Patents

Literature

39results about How to "No catalyst required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction

InactiveCN101659627AHigh hydroxyl valueHigh primary hydroxyl contentOxygen-containing compound preparationOrganic compound preparationEpoxyVegetable oil

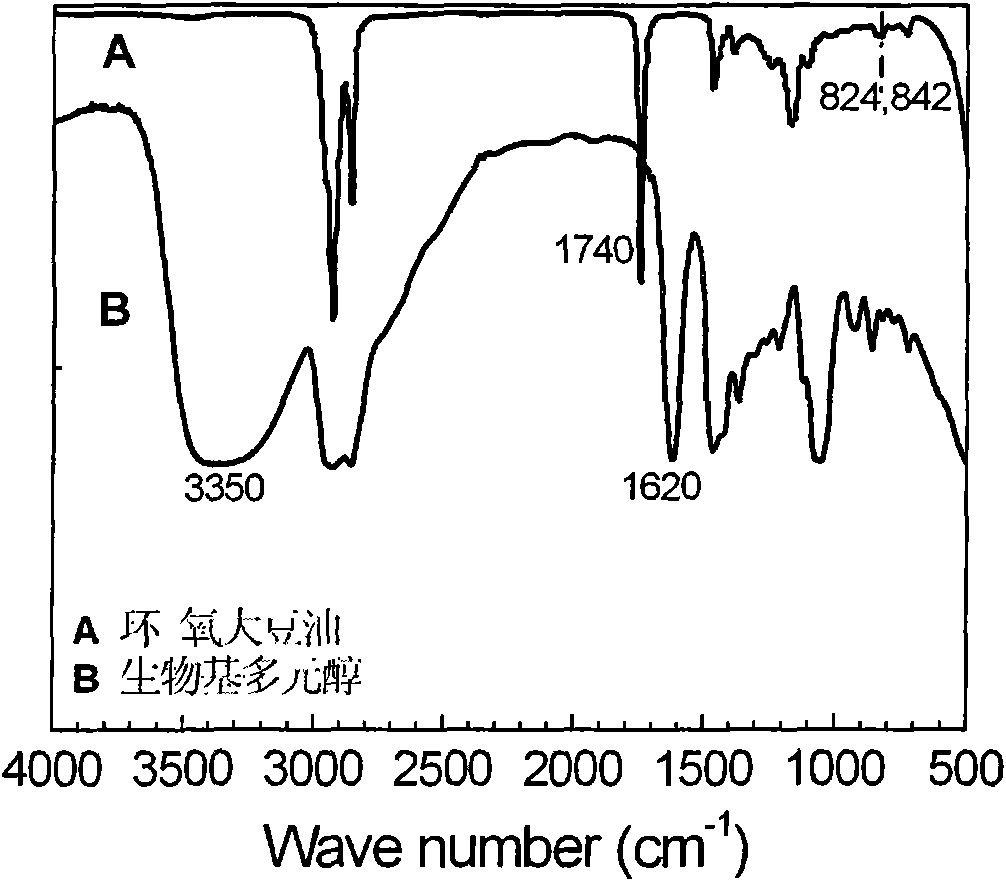

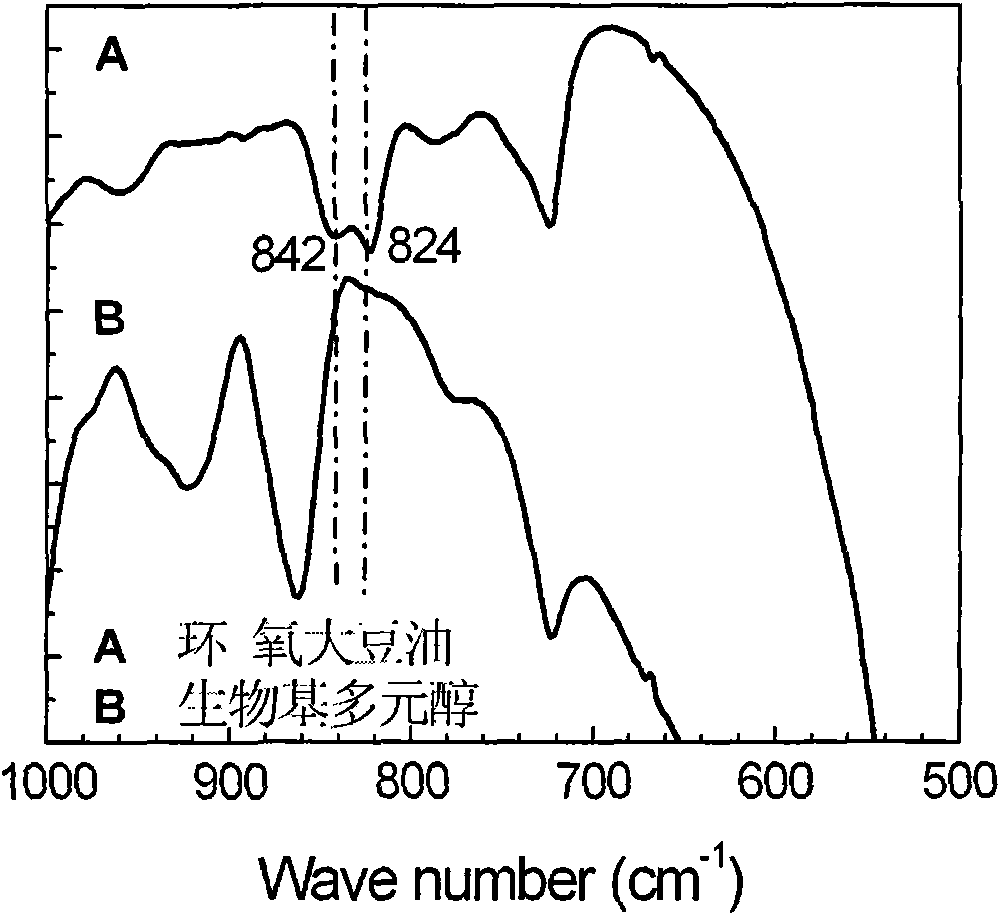

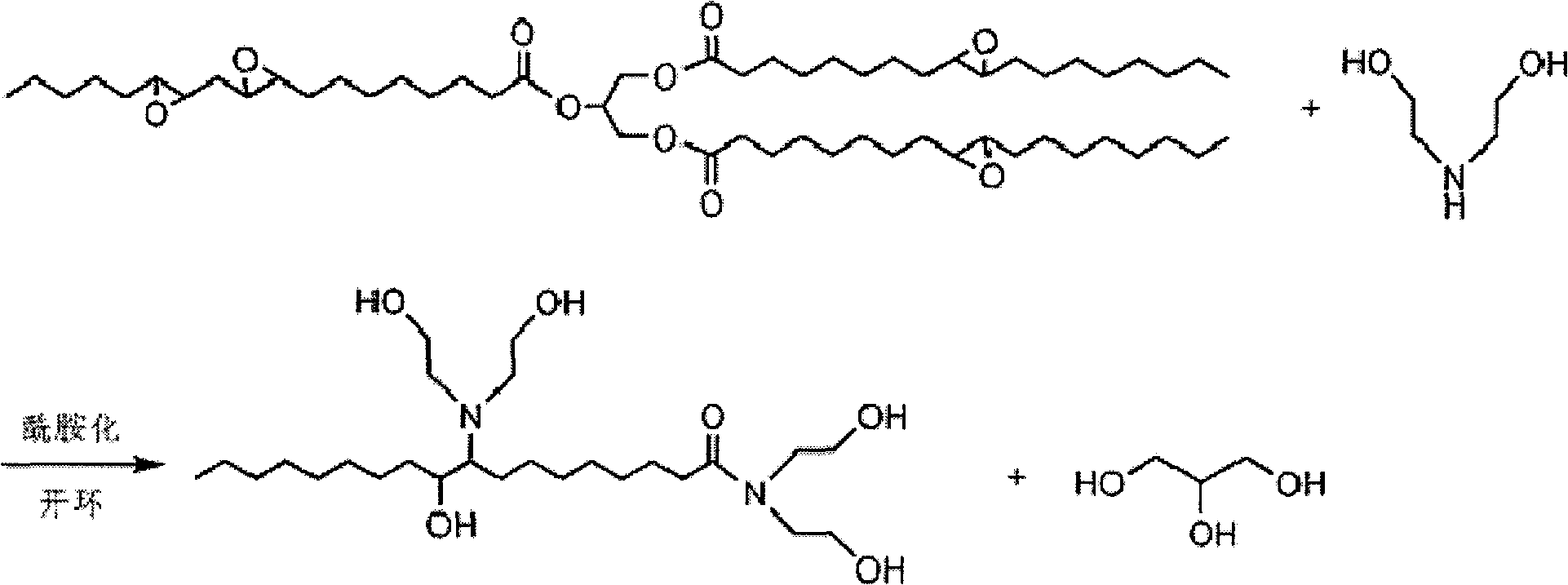

The invention discloses a high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-step reaction, which is obtained by the following one preparing step: accordingto the molar ratio of epoxy group to amino group being 1:1-1:1.1, leading the epoxidized vegetable oil and diolamine to simultaneously generate epoxy group ring opening reaction and ester group amidation reaction at the temperature of 80-140 DEG C for 2-16 hours, thus obtaining bio-base polyol. The high hydroxyl value bio-base polyol prepared by utilizing epoxidized vegetable oil through one-stepreaction is a novel bio-base polyol, and has the characteristics of high hydroxyl valve, high primary hydroxyl group content, short 'swing' chain, low viscosity and the like. The novel method for preparing the bio-base polyol is characterized by completing ring opening and amidation reactions by one step, having short processing procedures, capability of avoiding cross linking reaction, no need of catalyst, and no need of separating steps, being environment friendly, and easy to realize industrialized production, and the like.

