Comprehensive utilization method of pyrite concentrate and high-sulfur coal

A technology for sulfur concentrate and high-sulfur coal, which is applied in the fields of sulfur compounds, chemical instruments and methods, and sulfur preparation/purification, etc., can solve the problems of waste tailings, waste of resources, increase the cost of coal enterprises, etc., and achieve economic benefits. Good and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

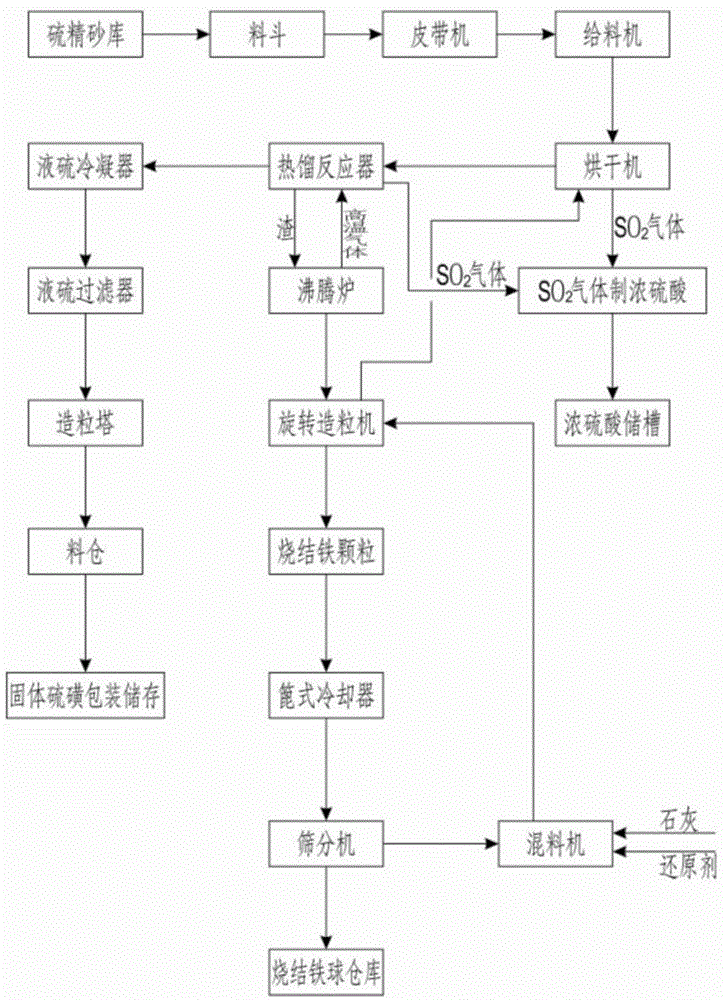

[0018] see figure 1 Summary of the invention: the present invention is a kind of comprehensive utilization method of sulfur fine sand and high-sulfur coal, and its purpose is to utilize sulfur fine sand and high-sulfur coal to prepare sulfur, sulfuric acid and high-quality ironmaking raw materials (sintered iron balls).

[0019] Technical solution of the present invention comprises following processing step:

[0020] 1. Sulfur concentrate is fed, transported, and dehydrated by a dryer to form dry powder sulfur concentrate.

[0021] 2. The dry powder sulfur concentrate is sent to the dry powder silo by the bucket elevator.

[0022] 3. The outlet of the silo is sent to the thermal distillation reactor by a speed-regulating screw conveyor.

[0023] 4. The thermal distillation reactor reacts and distills gaseous sulfur at a temperature of 700-900°C and condenses it into liquid sulfur through a liquid sulfur condenser.

[0024] 5. The liquid sulfur is refined by a special liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com