Friction lining not containing copper and preparation method thereof

A friction lining and friction powder technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of short service life, high braking noise, environmental pollution, etc., and achieve increased wear resistance and stable Friction coefficient, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

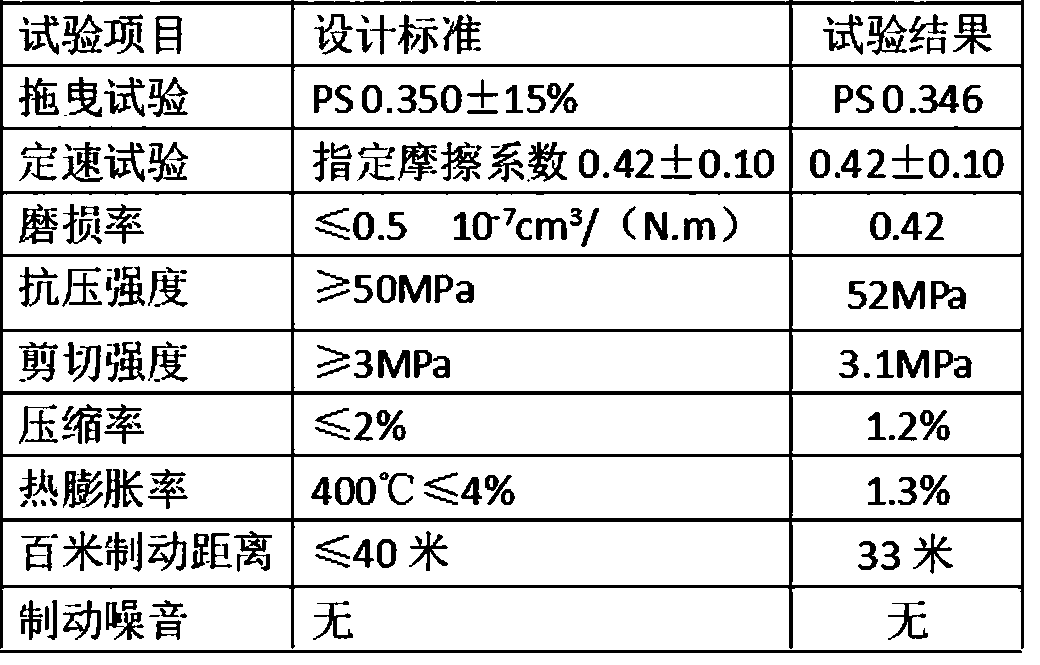

Embodiment 1

[0035] 1. Taking material

[0036] Take the following raw materials according to mass: 2 parts of aramid fibers, 15 parts of precipitated barium sulfate, 4 parts of nitrile rubber powder, 5 parts of cellulose fibers, and 15 parts of mineral fibers to obtain mixture A;

[0037] Mixture B was obtained by weighing 20 parts of potassium titanate, 4 parts of mica, 7 parts of resin, 5 parts of friction powder, 5 parts of antimony trisulfide, 15 parts of synthetic graphite, and 3 parts of fine rubber powder.

[0038] 2. Mixing

[0039] Put the mixture A into the plow-rake mixer with a reamer, plow for 15 minutes, and the reamer runs for 10 minutes; then put in the mixture B to mix it with the mixture A, plow for 30 minutes, and the reamer Run for 25 minutes to obtain a mixture; wherein, the coulter rotates at 400 rpm, the reamer at 1450 rpm, and the mixing temperature is not greater than 60°C

[0040] 3. Hot pressing

[0041] Install the predetermined type of mold on the 200T hydr...

