Patents

Literature

203 results about "Mass energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

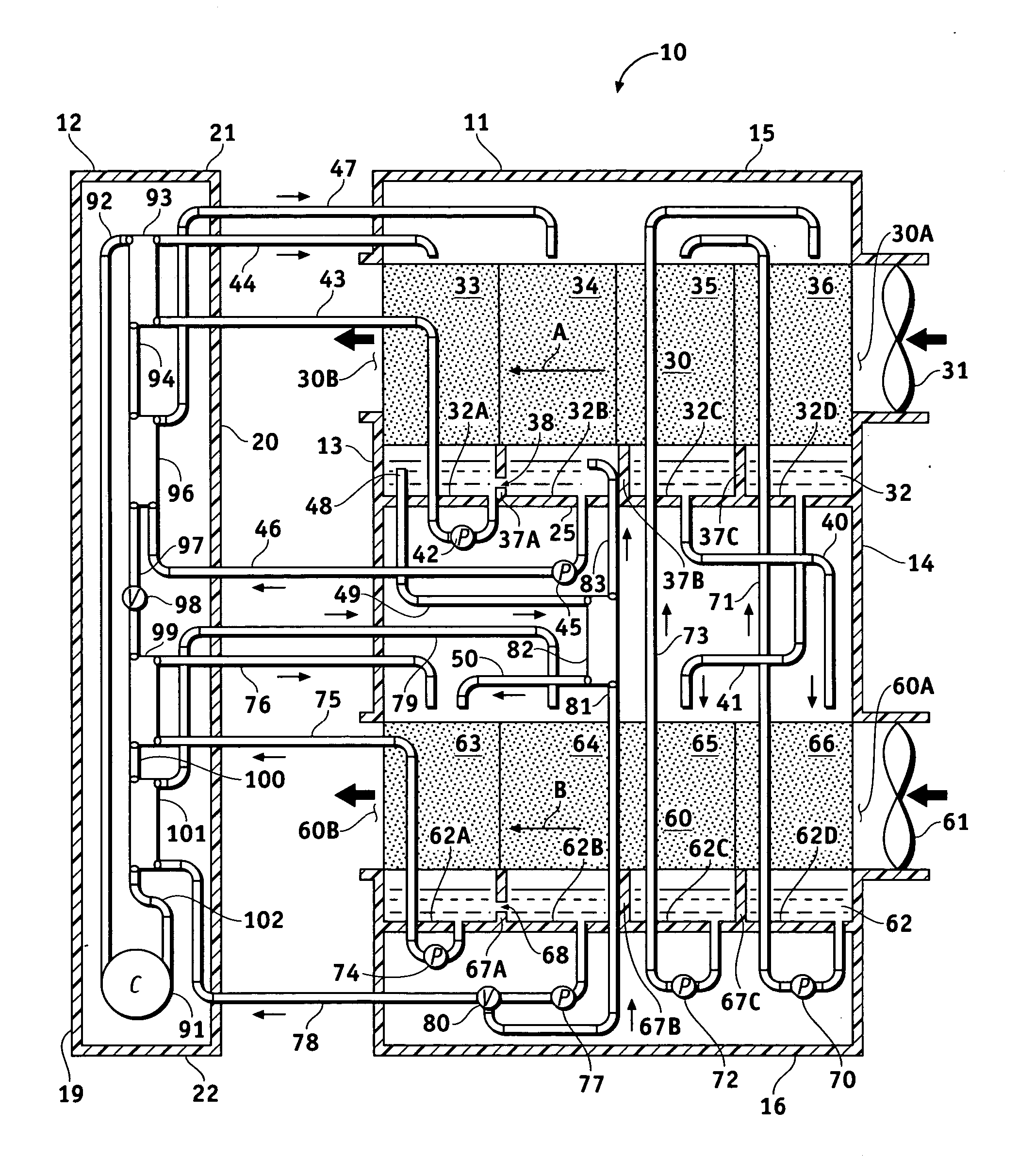

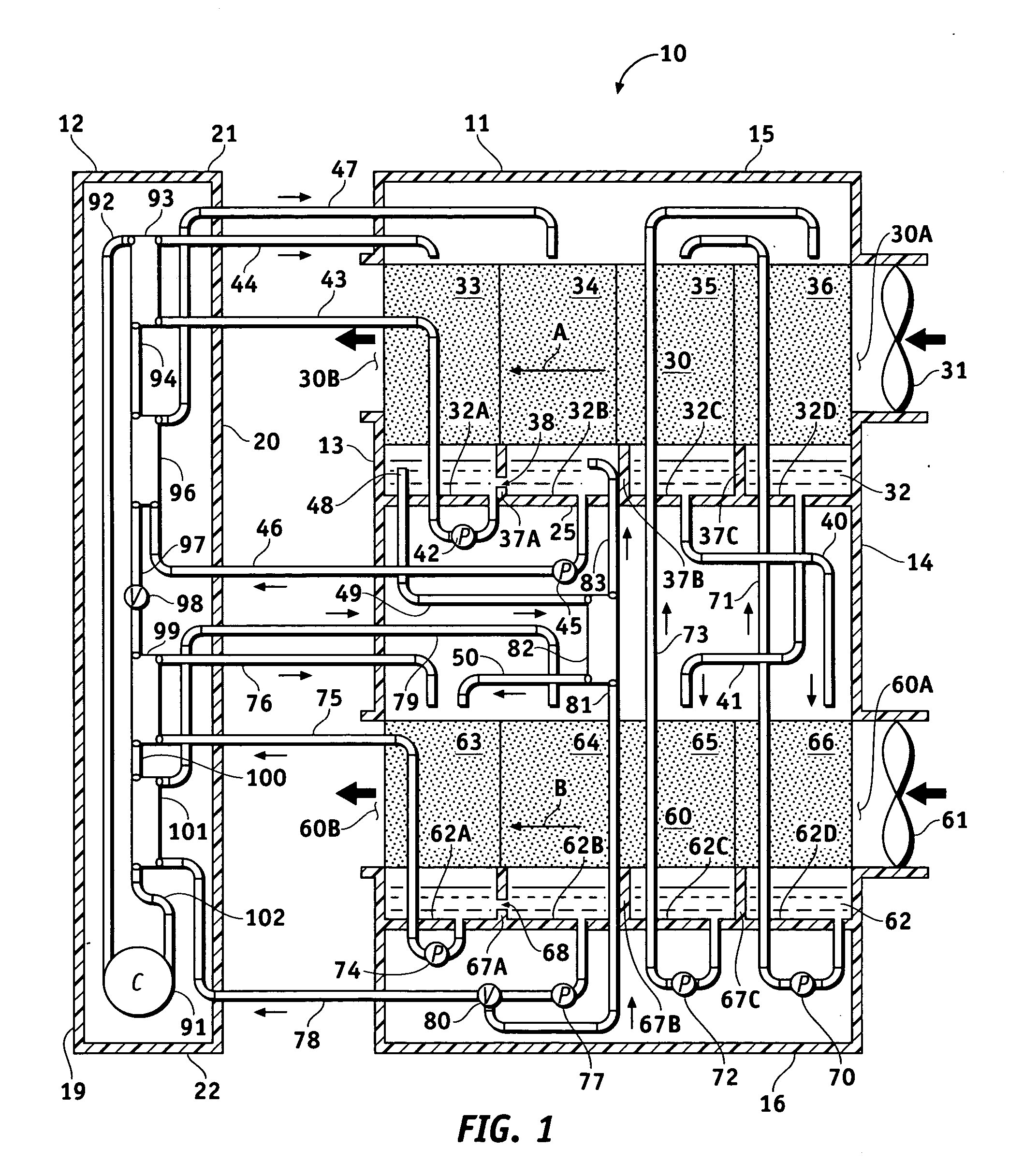

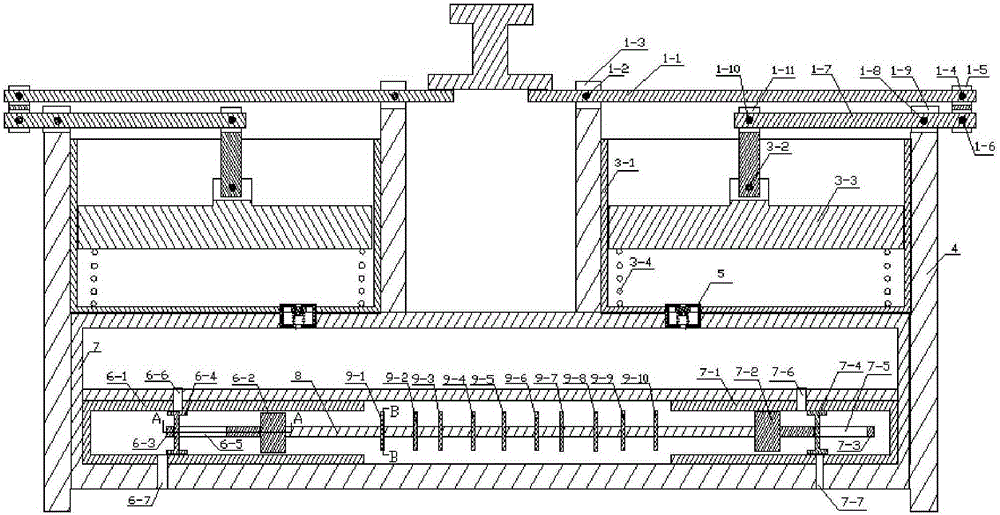

Systems and methods for conditioning air and transferring heat and mass between airflows

An air conditioning system includes a first chamber having a plurality of first sectors, a second chamber having a plurality of second sectors, a first airflow device forming a first airflow through the first chamber, a second airflow device forming a second airflow through the second chamber, and a heat and mass transfer substance flowing in a plurality of the first and second sectors, the substance interacting with the first and second airflows through the first and second chambers. Thermal inducement apparatus thermally interacts with the substance establishing a thermal gradient between the first sectors and a thermal gradient between the second sectors providing a heat and mass energy gradient for the first airflow through the first sectors and a reversed heat and mass energy gradient for the second airflow through the second sectors. Plumbing is provided, which moves the substance throughout the system.

Owner:ALBERS WALTER F +1

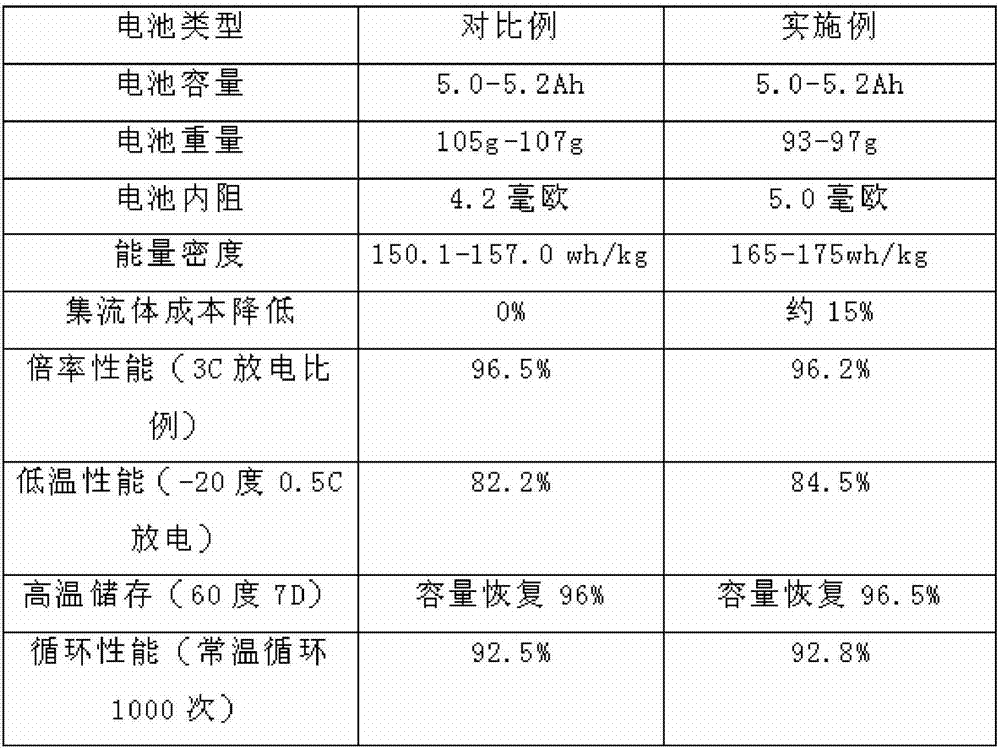

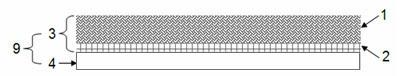

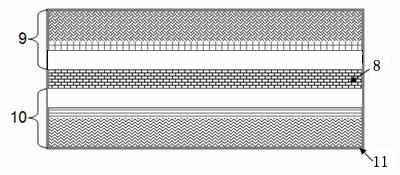

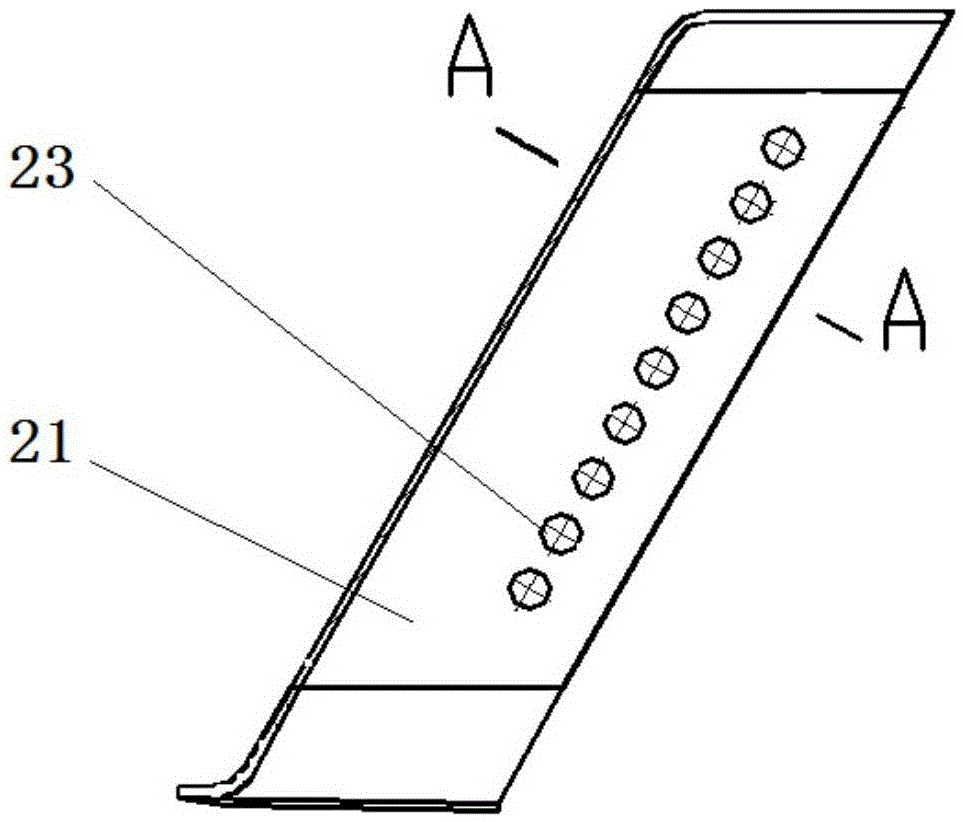

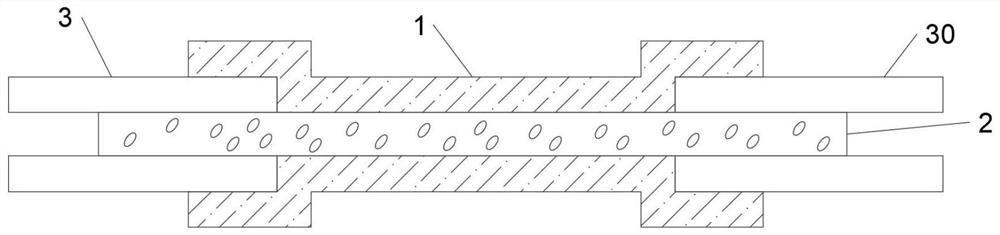

Composite current collector, and lithium ion secondary battery applying current collector

InactiveCN107221676AReduce weightHigh tensile strengthElectrode carriers/collectorsElectrolysisLithium-ion battery

The invention discloses a current collector, and an application of the current collector in a lithium ion battery, and concretely relates to a composite current collector, and a lithium ion secondary battery applying the current collector. The composite current collector comprises an upper metal layer, a lower metal layer and a nonmetal layer arranged between the upper metal layer and the lower metal layer, vacuum electroplating, electrolytic electroplating or composite bonding compounding is carried out between the upper metal layer and the nonmetal layer and between the nonmetal layer and the lower metal layer, and the thickness of the nonmetal layer is controlled to be 2-20 [mu]m; and the thickness of each of the upper metal layer and the lower metal layer is controlled to be 1-10 [mu]m. The above structure reduces the weight of the current collector and guarantees that the composite current collector have excellent tensile strength and excellent flexibility; the outer layer of the current collector is the metal layer, and has a conductive effect; and the above reasonable structure design substantially improves the mass energy density of the produced lithium ion secondary battery and effectively prolongs the cycle life of the battery.

Owner:JIANGSU DAOYING TECH CO LTD

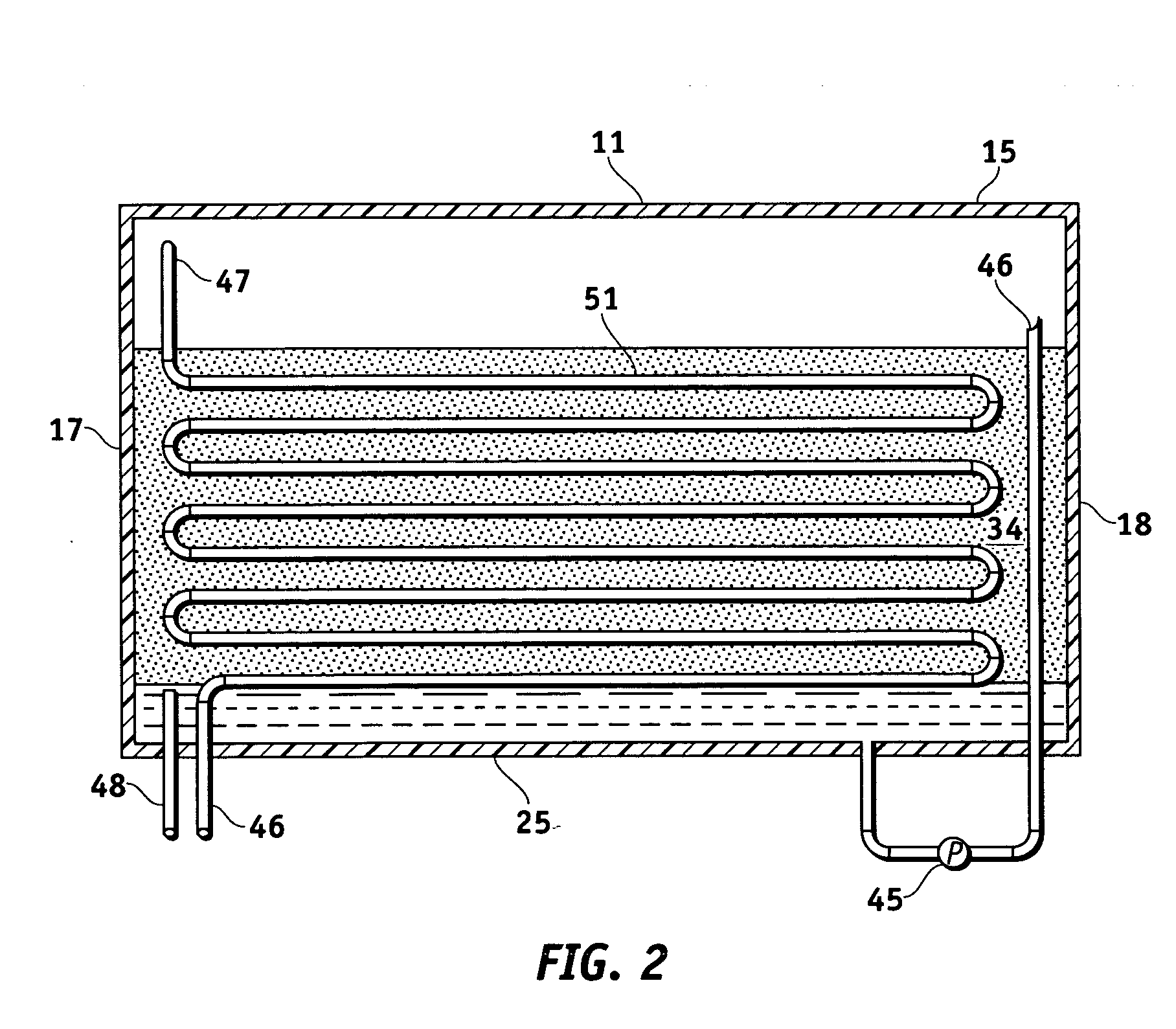

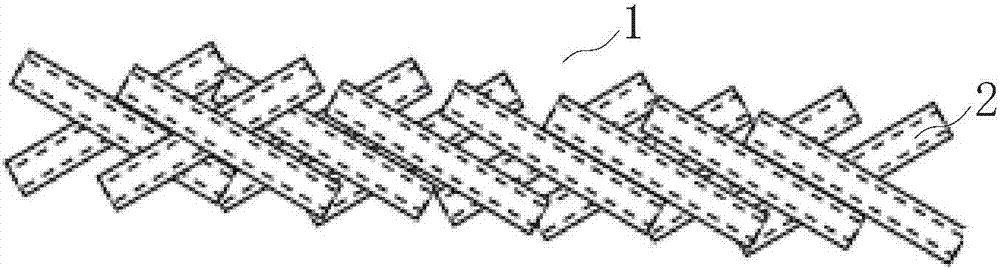

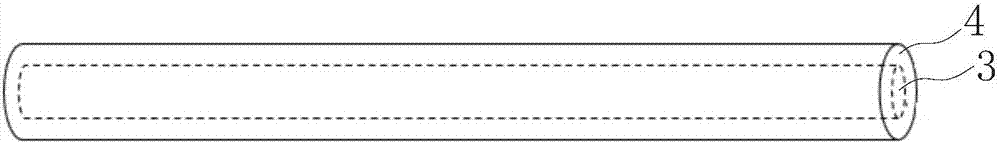

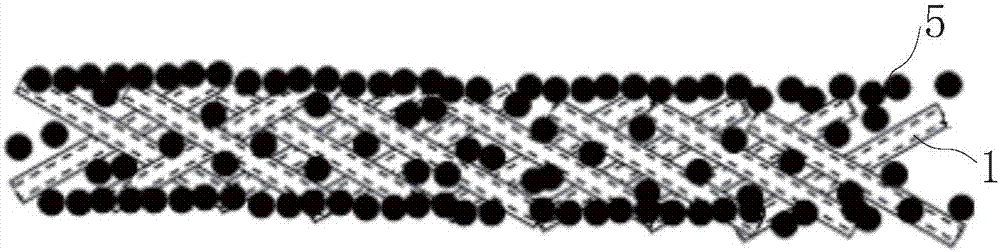

Flexible current collector, electrode containing flexible current collector, and battery

InactiveCN106898729AReduce interfacial internal resistanceIncrease productivityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesFiberInternal resistance

The invention discloses a flexible current collector, an electrode containing the flexible current collector, and a battery. The flexible current collector comprises a textile fabric base and a metal conductive coating; the fiber of the textile fabric is coated with the metal conductive coating; the thickness of the metal conductive coating is 200 nm to 5 microns. An electrode active material of the electrode containing the flexible current collector is loaded on the surface and / or in the hole of the flexible current collector. By adoption of the battery prepared from the electrode provided by the invention, the interface resistance of the battery can be effectively reduced, the electrode mass of unit area is reduced, and the mass energy density is improved; the flexible current collector provided by the invention has higher machining property relative to that of the traditional metal foil, so the production efficiency of the battery can be improved, and the production cost of the battery can be reduced; the current collector base is a macromolecular material and can be shrunk and fused at high temperature, so the safety performance of the battery is improved.

