Patents

Literature

205 results about "Precipitated sulphur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne antirust paint and preparation method thereof

ActiveCN105238232AImprove densification performanceImprove shielding effectAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses waterborne antirust paint and a preparation method thereof. The waterborne antirust paint is prepared from, by mass, 10-25 parts of waterborne acrylic acid modified epoxy ester, 0.6-1.2 parts of neutralizer, 20-30 parts of deionized water, 0.5-1.5 parts of dispersing agents, 0.2-0.5 part of defoaming agent, 14-18 parts of iron oxide red, 2-4 parts of mica powder, 6-10 parts of modified zinc phosphate, 10-14 parts of precipitated barium sulphate, 1-2 parts of propylene glycol, 10-15 parts of styrene-acrylic emulsion, 0.5-1.0 part of coalescing agent, 0.5-1.0 part of waterborne flush rust prevention agent, 0.5-1.5 parts of thickening agents and 0.2-0.5 part of mildew prevention agent. The waterborne antirust paint is high in film hardness, good in adhesive force and excellent in corrosion-resistant performance and mechanical performance, dryness and initial water resistance of paint films are remarkably improved due to the addition of styrene-acrylic emulsion, and the flush rust restraining performance of paint films is improved due to the addition of the waterborne flush rust prevention agent. Water serves as the diluent for the waterborne antirust paint, VOC emission in production and construction projects is greatly reduced, and the waterborne antirust paint is safe, environmentally friendly and capable of being widely used for paint coating on the aspects of steel structures, pipelines, automobile parts and the like.

Owner:西北永新涂料有限公司

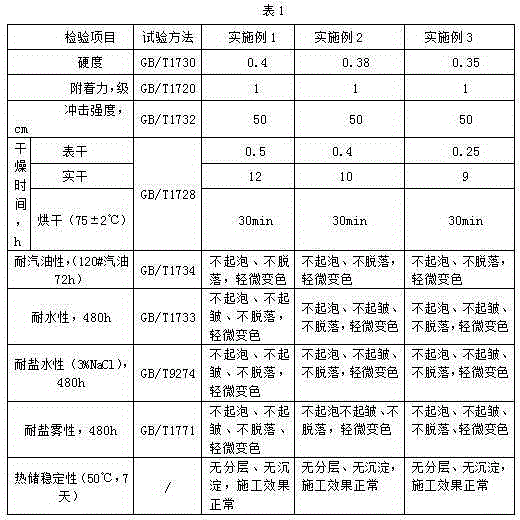

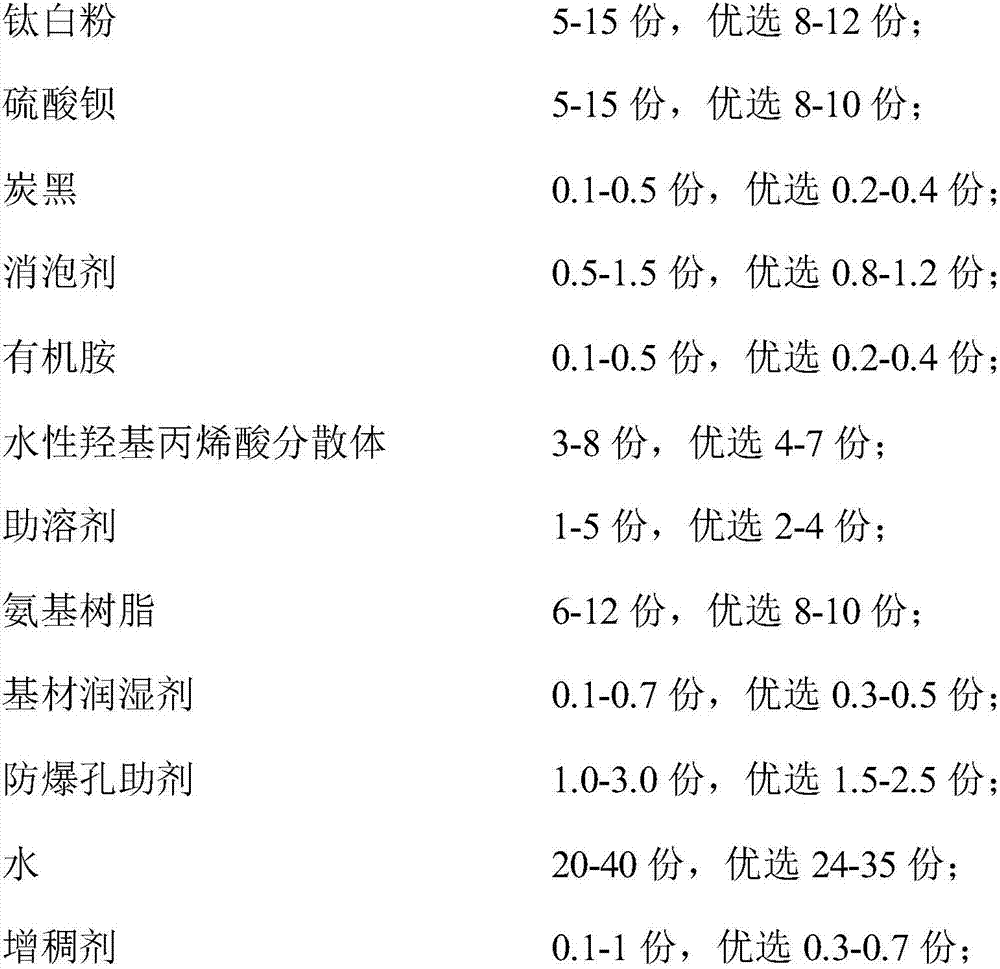

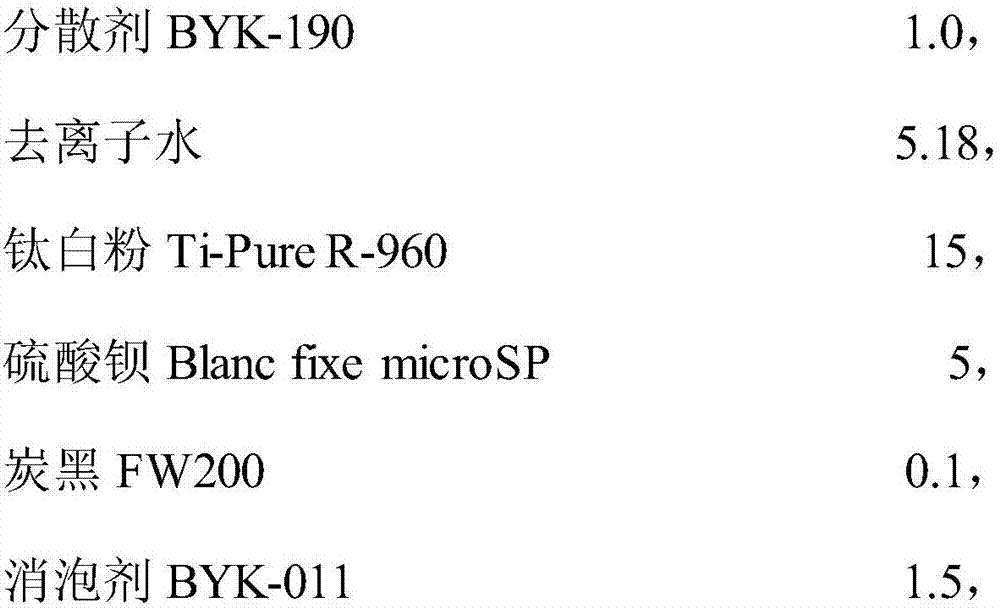

A waterborne automobile coating composition and a preparing method and applications thereof

InactiveCN107099238AImprove stone impact resistanceIncreased chemical resistancePolyurea/polyurethane coatingsPolyesterCooking & baking

A waterborne automobile coating composition is provided. The composition is prepared from, by weight, 20-60 parts of a waterborne polyurethane dispersoid, 1.0-3.5 parts of a dispersing agent, 5-15 parts of titanium dioxide, 5-15 parts of precipitated barium sulfate, 0.1-0.5 part of carbon black, 0.5-1.5 parts of a defoamer, 3-8 parts of a waterborne hydroxy acrylic acid dispersoid, 0.1-0.5 part of an organic amine, 6-12 parts of amino resin, 0.1-1 part of a substrate wetting agent, 1-3 parts of an explosion-proof auxiliary agent, 1-5 parts of a cosolvent, 20-40 parts of deionized water and 0.1-1 part of a thickening agent. The waterborne polyurethane dispersoid is a compound of a polycarbonate-type waterborne polyurethane dispersoid having hydroxy groups and a polyester-type waterborne polyurethane dispersoid preferably. The coating composition has excellent resistance to rock crash, and can meet requirements on an automobile coating process including three times of coating and one time of baking, namely a 3C1B process, in the field of environment protection.

Owner:WANHUA CHEM GRP CO LTD

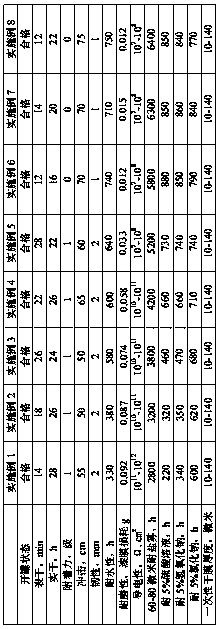

Low temperature curing powder coating and preparation method thereof

ActiveCN103333588AImprove mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to a low temperature curing powder coating and a preparation method thereof. The powder coating comprises the following components by weight percent: 28-30% of epoxy resin, 28-30% of low temperature curing polyester resin, 0.1-1% of low temperature curing catalyst, 0.1-0.4% of benzoin, 0.7-1.4% of imported flatting agent, 0.4-1% of hydrogenated castor oil, 5-10% of pigment, and 25-40% of precipitated barium sulphate. In the formula of the powder coating, the low temperature curing polyester resin and the low temperature curing catalyst are adopted, the film of the power coating product can be cured at lower curing temperature, and each mechanical property of the film can be guaranteed to be excellent, therefore, the powder coating is suitable for large-scale popularization and application.

Owner:JIANGSU HUAGUANG POWDER

Anti-rust primer for elementary surface treatment of steel material, and manufacturing method thereof

InactiveCN101298536AImprove adhesionImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsPolyesterLacquer

The invention relates to an antirust primer with rust and with elementary surface treatment used for steel materials and a manufacturing method, wherein, fluid A is made by mixing, agitating and grinding bisphenol-A epoxy resin, dimethylbenzene, n-butyl alcohol, tannin, precipitated barium sulfate, zinc phosphate, saponite, iron oxide red, simethicone, polyester modified polyphosphonate compound and polyamide wax micropowder, while fluid B is made from polyamide resin, the dimethylbenzene and the n-butyl alcohol; when in use, mix and cure the fluid A and the fluid B to form the coating film. The antirust primer with rust and with elementary surface treatment has excellent adhesion and corrosion resistance, which can be coated on steel surfaces with uneven rust, solid oxide scale residuals or old paint, and can be directly used and matched as a primer with other finish paints without using any other primers.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

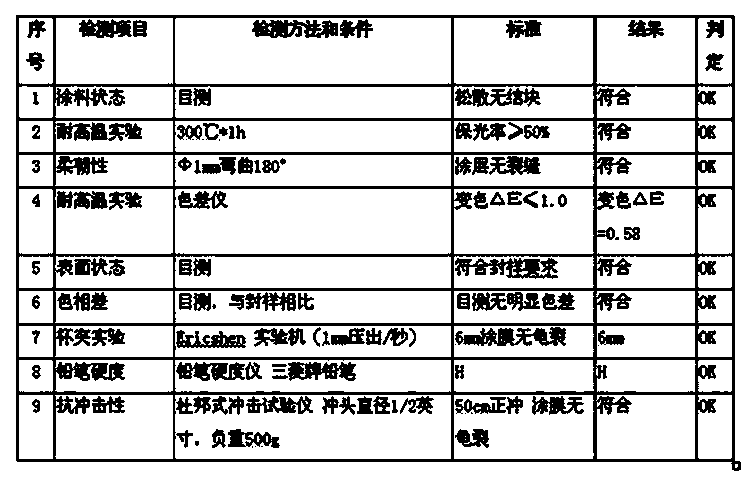

High-temperature-resistant powder coating with good gloss-retention performance and production method thereof

InactiveCN103965752AReduce sheddingReduce oxidationPowdery paintsPolyester coatingsPhosphoric Acid EstersFirming agent

The invention relates to a high-temperature-resistant powder coating with good gloss-retention performance. The high-temperature-resistant powder coating is characterized by comprising the following constituents in mass percentage: 58-62 parts of polyester resin, 4-5 parts of TGIC (Triglycidyl Isocyanurate) curing agent, 0.2-0.5 part of wax powder, 0.3-1 part of organic soil, 1.5-2.5 parts of ammonium polyphosphate temperature resistant auxiliary, 0.3-0.6 part of phosphite ester antioxidant, 0.1-0.3 part of a sand ripple agent, 0.6-1.2 parts of carbon black, 20-30 parts of precipitated barium sulphate, and 2-5 parts of asbestos powder.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Composition capable of reflecting sun heat radiation

ActiveCN101928483AReduce receptionCapable of reflecting solar heat radiationEpoxy resin coatingsPolyester coatingsEmissivityZinc

The invention discloses a composition capable of reflecting sun heat radiation, which comprises 50 to 400 weight parts of rutile titanium dioxide, 50 to 280 weight parts of zinc oxide and 50 to 450 weight parts of precipitated barium sulfate. In the composition capable of reflecting the sun heat radiation, the reflectivity and hemispherical emissivity of the sun heat radiation can at least reach 85 percent on the premise of low cost and low energy consumption. The composition can be used for heat-insulating building materials such as coatings, sections and the like.

