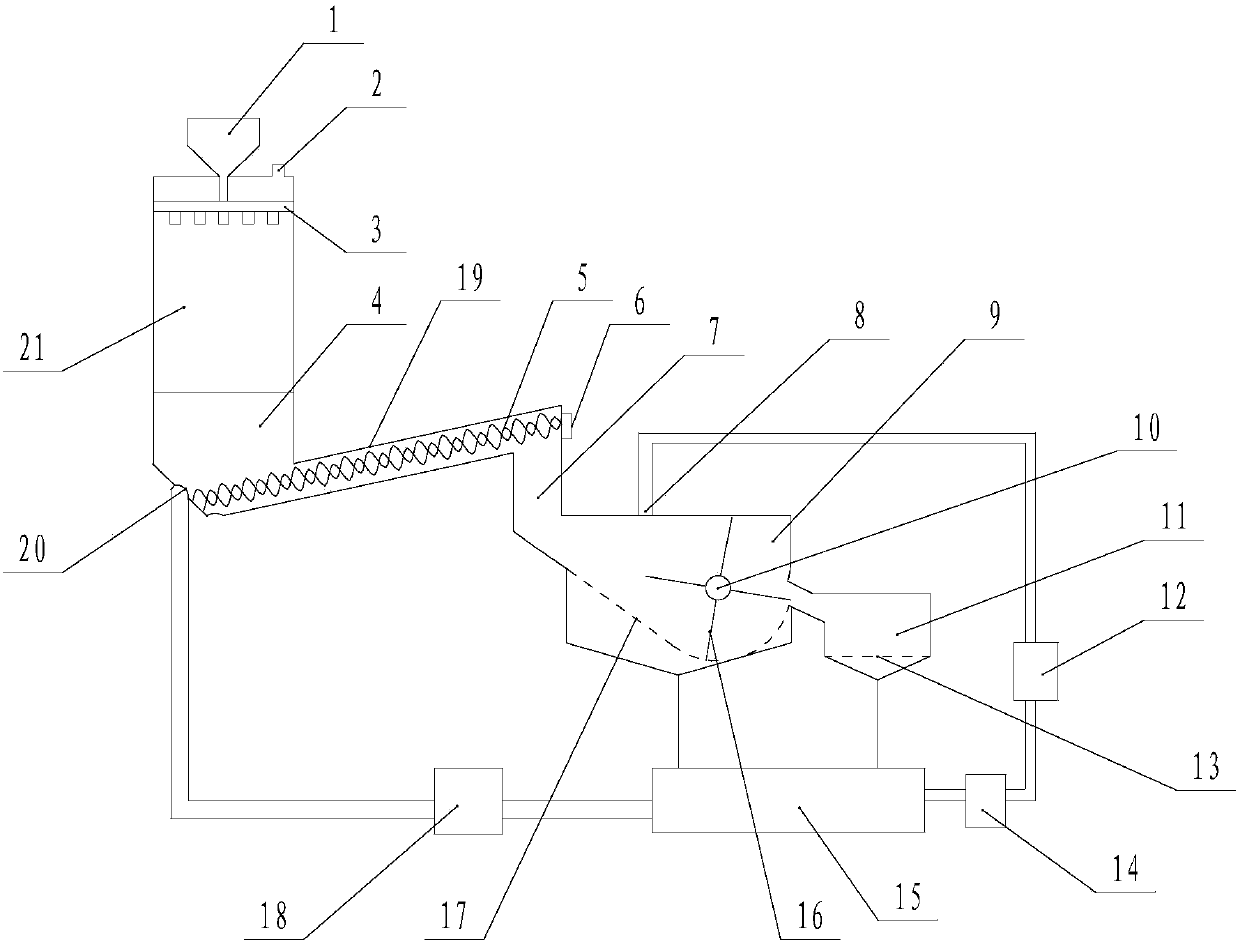

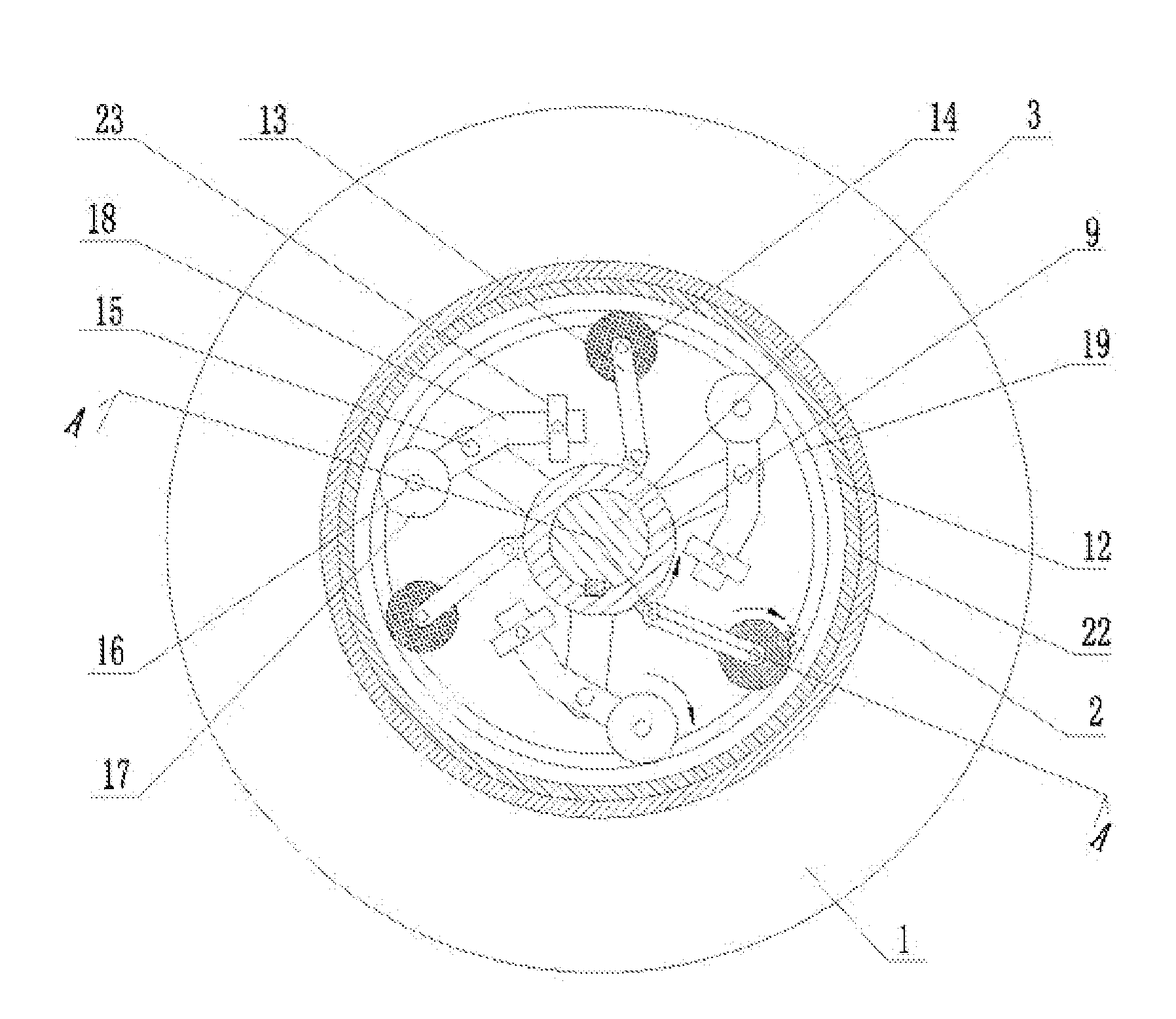

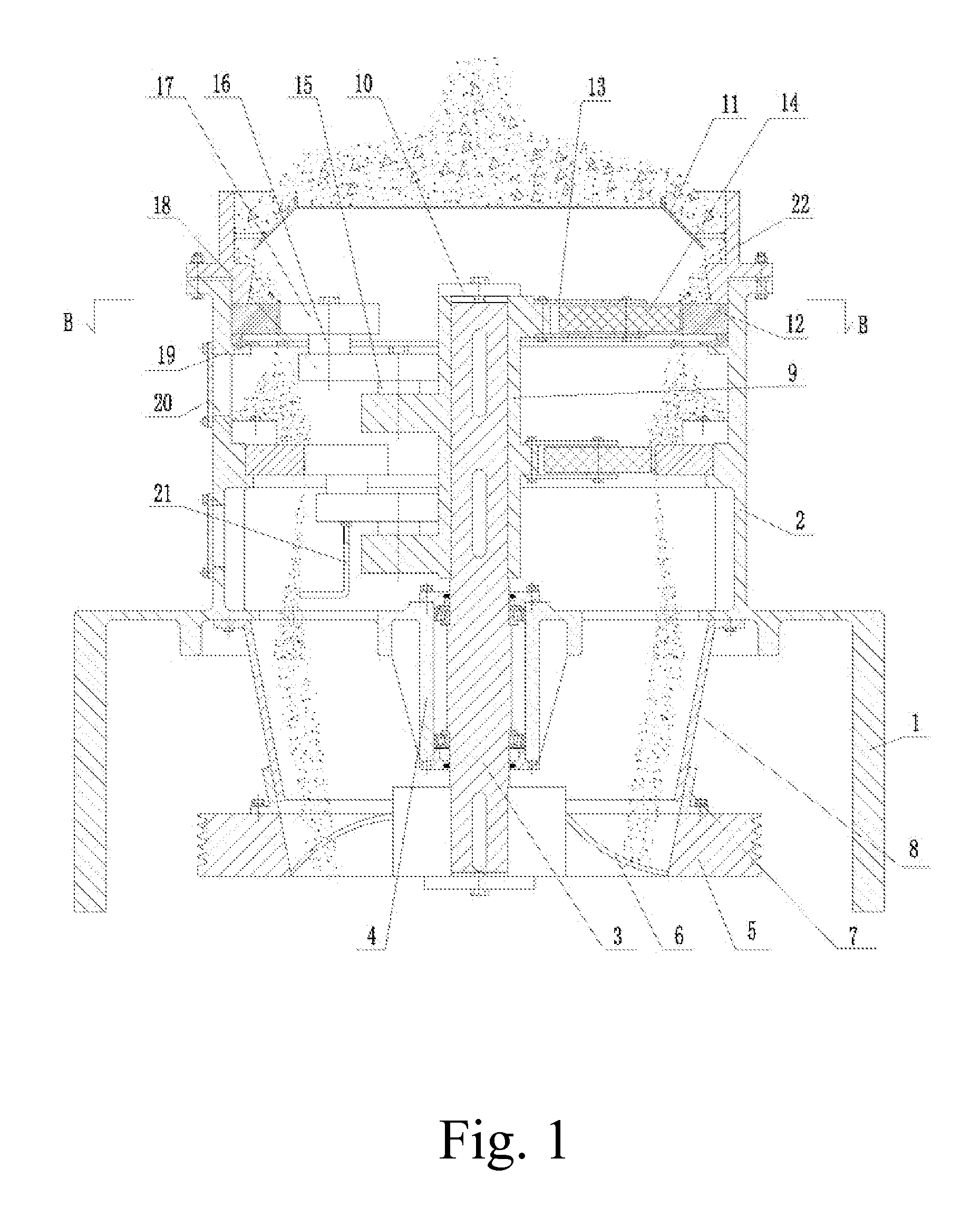

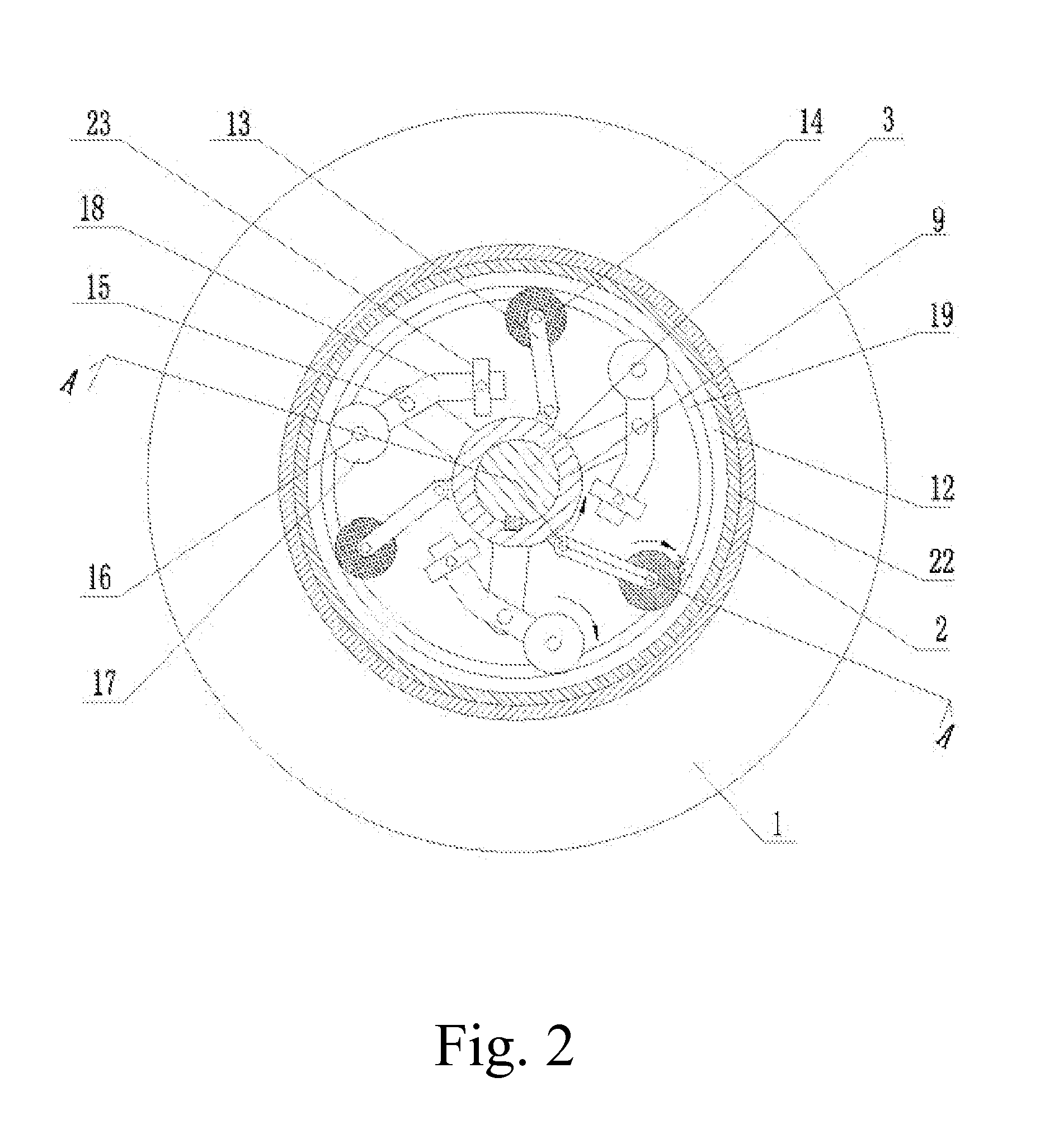

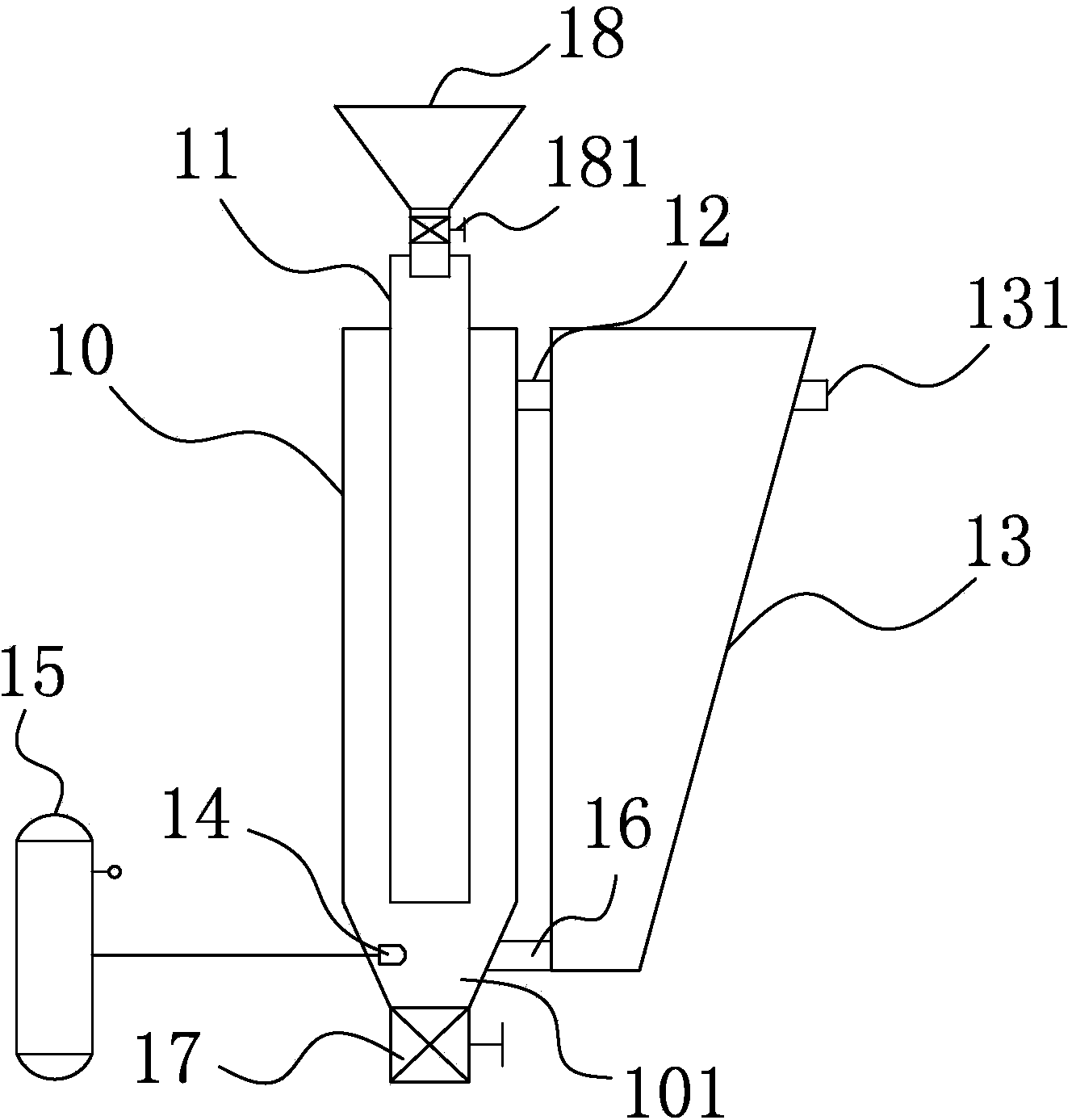

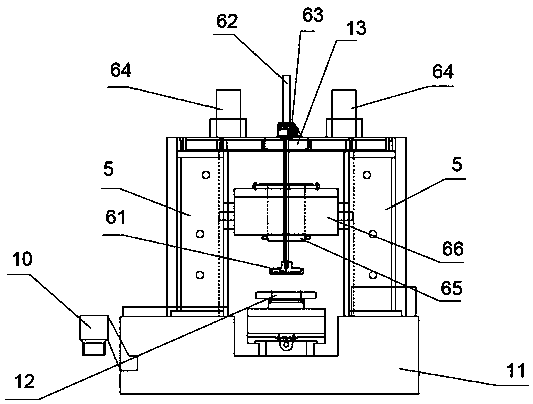

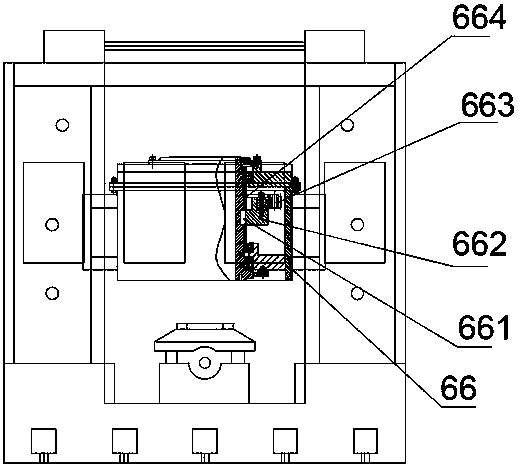

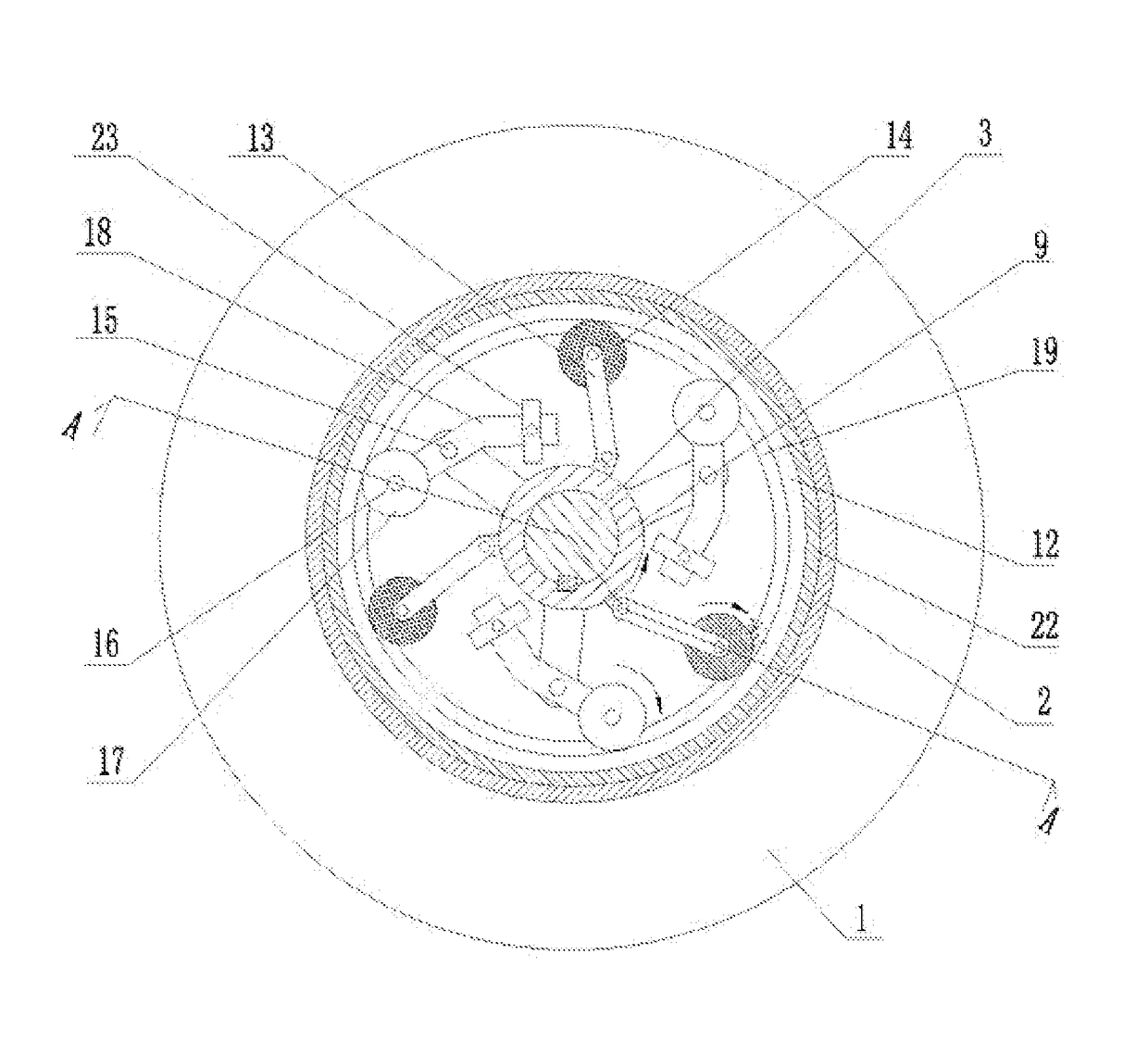

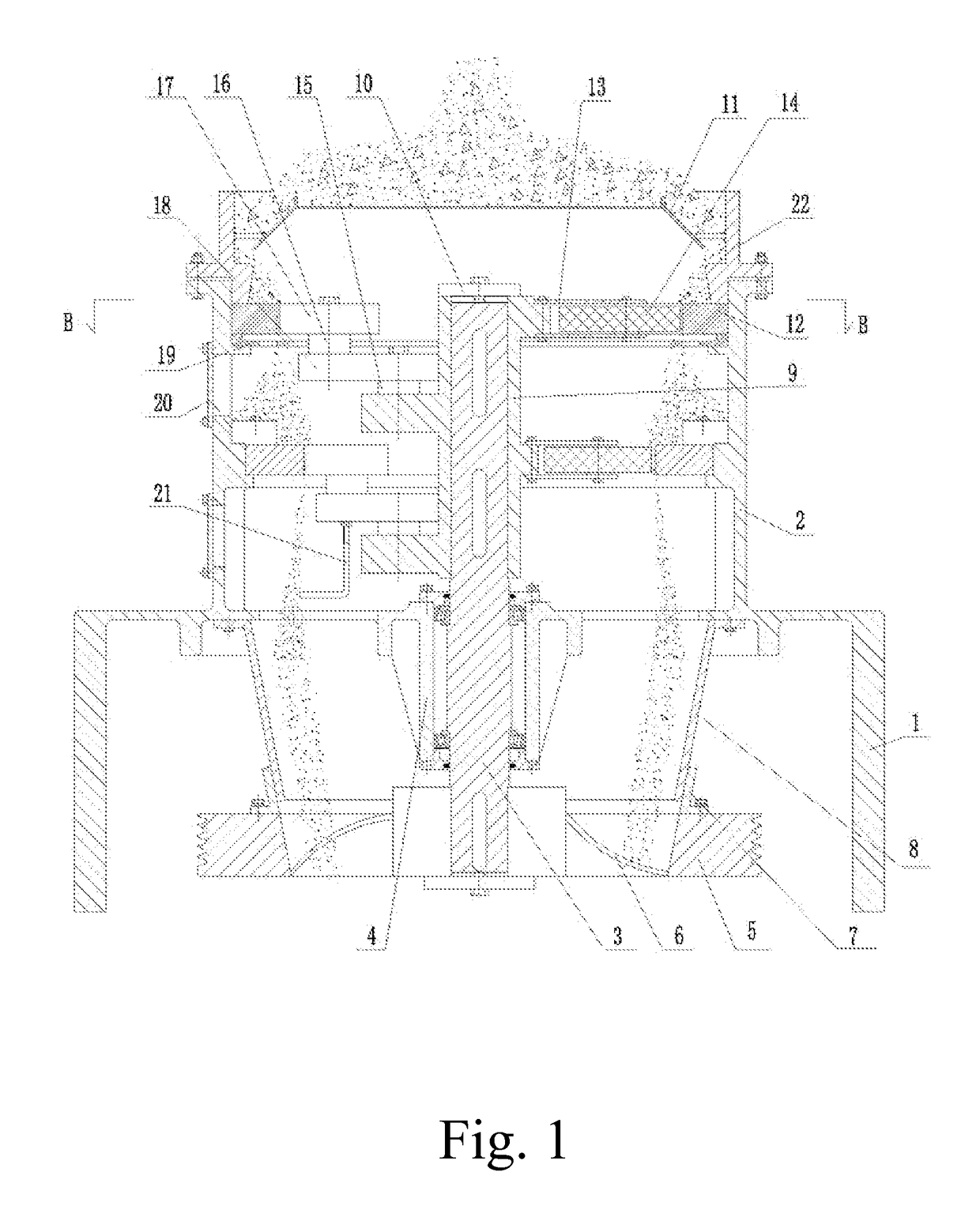

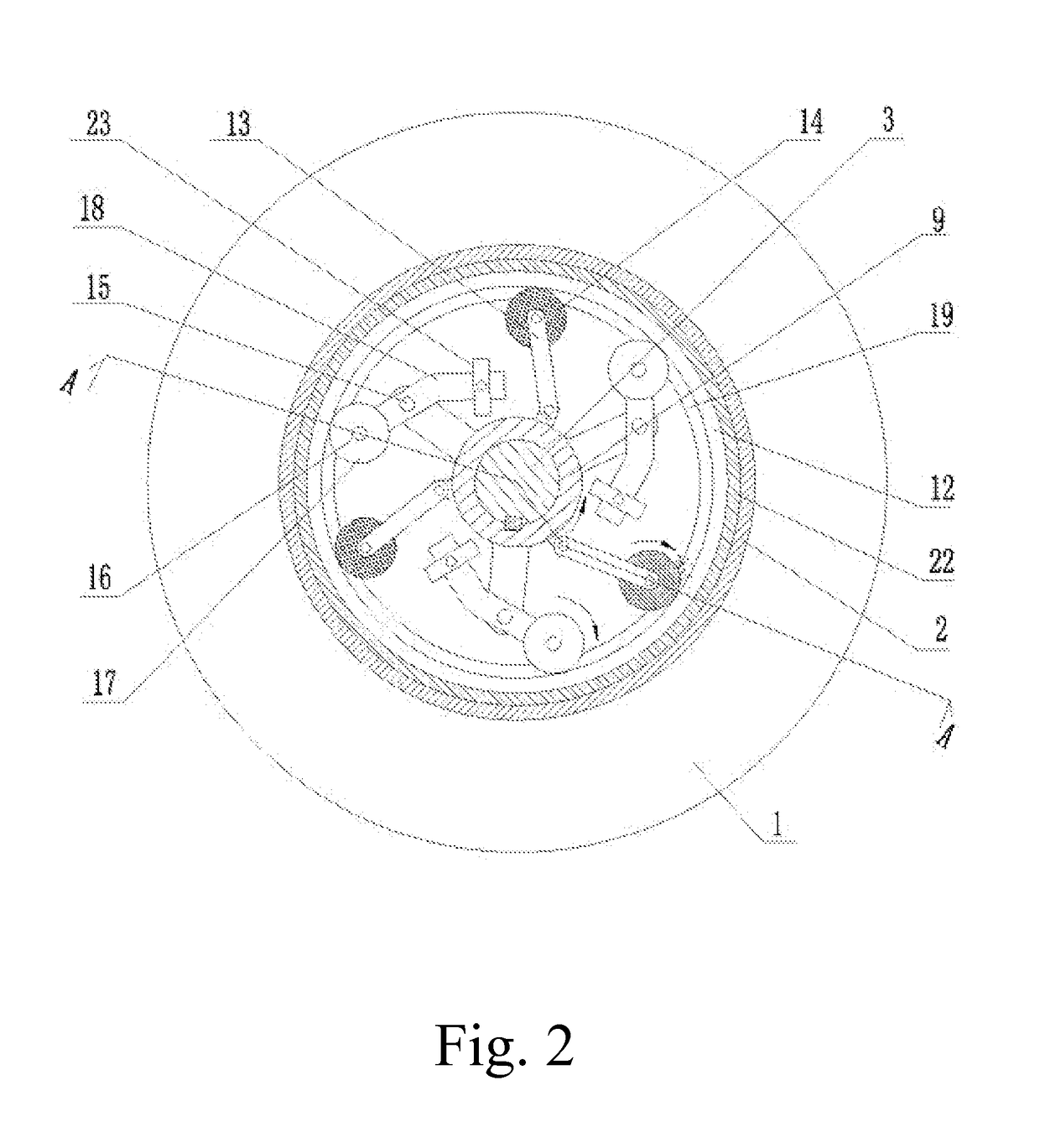

Sealing hammer type crushing splitter

InactiveCN103100462ANo dust pollutionCompact structurePreparing sample for investigationGrain treatmentsAgricultural engineeringFlywheel

The invention discloses a sealing hammer type crushing splitter comprising a feeding mechanism, a splitting mechanism and a framework, wherein the feeding mechanism comprises a feeding hopper, a sieve plate, a surge hopper, an electromagnetic vibration type feeder and a crushing device; the sieve plate is fixedly connected with the top of the framework; the feeding hopper is connected with the upper part of the sieve plate in a sealing manner; the electromagnetic vibration type feeder is arranged in the middle part of the framework; the surge hopper is arranged at the lower part of the sieve plate; the crushing device comprises a feeding motor, a belt wheel, a flywheel, a rotating shaft and a rotor