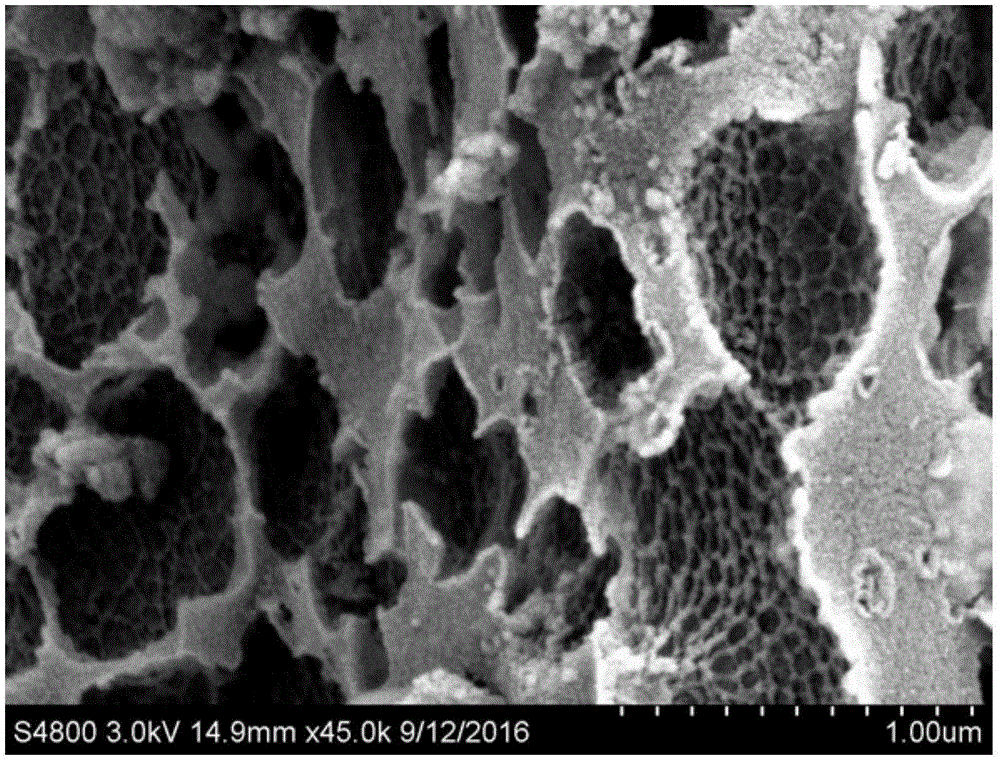

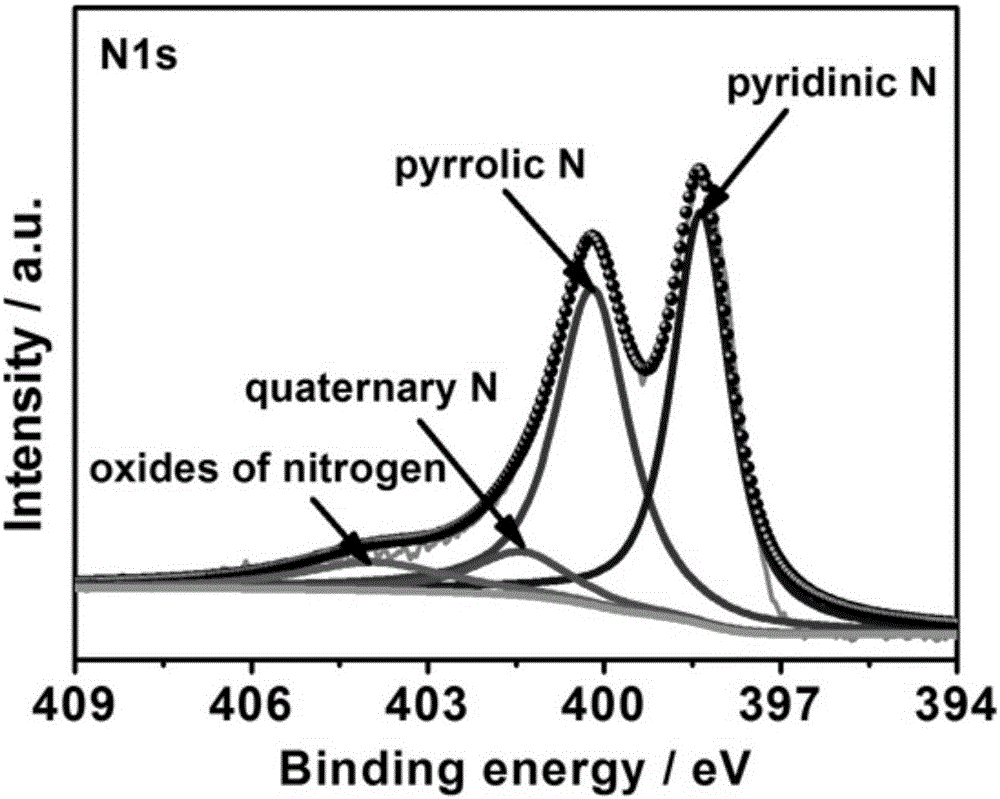

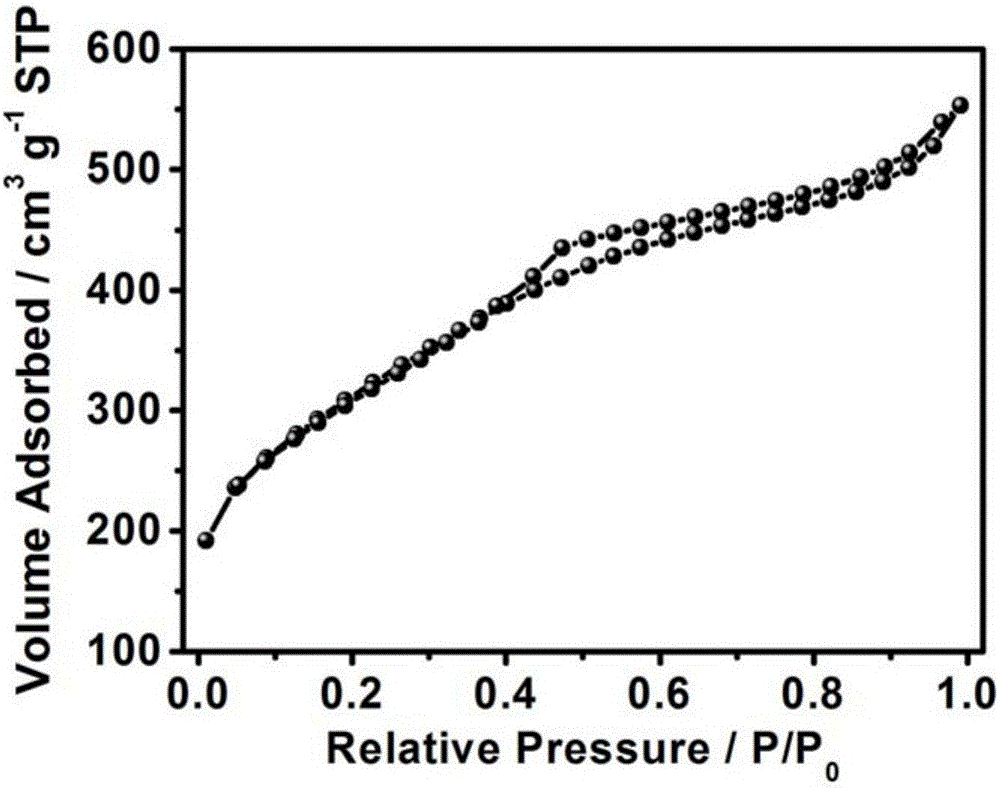

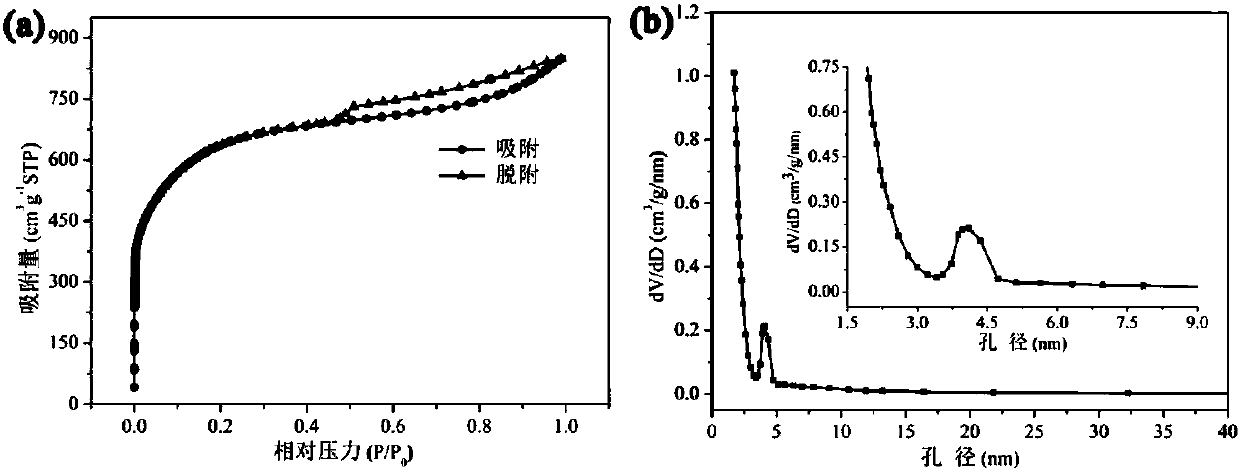

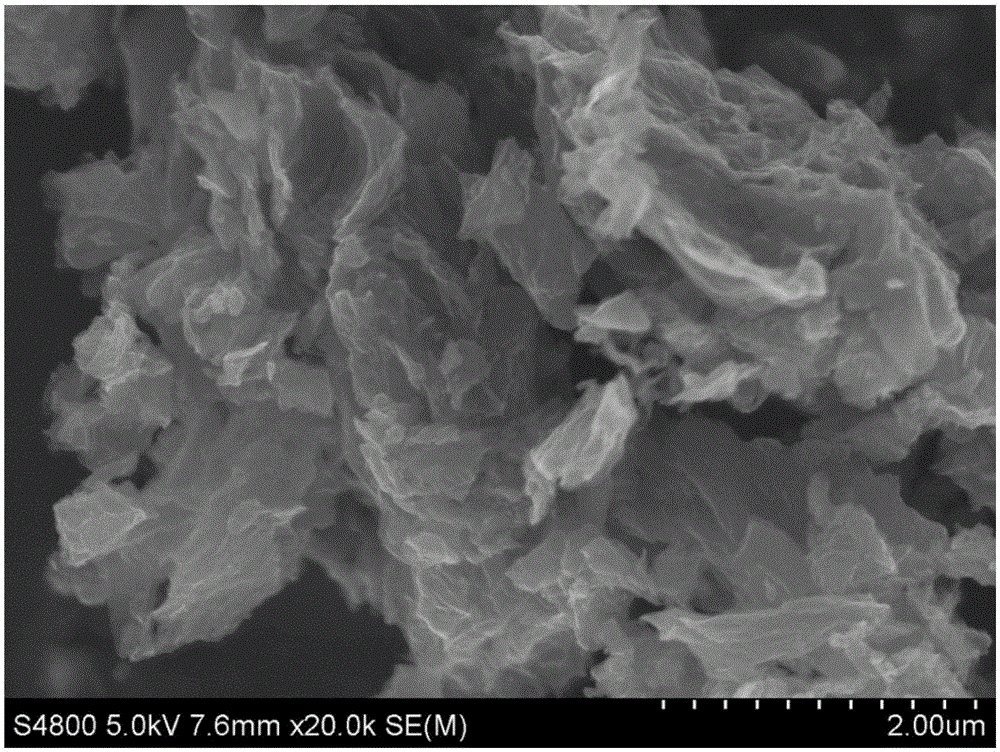

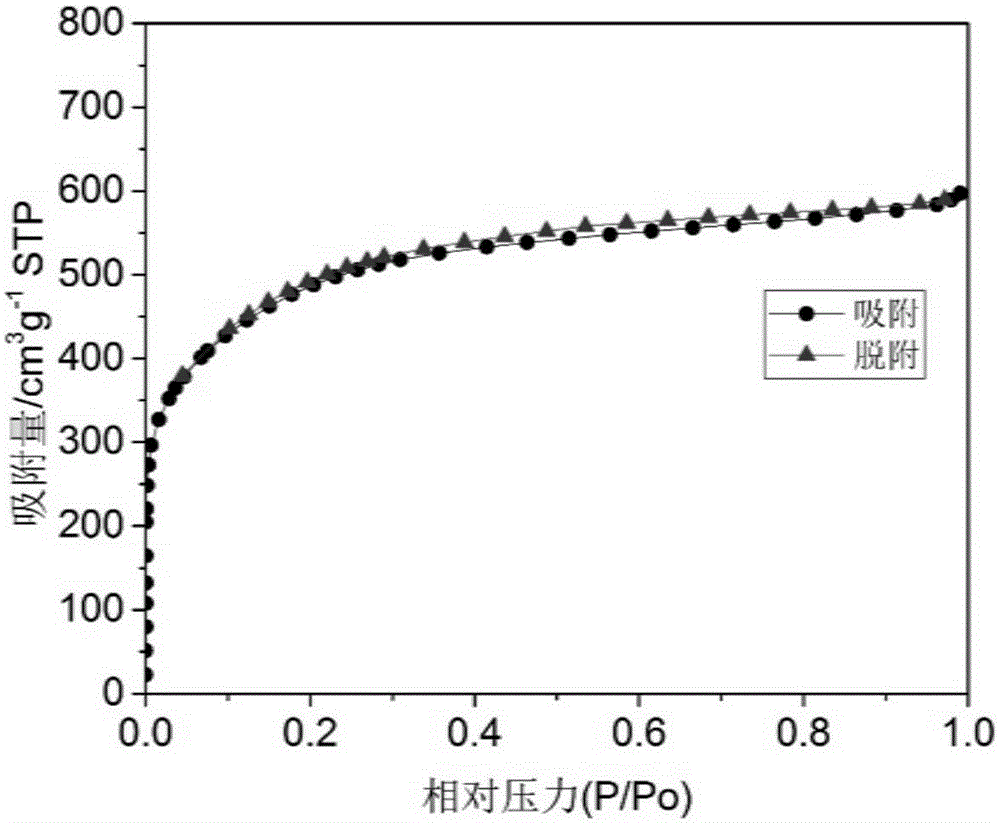

Nitrogen-doped porous carbon and preparation method as well as application of nitrogen-doped porous carbon to super-capacitor electrode material

ActiveCN106629724ALarge specific surface areaImprove pore utilizationCarbon compoundsHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses nitrogen-doped porous carbon and a preparation method as well as application of the nitrogen-doped porous carbon to a super-capacitor electrode material and belongs to the technical field of energy source materials and application. The nitrogen-doped porous carbon is prepared by taking natural waste products, namely peanut shells, as raw materials through steps of carrying out ball milling, sieving, carrying out high-temperature activation and washing. The nitrogen-doped porous carbon prepared by the invention has graded pores including micro-pores and medium pores; a main pore diameter range is 2nm to 5nm, the specific surface area is 1000 square meters per gram to 1200 square meters per gram, the nitrogen mass ratio is 8 percent to 10 percent and the mass specific capacitance is 290 Faraday per gram to 310 Faraday per gram; the mass energy density of a nitrogen-doped porous carbon based super-capacitor prepared from the nitrogen-doped porous carbon is 40 watt-hour per kilogram to 43 watt-hour per kilogram; the nitrogen-doped porous carbon has excellent circulating stability so that the nitrogen-doped porous carbon can be better applied to the field of super-capacitor electrodes.

Owner:ANHUI UNIVERSITY

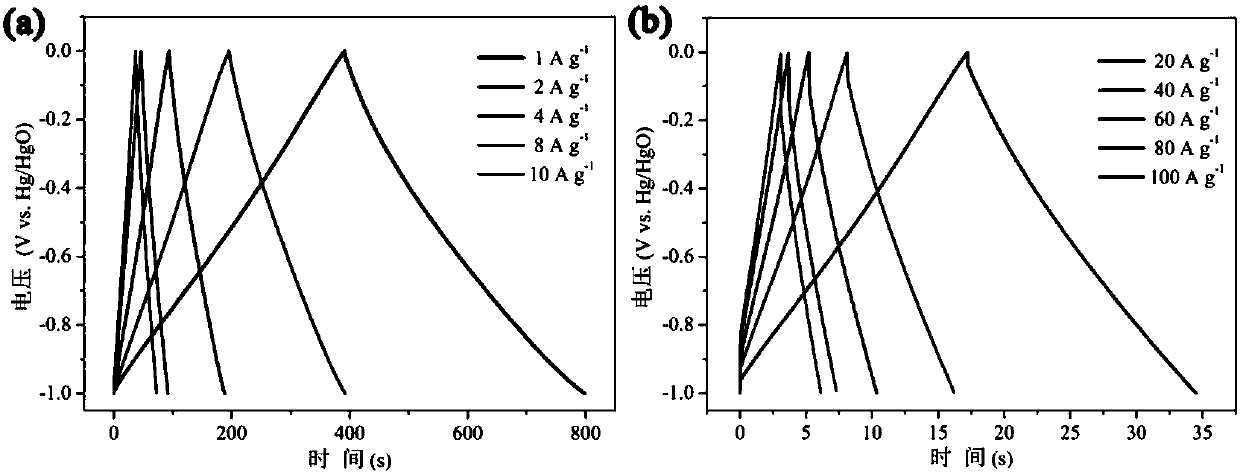

Nitrogen and sulfur co-doped hierarchical porous carbon composite material, and preparation method and application thereof

InactiveCN110627033AWidely distributedRich sourcesHybrid capacitor electrodesCarbon preparation/purificationCapacitanceCarbon composites

The invention discloses a nitrogen and sulfur co-doped hierarchical porous carbon composite material, and a preparation method and an application thereof, and belongs to the technical field of supercapacitor electrode materials. A natural polymer material which is abundant in the nature, low in price and easy to obtain is used as a carbon source, graphene oxide is added to improve the conductivity, an activator and a doping agent are added in advance, and a general two-step technology (high-temperature carbonization and chemical activation) for preparing a carbon material is simplified into one-step high-temperature annealing, so that the carbon material with a high specific surface area and a hierarchical porous three-dimensional structure is obtained; and nitrogen and sulfur doping improves the electrochemical performances of the material. The composite carbon material has the advantages of high mass specific capacitance, excellent high-current rate capability, ultra-long cycle life,high mass energy density and high power density when used as a high-performance electrode material for a supercapacitor. The preparation method has the advantages of simplicity, feasibility, low requirements on reaction deices, environmental friendliness, and suitableness for industrial production.

