Extinction barium and preparation method thereof

A technology of extinction barium and allyl phenoxyacetate, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of harmful substances, high product cost, and large consumption of raw materials, and reduce production Cost, low cost, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

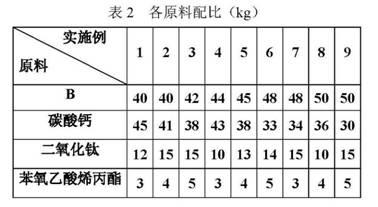

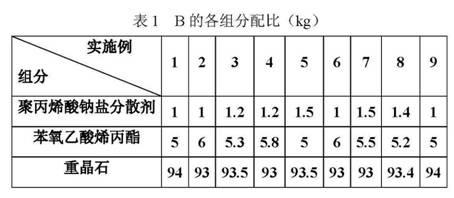

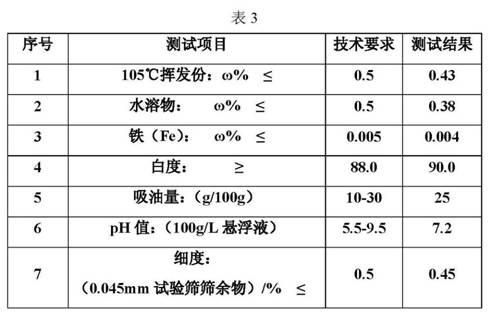

[0028] The preparation method of extinction barium, the specific steps are as follows: select the barite with a barium content of more than 95% to select, wash, dry, and after crushing, carry out ray milling on a ray mill to make the fineness reach about 400 meshes to obtain A . Add polyacrylic acid sodium salt dispersant and allyl phenoxyacetate to A, the proportion of each raw material is shown in Table 1, and then grind with a sand mill, the particle diameter of the mixture is controlled at about 5 μm, to obtain B; add carbonic acid to B Calcium, titanium dioxide and allyl phenoxyacetate are fully mixed to obtain the high-gloss barium product, and the ratio of each raw material is shown in Table 2.

Embodiment 4-6

[0030] The preparation method of extinction barium, the specific steps are as follows: select the barite with a barium content of more than 95% to select, wash, dry, and after crushing, carry out ray milling on a ray mill to make the fineness reach about 450 meshes to obtain A . Add polyacrylic acid sodium salt dispersant and allyl phenoxyacetate to A, the ratio of each raw material is shown in Table 1, and then use a sand mill to grind, the particle diameter of the mixture is controlled within the range of 6-8 μm to obtain B; Calcium carbonate, titanium dioxide and allyl phenoxyacetate were added to the mixture to obtain the high-gloss barium product through thorough mixing. The ratio of each raw material is shown in Table 2.

Embodiment 7-9

[0032] The preparation method of extinction barium, the specific steps are as follows: select the barite with a barium content of more than 95% to select, wash, dry, and after crushing, carry out ray milling on a ray mill to make the fineness reach about 500 meshes to obtain A . Add polyacrylic acid sodium salt dispersant and allyl phenoxyacetate to A, the ratio of each raw material is shown in Table 1, and then use a sand mill to grind, the particle diameter of the mixture is controlled within the range of 9 to 10 μm to obtain B; Calcium carbonate, titanium dioxide and allyl phenoxyacetate were added to the mixture to obtain the high-gloss barium product through thorough mixing. The ratio of each raw material is shown in Table 2.

[0033] As an alternative product of precipitated barium sulfate, it is compounded by adding calcium carbonate, titanium dioxide and related additives to barite ultrafine powder. The market price of relevant components is cheaper than precipitated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com