Owner:三河方元绿洲节能科技有限公司

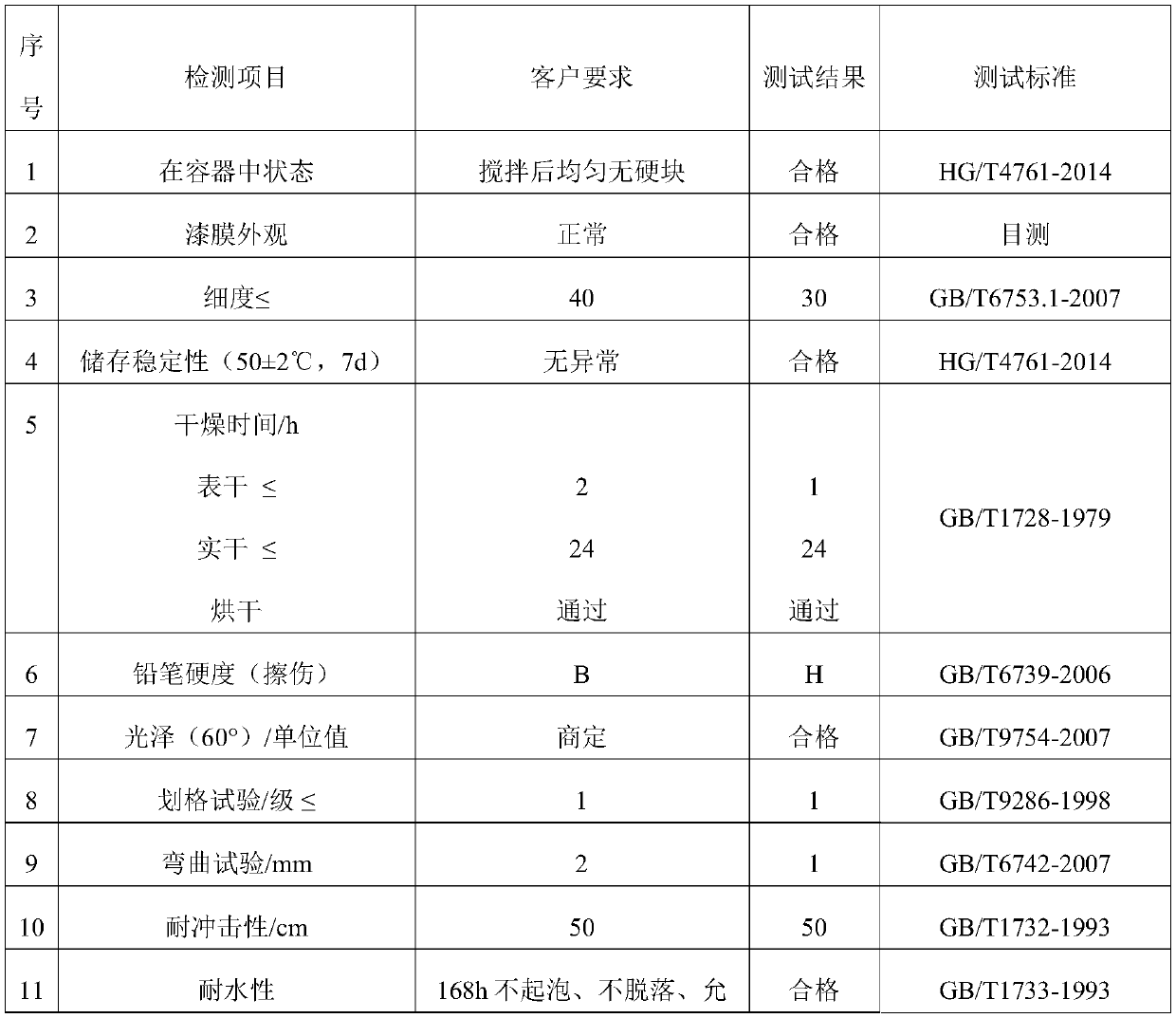

Water-based DTM polyurethane coating and preparation method thereof

ActiveCN111393888AWell mixedImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPhosphoric acidFirming agent

The invention relates to the technical field of coatings, and particularly discloses a water-based DTM polyurethane coating and a preparation method thereof. The water-based DTM polyurethane coating is prepared from a component A and a component B. The component A is prepared from, by mass, 40-60 parts of hydroxyl acrylic acid dispersion, 15-20 parts of titanium dioxide, 3-5 parts of modified zincphosphate, 3-5 parts of zinc aluminum phosphate, 5-10 parts of precipitated barium sulfate, 1-2 parts of a salt spray resistant auxiliary agent, 0.5-1 part of an anti-flash-rust auxiliary agent, 1-2parts of a dispersant, 0.2-0.4 parts of a defoaming agent, 0.5-1 part of a wetting leveling agent, 0.2-0.5 parts of a thickening agent, 2-5 parts of a coalescing agent, and 5-10 parts of deionized water. The component B is prepared from 10-25 parts of a water-based isocyanate curing agent. The coating provided by the invention is low in VOC content, has good water resistance, acid and alkali resistance, artificial aging resistance and salt spray resistance, and can meet the requirements of corrosion resistance and weather resistance.

Owner:石家庄市油漆厂

Environmental-friendly waterborne epoxy zinc phosphate anti-corrosion paint for steel structures and preparation method thereof

InactiveCN102533053AStrong complexing abilityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsZinc phosphateEmulsion

The invention belongs to the technical field of paint and particularly relates to environmental-friendly waterborne epoxy zinc phosphate anti-corrosion paint for steel structures and a preparation method of the environmental-friendly waterborne epoxy zinc phosphate anti-corrosion paint. The paint comprises an ingredient A and an ingredient B and is characterized in that the ingredient A consists of 25 to 40 weight parts of waterborne epoxy emulsion, 10 to 20 weight parts of rust-proof pigment, 5 to 15 weight parts of precipitated barium sulfate, 5 to 10 weight parts of mica powder, 5 to 10 weight parts of pigment, 0.5 to 2 weight parts of dispersing agents and 10 to 30 weight parts of water, and the ingredient B consists of 5 to 15 weight parts of curing agents, 1 to 5 weight parts of cosolvents and 3 to 8 weight parts of water, wherein the rust-proof pigment is compounded by zinc phosphate and aluminum triphosphate according to the weight ratio of 1:3, and the ingredient A and the ingredient B are mixed according to the weight ratio of 8:1. The paint belongs to the anti-corrosion paint with anti-corrosion and environmental-friendly effects in the field of the steel structures.

Owner:SHANGHAI MAMPLE NEW MATERIAL

Microporous composite brake pad for high-speed railway and manufacturing method of microporous composite brake pad

The invention relates to a microporous composite brake pad for a high-speed railway and a manufacturing method of the microporous composite brake pad. The microporous composite brake pad for the high-speed railway comprises the following compositions by weight percentage: 10-15 percent of modified resin, 8-15 percent of friction performance moderator, 20-40 percent of precipitated barium sulfate, 25-35 percent of graphite, 0.5-5 percent of aramid pulp, 10-20 percent of short carbon fiber, and 1-15 percent of zinc oxide. The raw materials are added into a high speed rake mixing machine to be mixed, and then the obtained mixed materials are placed in a molding die to be molded and then sintered to obtain the microporous composite brake pad. Compared with the prior art, though the microporous composite brake pad, the problems that in a domestic motor train unit brake pad, cracks, hot marks, black smoke and metal inlay are caused by a high-speed braked thermal load to affect the traffic safety, and the like can be solved, the microporous composite brake pad plays a role of protecting a couple material at a certain extent, the production cycle is short, and the production efficiency is high.

Owner:SHANGHAI RENPHEN COMPOSITE MARERIALS

Preparation method for aqueous floor coating

The invention relates to a preparation method for an aqueous floor coating. The aqueous floor coating is prepared from the components in parts by weight of 80-100 parts of a component A and 40-50 parts of a component B, wherein the component A is prepared from the following components in parts by weight of 30-35 parts of water, 15-25 parts of an aqueous epoxy curing agent, 1-3 parts of an adjuvant, 0.1-0.7 part of an antifoaming agent, 10-15 parts of quartz powder, 5-10 parts of precipitated barium sulfate and 0.2-0.8 part of a thickening agent; the component B is prepared from the following raw materials in parts by weight of 15-18 parts of liquid epoxy resin, 1-3 parts of a reactive diluent and 3-4 parts of an environment-friendly type organic solvent. The preparation method comprises the following steps: dispersing the raw materials of the component A at a high speed of 1000-2000rpm for 5-10 minutes; grinding the raw materials of the component A until the fitness is 10-30 microns; mixing the raw materials with the residual water at a speed of 500-800rpm for 3-10 minutes, so as to obtain the component A; mixing the raw materials of the component B at a speed of 200-600rpm for 10-20 minutes, so as to obtain the component B; mixing the component A and the component B at a ratio ranging from 1:1 to 1:3, so as to obtain the aqueous floor coating. The aqueous floor coating can avoid the environment pollution and damage on human health, has strong air permeability, is applicable to wet basal plane, and meets the requirements on the environmental friendliness.

Owner:张锦碧

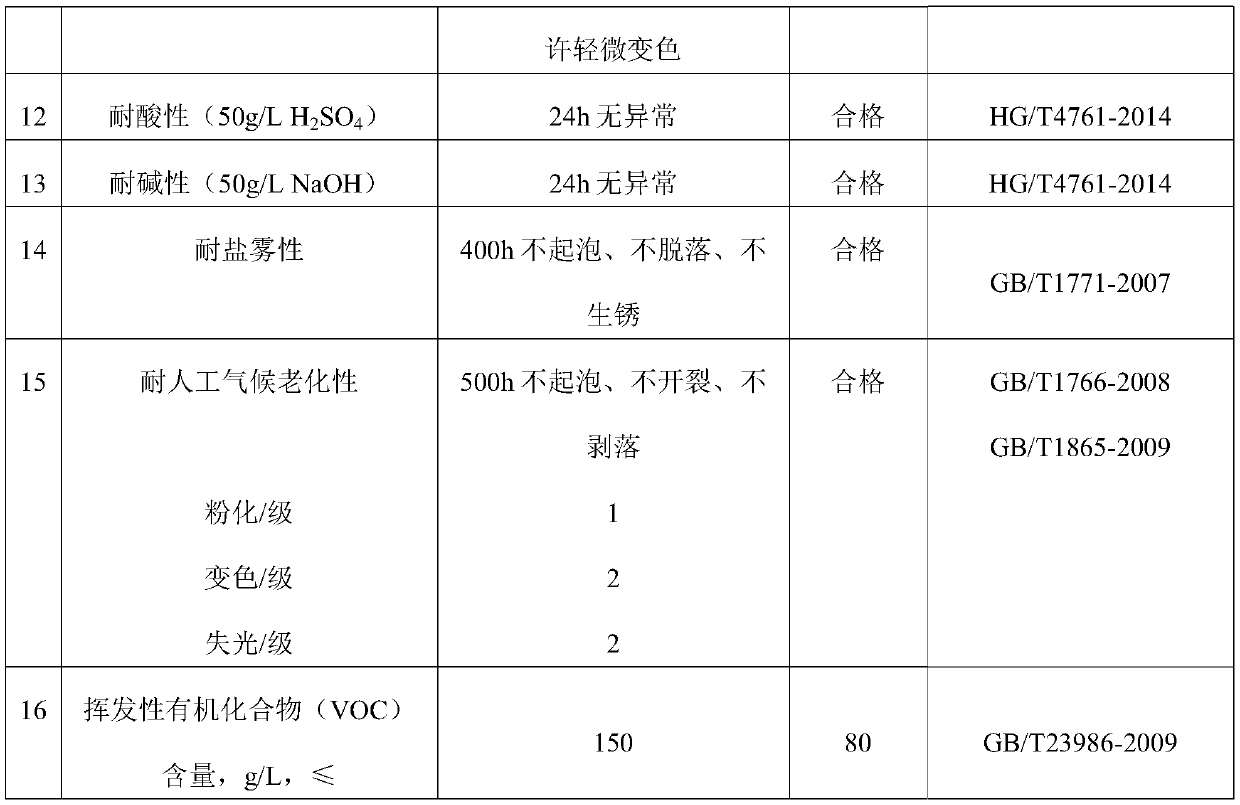

Pure-copper-imitated anti-corrosion powder coating

ActiveCN105038515ASolve the problem of difficult to achieve paint effectGood alkali resistanceAnti-corrosive paintsPowdery paintsEpoxySlag