Owner:WUHAN UNIV

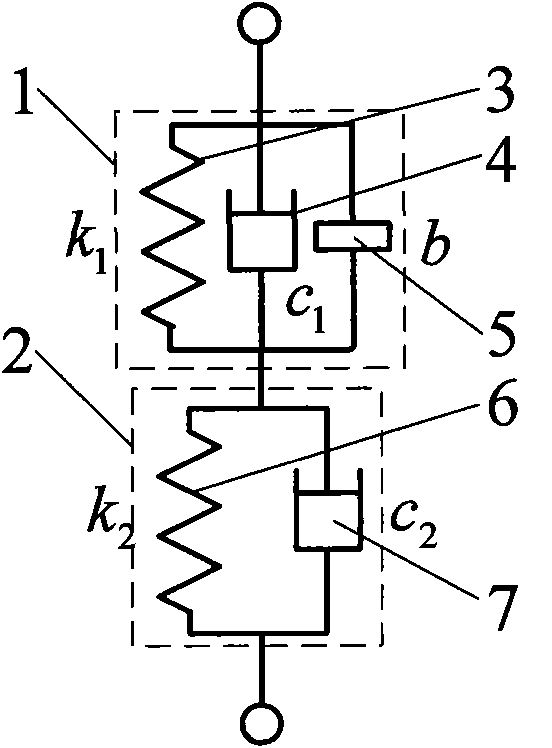

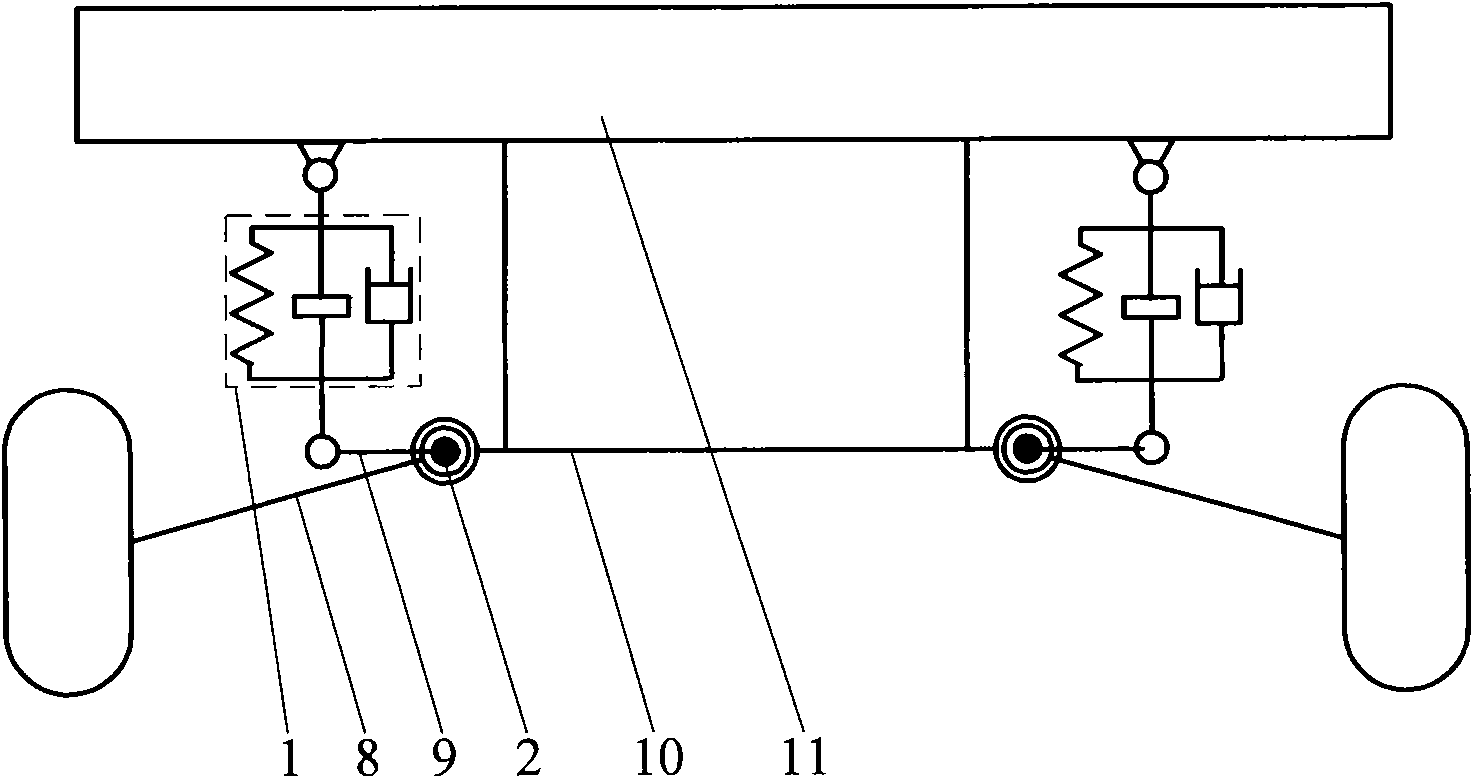

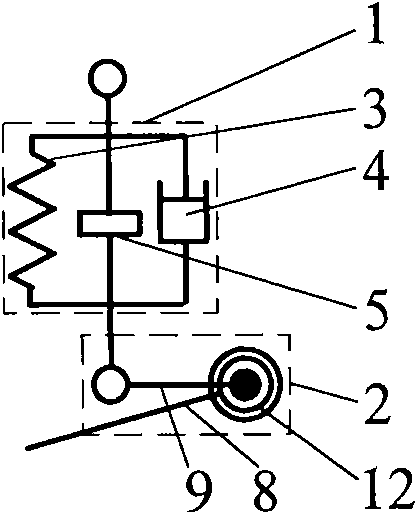

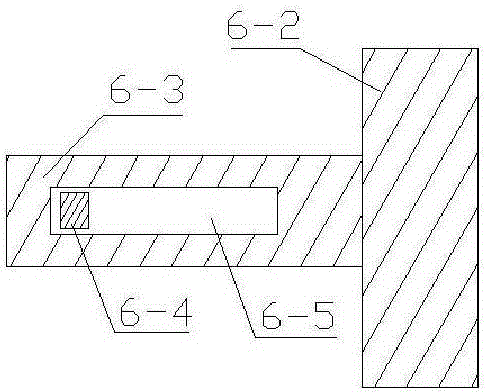

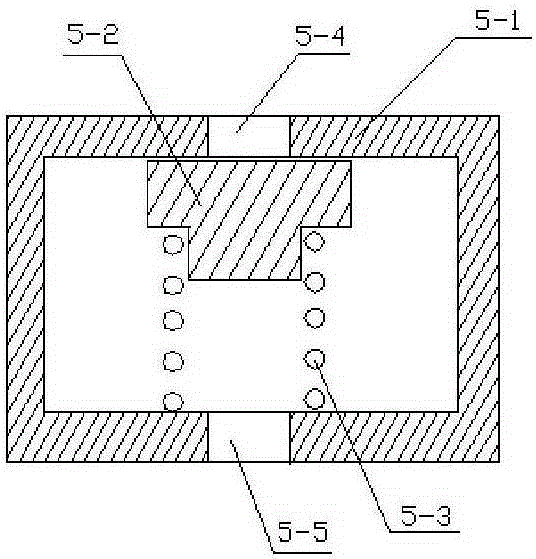

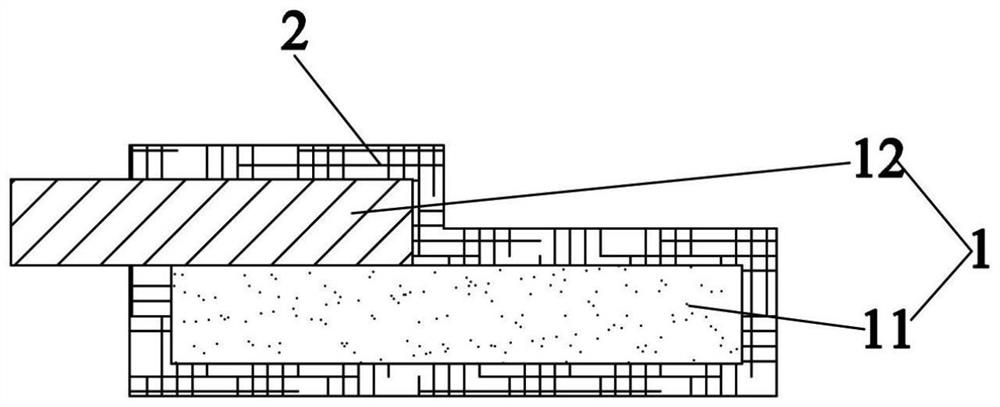

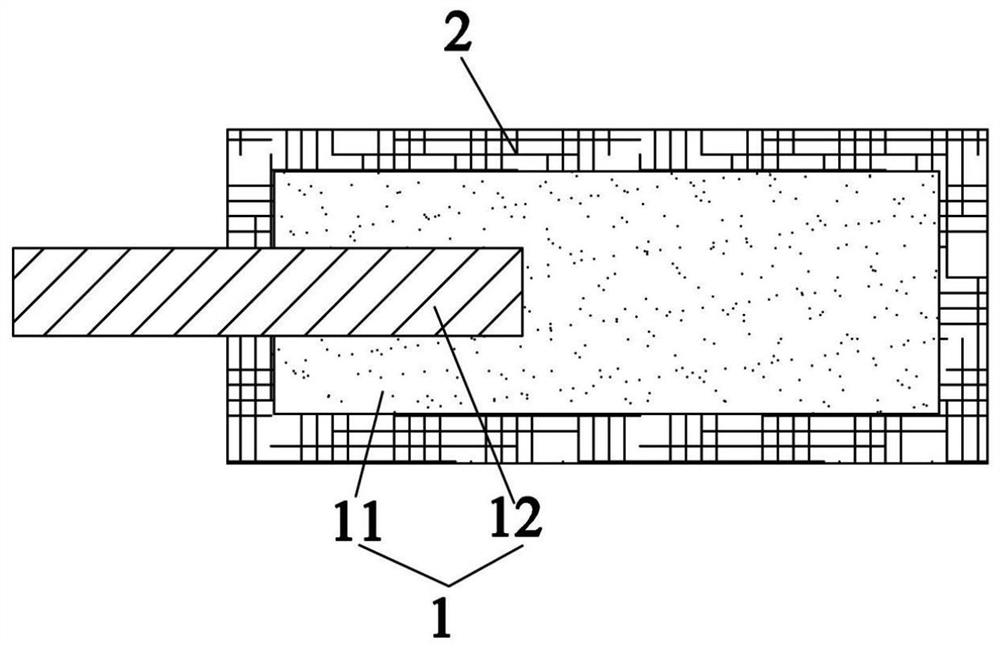

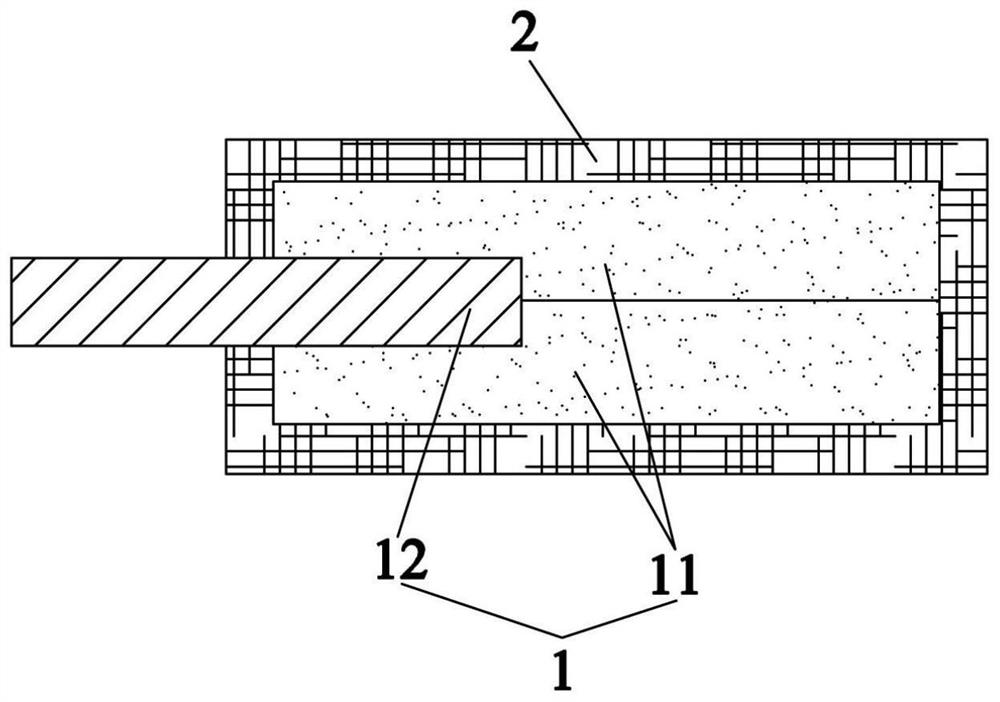

Inertial mass energy-accumulation type vehicle suspension

InactiveCN101961975ASmall footprintCompact structureResilient suspensionsInertial massControl theory

The invention discloses an inertial mass energy-accumulation type vehicle suspension, relating to the technical field of vehicle suspensions. The inertia mass energy storage type vehicle suspension is characterized by comprising a vehicle vibration isolator (1) and a wheel vibration isolator (2), wherein the vehicle body vibration isolator (1) comprises a spring A (3), a damper A (4) and an inertial mass energy accumulator (5), the spring A (3), the damper A (4) and the inertial mass energy accumulator (5) are connected in parallel; the wheel vibration isolator (2) comprises a spring B (6) and a damper B (7), and the spring B (6) and the damper B (7) are connected in parallel; and the vehicle body vibration isolator (1) and the wheel vibration isolator (2) are connected in series. The invention not only greatly improves the sitting comfortableness of vehicles, but also improves the driving safety and greatly promotes the overall properties of the suspension. The invention has the advantages of compact structure, small occupying area, easy arrangement, low cost, high reliability, and no needs of complicated controllers, control strategies, electronic elements and energy input.

Owner:JIANGSU UNIV

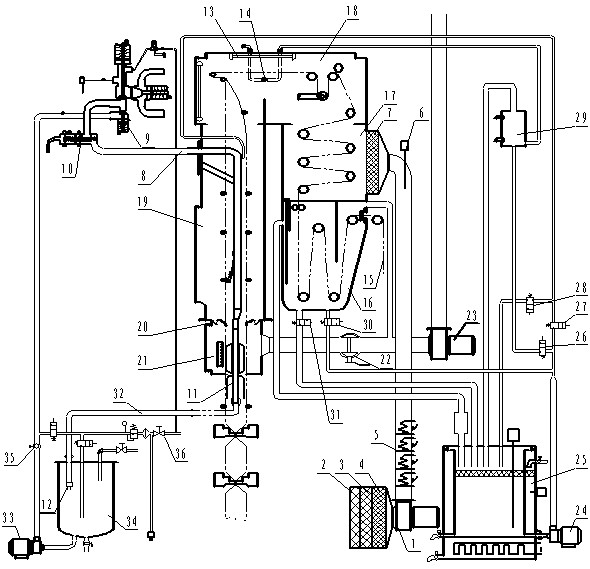

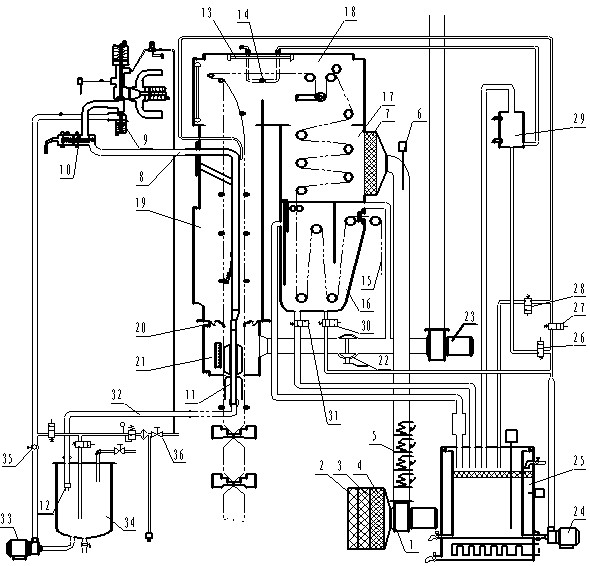

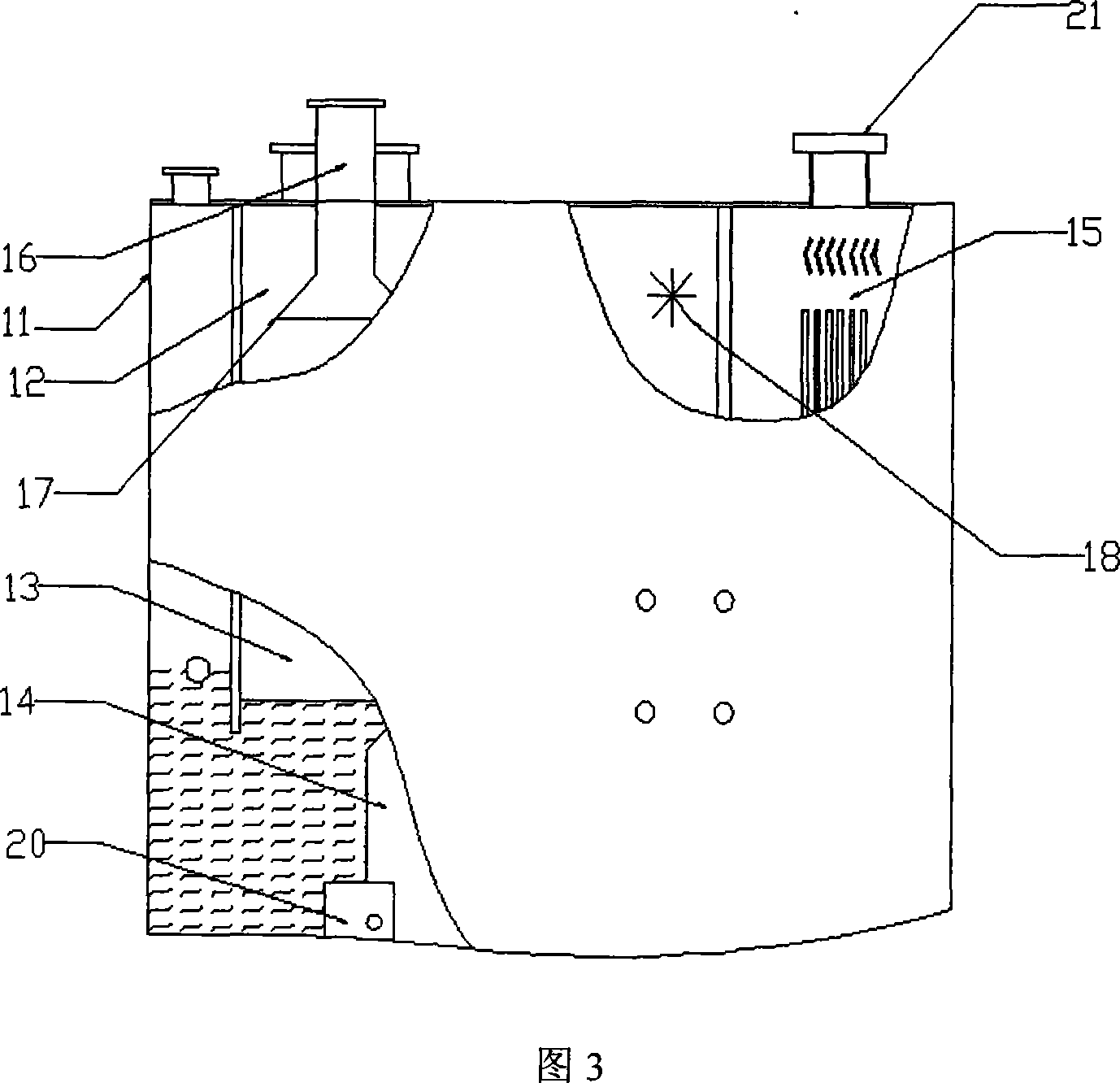

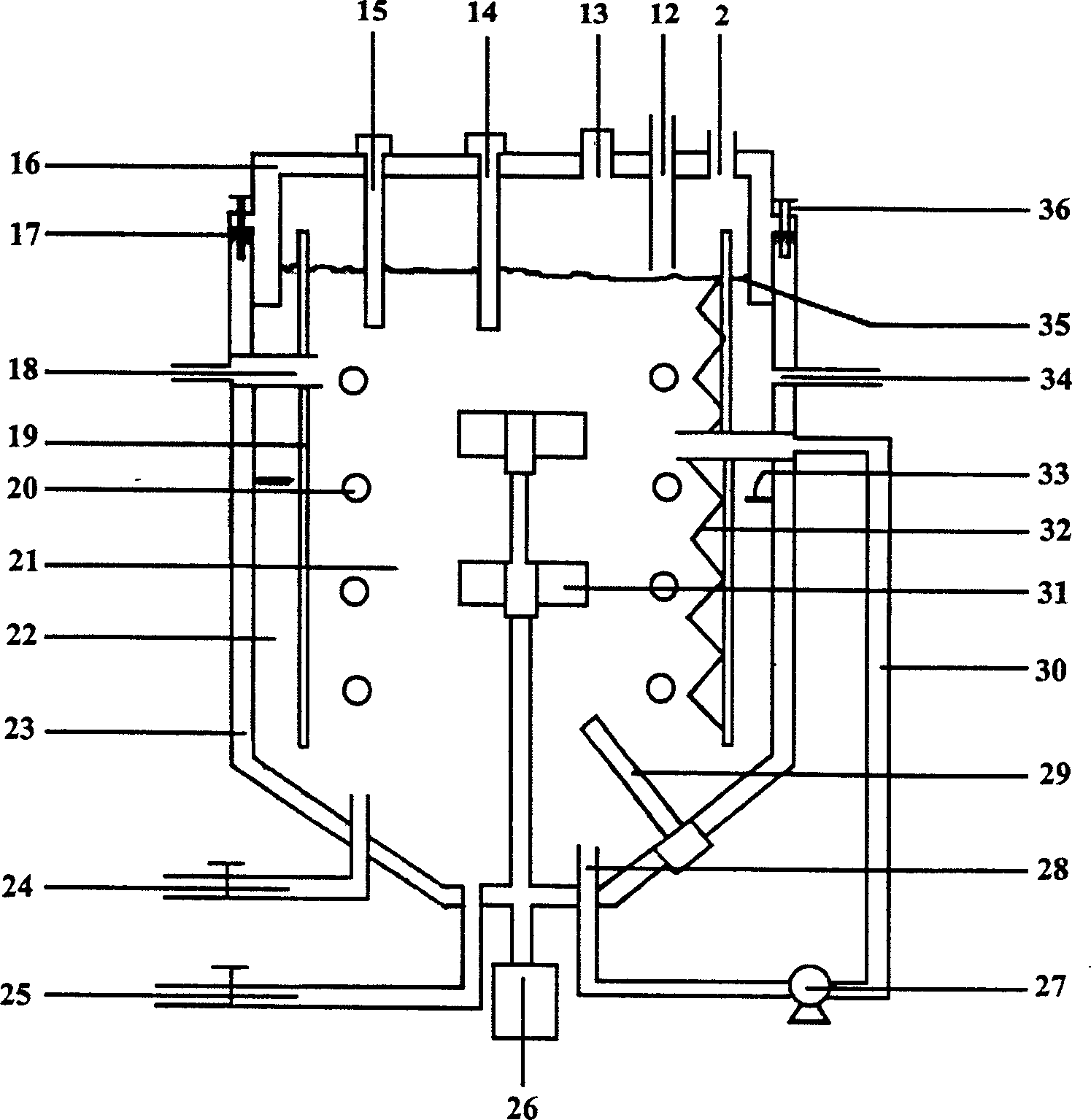

Sterilization treatment device for aseptic packaging system and sterilization treatment method

InactiveCN101985318ANot easy to damagePackage sterilisationPackaging machinesMechanical componentsAir filter

The invention provides a sterilization treatment device for an aseptic packaging system. The device is characterized by comprising an aseptic chamber and an air filter device; air is filtered through an air filter device, and then is sent to the aseptic chamber with a sterilization groove; an atomizing nozzle and an ultraviolet lamp are arranged on the top in the aseptic chamber; the atomizing nozzle is connected with a hydrogen peroxide device; a packaging material is passed through the sterilization groove, and is sterilized by the ultraviolet lamp; a filling tube is partially arranged in the aseptic chamber; the top end of the filling tube is connected with a cleaning valve through a flow control valve; and one end of the cleaning valve is connected with a steam input device. The invention also provides a method by utilizing the device, which comprises the following steps: forming the aseptic chamber; forming aseptic air by an air filter method; and sterilizing the packaging material by the hydrogen peroxide and the ultraviolet ray. The device and the method cannot consume mass water resource or mass energy like heating and cooling, and the packaging material and mechanical parts are not easy to be destroyed at the same time.