Owner:ZHEJIANG UNIV

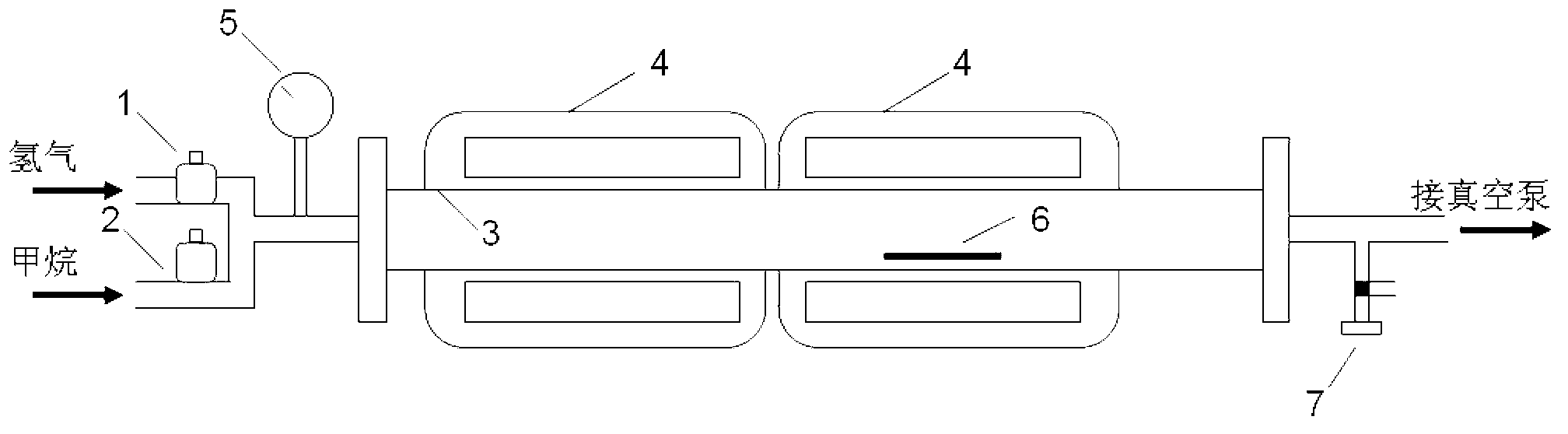

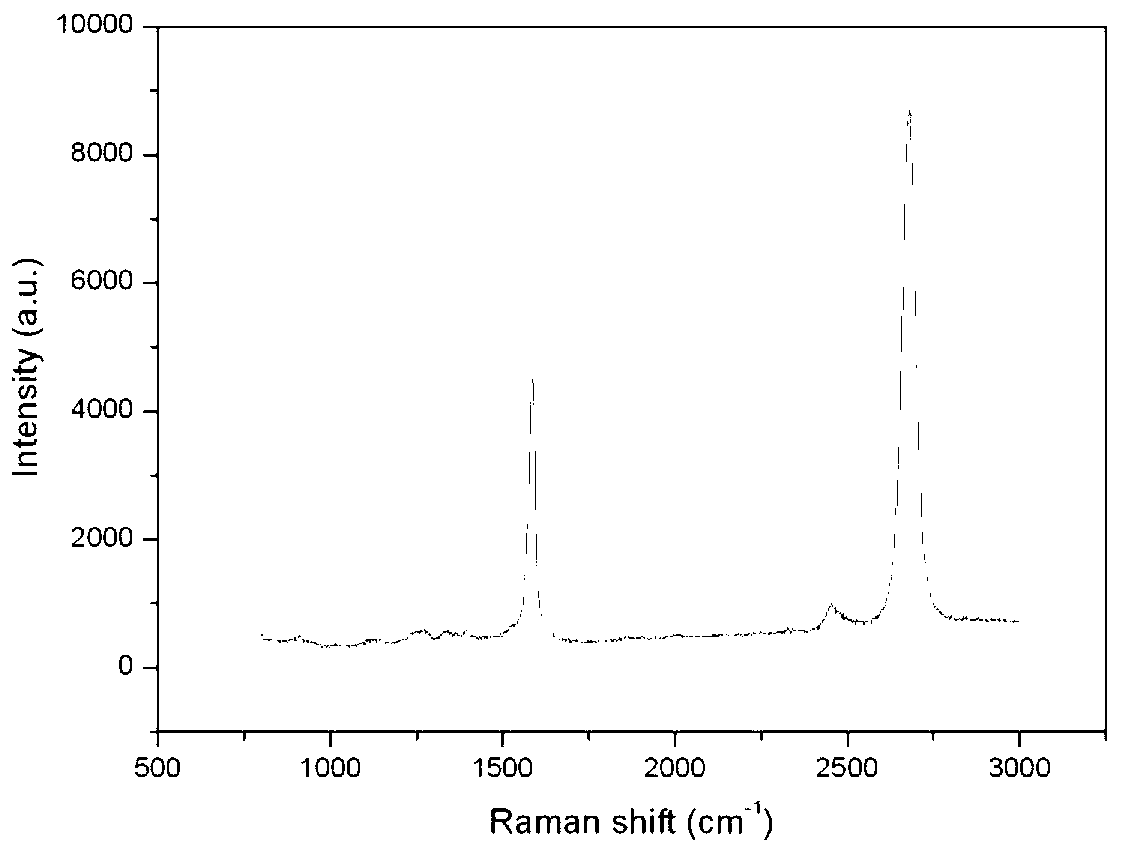

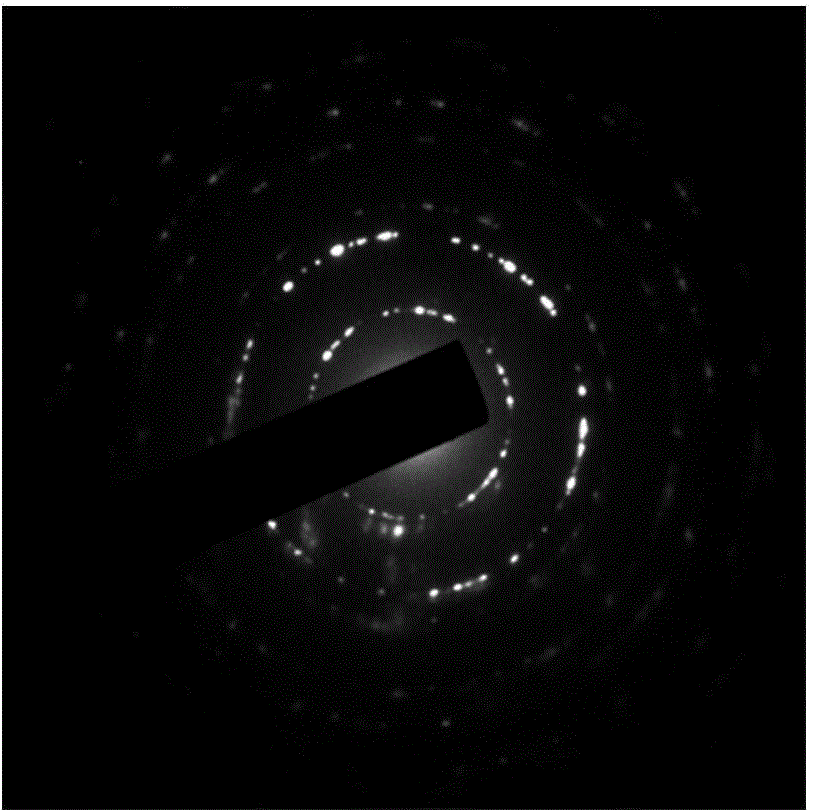

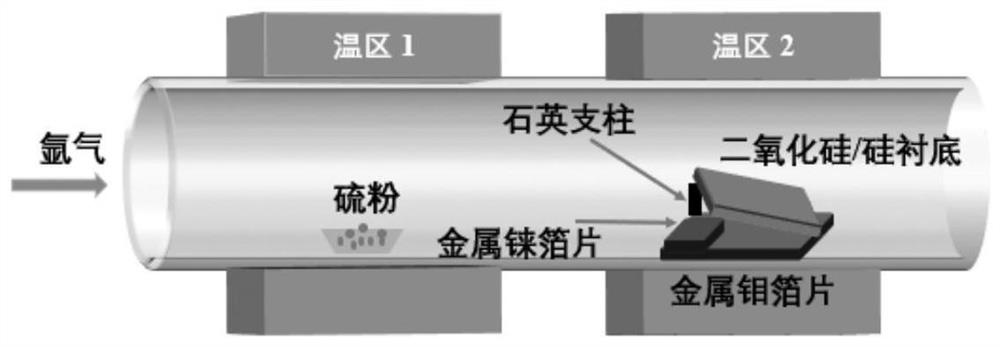

Low-temperature direct preparation method of graphene under double-temperature-zone control, and double-temperature-zone tube furnace

InactiveCN102849733APrecise control of growth temperatureSimple growth processGrapheneHydrogenDefective graphene

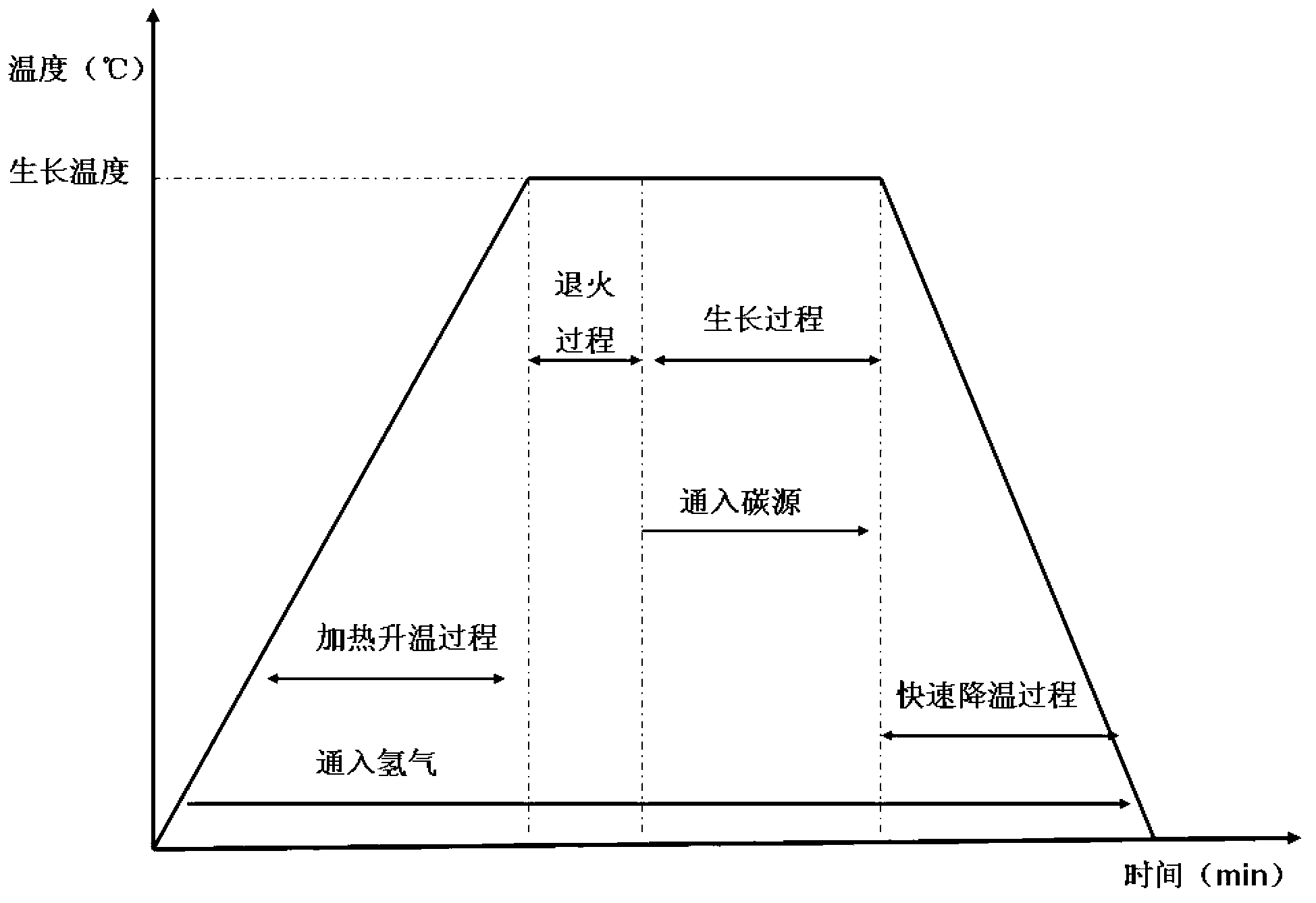

The invention discloses a low-temperature direct preparation method of graphene under double-temperature-zone control, and a double-temperature-zone tube furnace. The method comprises the steps of dividing a vacuum reaction furnace into a high-temperature zone and a low-temperature zone, putting transition metal into the high-temperature zone, directly putting substrate material into the low-temperature zone, vacuumizing, injecting hydrogen gas into the vacuum reaction furnace, heating the low-temperature zone to 100-1,000 DEG C, heating the high-temperature zone to 1,000-1,100 DEG C, introducing carbon source into the vacuum reaction furnace, cracking the carbon source in the high-temperature zone, and performing chemical vapor deposition (CVD) for 5-180 min in the low-temperature zone while keeping constant hydrogen gas flow, to obtain graphene directly deposited on the substrate. The preparation method has the advantages of simple growth process, no need of catalysis, low growth temperature of 100-1,000 DEG C, no restriction on substrate material, and large-area growth of graphene. The grown graphene has low defect peak, high crystal quality, excellent light transmittance and electrical conductivity.