hammerhead; the splitting mechanism comprises a splitting motor, a crank connecting rod, a splitter, guide rods, a reserved sample hopper and a waste sample hopper; the splitting motor is arranged on the lateral face of the framework; the splitter is movably connected with the lower part of the framework through the guide rods on the two lateral faces of the framework; one lateral face of the splitter is connected with the splitting motor through the crank connecting rod; and the reserved sample hopper and the waste sample hopper are arranged below the splitter. The sealing hammer type crushing splitter provided by the invention has the advantages of fully-sealed design, no dust pollution, compact structure, quick sample preparation speed and high production efficiency.

Owner:镇江市丰泰化验制样设备有限公司

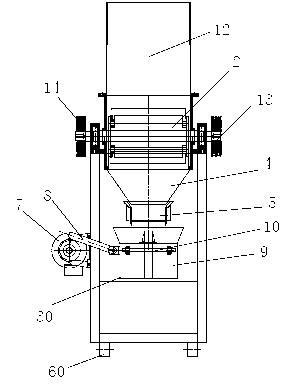

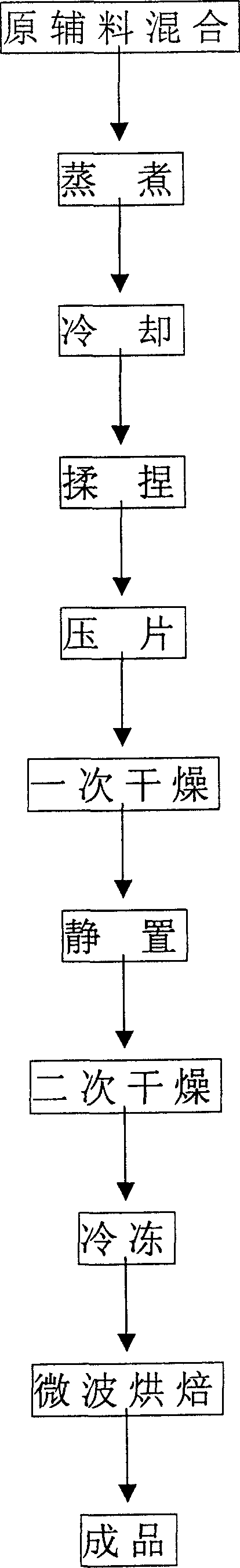

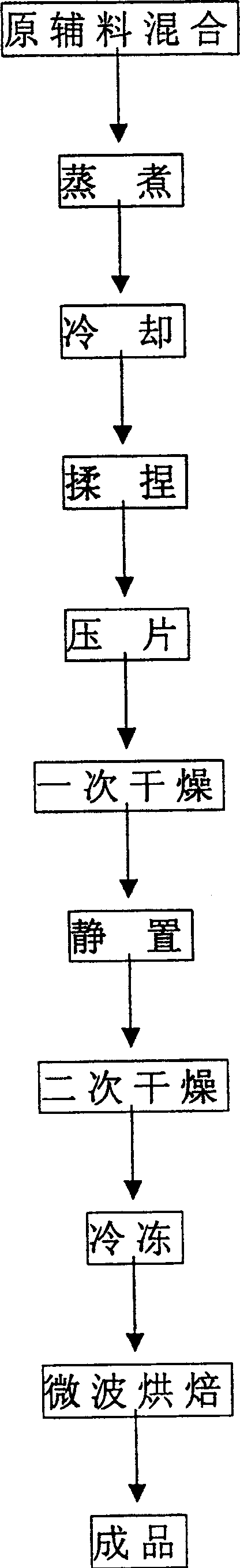

Microwave refrigerated dough for making crisp pancake and its making method

A frozen dough for roasting crisp cake by microwave is prepared from non-glutinous round-grained rice flour, potato starch, almond powder, glutinous rice flour, salt, chicken extract and water through mixing, steaming, cooling, kneading, pressing to become sheet, drying, laying aside, drying and freezing.