Owner:SHANGHAI PRECISE PACKAGING CO LTD

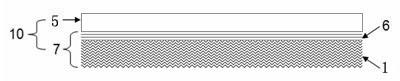

A kind of flexible current collector and lithium battery made of this current collector

ActiveCN102290578AImprove mass energy densityLow costElectrode carriers/collectorsSecondary cellsElectrolytic agentPole piece

The invention relates to a soft current collector and a lithium-ion battery made of a soft current collector, which is characterized in that the manufacturing method is as follows: first, the positive electrode is prepared: the positive electrode slurry is coated on the aluminum layer with a thickness of 0.1-10.0 μm, and the thickness of the plastic is 5.0~30.0μm aluminized plastic, the coating thickness is 0.08~0.20mm, after drying in a vacuum oven at 80~120oC, the positive electrode sheet is obtained; the negative electrode is prepared and the negative electrode slurry is coated on the copper layer with a thickness of 0.2~8.0μm , On the copper-plated plastic with a plastic thickness of 5.0~30.0μm, the coating thickness is 0.06~0.15mm, and the negative electrode sheet is obtained after drying in a vacuum oven at 80~120oC; the positive electrode sheet, PP or PE separator, and the negative electrode are sequentially The pole pieces are stacked and packed with aluminum-plastic film, and an appropriate amount of electrolyte solution 1MLiPF6+EC:DMC (1:1) is injected into the glove box; the aluminum-plastic film is hot-pressed and packaged to obtain a flexible lithium-ion battery. It effectively improves the mass energy density of the battery cell. The cost of the battery monomer is reduced; it has the advantages of low price, because the shape of the lithium-ion battery prepared by it can be arbitrary, ultra-thin, and the mass energy density is high.

Owner:CHINA FIRST AUTOMOBILE

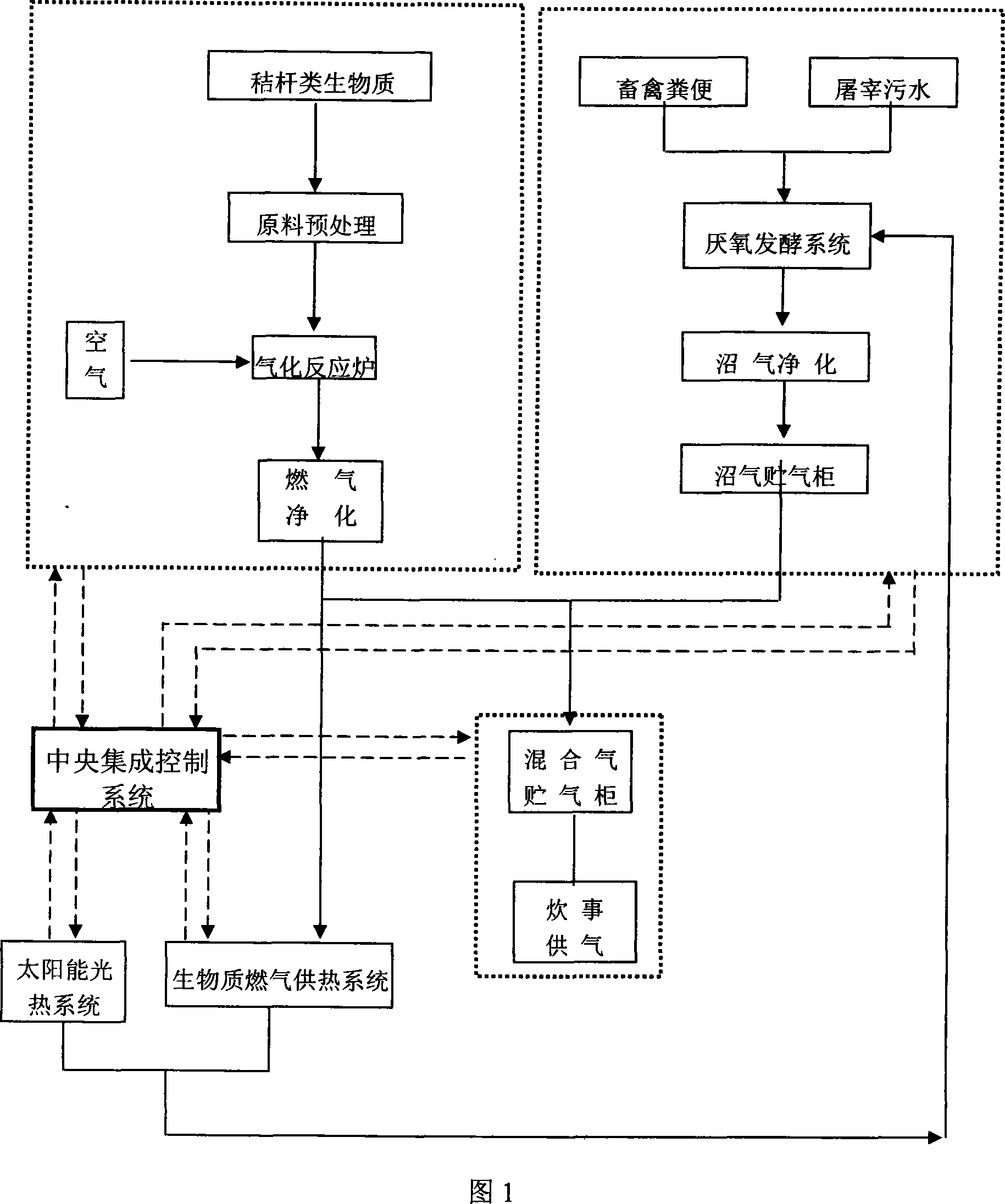

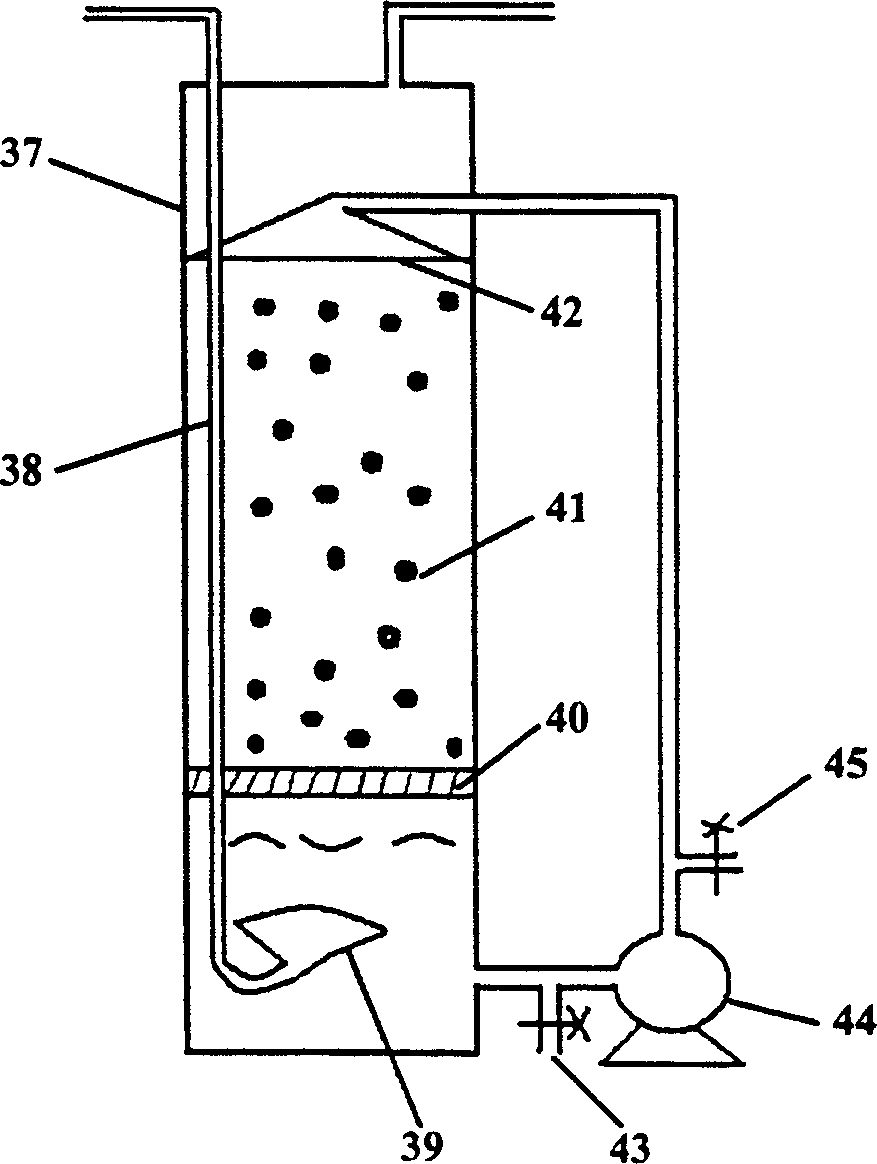

Biological energy-marsh gas fermentation-solar energy integrated utilization system

InactiveCN101063080AEfficient use ofAvoid corrosionSolar heat devicesGas production bioreactorsMarshFermentation

The invention discloses a biological mass energy-marsh gas fermentation-solar energy integrated usage system, which is characterized by the following: comprising biomass evaporated unit, marsh gas anaerobic fermentation unit, central integrated control unit, solar energy light hot unit, biomass gas heat supply unit, biomass fuel and marsh gas automatic mixed unit, fuel transmitting and distributing and user unit; connecting the central control unit and the other units separately; connecting the biomass gasifying unit with the biomass fuel heat supply unit, biomass fuel and marsh gas automatic mixed unit separately; connecting the marsh gas anaerobic fermentation unit with the biomass fuel and marsh automatic mixed unit; connecting the biomass fuel and marsh automatic mixed unit with fuel transmitting and distributing and user unit; connecting the solar energy light hot unit and biomass gas heat supply unit with the marsh gas anaerobic fermentation unit separately. This invention can transform the pollution as marsh gas source.

Owner:浙江网新百川环境科技有限公司

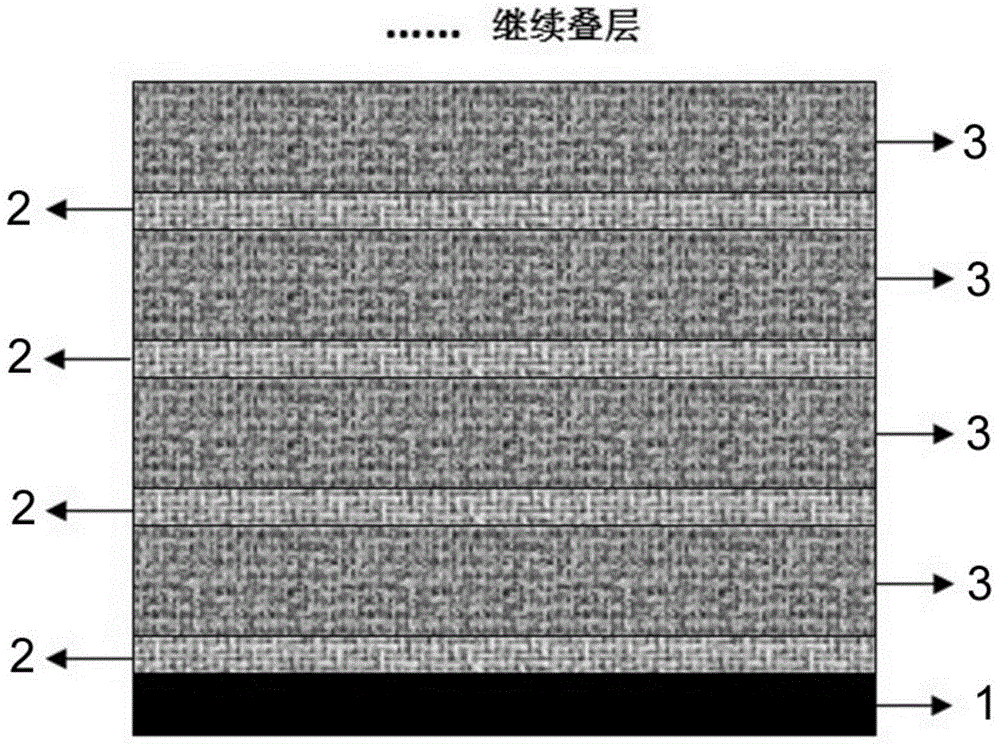

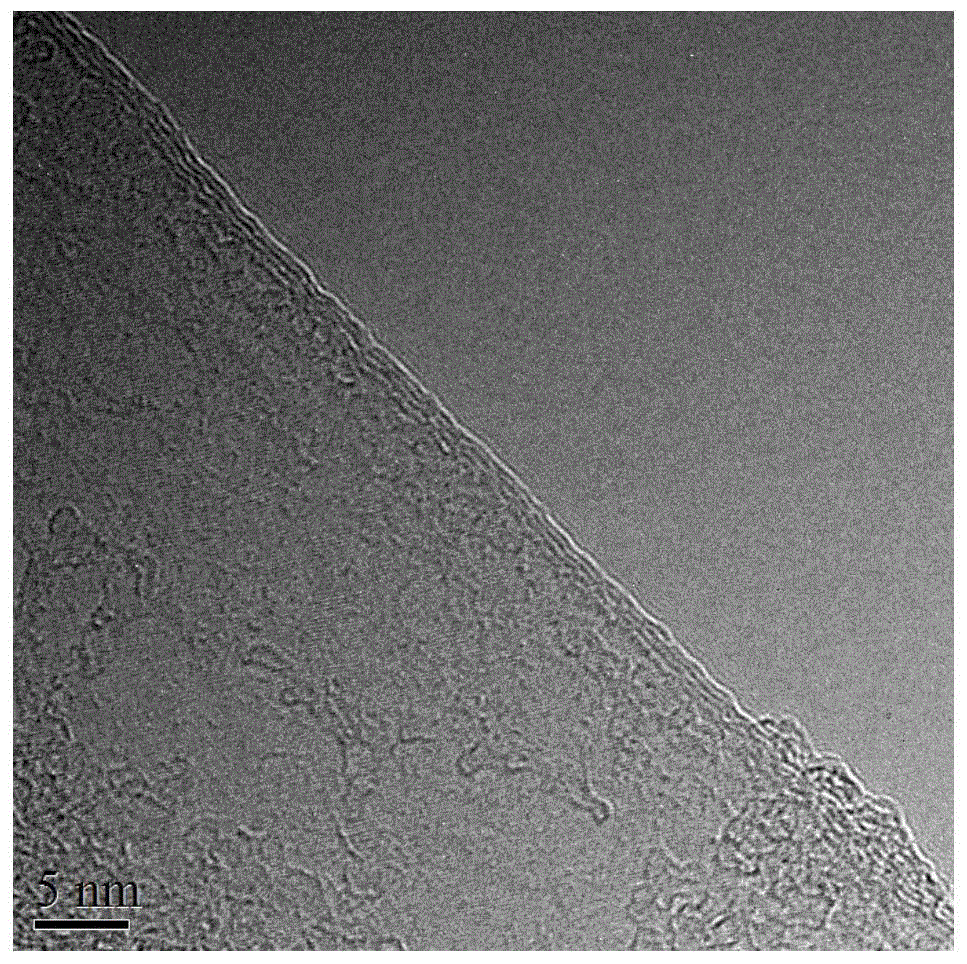

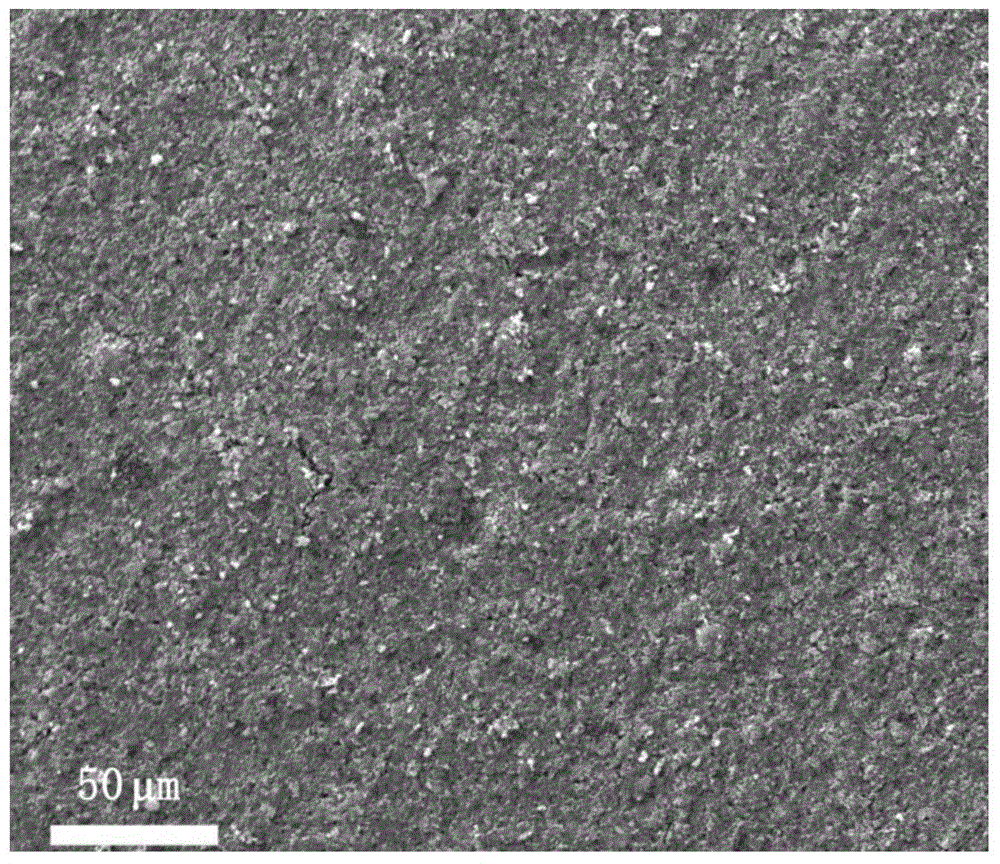

Lithium ion battery electrode structure and preparation method thereof

ActiveCN104425825AReduce dosageHigh densityMaterial nanotechnologySecondary cellsElectrical batteryNano carbon

The invention relates to a lithium ion battery electrode structure and a preparation method thereof, belonging to the technical field of a lithium ion battery. According to the method, a nano carbon material and an active substance are laminated, so that the content of non-active substances, such as positive and negative current collectors, positive and negative tabs and a diaphragm in positive and negative electrodes of the lithium ion battery can be reduced on the basis that the capacity of the lithium ion battery is not reduced, and the mass energy density and the volume energy density of the lithium ion battery can be greatly improved. The preparation method of the lithium ion battery electrode structure is compatible with the traditional process, so that the process is simple, the operation is convenient, the effect is obvious, and the application significant is great.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

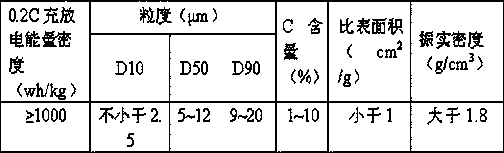

High-energy-density lithium ion power battery

InactiveCN107819154AIncrease energy densityPromote expansionCell electrodesFinal product manufactureHigh energyElectrical battery

The invention in particular discloses a high-energy-density lithium ion power battery. The battery comprises an anode piece, a cathode piece, a diaphragm, electrolyte and a battery case accessory, wherein the anode piece is composed of an anode current collector, an anode material coated on the surface of the anode current collector, an anode conductive agent and an anode binder; the cathode pieceis composed of a cathode current collector, a cathode material coated on the surface of the cathode current collector, a cathode conductive agent and a cathode binder, the anode material is a Ni-Co-Mn or Ni-Co-Al ternary anode material, and the cathode material is conductive carbon source coated silicon carbide or SiOx. The high-energy-density lithium ion power battery provided by the embodimentof the invention has the initial coulomb efficiency reaching 86.5% and the mass energy density reaching up to 280Wh / kg and can meet high energy density and long cycle life requirements of the power battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD +1

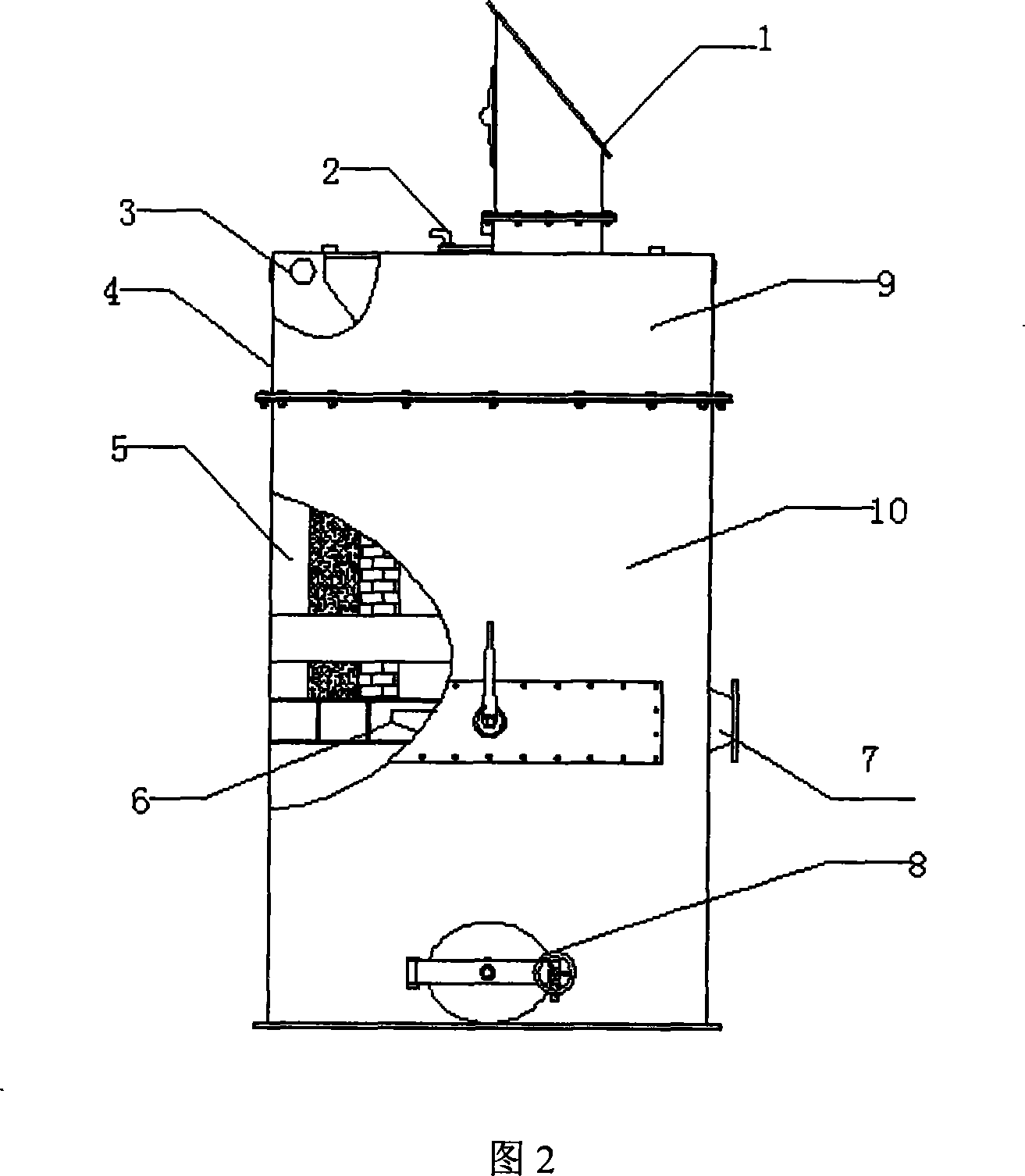

Biological mass-energy fuel boiler and its burning method

InactiveCN1900589AEfficient and clean combustionRealize comprehensive utilizationDamper arrangementSolid fuel combustionFlue gasEngineering

Characters of the invention are that suspension burning plus grate firing carry out in boiler; first, through conveying facilities, biomass energy fuel in sheet, granular or powder is fed equably through feed inlets with adjustable angles; next, secondary air under feed inlets sends fuel to fire box, and suspension burning is carried out in fire box under cooperation of primary air; then, based on burning properties and state to adjust primary / secondary air in order to guarantee high temperature in burning area, and prolong residence time of combustible and flue gas in high temperature; finally, in suspension burning, bigger fuel granules drop to fire grate to carry out grate firing, and adjusting angles of feed inlets and secondary air to make thickness of fuel layer even on fire grate, and adjusting primary air to ensure full burning. The invention strengthens burning and guarantees firing in time and full burning so as to realize clean burning biomass energy fuel.

