Device for easily demoulding concrete form and a demoulding method

A technology of concrete formwork and formwork, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., which can solve the problems of missing edges and corners of cast-in-place concrete structures, reducing the service life of formwork, unfavorable environmental protection and energy saving, etc. To achieve the effect of improving the quality of appearance and durability, prolonging the service life, and strong predictability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

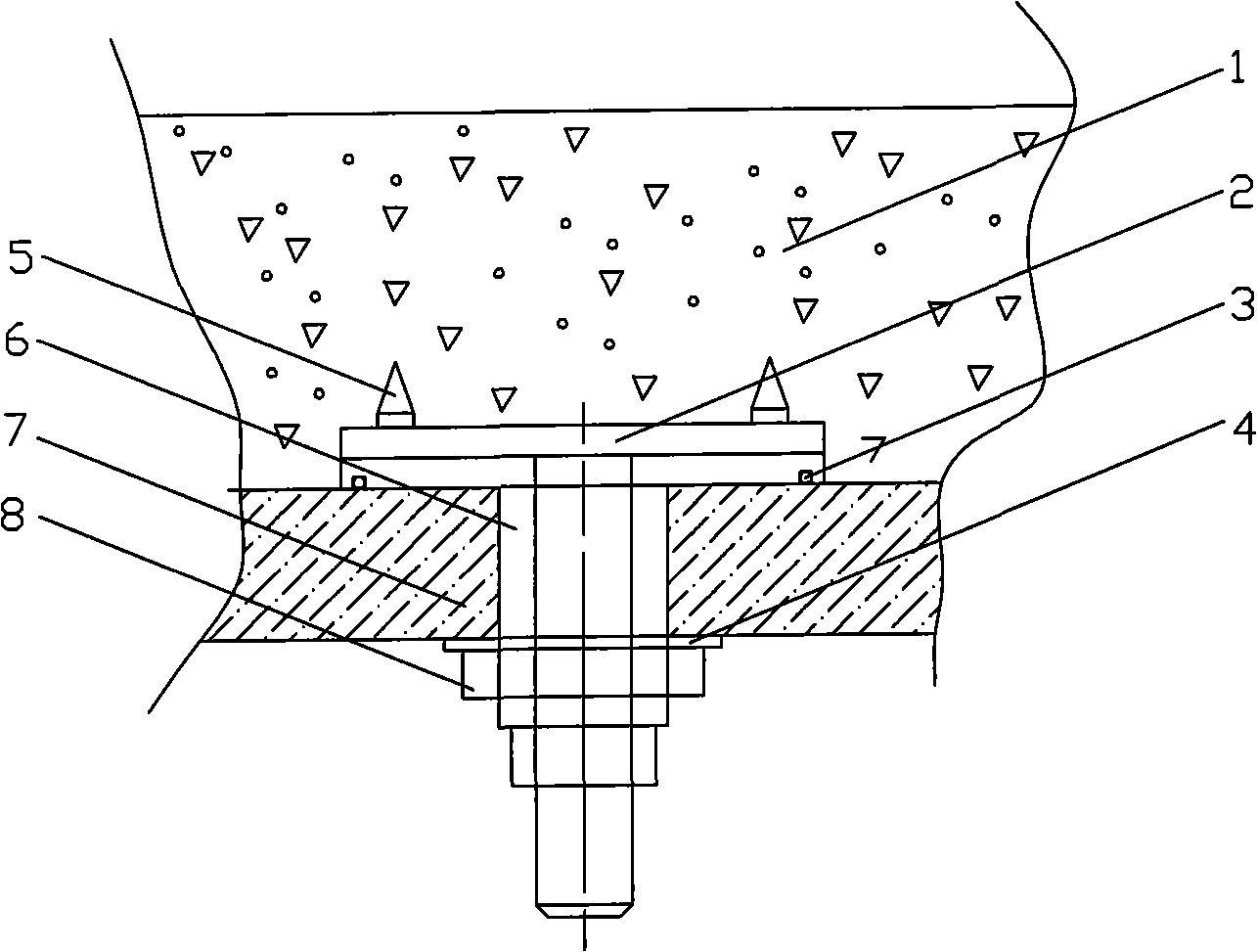