Owner:SHANDONG NORMAL UNIV

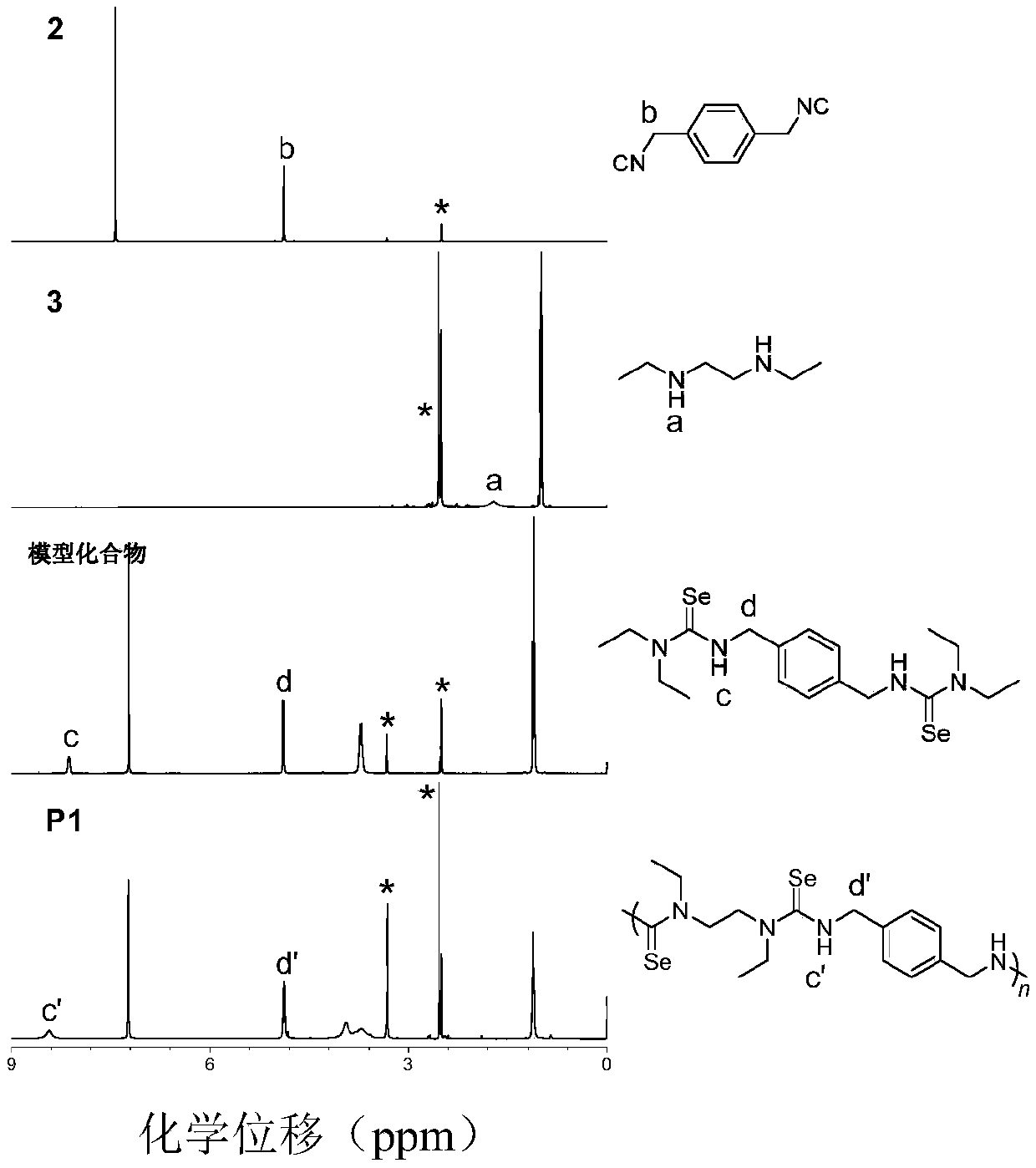

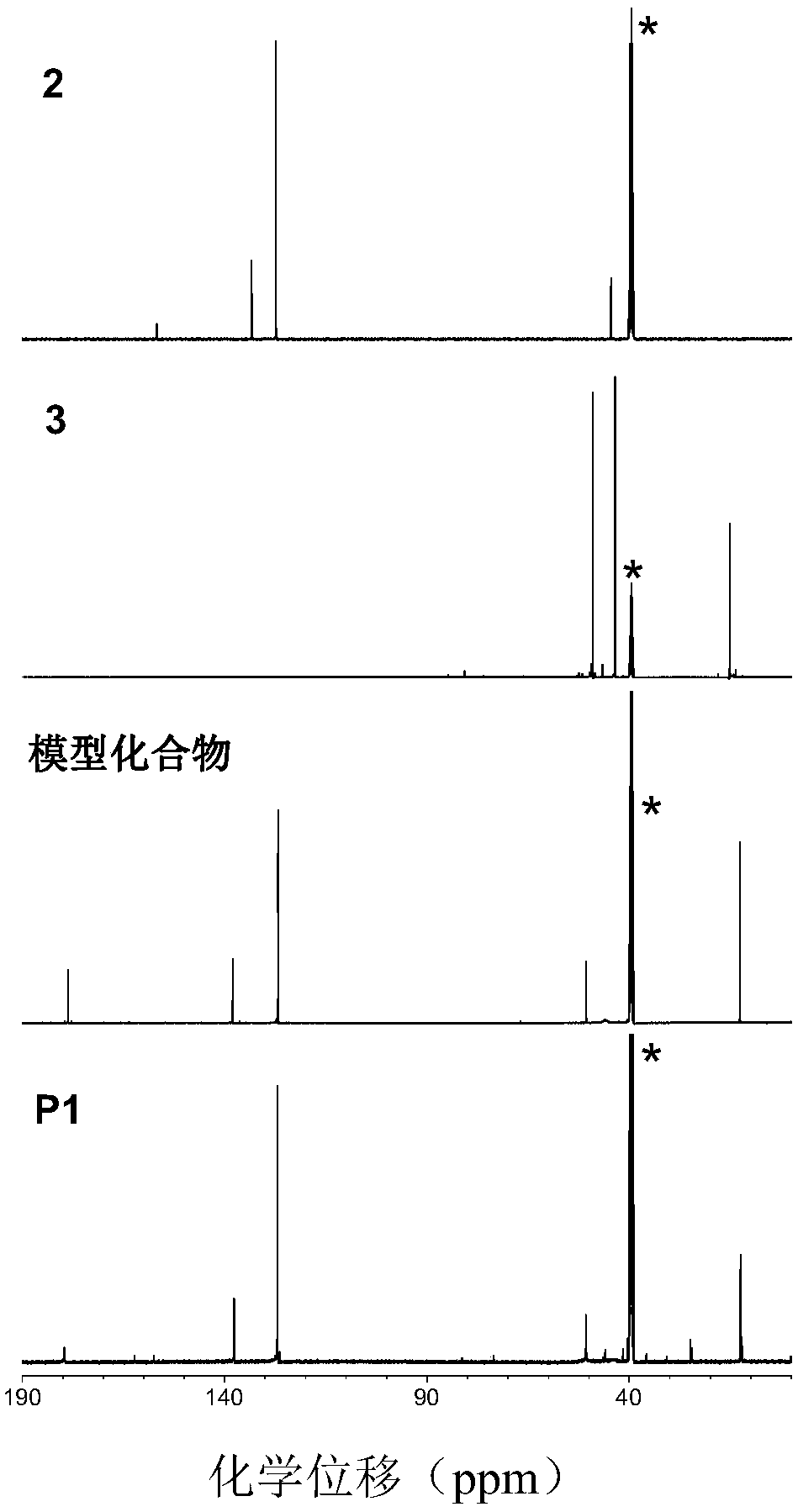

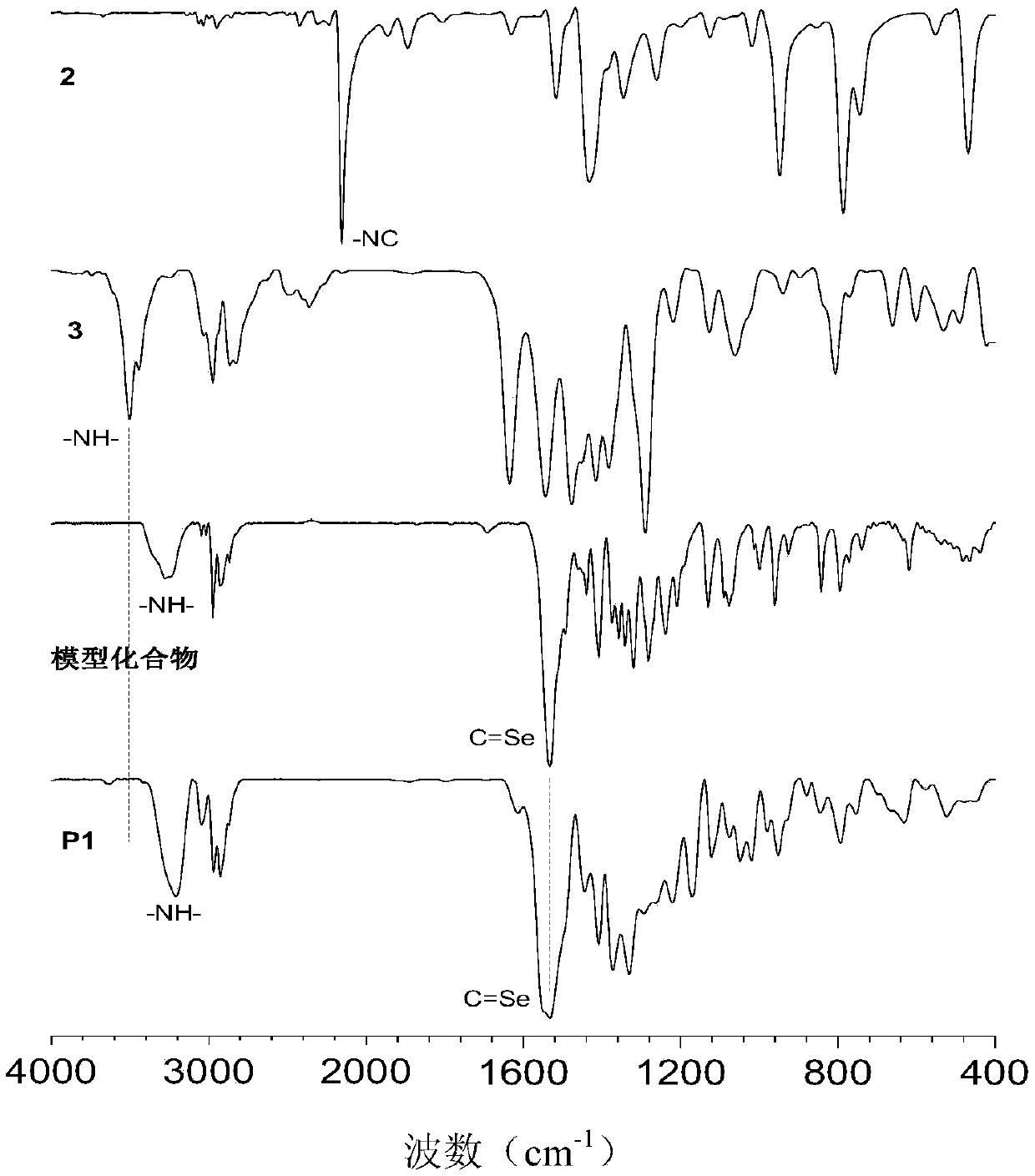

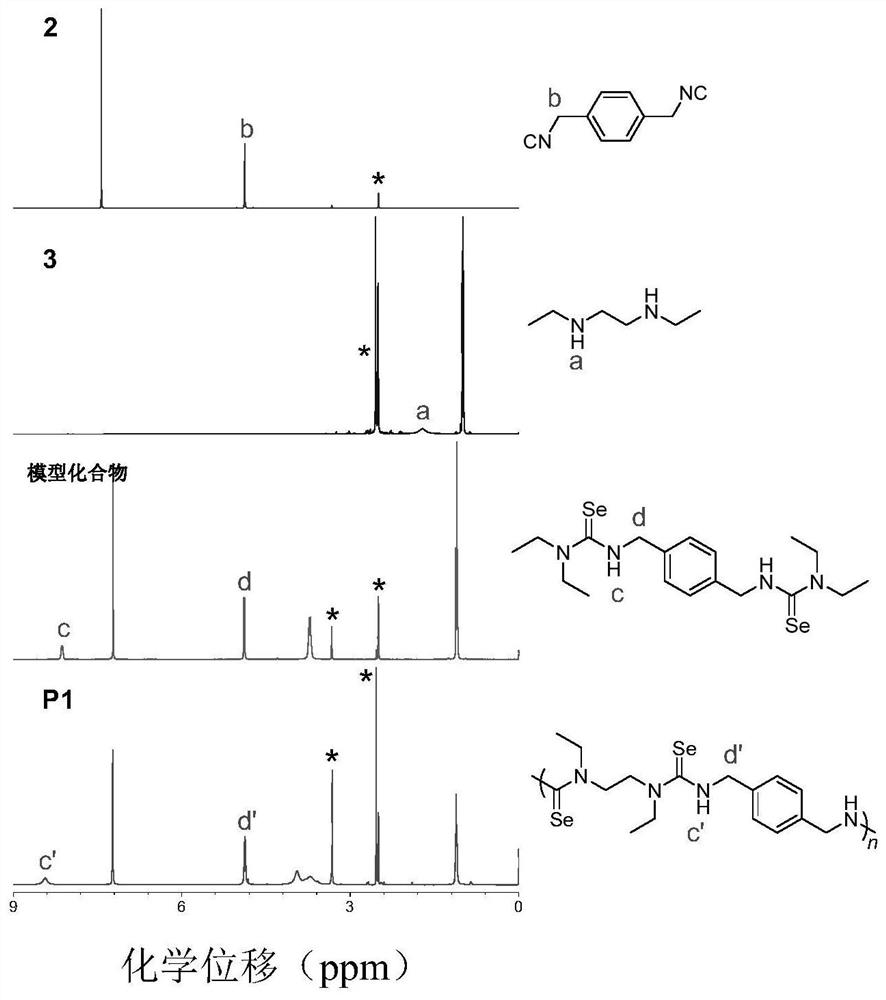

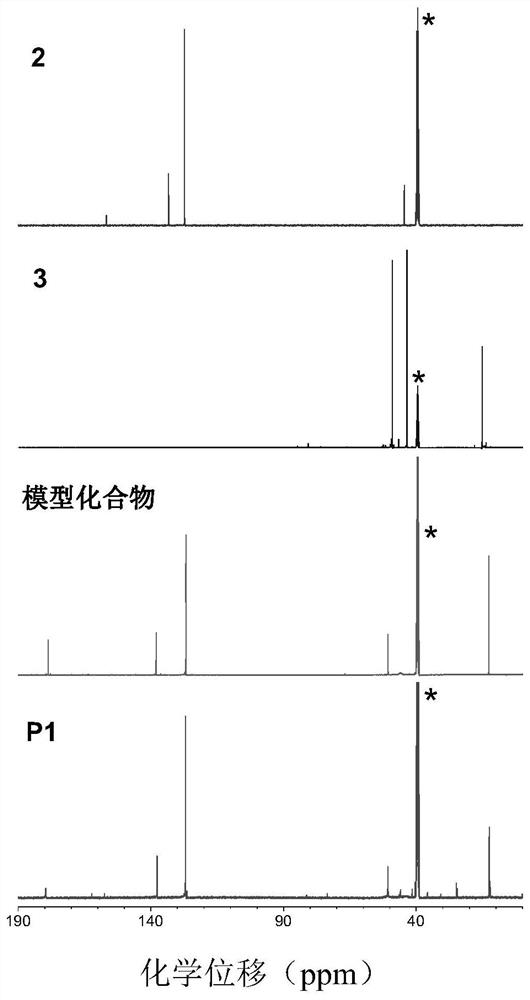

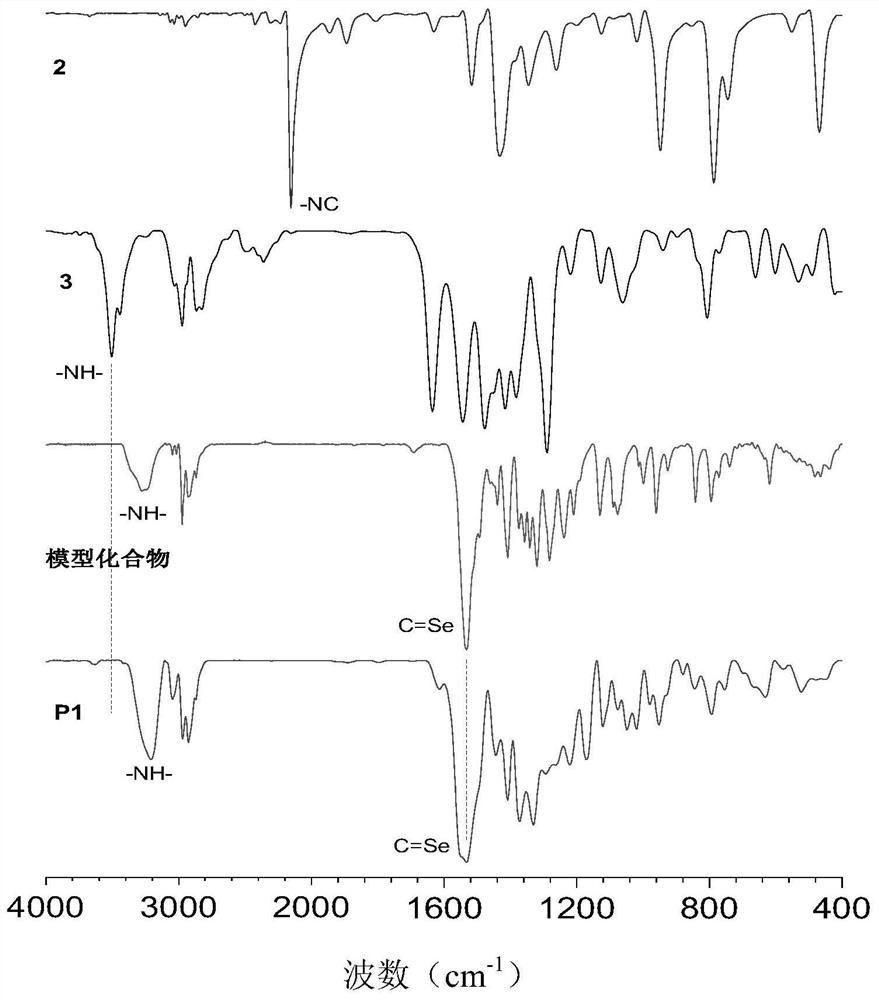

Method for preparing polyselenourea/polyselenoamide through multi-component polymerization of elemental selenium, isonitrile/alkyne and amine

The invention belongs to the technical field of preparation of selenium-containing polymers, and discloses a method for preparing polyselenourea / polyselenoamide through multi-component polymerizationof elemental selenium, isonitrile / alkyne and amine. The method comprises: carrying out a reaction on elemental selenium, a binary triple bond compound and a diamine in an organic solvent under an inert atmosphere, and subsequently treating to obtain a selenium-containing polymer, wherein the binary triple bond compound is binary isonitrile or binary alkyne, and the selenium-containing polymer is polyselenourea or polyselenoamide. According to the present invention, the method has characteristics of mild reaction conditions, high efficiency, energy saving, no catalyst, no by-product generation,atomic economy, green chemistry, low monomer toxicity, high atom utilization rate and high yield (more than or equal to 90%); the group has strong tolerance, and a variety of functional groups can beintroduced into the monomer; and the polyselenourea / polyselenoamide is stable, and can be degraded under specific conditions.

Owner:SOUTH CHINA UNIV OF TECH

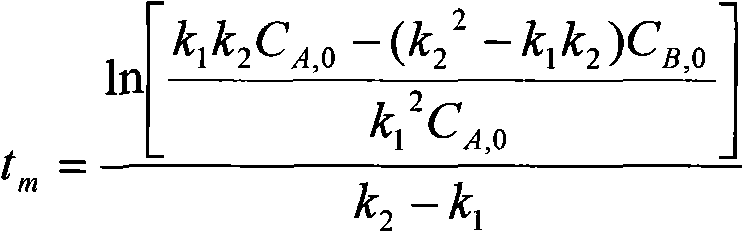

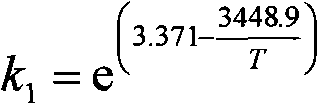

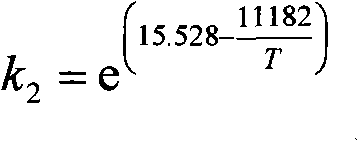

Subcritical hydrolysis method for preparing hexose with soluble fiber oligosaccharide

InactiveCN101845523ANo inhibitionHigh yieldFructose productionGlucose productionLiquid productCellulose

The invention relates to a subcritical hydrolysis method for preparing hexose with soluble fiber oligosaccharide, which comprises the following steps that: cellulose or wood fiber are pre-treated and primarily hydrolyzed to obtain mixture which contains soluble fiber oligosaccharide, and the concentration of oligosaccharide, hexose and other components in the mixture is determined. The reaction time for the maximum yield of the hexose is calculated and predicted according to the concentration of the oligosaccharide and the hexose, the set reaction temperature and other subcritical conditions with an oligosaccharide sub-critical hydrolysis kinetics law; and then oligosaccharide is hydrolyzed into glucose under the set subcritical hydrolysis conditions, the product is cooled and the reaction is terminated after the predicted reaction time is reached, and the liquid product is collected and obtained. The subcritical hydrolysis method for preparing hexose with soluble fiber oligosaccharide has simple process and quick reaction, can effectively control and optimize the subcritical process conditions, improves the yield of the target product hexose, provides a novel high-efficiency hydrolysis technical approach for turning the cellulose and the wood fiber waste into resources, is the basis for ethanol production through follow-up fermentation and other technologies, and has wide application prospect.

Owner:TSINGHUA UNIV

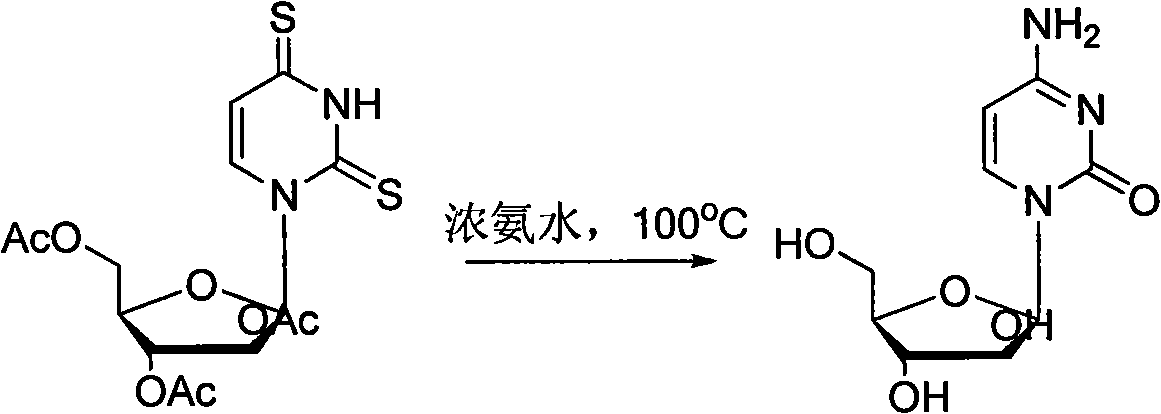

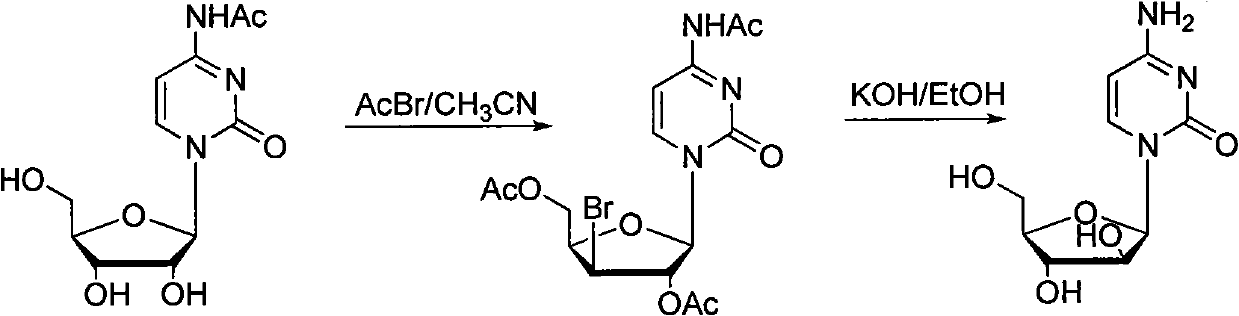

Technology for producing cytarabine through chemical synthesis method

InactiveCN101948492ARaw materials are cheap and easy to getReduce process stepsSugar derivativesSugar derivatives preparationCytarabineChemical synthesis

The invention discloses a technology for producing cytarabine through a chemical synthesis method, relating to a synthesis technology of an organic compound and aiming to provide a technology for producing the cytarabine through the chemical synthesis method, which has the advantages of cheap and available raw material, simple reaction condition, low cost, environmental protection and high yield. Based on the solving technical scheme, the technology for producing the cytarabine through the chemical synthesis method has a synthetic route which comprises the following synthesis steps of: firstly, reacting the cytarabine (1) used as a starting raw material with hexamethyldisilazane (HMDS) for 10-80h under the pressure of 5-20kg and at the temperature of 70-160 DEG C, cooling, stirring and vacuum concentrating a reaction system, and removing and recovering redundant hexamethyldisilazane to obtain an intermediate (II), wherein the dosage of the hexamethyldisilazane is 2-10 times larger than the weight of the cytarabine; secondly, dissolving the intermediate (II) into a proper solvent, and cooling or stirring to prepare crude cytarabine. The invention is used for preparing an anticancer drug.