Owner:上海四方锅炉厂

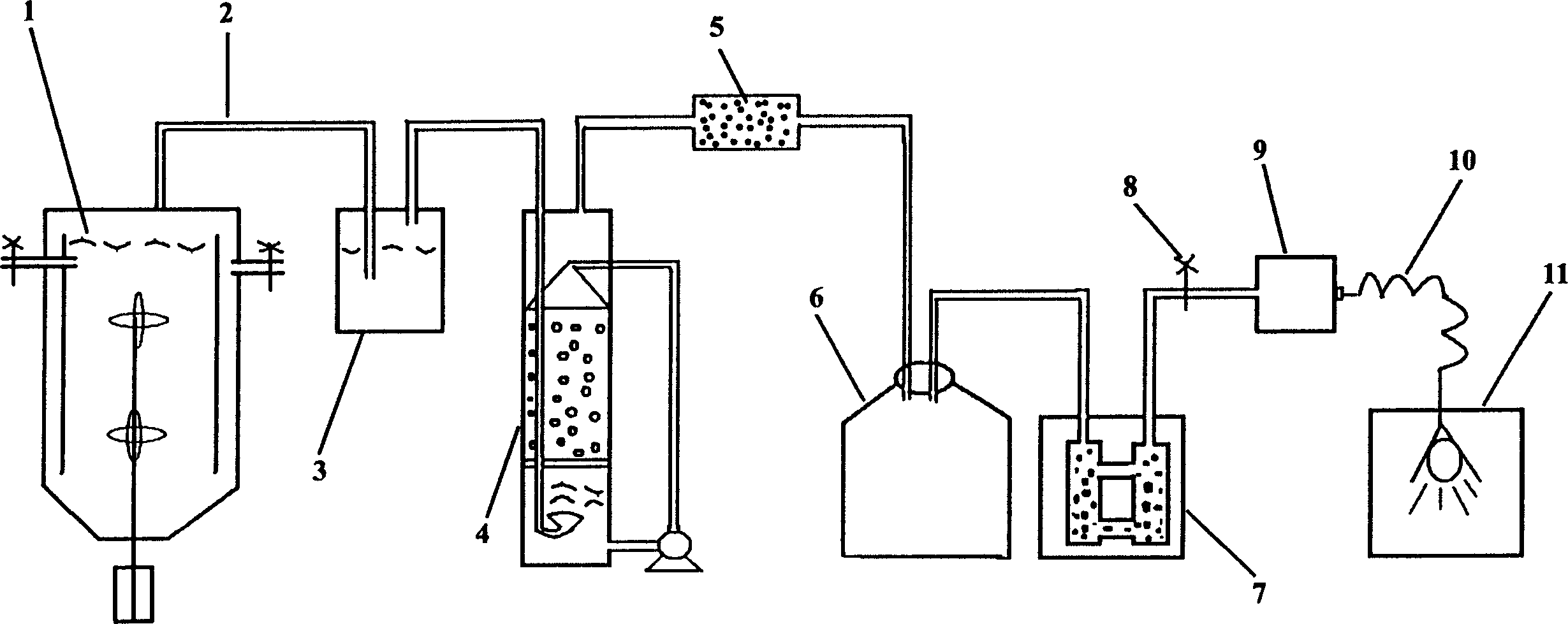

High-efficiency microorganism hydrogen preparation and hydrogen energy-electric energy conversion integrating apparatus

InactiveCN1528905AAchieve controllable transformationBioreactor/fermenter combinationsBiological substance pretreatmentsWater dischargeResource utilization

The invention refers to a device for producing hydrogen by using microbe to yeast organic substances and conversion of hydrogen energy and electricity energy. It sets biological hydrogen producing reaction device, gas purifying device inlet connects with the outlet of reaction device, the hydrogen device is connected with purifying device, hydrogen energy and electricity energy device inlet is connected with the outlet of hydrogen of hydrogen storing device. The invention converts each kinds of compound inorganic substances into simple substance which can be used by microbe by decomposing microbe, and generates hydrogen through high efficiency hydrogen generating microbe. Finally, they are converted into electricity energy in fuel battery. It can realizes the controllable conversion between biology mass-energy and electricity energy. It applies to organic waste water discharging industry process and resource utilization, environment protection process to organic waste and water in city environment protection department and resource utilization, and so on.

Owner:XIAMEN UNIV

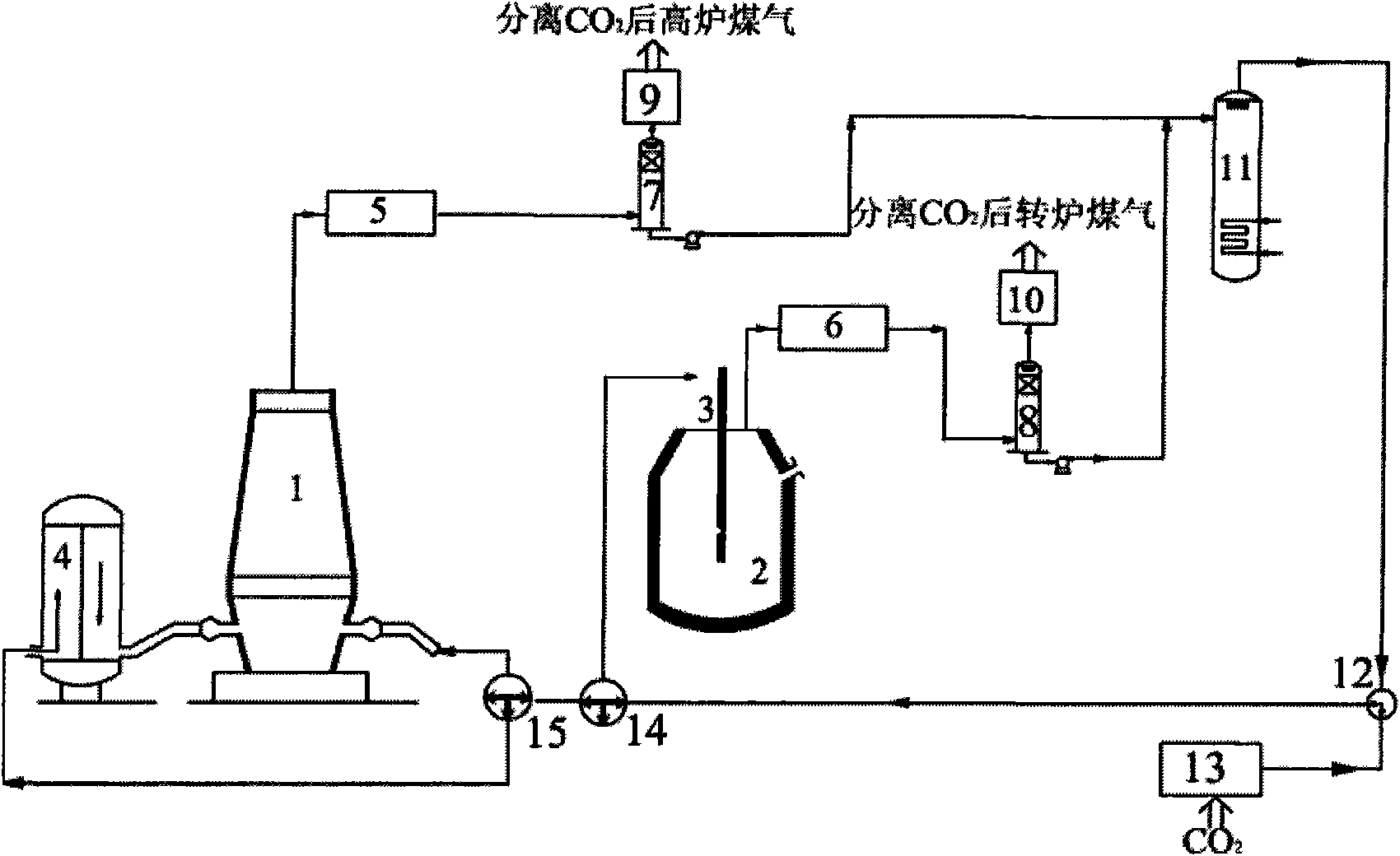

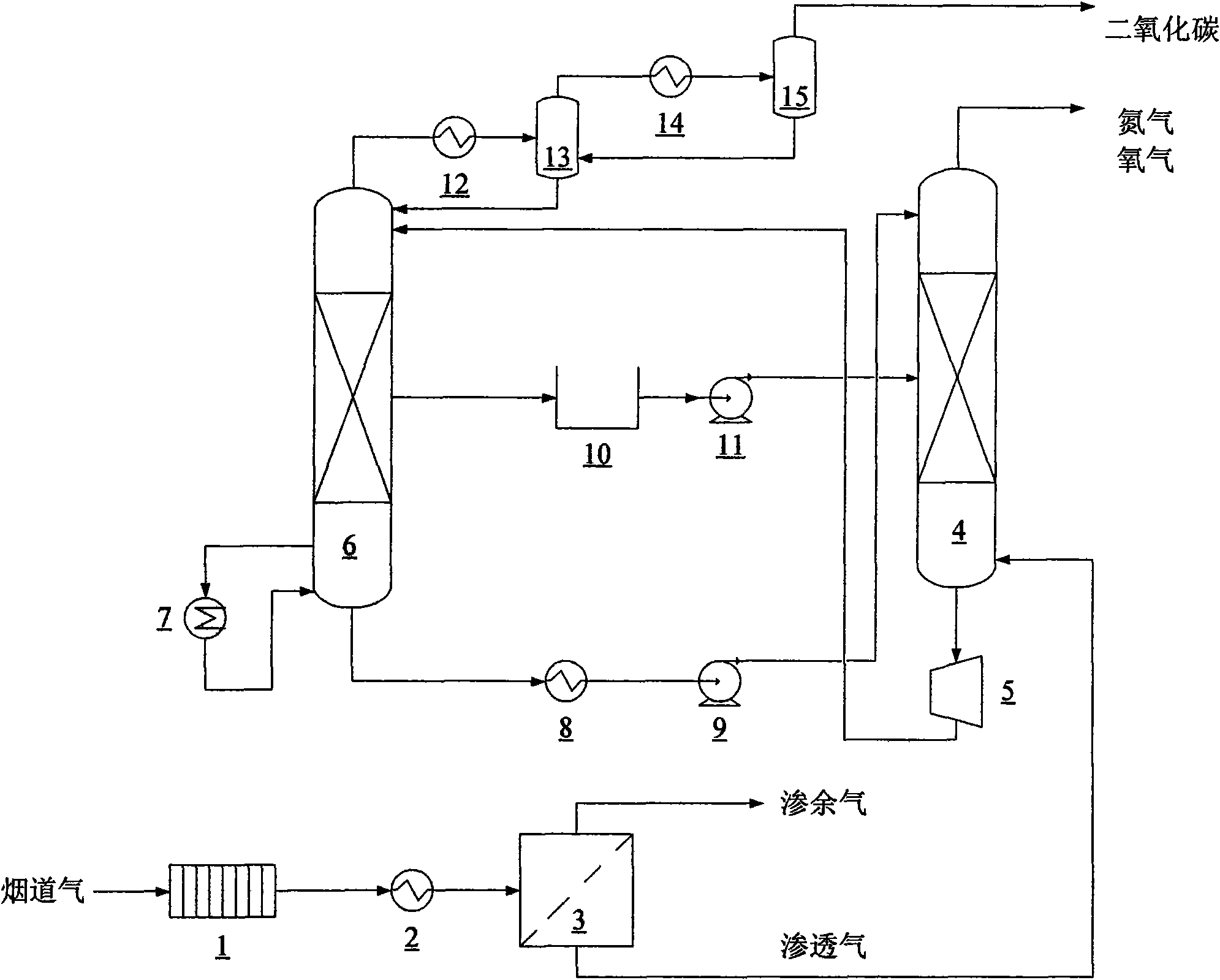

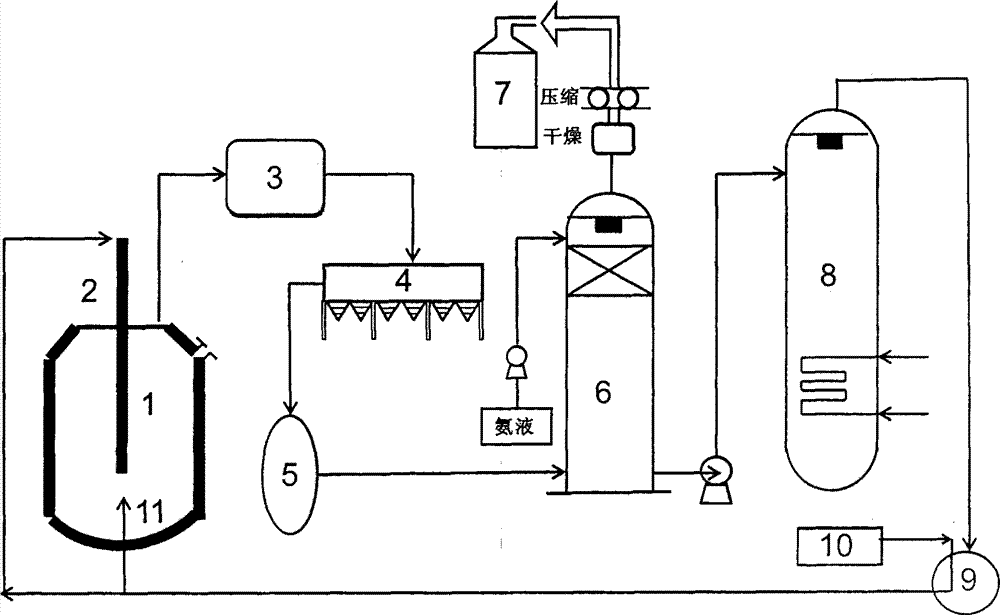

Method for separating, reclaiming and recycling CO2 in gas of blast furnace and converter

InactiveCN101603104AEmission reductionReduce consumptionBlast furnace detailsManufacturing convertersSlagTower

The invention relates to a method for separating, reclaiming and recycling CO2 in gas of a blast furnace and a converter respectively, belongs to the fields of ferrous metallurgy and greenhouse gas discharge reduction, and provides an energy-saving technique for improving the mass energy of the gas and reducing the discharge of CO2. The method integrates and optimizes the reclamation and recycle of the gas of the blast furnace and the converter; the reclamation and separation of the CO2 in the gas are executed by a gas treatment system, an absorption tower and a regeneration tower with a built-in boiler, and a chemical absorption system is additionally provided; and the reclaimed CO2 and partial external CO2 can be used for blasting in a hot-blast stove of the blast furnace and carrying gas for injection fuel, and the reclaimed CO2 also can be used for replacing N2 to carry out slag splashing protection for the converter. The method realizes the recycle of the CO2 during iron making in the blast furnace and steel making in the converter, also can use the external CO2 reclaimed from the industrial waste gas in the industries of power, chemical engineering and the like, reduces the discharge of the CO2, realizes an environment-friendly steel production process, and has remarkable social and environmental benefits.

Owner:PEKING UNIV

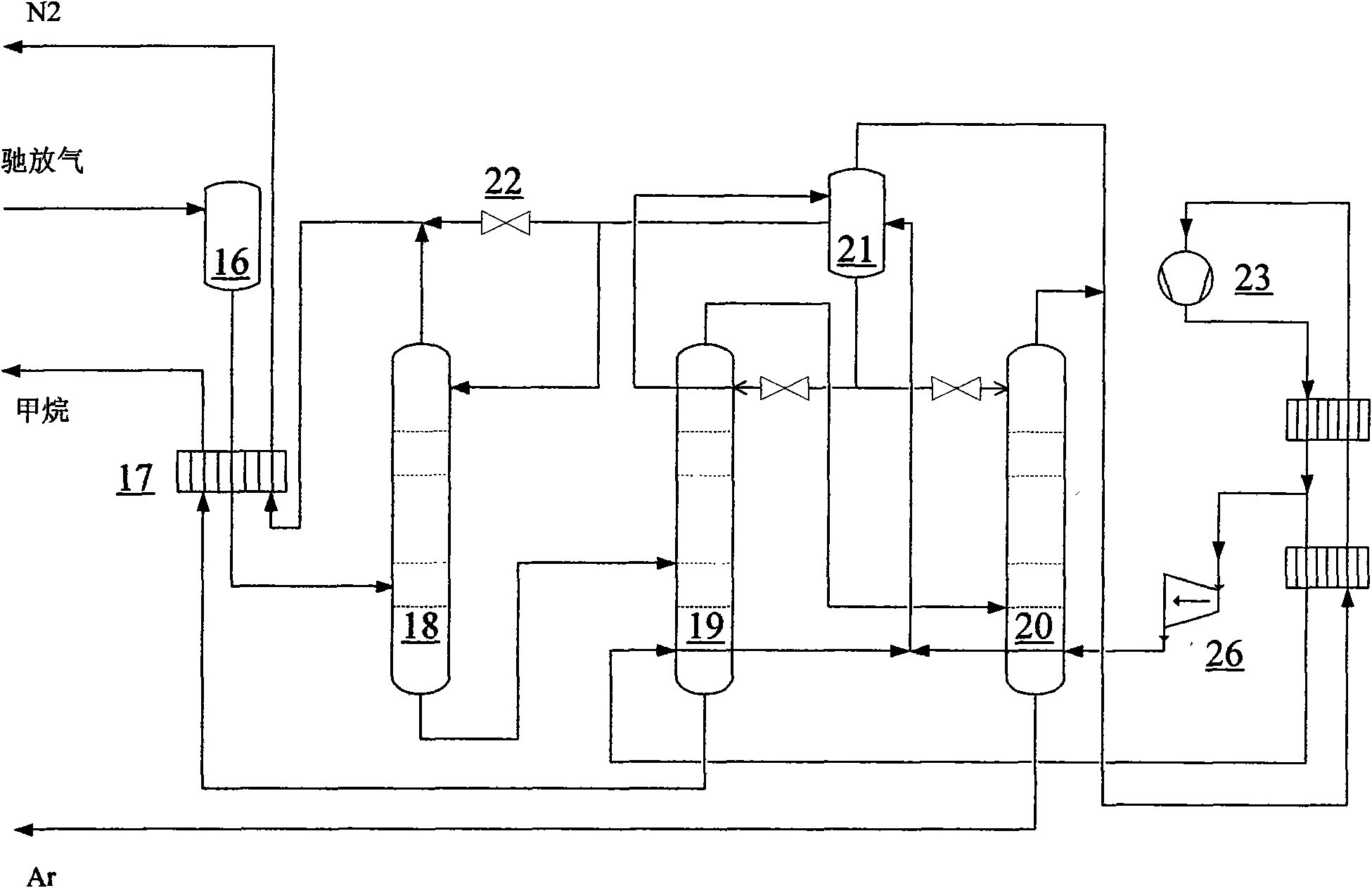

Natural gas type synthesis ammonia energy-saving and emission-reduction technology

InactiveCN101643220AEmission reductionReduce energy consumptionEnergy inputNoble gas compoundsProcess systemsCombined method

The invention discloses a natural gas type synthesis ammonia energy-saving and emission-reduction technology, which is characterized in that: a methodology of process systems engineering is adopted torealize mass-energy comprehensive integration, particularly comprising the following steps: carbon dioxide in one section of furnace flue gas is recovered by adopting a combined method of membrane separation and chemical adsorption; deeply cooling, distilling and recovering argon gas in purge gas of a hydrogen recovery device; a great quantity of low-temperature waste heat at the outlet positionof the top of a regenerating tower and an ice engine is recycled by adopting heat pump technology, so as to save cold of the ice engine and pre-heating boiler water; a similar device is used as a reference, the proposal is close to zero discharge, greenhouse gas emission load can be reduced by 50 percent to 100 percent, and carbon dioxide and argon gas are by-products at the same time, and the unit consumption of a product can reach 31GJ / tNH3, and compared with the original process, the energy saving can reach 5 percent to 15 percent. The technology is particularly suitable for the existing synthesis ammonia device which takes natural gas as raw material, so as to carry out energy-saving and emission-reduction technology reconstruction, the energy consumption of the natural gas type synthesis ammonia device based on the design of the proposal is the lowest level in the national similar devices.

