Patents

Literature

67results about How to "Avoid cross-linking reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction

InactiveCN101659627AHigh hydroxyl valueHigh primary hydroxyl contentOxygen-containing compound preparationOrganic compound preparationEpoxyVegetable oil

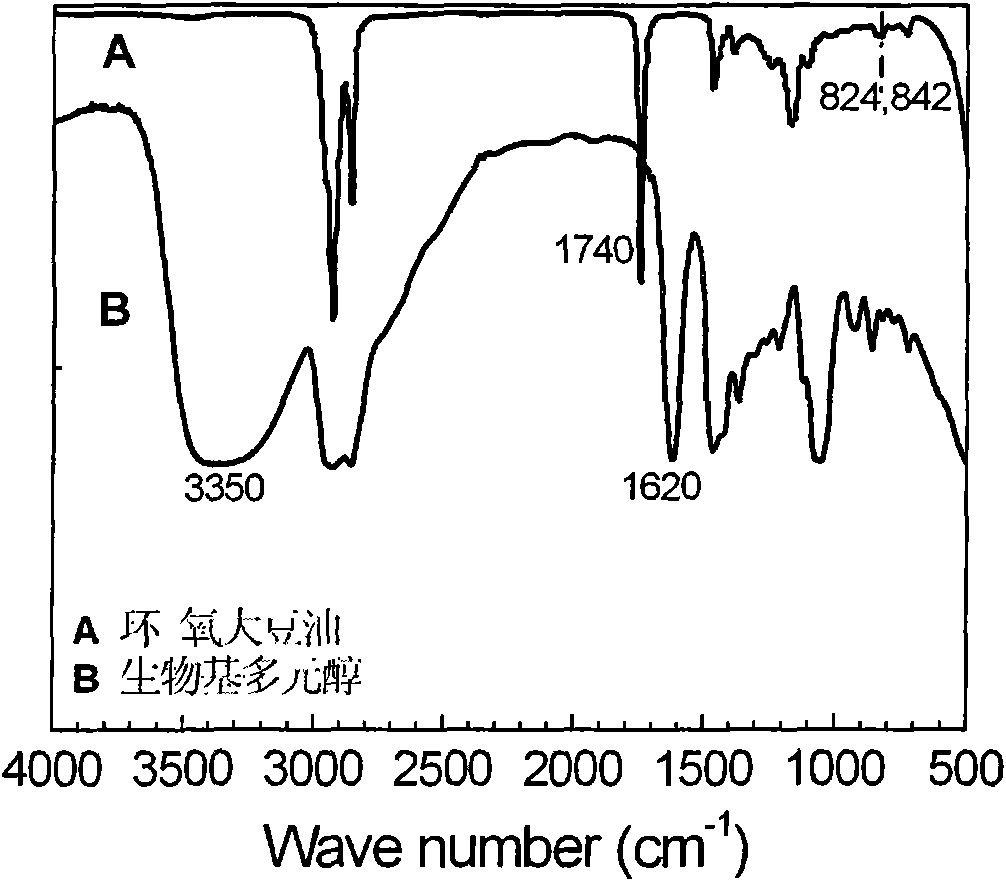

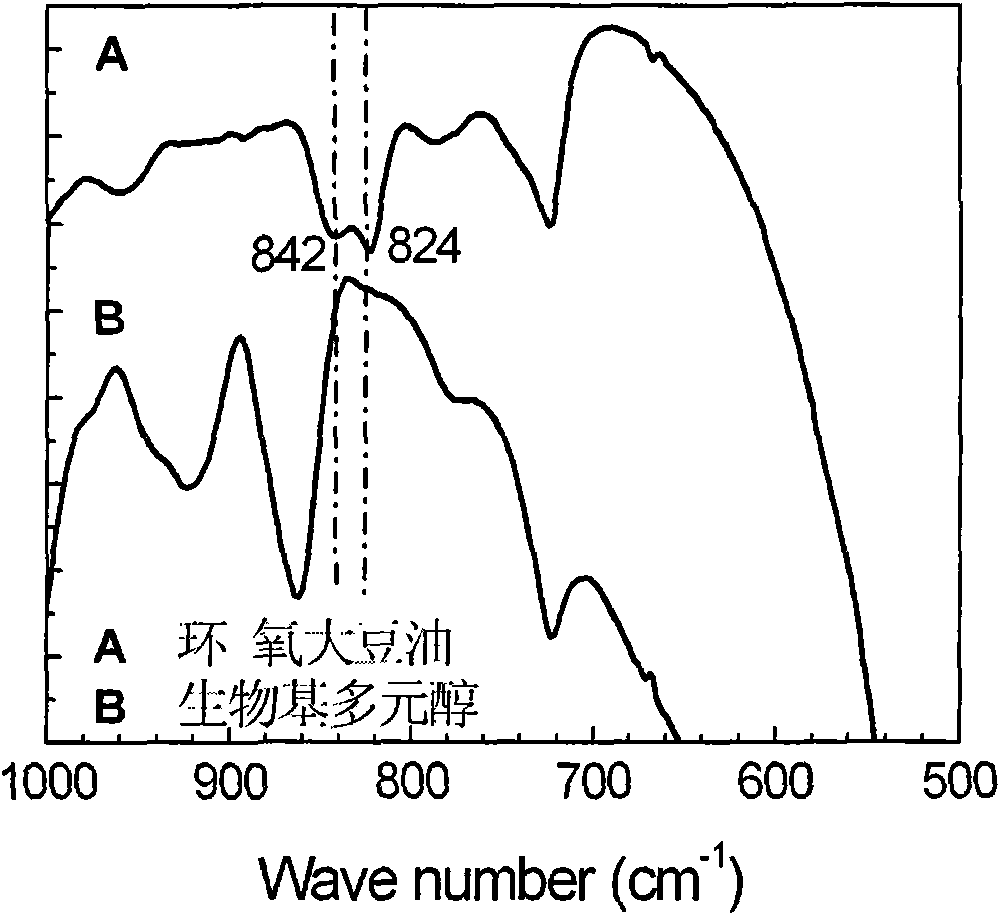

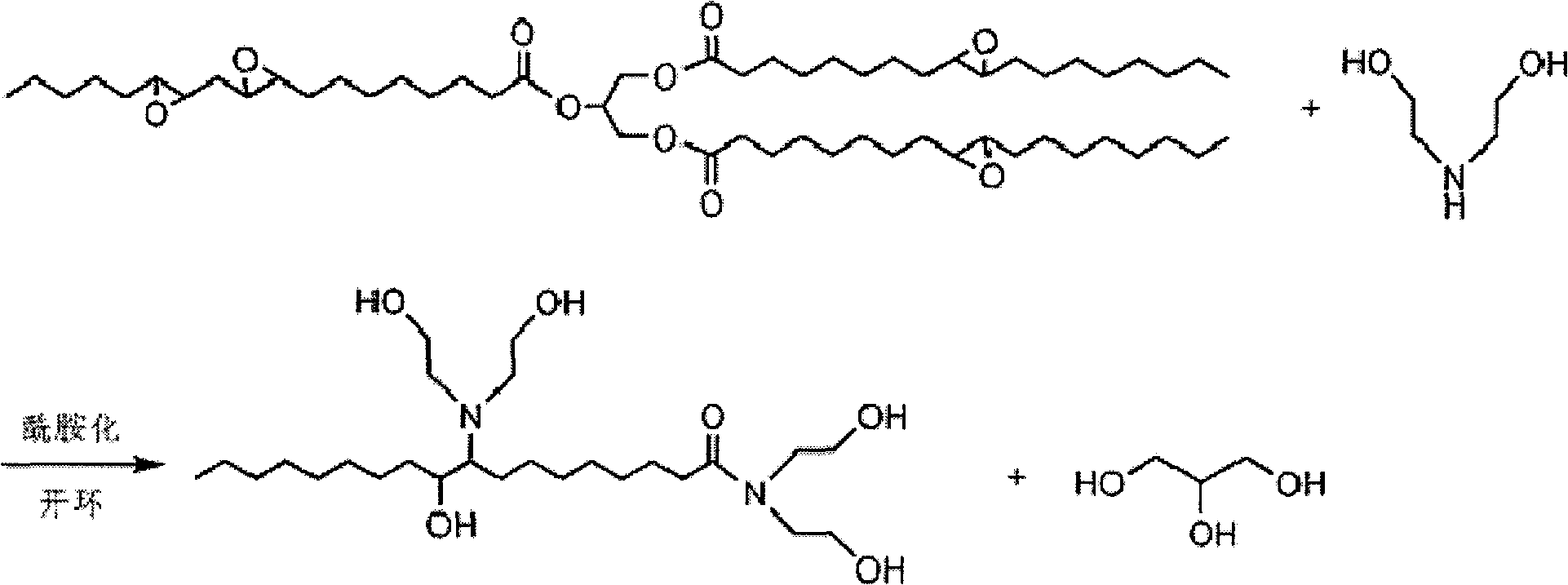

The invention discloses a high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction, which is obtained by the following one preparing step: accordingto the molar ratio of epoxy group to amino group being 1:1-1:1.1, leading the epoxidized vegetable oil and diolamine to simultaneously generate epoxy group ring opening reaction and ester group amidation reaction at the temperature of 80-140 DEG C for 2-16 hours, thus obtaining bio-base polyol. The high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-stepreaction is a novel bio-base polyol, and has the characteristics of high hydroxyl valve, high primary hydroxyl group content, short 'swing' chain, low viscosity and the like. The novel method for preparing the bio-base polyol is characterized by completing ring opening and amidation reactions by one step, having short processing procedures, capability of avoiding cross linking reaction, no need of catalyst, and no need of separating steps, being environment friendly, and easy to realize industrialized production, and the like.

Owner:ZHEJIANG UNIV

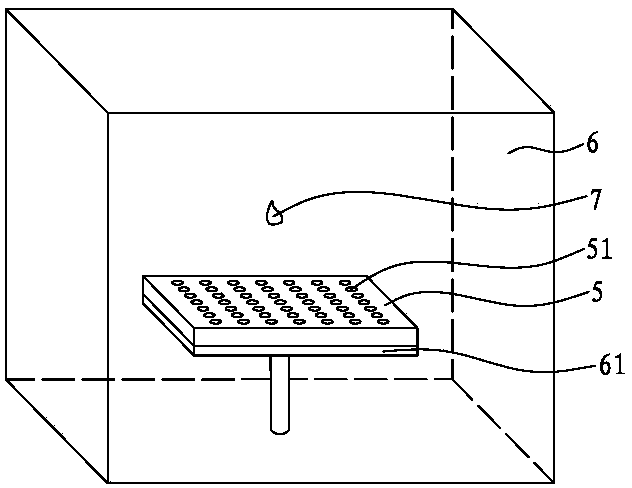

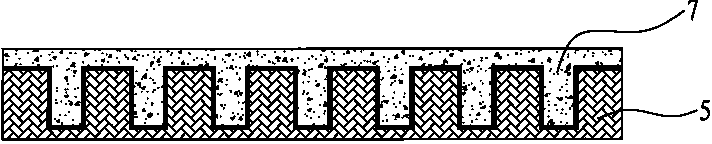

Manufacturing method of micro lens array mold

InactiveCN103353627AIncrease freedomGood surface smoothnessSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusDegrees of freedomMicro lens array

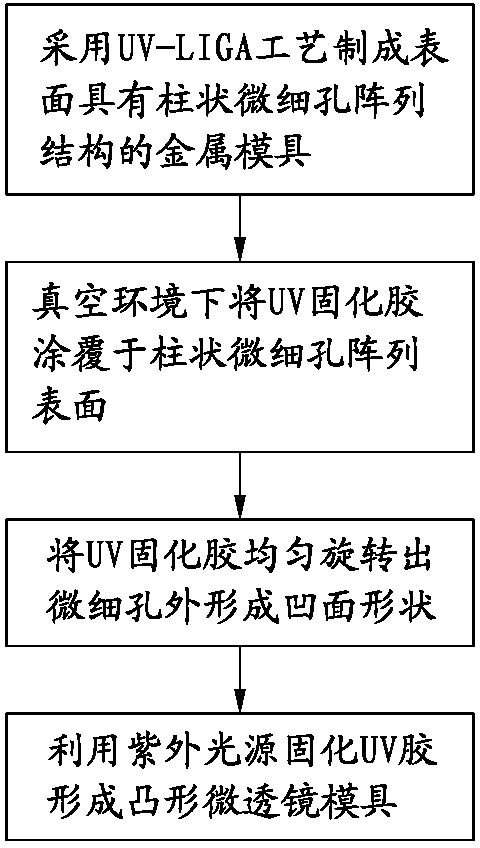

The invention discloses a manufacturing method of a micro lens array mold. The method mainly comprises the following steps that 1. A UV-LIGA technology is used to make a metallic nickel mold whose surface possesses a columnar micro hole array structure; 2. In a vacuum environment, a UV solidification glue is coated in the columnar micro hole array of the nickel mold; 3. An obtained product is rotated so that a part of the UV solidification glue is uniformly rotated out of the micro hole and a stable concave shape is formed, and then an ultraviolet source is used to solidify the solidification glue so that the micro lens array mold can be obtained. By using the method, because a rotation mode is directly used, a micro lens mold cavity possesses good surface flatness so as to guarantee an optical characteristic of the manufactured micro lens array. Through adjusting a viscosity of the UV glue, a rotation rate and other modes, rise and curvature of the micro lens are controlled so as to adjust a focal length of the micro lens and increase a degree of freedom of manufacturing the micro lens array.