Owner:JIANGNAN UNIV

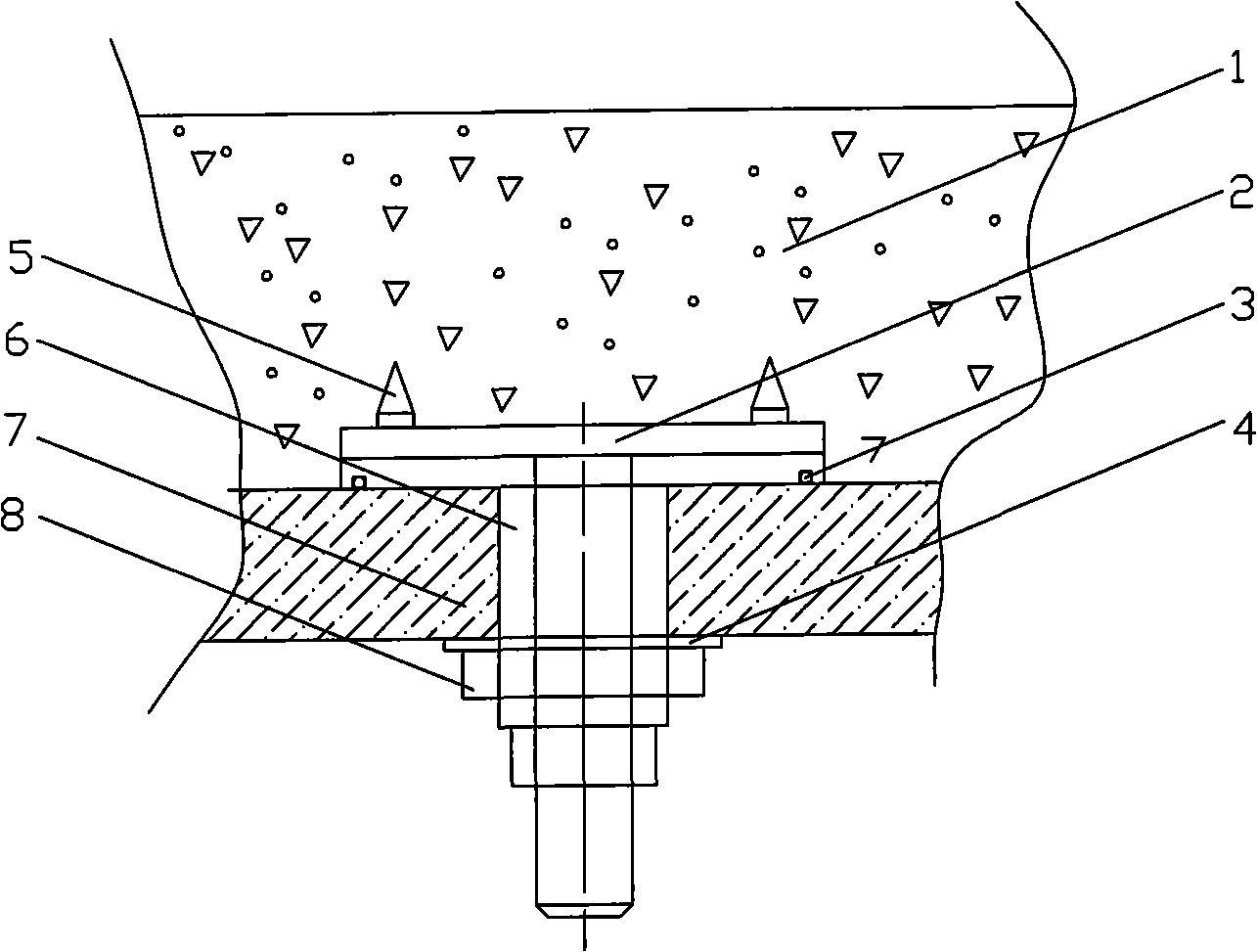

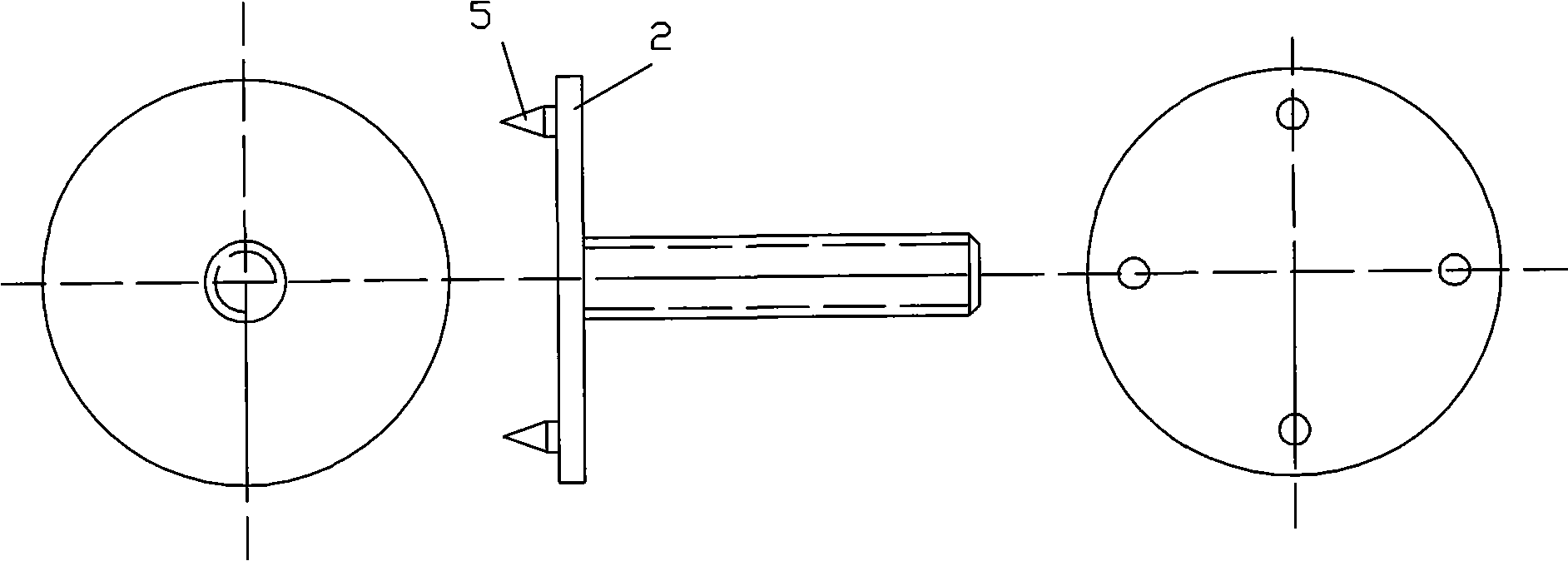

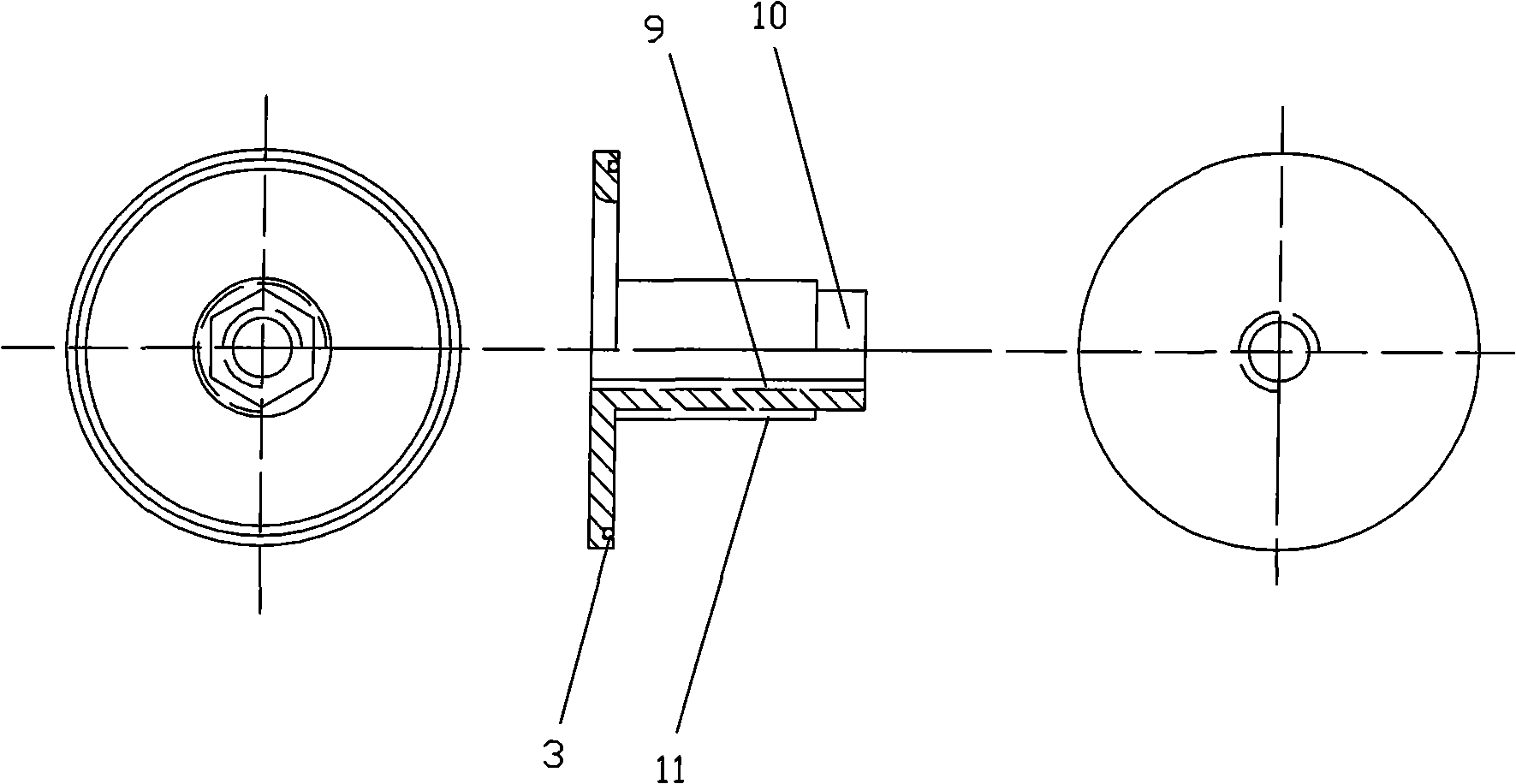

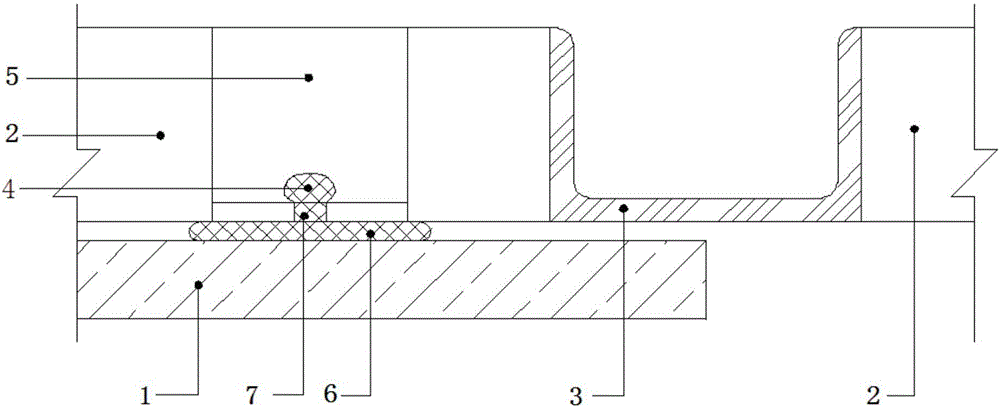

Device for easily demoulding concrete form and a demoulding method

ActiveCN101525940AAvoid pollutionImprove general performanceForming/stuttering elementsSocial benefitsEconomic benefits

The invention provides a device for easily demoulding concrete form and a demoulding method, belonging to the field of architectural construction. The device comprising a form board, a fixed plate with a threaded rod and a six point sleeve with internal and external threads; wherein, the internal surface of the end part of the sleeve is sealed with the surface of the form board by an alkali-resisting O-shaped seal ring; the sleeve penetrates through the hole of the form board, is fixed by a nut out of the form board in a way that passing through a carrier ring, and forms a hexagonal structure on the end part; and the fixed plate with the threaded rod and the sleeve with the internal and external threads are connected in a sealing way by screw thread thereof. After the concrete reaches to demoulding intensity, twisting the sleeve, the form board relatively moves to the concrete so as to be separated, and the bolt connection set is dissembled from the form board so as to be used at the next time. The form board does not need to be coated with separant, therefore, the invention is free of noise and dust pollution, has simple structure, strong popularity and convenient operation, is safe and reliable, has fast demoulding speed, improves demoulding work efficiency, reduces labor intensity of workers, prolongs the service life of form board and heightens the appearance quality of the concrete. The device can achieve good social benefit, economic benefit and environmental benefit.

Owner:湖北中浩建筑有限责任公司

Waste plastic recovery and granulation method and device thereof

InactiveCN107914350ANo noise pollutionNo dust pollutionCoatingsPlastic recyclingPelletizingEngineering

The invention discloses a waste plastic recovery and granulation method and a device thereof, and belongs to the field of plastic granule production and processing technologies. According to the invention, problems of high cost and severe pollution in the prior art are solved. The method of the invention comprises the following steps: washing recovered waste plastic, drying and fusing, and modifying the fused solution by adding a plastic modifier; sending the fused solution into a granulation tower, distributing by a distributor to turn the fused solution into liquid drops and letting the liquid drops fall into a water tank to form plastic granules, letting the plastic granules enter a cooling tank through a feeding pipeline, and sending the cooled plastic granules into a storage bin through a feed divider so as to obtain the finished product plastic granules. The waste plastic recovery and granulation device comprises the granulation tower, the cooling tank and the storage bin. The upper part of the granulation tower is provided with the distributor which is connected to a sprue. The water tank is arranged below the granulation tower. The water tank and the cooling tank are connected through a feeding pipeline. The feed divider is arranged inside the cooling tank, a discharge port of which is connected to the storage bin. The method and the device of the invention can be usedfor recovery and granulation of waste plastic.

Owner:连云港海润包装有限公司

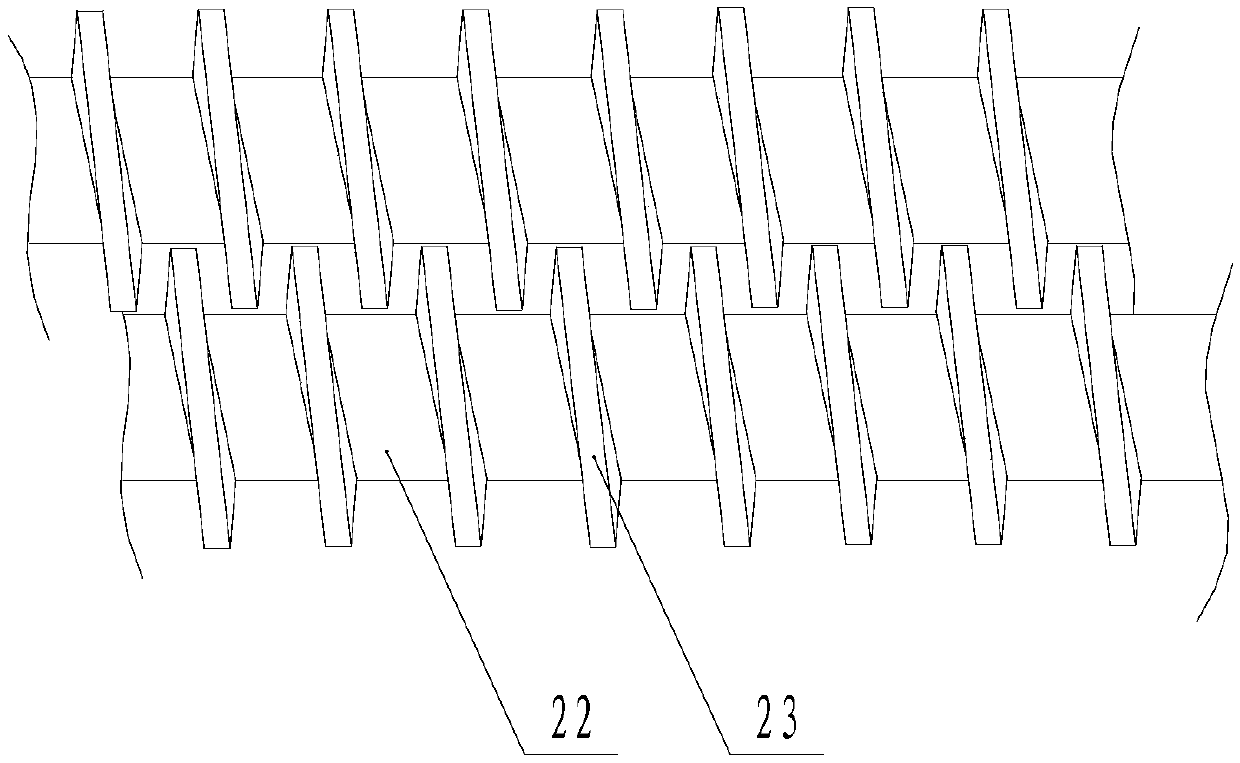

Continuous rolling and direct facing technique of middle (high) density beaverboard and equipment thereof

InactiveCN101274441ANo dust pollutionShort processPlywood pressesVeneer pressesEngineeringSurface plate

The invention relates to a technique of direct facing for medium (high) density fiber board produced by continuous rolling and equipment thereof. The technique and the equipment thereof utilize the production technique of continuous rolling of the medium (high) density fiber board and combine with the additional facing material convey technique and the direct facing technique of the fiber board and the facing. During the whole process, the linear speed of the conveying of the facing material is adjusted to be consistent with the discharging linear speed of the fiber board produced by continuous rolling. The technique spares the polishing process, thus having no dust pollution and being beneficial for the health of the operator; heat of the fiber board when coming out from a pressing machine is directly used for facing and the heating process in the traditional facing technique is shortened, thus saving the resources and reducing energy consumption; the equipment adopted in the technique is simple, practical and high effective; the facing board produced by the technique has low cost and can replace veneer to be applied to the facing of the case bodies of furniture, TV, sound boxes and other video and audio apparatus as well as other upscale packaging materials.