Owner:董宏光 +1

Mass energy conversion device adopting gas energy storage and double-cylinder reciprocation vibrating piezoelectric transduction and applied to railway remote monitoring

InactiveCN105201766ASave energyLong-term automatic operationPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesThermal energy storageEngineering

A mass energy conversion device adopting gas energy storage and double-cylinder reciprocation vibrating piezoelectric transduction and applied to railway remote monitoring comprises a box, travel transforming mechanisms, pressure energy storage mechanisms, a high-pressure gas storage cavity and a pneumatic power generation mechanism. The device can convert vibration kinetic energy during train operation into electric energy and provide energy for railway remote monitoring equipment, and long-term stable remote monitoring for safe operation of the railway can be realized in an environment without power and a power supply.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

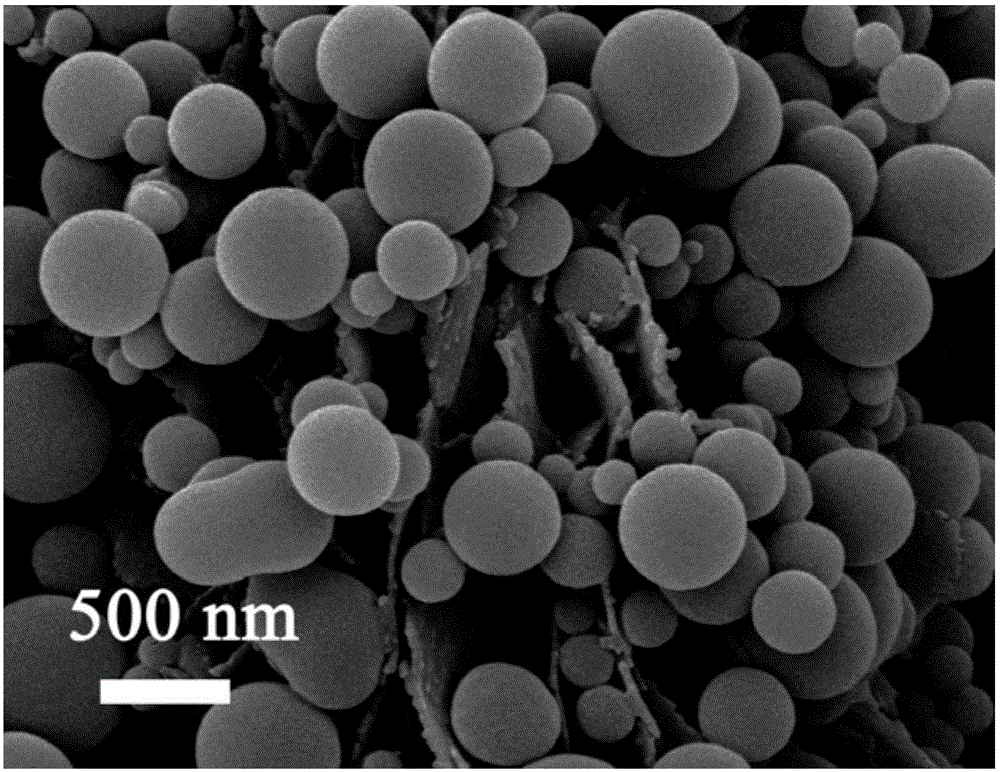

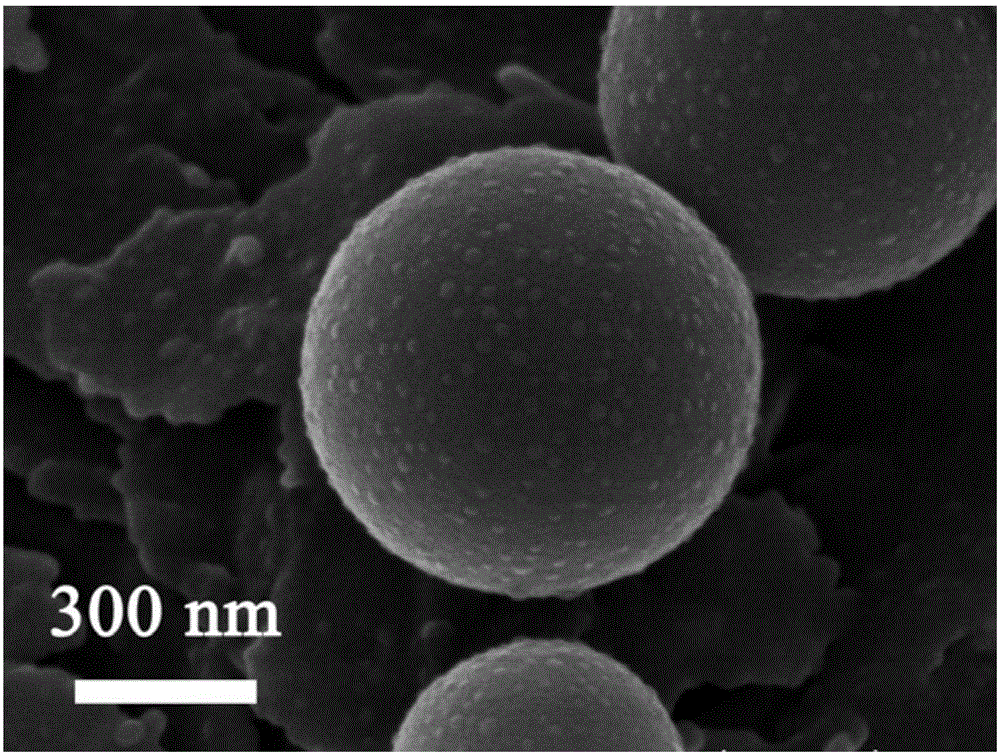

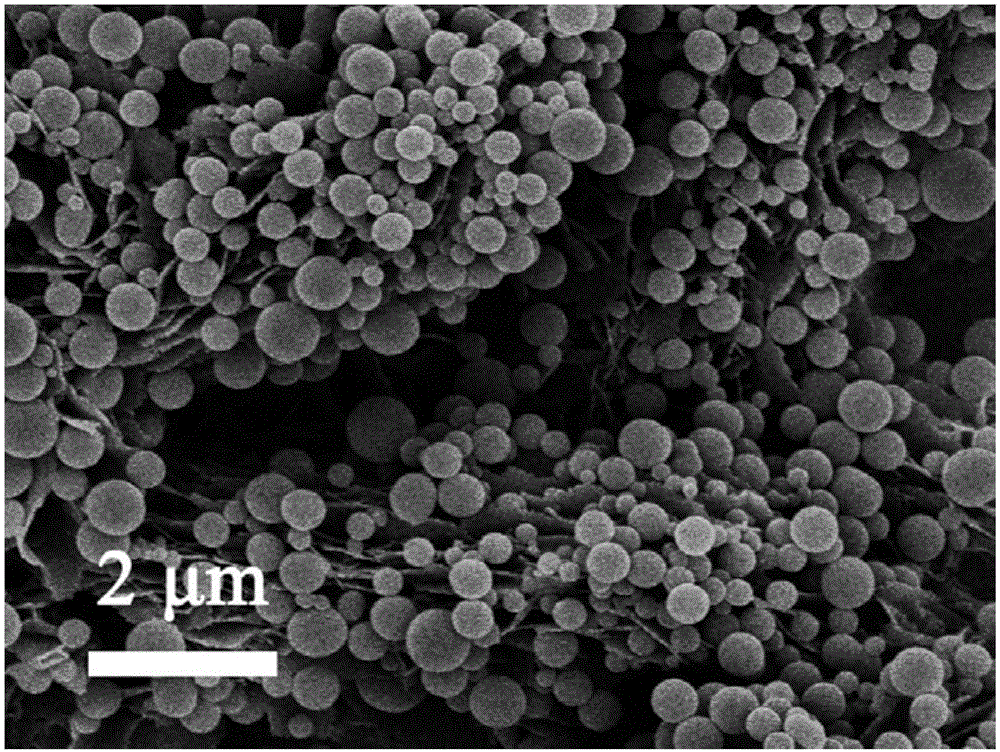

Foam nickel-loaded nanometer flower spherical carbon and sulfur composite lithium-sulfur battery positive electrode material and preparation method thereof

ActiveCN105789585ASimple methodGood repeatabilityCell electrodesLi-accumulatorsElectrical batteryHigh energy

The invention discloses a foam nickel-loaded nanometer flower spherical carbon and sulfur composite lithium-sulfur battery positive electrode material and a preparation method thereof. The preparation method comprises the following steps of generating a zinc oxide nanosheet as a sacrificial template through early hydrothermal reaction; performing hydrothermal charring on glucose at the temperature of 180-240 DEG C, reacting for 3-6 hours, and generating a foam nickel-loaded three-dimensional crosslinking carbon nanosheet and carbon nanosphere composite structure; then, sulfurizing by a melting method, using carbon disulfide as a solvent, and reacting, so as to prepare a target material. The diameter of the nanometer sphere is 100 to 800nm, and the thickness of the nanosheet is 10 to 50nm. The foam nickel-loaded nanometer flower spherical carbon and sulfur composite lithium-sulfur battery positive electrode material has the advantages that the flexible self-support is realized, the discharging capacity is high, the circulating stability is high, and the rate property is high; the mass energy density and rate property of active substances are greatly improved; the material is suitable for high-energy density energy storage devices; the application prospect is broad in the fields of instant communication, aerospace and the like.

Owner:ZHEJIANG UNIV

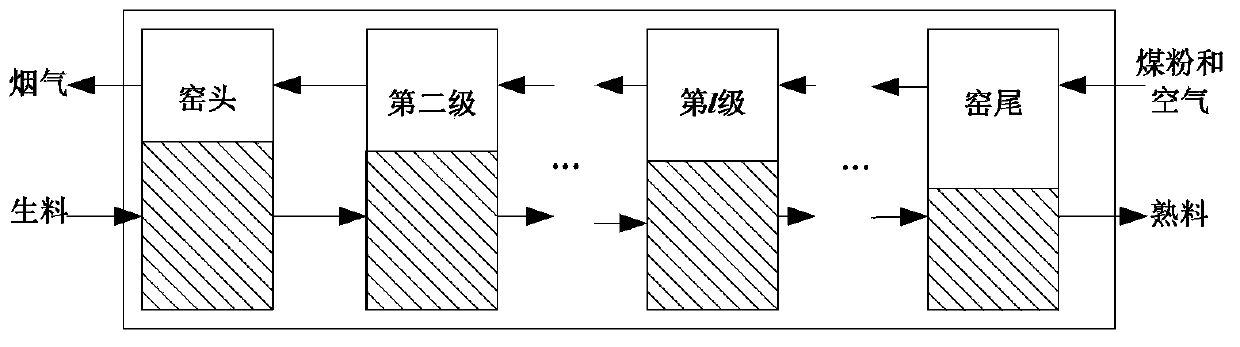

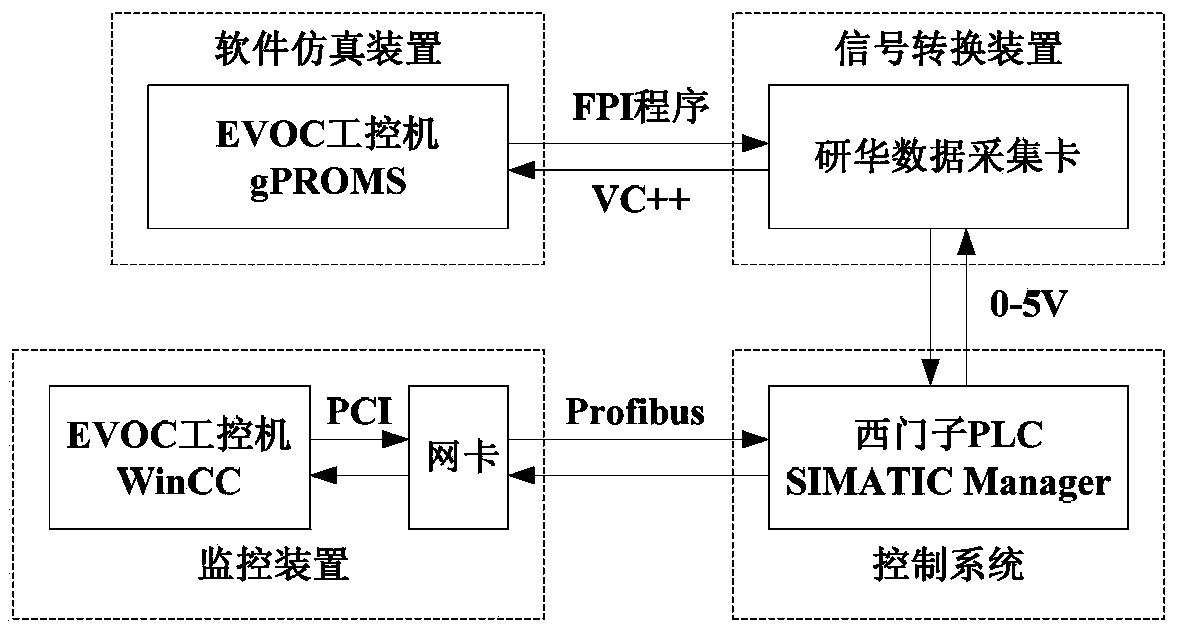

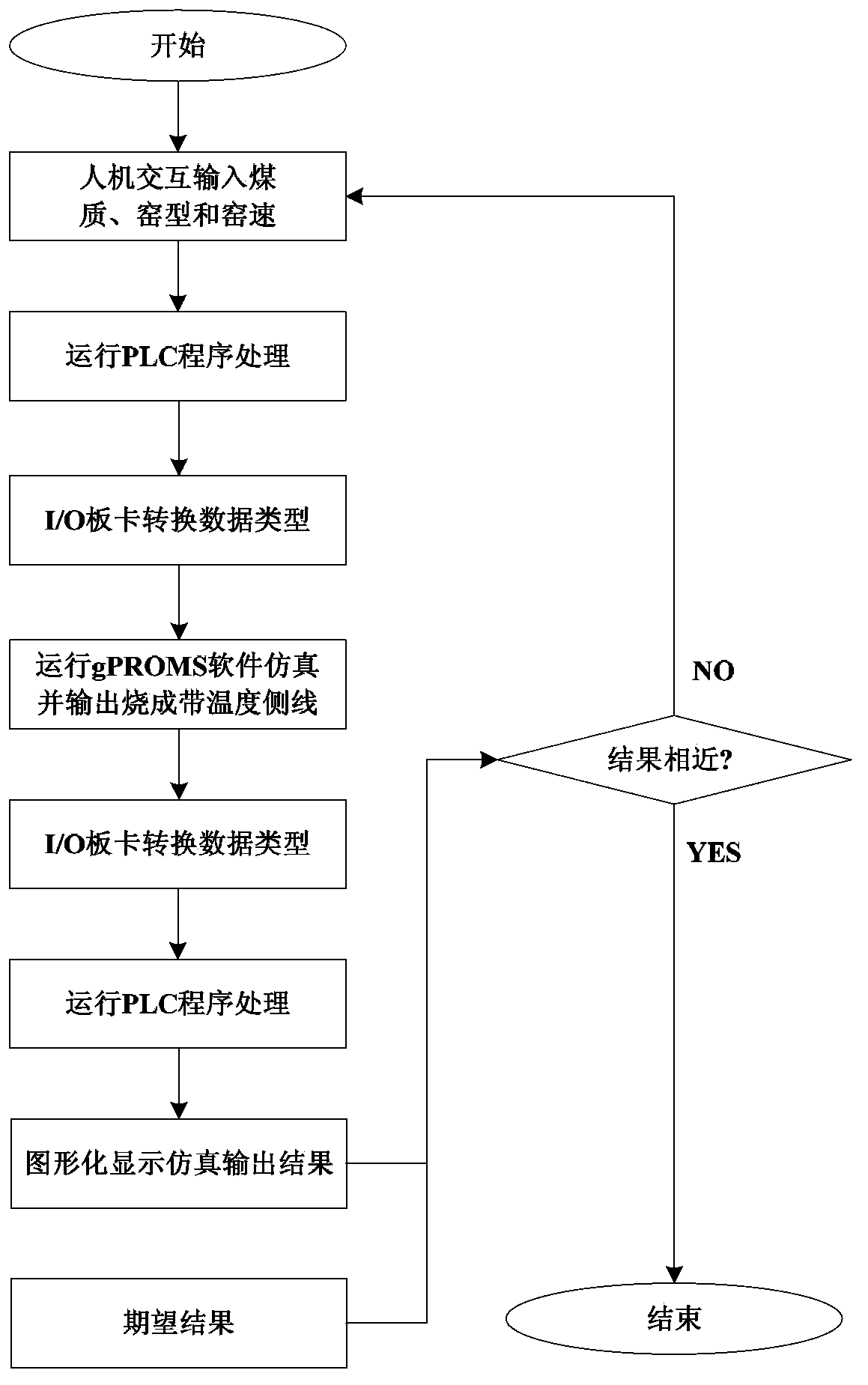

Semi-physical simulation platform and simulation method thereof used in cement clinker calcining process

ActiveCN103399779AImprove the speed of solvingImprove readabilityEnergy efficient ICTEnergy efficient computingProcess dynamicsSoftware emulation

The invention relates to a semi-physical simulation platform used in a cement clinker calcining process. According to the semi-physical simulation platform used in the cement clinker calcining process, a software simulation device, a signal conversion device, a control system and a monitoring device are connected in sequence. A simulation method of the semi-physical simulation platform comprises the steps that procedure parameters are input into a cement clinker calcining process dynamic model established by the monitoring device and sent to the control system; the procedure parameters are output by the control system to the signal conversion device, data conversion is carried out on the procedure parameters by the signal conversion device, and the procedure parameters are then output to a memory of the software simulation device to be stored; the software simulation device acquires virtual working condition parameters; the virtual working condition parameters output by the software simulation device are fed back to the control system by the signal conversion device; the virtual working condition parameters of the control system are received by the monitoring device and then are displayed through a human-computer interaction interface in an imaging mode. According to the modeling of the semi-physical simulation platform and the simulation method thereof used in the cement clinker calcining process, the dynamic variation rule of in-kiln gas-solid interphase energy and mass exchange is described from the view of mechanisms based on basic principles of mass conservation, energy conservation and macroscopic reaction kenitics.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