Owner:XIAMEN UNIV OF TECH

Radiation crosslinked polyethylene pipe and its preparation method

ActiveCN1282699CImproved chemical purityAvoid cross-linking reactionsTubular articlesPolymer scienceCross linker

The invention relates to a radiation crosslinked polyethylene pipe, which has a three-dimensional network crosslinked molecular structure, and the pipe is made of a certain proportion of mixed polyethylene resin, antioxidant and stearate lubricant. The raw material is extruded into a tube by a tube extruder at a temperature below 235°C, and then irradiated by electron rays; the ratio of each component in the raw material is: polyethylene resin 98.5-99.0%wt, antioxidant 0.1 ~0.6%wt, stearate lubricant 0.5~1.0%wt; molecular crosslinking degree inside the pipe ≥60%. The invention provides a radiation cross-linked polyethylene pipe material which does not need to add a cross-linking agent, has low raw material cost, high extrusion production efficiency and high chemical purity of the product.

Owner:FSPG HI TECH

Radiation crosslinked polyethylene pipe and its preparation method

ActiveCN1670068AImprove chemical purityImprove pipe extrusion efficiencyTubular articlesCross-linkPolymer science

The invention relates to a radiation crosslinked polyethylene tube, which has a stereoscopic netted cross-linking molecular structure, and the process comprises: extruding the mixture in a finite proportion of polyvinyl resin, anti-oxidizing agents and stearic acid salt lubricating agents as raw materials in the temperature of less than 235 Deg. C to get the tubes by a tube extruder, then radiating by electron-beams to get the product. The components of the said raw materials is with a proportion of polyvinyl resin of 98.5-99.0 wt%, anti-oxidizing agents of 0.1-0.6 wt% and stearic acid salt lubricating agents of 0.5-1.0 wt%, and the degree of molecular crosslinking in the inner of the said tubes is more than 60 %.

Owner:FSPG HI TECH

Hydrogenated styrene-modified dicyclopentadiene petroleum resin and preparation method thereof

The invention discloses hydrogenated styrene-modified dicyclopentadiene petroleum resin and a preparation method thereof, and belongs to the technical field of petrochemical engineering. The hydrogenated styrene-modified dicyclopentadiene petroleum resin disclosed by the invention has a softening point of 90-130 DEG C, a Gardner chromaticity of 0-1, a weight-average molecular weight of 400-1000 and a molecular weight distribution index of 1.5-2.5. A method for preparing the hydrogenated styrene-modified dicyclopentadiene petroleum resin disclosed by the invention comprises the following steps: reaction raw material mixing, reaction raw material thermal polymerization reaction, purification and hydrogenation reaction. According to the method disclosed by the invention, a high-purity cyclopentadiene monomer and a styrene monomer are used as raw materials and mixed, and the various process parameters of the thermal polymerization reaction are strictly controlled by adjusting the proportion of the various components, thus the occurrence of cross-linking during the thermal polymerization process can be prevented, and favourable conditions are provided for the subsequent hydrogenation reaction, so that the performances of solubility, chromaticity, stability and the like of the hydrogenated resin are remarkably improved.

Owner:安徽同心新材料科技有限公司

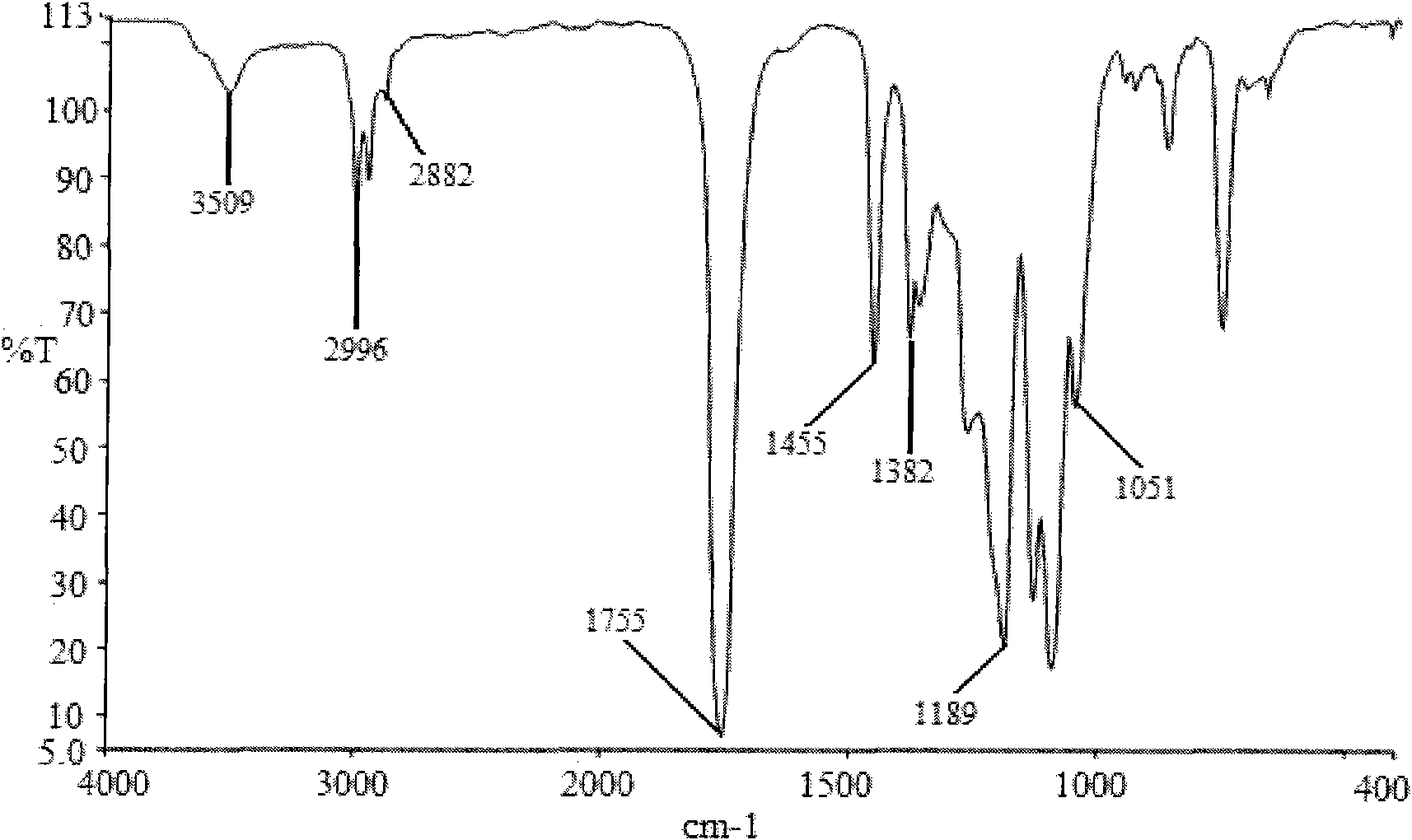

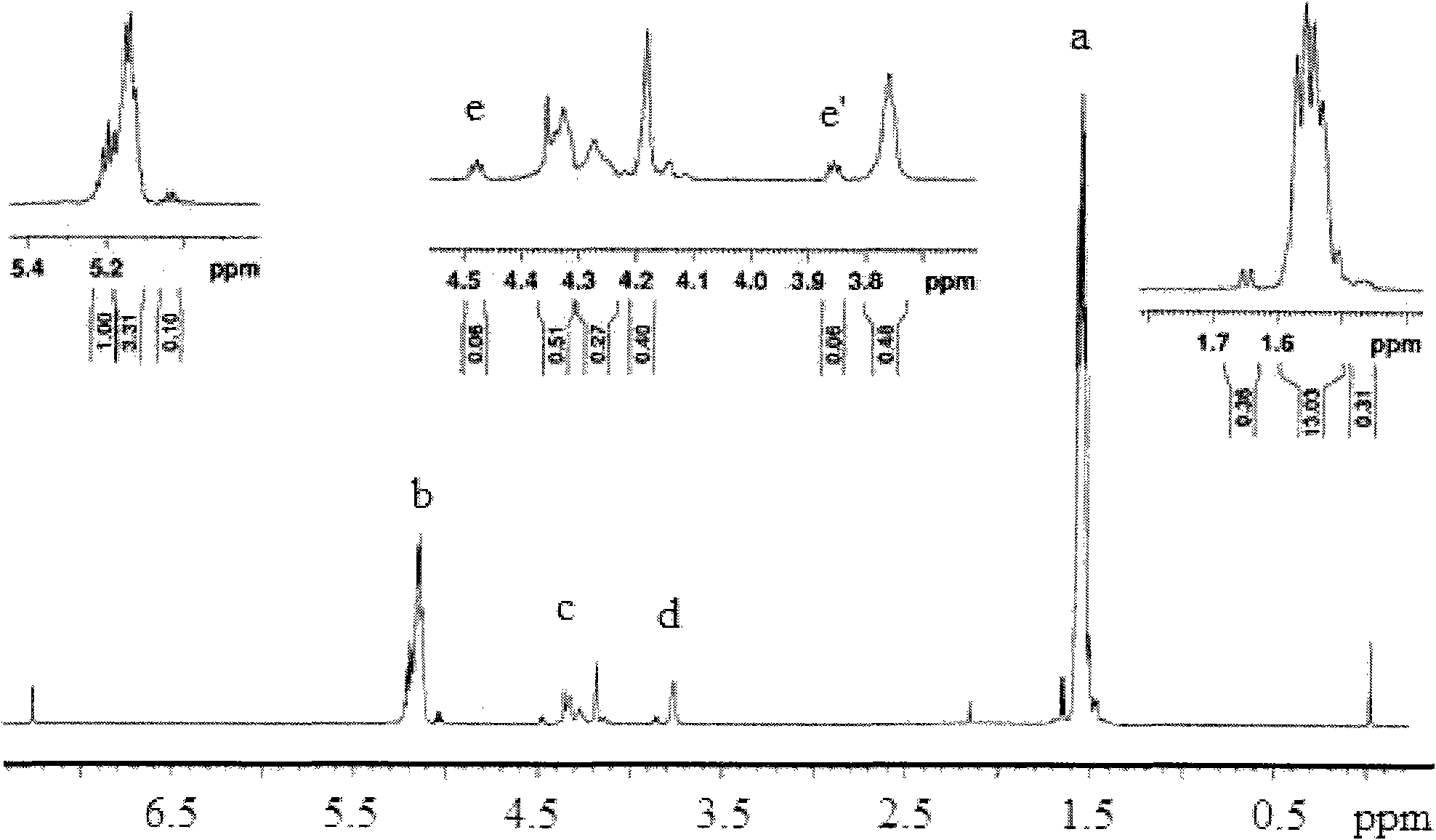

Preparation method of shape memory polyurethane based on lactide and 1, 4-p-dioxanone

The invention discloses a preparation method of shape memory polyurethane based on lactide and 1, 4-p-dioxanone. The preparation method comprises the following steps of: firstly carrying out vacuum melting reaction on the 1, 4-p-dioxanone, stannous octoate and small molecule diol to generate hydroxyl-terminated polybutadiene (1, 4-p-dioxanone), carrying out vacuum melting reaction on the hydroxyl-terminated polybutadiene and the lactide as well as the stannous octoate to prepare the hydroxyl-terminated polybutadiene (lactide-co-1, 4-p-dioxanone), then reacting the hydroxyl-terminated polybutadiene with diisocyanate as well as the stannous octoate in a benzene solvent to generate prepolymer, and then reacting the prepolymer with an isopropyl alcohol solution of chain extender small molecule diol or small molecule diamine to prepare shape memory polyurethane. The invention adopts a tow-step method to prepare hydroxyl-terminated polybutadiene (lactide-co-1, 4-p-dioxanone), takes the benzene solvent as a pre-polymerization reaction solvent, introduces isopropanol as a cosolvent in the chain extension reaction, and can enhance reaction controllability, reduce by-product production, enhance product yield and obtain high molecular weight chain-shaped shape memory polyurethane with excellent shape memory performance.