Owner:JIANGSU DAJIANG WOOD IND

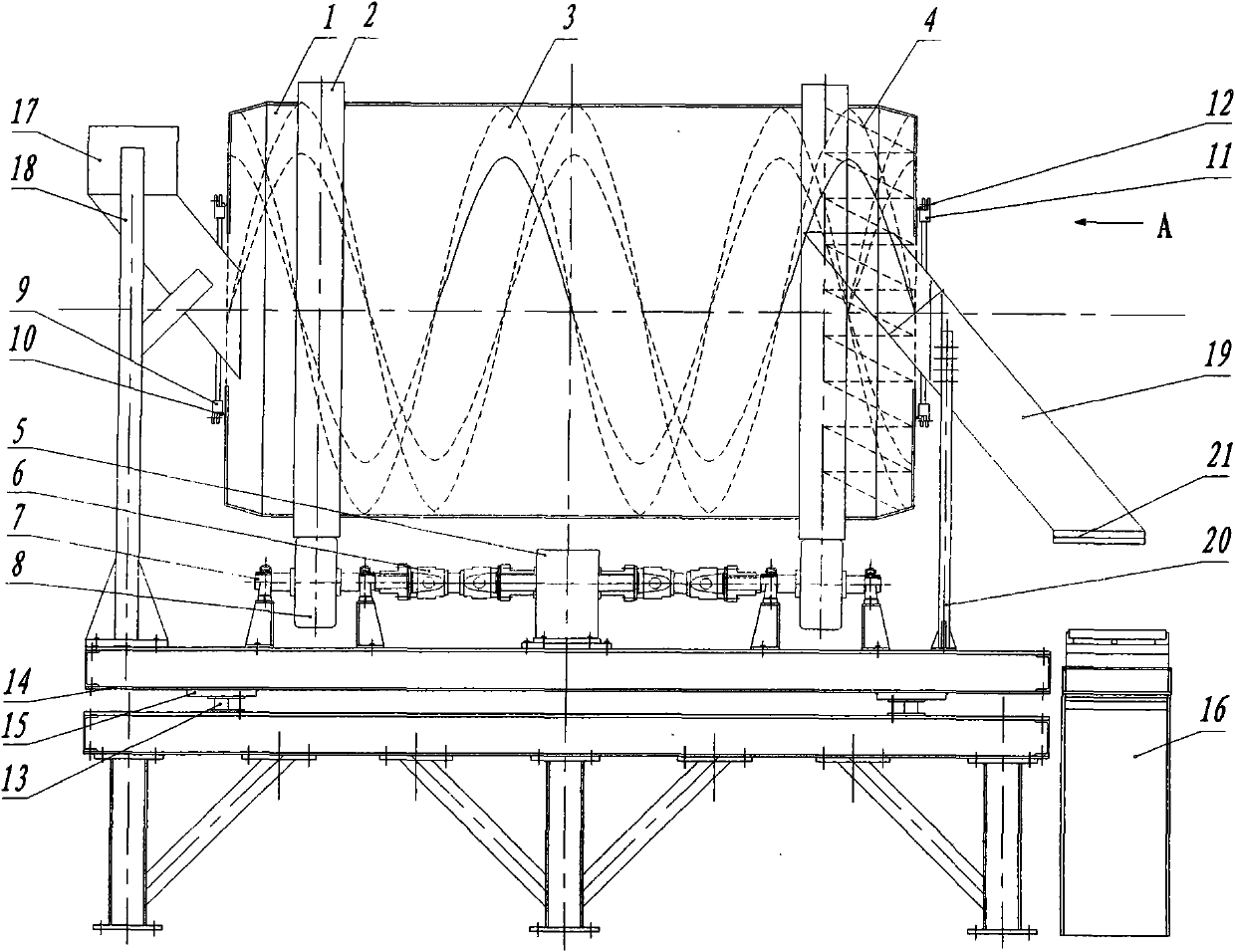

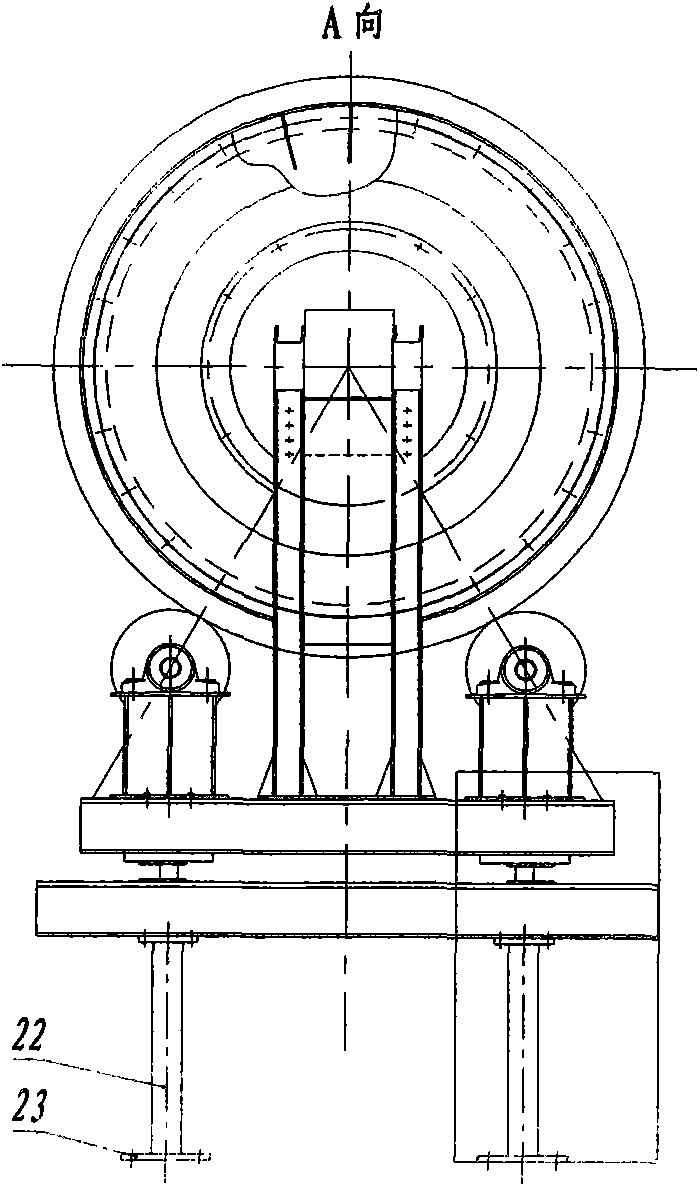

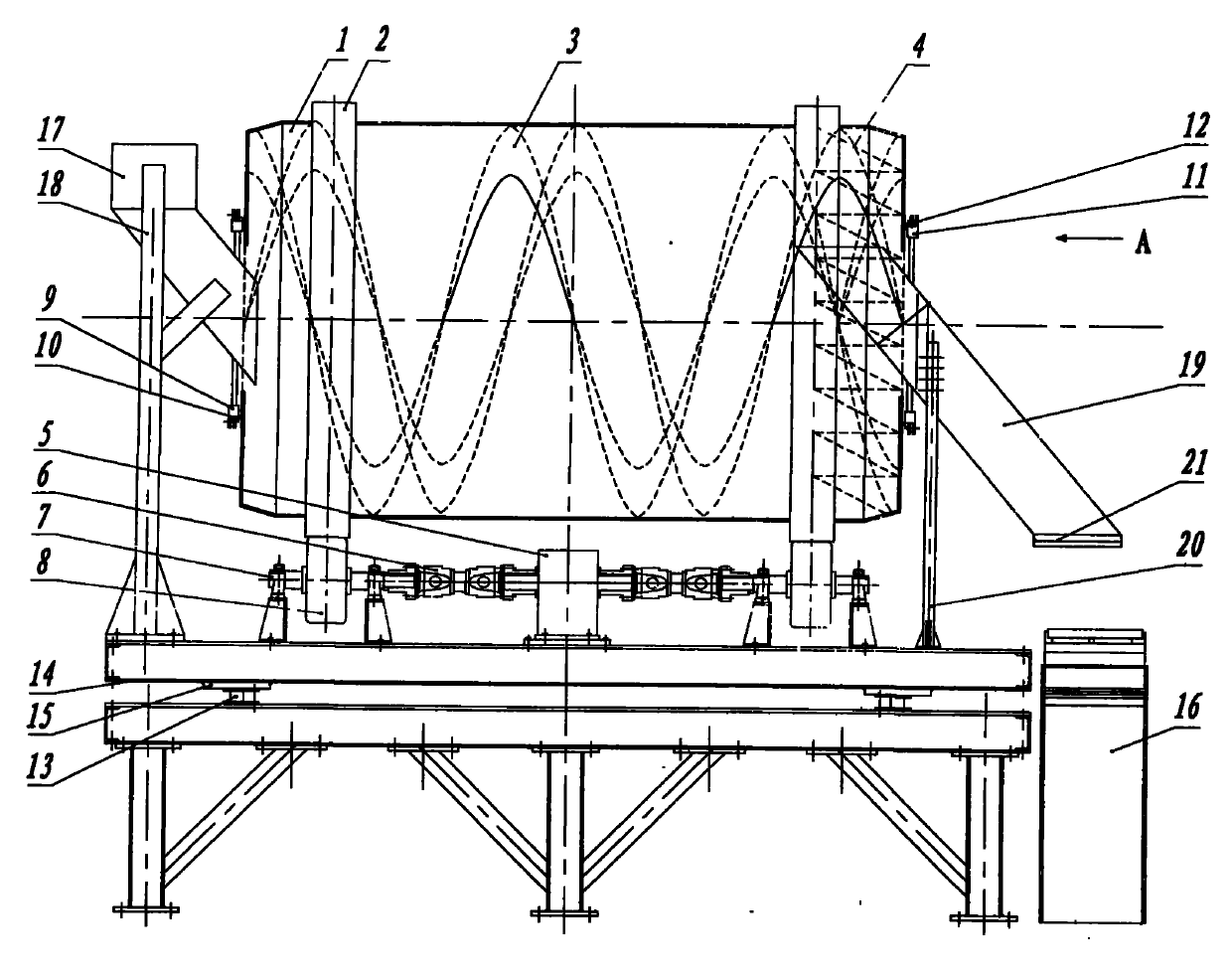

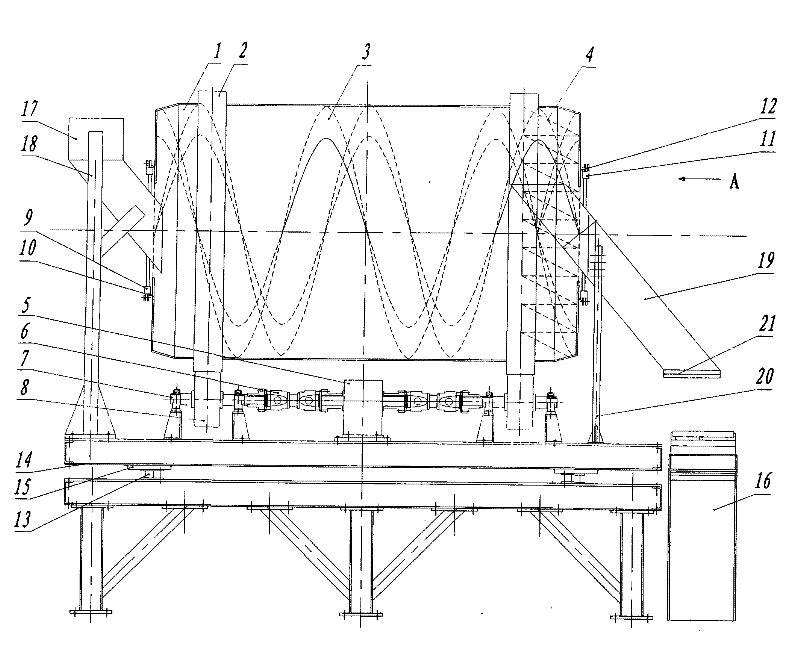

Mixer for mixing rubber and plastic particles

The invention relates to a mixer for mixing rubber and plastic particles, which comprises a mixing roller device and a transmission device which are matched with each other. Both the mixing roller device and the transmission device are arranged on a weighing device which is arranged on a support base. The weighing device, the mixing roller device and the transmission device are respectively connected with a control system which is arranged on one side of the support base through circuits. The mixing roller device is driven by a driving wheel through a rolling ring to rotate. The roller has positive rotation and reverse rotation. During positive rotation, an inner spiral pushing auger drives material particles in the roller to lift, rotate, roll and move tangentially and axially along the roller to uniformly mix the materials. Meanwhile, the materials move to the side of a discharge outlet axially under the action of a spiral thrusting force, and the materials are discharged from the discharge outlet through a material lifting plate finally. The mixer for mixing the rubber and plastic particles has the characteristics of high production efficiency, excellent mixing effect, high discharge speed, adjustable speed, accurate discharge, capacity of preventing the material particles from re-bonding, full-automatic control, full closeness, no dust or noise pollution, and the like.

Owner:SHANDONG UNIV

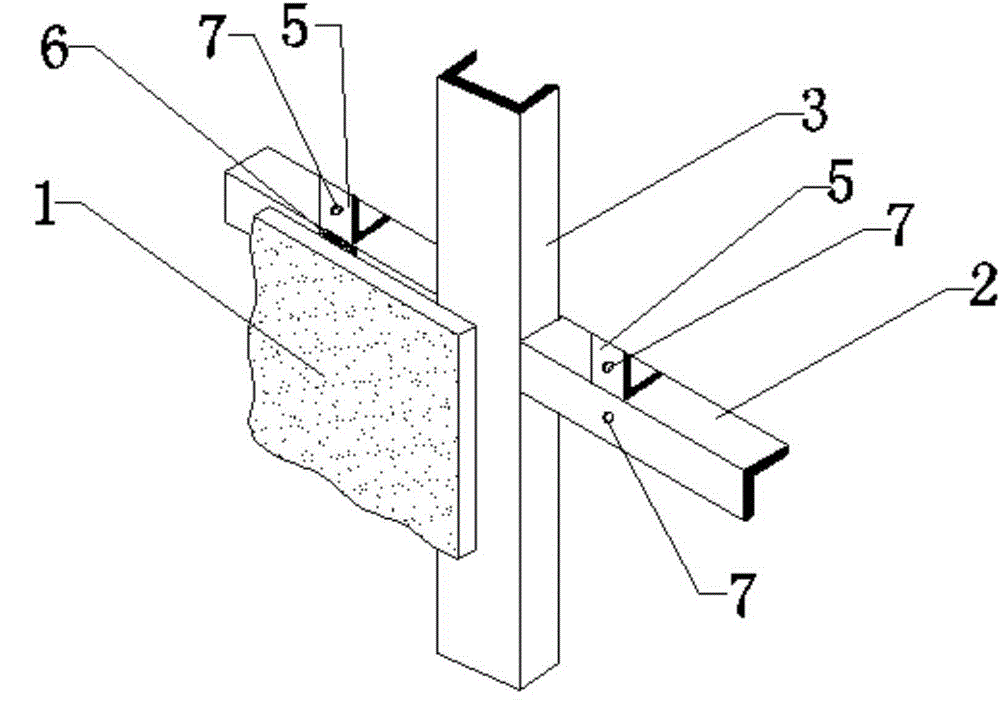

Stone dry bonding mounting structure unit and mounting method thereof

The invention discloses a stone dry bonding mounting structure unit and a mounting method thereof. The stone dry bonding mounting structure unit comprises stone, a transverse keel, a vertical keel, four glue penetration holes and two corner connectors, wherein the vertical keel is connected to a wall surface; the transverse keel is connected to the vertical keel; the upper end of the stone is connected to the transverse keel; the two corner connectors are fixed on the transverse keel and are symmetrically distributed on two sides of the vertical keel; the lower end of the stone is connected with the two corner connectors; two of the four glue penetration holes are respectively distributed in surfaces, which are in contact with the stone, of the two corner connectors; the other two glue penetration holes are uniformly distributed on a surface, which is in contact with the stone, of the transverse keel; epoxy resin structure glue layers coat portions, which correspond to the four glue penetration holes, of the stone; and the stone, the transverse keel and the corner connectors are connected to one another through the coated epoxy resin structure glue layers. Glue nails have a reinforcing effect, the problem that a dry hanging method is unsafe when the thickness of a dry hanging stone plate is insufficient can be solved, and construction efficiency is improved.

Owner:GOLD MANTIS CONSTR DECORATION

Environment-friendly degradable child colored oiled crayon and preparation method thereof

The invention provides an environment-friendly degradable child colored oiled crayon. The colored oiled crayon comprises the following components the content of which is in mass fraction: 0.3-12% of chromogenic reagent, 6-15% of color-developing agent, 35-53% of emulsifying wax, 15-20% of polyethylene glycol, 12-25% of stearic acid, and 2-15% of talcum powder. The child colored oiled crayon disclosed by the invention overcomes the shortcoming that the existing child crayon is difficult to erase, and has the advantages that after writing, color can be removed by wiping with water, and no trace is left. The colored oiled crayon is dust-pollution-free, environment-friendly, non-toxic and innocuous, and can be not only used as a child crayon, but also used to write on a whiteboard for teaching. The production process is simple and mass production of the crayon is easy to realize.

