Preparation method of high-throwing-power emulsion

A technology of throwing power and emulsion, which is applied in the field of preparation of high throwing power emulsion, which can solve complex and difficult problems, reduce the thickness of the paint film on the outer panel, etc., and achieve the effects of reducing types, low solvent content, and reducing VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

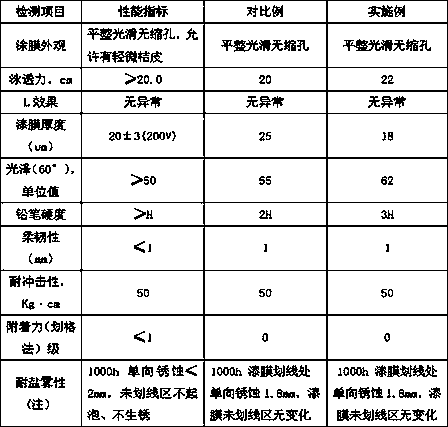

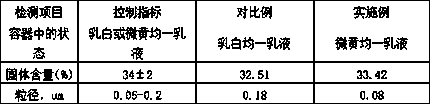

Examples

Embodiment

[0031] 1. Preparation of crosslinking agent:

[0032] S1. Put 7.6% methyl ethyl ketone and 10.8% trimethylol propane into the dropping tank, turn on the stirring, and raise the temperature of the dropping tank to 65°C (not to exceed 75°C), so that the trimethylol propane is dissolved in the methyl ethyl ketone , prepared into a mixed solution and kept warm at 50-75°C for use;

[0033] S2. Add 43.5% toluene diisocyanate, 5% methyl ethyl ketone, and 0.02% dibutyltin dilaurate into the reaction kettle, stir under nitrogen atmosphere, and raise the temperature to 45°C; then slowly add the mixed solution obtained in S1 dropwise at a uniform speed, The temperature of the reaction kettle is controlled at 55-60 ° C, fully stirred, and the temperature is kept for 1 hour after the mixture is added dropwise;

[0034] S3. Continue to add 33.08% ethylene glycol butyl ether dropwise, and control the temperature of the reactor at 65-70°C. After the dropwise addition, keep the temperature at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com