Owner:CHONGQING UNIV

Method for nano modification of polyacrylamide flocculant

ActiveCN105175636AEasy to operateMild conditionsWater/sewage treatment by sorptionNitrogen gasBottle

The invention discloses a method for nano modification of polyacrylamide flocculant, and belongs to the field of environment-friendly water treatment materials. The method includes the steps that chitosan is completely dissolved in an acetic acid solution in a magnetic stirring state, a sodium tripolyphosphate solution is added drop by drop, stirring is continued, and the mixed solution is put in an ultrasonic device to prepare a nano chitosan solution ultrasonically; acrylamide monomers and photoinitiator are added into the obtained solution and dissolved through stirring, nitrogen is introduced to remove oxygen and seal a reaction bottle, and the reaction bottle is placed under a low-voltage ultraviolet lamp to generate milk white colloid through illumination polymerization; the colloid is soaked in a mixed solution of absolute ethyl alcohol and acetone, flushed with distilled water, put into a vacuum drying oven to be dried, ground and screened to obtain the final nano chitosan / polyacrylamide flocculant in a white powder form. Reaction conditions are moderate, polymerization time is short, condensation cooling is not needed, energy consumption and cost are reduced, industrialization is easy, and the obtained modified polyacrylamide flocculant has adsorption and bridging capacity.

Owner:HOPE (NANJING) LIFE SCI INNOVATION INST CO LTD

Polyfunctional-group-modified polysiloxane emulsifier and preparation method thereof

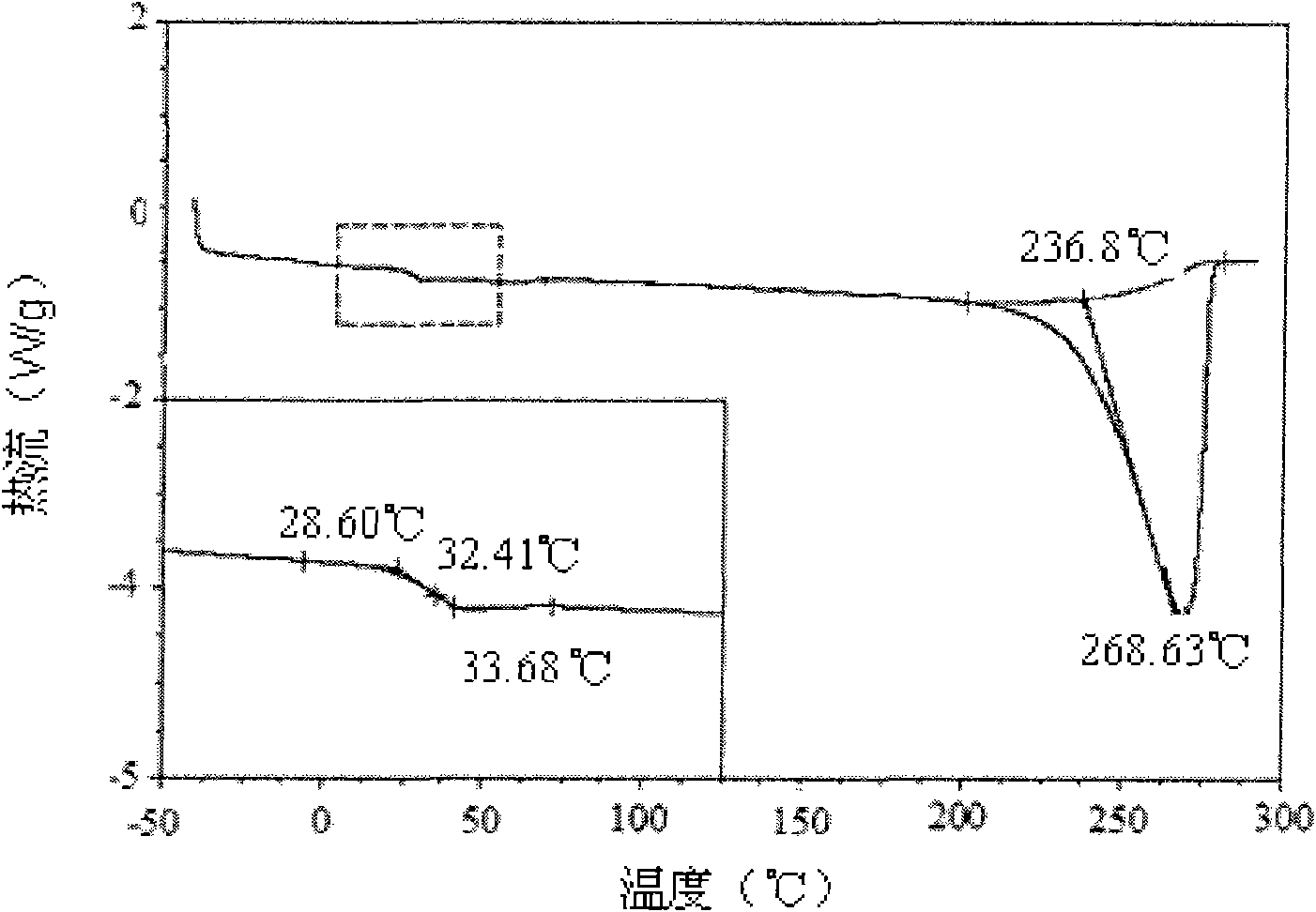

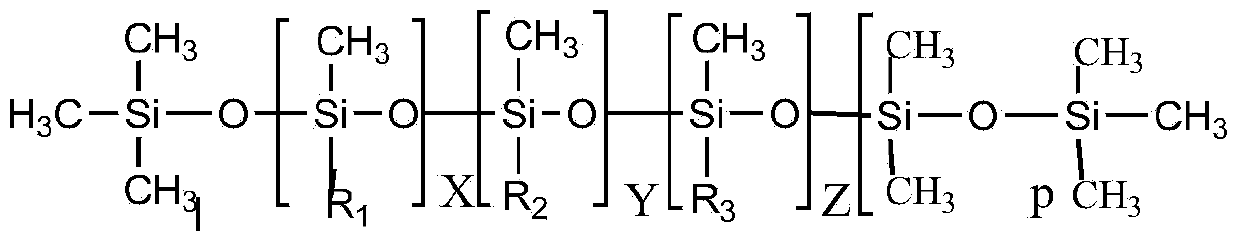

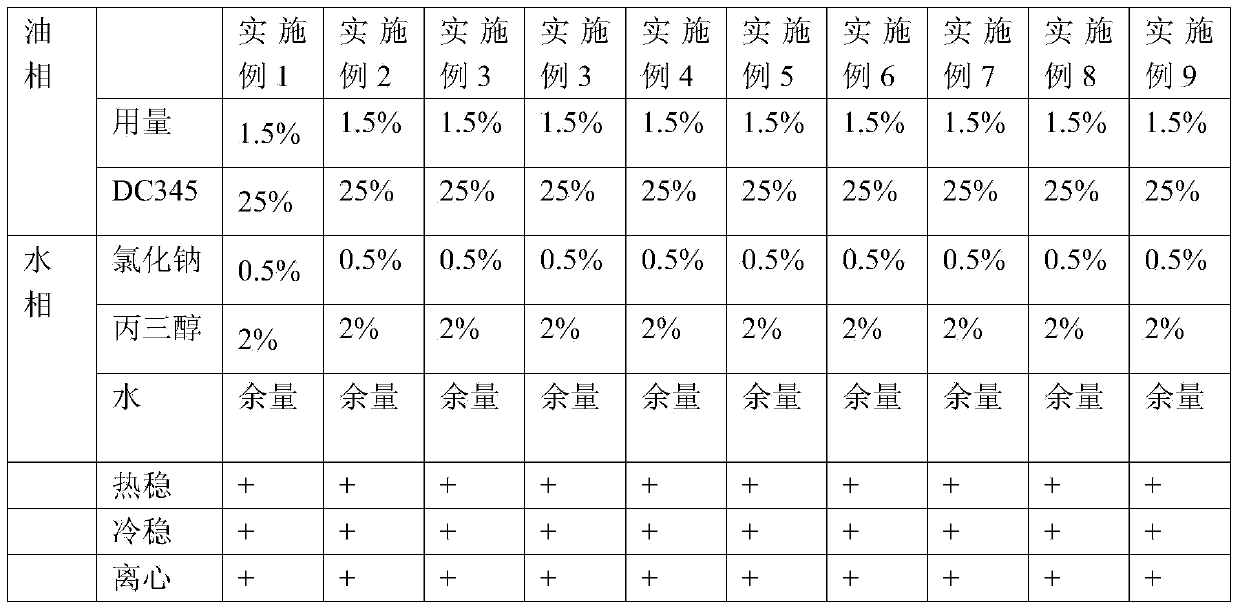

ActiveCN104177620AConsistent reactivityAvoid cross-linking reactionsTransportation and packagingMixingAlkaneAlpha-olefin

The invention discloses a polyfunctional-group-modified polysiloxane emulsifier which is prepared by carrying out silicon hydrogenation reaction on low-hydrogen-content silicon oil, terminated polyether or polyether, methoxypolyethylene glycol acrylate or methoxypolyethylene glycol methacrylate, and long-chain alpha-olefin used as raw materials. The structure of the polyfunctional-group-modified polysiloxane emulsifier is disclosed in the specification, wherein R1 is a polyether chain segment, R2 is an alkane chain segment, and R3 is a methoxypolyethylene glycol acrylate or methoxypolyethylene glycol methacrylate chain segment. By adopting proper reaction monomers, the reaction activities of the monomers are approximate to the same to avoid the crosslinking reaction among the monomers, and thus, the method has the advantages of more thorough reaction, fewer monomer residues, fewer side reactions, favorable production reproducibility and more stable product quality. By optimizing the screening, proper functional groups are adopted to modify the polysiloxane, so that the adaptability of the product is enhanced. When being used as a W / O emulsifier, the polyfunctional-group-modified polysiloxane emulsifier can obtain soft and smooth skin sensation and have high emulsifying stability.

Owner:ZHANGJIAGANG GREAT CHEM

Cationization silk fibroin and preparation method thereof

ActiveCN104119451AGuaranteed biodegradabilityImprove targetingPeptide preparation methodsOther foreign material introduction processesGene deliveryCarboxylic acid

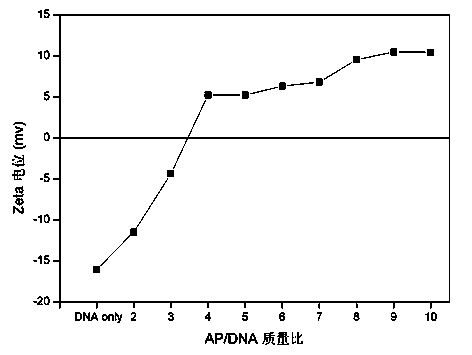

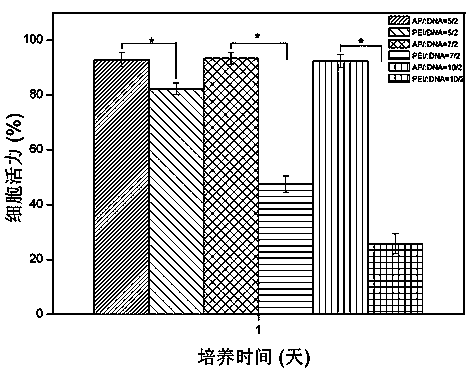

The invention discloses a cationization silk fibroin and a preparation method thereof, and belongs to the technical field of medical high-molecular materials. The cationization silk fibroin is obtained through reaction by coupling protamine sulfate mediated by water-soluble 2-imido thiacyclopentane hydrochloride with silk fibroin activated by sulfo-succinimido-4-[N-maleimide methyl]-cyclohexane-1-carboxylate. The cationization silk fibroin disclosed by the invention has the advantages of good biocompatibility and degradability, controllability in surface charge density, effective DNA (Deoxyribonucleic Acid) compression and protection capacity, higher transfection efficiency and uniqueness in cell targeting and cell nucleus positioning function. The cationization silk fibroin disclosed by the invention can form a cationization silk / gene compound with a gene substance through electrostatic action, and the cationization silk / gene compound is a novel biodegradable cationization silk gene transfer vector with cell targeting and a cell nucleus positioning function.

Owner:SUZHOU UNIV

Preparation and curing method of sodium alginate-lignin composite gel beads

PendingCN110947368AHigh lignin solubilityHigh lignin contentOther chemical processesAlkali metal oxides/hydroxidesMicrospherePlasticizer

The invention relates to a preparation and curing method of sodium alginate-lignin composite gel beads. The method comprises the following steps of mixing a sodium alginate solution with an organic solution of lignin, and dropwisely adding the mixed solution into a calcium chloride or zinc chloride solution by using an injector to obtain the composite gel beads; and carrying out coating and curingtreatment on the composite gel beads by using the sodium alginate solution and the calcium chloride solution. According to the method, ethylene glycol and glycerin which are low in toxicity and smallin pollution are used as solvents to dissolve the lignin, the lignin can be fully dissolved and can also be used as a plasticizer when sodium alginate-lignin is gelatinized, and other toxic and harmful cross-linking agents are prevented from being used. The prepared composite gel beads have high lignin content, high strength, regular shape and uniform particle size, and a certain microsphere formcan be still maintained after further curing treatment. The method is mild in reaction condition, simple, easy to operate and low in manufacturing cost, and a simple and effective storage way is provided for further comprehensive application of the lignin composite gel beads.