Owner:浙江奥乐奥新材料科技有限公司

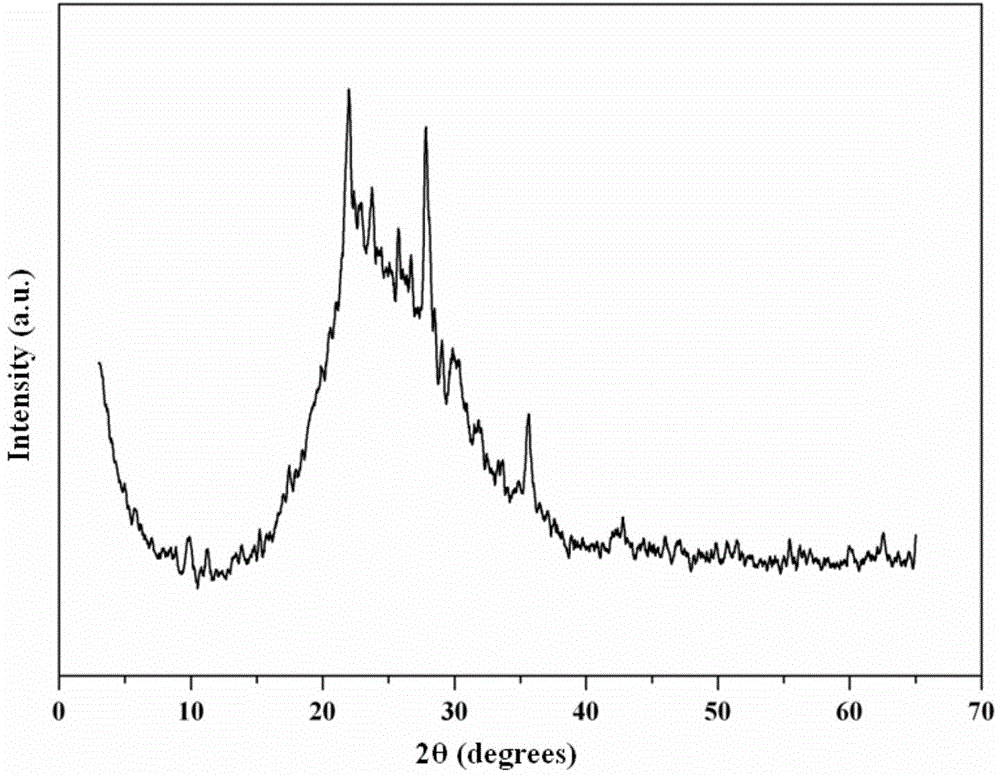

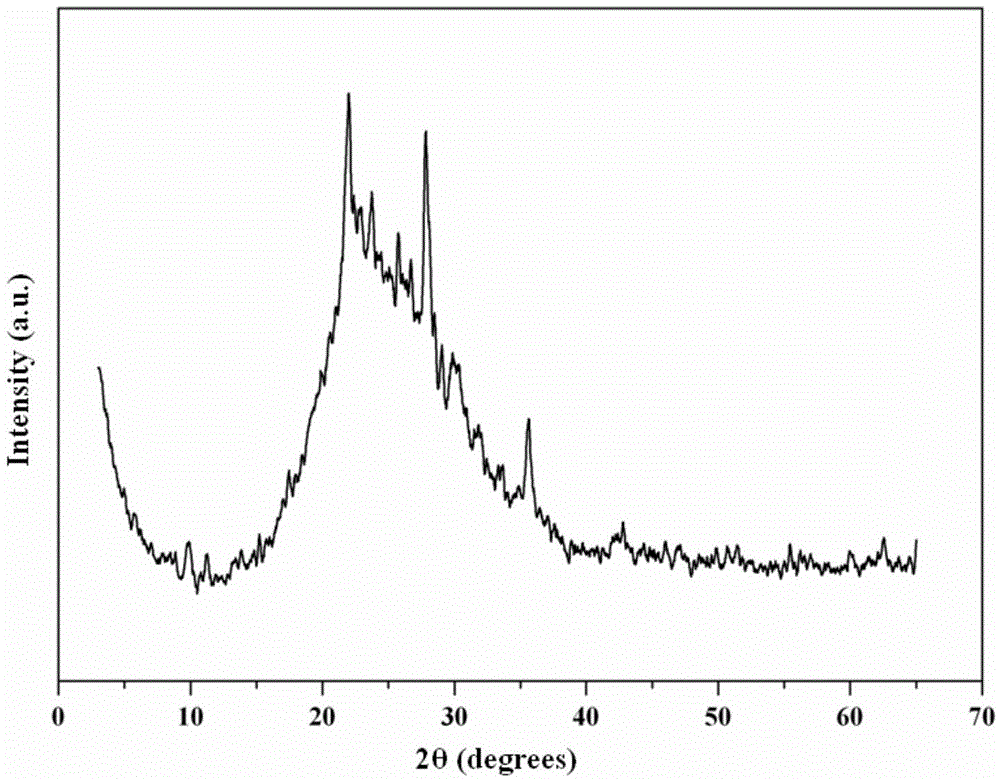

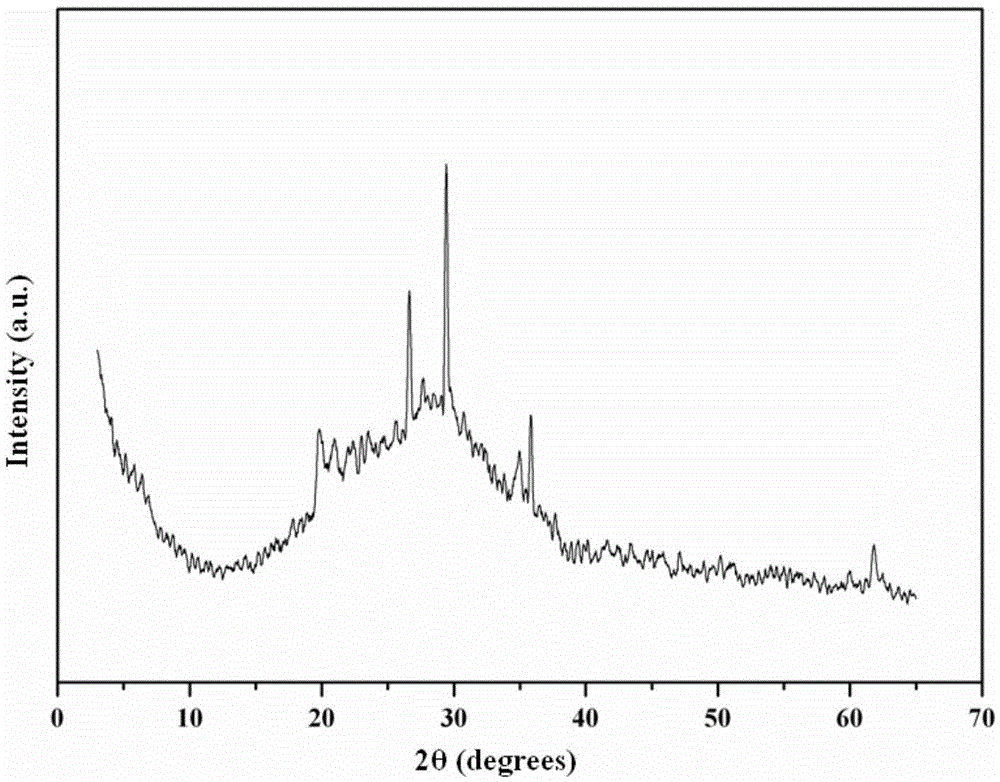

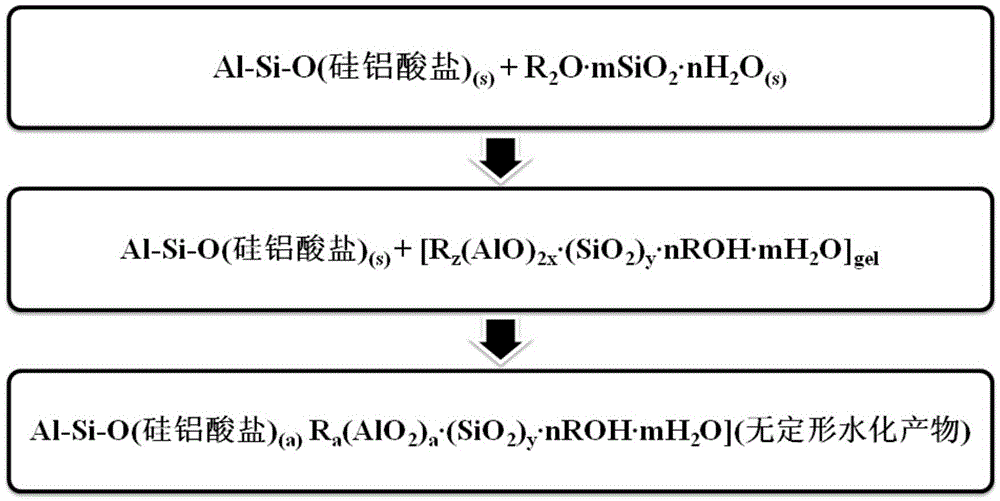

Artificial perlite and puffed products and preparation method of artificial perlite

The invention relates to artificial perlite and puffed products and a preparation method of artificial perlite. The artificial perlite is prepared by the following steps: by using calcium bentonite and an alkali metal silicate aqueous solution as raw materials, properly introducing an auxiliary function aid; and puffing at a certain temperature to obtain the artificial perlite puffed product. The preparation method is a moulding and mixture-ageing method and a mechanical shearing method. The artificial perlite is high in utilization ratio of raw materials and low in puffing temperature. The puffed products are numerous in variety, stable and controllable in physical and chemical properties, and good in mechanical strength and fireproof performance. The preparation method is simple in preparation process and basically free from dust pollution in the preparation process, and is suitable for industrial production.

Owner:宁波荣山新型材料有限公司

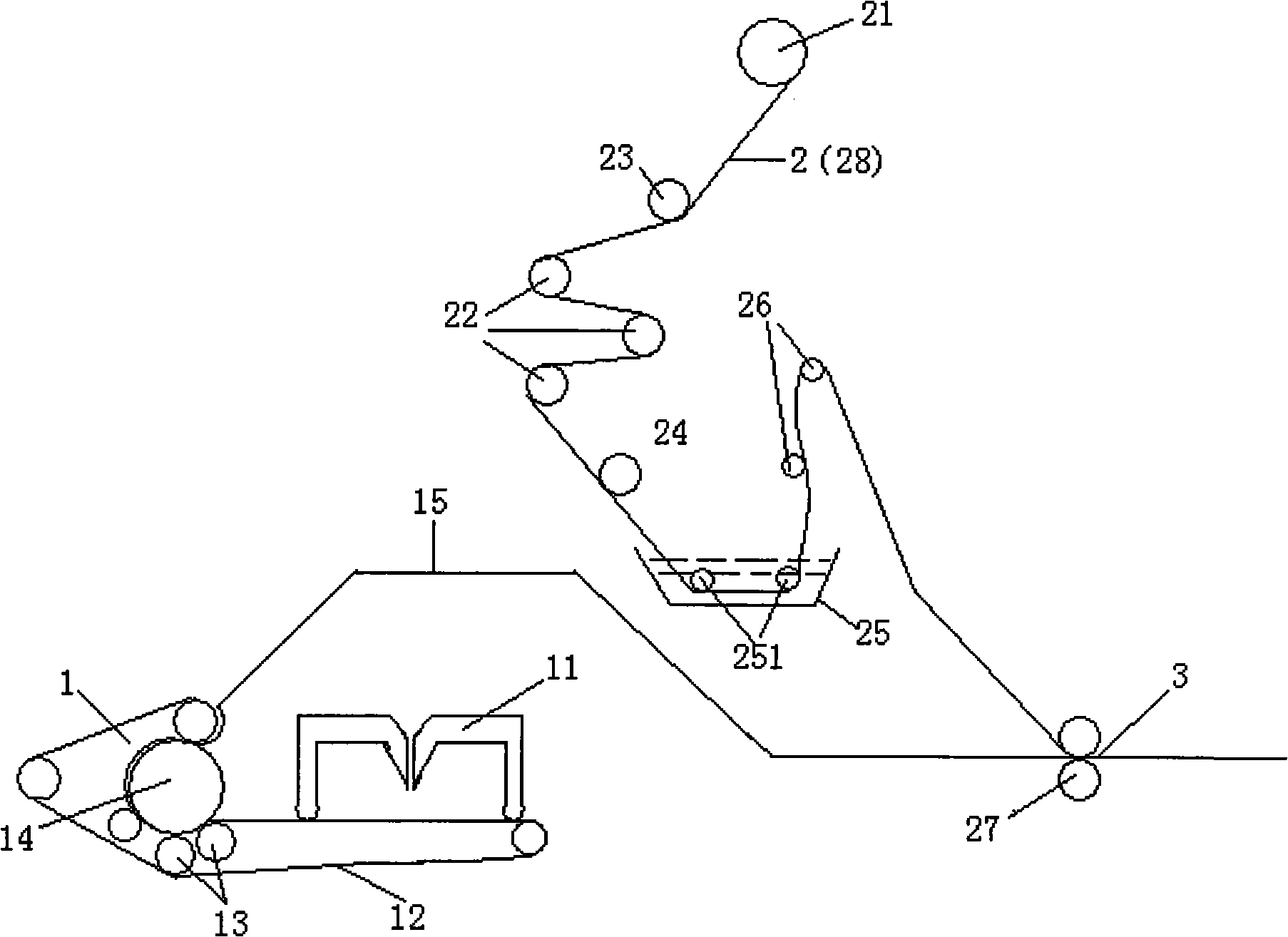

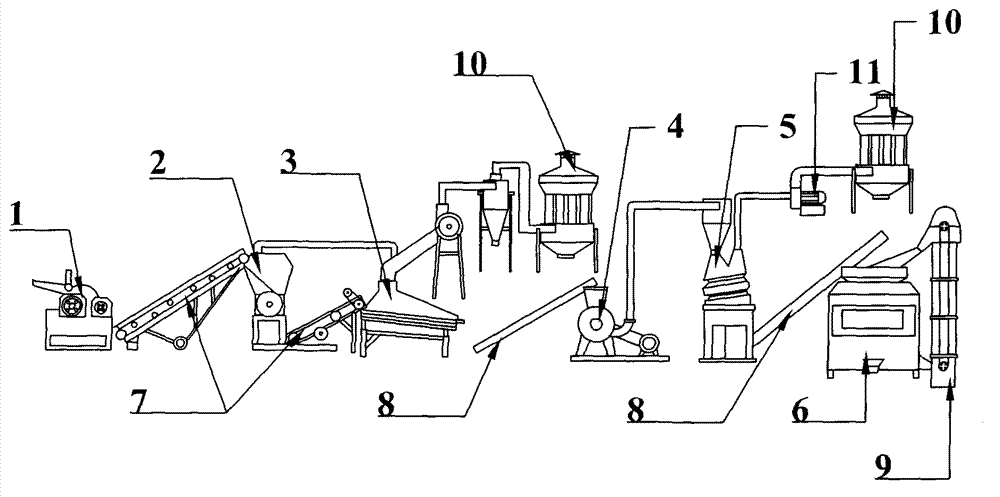

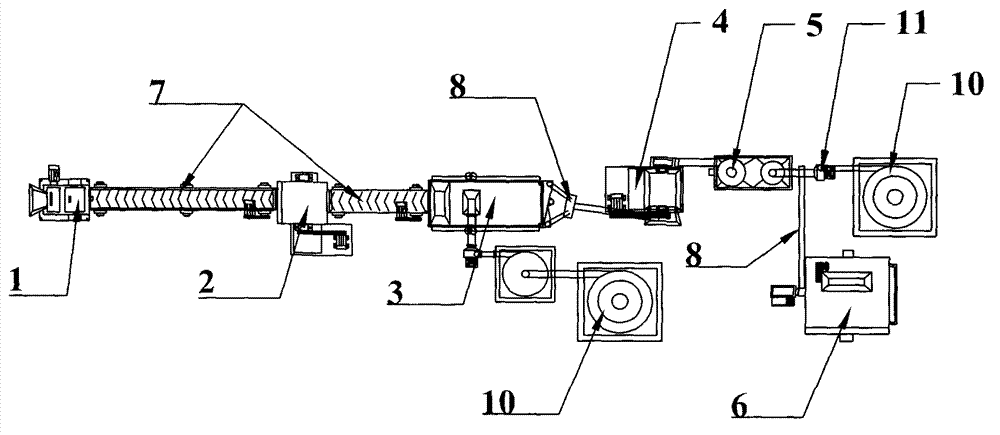

Scrap copper wire material separation treatment system and corresponding separation process

The invention discloses a scrap copper wire material separation treatment system and a corresponding separation process. The traditional water type separation after pulverization not only causes resource waste, but also pollutes the environment seriously; the dry type separation after pulverization has the defects of incomplete separation and low-purity products due to the fact that the process is short. The scrap copper wire material separation treatment system comprises a cutting machine, a crushing machine, a wind vibration separator, a pulverizer, a gravity sorting machine and a high-voltage electrostatic separator; a magnetic separation conveyor is arranged between the cutting machine and the crushing machine, and another magnetic separation conveyor is arranged between the crushing machine and the wind vibration separator; a spiral conveyor is arranged between the wind vibration separator and the crushing machine, and another spiral conveyor is arranged between the gravity sorting machine and the high-voltage electrostatic separator; the high-voltage electrostatic separator is provided with a bucket elevator. The separation treatment system has complete separation and high-purity products; the rational process not only increases the production efficiency, but also saves the human resource; and the entire process has no dust or secondary pollution.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

Flexible vertical grinder

InactiveUS20150217298A1Reduce grinding consumptionImprove crushing efficiencyGrain treatmentsEngineeringBalance wheel

Owner:HUNAN ZHONGHONG HEAVY MACHINERY

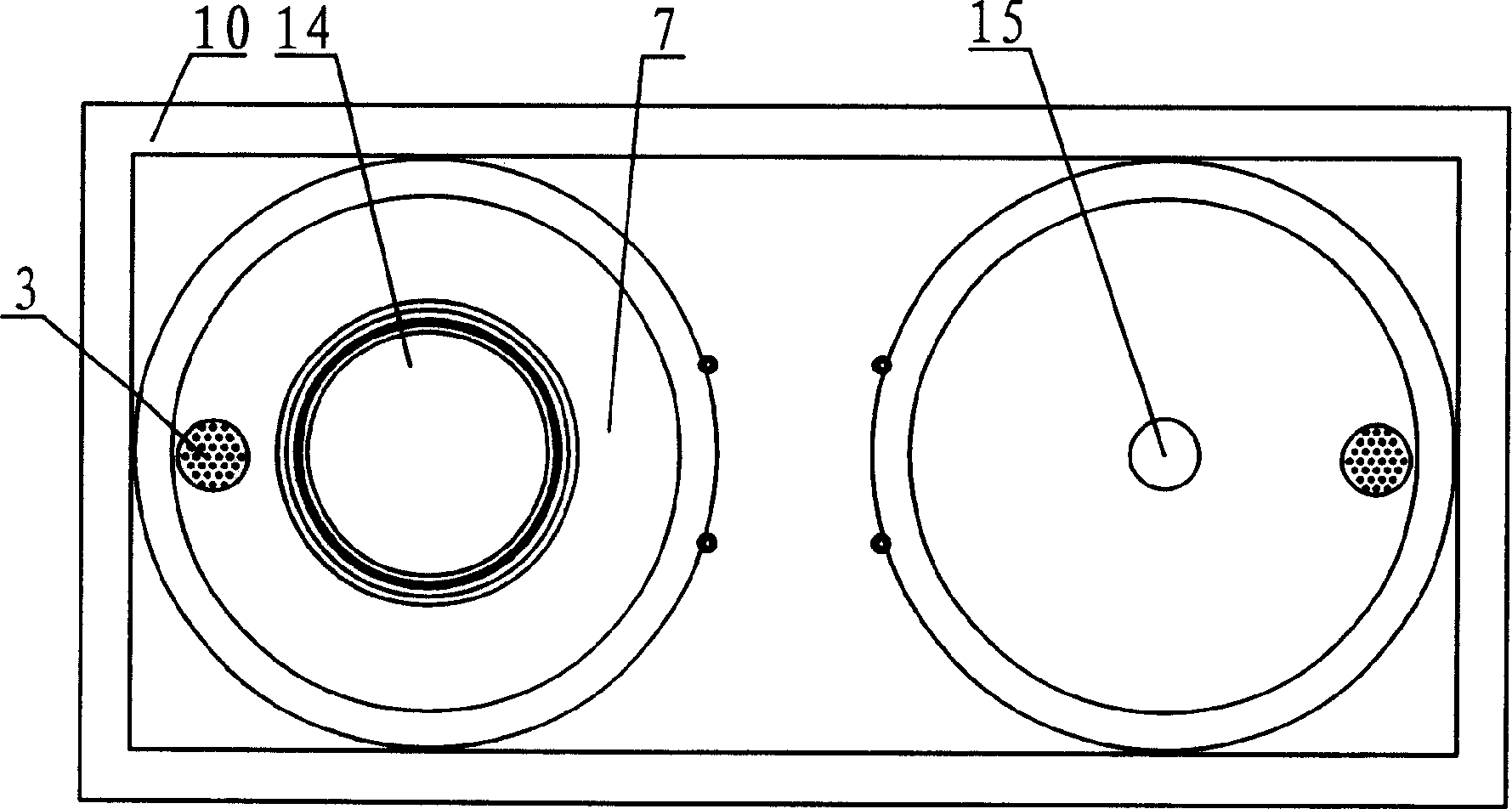

Two-site polishing machine

InactiveCN1608802AConvenient manual polishingImprove work efficiencyGrinding drivesFlexible-parts wheelsFiberEngineering

The two-site polishing machine includes frame, polishing plate and driving mechanism. The polishing plate is set on the frame and driven with the driving mechanism, and surface of the polishing plate includes outer layer of fibrous fabric. The polishing machine has two polishing plates, including one planar plate and one convex plate. The present invention makes it possible for the user to use the planar plate and the convex plate alternately in polishing plane, convex surface and concave surface of the product in high work efficiency.

