Water-based two-component polyurethane coating and preparation method thereof

A polyurethane coating, water-based two-component technology, applied in the field of coatings, can solve the problem of low reaction speed, achieve the effect of improving hydroxyl activity, mechanical properties and chemical resistance, and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

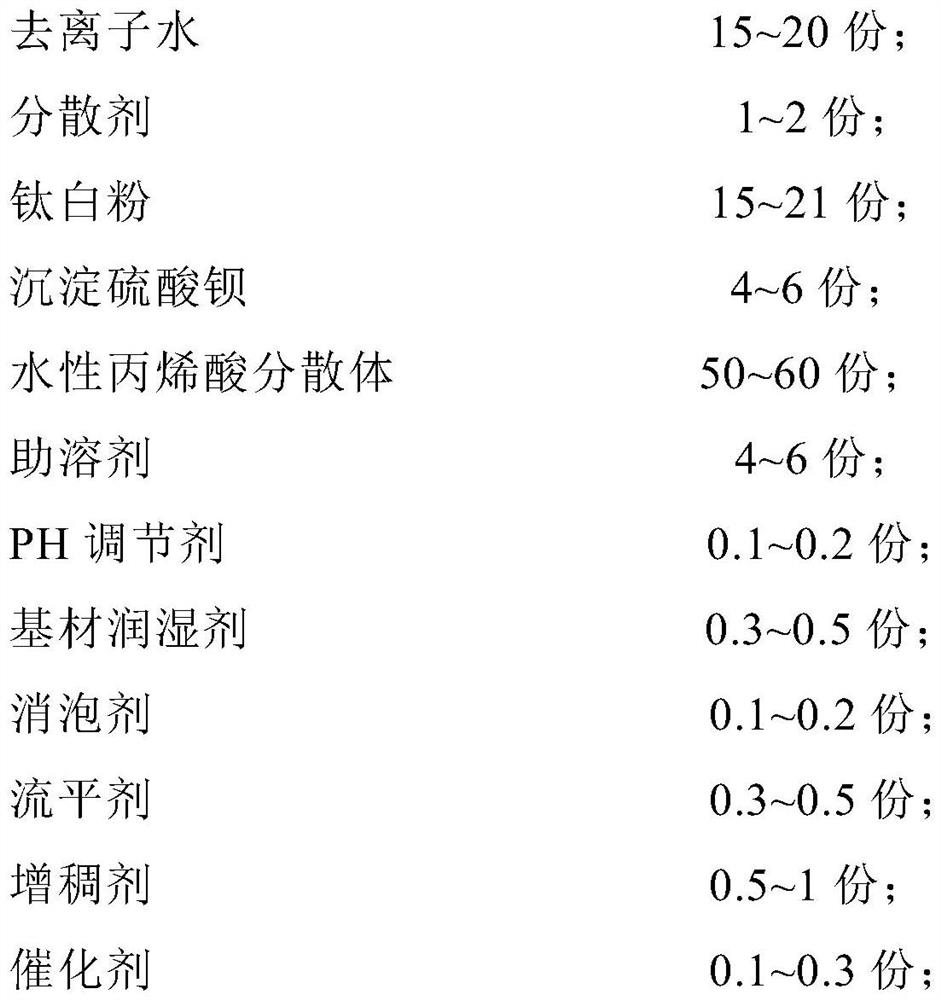

[0060] A water-based two-component paint, comprising a main agent and a hardener, the main agent is composed of the following components in parts by weight:

[0061]

[0062]

[0063] Hardener consists of the following components in parts by weight:

[0064] 80 parts of water-based isocyanate;

[0065] Propylene glycol diacetate 20 parts.

Embodiment 2

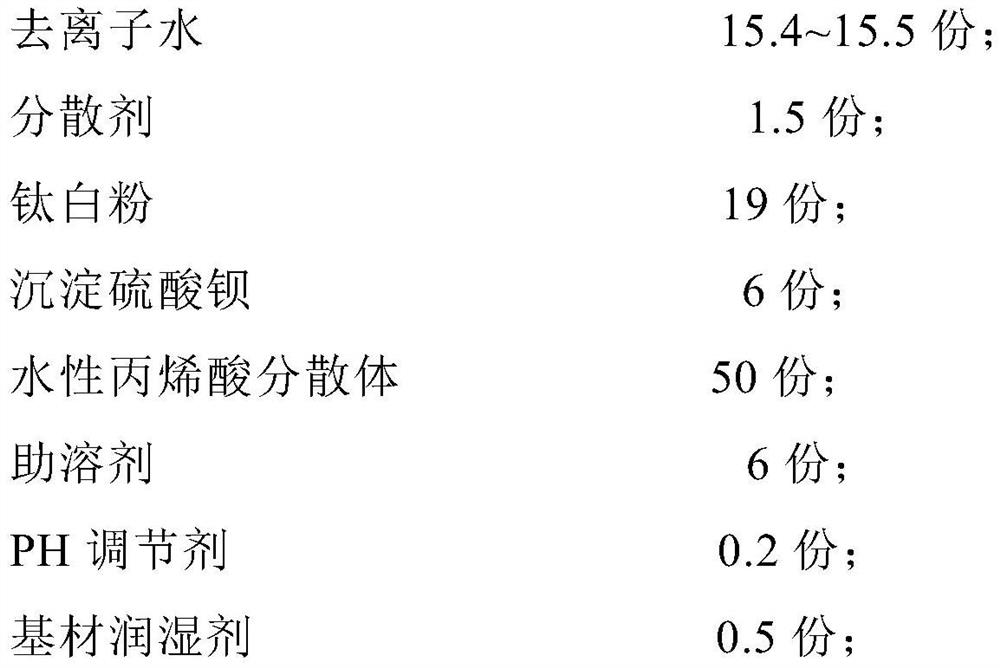

[0067] A water-based two-component paint, comprising a main agent, a hardener and a catalyst, the main agent is composed of the following components in parts by weight:

[0068]

[0069] Described hardening agent is made up of the following composition that accounts for weight part:

[0070] 80 parts of water-based isocyanate;

[0071] Propylene glycol diacetate 20 parts.

[0072] The waterborne two-component polyurethane coating of above-mentioned 2 embodiments is obtained by following preparation method:

[0073] The main ingredient preparation method comprises the following steps:

[0074] 1) Grinding color paste

[0075] a. Prepare the raw materials according to the above ratio;

[0076] b. Add 80% deionized water in the formula amount into the dispersion container, slowly add the dispersant in the formula amount under stirring, stir and disperse to a uniform state;

[0077] c. Under stirring, slowly add the formula amount of titanium dioxide, precipitate barium su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com