The invention belongs to the field of powder coating preparation, and particularly relates to a pure-copper-imitated anti-corrosion powder coating. The pure-copper-imitated anti-corrosion powder coating is composed of, by weight, 35-40 parts of epoxy resin, 35-40 parts of terminal carboxyl group saturated polyester resin, 1-1.2 parts of flatting agents, 10-19 parts of precipitated barium sulphate, 4-5 parts of pearl powder, 3-4 parts of red gold powder, 0.5-0.8 part of benzoin, 1.5-2 parts of polyethylene wax and 5-6 parts of nickel slag powder. According to the pure-copper-imitated anti-corrosion powder coating, the pearl powder and the red gold powder are bound to be added, metallic pigment particles are bonded on powder coating particles to prepare a coating layer with the metal effect, and therefore the problem that the powder coating is difficult to achieve the paint effect can be well solved; nickel slag is added in the powder and is rich in amphoteric oxide of Al2O3 and Fe2O3, the amphoteric oxide can react with acid and alkali, and therefore the good acid and alkali resistance effects can be well achieved.

Owner:浙江捷宇新材料科技股份有限公司

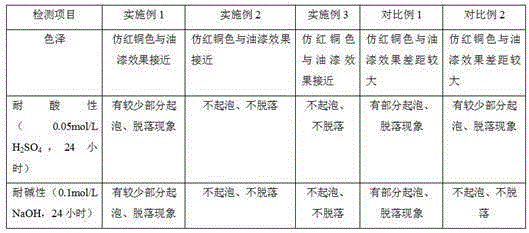

Method and system for compounding fertilizer from manure without nutrient emission

ActiveUS10793483B2Less efficaciousLess expenseBio-organic fraction processingLiquid degasification with auxillary substancesMilk cow'sWater vapor

A system and method for reclaiming nutrients from dairy manure includes a centrifuge for separating a liquid fraction of the manure from a solid fraction comprising organic material; a mechanical vapor recompression evaporator (“MVR”) to receive the liquid fraction from the centrifuge and evaporating the liquid fraction by mechanical vapor recompression to produce ammonia-laden water vapor and a concentrated nutrient slurry; a dryer for drying the nutrient slurry to a selected moisture content to be available as an ingredient in compounded fertilizer; and an ammonia stripping tower assembly to receive ammonia-laden water vapor from the MVR and from it to precipitate ammonium sulphate salt and condense water as separate products.

Owner:DARITECH

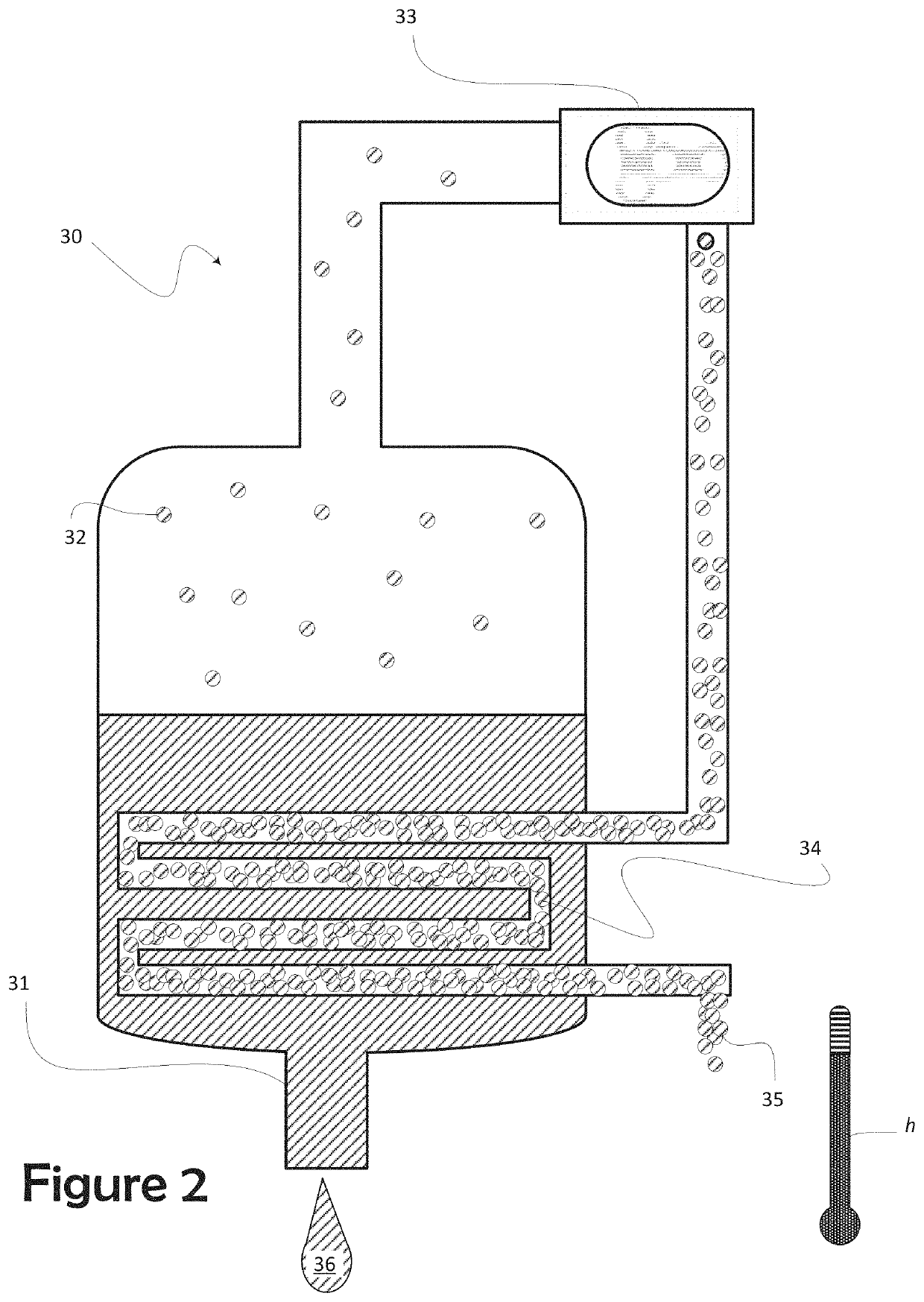

Wet and dry joint-coating primer for heat shrinkable tape and manufacturing method thereof

ActiveCN101942263AImprove constructabilityGood storage stabilityAnti-corrosive paintsEpoxy resin coatingsGas phasePolyamide

The invention relates to a wet and dry joint-coating primer for a heat shrinkable tape and a manufacturing method thereof. The joint-coating primer comprises a liquid A and a liquid B, wherein the liquid A is prepared from bisphenol A epoxy resin, novolac epoxy resin, long-chain polyamine amide, polar acid ester sodium salt, a high molecular weight amine polycarboxylate derivate solution, a polyether modified dimethyl polysiloxane solution, an alkyl-aryl modified dimethyl siloxane solution, a gamma-amino propyltriethoxysilane solution, carbon black, precipitated barium sulfate, mica powder, talcum powder, gas-phase silicon oxide, glass flake and activated polyamide wax, and the liquid B is prepared from modified alicyclic amine and phenolic aldehyde amine. In use, the liquid A and the liquid B are mixed and cured into a coating which has fine corrosion resistance and high curing speed. Besides, no matter whether the coating is dry or not, the coating has high bonding power up to 100N / cm with the heat shrinkable tape, enables the coated joint to have fine sealability, impermeability and chemical corrosion resistance, has the advantage of convenient on-site construction and ensures the joint-coating quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Single-layer contamination-resisting highly effective water-proof elastic dope

The invention relates to single layer fouling resistant water proof elastic coating, which comprises components with the weight proportion being as follows: 10-20 percent of water, 0.1-0.2 percent of multi-purpose accessory ingredient, 0.1-0.2 percent of wetting agent, 0.4-0.8 percent of dispersant, 0.3-0.8 percent of antibubbling agent, 1.5-3.0 percent of propylene glycol, 16-20 percent of rutile type titanium white powder, 6-8 percent of precipitated barium sulfate, 5-8 percent of large calcium carbonate, 3-5 percent of nontransparent polymer, 38-45 percent of latex, 0.8-1.5 percent of Texanol, 0.5-1 percent of fouling resistant accessory ingredient, 0.1-0.2 percent of anticorrosion agent, and 0.6-0.9 percent of thickening agent. The product overcomes the deficiencies of poor water tolerance, poor water resistance, poor fouling resistance, etc. of the traditional elastic coating, and has the outstanding waterproof performance, fouling resistant performance and good breaking strength, and can obviously improve the performances of waterproofing, fouling resistant and crack resistant. The invention can prevent and cover the crackles on the building and can ensure that the outer wall surface of the building can keep clean and magnificent for a long time.