Owner:QILU UNIV OF TECH

Styrene modified dicyclopentadiene petroleum resin and preparing method thereof

The invention discloses styrene modified dicyclopentadiene petroleum resin and a preparing method thereof and belongs to the technical field of petrochemical industry. The styrene modified dicyclopentadiene petroleum resin has a softening point 90 DEG C to 130 DEG C, Gardner color scale 4 to 5, weight-average molecular weight 400 to 1000, and molecular weight distribution index 1.5 to 2.5. The preparing method includes the steps of mixing of reaction materials, thermal polymerization reaction of the reaction materials, and purification of the reaction materials. The high-purity cyclopentadiene monomer and the styrene monomer are mixed; by adjusting the ratio of the components and strictly controlling various process parameters of thermal polymerization reaction, cross-linking in the thermal polarization process can be prevented, and the performances, such as solubility, color scale and compatibility with elastomers, of the styrene modified dicyclopentadiene petroleum resin are evidently improved.

Owner:安徽同心新材料科技有限公司

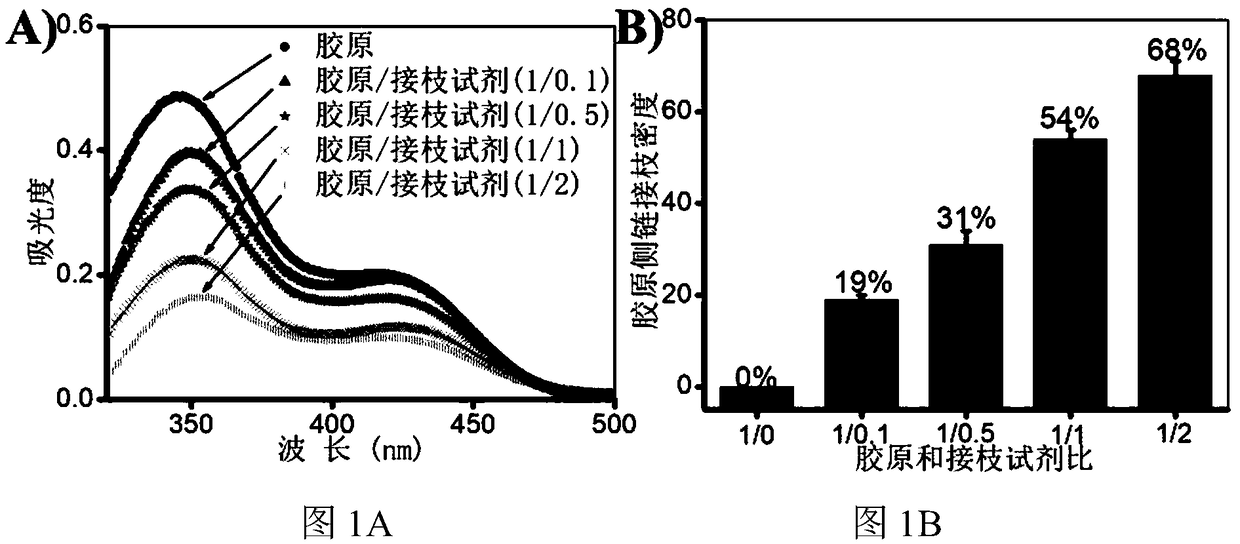

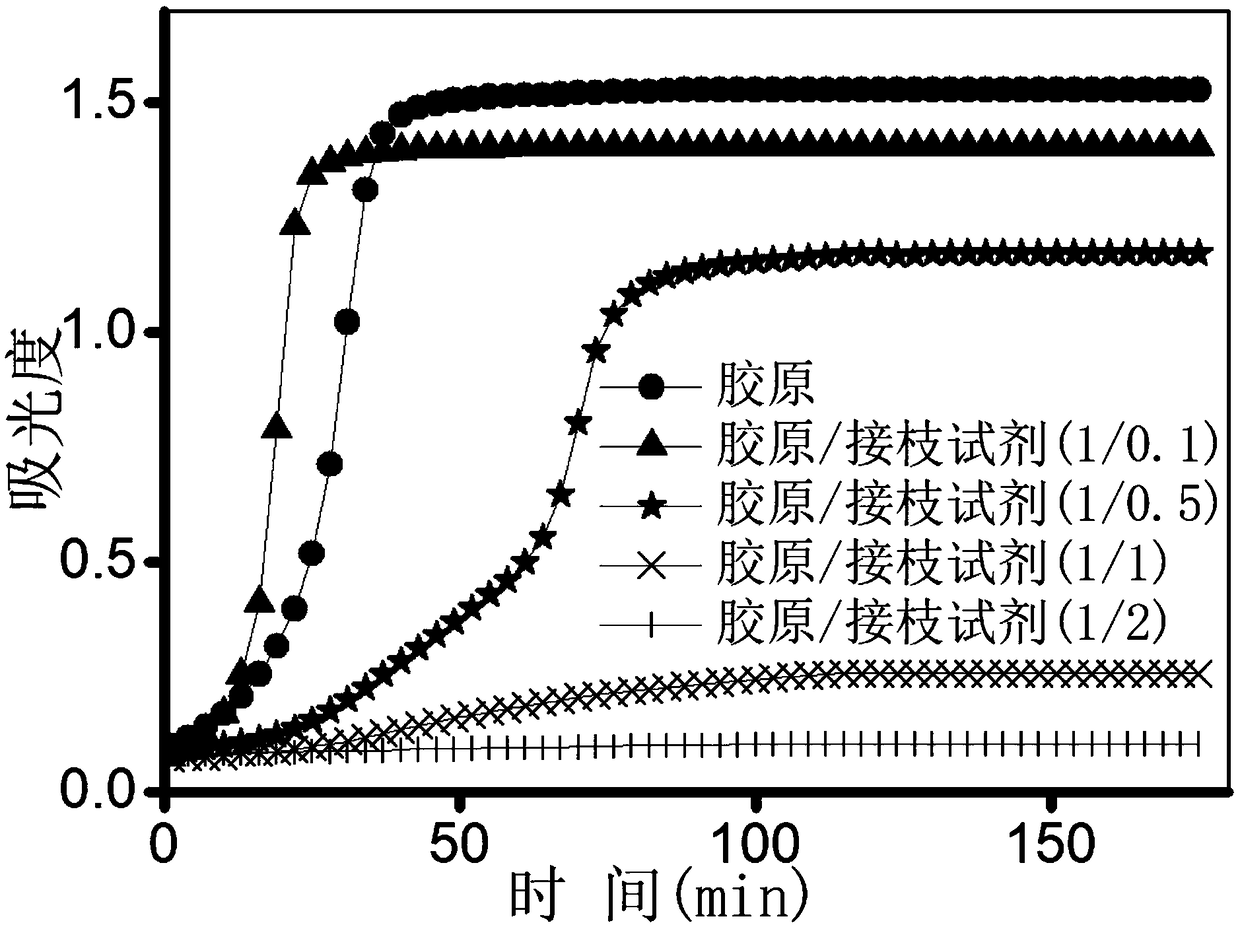

Acrylic acid grafting natural collagen with fibrillation performance and preparation method thereof

The invention discloses acrylic acid grafting natural collagen with fibrillation performance and a preparation method thereof. The preparation method comprises the following steps of (1) dissolving natural collagen by acid solvents to obtain a natural collagen solution; (2) performing primary dialysis on the natural collagen solution obtained in the step (1) by using a phosphate buffer solution; removing acetic acid molecules; (3) dripping the phosphate buffer solution with dissolved N-hydroxysuccinimide acrylate or acrylic anhydride into the solution obtained in the step (2); performing uniform mixing for reaction; (4) performing secondary dialysis on the solution obtained after the reaction in the step (3); performing freeze drying to obtain the acrylic acid grafting natural collagen with fibrillation performance. Through simple and mild reaction conditions, the covalent bond grafting on the natural collagen can be realized; the grafting rate of the grafting natural collagen is regulated and controlled; the grafting modified natural collagen with fibrillation capability is obtained.

Owner:WUHAN POLYTECHNIC UNIVERSITY

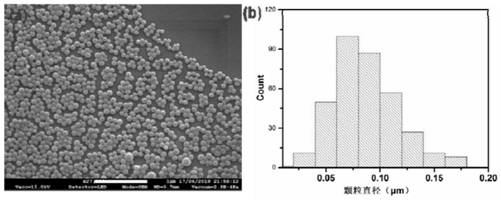

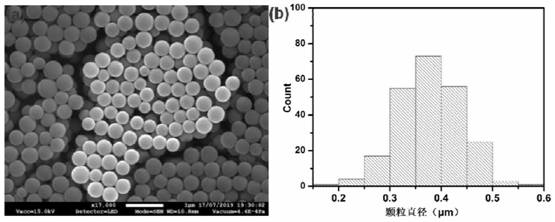

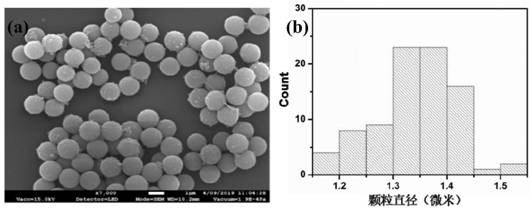

Preparation method and application of monodisperse hydrothermal carbon spheres

PendingCN113336215AAvoid cross-linking reactionsGood reproducibilityIon-exchange process apparatusSilicaAqueous solutionPolysaccharide

The invention discloses a preparation method of nano-to-micron monodisperse hydrothermal carbon spheres. The preparation method comprises the following steps: preparing an aqueous solution of monosaccharide or polysaccharide; adding a weakly polar or non-polar micromolecular solvent into the aqueous solution as a regulating agent to obtain a mixed solution; and performing hydrothermal reaction on the mixed solution to obtain the hydrothermal carbon spheres. The simple small-molecule solvent is used as a regulating agent to inhibit the growth rate of crystal nucleus and control the formation process of the interface of the hydrothermal carbon sphere, so that the cross-linking reaction of a single hydrothermal carbon sphere is effectively avoided, and then the monodisperse carbon sphere with controllable nano-to-micron size is induced and synthesized; and the method has the advantages of being excellent in controllability and reproducibility, quite low in price, easy to obtain, environmentally friendly, capable of achieving large-scale production and the like.

Owner:赵昆

Hydrolysis resistant plastification polylactic acid composition and thin film thereof

InactiveCN101759970AAvoid cross-linking reactionsAvoid excessive melt viscosityPlasticizerPolylactic acid

This invention belongs to the field of high-molecular material, disclosing a hydrolysis resistant plastification polylactic acid composition and a thin film thereof, and consisting of 50-89 parts of polylactic acid resin by weight, 10-49 parts of plasticizer by weight and 0.5-5 parts of anti-hydrolysis stabilizing agent by weight; and after being pre-mixed, the composition is formed and processed to be a thin film. The thin film obtained in the invention has good hydrolysis resistance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

A kind of styrene-butadiene-styrene modified dicyclopentadiene petroleum resin and preparation method thereof

The invention discloses styrene-butadiene-styrene modified dicyclopentadiene petroleum resin and a preparation method thereof; the styrene-butadiene-styrene modified dicyclopentadiene petroleum resin comprises styrene, butadiene, cyclopentadiene monomer, an inert solvent, an initiator, a terminator, an anti-aging agent, an antioxidant, and a modifier. The preparation method comprises: first, preparing styrene-butadiene-styrene oligomer, weighing cyclopentadiene monomer and an inert solvent, adding them into a reactor, and polymerizing for 4-6 h; second, adding the styrene-butadiene-styrene oligomer, an antioxidant and a modifier, stirring and mixing well, and reacting continuously for 3-5 h; third, purifying the reaction product to obtain the modified dicyclopentadiene petroleum resin. The modified dicyclopentadiene petroleum resin has good adhesiveness and good stability, the compatibility of the petroleum resin with an elastomer material is improved greatly, the applicable range of the modified petroleum resin is widened greatly, and the petroleum resin is well worthy of application.