Owner:WUHAN UNIV

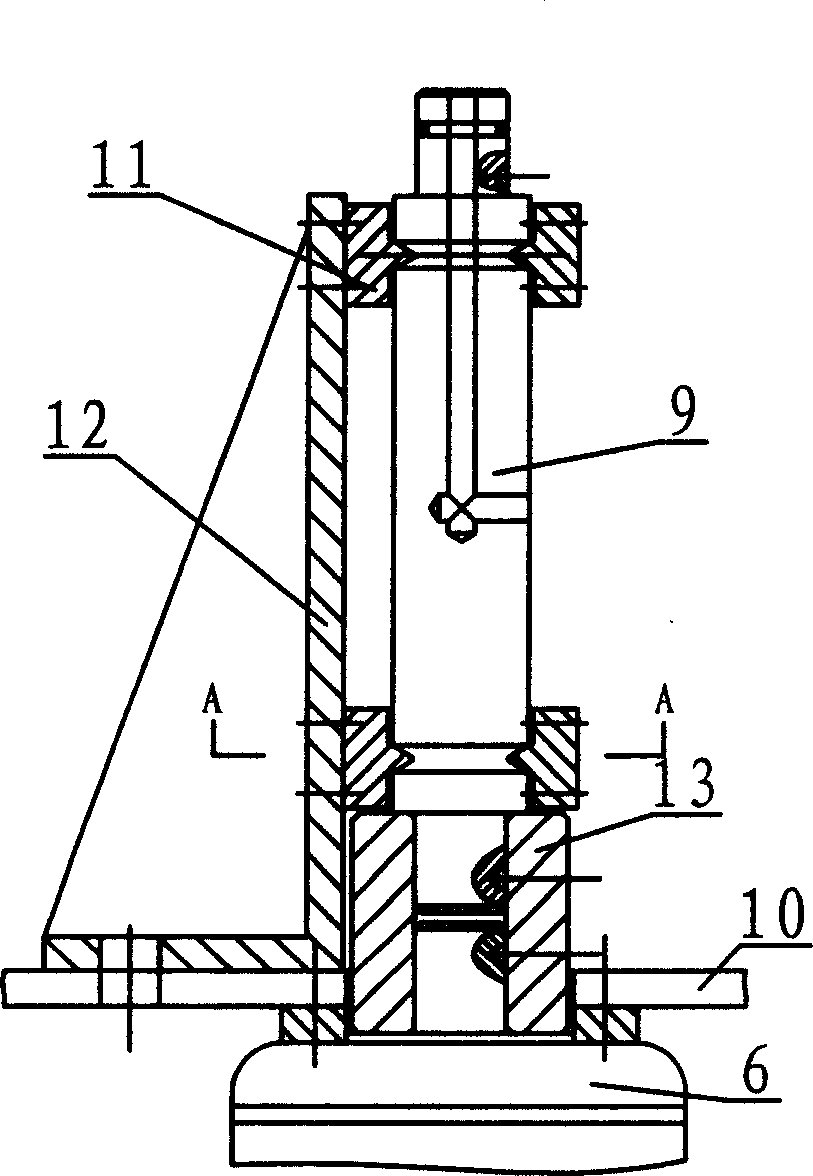

Mechanism for grinding hydromica with high pressure water

ActiveCN103962212ANo dust pollutionReduce energy consumptionGrain treatmentsSpray nozzleEnvironmental resistance

The invention provides a mechanism for grinding hydromica with high pressure water, and belongs to the technical field of hydromica grinding. The mechanism comprises a columnar grinding pipe; a feeding pipe is sleeved with the grinding pipe; the side wall of the grinding pipe is connected with an overflow tank by a water outlet pipe; an overflow port is formed in the upper end of the overflow tank; a high-pressure water spray nozzle is arranged at the bottom of the grinding pipe, and connected with a high pressure water pump. The hydromica is ground with high pressure water, dust pollution is avoided during the grinding process, the energy consumption is low, the mechanism has an environment-friendly effect, the whole grinding process can be carried out continuously, and the grinding effect is good.

Owner:ZHEJIANG COLORAY TECH DEV

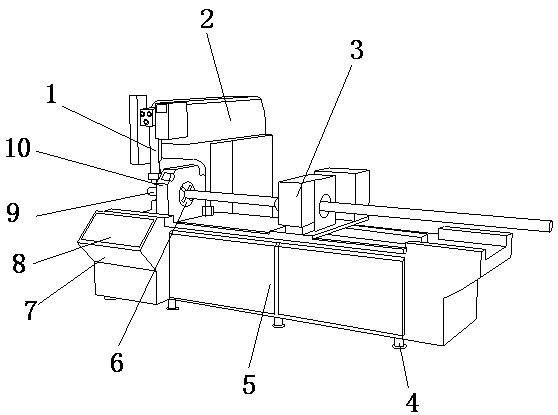

Full-automatic numerical control bar cutting machine for silicon crystal bar

PendingCN108372598AHigh degree of automationNo dust pollutionWorking accessoriesFine working devicesDust pollutionCrystal

The invention discloses a full-automatic numerical control bar cutting machine for a silicon crystal bar. The machine comprises a feeding area, a stock bin and a tool rest; the stock bin is connectedto the feeding area; a mechanical arm is arranged between the stock bin and the tool rest; a cutter head is arranged on the tool rest; a grooving power head is arranged behind the tool rest; an automatic chip discharging head is arranged on the side surface of the tool rest, and the tool rest is erected on stand columns and comprises a lifting sleeve capable of ascending and descending vertically;a rotatable rotating sleeve is arranged in the lifting sleeve; the tool disc is connected to the bottom of the rotating sleeve; and a pressure plate is arranged in the center of the tool rest. According to the machine, after the silicon crystal bar enters the stock bin from the feeding area, the silicon crystal bar is clamped to the position below the tool rest through the mechanical arm, the pressure plate presses the silicon crystal bar downwards so as to press and position the silicon crystal bar, descending of the tool rest and rotating of the rotating sleeve enable the tool disc to carryout outer cylindrical cutting on the silicon crystal bar, and cut excess materials fall into the automatic chip discharging head to be collected and recycled. The machine has the advantages that theautomation degree is high, dust pollution can be avoided, the excess materials can be collected and recycled, so that energy conservation and environmental protection can be realized, only one hour isneeded for cutting each time, and the working efficiency is high.

Owner:江阴华芯源半导体装备有限公司

Mixer for mixing rubber and plastic particles

The invention relates to a mixer for mixing rubber and plastic particles, which comprises a mixing roller device and a transmission device which are matched with each other. Both the mixing roller device and the transmission device are arranged on a weighing device which is arranged on a support base. The weighing device, the mixing roller device and the transmission device are respectively connected with a control system which is arranged on one side of the support base through circuits. The mixing roller device is driven by a driving wheel through a rolling ring to rotate. The roller has positive rotation and reverse rotation. During positive rotation, an inner spiral pushing auger drives material particles in the roller to lift, rotate, roll and move tangentially and axially along the roller to uniformly mix the materials. Meanwhile, the materials move to the side of a discharge outlet axially under the action of a spiral thrusting force, and the materials are discharged from the discharge outlet through a material lifting plate finally. The mixer for mixing the rubber and plastic particles has the characteristics of high production efficiency, excellent mixing effect, high discharge speed, adjustable speed, accurate discharge, capacity of preventing the material particles from re-bonding, full-automatic control, full closeness, no dust or noise pollution, and the like.

Owner:SHANDONG UNIV

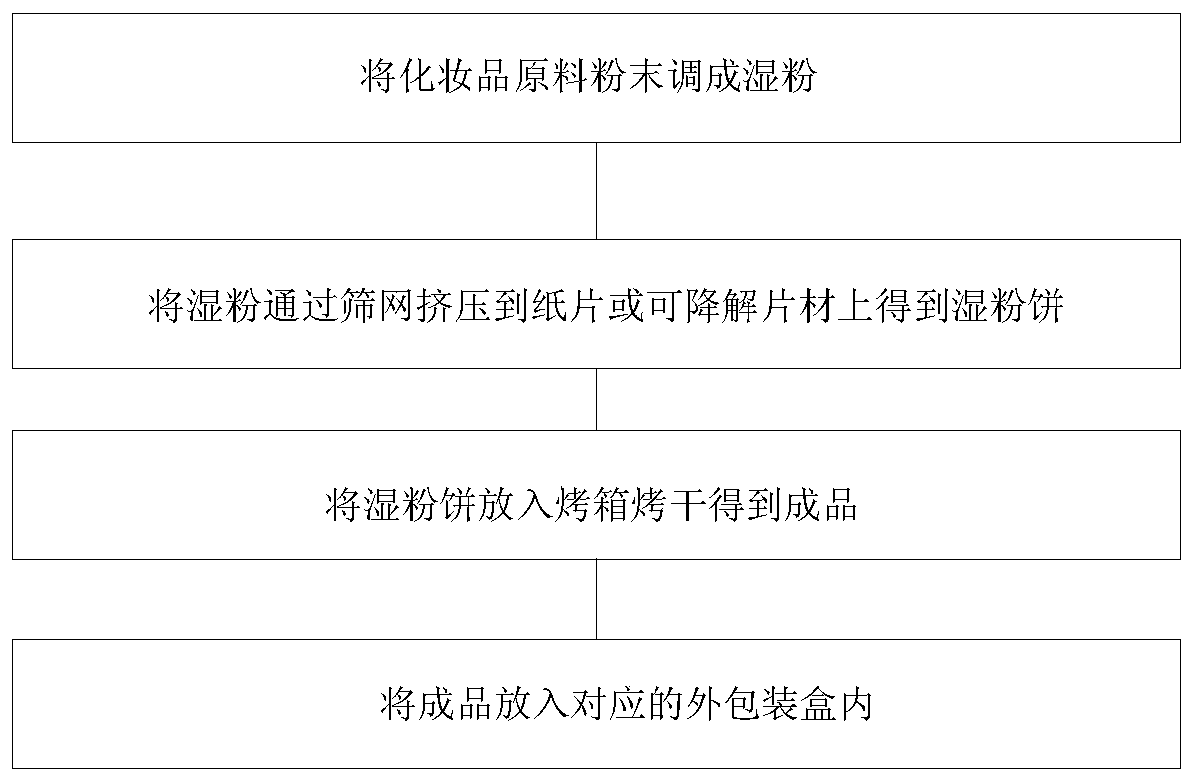

Powder cosmetics forming method

InactiveCN110143008AReduce lossReduce manufacturing costHeating arrangementShaping pressMetallurgyPollution

The invention discloses a powder cosmetics forming method. The powder cosmetics forming method comprises the following steps that a diluting agent is added into cosmetics raw material powder to form wet powder in a blending manner; S2, wet powder is extruded to a paper sheet or degradable sheet through a screen net to obtain wet pressed powder, the screening net is internally provided with one ormultiple forming spaces, and the shape of the forming spaces is consistent with the preset product shape; S3, the paper sheet or degradable sheet and the wet pressed powder are jointly put into an oven to enable liquid to be evaporated and dried at the temperature of 50 to 80 DEG C, and a finished product is obtained; and S4, the finished product is put into a corresponding outer packaging box. According to the method, a large device is not needed, a steel mold or aluminum vessel is not needed, the energy losses can be greatly reduced, production cost is saved, in the full process, wet powderis adopted for preparing, and powder pollution and pollution discharge do not completely exist.