Owner:董善刚

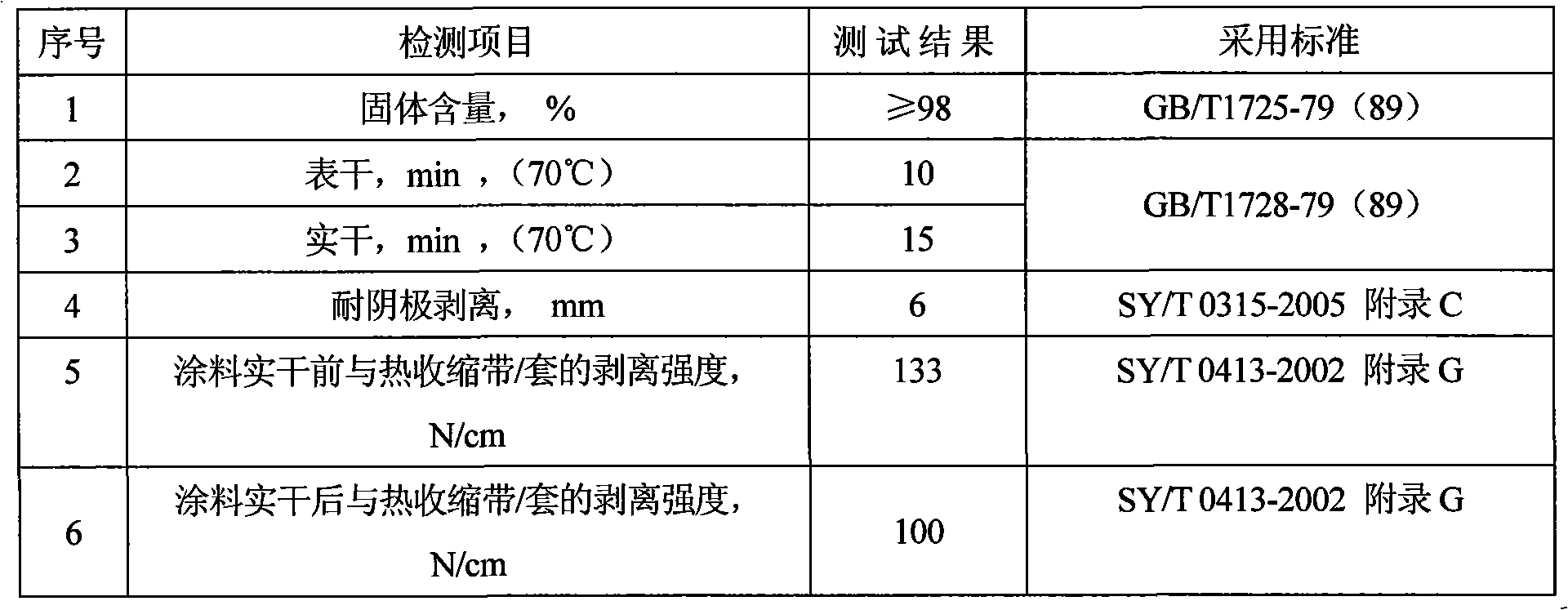

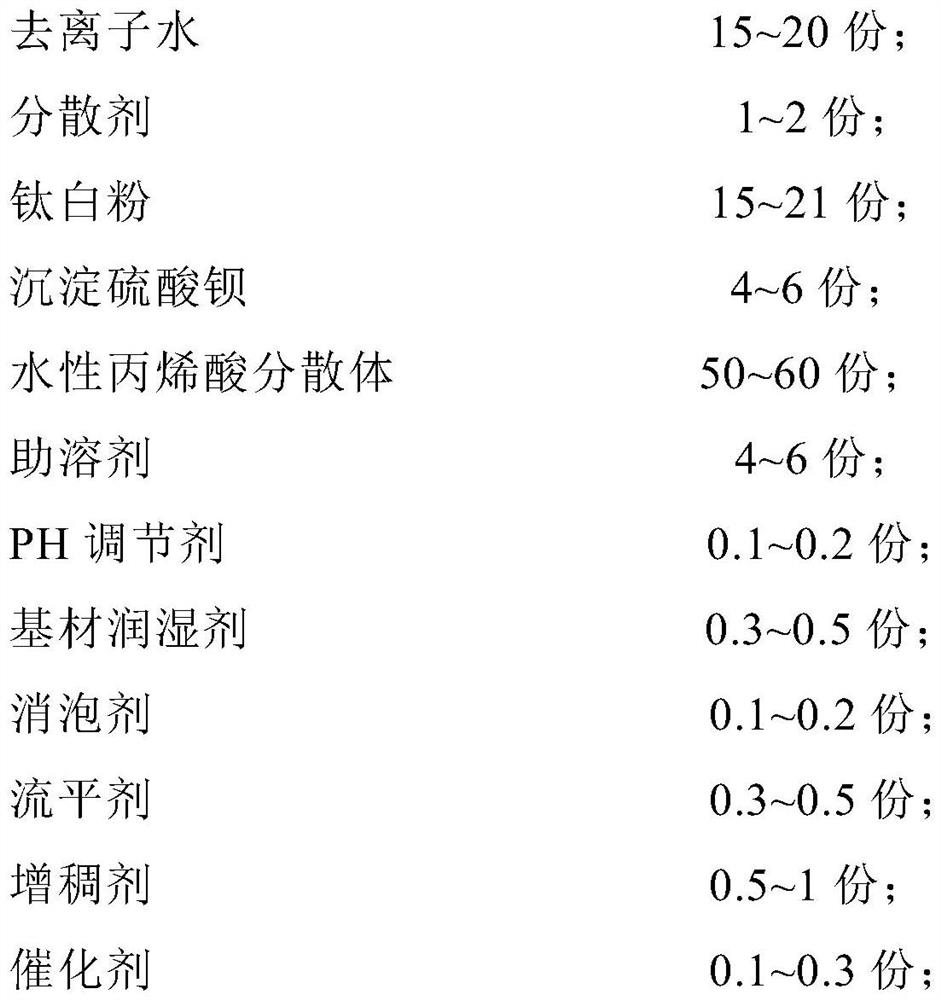

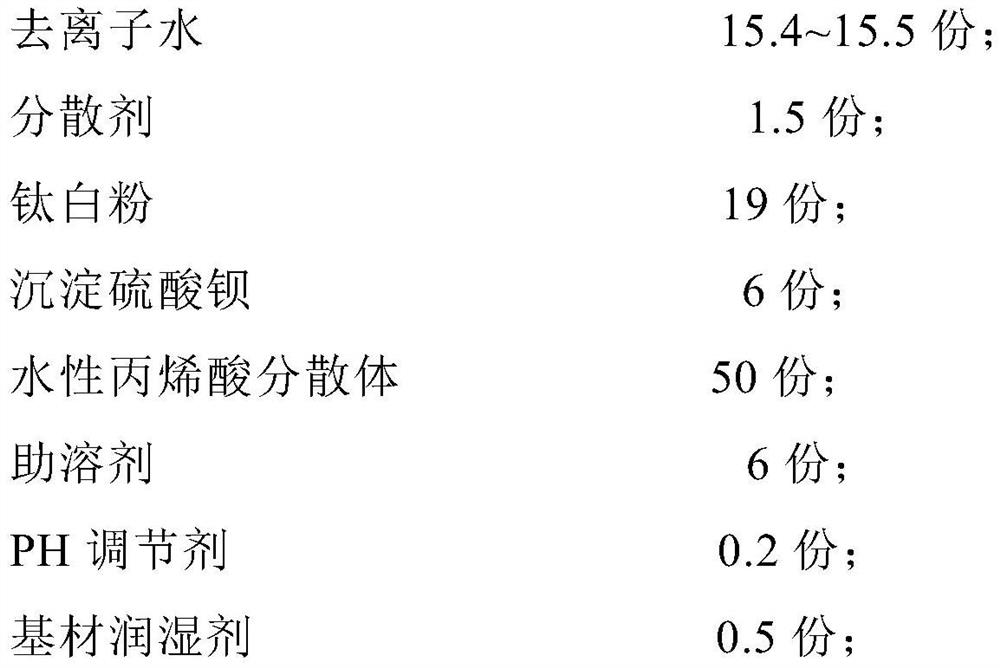

Water-based two-component polyurethane coating and preparation method thereof

InactiveCN111944409AIncrease the speed of crosslinkingExpand the structural networkPolyurea/polyurethane coatingsPtru catalystHigh activity

The invention relates to a waterborne two-component polyurethane coating. The waterborne two-component polyurethane coating comprises a main agent and a hardening agent. The main agent comprises the following components in parts by weight: 15-20 parts of deionized water, 1-2 parts of dispersing agent, 15-21 parts of titanium dioxide, 4-6 parts of precipitated barium sulfate, 50-60 parts of waterborne hydroxy acrylic acid secondary dispersion, 4-6 parts of a cosolvent, 0.1-0.2 part of a pH regulator, 0.3-0.5 part of substrate wetting agent, 0.1-0.2 part of a defoaming agent, 0.3-0.5 part of a leveling agent, 0.5-1 part of a thickener and 0.1-0.3 part of a catalyst. The hardening agent comprises the following components in parts by weight: 70 to 80 parts of water-based isocyanate and 20 to 30 parts of propylene glycol diacetate. In addition, autonomously modified high-activity organic metal salt is selected as a catalyst and is added into the main agent. On the premise of not influencingcomprehensive performance, the invention provides a feasible scheme for improving the mechanical performance and chemical resistance of the coating and improving the hard drying speed of the water-based 2K-PU under the condition of room-temperature drying.

Owner:DONGLAI COATING TECH SHANGHAI

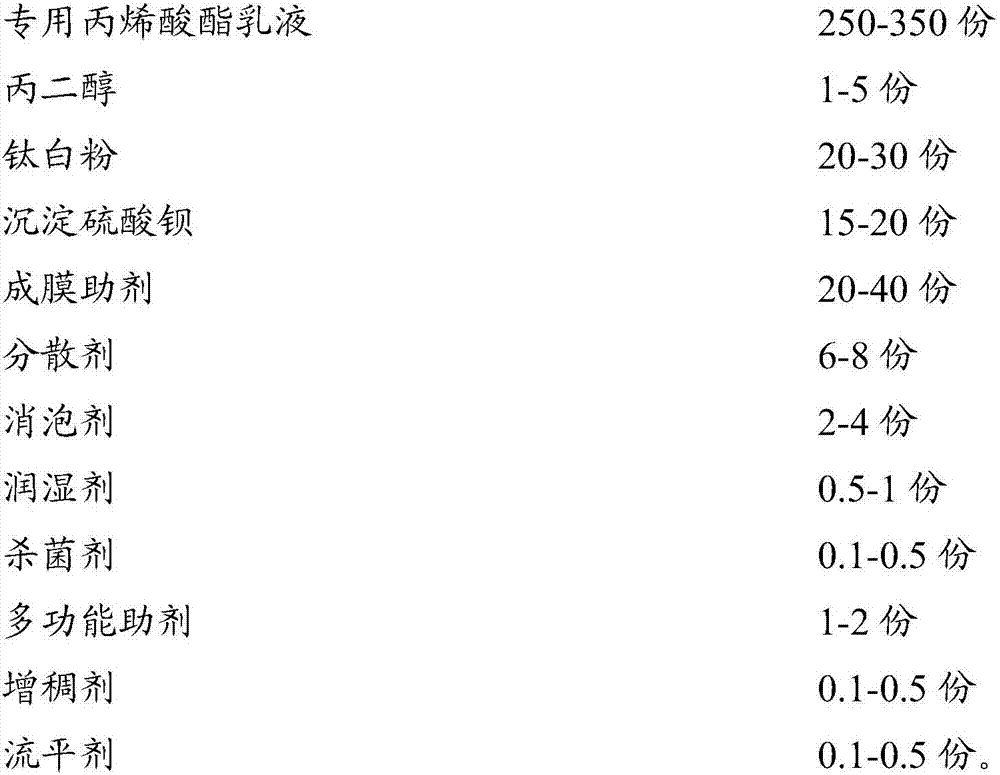

Single-component acrylate coating with corrosion-resisting and wear-resisting properties

InactiveCN106957579AIncrease crosslink densityIncrease the crosslink density, greatly improve the water resistance of the coatingAntifouling/underwater paintsPaints with biocidesDrying timeCorrosion

The invention discloses a single-component acrylate coating with corrosion-resisting and wear-resisting properties and belongs to the field of coating preparation. The single-component acrylate coating with corrosion-resisting and wear-resisting properties is prepared from the following components in parts by weight: 200-400 parts of a special acrylate emulsion, 1-10 parts of propylene glycol, 20-40 parts of titanium dioxide, 10-20 parts of precipitated barium sulphate, 20-50 parts of a coalescing agent, 5-10 parts of a dispersant, 1-5 parts of a defoamer, 0.1-1 part of a wetting agent, 0.1-1 part of a bactericide, 0.5-2 parts of a multifunctional assistant, 0.1-1 part of a thickener, 0.1-1 part of a flatting agent and 0.1-1 part of an acrylic thickener. The coating disclosed by the invention is good in water resistance, corrosion resistance and wear resistance, short in drying time and good in ventilating property, the film is not bubbled and does not fall off, and the coating can be used in an environment of 20 DEG C below to 95 DEG C and can be applied to industrial anti-corrosive fields such as terrace coatings, metal anti-corrosive coatings, ship coatings and the like.