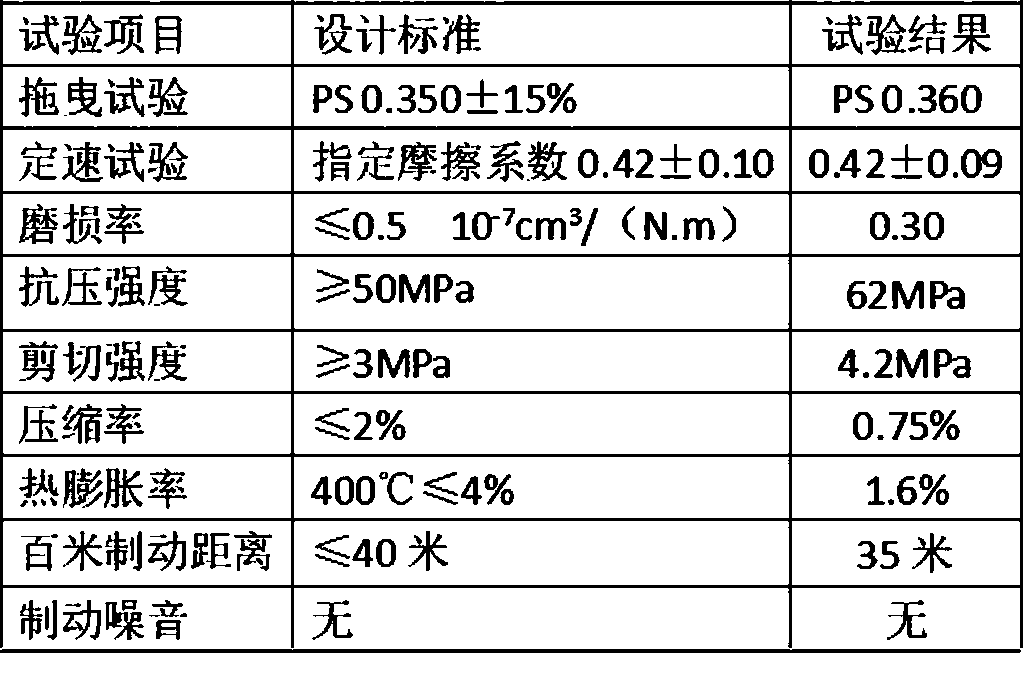

Embodiment 2

[0056] 1. Taking material

[0057] Take the following raw materials according to mass: 4 parts of aramid fibers, 10 parts of precipitated barium sulfate, 5 parts of nitrile rubber powder, 5 parts of cellulose fibers, and 15 parts of mineral fibers to obtain mixture A;

[0058] Mixture B was obtained by weighing 20 parts of potassium titanate, 8 parts of mica, 10 parts of resin, 5 parts of friction powder, 5 parts of antimony trisulfide, 10 parts of synthetic graphite, and 3 parts of fine rubber powder.

[0059] 2. Mixing

[0060] Put the mixture A into the plow-rake mixer with a reamer, plow for 15 minutes, and the reamer runs for 10 minutes; then put in the mixture B to mix it with the mixture A, plow for 30 minutes, and the reamer Run for 25 minutes to obtain a mixture; wherein, the coulter rotates at 400 rpm, the reamer at 1450 rpm, and the mixing temperature is not greater than 60°C

[0061] 3. Hot pressing

[0062] Install the predetermined type of mold on the 200T hyd...

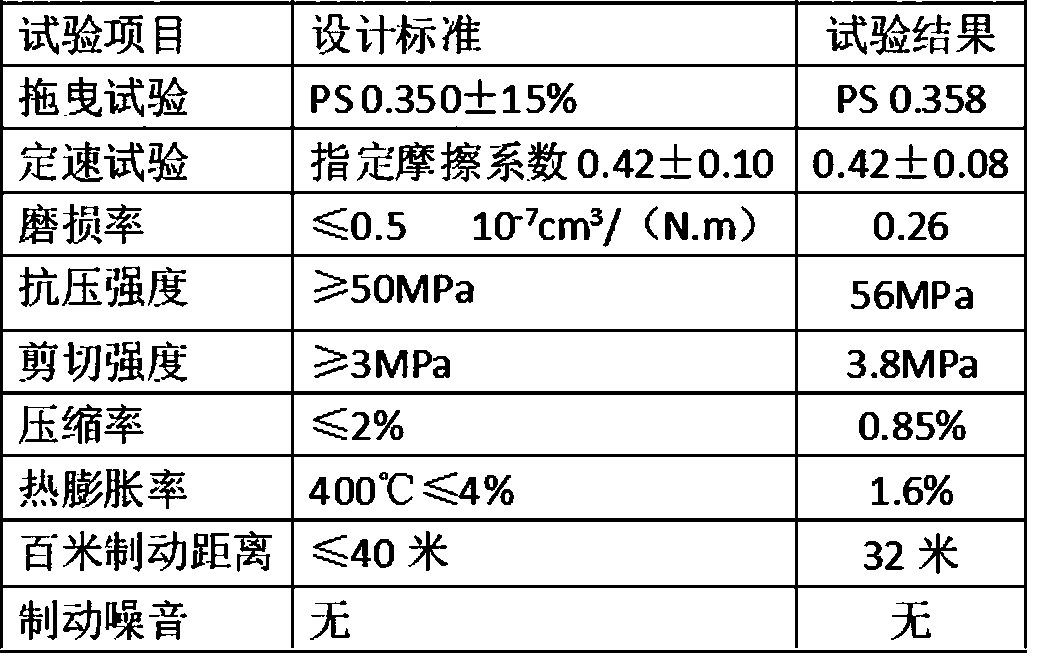

Embodiment 3

[0077] 1. Taking material

[0078] Take the following raw materials according to mass: 4 parts of aramid fibers, 20 parts of precipitated barium sulfate, 3 parts of nitrile rubber powder, 4 parts of cellulose fibers, and 10 parts of mineral fibers to obtain mixture A;

[0079] Mixture B was obtained by weighing 25 parts of potassium titanate, 10 parts of mica, 9 parts of resin, 6 parts of friction powder, 4 parts of antimony trisulfide, 15 parts of synthetic graphite, and 4 parts of fine rubber powder.

[0080] 2. Mixing

[0081] Put the mixture A into the plow-rake mixer with a reamer, plow for 15 minutes, and the reamer runs for 10 minutes; then put in the mixture B to mix it with the mixture A, plow for 30 minutes, and the reamer Run for 25 minutes to obtain a mixture; wherein, the coulter rotates at 400 rpm, the reamer at 1450 rpm, and the mixing temperature is not greater than 60°C

[0082] 3. Hot pressing

[0083] Install the predetermined type of mold on the 200T hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com