Owner:HENAN NORMAL UNIV +1

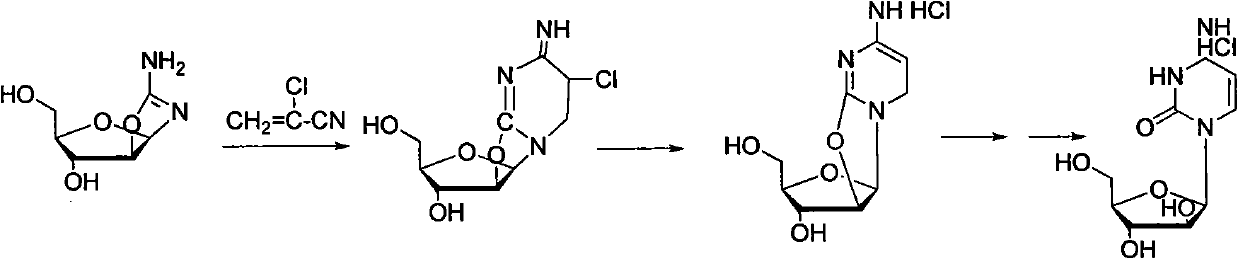

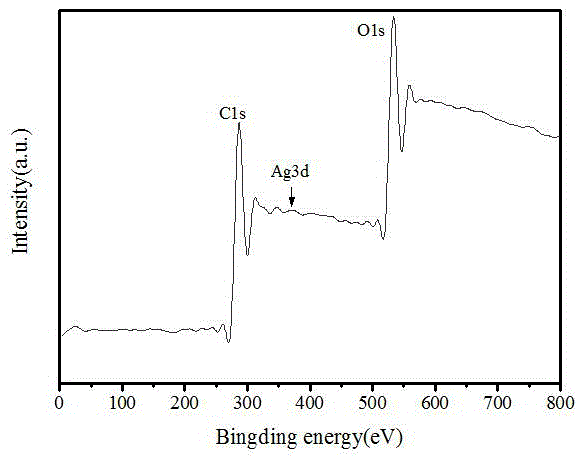

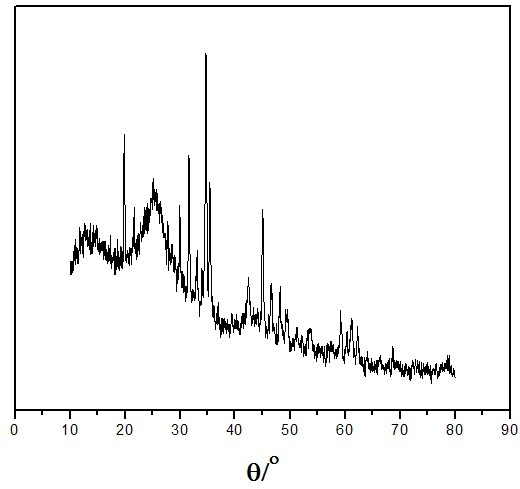

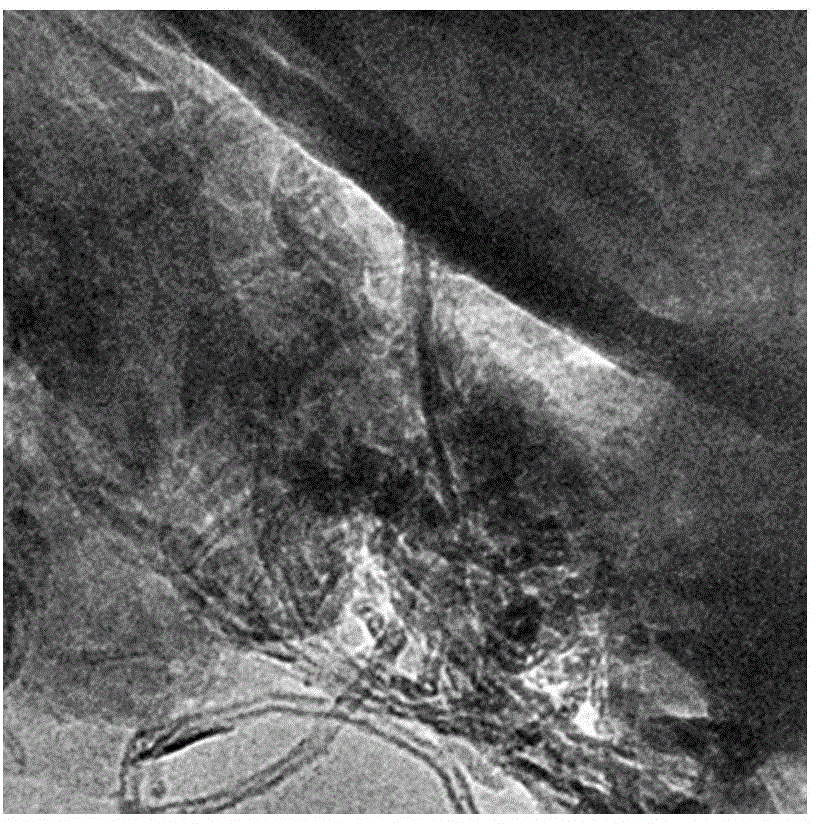

Preparation of Ag/CNTs/GO compound with sandwich structure

InactiveCN105596366AHighly regulatedNo catalyst requiredAntibacterial agentsInorganic active ingredientsEnterobacterCarbon nanotube

The invention discloses an Ag / CNTs / GO compound with a sandwich structure and a preparation method thereof. In the sandwich structure, the upper layer and the lower layer are graphene oxide thin layers, and the middle is a carbon nanotube layer with a hollow structure, wherein nano-silver particles are uniformly dispersed in graphene oxide and carbon nanotubes. The method provided by the invention has the advantages of simplicity and practicability, convenient operation, easy control, simplicity and environmental protection. Also, the prepared Ag / CNTs / GO compound with a sandwich structure strengthens the collaborative immobilization capacity of graphene and carbon nanotubes to nano-silver, so that the compound can have very good stability, and the dispersibility of nano-silver particles are improved. At the same time, the compound also shows a strong inhibitory effect on Gram positive bacteria (staphylococcus aureus) and Gram negative bacteria (Escherichia coli) and other strains.

Owner:FUZHOU UNIVERSITY

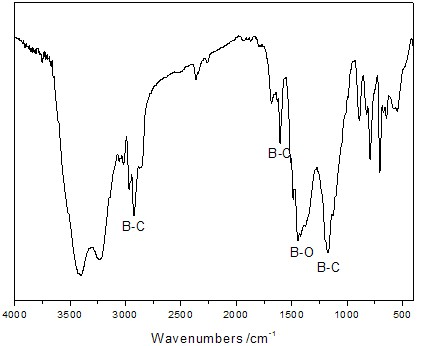

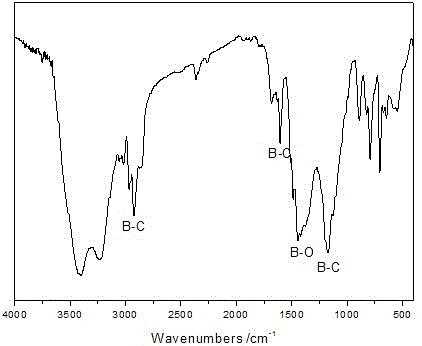

Preparation method for boron carbide precursor

A preparation method for a boron carbide precursor includes the steps: (1) taking borane, mono-functional olefin and bi-functional olefin in the mass ratio of 1: (0.1-20): (0.1-20); (2) adding the mono-functional olefin or / and the bi-functional olefin into a reactor with stirring and distilling devices, repeatedly vacuumizing and filling dried nitrogen into the reactor for at least three times, and pre-cooling the reactor to the temperature ranging from -2 DEG C to -35 DEG C; (3) adding the borane, and continuously carrying out stirring reaction at the room temperature under the protection ofthe N2 atmosphere, wherein the stirring rate is 60-240r / min, and reaction time ranges from 2h to 72h; and (4) increasing the temperature of the system at the temperature rise rate of 0.1-30 DEG C / minto 30-400 DEG C, removing solvent composition in the system by means of reduced pressure distillation, and cooling to the room temperature so that the boron carbide precursor is prepared. The preparation method for the boron carbide precursor is low in production cost, and the boron carbide precursor prepared by the method is good in solubility and high in productivity.

Owner:NAT UNIV OF DEFENSE TECH

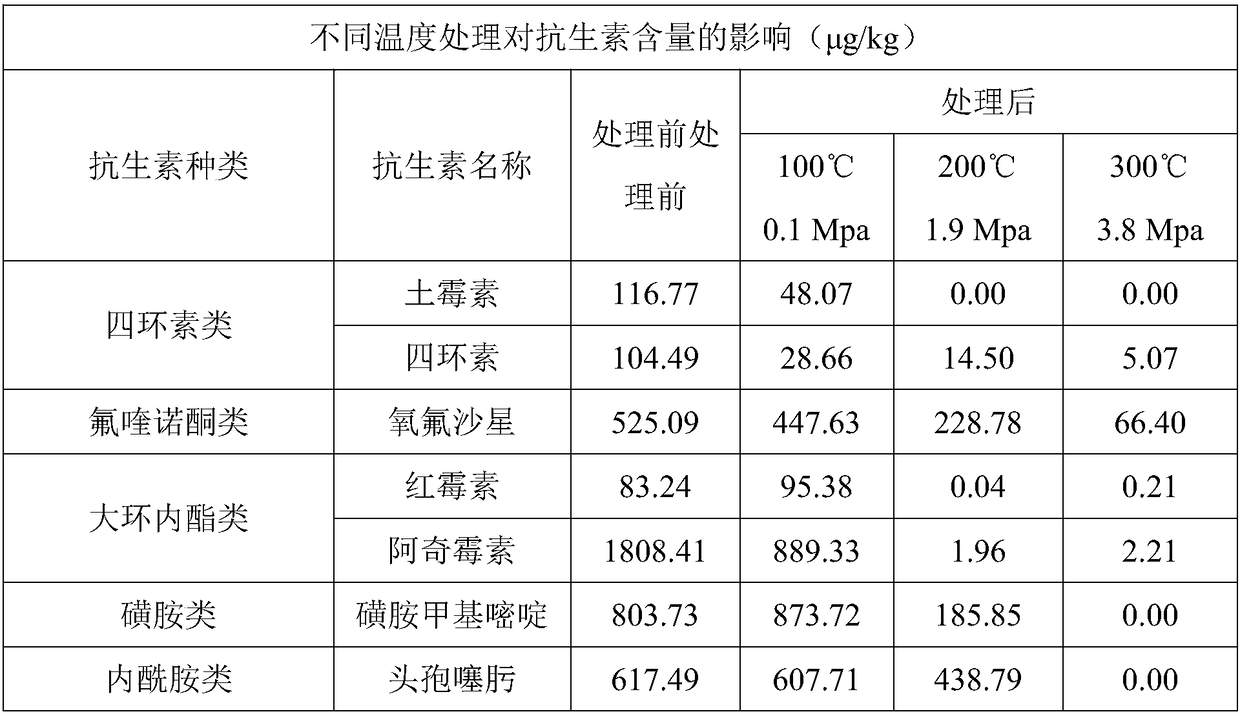

Method for effectively reducing content of antibiotics in livestock and poultry manure

InactiveCN108147521AEfficient degradationAvoid harmWater treatment parameter controlSludge treatment by oxidationBiotechnologyPoultry manure

The invention discloses a method for effectively reducing content of antibiotics in livestock and poultry manure. Specifically, the livestock and poultry manure is thrown into a critical hydrolysis reaction kettle, wherein the temperature is greater than or equal to 200 DEG C and the pressure is greater than or equal to 1.8 MPa; the pressure is maintained for over 20 minutes, then the pressure isrelieved, and a material is discharged. The method disclosed by the invention is safe and reliable; the content of the antibiotics in the livestock and poultry manure is reduced with high removal rate.

Owner:厦门康浩生态农业有限公司

Preparation method for acetophenone

InactiveCN101125806ALower synthesis costThe synthesis method is simpleOrganic compound preparationCarbonyl compound preparationOrganic synthesisRoom temperature

The invention relates to a preparation method of hypnone, in particular to a method for preparing hypnone by direct photooxidation under the condition with Alpha-vinyltoluene and without catalyst. The invention belongs to the technical field of organic synthesis application. The Alpha-vinyltoluene and acetonitrile with the volume ratio of 1: (0.4 to 100) are put into a light reactor and stirred. The hypnone is prepared after putting through condensed water into a reactor casing and adjusting the flow rate, maintaining reaction temperature to be room temperature, inletting oxygen into the reactor with the flow rate of 2 to 15ml / min, lighting a 125w medium pressure mercury lamp and reacting for 0.5 to 20 hour(s). The method can be used for synthesizing hypnone directly at room temperature without catalysts so as to reduce synthesis cost; furthermore, the method has the advantages of less toxicity and being environment protective.

Owner:EAST CHINA NORMAL UNIV

Method for preparing acetylene by cracking waste grease with thermal plasma

ActiveCN103333043AHigh value-added utilizationSolve the problem of flow into the food marketHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon crackingPlasma jetHydrogen

The invention discloses a method for preparing acetylene by cracking waste grease with thermal plasma. The method comprises the following steps of: introducing a working gas to a plasma generator, and forming thermal plasma jet after arcing; and filtering and atomizing the waste grease, mixing the waste grease with a delivered gas, introducing the mixture to the thermal plasma jet in the plasma generator, performing millisecond cracking reaction, and quenching with a cooling medium to obtain cracked gas containing acetylene. The working gas is one or more of hydrogen, argon and nitrogen; the delivered gas is one or more of hydrogen, argon and nitrogen, and can be the same as or different from the working gas; and the cooling medium is one or more of water, hydrogen and waste grease serving as raw materials. According to the method, the waste grease is used as a raw material, so that high value-added utilization of the waste grease is realized, and environmental pollution is reduced; and the method is short in process flow, environment-friendly, economic, efficient, high in utilization rate of the raw materials and high in yield of the acetylene product.

