Sandwiched interlayer structure Ni(OH)2/CNTs/Ni(OH)2 composite material preparing method

A technology of sandwich structure and composite material, which is applied in the directions of double-layer capacitors, hybrid capacitor electrodes, electrolytic capacitors, etc., can solve the problems of high electronic conductivity, low capacity and energy density, and large specific surface area of carbon materials, and achieves simple process, The effect of improving conductivity, specific capacity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

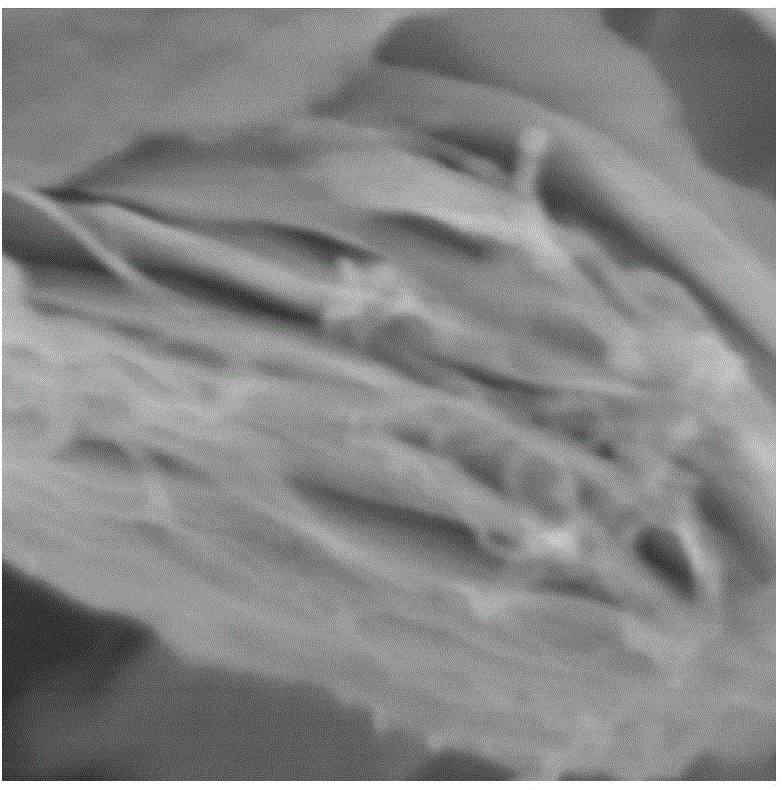

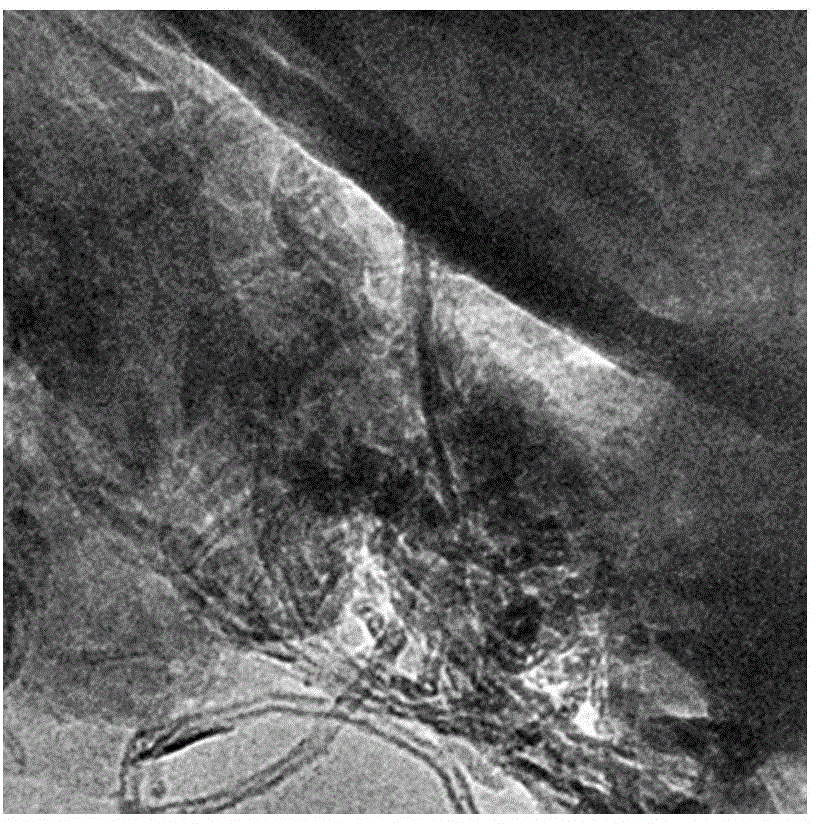

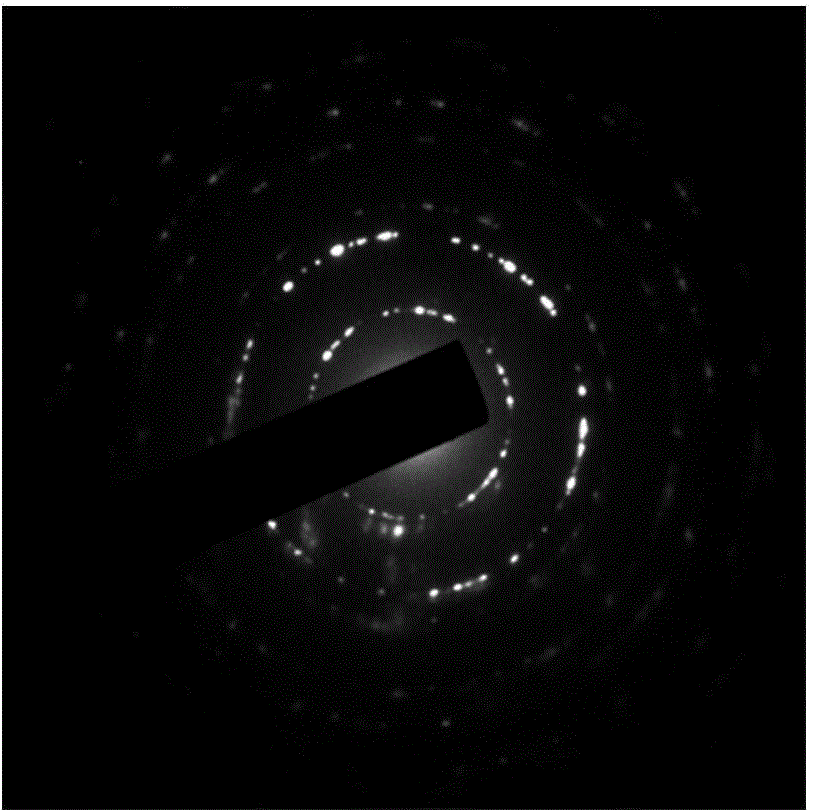

[0041] 1) Layered Ni(OH) 2 synthesis of structures

[0042] The first step, accurately weigh 0.03565g NiCl 2 ·6H 2 O, dissolved in 5mL oleylamine and 5mL octylamine mixed solution, NiCl 2 ·6H 2 The concentration of O dispersed in the mixed solution of oleylamine and octylamine is 0.015mol / L; the volume ratio of oleylamine to octylamine is 1:1; a 50mL round bottom flask equipped with a magnetic stirrer, a reflux condenser, and a thermometer is placed In an oil bath, heat under reflux at 120°C for 2h in an oil bath, and cool to room temperature naturally.

[0043] The second step, accurately weigh 0.1349g KBH 4 , dissolved in 50mL deionized water and mixed well. Draw 10mL KBH with a syringe 4 solution, slowly dropwise added to the above solution, and then let stand for 48h. KBH 4 The concentration of the solution is 0.05mol / L; the solution changes from the initial light blue to colorless, and a light green precipitate is obtained at the oil-water two-phase interface, wh...

Embodiment 2

[0055] Layered Ni(OH) 2 The preparation method of material comprises the following steps:

[0056] NiCl 2 ·6H 2 O dissolved in the mixed solution of oleylamine and octylamine, NiCl 2 ·6H 2 The concentration of O dispersed in the mixed solution of oleylamine and octylamine is 0.01mol / L; the volume ratio of oleylamine to octylamine is 1:1; heating to reflux, the heating temperature is 120 °C, and the reflux time is 2h; naturally cool to Room temperature; add KBH at a concentration of 0.03mol / L 4 The solution was washed repeatedly after standing, and the standing time was 30h; repeated washing refers to alternating washing with absolute ethanol and deionized water, and vacuum drying at a temperature of 50°C for 15h to obtain layered Ni(OH) 2 Material.

[0057] The preparation method of acidified multi-walled carbon nanotubes comprises the following steps:

[0058] Dissolving multi-walled carbon nanotubes in H 2 SO 4 and HNO 3 In the mixed solution, multi-walled carbon n...

Embodiment 3

[0062] Layered Ni(OH) 2 The preparation method of material comprises the following steps:

[0063] NiCl 2 ·6H 2 O dissolved in the mixed solution of oleylamine and octylamine, NiCl 2 ·6H 2 The concentration of O dispersed in the mixed solution of oleylamine and octylamine is 0.02mol / L; the volume ratio of oleylamine to octylamine is 1:1.5; heating to reflux, the heating temperature is 120°C, and the reflux time is 2h; naturally cool to Room temperature; add KBH with a concentration of 0.04mol / L 4 The solution was washed repeatedly after standing still, and the standing time was 60h; repeated washing refers to alternating washing with absolute ethanol and deionized water, and vacuum drying at a temperature of 80°C for 10h to obtain layered Ni(OH) 2 Material.

[0064] The preparation method of acidified multi-walled carbon nanotubes comprises the following steps:

[0065] Dissolving multi-walled carbon nanotubes in H 2 SO 4 and HNO 3 In the mixed solution, multi-walled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com