Owner:安徽同心新材料科技有限公司

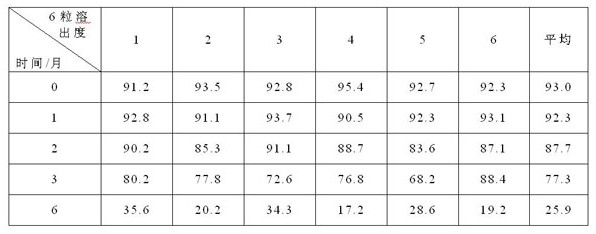

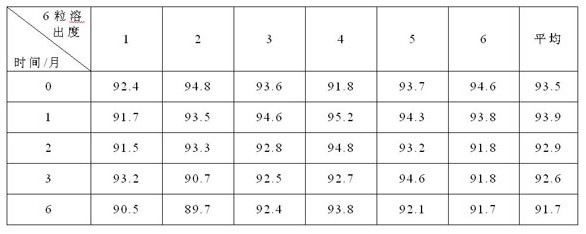

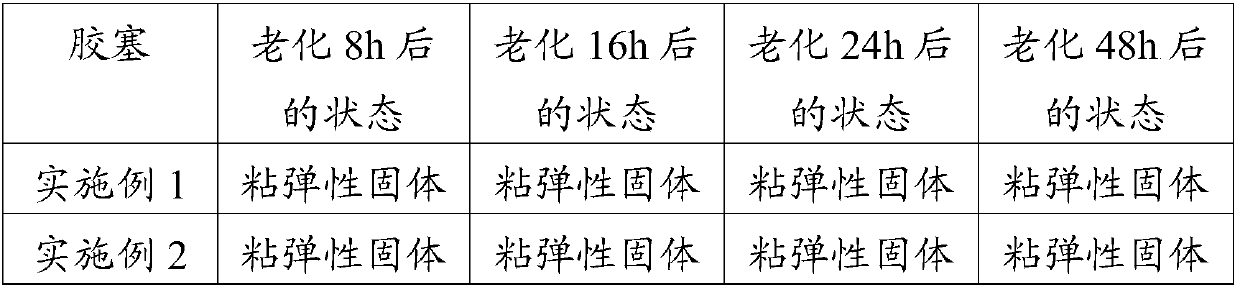

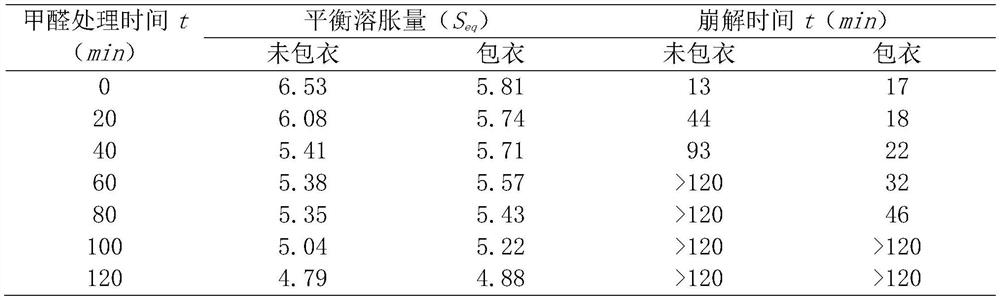

Gelatin hollow capsule with anti-crosslinking effect and preparation method thereof

ActiveCN111840247AInhibition of reaction progressAvoid reactionOrganic active ingredientsInorganic non-active ingredientsPolymer sciencePlasticizer

The invention provides a gelatin hollow capsule with an anti-crosslinking effect and a preparation method thereof. The gelatin hollow capsule comprises the following components in parts by weight: 1000 parts of gelatin, 2-10 parts of a plasticizer, 2-15 parts of an antioxidant, 2-10 parts of a pH regulator, 0-30 parts of a coloring agent and 2800-4000 parts of purified water, wherein the concentration of a gelatin solution is 25%-35%. The invention further provides a preparation method of the gelatin hollow capsule with the anti-crosslinking effect. The gelatin hollow capsule prepared by the method has an obvious anti-crosslinking effect; by adjusting the raw material indexes and the auxiliary material composition of the gelatin hollow capsule, the capsule prone to cross-linking reaction can be prevented from generating cross-linking reaction to influence the dissolution rate of the preparation in the accelerated stability experiment process, and meanwhile, the risk that the bioequivalence experiment of the capsule prone to cross-linking is not equivalent can be reduced.

Owner:青岛益青生物科技股份有限公司

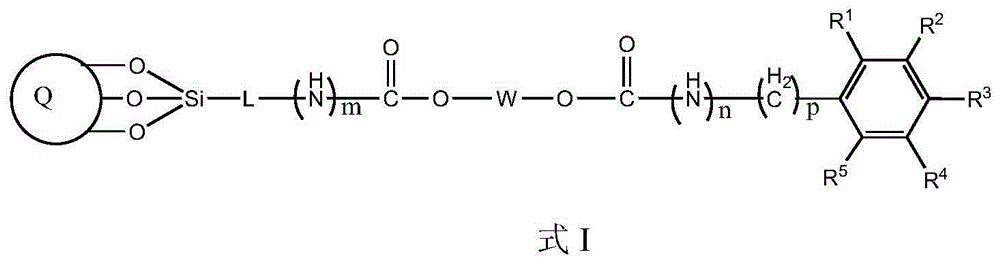

Bonding polysaccharide chiral stationary phase and preparation method thereof

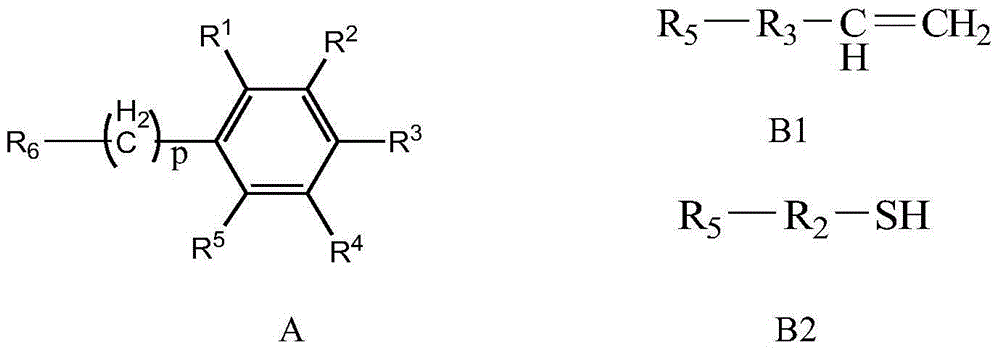

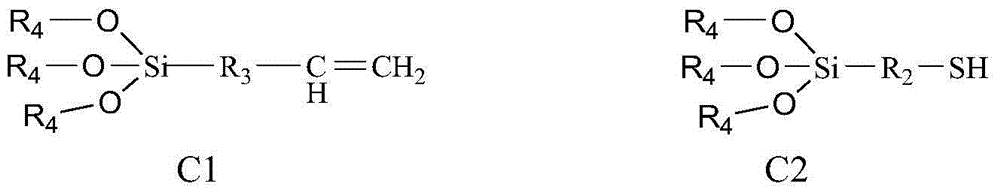

The invention discloses a bonding polysaccharide stationary phase. The bonding polysaccharide stationary phase comprises the following structural general formula (as shown in the description), wherein Q represents a stationary phase substrate; L is -R<2>SCH<2>CH<2>R<3>- or -R<3>CH<2>CH<2>SR<2>-; R<2> and R<3> are separately and independently selected from substituted or unsubstituted alkylidene groups and arylene; m and n are separately and independently selected from 0 and 1; p is an integer between 0 and 8; R<1> and R<5> are separately and independently selected from halogen, alkyl groups and alkoxy groups; and W represents polysaccharide. The bonding polysaccharide stationary phase disclosed by the invention is in chemical bond connection, so that a crosslinking reaction between polysaccharide molecules is avoided, the helical structure of the polysaccharide molecules is furthest reserved, exerting excellent chiral resolution capacity is facilitated, and besides, the solvent resistance is improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Temporary plugging agent for well killing and preparation method thereof

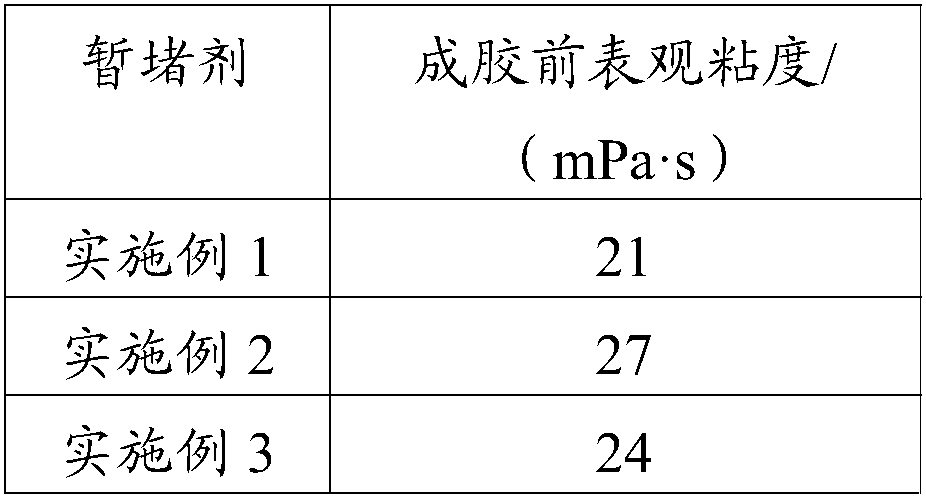

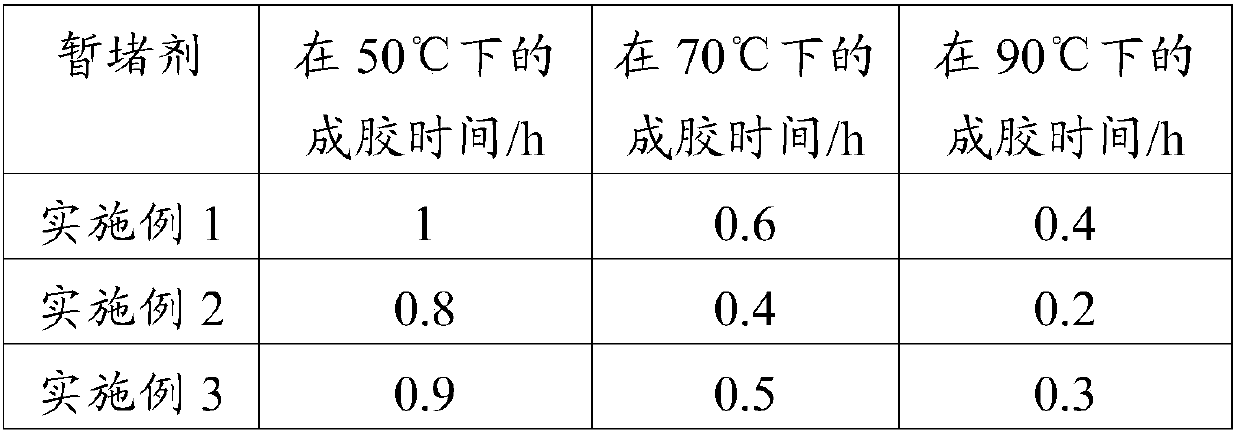

The invention discloses a temporary plugging agent for well killing and a preparation method thereof, and belongs to the field of oilfield chemistry. The temporary plugging agent for well killing is obtained by crosslinking the following components in percentage by mass: 1.0%-5.0% of a crosslinking monomer, 1.0%-5.0% of oil, 0.5%-2.0% of a dispersing agent, 2.0%-5.0% of a crosslinking agent, 2.0%-10.0% of polyol, and 0.05%-1.0% of a gel breaker, with the balance being water, and the crosslinking monomer being plant gum. The temporary plugging agent is low in viscosity before gelling, easy to pump and inject, high in viscosity after gelling, wide in applicable temperature range, capable of resisting high temperature of 120 DEG C, capable of quick gel breaking after being in contact with acidic substances, short in plug removal time and small in damage to a reservoir after plant gum breaking.