Owner:ZHEJIANG UNIV

Method for anhydride modified melamine resin

InactiveCN103012707AThe process steps are simpleAchieving a Controlled ResponseSolventMelamine resin

The invention provides a method for an anhydride modified melamine resin. The method is free from catalysts, solvents and purification. By adopting the method, the controllable reaction for one-substitution to three-substitution can be realized, and the anhydride modified melamine resin can be directly produced in a one-step way.

Owner:乌鲁木齐益好天成新型节能材料有限公司 +1

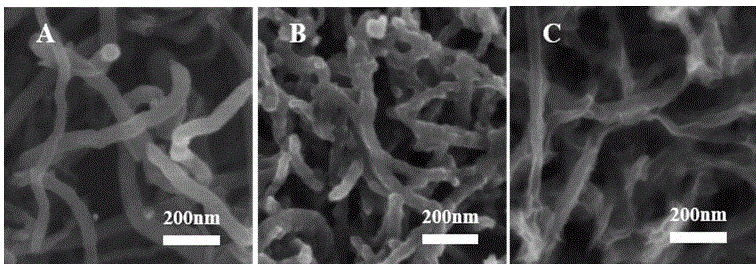

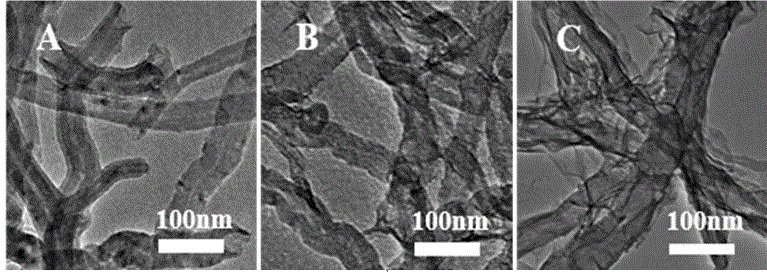

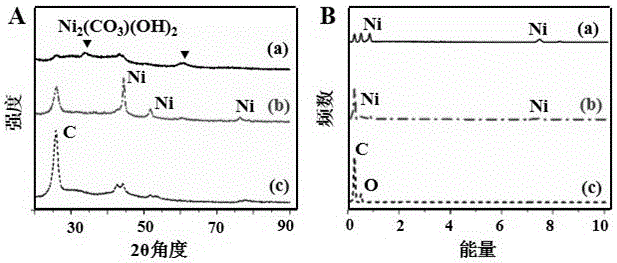

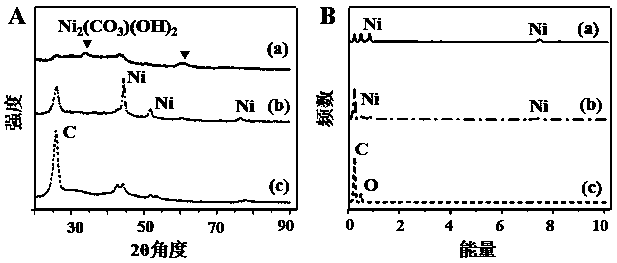

Preparation method of tubular sandwich-structure CNT@Ni@Ni2(CO3)(OH)2 composite material

InactiveCN106486294AGood lookingShape stableHybrid capacitor electrodesHybrid/EDL manufactureCalcium Chloride HexahydrateCarbon nanotube

The invention discloses a preparation method of a tubular sandwich-structure CNT@Ni@Ni2(CO3)(OH)2 composite material. The preparation method comprises the steps of uniformly dispersing nickel chloride hexahydrate and functionalized multi-wall carbon nanotube in ethylene glycol, adding a reducing agent hydrazine for high-temperature back flow, centrifugally collecting a product, repeatedly washing the product, and performing vacuum drying to obtain core-shell structure CNT@Ni; and dissolving the core-shell structure CNT@Ni and the nickel chloride hexahydrate in deionized water, placing the core-shell structure CNT@Ni and the nickel chloride hexahydrate in a semi-permeable membrane, dissolving sodium carbonate in the deionized water, placing the sodium carbonate outside the semi-permeable membrane, centrifugally collecting a product after standing for a night, repeatedly washing the product, and performing vacuum drying to obtain the tubular sandwich-structure CNT@Ni@Ni2(CO3)(OH)2 composite material. On the basis of combining an oxygen-containing metal compound and a carbon material, a metal nickel monomer is added, thus, the conductivity of the whole material can be improved, meanwhile, the specific capacity of the composite material is also greatly improved, and the cycle lifetime of the composite material is also greatly prolonged. The composite material has the advantages of process simplicity, preparation condition universality, product morphology stability and high purity, the product is convenient and simple to process and is suitable for medium-scale industrial production.

Owner:TONGJI UNIV

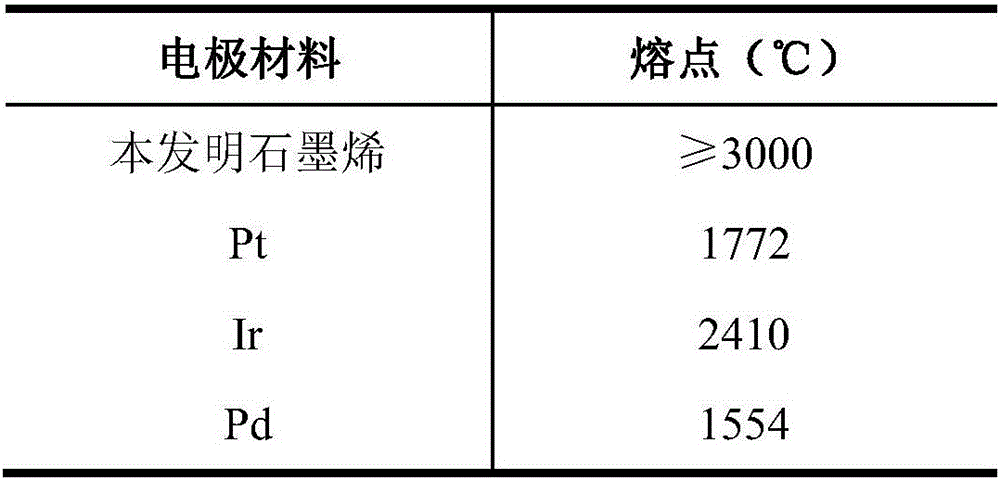

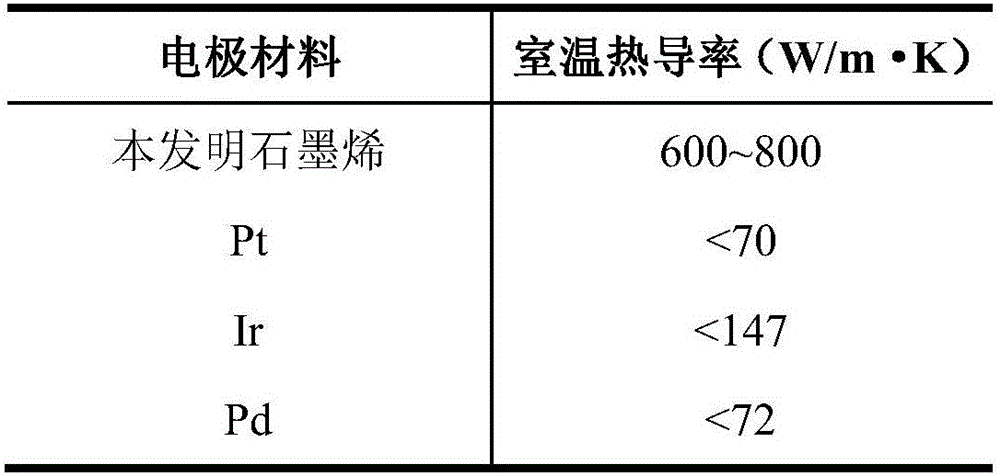

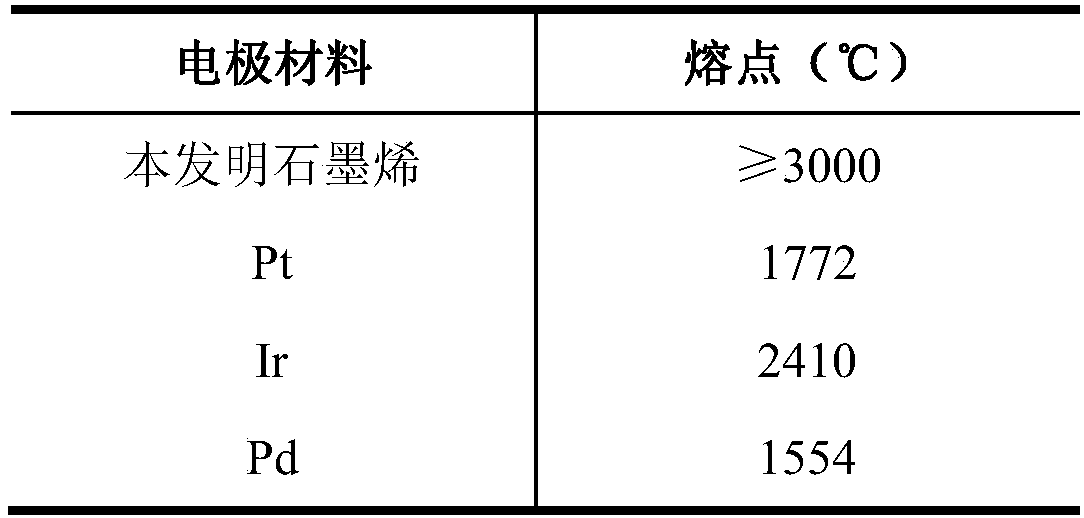

Method for preparing graphene electrode in high-temperature piezoelectric sensor

InactiveCN106191806AImprove adhesionImprove conductivityChemical vapor deposition coatingShielding gasGraphene electrode

The invention provides a method for preparing a graphene electrode in a high-temperature piezoelectric sensor. The method includes the following steps that a pretreated high-temperature piezoelectric crystal plate of the high-temperature piezoelectric sensor is placed into a plasma chemical vapor deposition cavity, the cavity is closed, and a vacuum pump is started; when air pressure inside the cavity is lowered to 10<-5> Torr or below, shielding gas and carbureted hydrogen gas are connected in to adjust the pressure intensity inside the cavity; and a vacuum reacting furnace is started for heating and warming, a plasma source is switched on to perform constant temperature deposition, and accordingly the graphene electrode can be obtained. According to the preparation method of the graphene electrode, the high-temperature piezoelectric crystal plate is used as a substrate, a small or large number of layers of graphene are grown on the surface of the crystal plate without metal catalysis as the electrode through the plasma enhanced chemical vapor deposition (PECVD) technique directly, adhesive force between a graphene thin film and the crystal plate is good, and electrical conductivity of the graphene thin film is excellent.

Owner:JIANGNAN GRAPHENE RES INST

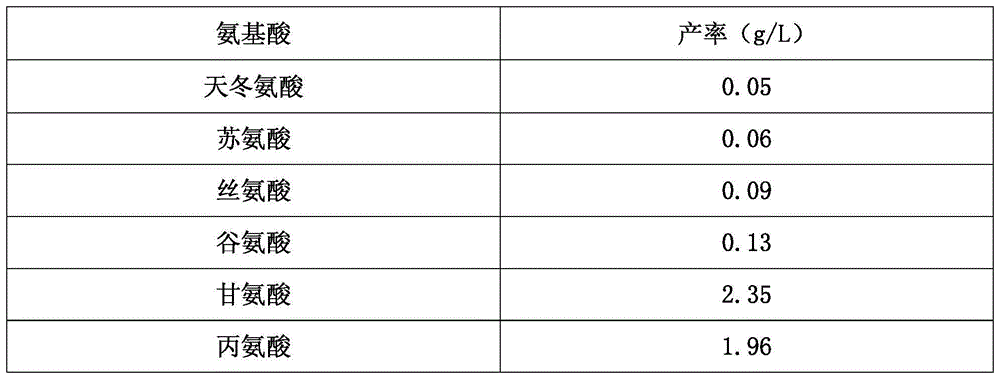

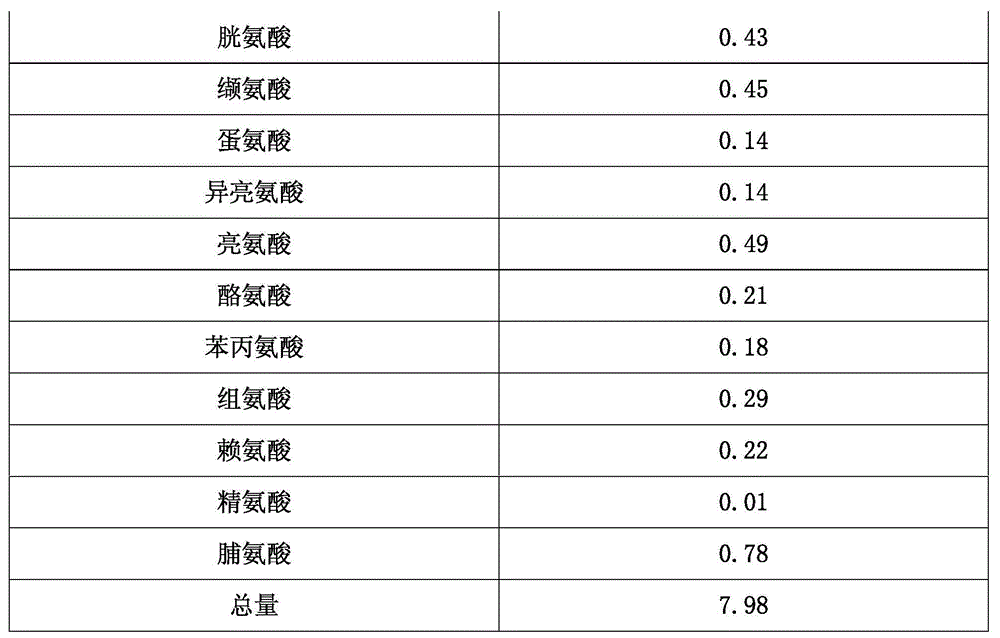

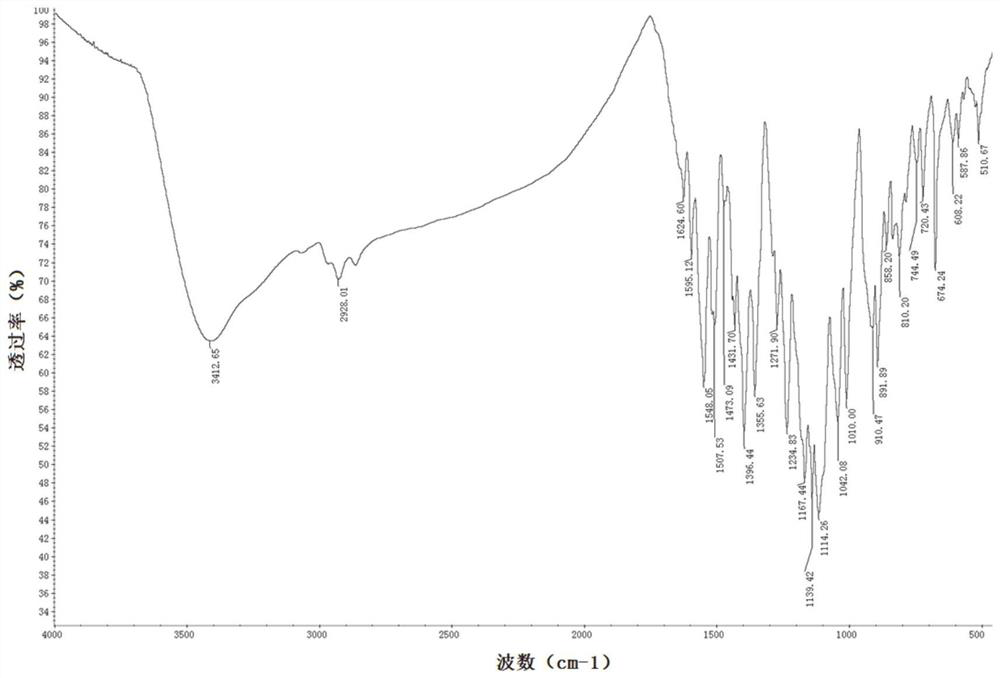

Technological method for innocent treatment of animals dying from diseases through subcritical water

InactiveCN104971935AExtensive and renewable resourcesReduce pollutionSolid waste disposalAnimal scienceDead body

The invention discloses a technological method for innocent treatment of animals dying from diseases through subcritical water. The technological method includes the steps that crushed animal carcasses are sealed after the addition of purified water; the animal carcasses are put at the temperature of 170-240 DEG C and the pressure of 0.5-3.6 Mpa, and the temperature and the pressure are kept for certain time; preferably, the temperature and the pressure are kept for 1-2 hours. According to the technological method for innocent treatment of the animals dying from diseases through subcritical water, the animals dying from diseases and waste of the animals are used, and therefore various liquid amino acid with high yield can be prepared through the method. The technological method is low in cost, convenient to implement and simple, the environment and the waste are utilized, and the technological method is worthy of being popularized greatly.