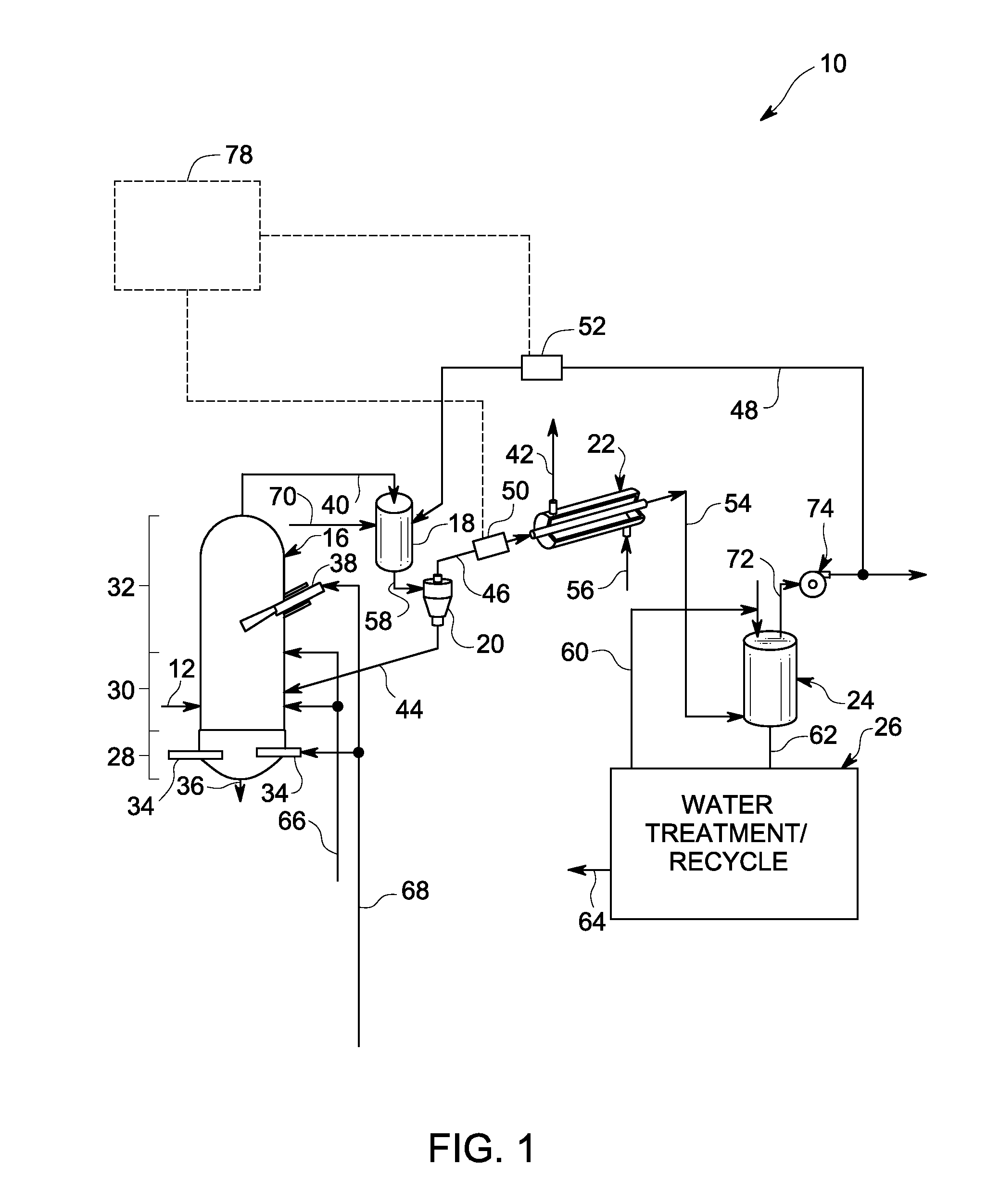

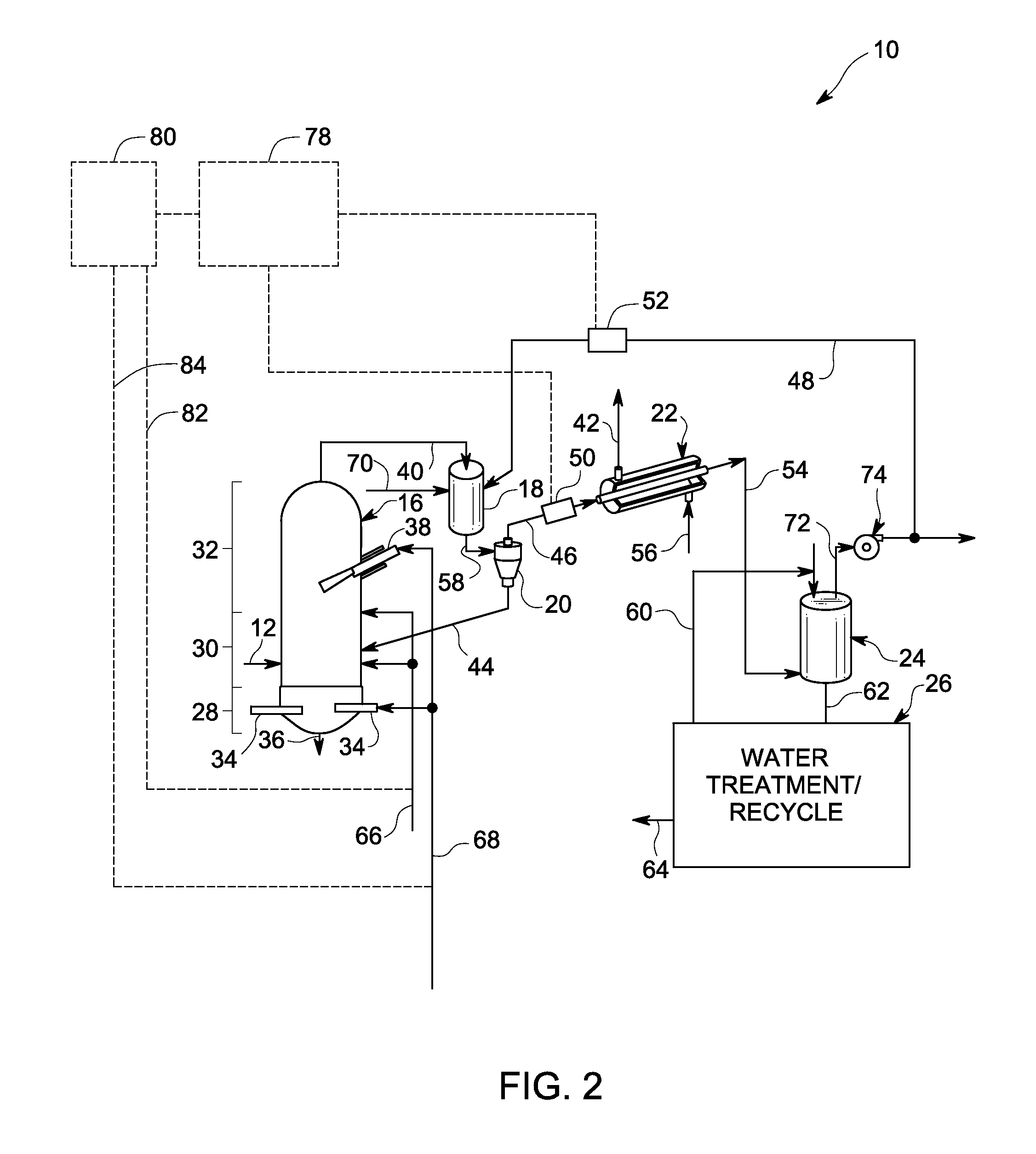

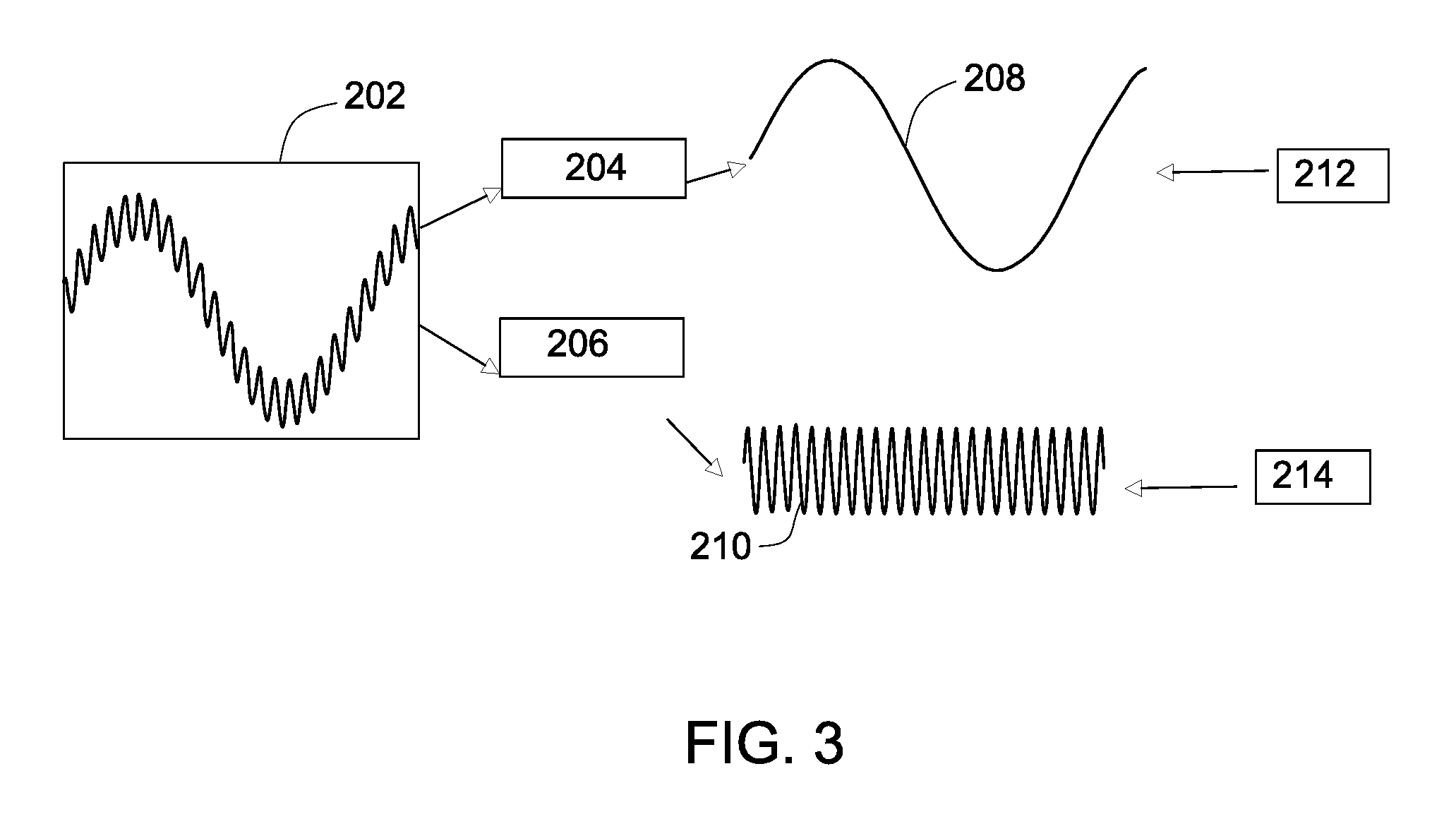

Sensing and control for plasma-assisted waste gasification

A plasma-assisted waste gasification system including a sensing mechanism and process for converting waste stream reaction residues into a clean synthesis gas (syngas) is disclosed. The gasification system includes a first sensor located between a gas quench unit and a heat recovery unit to measure a first temperature and first flow rate of the synthesis gas exiting the gas quench unit; a second sensor to measure a second temperature and a second flow rate of a low temperature synthesis gas entering the gas quench unit; wherein the first sensor and the second sensor are connected to an inferential sensing mechanism. The inferential sensing mechanism is capable of estimating the temperature of the synthesis gas in the reactor, based on the measured first temperature and first flow rate, and the measured second temperature and second flow rate, using a mass-energy balance relationship that is based on the measurements of the two sensors. Another aspect of the invention relates to a control unit to control the temperature of the reactor to a required operating temperature range.

Owner:GENERAL ELECTRIC CO

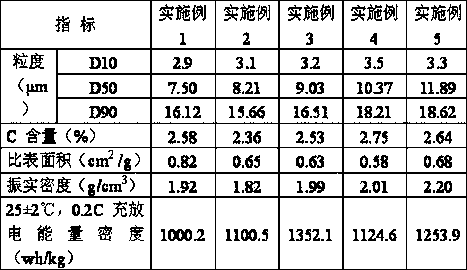

Preparation method of lithium-nickel-cobalt-aluminum composite oxide cathode material for lithium ion battery

Owner:济宁市无界科技有限公司

Nanometer titania photocatalyst for degrading VOC and preparation method of nanometer titania photocatalyst for degrading VOC

InactiveCN104174391AMicrostructural changesEasy to separatePhysical/chemical process catalystsDispersed particle separationHigh concentrationCalcination

The invention discloses a preparation method of a nanometer titania photocatalyst for degrading VOC. The method comprises the following steps: S1, putting nanometer titania powder into a tube furnace, and then introducing ammonia gas of which the purity is not lower than 99.9%; S2, heating up the furnace body to 550-750 DEG C at the heating rate of 4 DEG C / min to 10 DEG C / min, and carrying out heat preservation, wherein the ammonia gas is lastingly introduced in the process S2; S3, carrying out vacuum calcination under the condition that the air pressure is lower than the barometric pressure in the tube furnace, wherein the heat preservation temperature in the S3 is the same as that in the S2; and S4, cooling and taking out a sample. The nanometer titania photocatalyst prepared by adopting the method disclosed by the invention has the relatively strong visible light absorption ability and relatively low electron-cavity recombination rate, high-concentration benzene pollutants can be quickly and completely degraded, and 5.256*10<-3>mg of benzene contained in a space of 0.002m<3> can be completely degraded only by consuming 0.1g of mass energy within four hours under visible light irradiation.

Owner:HUAZHONG UNIV OF SCI & TECH

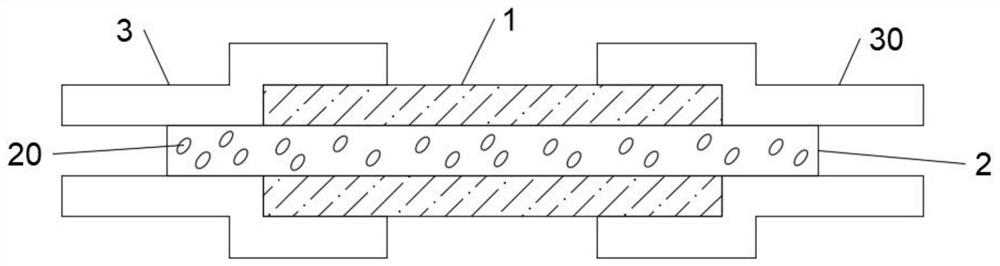

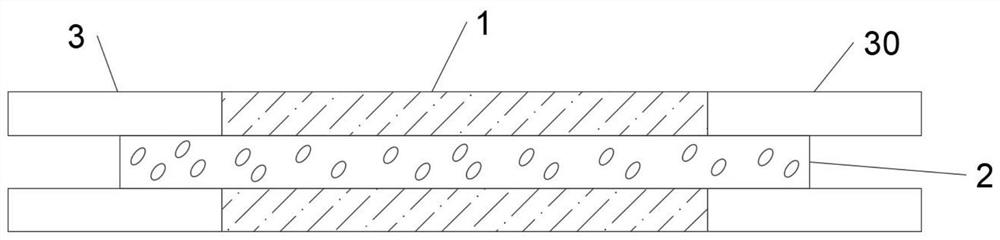

Current collector, pole piece and battery

PendingCN111933953AReduce weightImprove mass energy densityElectrode carriers/collectorsSecondary cellsMetallic materialsEngineering

The invention belongs to the technical field of batteries, and particularly relates to a current collector which comprises a substrate layer and a conductive layer. The conductive layer is arranged onthe surface of the substrate layer, the substrate layer comprises a polymer layer and a metal material layer which are connected with each other, the metal material layer is connected with the conductive layer, and part of the metal material layer is exposed out of the conductive layer. In addition, the invention also relates to a pole piece and a battery. Compared with the prior art, the currentcollector has the advantages that the metal consumption is reduced, the mass energy density of the battery is improved, the current collector can be structurally damaged at the initial stage of thermal runaway, and the thermal runaway of the battery can be prevented.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

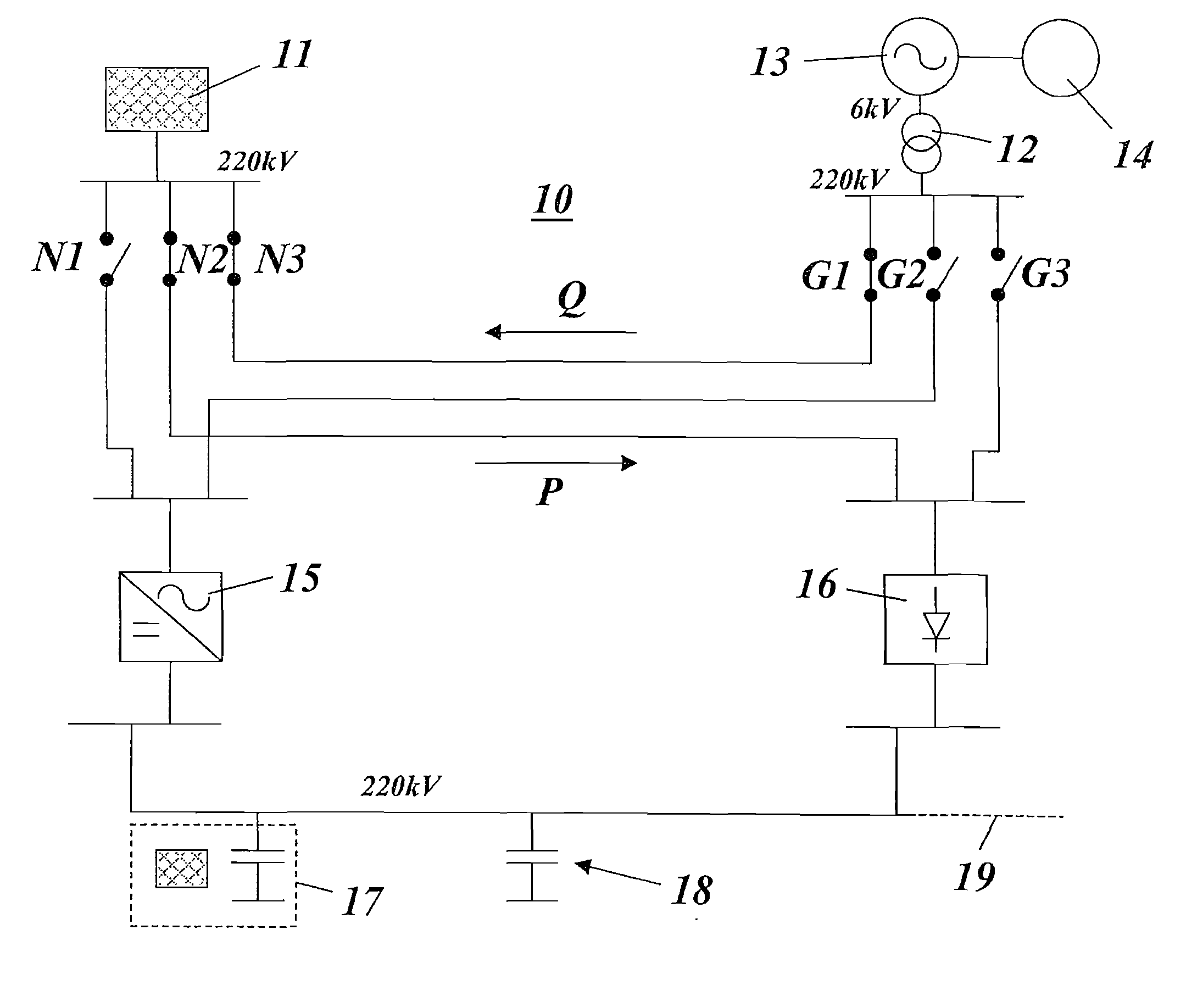

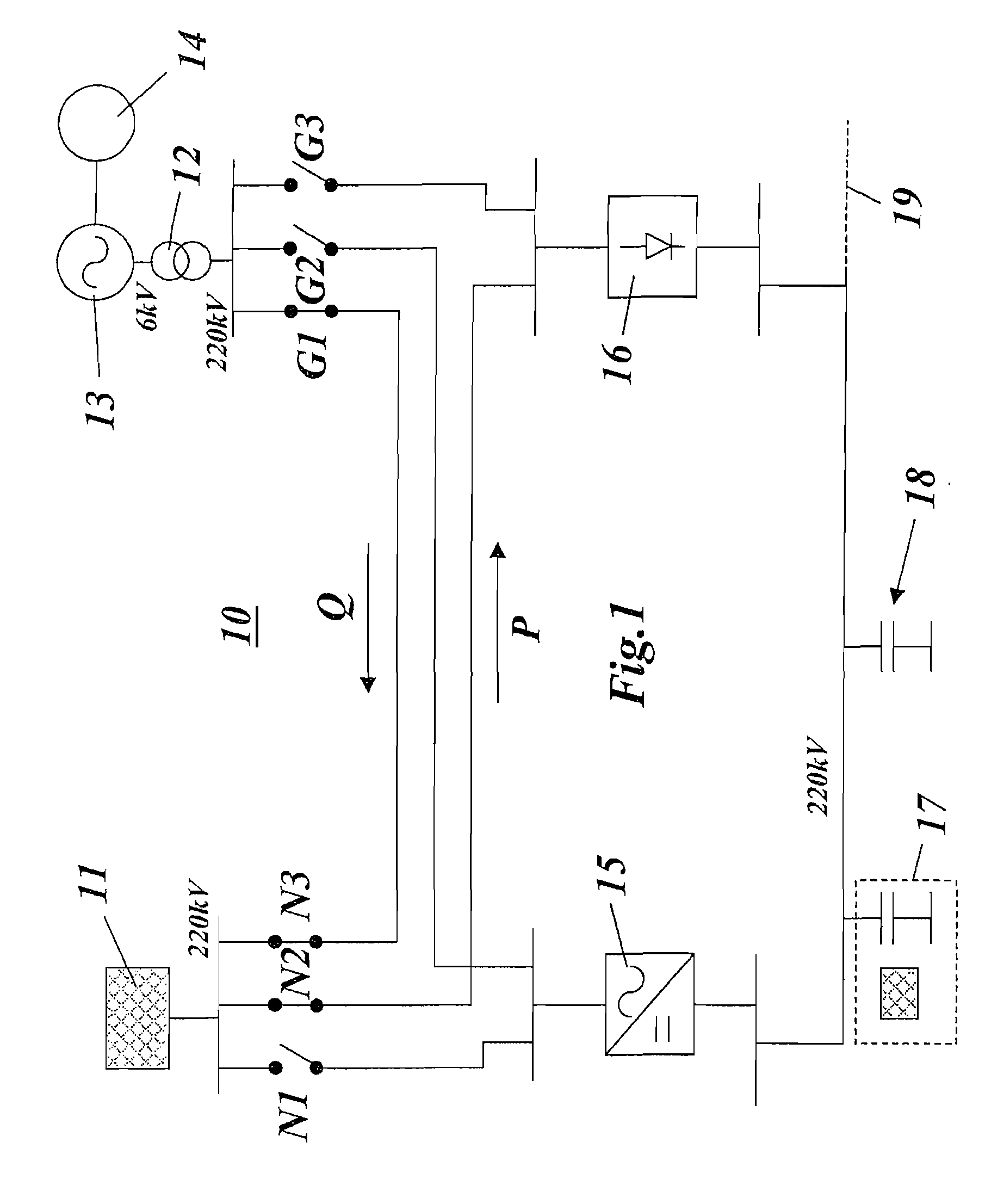

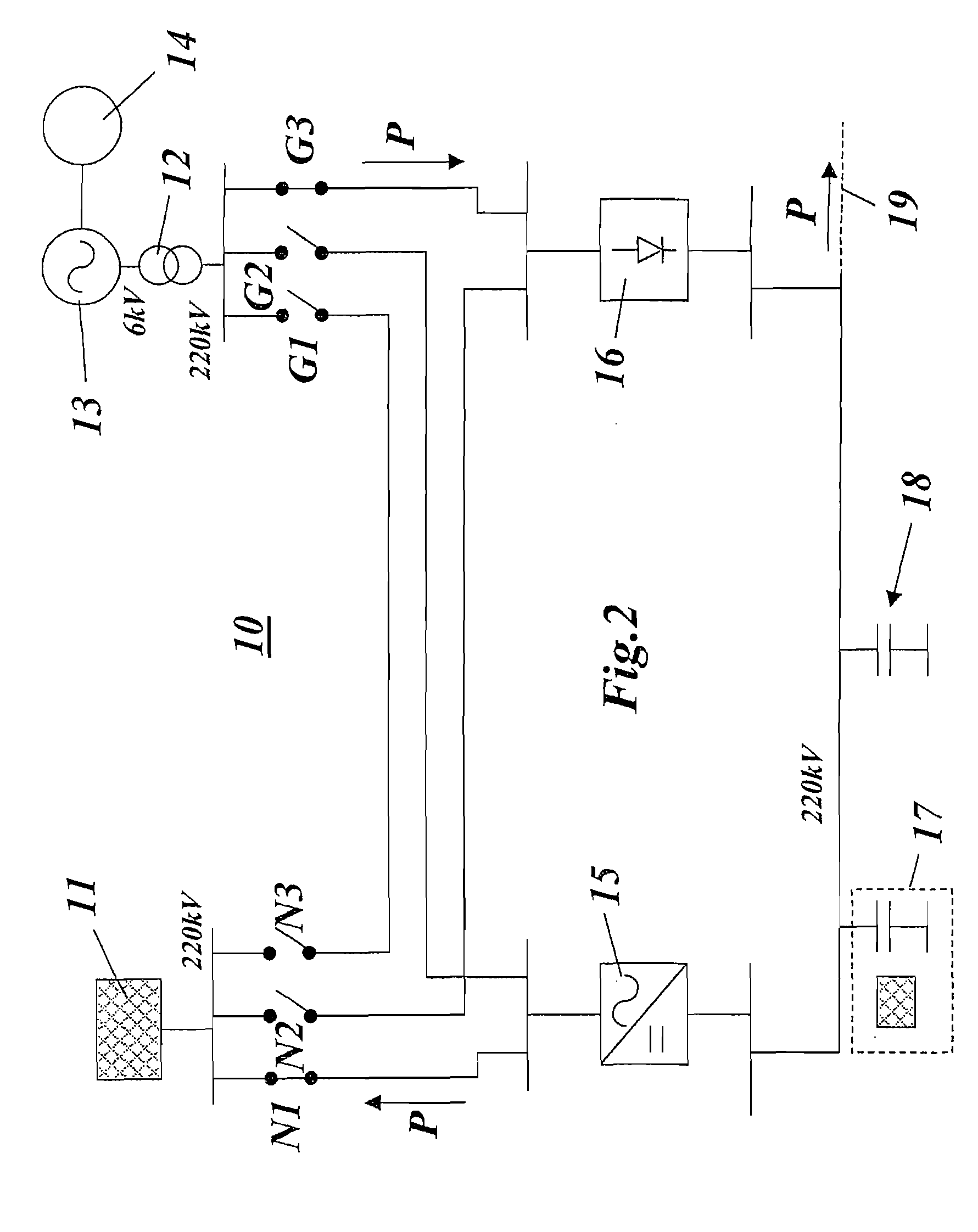

Electrical installation for coupling a power supply system and a central direct current branch and method for operating an installation of this type

InactiveUS20070085421A1Network stabilityThe process is simple and effectiveElectrical storage systemLoad balancing in dc networkElectrical devicesMass energy

An electrical installation includes a power supply network, an AC / DC converter, a central DC branch, and a rotating mass energy store. The power supply network is connectable to the central DC branch selectively via one of the AC / DC converter and the rectifier bridge. The rotating mass energy store is connectable to the central DC branch selectively via one of the AC / DC converter and the rectifier bridge and connectable directly to the power supply network. In addition, a method for operating of the electrical installation includes selectively connecting the rotating mass energy store according to a status of the power supply network to the central DC central branch via one of the AC / DC converter and the rectifier bridge and directly to the power supply network