Owner:PETROCHINA CO LTD

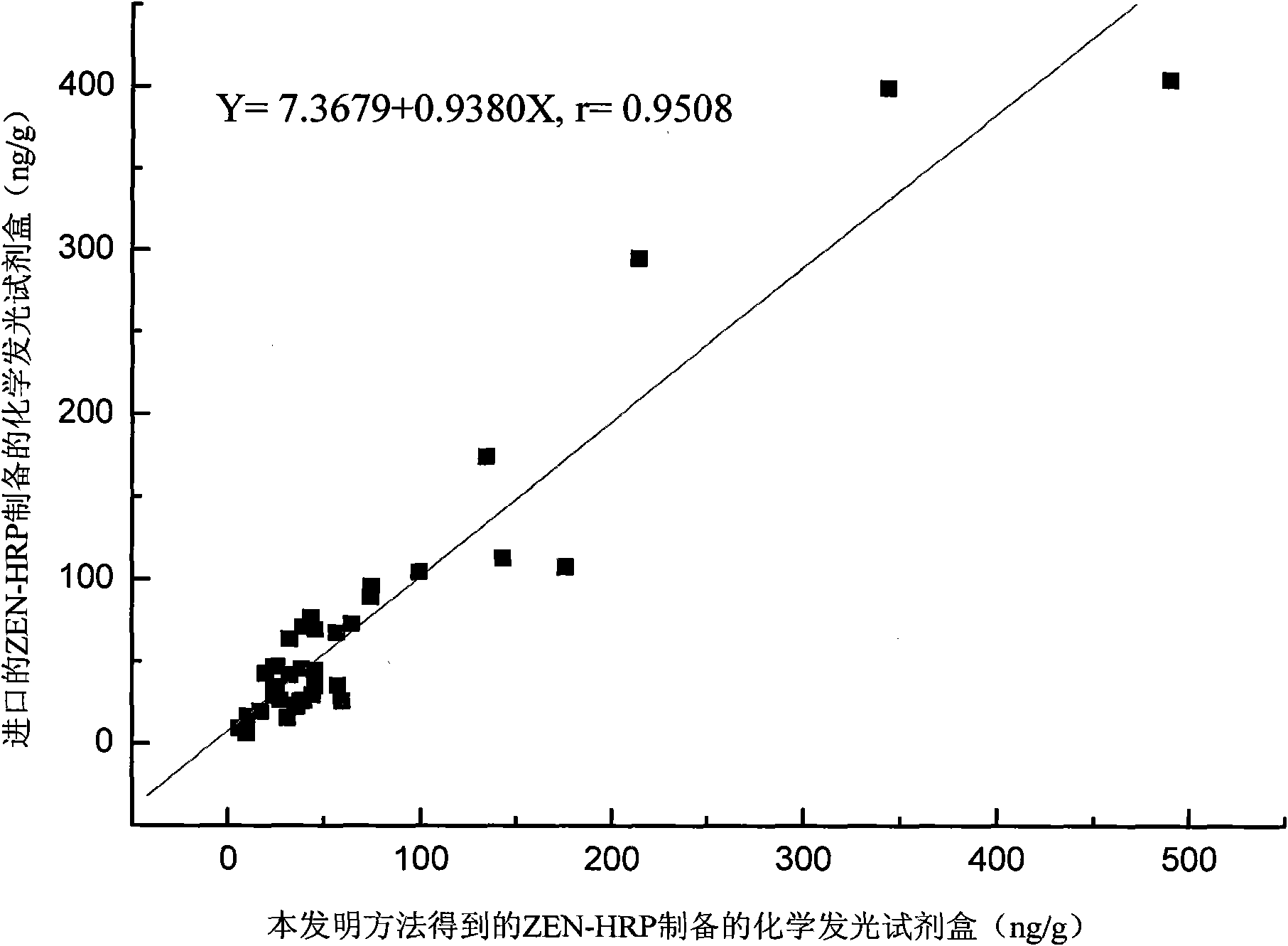

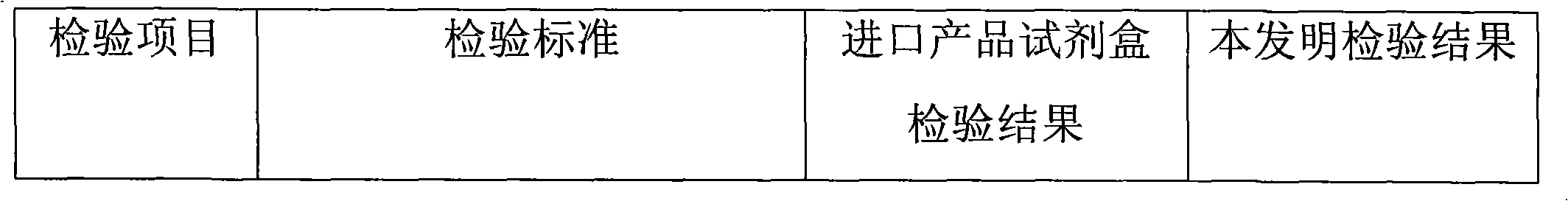

Synthesis process of horseradish peroxidase enzymelabeled zearalenone

ActiveCN102051389AImprove chemical structureImprove effectivenessFermentationPeroxidaseHorseradish peroxidase

The invention discloses a synthesis process of horseradish peroxidase enzymelabeled zearalenone. In the synthesis process, a carboxylated product is obtained by carboxylating zearalenone, and the horseradish peroxidase enzymelabeled zearalenone is obtained by a condensation reaction of the carboxylated product and horseradish peroxidase enzyme. The preparation process of detecting the key component horseradish peroxidase enzymelabeled product in the CLIA (Chemiluminescence Immunoassay) field is a formidable difficult all along. Accordingly, the synthesis process of the horseradish peroxidase enzymelabeled zearalenone, which is provided by the invention, is simple and practical and has low cost and favorable market application prospects.

Owner:CHEMCLIN DIAGNOSTICS CO LTD

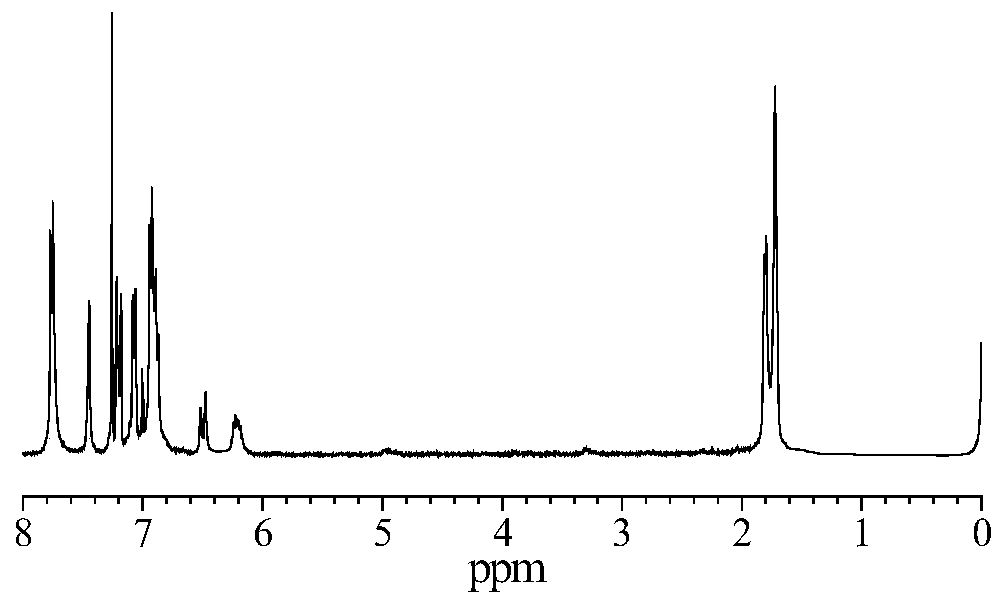

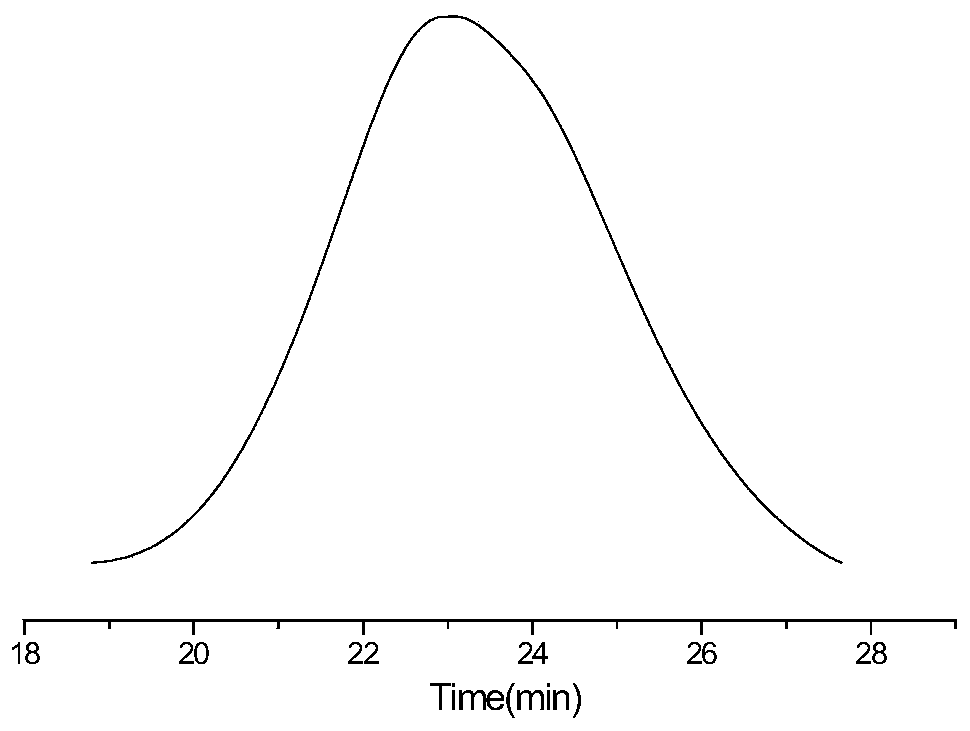

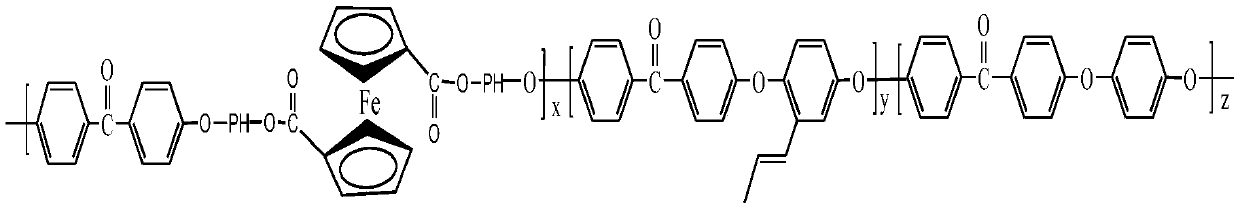

Preparation method of poly(ether-ether-ketone) resin containing ferrocene/DOPO group and crosslinked alkenyl

InactiveCN109851729AAvoid cross-linking reactionsHigh glass transition temperaturePoly ether ether ketoneOrganic solvent

The invention relates to a preparation method of a poly(ether-ether-ketone) resin containing a ferrocene / DOPO group and crosslinked alkenyl. The preparation method comprises following steps: adding acompound liquid containing ferrocene, difluorobenzophenone (DFBP), and a catalyst (I) into an organic solvent (I) according to a certain mole ratio, carrying out secondary reactions under the action of N2 flow; then adding a mixed solution of allyl containing bisphenol and DFBP, raising the temperature to carry out reactions, pouring the reaction liquid into water, carrying out precipitation, filtering, and drying to obtain the poly(ether-ether-ketone) resin. A bisphenol unit containing ferrocene and a DOPO group into the poly(ether-ether-ketone) resin to overcome the problems that the productof industrial NaOH salt forming reactions can be degraded easily, the reactions are difficult to control, and alkali pollution happens. An allyl bisphenol monomer is introduced into the resin to avoid crosslinking reactions of double bonds after long time high temperature reactions. A new approach and a new method are provided for obtaining a flame retardant resin system having a strong flame retardant performance and excellent properties.

Owner:FUJIAN NORMAL UNIV

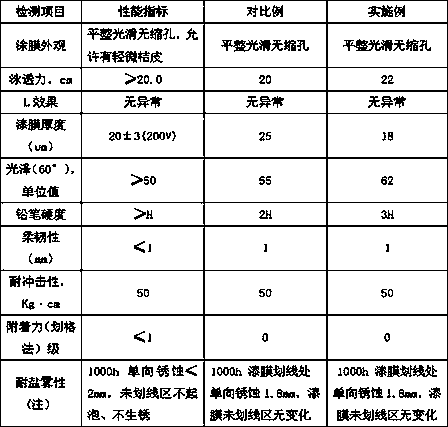

High-performance anti-corrosion coating for metal surface treatment

InactiveCN110643210AImprove water resistanceGood dispersionAntifouling/underwater paintsPaints with biocidesEpoxyPolyethylene glycol

The invention provides a high-performance anti-corrosion coating for metal surface treatment. The high-performance anti-corrosion coating for metal surface treatment is prepared from the following components in parts by mass: 30-45 parts of silica sol, 12-16 parts of epoxy resin, 8-15 parts of polyimide resin, 2-4 parts of ketimine, 2-5 parts of fluorite powder, 1-3 parts of aminosilane, 2-4 partsof polyethylene glycol, 3-6 parts of hydroxyalkylphenol polyoxyethylene ether, 3-8 parts of 8-hydroxyquinoline copper, 4-10 parts of an antirust agent and 5-10 parts of a corrosion inhibitor. The high-performance anti-corrosion coating has the advantages of excellent corrosion resistance, excellent rust resistance, acid and alkali resistance, smooth coating, uniform paint dispersion, high adhesive force and high drying speed, and is suitable for popularization.