Owner:厦门康浩科技有限公司

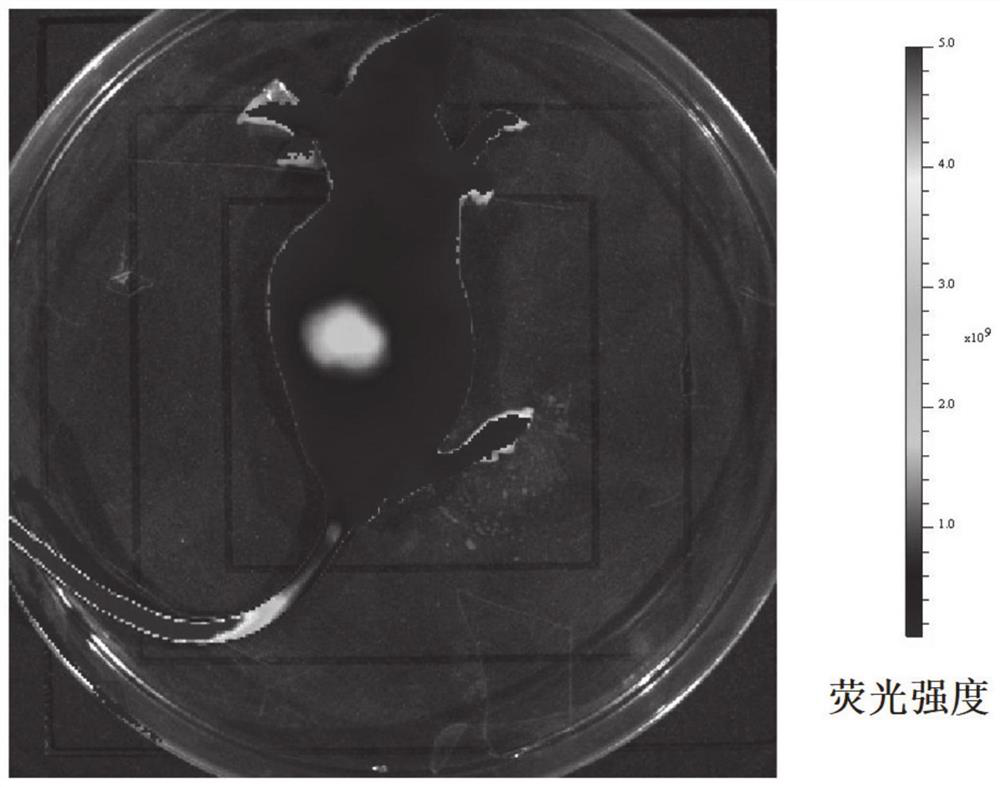

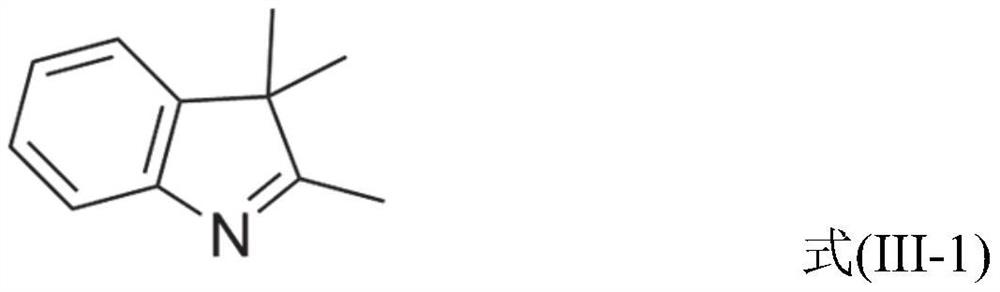

Preparation method and application of heptamethine indocyanine dye

ActiveCN111662568AImprove production efficiencyShort synthetic routeMethine/polymethine dyesFluorescence/phosphorescenceCycloalkeneFluorescence

The invention discloses a preparation method and application of a heptamethine indocyanine dye, and belongs to the field of polymethine indocyanine dyes and preparation thereof. The method comprises the following steps: 1) carrying out a heating reaction on raw materials containing a 2,3,3-trimethylindole derivative and a nucleophilic substituted compound under a vacuum condition to obtain an organic ammonium salt; and 2) carrying out a heating reaction on a solution containing the organic ammonium salt obtained in the step 1) and a cycloalkene derivative under a closed condition. According tothe invention, the structural formula of the heptamethine indocyanine dye is represented by a formula (I); the dye has near-infrared light absorption and fluorescence development performances and canbe used as a probe auxiliary agent; and the method is short in synthetic route, green in solvent, simple in process, free of noble metal catalysis, large in single reaction amount, high in product yield and purity, high in universality and capable of being used for synthesizing products of various structure types.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

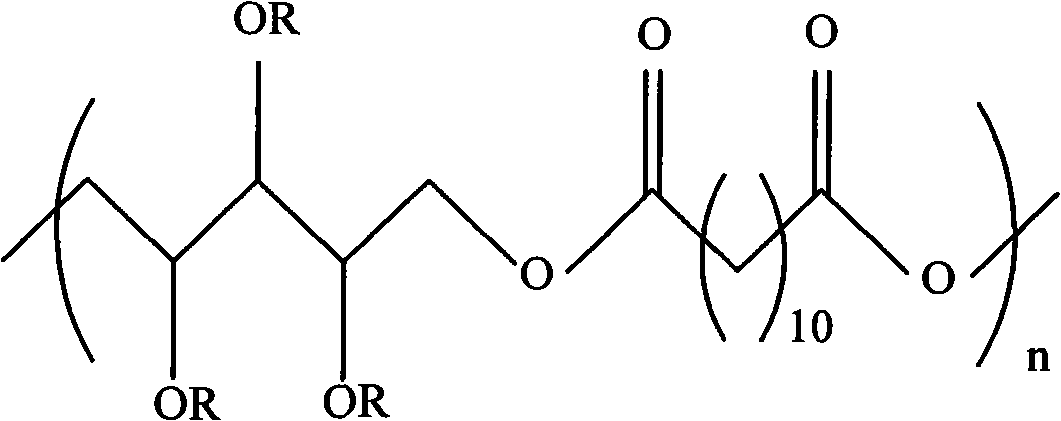

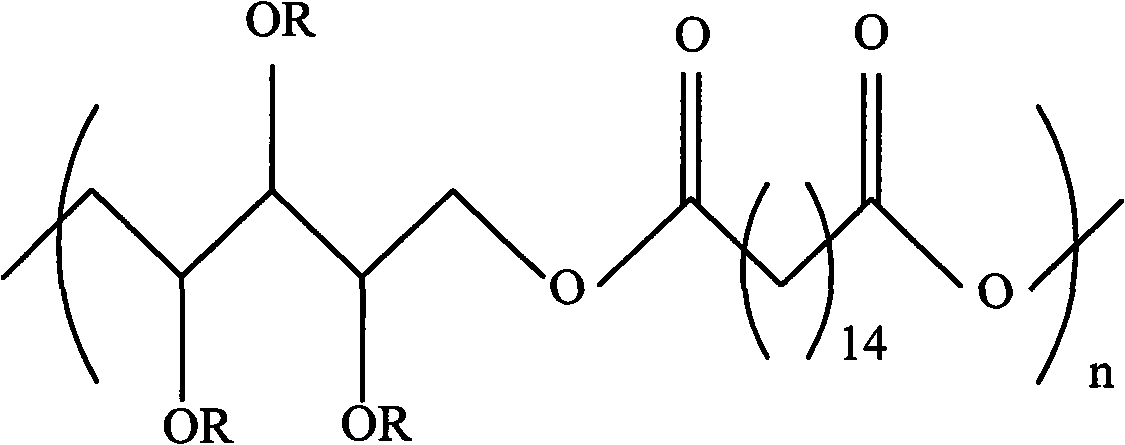

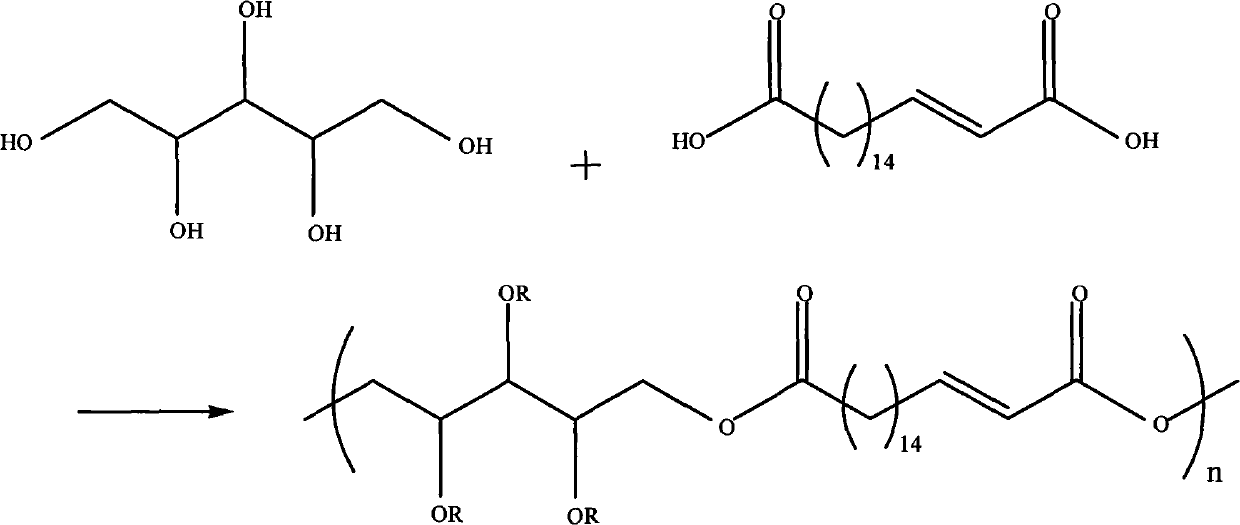

Polyester elastomer and preparation method thereof

The invention relates to a polyester elastomer and a preparation method thereof. The xylitol base polyester elastomer is obtained by adopting a melting polycondensation method with xylitol as a main elastomer and itaconic acid, succinic acid, dodecanedioic acid, hexadecanedioic acid, octadecyl diacid and octadecadienoic acid as comonomers. The elastomer has higher biocompatibility and biodegradability and low toxicity; the xylitol belongs to a polyhydroxyl monomer; when the xylitol copolymerized with other monomers, the xylitol can adjust the crosslinking density of a polymer by changing the category and composition of the comonomer, thereby realizing controllable performance; and accordingly, the polymer has a wide application range. The invention has the advantages of simple preparation method, no catalyst and simple post treatment, and the obtained polyester elastomer has high biocompatibility; by controlling monomer molar ratio and reaction condition, the mechanical performance, hydrophobic performance and water absorption rate of the material can be adjusted; and the material is expected to be used as a medicament slow-release carrier, a styptic preparation, bone wax, a tissue engineering bracket, a surgical operation anti-adhesion film, and the like.

Owner:JIANGNAN UNIV

Method for preparing acetylene by cracking waste grease with thermal plasma

ActiveCN103333043BHigh value-added utilizationSolve the problem of flow into the food marketHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon crackingOil and greasePlasma jet

The invention discloses a method for preparing acetylene by cracking waste grease with thermal plasma. The method comprises the following steps of: introducing a working gas to a plasma generator, and forming thermal plasma jet after arcing; and filtering and atomizing the waste grease, mixing the waste grease with a delivered gas, introducing the mixture to the thermal plasma jet in the plasma generator, performing millisecond cracking reaction, and quenching with a cooling medium to obtain cracked gas containing acetylene. The working gas is one or more of hydrogen, argon and nitrogen; the delivered gas is one or more of hydrogen, argon and nitrogen, and can be the same as or different from the working gas; and the cooling medium is one or more of water, hydrogen and waste grease serving as raw materials. According to the method, the waste grease is used as a raw material, so that high value-added utilization of the waste grease is realized, and environmental pollution is reduced; and the method is short in process flow, environment-friendly, economic, efficient, high in utilization rate of the raw materials and high in yield of the acetylene product.

Owner:ZHEJIANG UNIV

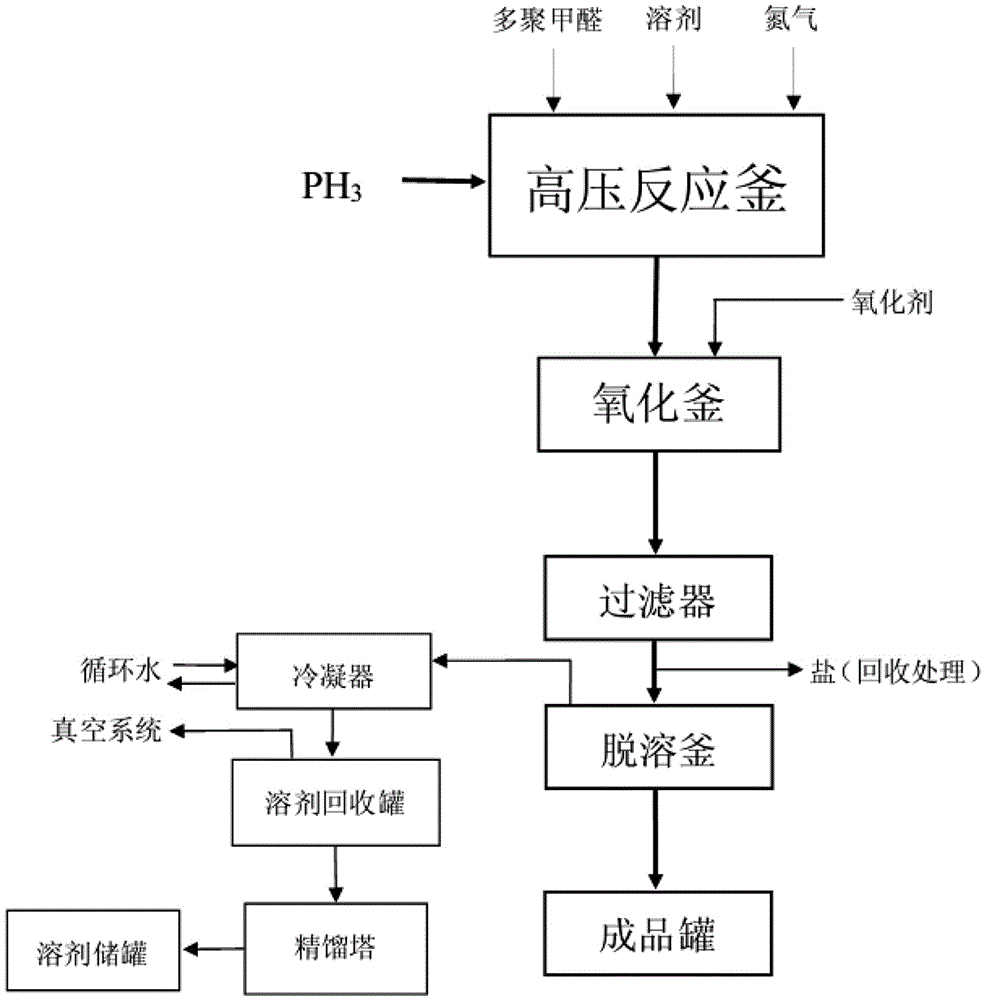

A high-pressure oxidation synthesis process and equipment for trihydroxymethylphosphine oxide

ActiveCN104262395BSimple process routeReduce processGroup 5/15 element organic compoundsPtru catalystSodium phosphates

The invention relates to a high-pressure oxidation synthesis process and equipment for trishydroxymethylphosphine oxide (THPO). The production process includes the following steps: adding organic solvent and paraformaldehyde into the high-pressure reaction kettle, feeding nitrogen protection, stirring to raise the temperature to 60~100°C, feeding PH3 gas to pressurize, and maintaining the pressure inside the kettle at 3.0~5.0MPa, After reacting for 1~3h, lower to normal pressure and normal temperature; transfer all the materials to an oxidation kettle, add an oxidant, heat up to 30~120°C, stir and react for 3~6h, then drop to room temperature; filter the materials through a filter, and transfer the filtrate to Desolventizing kettle, vacuum distillation, the desolventizing temperature is 55~85℃, when the moisture content of the material is less than 2%, the material is transferred to the finished product tank. The invention has the advantages of simple process route, few procedures and low operation intensity; no catalyst and low production cost; comprehensively utilizes the by-product PH3 in the production of sodium hypophosphite; has no pollution to the environment and is environmentally friendly.

