Asphalt mixture modifier particles and preparation method thereof

A granule and mixture technology, which is applied in the field of asphalt mixture modifier granules and its preparation, can solve the problems of difficult granulation, good performance of SBS modified asphalt mixture, shortening the crosslinking reaction time of SBS modified asphalt, etc., to achieve Improve high and low temperature performance, prevent cross-linking reaction, shorten the time and effect of vulcanization and cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1. Prepare materials according to the following proportions by weight:

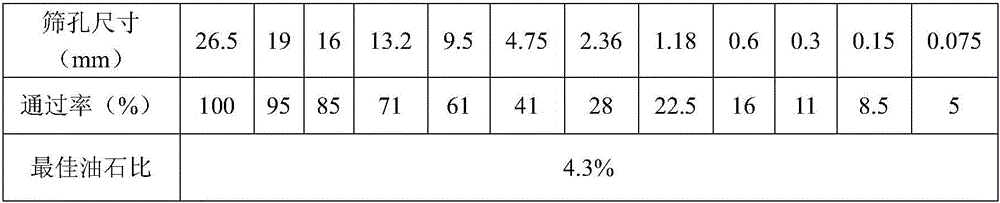

[0068]

[0069] 2. Mix SBS and anti-scorching agent evenly at room temperature to obtain the first mixture;

[0070] The first mixture is fed through the feeding port of the twin-screw extruder, and the material is extruded and conveyed. The temperature at this stage is 120°C-160°C, and the twin-screw speed is controlled below 500r.p.m;

[0071] Set up a second feed port at the end of the heating system, add cross-linking agent and accelerator to prepare a second mixture, at this time, the temperature is controlled below 120°C (controlled by cooling water) to prevent cross-linking and blocking the discharge port;

[0072] The strip material coming out of the machine head is cooled and separated in a water bath environment. The water temperature is generally controlled at 50-60℃ to prevent the strip from being broken when the temperature is too low and the temperature is too high. After the water temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| residual stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com