Owner:南京思达捷信息科技有限公司

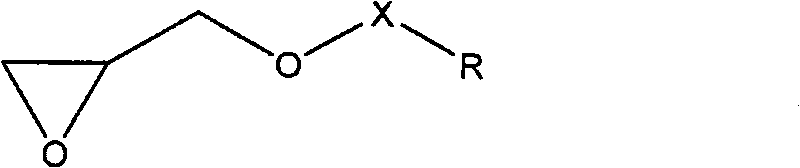

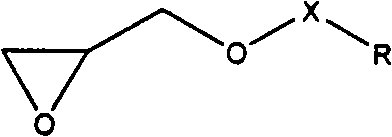

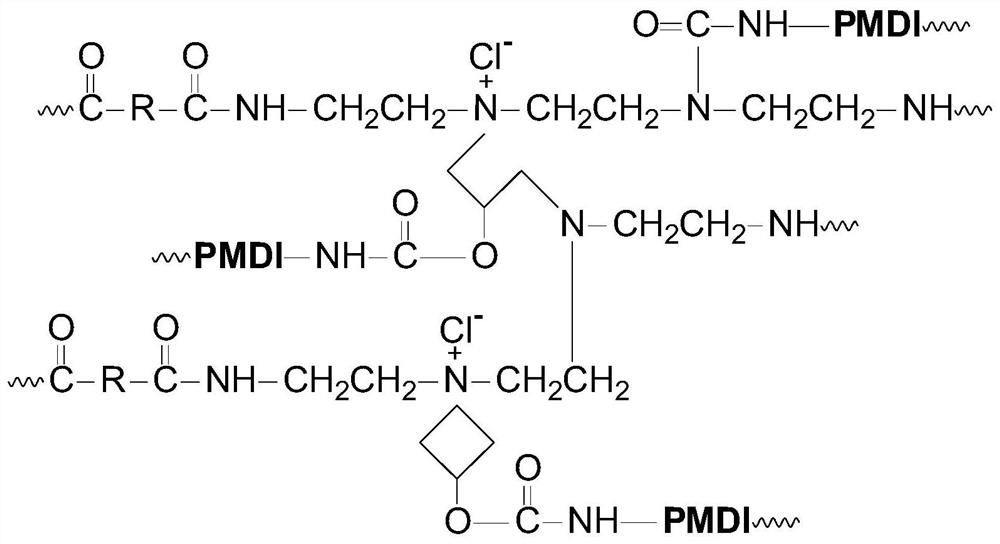

Waterproof polyamide-based adhesive and preparation method thereof

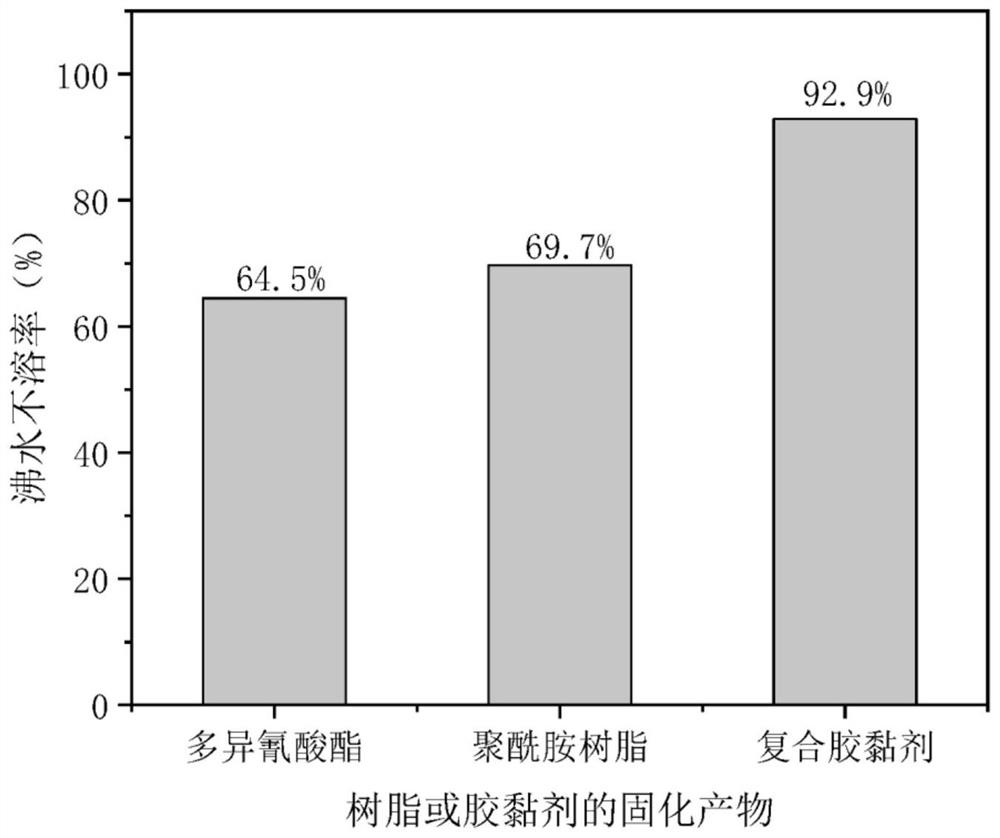

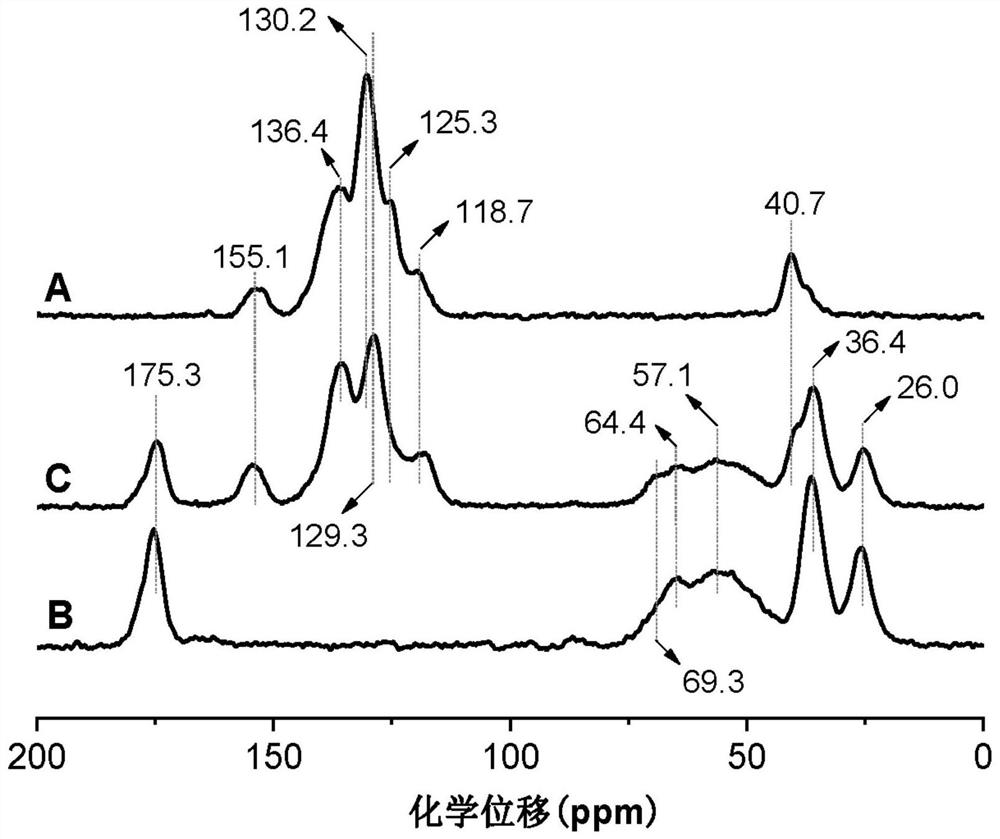

ActiveCN112322243AReduce the degree of polymerizationGood emulsificationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a waterproof polyamide-based adhesive and a preparation method thereof, and relates to an adhesive and a preparation method thereof. The invention aims to solve the technical problems of high cost and non-ideal water resistance of the formaldehyde-free adhesive for an artificial board. A method for preparing a dispersing agent comprises the following steps: stirring and heating adipic acid or an adipic acid / organic binary anhydride mixture and a polyamine compound, adding water, adding epoxy chloropropane, heating, and reacting to obtain the dispersing agent. The adhesive is prepared by uniformly stirring a polyamide-based aqueous cross-linking dispersant, water, polymethylene polyphenyl polyisocyanate (PMDI) and an inorganic filler at room temperature in parts by weight. According to the polyamide-based water-based polymer composite adhesive, the PMDI dosage can be reduced by 33%, the adhesive cost is reduced, the working life is long, and formaldehyde and an organic solvent are not used in the preparation process. The product can effectively solve the problem of high cost of the existing formaldehyde-free soybean adhesive for artificial boards, and has theadvantages of excellent boiling water resistance and environment friendliness. The invention belongs to the technical field of adhesives.

Owner:NORTHEAST FORESTRY UNIVERSITY

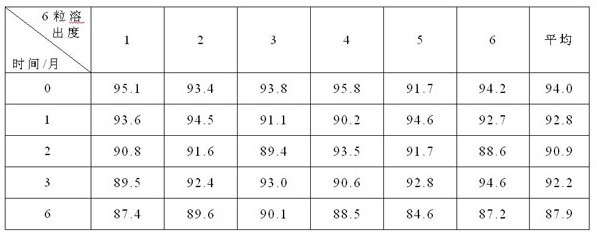

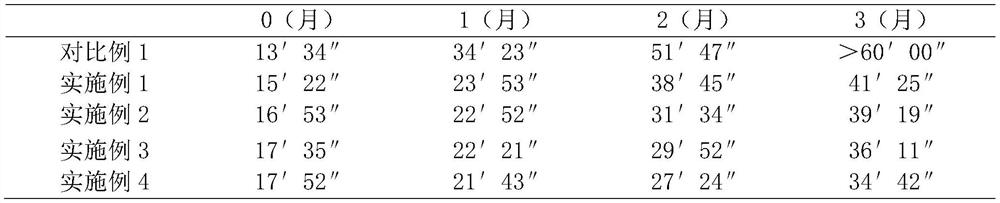

Soft capsule shell and preparation method thereof

ActiveCN111643476AImprove stabilityImprove bioavailabilityCapsule deliveryMacromolecular non-active ingredientsCelluloseSoftgel

The invention relates to the technical field of soft capsules, in particular to a soft capsule shell and a preparation method thereof. A layer of film coat is arranged between a gelatin capsule shelland contents of a soft capsule, and the film coat consists of hydroxypropyl methyl cellulose HPMC, glycerin and water. According to the soft capsule provided by the invention, the film coat is coatedin the soft capsule, so that the capsule shell is avoided from being in direct contact with the contents, low molecule aldehydes in the soft capsule can be prevented from generating a crosslinking reaction with the gelatin capsule shell, an aging phenomenon of the capsule shell is relieved, and the stability of the soft capsule is increased. The soft capsule shell can effectively reduce the generation probability that the low molecule aldehydes have the crosslinking reaction with the gelatin capsule shell, the disintegration time increase of the obtained coated soft capsule is slow, and the biological availability of the soft capsule is effectively increased.

Owner:SHINEWAY PHARMA GRP LTD

Asphalt mixture modifier particles and preparation method thereof

ActiveCN106221108AImprove low temperature performanceImprove aging resistanceCross-linkPolymer science

The invention discloses asphalt mixture modifier particles and a preparation method thereof. The preparation method includes the steps that a raw material SBS and a scorch retarder are mixed to be uniform at normal temperature, and a first mixture is prepared; then heating melting treatment is carried out; a cross-linking agent and an accelerant are added at the later stage of heating melting treatment, and a second mixture is prepared; then extrusion treatment is carried out to obtain strip-shaped materials; the strip-shaped materials are chopped, and the asphalt mixture modifier particles are obtained. The asphalt mixture modifier particles are prepared from, by weight, 90-97 parts of SBS, 0.3-3 parts of scorch retarder, 0.4-5 parts of cross-linking agent and 1-5 parts of accelerant. According to the granulation process, SBS and the cross-linking agent are not cross-linked at the granulation process stage, when SBS and the cross-linking agent are added into an asphalt mixture, under the effect of shear dispersion of high-temperature stone, a cross-linking reaction is generated while swelling dispersion is carried out, a net-shaped structure is formed, asphalt is evenly wrapped by the net-shaped structure, and the high-low-temperature performance, the aging resistance, mechanical performance and the like of an SBS modified asphalt concrete system can be improved.