Owner:北京华腾东光科技发展有限公司

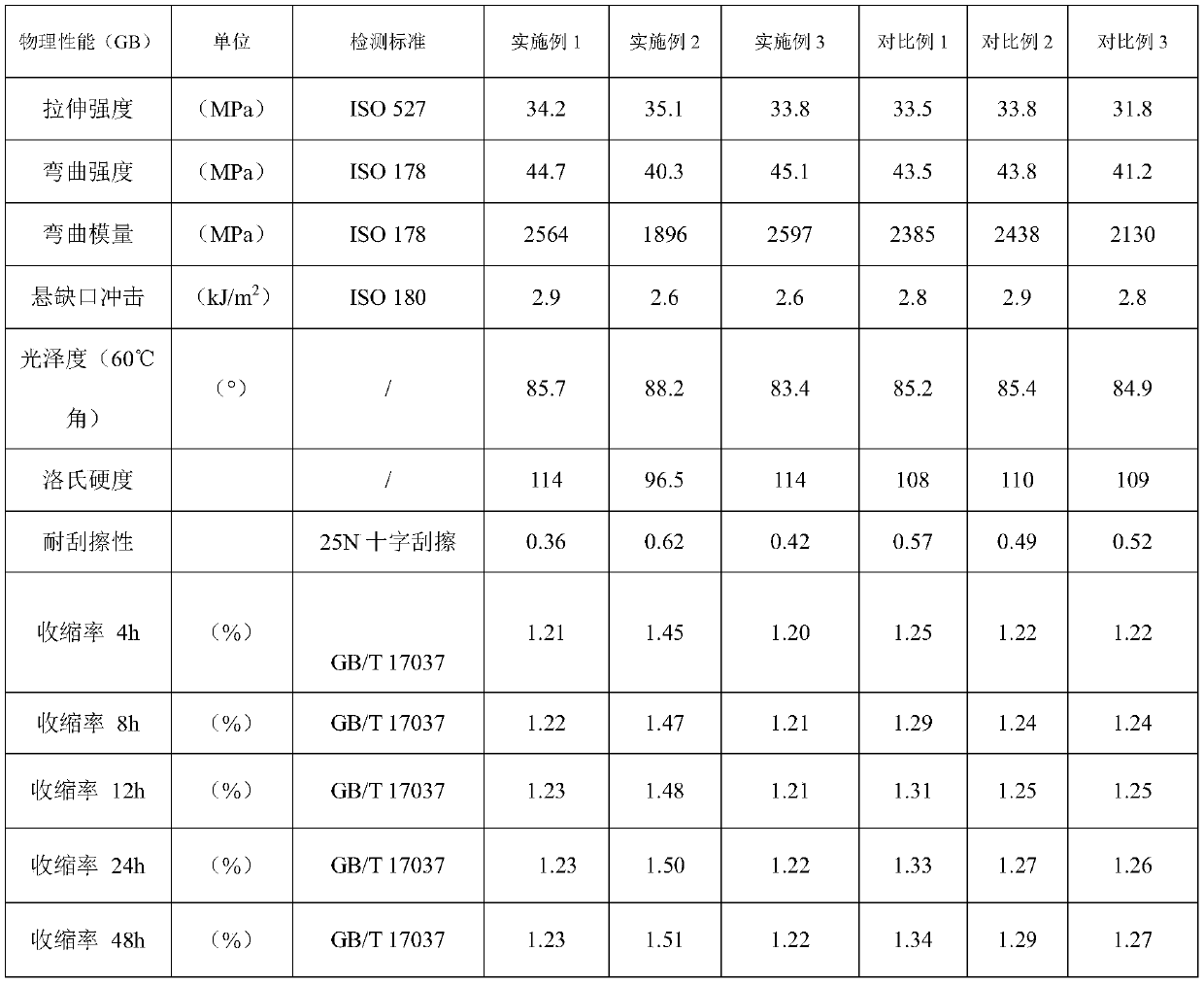

Polypropylene composite material for household appliance shell and preparation method thereof

The invention discloses a polypropylene composite material for a household appliance shell and a preparation method thereof. The material comprises the following raw materials in parts by weight: 80-96 parts of homo-polypropylene, 2-17 parts of precipitated barium sulfate, 1-7 parts of whiskers, 0.1-0.5 part of a nucleating agent, 0.2-0.4 part of an antioxidant, 0.5-0.7 part of a dispersing agent,0-2 parts of a scratch-resistant agent, 0-5 parts of talcum powder and 0-1 part of toner, wherein the isotacticity of the homo-polypropylene is 97-98%, and the crystallinity of the homo-polypropyleneis greater than or equal to 80%. According to the polypropylene composite material prepared by the invention, an injection molding product has the characteristics of high gloss, scratch resistance, low after-shrinkage and the like, the defect of large after-shrinkage of a polypropylene material is overcome, and the technical bottleneck of PP household appliance shell materials is solved.

Owner:ORINKO NEW MATERIAL CO LTD

Water-based aminoacrylic conductive flame-retardant dip-coating paint

The invention relates to a water-based aminoacrylic conductive flame-retardant dip-coating paint which contains the following components in parts by mass: 70-90 parts of electrolytic copper powder, 5-10 parts of flame retardant, 40-50 parts of water-based acrylic resin, 10-20 parts of amino resin, 1-5 parts of aluminum tripolyphosphate, 1-5 parts of porcelain clay, 1-3 parts of high-pigment carbon black, 1-3 parts of precipitated barium sulfate, 0.1-1 part of strontium yellow and 25-35 parts of distilled water. The water-based aminoacrylic conductive flame-retardant dip-coating paint provided by the invention can be used as a refrigerator compressor paint, can be coated on automobile parts, instruments and meters as well as household appliances to shield electromagnetic waves generated thereby, and has a flame retardant effect.

Owner:WUJIANG WUHUA HARDWARE PROD

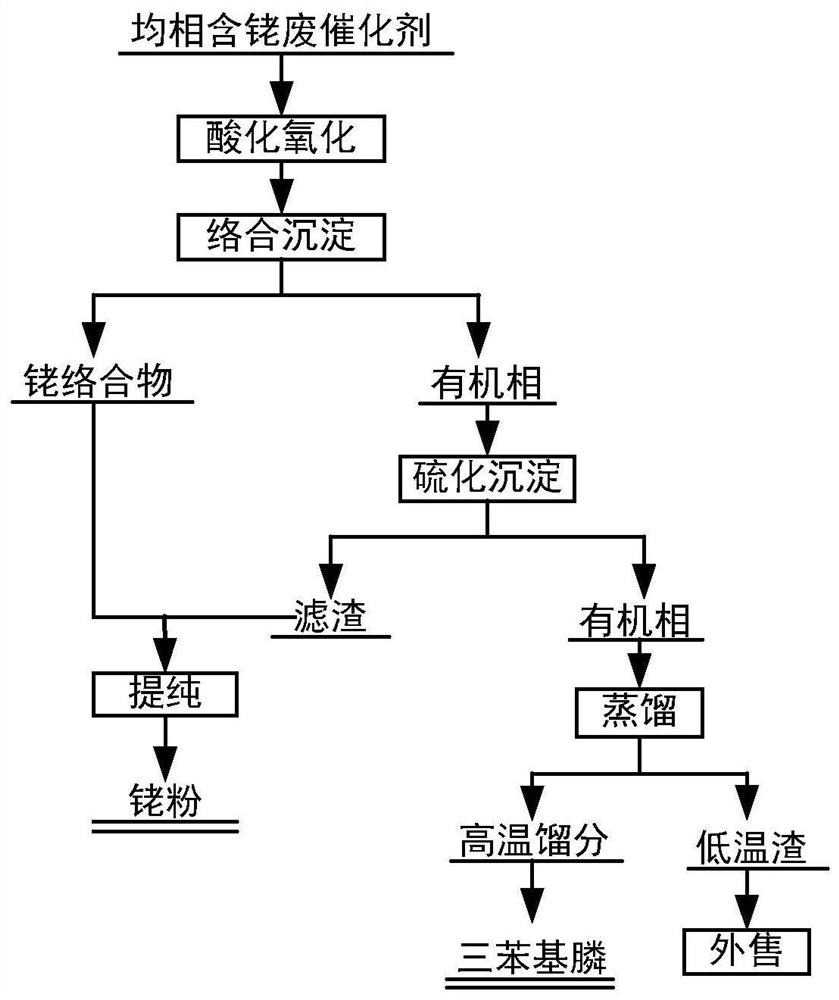

Method for recovering rhodium from homogeneous waste catalyst containing rhodium

ActiveCN111996386AReduce lossImprove solubilityProcess efficiency improvementPtru catalystSulfidation

The invention discloses a method for recovering rhodium from a homogeneous waste catalyst containing rhodium. The method of acidification oxidation-complex precipitation-sulfide precipitation is adopted. Firstly acidification-oxidation is adopted to interrupt the 'bridging' of rhodium in rhodium-phosphine catalyst in the waste catalyst, and then a specific complexing precipitant is adopted to generate a complex precipitate of rhodium, so that the recovery rate of rhodium reaches 95.23% in one step, the main body of rhodium in the waste catalyst is recovered in one step, the dispersion of the rhodium is effectively reduced, and the recovery rate of the rhodium is improved; and in addition, in the acidification-oxidation process step, a small part of rhodium is directly oxidized into Rh3+, the part is recovered by a vulcanization precipitation method, and the final recovery rate of the rhodium can reach more than 97% by combination of the two kinds of recovery. The complex precipitate and the sulfide precipitate generated in the recovery process are easy to treat, toxic substances are not generated, and the method is safe, green and environmentally friendly.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST

Silk screen printing ink for metal

The invention relates to silk screen printing ink for metal, which comprises the following components in parts by mass: 25-30 parts of colloidal calcium carbonate, 10-20 parts of ethylene glycol butyl ether, 15-30 parts of china clay, 35-40 parts of titanium dioxide, 50-60 parts of linseed alkyd resin, 10-15 parts of precipitated barium sulphate, 15-20 parts of butylated melamine resin, 15-20 parts of paraffin, 15-20 parts of painter naphtha, 30-40 parts of dehydrated castor alkyd resin and 1-2 parts of n-butyl alcohol. The silk screen printing ink for the metal is high in production efficiency, low in energy consumption, and good in surface hardness, friction resistance and light resistance, and the labor intensity of a worker is reduced greatly.

Owner:苏州凹凸彩印厂

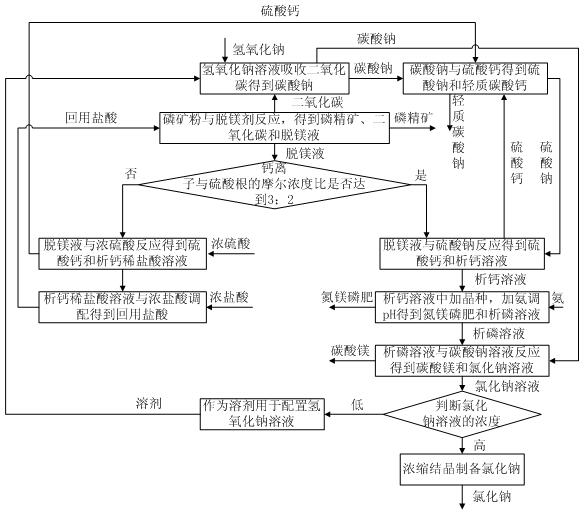

Chemical magnesium removal method for collophanite and free of tailings

ActiveCN112279227ANo emissionsImprove resource utilizationCalcium/strontium/barium carbonatesMagnesium carbonatesPhosphoric acidPrecipitated sulphur

The invention discloses a chemical magnesium removal method for collophanite and free of tailings, and belongs to the technical field of phosphorite magnesium removal. According to the method, dilutedhydrochloric acid is used for chemical magnesium removal, and phosphate concentrate, CO2 and magnesium removal liquid are obtained. The method comprises the steps: introducing CO2 into a NaOH solution to obtain a sodium carbonate solution; mixing the sodium carbonate solution with calcium sulfate for reaction to obtain a sodium sulfate solution and light calcium carbonate; adding sulfuric acid into the magnesium-removed solution to precipitate calcium sulfate to obtain calcium sulfate and a diluted hydrochloric acid solution containing phosphorus and magnesium, wherein the hydrochloric acid solution is used for preparing diluted hydrochloric acid and continuously used for removing magnesium from collophanite, and the process is repeated; when the molar concentration of calcium ions in themagnesium removal solution and the molar concentration of phosphate radicals reach 3: 2, precipitating calcium sulfate by using a sodium sulfate solution, adding ammonia water into the obtained filtrate to adjust the pH value, and precipitating to obtain a nitrogen-magnesium-phosphorus fertilizer and a phosphorus precipitation filtrate; adding a sodium carbonate solution into the phosphorus precipitation filtrate to obtain magnesium carbonate and a sodium chloride solution; and concentrating and crystallizing the sodium chloride solution to obtain sodium chloride.

Owner:HUBEI EZHONG ECOLOGICAL ENG CO LTD

Method for production of polyolalkyl ethers

A process for making polyol alkyl ether involving: (a) providing a polyol; (b) deprotonating the polyol with a base to form a first reaction product; (c) continuously removing water from the first reaction product to form a second reaction product; (d) providing an alk(en)yl (ether) sulfate; (e) reacting the alk(en)yl (ether) sulfate with the second reaction product to form a third reaction product containing a sulfate salt; (f) precipitating the sulfate salt from the third reaction product by adding from about 10 to 20 mol of water per mol of alk(en)yl (ether) sulfate to the third reaction product, at a temperature of from about 50 to 100° C.; (g) forming an aqueous and / or solid phase containing the polyol alkyl ether; and (h) separating the polyol alkyl ether from the aqueous and / or solid phase.