Owner:湖北省兴发磷化工研究院有限公司

Preparation method of a tubular sandwich structure cnt@ni@ni2(co3)(oh)2 composite material

InactiveCN106486294BGood lookingShape stableHybrid capacitor electrodesHybrid/EDL manufactureCarbon nanotubeOxygen

The invention discloses a preparation method of a tubular sandwich-structure CNT@Ni@Ni2(CO3)(OH)2 composite material. The preparation method comprises the steps of uniformly dispersing nickel chloride hexahydrate and functionalized multi-wall carbon nanotube in ethylene glycol, adding a reducing agent hydrazine for high-temperature back flow, centrifugally collecting a product, repeatedly washing the product, and performing vacuum drying to obtain core-shell structure CNT@Ni; and dissolving the core-shell structure CNT@Ni and the nickel chloride hexahydrate in deionized water, placing the core-shell structure CNT@Ni and the nickel chloride hexahydrate in a semi-permeable membrane, dissolving sodium carbonate in the deionized water, placing the sodium carbonate outside the semi-permeable membrane, centrifugally collecting a product after standing for a night, repeatedly washing the product, and performing vacuum drying to obtain the tubular sandwich-structure CNT@Ni@Ni2(CO3)(OH)2 composite material. On the basis of combining an oxygen-containing metal compound and a carbon material, a metal nickel monomer is added, thus, the conductivity of the whole material can be improved, meanwhile, the specific capacity of the composite material is also greatly improved, and the cycle lifetime of the composite material is also greatly prolonged. The composite material has the advantages of process simplicity, preparation condition universality, product morphology stability and high purity, the product is convenient and simple to process and is suitable for medium-scale industrial production.

Owner:TONGJI UNIV

A method for preparing polyselenourea/polyselenoamide by multi-component polymerization of elemental selenium, isonitrile/alkyne and amine

The invention belongs to the technical field of preparation of selenium-containing polymers, and discloses a method for preparing polyselenourea / polyselenoamide through multi-component polymerizationof elemental selenium, isonitrile / alkyne and amine. The method comprises: carrying out a reaction on elemental selenium, a binary triple bond compound and a diamine in an organic solvent under an inert atmosphere, and subsequently treating to obtain a selenium-containing polymer, wherein the binary triple bond compound is binary isonitrile or binary alkyne, and the selenium-containing polymer is polyselenourea or polyselenoamide. According to the present invention, the method has characteristics of mild reaction conditions, high efficiency, energy saving, no catalyst, no by-product generation,atomic economy, green chemistry, low monomer toxicity, high atom utilization rate and high yield (more than or equal to 90%); the group has strong tolerance, and a variety of functional groups can beintroduced into the monomer; and the polyselenourea / polyselenoamide is stable, and can be degraded under specific conditions.

Owner:SOUTH CHINA UNIV OF TECH

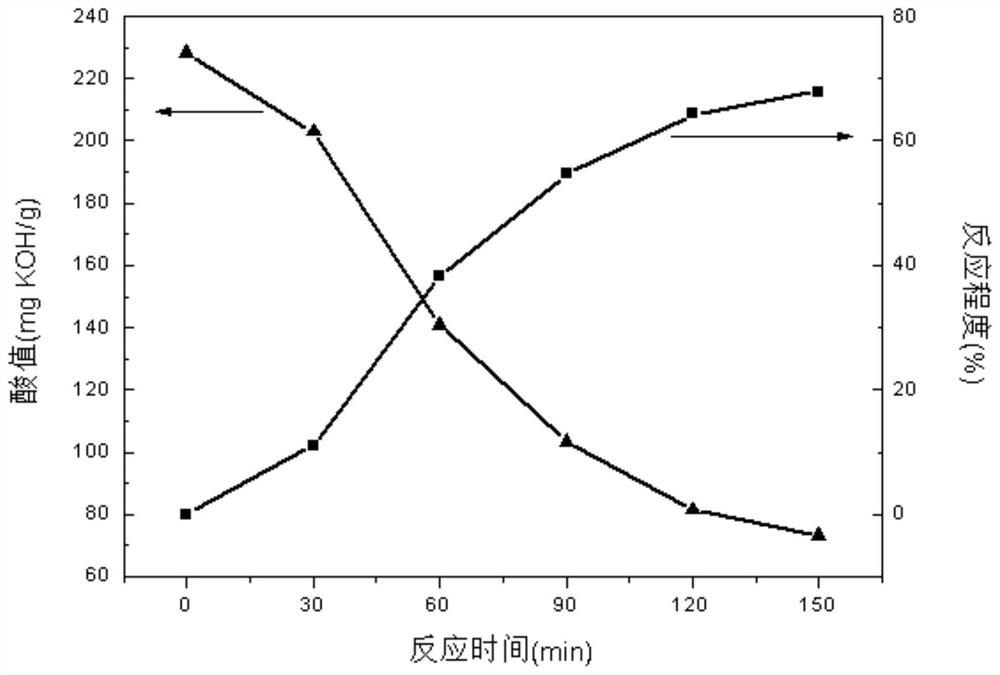

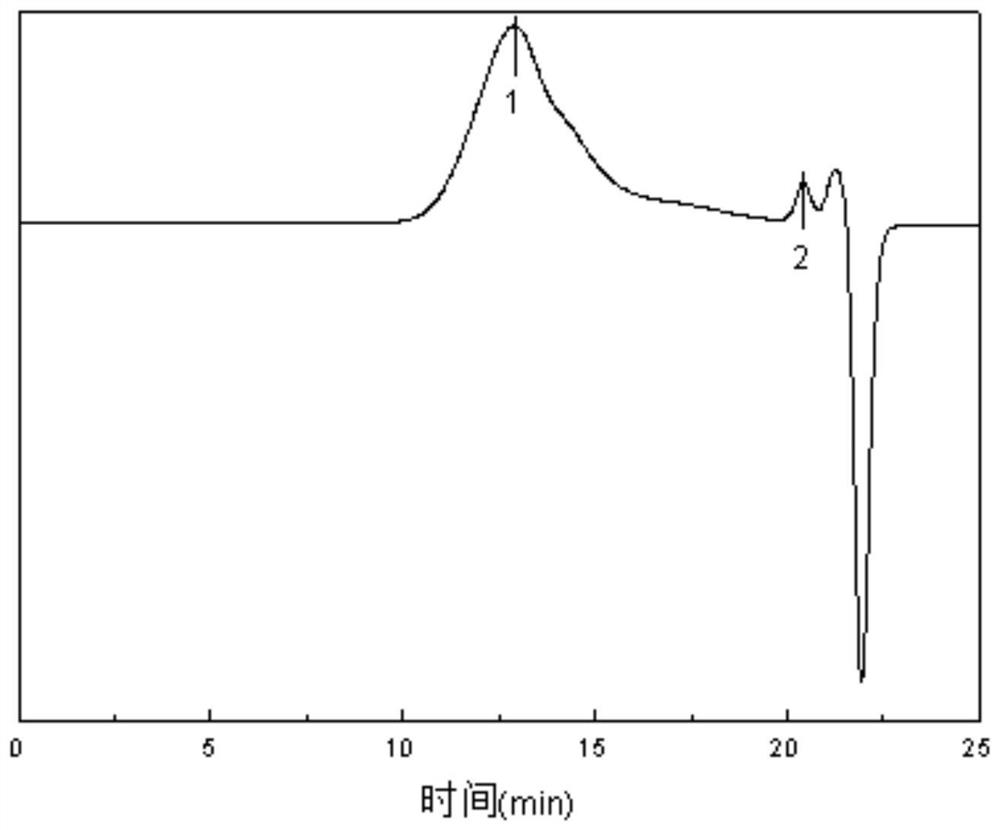

A kind of fully bio-based unsaturated polyester prepolymer for dynamic vulcanization with polylactic acid and preparation method thereof

The invention provides a fully bio-based unsaturated polyester prepolymer for dynamic vulcanization with polylactic acid and a preparation method thereof. Then, the preliminary esterification product is subjected to polycondensation reaction under vacuum conditions to obtain a first prepolymer; the first prepolymer is freeze-dried to prepare a fully bio-based unsaturated polyester prepolymer. The invention adopts polybasic acid and diol as biomass raw materials, and the price is low; a one-pot method is adopted to prepare a fully bio-based unsaturated polyester prepolymer, the process is simple, easy to operate, and the prepolymer is successfully purified in the purification process The double bond is preserved, and the active functional group is reserved for the subsequent dynamic vulcanization. After dynamic vulcanization with polylactic acid, it can not only significantly improve the physical and mechanical properties of polylactic acid such as toughness, but also ensure the prepared biodegradable polylactic acid. Fully bio-based properties of blend materials.

Owner:ZHENGZHOU UNIV

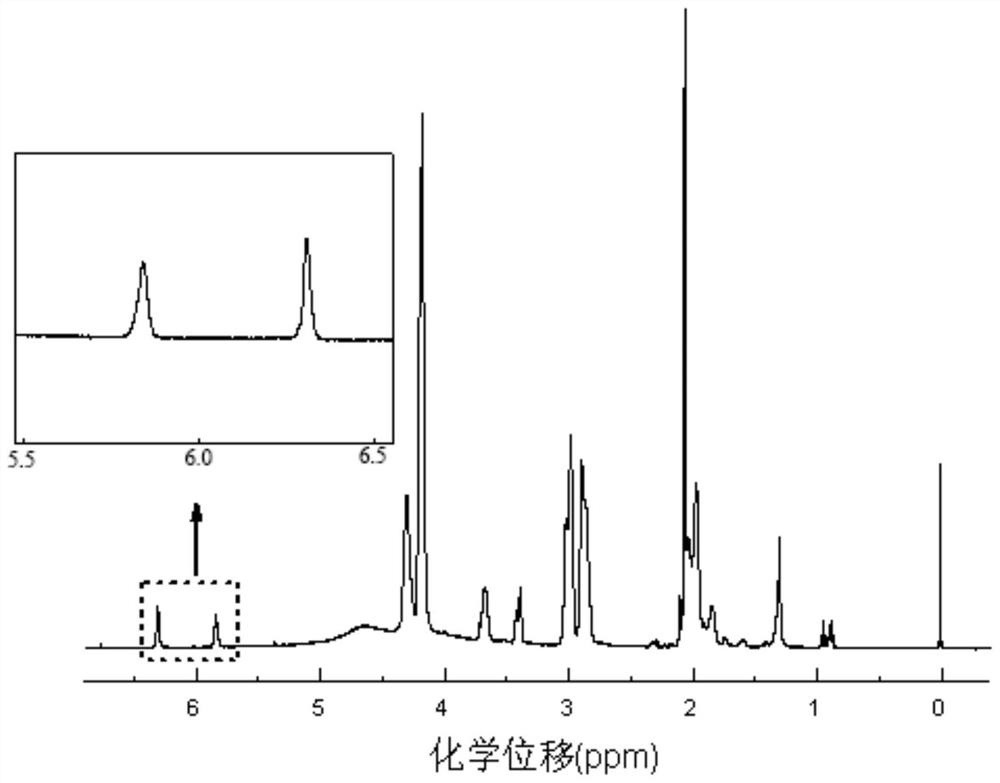

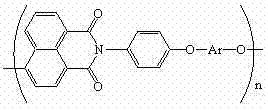

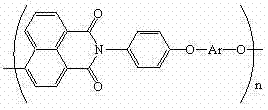

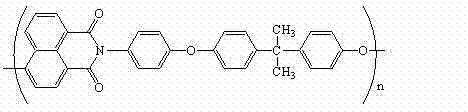

Polyarylether light-emitting material with main chain containing naphthalimide and synthesis method thereof

InactiveCN102391496BOvercoming performance degradation defectsImprove thermal stabilityLuminescent compositionsPtru catalystDisplay device

The invention belongs to the technical field of light-emitting materials of photoelectric display devices and particularly relates to a synthesis method of a polyarylether light-emitting material with a main chain containing naphthalimide. The important contents of the synthesis method are as follows: halogenated naphthalic acid anhydride and halogenated aromatic amine are used to synthesize halogenated naphthalimide monomer, and then the halogenated naphthalimide monomer and the prepared bisphenol sodium salt are subjected to nucleophilic substitution reaction to obtain the polyarylether light-emitting material with the main chain containing a naphthalimide structure. Compared with the prior art, the invention has the following advantages that the advantages of small molecules and polymers are combined; and in the preparation process of the material, the cost of raw materials is low, a metal catalyst is not needed, the process is short and the product is easy for purification. The polyarylether light-emitting material prepared by the invention has good stability and good light-emitting performance, can be dissolved in different solvents, is conveniently coated into a film, and isapplicable to manufacture of organic light-emitting devices.

Owner:SHANGHAI UNIV

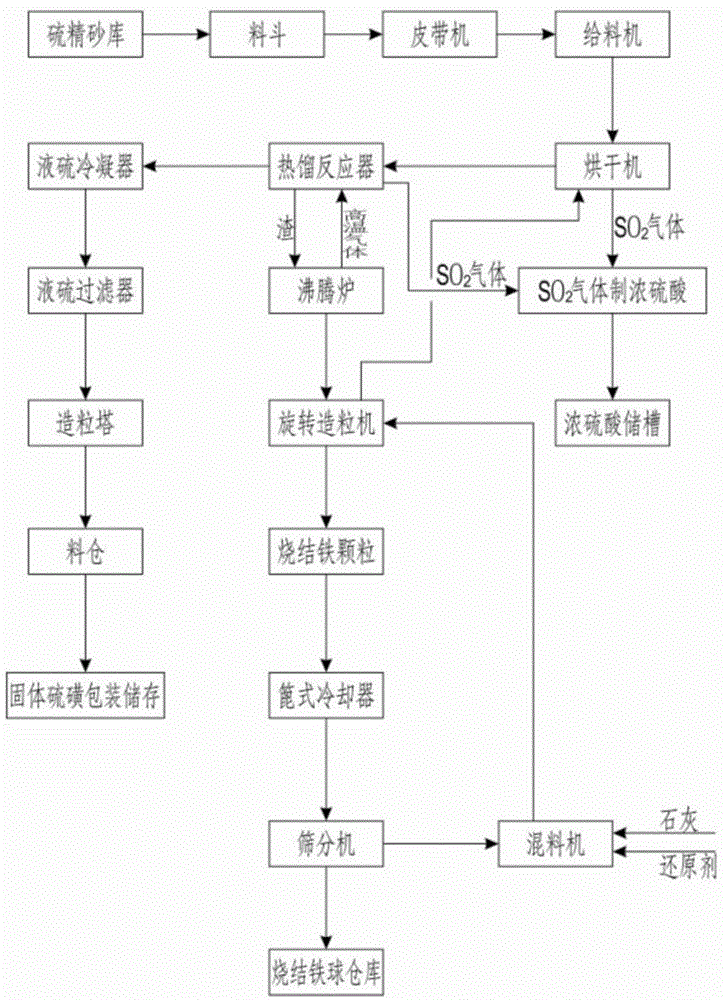

Comprehensive utilization method of pyrite concentrate and high-sulfur coal

InactiveCN106006570ANo secondary pollutionSave energyEnergy inputSulfur preparation/purificationBoiling processPyrite

The invention discloses a comprehensive utilization method of pyrite concentrate and high-sulfur coal. With pyrite concentrate as a raw material, the method comprises the following steps: extracting sulfur from pyrite concentrate by a thermal distillation process to prepare sulfur S; further desulfurizing the slag after the sulfur extraction by a boiling process to obtain SO2 gas; preparing sulfuric acid from the SO2 gas; and finally, with the desulfurized slag and high-sulfur coal as raw materials and in the presence of flux, sintering to obtain a sintered iron ball. The method turns waste into wealth and realizes mass-energy balance with the most economical technology and has a broad application prospect.