Owner:李辉

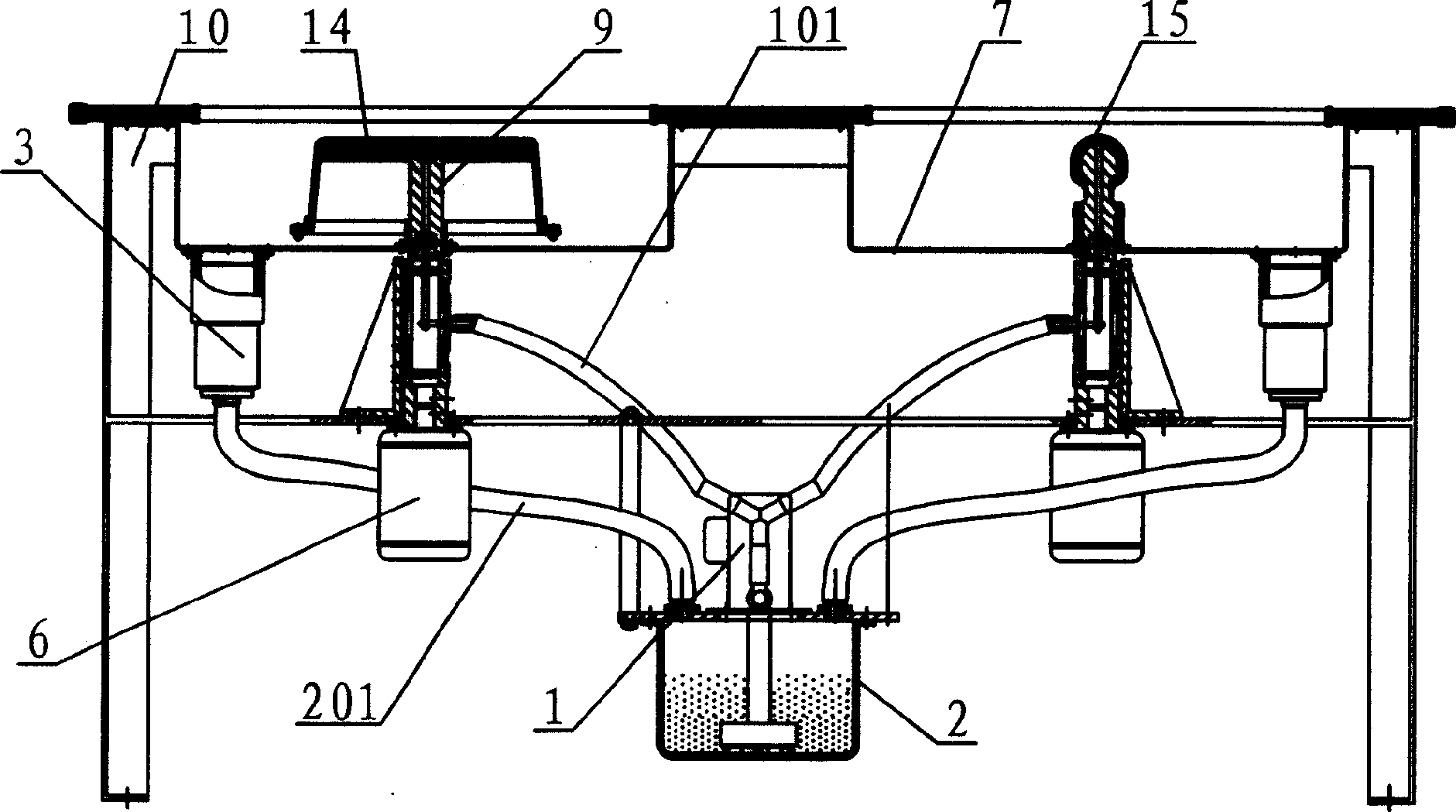

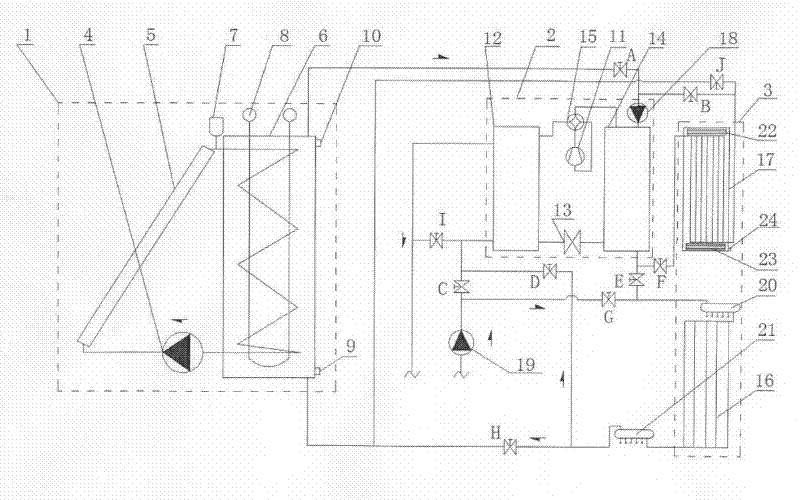

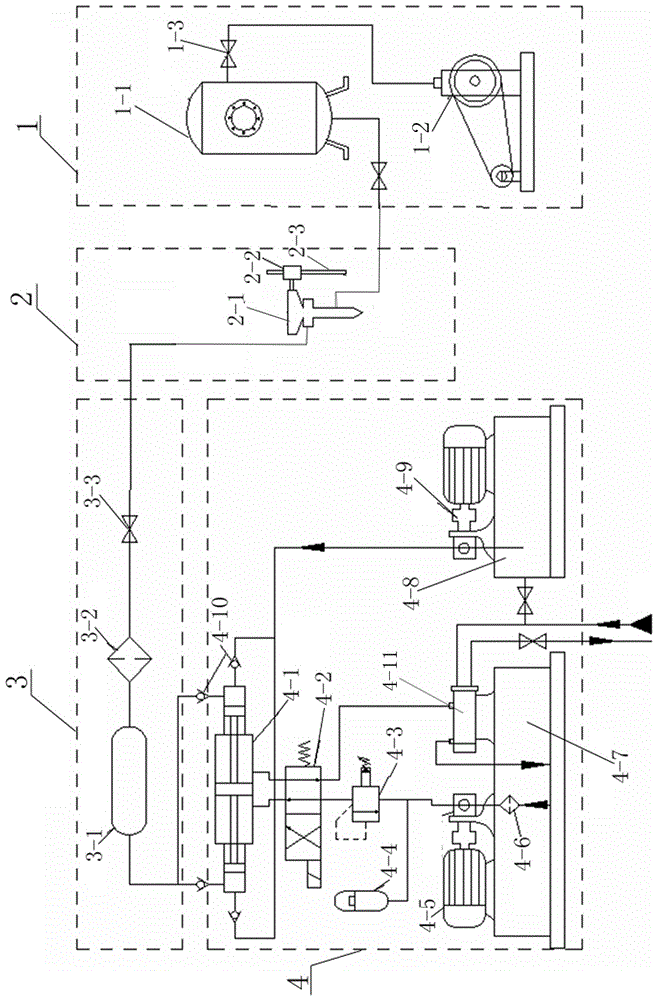

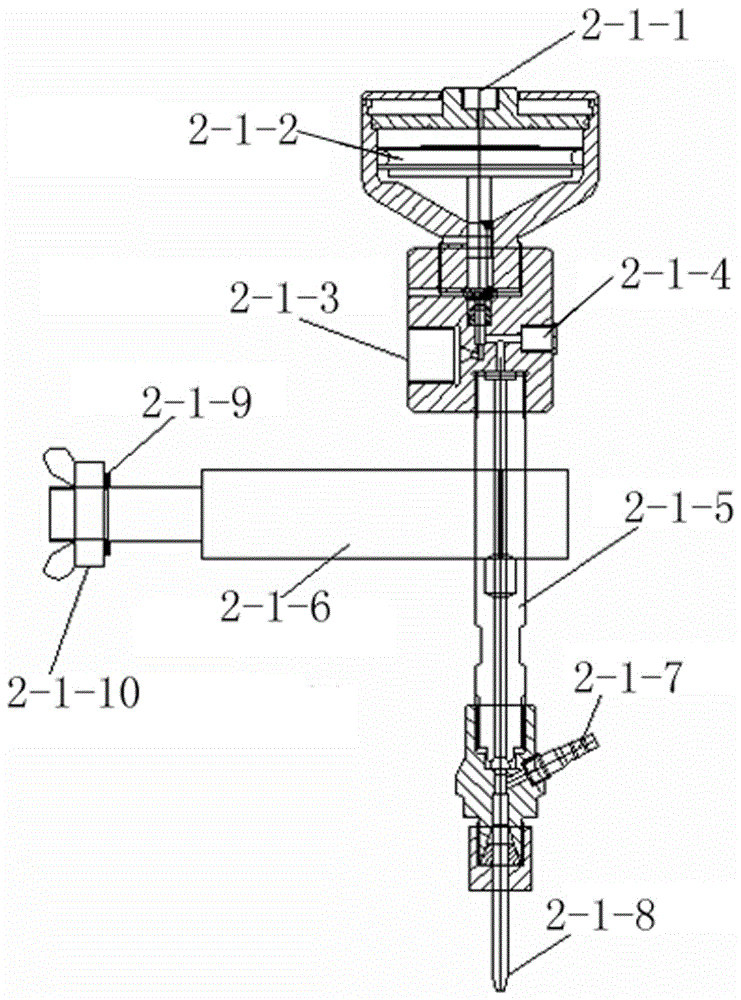

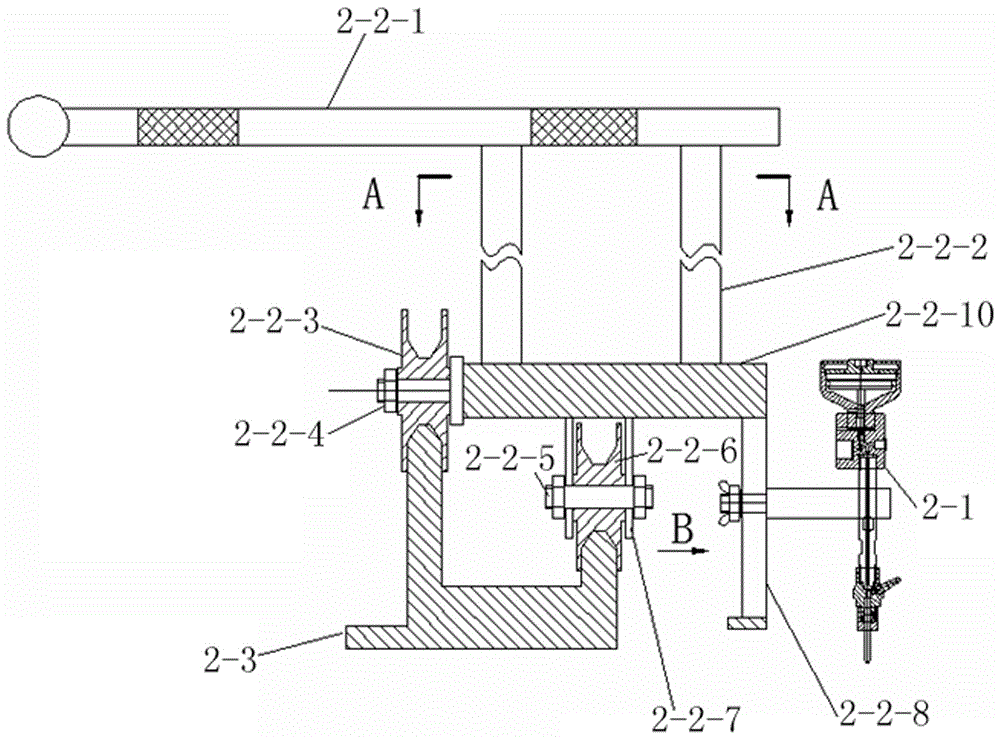

Capillary network heat pump system utilizing solar energy

InactiveCN101936624BFree of ChargeLower condensation temperatureHeat pumpsSolar heat devicesCapillary networkWater source

The invention discloses a capillary network heat pump system utilizing solar energy, comprising a solar heat-collecting circulating system, a heat pump circulating system and a capillary network circulating system. The solar heat-collecting circulating system comprises a solar water circulating pump, a solar heat-collecting pipe, a heat-collecting water tank, a vent valve, an auxiliary electric heater, a watercomplementing hole and a hot water hole, the heat pump circulating system comprises a refrigerant circulating system and a water circulating system, the refrigerant circulating system comprises a compressor, a condenser, an electronic expansion valve, an evaporator and a four-way reversing valve, the water circulating system comprises a circulating water pump at a heat source side, asystem circulating water pump, a water collecting / distributing device, a by-pass valve and a connecting valve, and the capillary network circulating system comprises a capillary network for radiationand a weight air conditioner cabinet. The invention has the advantages that solar energy is combined with the radiation heat exchange between a water source heat pump and the tail ends of the capillary network and the system has characteristics of independent dehumidification, convenient mounting, energy saving, high efficiency, no noise, environmental protection, softness and comfortableness.

Owner:郑州中南科莱空调设备有限公司

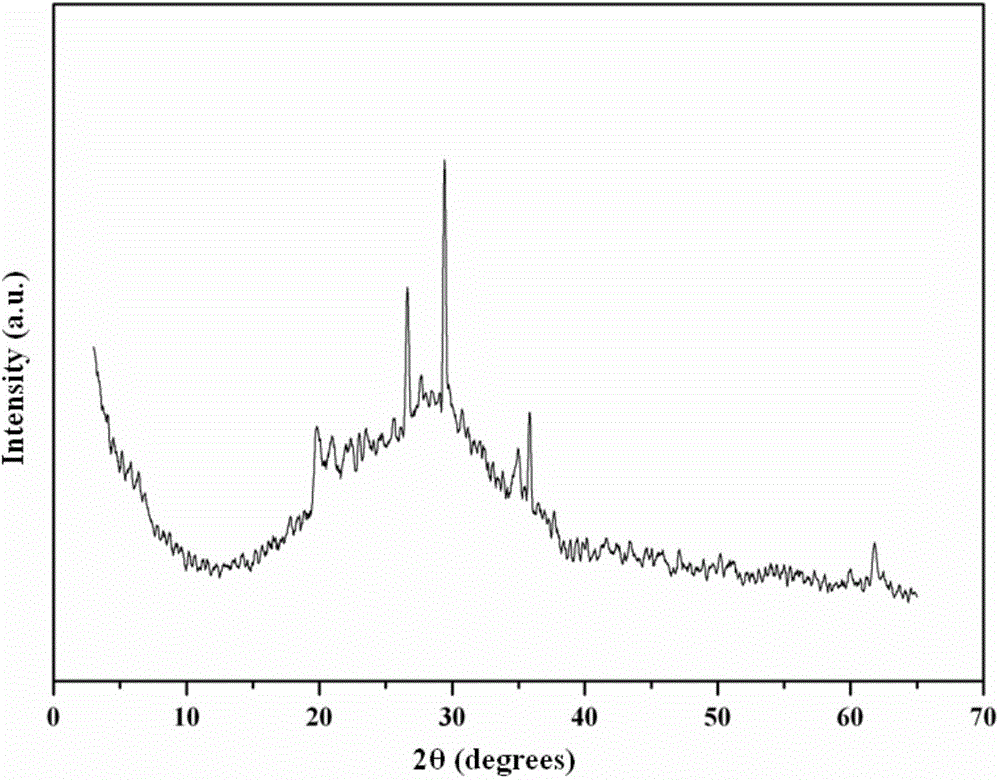

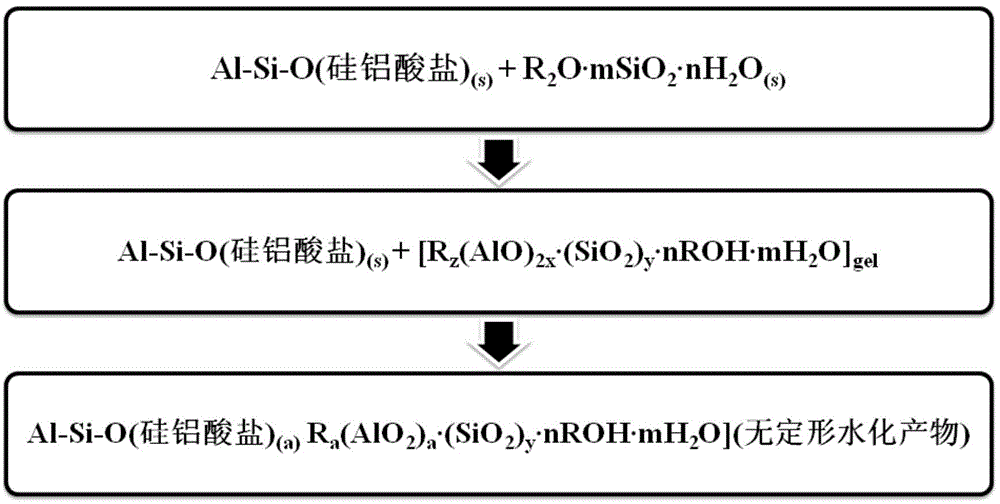

A kind of artificial perlite and expanded product and preparation method thereof

The invention relates to artificial perlite and puffed products and a preparation method of artificial perlite. The artificial perlite is prepared by the following steps: by using calcium bentonite and an alkali metal silicate aqueous solution as raw materials, properly introducing an auxiliary function aid; and puffing at a certain temperature to obtain the artificial perlite puffed product. The preparation method is a moulding and mixture-ageing method and a mechanical shearing method. The artificial perlite is high in utilization ratio of raw materials and low in puffing temperature. The puffed products are numerous in variety, stable and controllable in physical and chemical properties, and good in mechanical strength and fireproof performance. The preparation method is simple in preparation process and basically free from dust pollution in the preparation process, and is suitable for industrial production.

Owner:宁波荣山新型材料有限公司

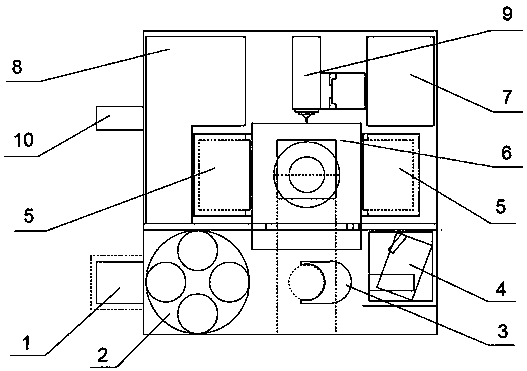

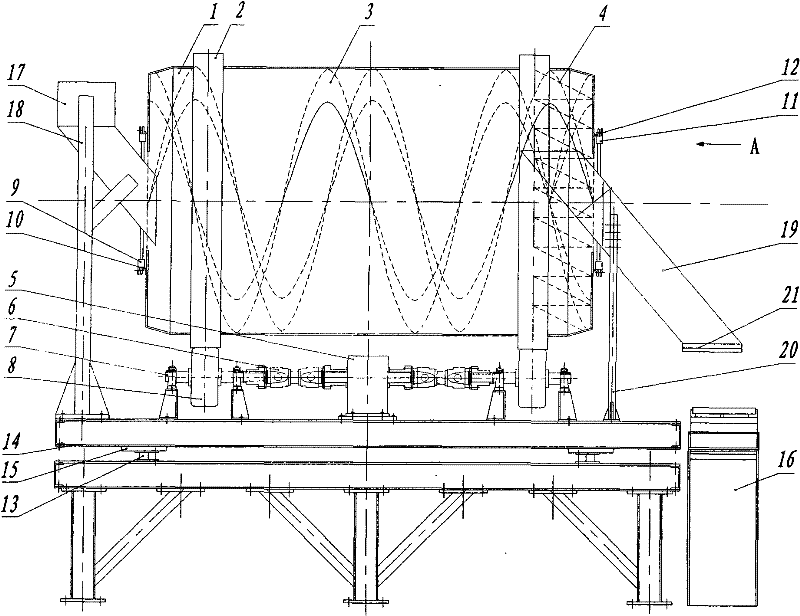

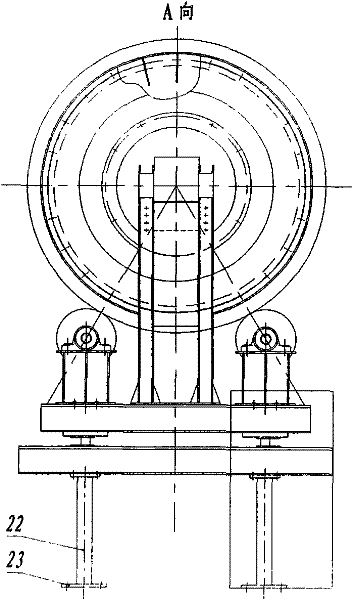

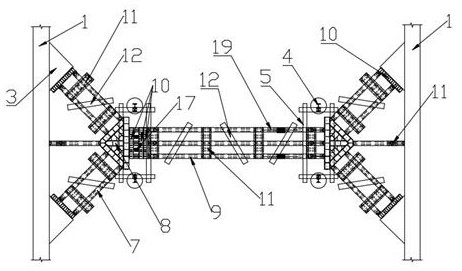

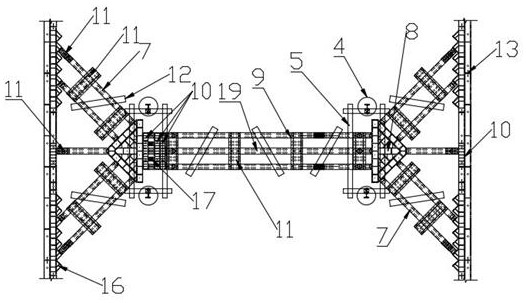

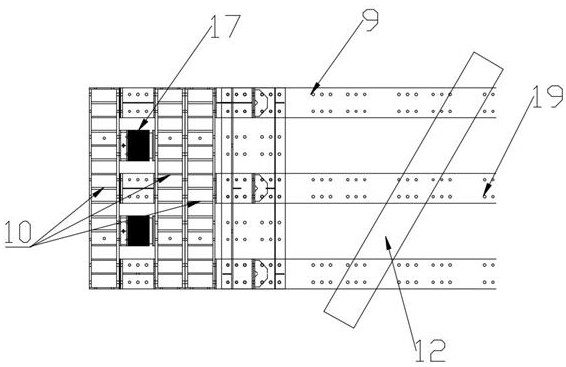

Flexible vertical grinder

InactiveUS9764328B2Operation efficiency is highReasonable structureGrain treatmentsEngineeringGrinding wheel

A flexible vertical grinder, having a main shaft mounting frame (4) on a grinder frame (1); a main shaft (3) is mounted on the main shaft mounting frame; a stelliform bracket (9) is mounted on the main shaft; a hammer wheel grinder and a material-sorting balance wheel device are mounted on the stelliform bracket; the material-sorting balance wheel (4) and the hammer wheel (17) are on the same horizontal plane. The vertical grinder can apply different grinding forces according to different specific surface areas of the to-be-ground material, and can grind materials of different grades properly but not excessively, thus greatly improving crushing efficiency, having good overall rigidity and stable operation, and facilitating maintenance.

Owner:HUNAN ZHONGHONG HEAVY MACHINERY CO LTD

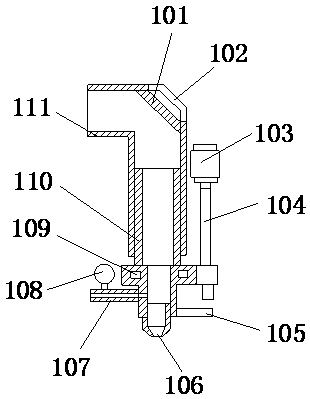

Chipless cutting device for cutting PVC plastic pipe

InactiveCN111037107AFlat and chip-free cutting surfaceNo pollution in the processLaser beam welding apparatusTubular articlesEngineeringLaser cutting

The invention relates to a chipless cutting device for cutting a PVC plastic pipe. The chipless cutting device structurally comprises a laser cutting device, a driving motor, a pipe body middle section fixing base, supporting legs, a machine body, a pipe body fixing clamp, an operation table, a touch panel, a pipe body and a pipe body front end fixing base. The laser cutting device comprises a reflector, a reflector cooling water jacket, a servo motor, a ball screw, a position sensor, a laser cutting nozzle, an oxygen inlet pipe, an oxygen pressure gauge, a lens cooling water jacket, a focusing lens and a shell. in order to achieve laser chipless accurate machining and cutting of the PVC plastic pipe, the cutting device is provided with the laser cutting device, accurate positioning can beachieved through the position sensor, laser beams are emitted through the laser cutting nozzle for cutting, and the cutting face of the PVC plastic pipe can be flat, chipless and pollution-free.