Owner:COGNIS DEUT GMBH & CO KG

Extinction barium and preparation method thereof

ActiveCN102115618AGood dispersionReduce pollutionPigment treatment with macromolecular organic compoundsPigment physical treatmentAllyl phenoxyacetatePrecipitated sulphur

The invention belongs to the field of metallic barium compounds, and particularly relates to a preparation method of extinction barium, which comprises the following steps: a. selecting barite with the barium content of higher than 95%, cleaning, and airing; b. pulverizing the aired barite, carrying out Raymond milling on a Raymond mill to obtain a product A of which the granularity is up to 400-500 meshes; c. adding sodium polyacrylate dispersing agent and allyl phenoxyacetate into the product A, and milling with a sand mill while controlling the particle diameter of the mixture within 5-10 mu m, thereby obtaining a product B; and d. adding calcium carbonate, titanium dioxide and allyl phenoxyacetate into the product B, and thoroughly mixing to obtain the extinction barium product. The method provided by the invention does not need heating, thereby saving the burning coal and being beneficial to energy saving and emission reduction; and no toxic or harmful substances are generated inthe production process. Compared with the prior art, the high-dispersivity precipitated barium sulfate provided by the invention has the advantages of small granularity, high dispersivity, low cost, and low environmental pollution in the production process.

Owner:杭州富阳白玉化工有限公司

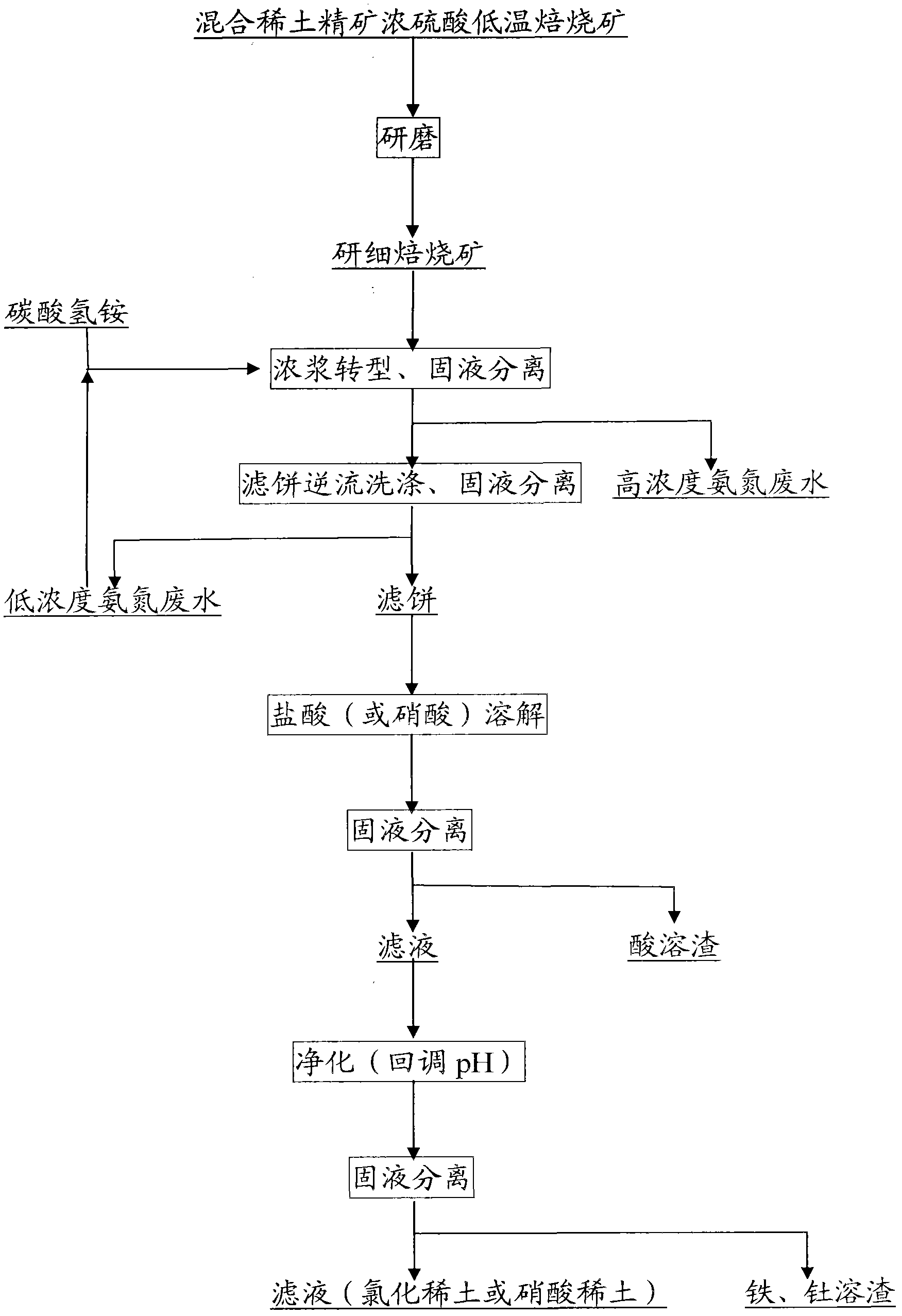

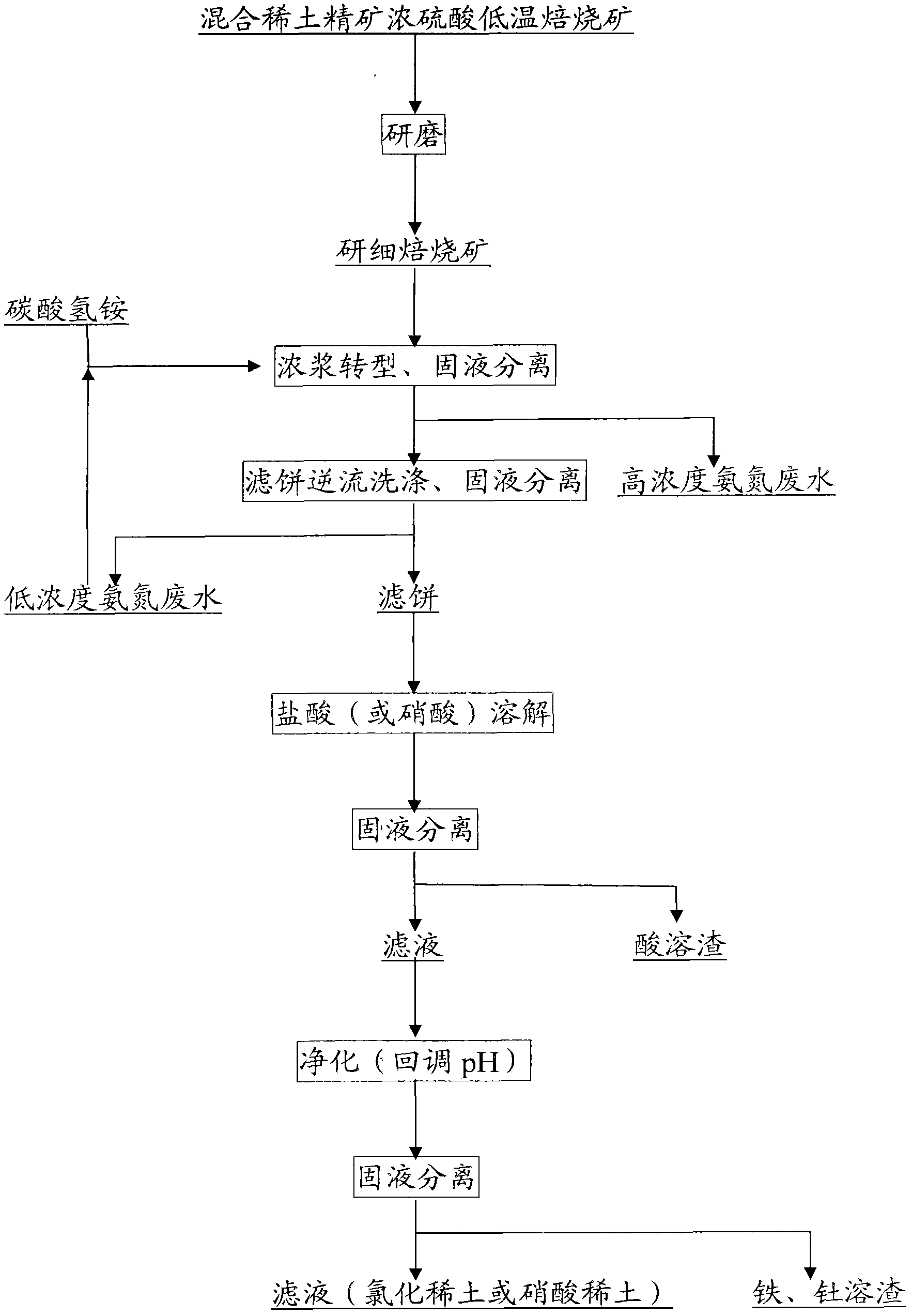

Transformation method for mixed rare earth concentrate and concentrated sulfuric acid low-temperature roasted ore

InactiveCN102560158AAchieve separationAchieve transformationProcess efficiency improvementSulfate radicalsPhosphate

The invention relates to a transformation method for mixed rare earth concentrate and concentrated sulfuric acid low-temperature roasted ore. The method is characterized by comprising the following steps: (1) grinding and concentrated pulp transformation reaction, namely adding ammonium hydrogen carbonate and water into the roasted ore to form a mixture, grinding the mixture in the concentrated pulp state, transforming the mixture into concentrated pulp, and performing solid liquid separation; (2) acid dissolution, namely dissolving the solid obtained in the concentrated pulp transformation step by using acid and filtering; and (3) purification, namely adjusting the pH value of the filtrate obtained in the acid dissolution step, precipitating iron and thorium ions, precipitating sulfate radicals, and performing solid liquid separation. According to the method, the ammonium hydrogen carbonate completely contacts and reacts with the roasted ore; the problem that rare earth phosphate precipitate is easy to generate because the pH value is adjusted by adding alkaline substances after water leaching is solved; the complex transformation method of performing complex salt precipitate alkaline transformation and acid dissolution after water leaching is avoided; and phosphorus and thorium resources can be recovered.

Owner:BERIS ENG & RES CORP

Long effective single component whitening pulp applied under normal temperature

This invention is an enduring effect normal temperature simple group bleach paste. It contains: The sodium hypochlorite it contains effective content of chlorine is 120-160g / L, as the main bleach material, the thickener is zinc oxide it content great then or equal to 99.5%, the sticker is polypropylene acid sodium, the ratio of their weight is 100:1-1:10. It may use sodium hypochlorite compose with zinc oxide, the ratio between their weight is 100:30-80, also may use sodium hypochlorite compose with polypropylene acid sodium, the ratio between their weight is 100:100:1-10. The zinc oxide may use the precipitate of barium sulphate, transparent soap instead, the flow ability of this product is 45-55mm.

Owner:王喜武

Formula and preparation method of high-glossiness filled PP (polypropylene)

The invention discloses a formula of high-glossiness filled PP. The formula comprises the following components, by weight, 31-65 parts of PP, 30-60 parts of barium sulfate, 0.5-1.5 parts of a titanate coupling agent, 0.2-1 part of an antioxidant, 0.5-1 part of a lubricant, 3-5 parts of POE (polyethylene octene elastomer), and 0.5-1 part of other processing assistants. The invention also discloses a preparation method of the high-glossiness filled PP. The preparation method comprises the following steps: 1, stirring the raw material barium sulfate, and adding the titanate coupling agent drop by drop to obtain a processed precipitate barium sulfate; 2, stirring the raw material PP, adding white oil, adding the oxidant, the lubricant and other processing assistants, adding the POE, finally adding the processed precipitate barium sulfate, and stirring to obtain semi-finished filled PP; and 4, extruding the semi-finished filled PP, cooling, and pelletizing to obtain the filled PP. The filled PP produced in the invention has the advantages of good appearance, uniform dispersion, high glossiness, good physical properties, and long service life.