Owner:刘松

A kind of preparation method of graphene electrode in high temperature piezoelectric sensor

InactiveCN106191806BReduce transferAvoid introducingChemical vapor deposition coatingShielding gasGraphene electrode

The invention provides a method for preparing a graphene electrode in a high-temperature piezoelectric sensor. The method includes the following steps that a pretreated high-temperature piezoelectric crystal plate of the high-temperature piezoelectric sensor is placed into a plasma chemical vapor deposition cavity, the cavity is closed, and a vacuum pump is started; when air pressure inside the cavity is lowered to 10<-5> Torr or below, shielding gas and carbureted hydrogen gas are connected in to adjust the pressure intensity inside the cavity; and a vacuum reacting furnace is started for heating and warming, a plasma source is switched on to perform constant temperature deposition, and accordingly the graphene electrode can be obtained. According to the preparation method of the graphene electrode, the high-temperature piezoelectric crystal plate is used as a substrate, a small or large number of layers of graphene are grown on the surface of the crystal plate without metal catalysis as the electrode through the plasma enhanced chemical vapor deposition (PECVD) technique directly, adhesive force between a graphene thin film and the crystal plate is good, and electrical conductivity of the graphene thin film is excellent.

Owner:JIANGNAN GRAPHENE RES INST

Two-dimensional carbon nanosheet with thickness capable of being accurately controlled and preparation method thereof

ActiveCN112246266APreserve structural featuresGood repeatabilityMaterial nanotechnologyPhysical/chemical process catalystsPtru catalystFuel cells

The invention provides a two-dimensional carbon nanosheet with the thickness capable of being accurately controlled and the preparation method thereof, wherein the thickness of the carbon nanosheet with the thickness capable of being accurately controlled can be accurately controlled from 5.1 nm to 92.3 nm, and the carbon nanosheet has a high specific surface area and intrinsic nitrogen doping with atomic-scale uniform distribution. The preparation method comprises the following steps: by taking 4,4'-biphenyl diamine and 1,2,4,5-pyromellitic dianhydride as monomers, carrying out stepwise polymerization to form an amphiphilic alternating copolymer; by using the amphiphilic alternating copolymer as an assembly unit, carrying out an intramolecular imidization reaction to induce the amphiphilic alternating copolymer to perform crystallization driving self-assembly, thereby forming the polymer nanosheet of which the thickness can be accurately controlled; and calcining the polymer nanosheetin an inert atmosphere to obtain the two-dimensional carbon nanosheet with accurately controllable thickness. The two-dimensional carbon nanosheet has high specific surface area and atomic-scale uniformly distributed intrinsic nitrogen doping, can be used as a catalyst for electrocatalytic oxygen reduction, shows excellent electrocatalytic performance and can be used as a catalyst of a fuel cell.

Owner:NINGXIA UNIVERSITY

Sandwiched interlayer structure Ni(OH)2/CNTs/Ni(OH)2 composite material preparing method

InactiveCN104465120AGood lookingShape stableHybrid capacitor electrodesDouble layer capacitorsVacuum dryingNanotube

The invention discloses a sandwiched interlayer structure Ni(OH)2 / CNTs / Ni(OH)2 composite material preparing method. The method includes the following steps that polyvinyl pyrrolidone is dissolved in deionized water, and the polyvinyl pyrrolidone and the deionized water are stirred and evenly mixed; layered Ni(OH)2 materials are added in and dissolved in the solution, stirring is performed for the first time, products are collected in a centrifuging mode, vacuum drying is performed for the first time after washing is performed repeatedly, and then processed Ni(OH)2 can be obtained; the processed Ni(OH)2 and acidulated multi-wall carbon nanometer tubes are dissolved in deionized water, stirring is performed, after one night, products are collected in a centrifuging mode, vacuum drying is performed for the second time after washing is performed repeatedly, and sandwiched interlayer structure Ni(OH)2 / CNTs / Ni(OH)2 composite materials are obtained. According to the method, metal hydroxide is doped with carbon materials, and therefore not only can agglomeration of the metal hydroxide be prevented, but also the electrical conductivity and the specific capacity of the metal hydroxide can be greatly improved.

Owner:TONGJI UNIV

Preparation method for boron carbide precursor

A preparation method for a boron carbide precursor includes the steps: (1) taking borane, mono-functional olefin and bi-functional olefin in the mass ratio of 1: (0.1-20): (0.1-20); (2) adding the mono-functional olefin or / and the bi-functional olefin into a reactor with stirring and distilling devices, repeatedly vacuumizing and filling dried nitrogen into the reactor for at least three times, and pre-cooling the reactor to the temperature ranging from -2 DEG C to -35 DEG C; (3) adding the borane, and continuously carrying out stirring reaction at the room temperature under the protection of the N2 atmosphere, wherein the stirring rate is 60-240r / min, and reaction time ranges from 2h to 72h; and (4) increasing the temperature of the system at the temperature rise rate of 0.1-30 DEG C / min to 30-400 DEG C, removing solvent composition in the system by means of reduced pressure distillation, and cooling to the room temperature so that the boron carbide precursor is prepared. The preparation method for the boron carbide precursor is low in production cost, and the boron carbide precursor prepared by the method is good in solubility and high in productivity.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method for acetophenone

InactiveCN100522911CLower synthesis costThe synthesis method is simpleOrganic compound preparationCarbonyl compound preparationOrganic synthesisRoom temperature

Owner:EAST CHINA NORMAL UNIV

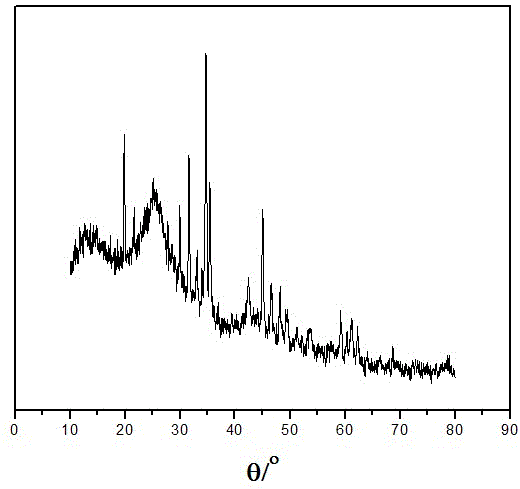

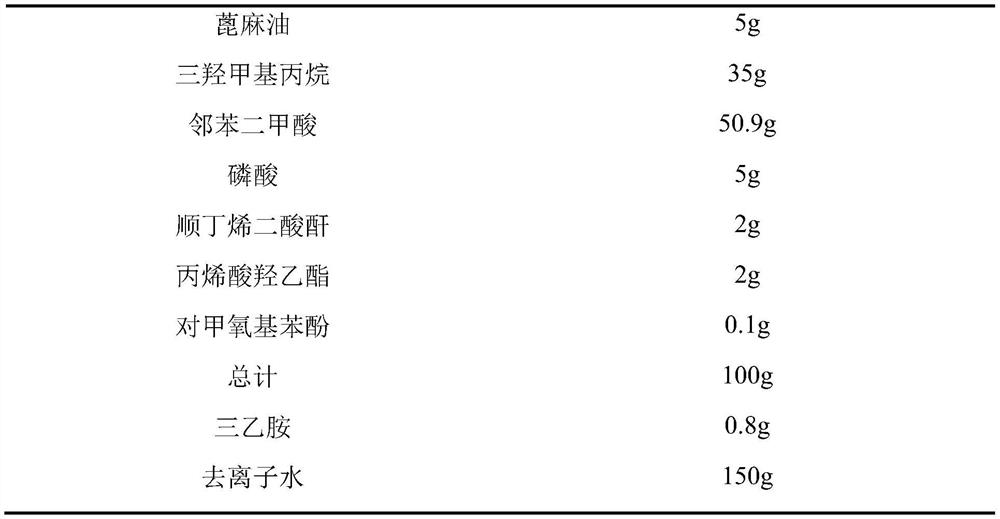

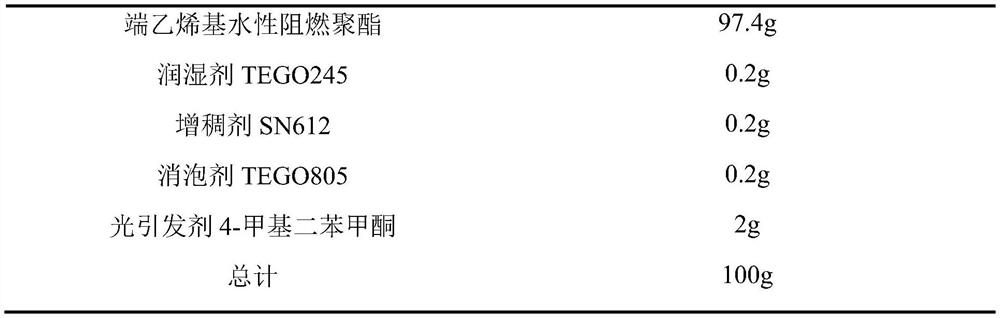

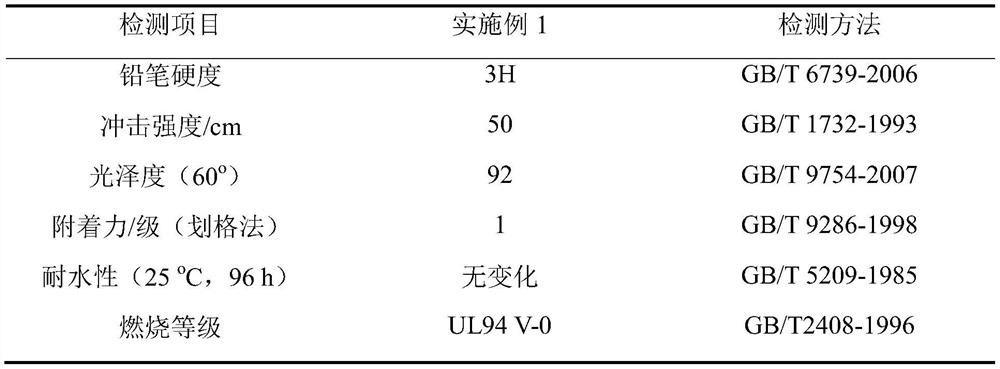

A kind of synthetic method for uv-led cured terminal vinyl water-based flame-retardant polyester

ActiveCN110294840BReduce hydrogen bondingLow viscosityFireproof paintsPolyester coatingsPolyesterPolymer science

Owner:CHINA THREE GORGES UNIV +1

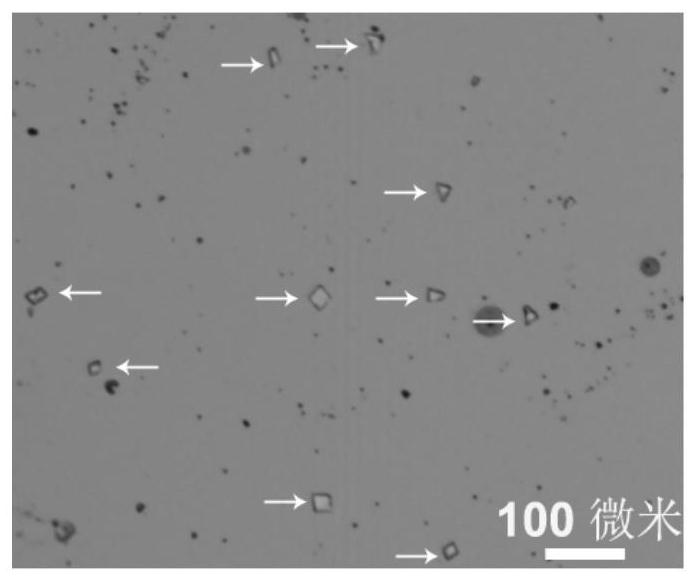

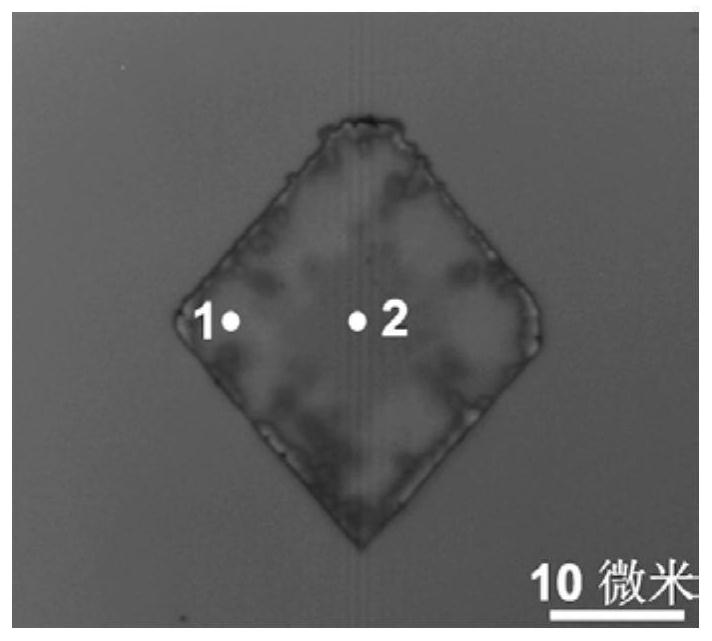

Preparation method of two-dimensional rhenium sulfide-molybdenum sulfide vertical heterostructure

PendingCN114420567AAchieve growthLow costSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionChemical vapor deposition

The invention discloses a preparation method of a two-dimensional rhenium sulfide-molybdenum sulfide vertical heterostructure, which comprises the following steps: by adopting a chemical vapor deposition method, taking Si / SiO2 as a substrate, taking a metal rhenium foil (Re) as a rhenium source, taking a metal molybdenum foil (Mo) as a molybdenum source, flatly laying the metal rhenium foil on the surface of one end of the metal molybdenum foil, inversely buckling the substrate on the metal molybdenum foil, and reacting with sulfur vapor to obtain the two-dimensional rhenium sulfide-molybdenum sulfide vertical heterostructure. A two-dimensional ReS2 / MoS2 vertical heterostructure with multiple layers of ReS2 as a bottom layer and double layers of MoS2 as a top layer is prepared on a substrate. The obtained two-dimensional ReS2 / MoS2 vertical heterojunction material is a crystal formed by stacking two crystals with different sizes, shows a remarkable luminescent property, can be used as a channel material of a transistor to be applied to the field of ultrathin electronic devices, and has potential application in the field of efficient light detectors.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com