Owner:江苏泛亚橡塑新材料有限公司

Microwave refrigerated dough for making crisp pancake and its making method

A frozen dough for roasting crisp cake by microwave is prepared from non-glutinous round-grained rice flour, potato starch, almond powder, glutinous rice flour, salt, chicken extract and water through mixing, steaming, cooling, kneading, pressing to become sheet, drying, laying aside, drying and freezing.

Owner:JIANGNAN UNIV

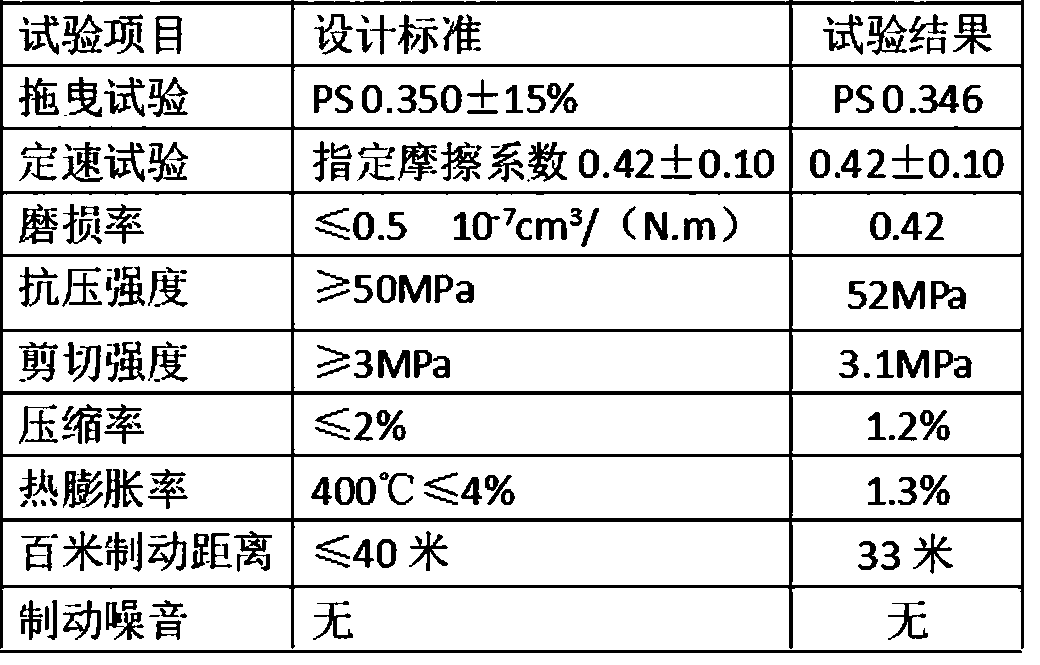

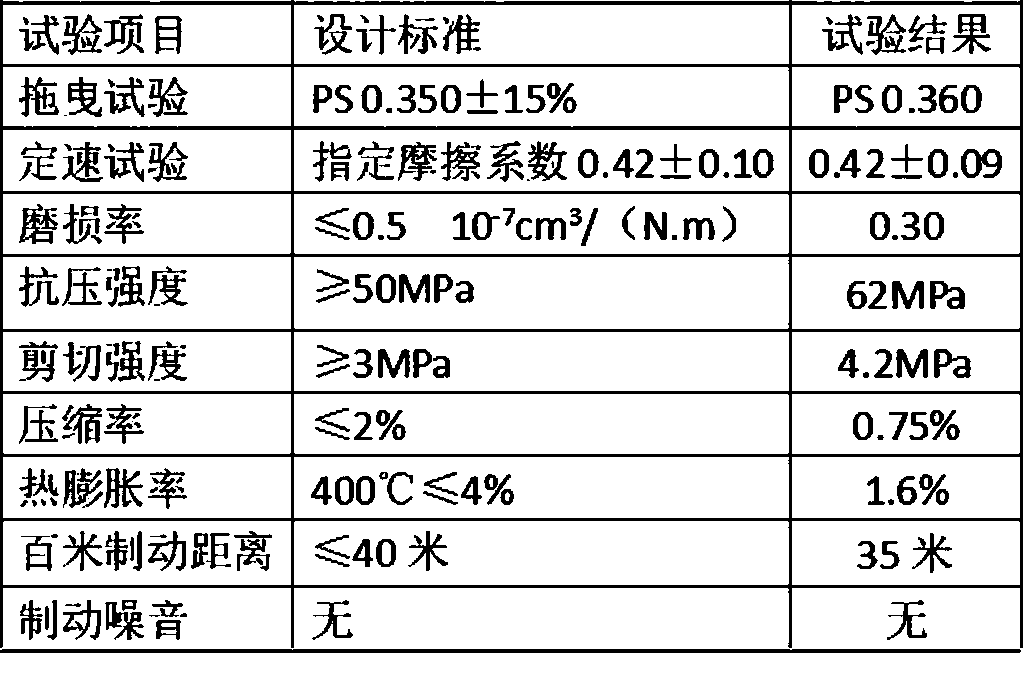

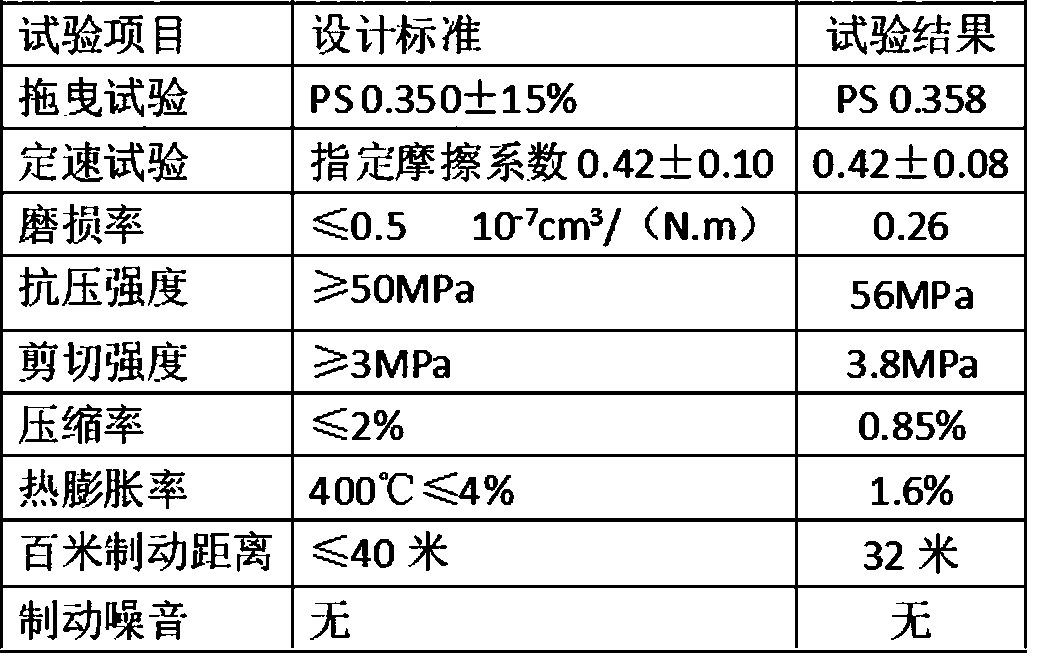

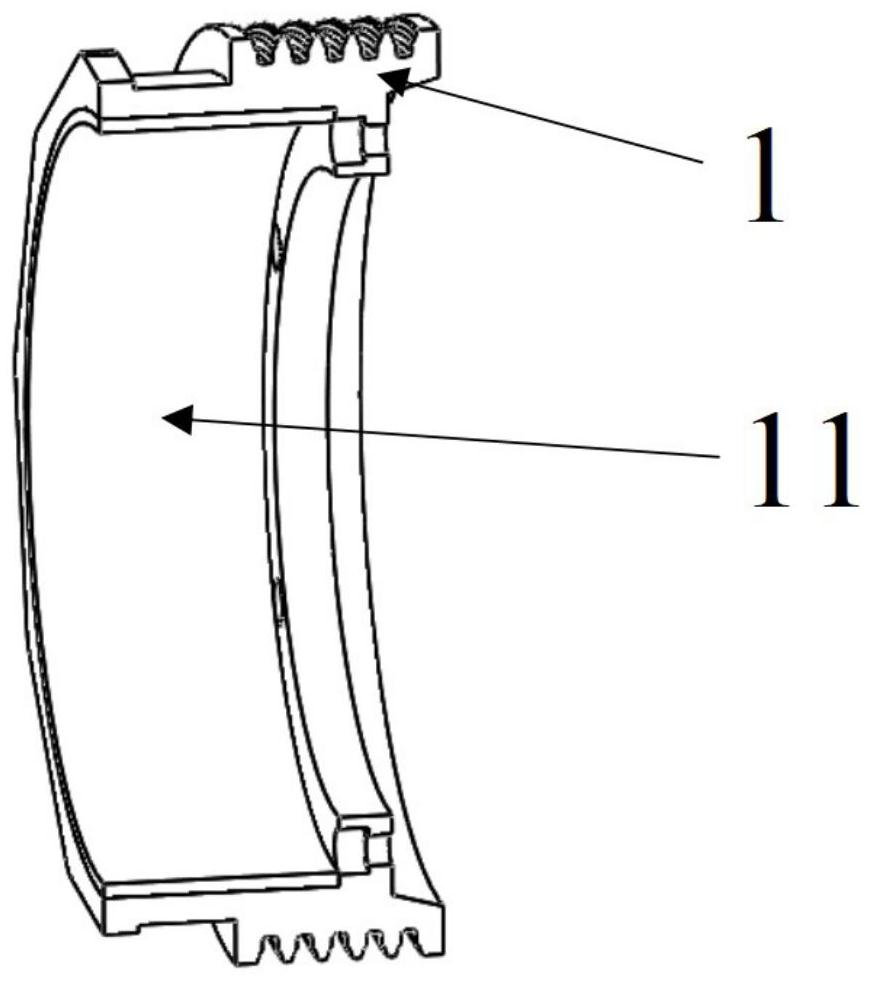

Friction lining not containing copper and preparation method thereof

InactiveCN111350781AReduce weightImprove structural strengthOther chemical processesFriction liningPolymer scienceVulcanization

The invention belongs to the technical field of friction materials and particularly relates to a friction lining not containing copper and a preparation method thereof. The friction lining comprises 9to 15 parts of a butyronitrile modified resin adhesive, 4 to 9 parts of a reinforcing agent comprising aramid fiber and / or cellulosic fiber, 28-53 parts of a friction increasing agent comprising potassium titanate, friction powder, mineral fiber and / or fine rubber powder, 11-30 parts of a lubricant comprising synthetic graphite, mica and / or antimony trisulfide, and 10 to 20 parts of a filler comprising precipitated barium sulphate or feldspar powder. The friction lining is stable in friction performance, resists heat fade, is high in structural strength, resists wear, does not contain copperor other metal compositions, and is green, environmentally-friendly and free of pollution. The preparation method has the characteristics of being simple in technological process, convenient in raw material selection and low in preparation cost and facilitating production and processing.

Owner:HENGSHUI ZHONGCHENG FRICTION MATERIAL

Water jet cutting device and rapid repair method for airport runway crater based on water jet cutting device

ActiveCN104074125BExcellent cutting and dressing speedNo damageRoads maintainenceWater concentrationEngineering

Owner:GUILIN UNIV OF ELECTRONIC TECH

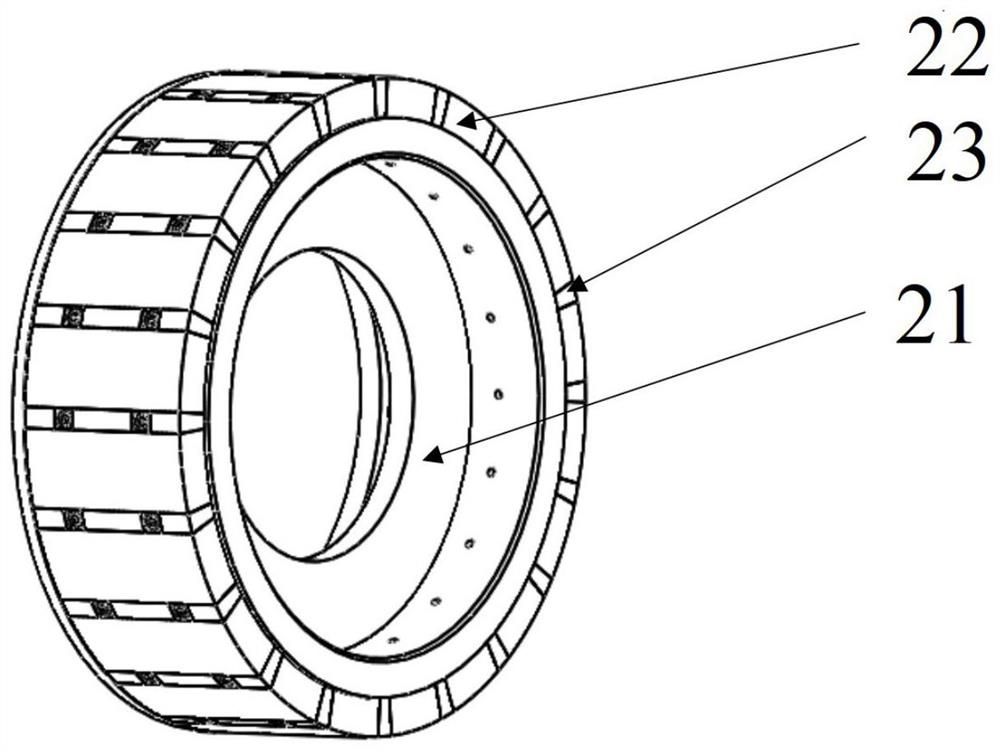

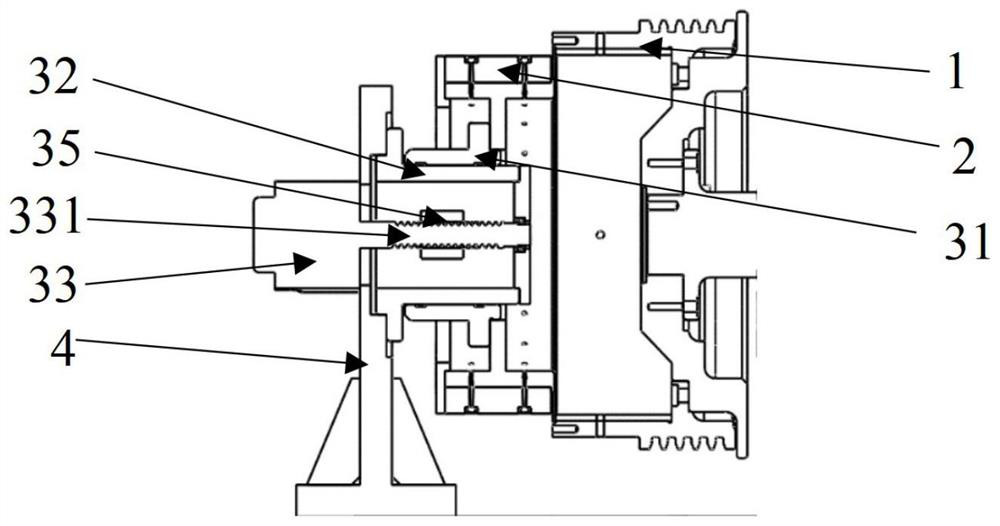

Elevator traction sheave permanent magnet safety retarding device

The invention relates to a permanent magnet safety retarding device for an elevator traction sheave. The permanent magnet safety retarding device comprises a first magnetic piece fixed to the inner circumferential side wall of the traction sheave. Damping force can be generated between the second magnetic part and the first magnetic part to slow down the traction wheel, the second magnetic part and the first magnetic part are coaxially arranged, and the second magnetic part can move to the hollow inner cavity of the first magnetic part or be far away from the first magnetic part in the axial direction of the second magnetic part; and the driving assembly is used for driving the second magnetic piece to move in the axial direction of the second magnetic piece and is arranged on the second magnetic piece. The elevator has the beneficial effects that under the action of a permanent magnetic field formed between the first magnetic part and the second magnetic part, the traction wheel rotates around the shaft to form damping force for preventing relative movement of the traction wheel and the second magnetic part, so that the traction wheel drives the car to run at a speed, and passengers are prevented from being injured due to overlarge speed reduction of the car during emergency braking. When braking of the traction wheel and braking of the safety clamp are both invalid, the traction wheel is decelerated through the interaction between the first magnetic part and the second magnetic part, and then the lift car can run in a decelerated mode all the time.

Owner:MAGNA MAGNETOMOTIVE CO LTD

A kind of flexible spraying material for mine roadway support and its preparation method and application

Owner:赣州创可通科技有限公司

Three-limb-shaped rigid combined supporting system

ActiveCN114482066ANo pollution in the processReduce the impactExcavationsPhotovoltaic energy generationSupporting systemPurlin

The invention discloses a three-limb type rigid combined supporting system, and relates to the technical field of foundation pit supporting, the supporting system comprises a first-layer supporting system and a second-layer supporting system, and the first-layer supporting system and the second-layer supporting system are connected into a whole through a connecting piece; the first-layer supporting system and the second-layer supporting system are both connected with bored piles, and the bored piles are connected with H-shaped section steel supports in the splayed supports in the first-layer supporting system and section steel enclosing purlins in the second-layer supporting system through I-shaped force transmission pieces correspondingly. The high-strength bolts are adopted to connect the multiple pieces of profile steel to form a support, compared with a traditional support, the joint strength is high, the rigidity is large, the stability is good, all parts can be prefabricated in a factory and rapidly installed and positioned on site, accuracy is achieved, meanwhile, the construction speed is guaranteed, and meanwhile the later-period disassembling process of the three-limb-shaped profile steel combined supporting system is convenient, simple and fast.

Owner:EAST CHINA JIAOTONG UNIVERSITY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com