Owner:杨谢

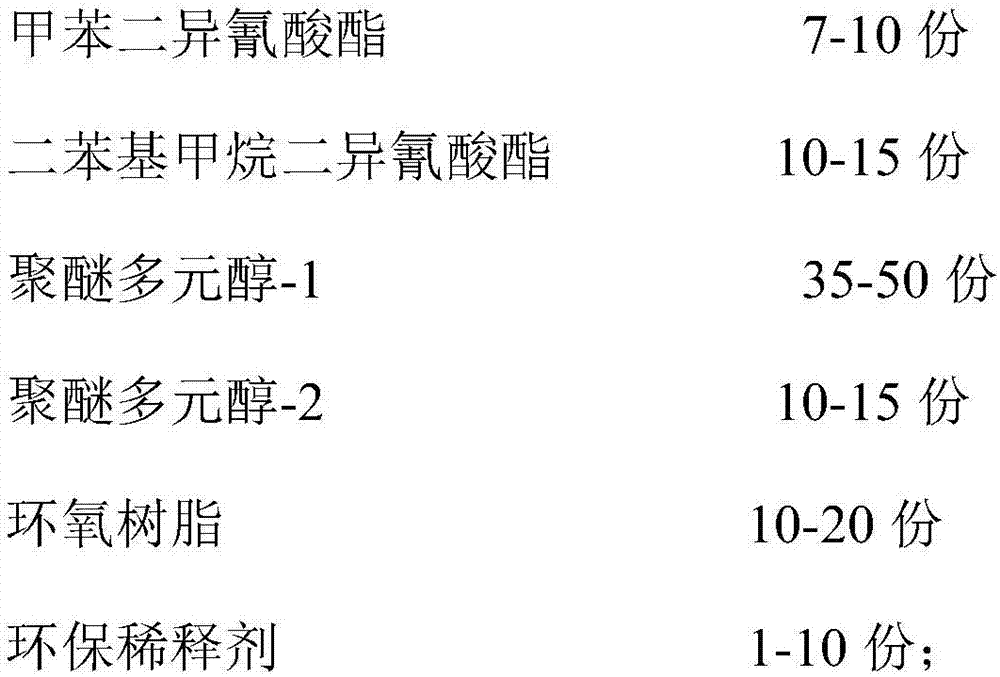

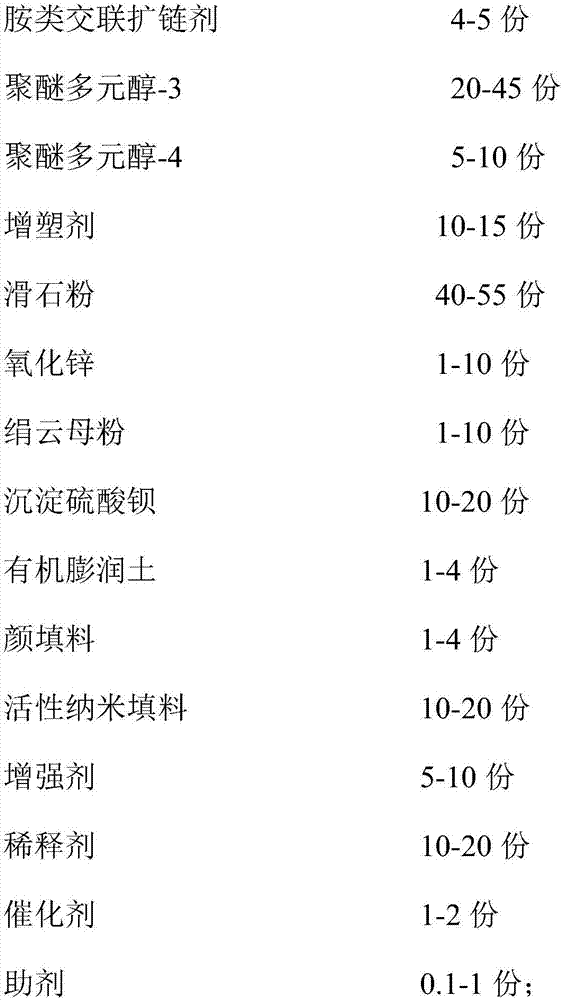

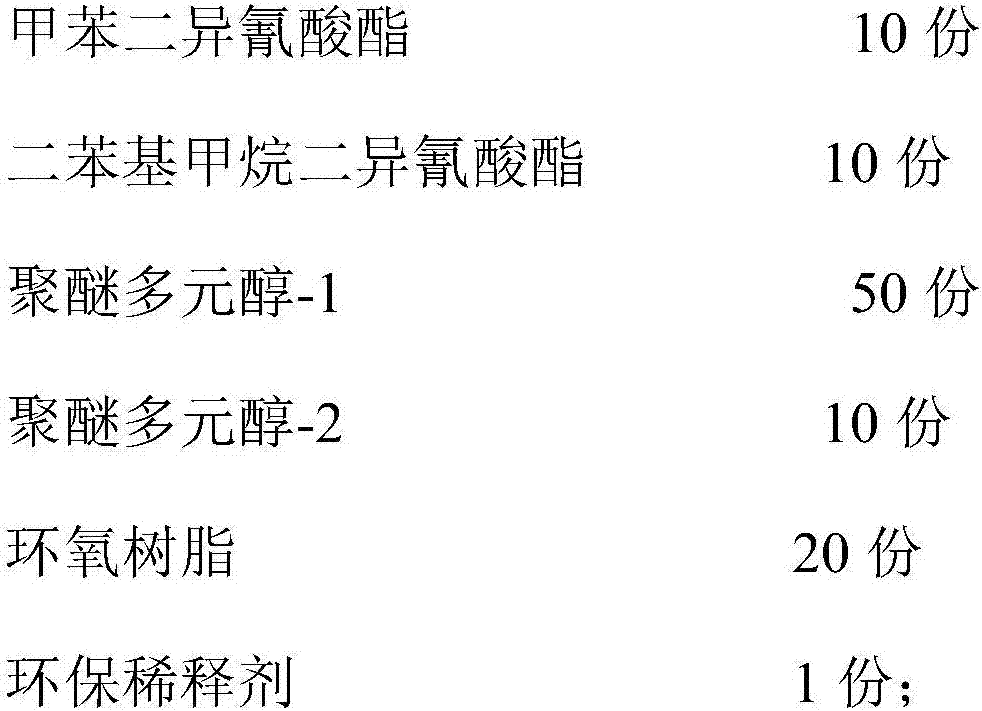

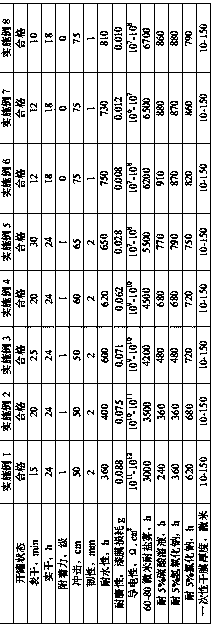

Two-component impervious environment-friendly material for pipeline and preparation method thereof

ActiveCN107163824AHigh elongationGood application effectPolyurea/polyurethane coatingsCross-linkEpoxy

The invention discloses a two-component impervious environment-friendly material for a pipeline. The material is prepared by mixing a component A and a component B in a weight ratio of 1: 1-3. The component A comprises 7 to 10 parts of toluene diisocyanate, 10 to 15 parts of methyl diphenylene diisocyanate, 35 to 50 parts of polyether polyol-1, 10 to 15 parts of polyether polyol-2, 0 to 20 parts of epoxy resin and 1 to 10 parts of an environment-friendly diluent. The component B comprises 4 to 5 parts of an amine cross-linking chain extender, 20 to 45 parts of polyether polyol-3, 5 to 10 parts of polyether polyol-4, 10 to 15 parts of a plasticizer, 40 to 55 parts of talcum powder, 1 to 10 parts of zinc oxide, 1 to 10 parts of sericite powder, 10 to 20 parts of barium sulfate precipitate, 1 to 4 parts of organic bentonite, 10 to 20 parts of an active nanometer filling material, 5 to 10 parts of a reinforcing agent, 10 to 20 parts of a diluent, 1 to 2 parts of a catalyst and 0.1 to 1 part of an auxiliary agent. The material provided by the invention has integrated environment friendliness, wear resistance, impermeability and high elongation percentage; nanotechnology is introduced so as to further improve the application performance of the material; and the material is specially applied to pipelines, and pipelines prepared from the material are environment-friendly and have long service life.

Owner:CHANG HAI TIANJIN CHEM TECH DEVCO

Aqueous epoxy fullerene heavy-duty anticorrosion coating and preparation method thereof

ActiveCN109971316AImprove toughnessImprove conductivityAnti-corrosive paintsEpoxy resin coatingsFirming agentSilicon dioxide

The invention relates to an aqueous epoxy fullerene heavy-duty anticorrosion coating and a preparation method thereof. The aqueous epoxy fullerene heavy-duty anticorrosion coating includes a componentA and a component B; the component A comprises the following components by weight percent: 10-20% of a first aqueous epoxy cure agent, 3-5% of fullerene pulp, 1-2% of graphene slurry, 5-8% of titanium dioxide, 0.1-0.2% of carbon black, 2-5% of aqueous zinc phosphate, 0.3-0.8% of a dispersing agent, 0.3-0.6% of a defoaming agent, 0.5-1% of a corrosion inhibitor, 0.3-0.5% of aqueous organobentonite, 0.2-0.4% of fumed silica, 2-4% of aqueous wax slurry, 10-20% of precipitate barium sulfate, 10-20% of quartz powder, 20-35% of conductive mica powder, 1-2% of cosolvent and 6.2-7.3% of deionized water; the component B is an aqueous epoxy resin emulsion. This product has excellent abrasion resistance, corrosion resistance, electrical conductivity, chemical resistance, impact toughness and excellent workability.

Owner:江拥

Low-temperature cured outdoor super-weather-resistant and corrosion-resistant powder coating and preparation method thereof

PendingCN111253841AOutstanding and Beneficial Technical EffectsReduce consumptionAnti-corrosive paintsPowdery paintsWeather resistanceAntioxidant

The invention belongs to the technical field of powder coatings, and relates to a low-temperature cured outdoor super-weather-resistant and corrosion-resistant powder coating. The coating is preparedfrom the following components in parts by mass: 100 parts of super-weather-resistant polyester resin, 30-50 parts of precipitated barium sulfate, 5-10 parts of TGIC, 0.1-1 part of an ultraviolet lightabsorber, 0.1-1 part of an antioxidant and a plurality of auxiliaries. The invention also provides a preparation method of the powder coating. The preparation method comprises the following steps: premixing the components, and then sequentially carrying out melting, mixing, tabletting, cooling, crushing, grinding, cyclone separation and screening to obtain finished powder. The low-temperature cured outdoor super-weather-resistant and corrosion-resistant powder coating provided by the invention can be cured at a low temperature, so that energy sources are saved, and the application range of the powder coating is also expanded; and meanwhile, the weather resistance and the corrosion resistance are very good.