Owner:BEIJING ZHONGLU PAVING TECH +1

Polymerization inhibitor and glass fiber reinforced plastic profiled bar comprising same

The invention relates to a polymerization inhibitor which comprises the following components in parts by weight: 10 parts of p-tert-butylcatechol, 10 parts of p-benzoquinone and 80 parts of styrene. Meanwhile, the invention further discloses a glass fiber reinforced plastic profiled bar comprising the polymerization inhibitor. The glass fiber reinforced plastic profiled bar comprises 60-70% of glass fibers and 30-40% of a resin formula material, wherein the resin formula material comprises the following components in parts by weight: 100 parts of resin, 10-30 parts of filler, 2-4 parts of a mill base, 0.8-1.5 parts of a release agent, 0.5-1 part of an initiator, 0.5-2 parts of an accelerant, 0.1-0.3 part of an antioxidant and 0.1-0.2 part of the polymerization inhibitor. According to the invention, the gelling time of the resin formula material under a condition of 35-60 DEG C is prolonged, a cross-linking reaction in advance in a resin trough is avoided, and solid particles are prevented from blocking a die port, so that the continuity of production is guaranteed.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

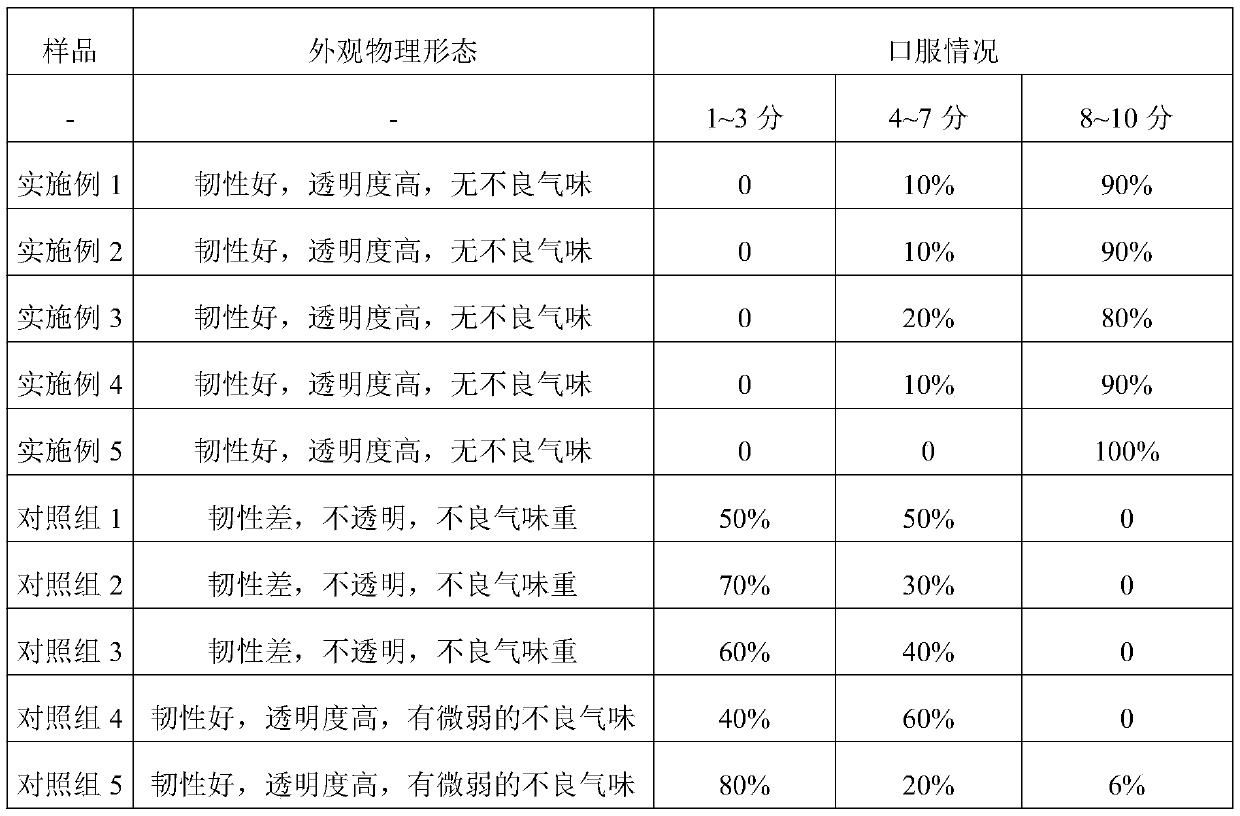

Chewable nutritional supplement plant soft capsule and preparation method thereof

InactiveCN109846849ANutritional diversityProportion scienceHydroxy compound active ingredientsMetabolism disorderBiotechnologyMushroom

The present invention relates to a chewable nutritional supplement plant soft capsule and a preparation method thereof, and solves problems that in the prior art gelatin soft capsules dissolve slowlyin water, and are easy to produce accumulated balls to delay a dissolution speed, obvious in disintegration delay, low in production efficiency, large in safety hazards, easy to be sticky on outside,and poor in chewability. The chewable nutritional supplement plant soft capsule is provided. Filling materials inside a capsule shell comprise the following raw material components in parts by weight:10-20 parts of seaweed powder, 1-10 parts of mushroom powder, 1-2 parts of spinach powder, 1-10 parts of milk mineral salt, 1-2 parts of malt powder, 1-2 parts of milk powder, 2-6 parts of lactitol,0.1-6 parts of siraitia grosvenorii powder, and the remaining 40-82.9 parts of olive oil; the capsule shell comprises raw materials of a gelling agent and a plasticizer; and the gelling agent is hydroxypropyl starch and the plasticizer is any one or more of lactose, microcrystalline cellulose and glucose. At the same time, the preparation method of the chewable nutritional supplement plant soft capsule is also provided. The chewable nutritional supplement plant soft capsule can be widely applied in the field of health-care food.

Owner:WEIHAI BAIHE BIOTECH

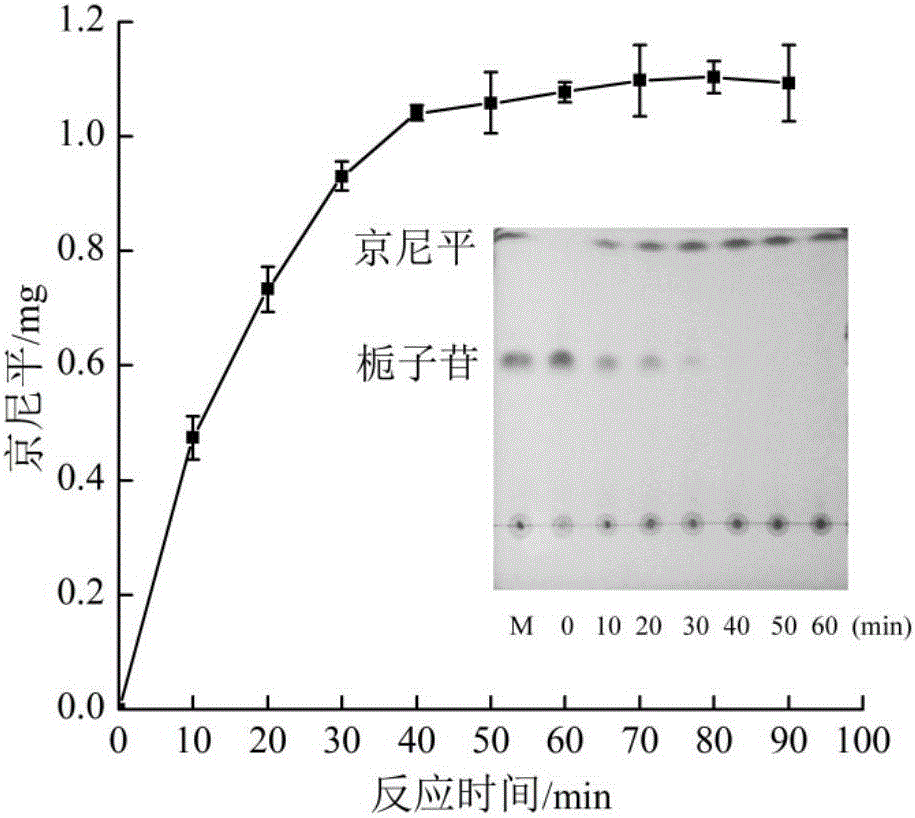

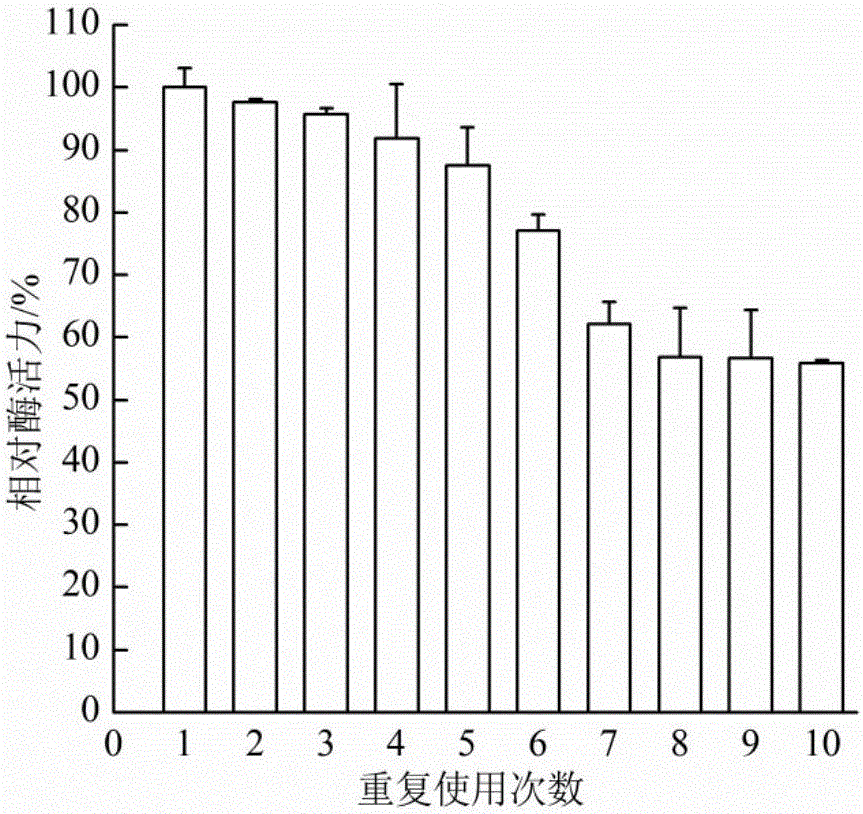

Preparation method of genipin

ActiveCN106701858AImprove efficiencyHigh enzyme loadingFermentationOn/in inorganic carrierAlgluceraseDispersity

The invention discloses a preparation method of genipin. The preparation method comprises the following steps: carrying out glutaraldehyde crosslinking on amination-modified nano SiO2 particles and beta-glucosaccharase to obtain a nano immobilized enzyme, and carrying out high-efficiency hydrolysis on the substrate jasminoidin by using the nano immobilized enzyme to obtain the genipin. The nano immobilized enzyme prepared in the method has favorable dispersity and is recyclable in the reaction system; and the method has the advantages of high genipin yield and purity, and thus, can effectively prepare genipin.

Owner:NANJING UNIV OF SCI & TECH

Building material and preparation method thereof

InactiveCN109180106AGood environmental characteristicsStrong environmental protectionFiberPolyvinyl alcohol

The invention discloses a building material. The building material comprises, by weight, 5-25 parts of triethanolamine, 6-18 parts of silicon oxide, 6-18 parts of heavy calcium carbonate, 2-18 parts of polyvinyl alcohol, 3-13 parts of expanded perlite, 3-15 parts of sodium silicate, 1-17 parts of deionized water, 3-15 parts of Portland cement, 4-18 parts of glass beads, 4-18 parts of fly ash, 4-18parts of polyacrylonitrile fiber, 4-18 parts of modified epoxy resin, 3-13 parts of 2-hydroxy-4-methoxybenzophenone, 6-18 parts of heptyl 4-hydroxybenzoate, 3-17 parts of sulfonated melamine-formaldehyde resin and 3-13 parts of brominated bisphenol A epoxy resin. The building material has the advantages of good fracture resistance, good ultraviolet radiation resistance and long service life.

Owner:孙浩

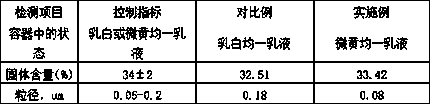

Preparation method of high-throwing-power emulsion

ActiveCN110804364AReduce typesLarge particle sizePaints for electrolytic applicationsEpoxy resin coatingsDiethylenetriamineCross linker

The invention discloses a preparation method of a high-throwing-power emulsion. The preparation method comprises the steps of cross-linking agent preparation, chain extension, amination, neutralization and emulsification, wherein during chain extension, dimethyl benzylamine is added twice, bisphenol-A polyoxyethylene ether, methyl monoethanolamine, diethylenetriamine ketimine, trimethylolpropane and other materials are adopted, and temperature and time parameters in the preparation process are designed and controlled. Through the preparation method, the emulsion with high throwing power can beprepared, the throwing power can reach 22cm, and the storage stability of the emulsion is improved obviously.

Owner:湖南伟邦汽车涂料有限公司

Isoprene modified dicyclopentadiene petroleum resin, and preparation method thereof

The invention discloses an isoprene modified dicyclopentadiene petroleum resin, and a preparation method thereof. The isoprene modified dicyclopentadiene petroleum resin comprises a cyclopentadiene monomer, isoprene, an inert solvent, an antioxidant, an initiator and a terminator. The preparation method comprises the following steps: initiating the polymerization of the isoprene to prepare a 3,4-isoprene / 1,4-isoprene block oligomer, modifying cyclopentadiene polymerized petroleum resin, and purifying the modified petroleum resin to obtain the isoprene modified dicyclopentadiene petroleum resin. The modified petroleum resin has the advantages of good caking property, high softening point, greatly increased compatibility with elastomer material, low chroma, enlargement of the application range of petroleum resin, and good application values. The preparation method is simple and easy, and is suitable for being promoted and applied.

Owner:安徽同心新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com