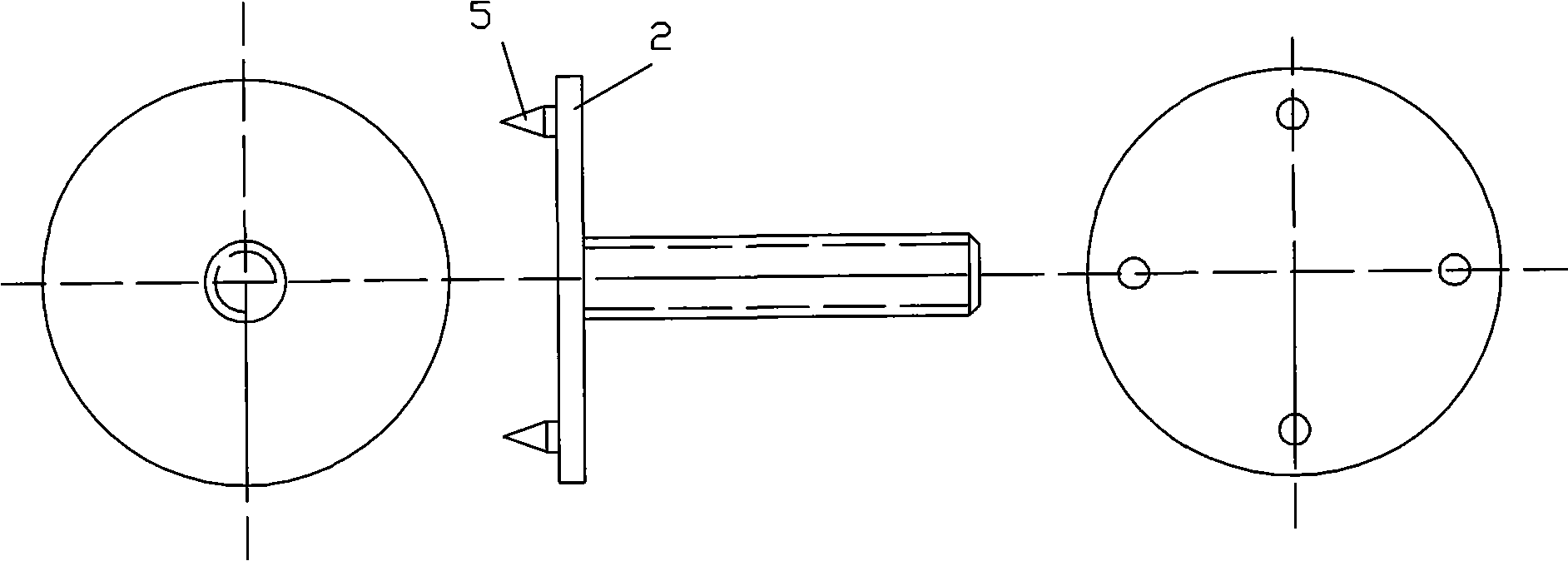

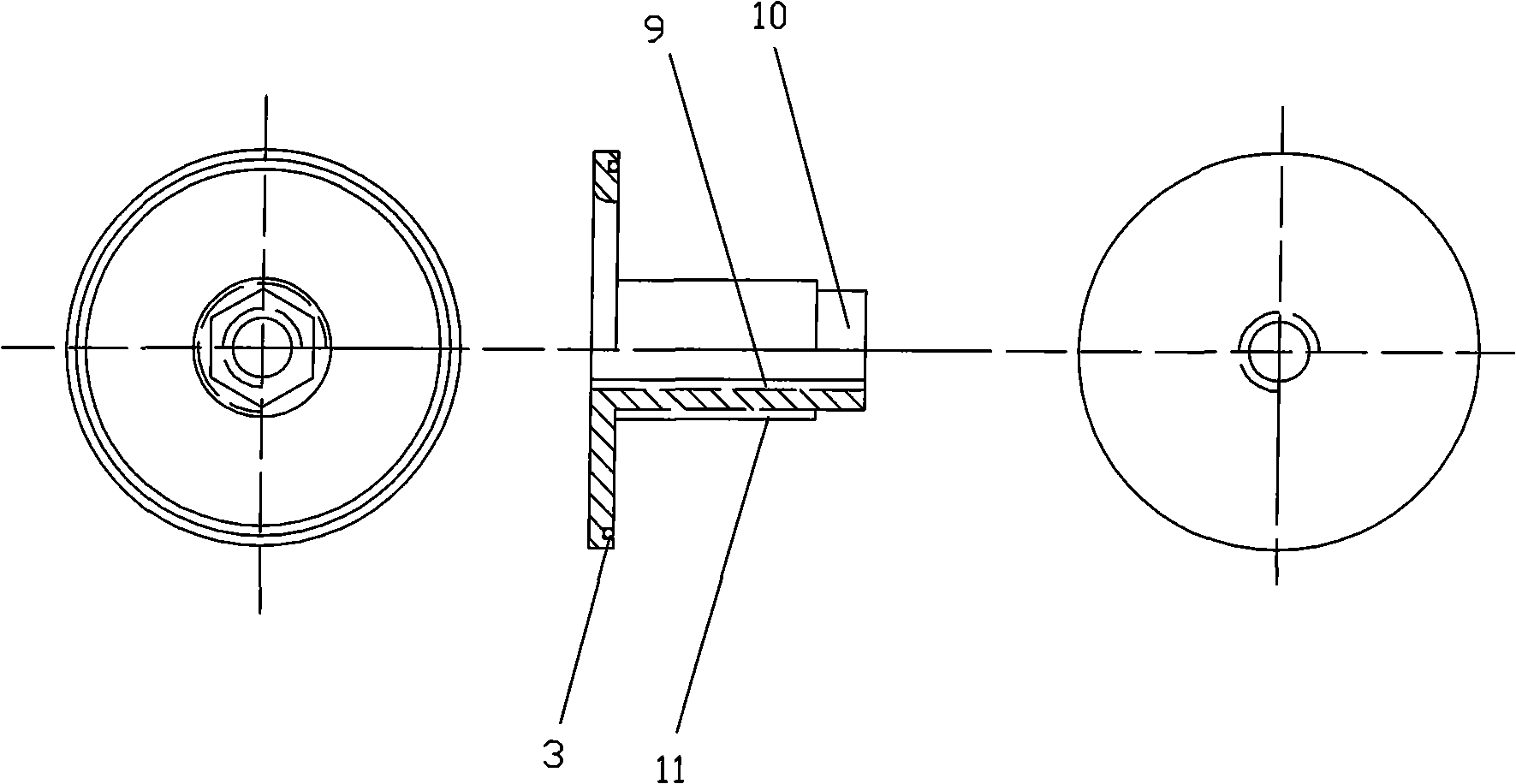

[0023] For a further understanding of the invention, see figure 1 The easy-to-detach concrete formwork device includes a formwork 7, a fixing plate 2 with a screw rod, and a hexagonal sleeve 6 with inner and outer wires. The formwork is provided with a plurality of through holes for installing the sleeves. The sealing ring 3 is sealed with the surface of the template 7, the sleeve passes through the hole of the template 7, and is fixed by a nut outside the template through a gasket and is arranged at the end to form a hexagonal structure 10. The fixed plate with the screw and the sleeve with inner and outer wires pass through themselves The thread is sealed and connected, and the two end planes are tightly connected, and four conical nails are evenly distributed on the surface of the fixing plate with the screw rod.

[0024] Before installation, drill holes on the template 7 as required, insert the inner and outer wire hexagonal sleeve 6 equipped with the alkali-resistant "O" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com