Owner:浙江绿环新材料科技有限公司

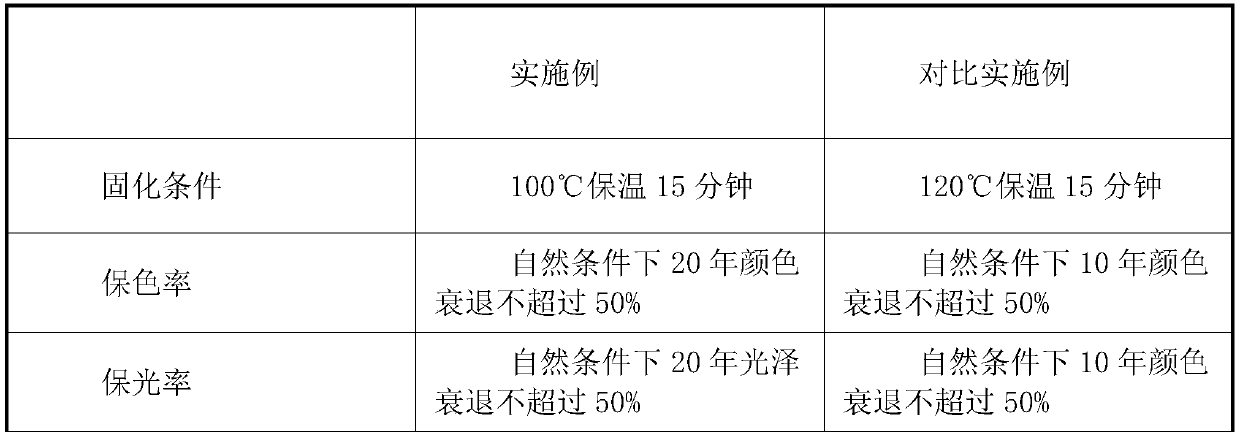

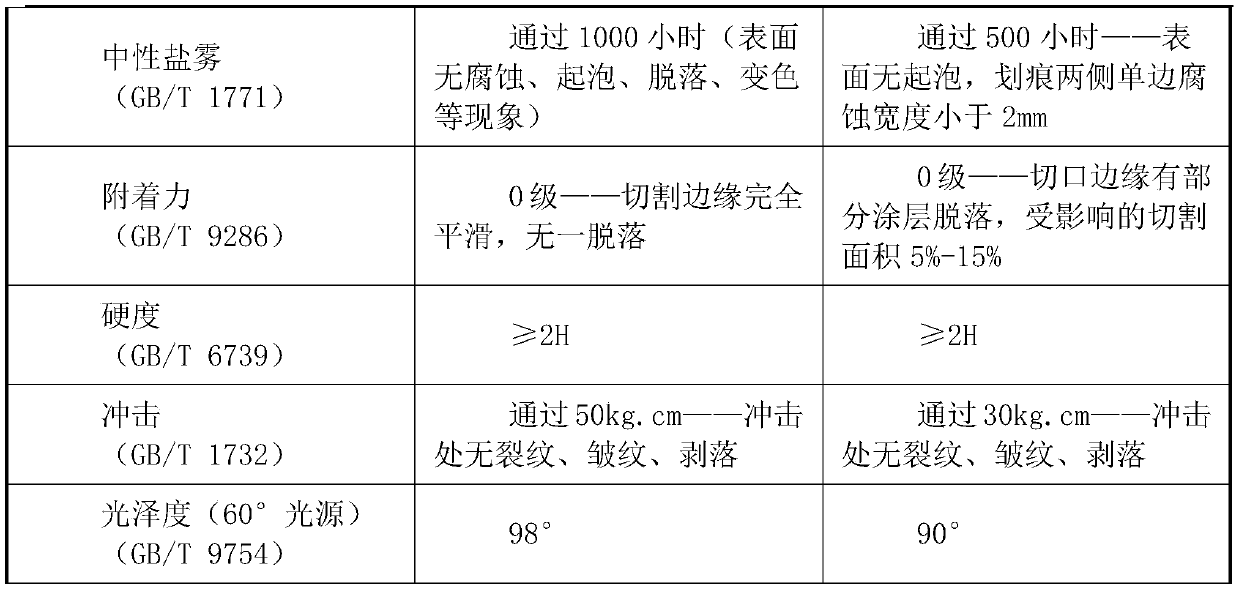

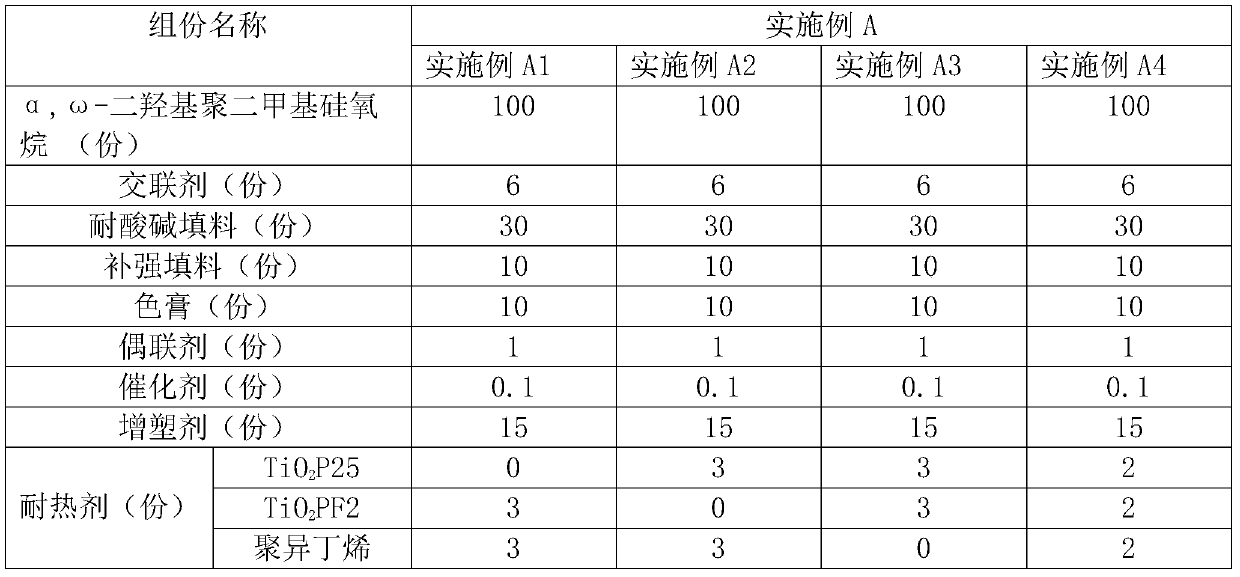

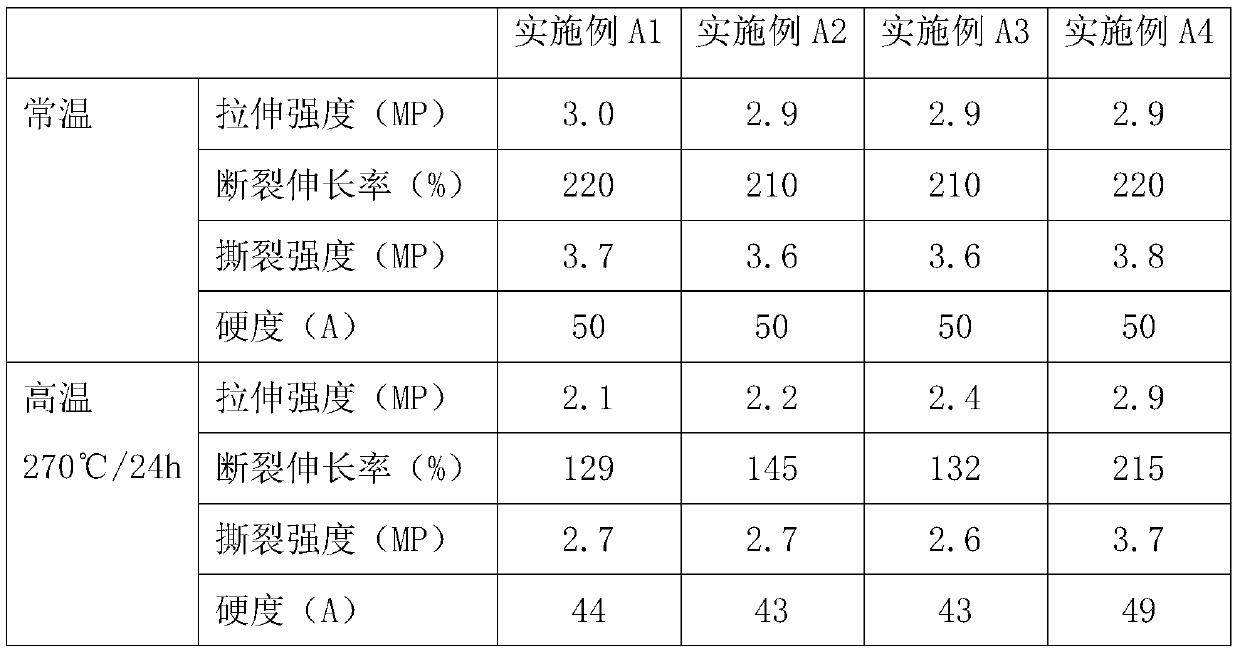

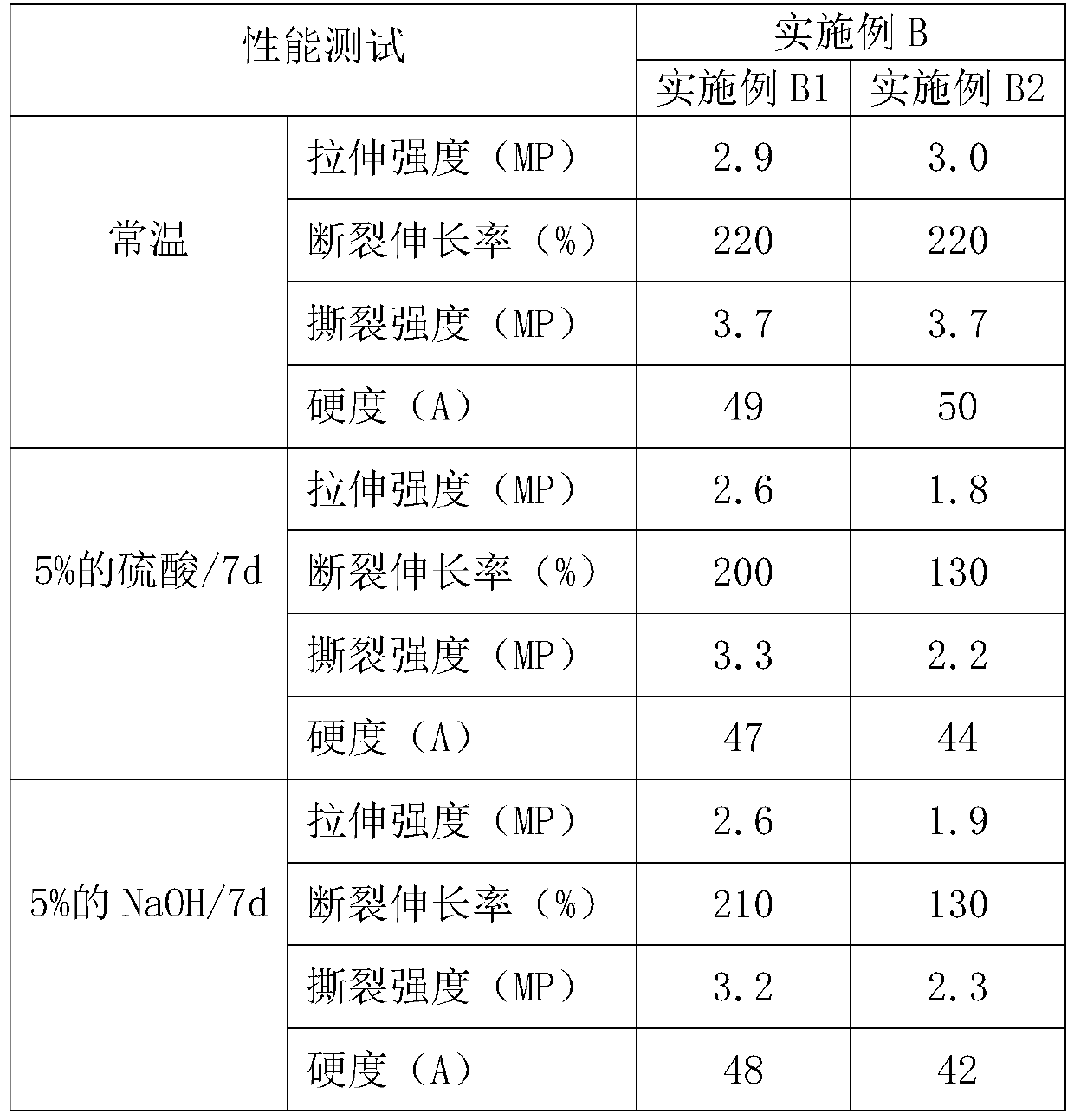

Heat-resistant and acid-alkali-resistant organic silica gel

ActiveCN110938405AImprove thermal stabilityGood acid and alkali resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPtru catalystCross linker

The invention discloses a heat-resistant and acid-alkali-resistant organic silica gel comprising, by weight, 90 to 110 parts of alpha, omega-dihydroxy polydimethylsiloxane, 4 to 10 parts of a cross-linking agent, 25 to 40 parts of an acid and alkali resistant filler, 6 to 14 parts of a reinforcing filler, 5 to 10 parts of a color paste, 0.8 to 1.5 parts of a coupling agent, 0.1 to 0.3 part of a catalyst, 2 to 10 parts of a heat-resistant agent and 10 to 20 parts of a plasticizer; wherein the acid and alkali resistant filler comprises ultrafine precipitated barium sulfate; and the heat-resistant agent is composed of TiO2P25, TiO2PF2 and polyisobutene. According to the heat-resistant and acid-alkali-resistant organic silica gel, a heat resistant agent composed of TiO2P25, TiO2PF2 and polyisobutene, and ultrafine precipitated barium sulfate taking as an acid-alkali-resistant filler are added into alpha, omega-dihydroxy polydimethylsiloxane, so that the thermal stability and acid and alkali resistance of the organic silica gel can be greatly improved, and the product can resist the environment of 270 DEG C for 24 hours, 5% sulfuric acid (7 days) and 5% NaOH (7 days).

Owner:GUANGZHOU GLORYSTAR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com