Owner:ALSTOM TECH LTD

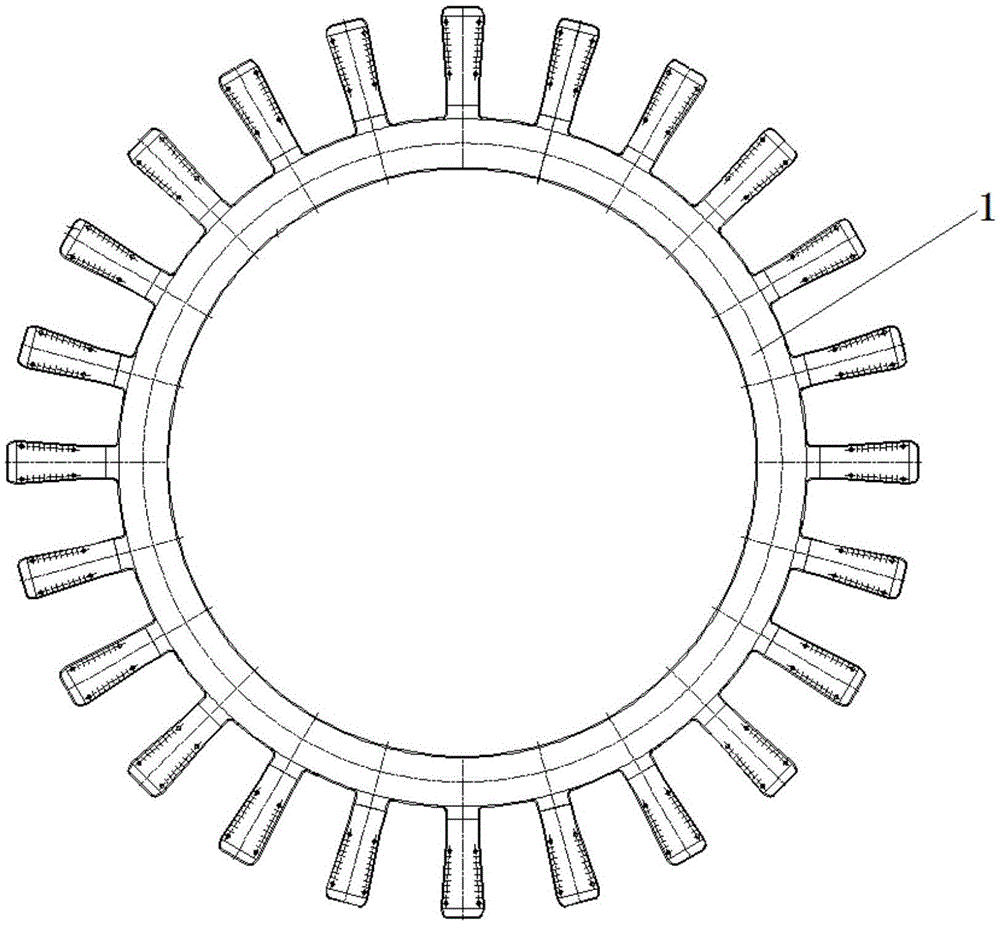

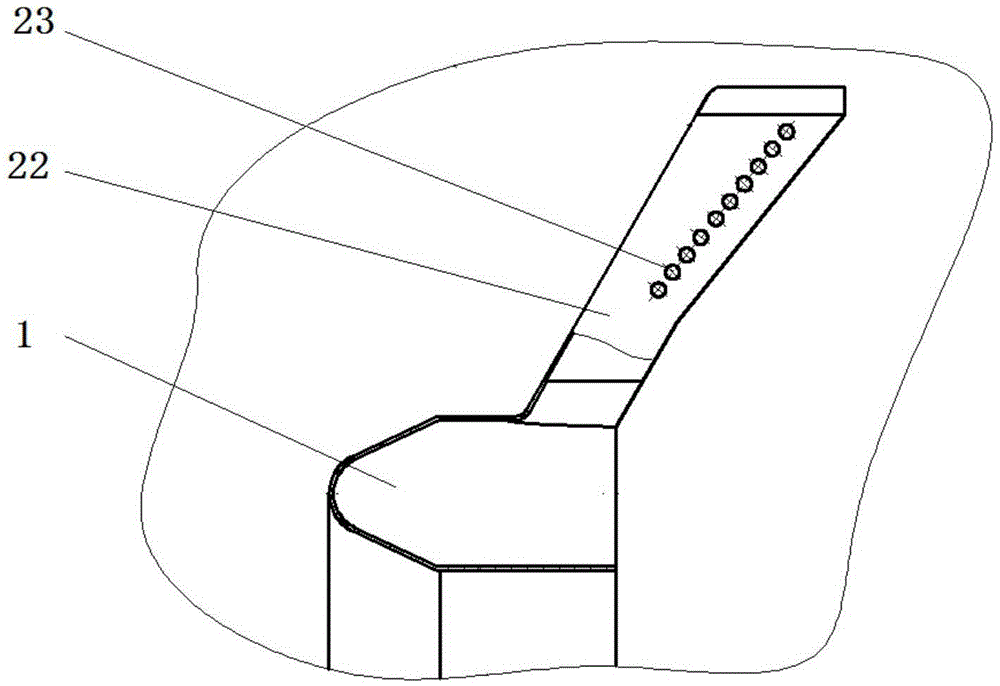

Flame stabilizer

ActiveCN105546578AWiden the boundary of lean flameoutImprove combustion efficiencyContinuous combustion chamberAviationLiquid state

The invention relates to an aviation gas turbine engine afterburner flame stabilization technology, in particular to a flame stabilizer which at least solves the problem that mixed gasoline gas in a recirculation zone of the conventional flame stabilizer is lean. The flame stabilizer is positioned in an outer duct of an afterburner, and is a radial flame stabilizer which extends outwards from an annular flame stabilizer at a junction of an inner duct and the outer duct; the flame stabilizer is provided with a first wall surface and a second wall surface that are symmetrically distributed; and a plurality of air suction holes are symmetrically formed in the first wall surface and the second wall surface. Low-pressure air in the recirculation zone can be used to suck liquid-state fuel oil nearby the wall surfaces of the flame stabilizer, and a lean oil flameout boundary of the flame stabilizer can be widened. In addition, a mass-energy exchange rate in the recirculation zone can be increased, the combustion efficiency of the flame stabilizer can be improved, and the stable combustion range can be widened.

Owner:AECC SHENYANG ENGINE RES INST

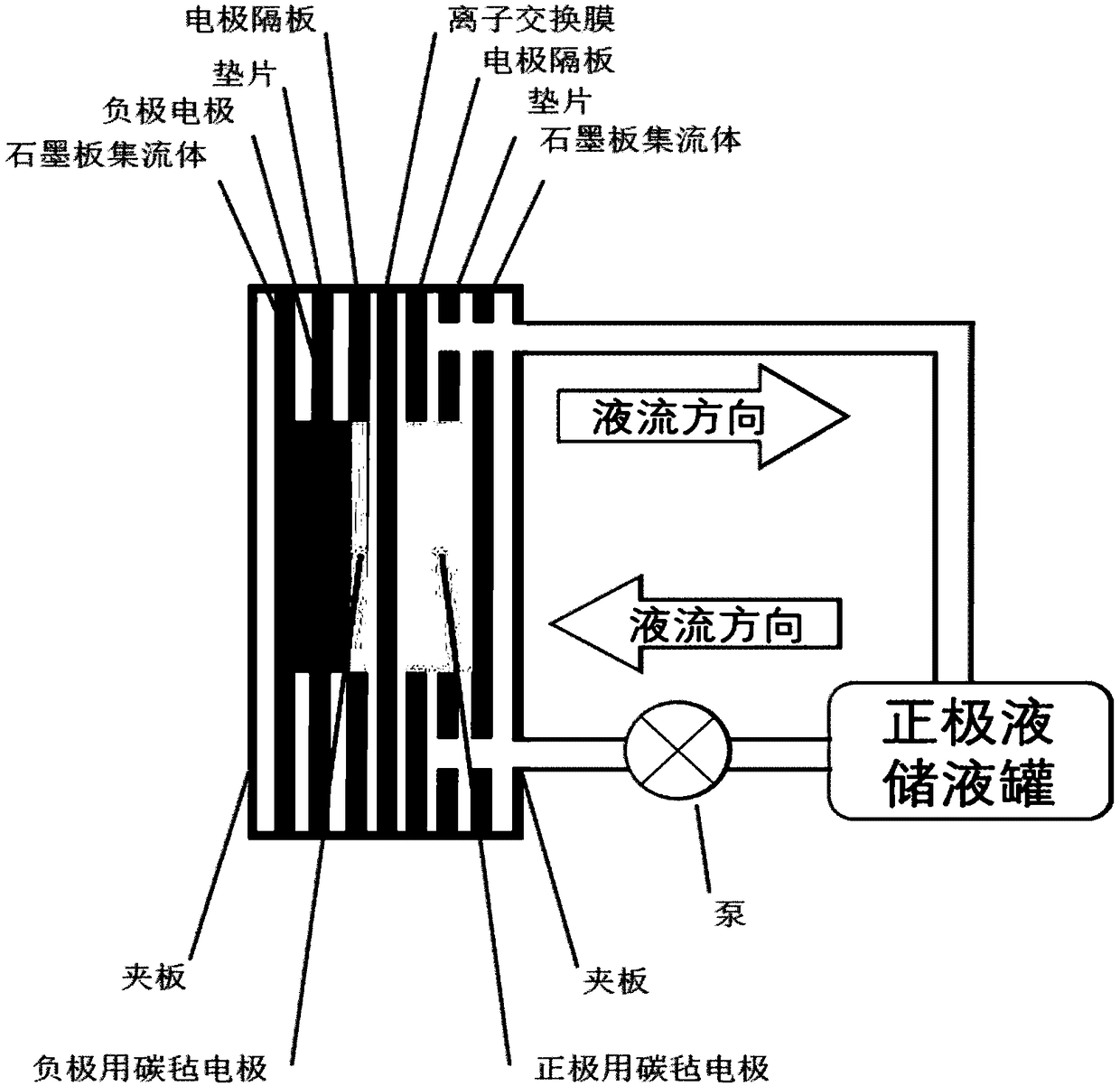

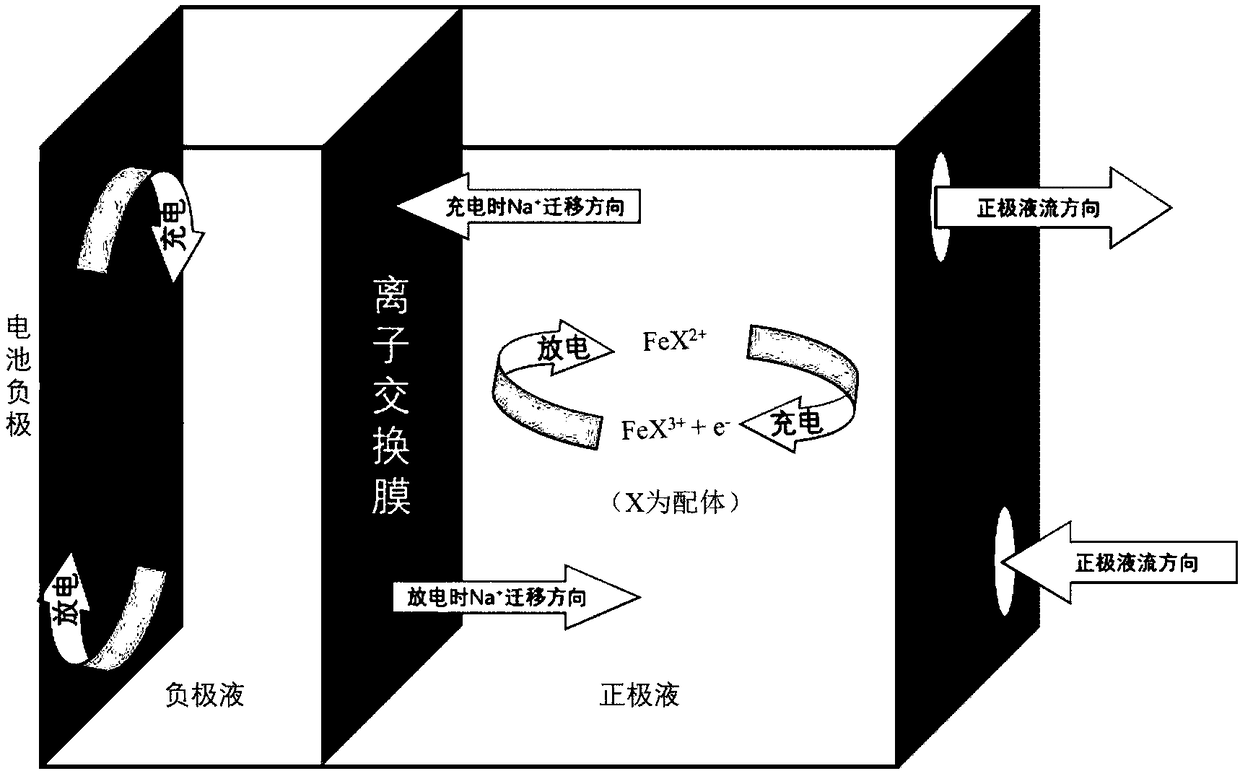

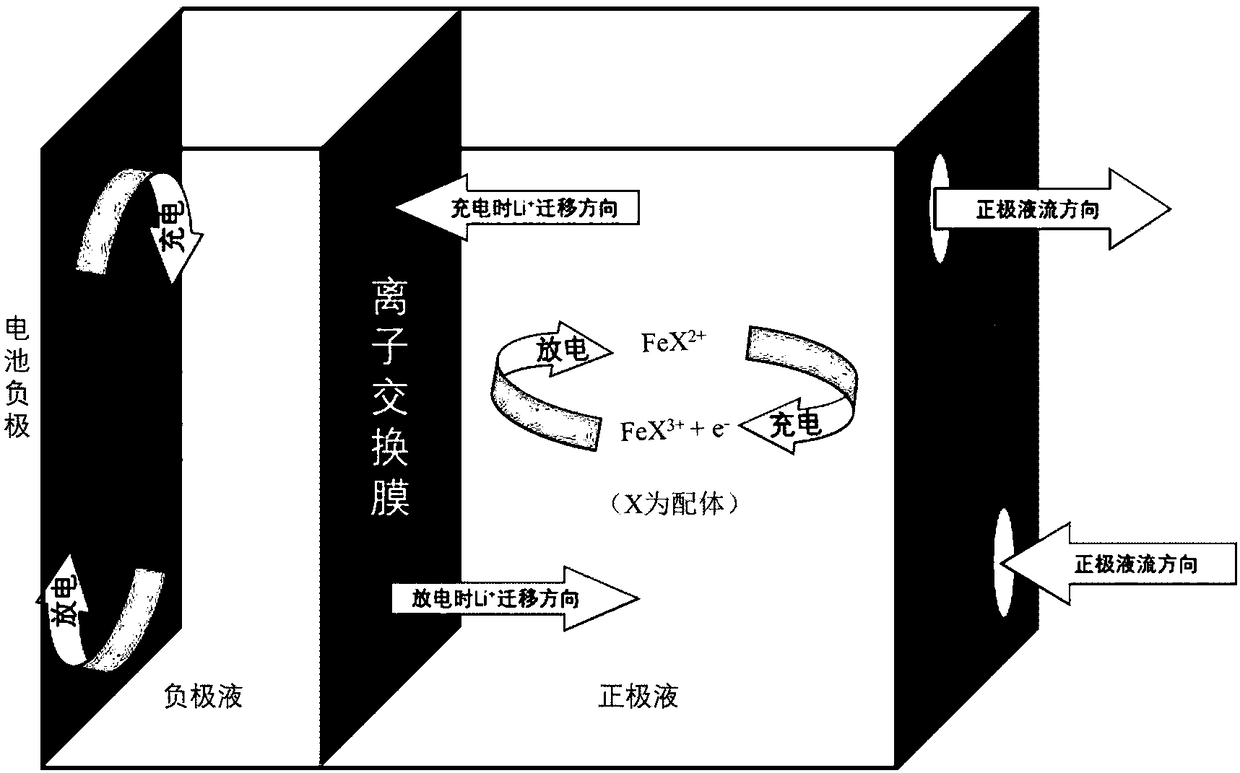

Semi-solid flow battery with ion-embedded solid negative electrode

InactiveCN108365246AImprove charge and discharge performanceExtended service lifeReactant parameters controlElectrolyte stream managementWater basedHigh energy

The invention belongs to the technical field of electrochemistry, and concretely relates to a semi-solid flow battery with an ion-embedded solid negative electrode. The system of the battery comprisesa sodium titanium phosphate or lithium titanium phosphate negative electrode, a negative electrode liquid composed of an aqueous solution containing one or two of a sodium ion and a lithium ion, an ion exchange membrane, and a positive electrode liquid formed by an aqueous solution containing an iron ion complex and one or two of the sodium ion and the lithium ion. The high-energy density solid-state water-based negative electrode material sodium titanium phosphate or lithium titanium phosphate is adopted to replace a liquid negative electrode in a traditional liquid flow battery, so the advantages of separate energy and power design, high safety and long cycle life of the liquid flow battery are kept; and the semi-solid flow battery is not limited by the concentration of a solute, so theenergy density of the negative side is greatly improved, and the impedance of the battery is greatly reduced, thereby the volumetric energy density, the mass energy density and the working efficiencyof a whole battery module are greatly improved.

Owner:FUDAN UNIV

Production method of superfine boron phosphate

The invention relates to a method for effectively manufacturing high-purity superfine boron phosphate with low energy consumption. The method uses boric acid and phosphoric acid as materials, and uses organic solvent as a medium, and comprises the following steps of: mixing the boric acid, the phosphoric acid and the organic solvent; further completing distillation, solvent removal, drying treatment and other processes with catalyst or without catalyst; and acquiring a high-quality superfine boron phosphate product. The superfine boron phosphate prepared by adopting the method has comprehensive cost of materials, labor and energy consumption lower than corresponding cost of other the prior manufacturing methods, and does not pollute environment as other byproducts except water are not generated in the manufacturing process; the manufacturing process is completed at a lower temperature, thereby saving mass energy; and the product has high purity. The method has double significances of environmental protection and energy conservation.

Owner:刘启波

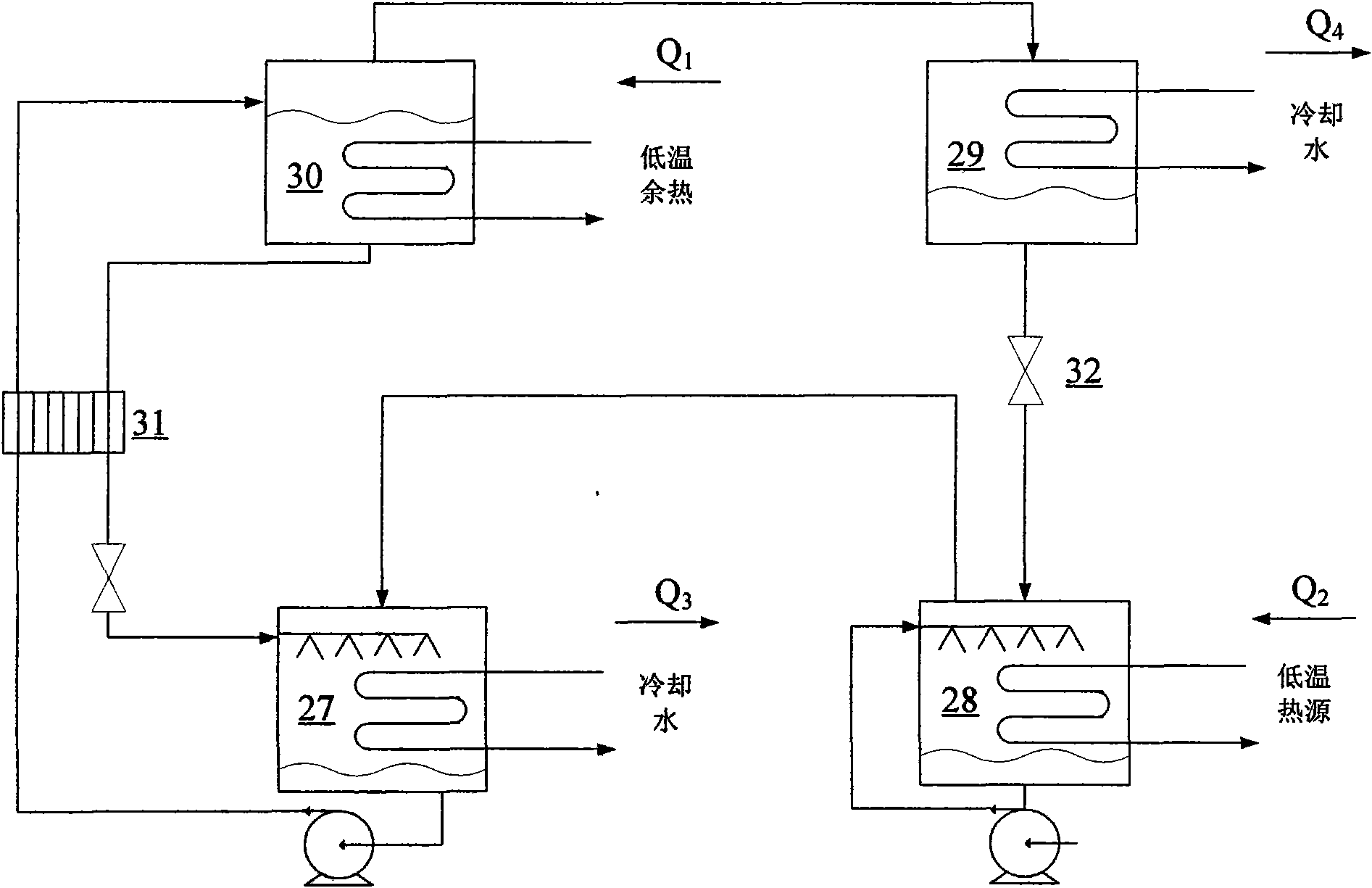

Converter gas mass-energy conversion and CO2 cycle steelmaking method

InactiveCN103776272AEmission reductionAchieve recyclingChemical industryIncreasing energy efficiencySteelmakingCo2 absorption

The invention relates to a method for converter gas CO2 separation and recycling, belongs to the field of ferrous metallurgy and greenhouse gas emission reduction, and provides an energy-saving technology for improving gas mass-energy and reducing CO2 emission. The method for converter gas CO2 separation and recycling is characterized in that high temperature gas discharged from a converter firstly enters a high-temperature waste heat recovery system for high-temperature sensible heat utilization, is conveyed to a low-temperature waste heat recovery system for waste-heat utilization after passing through a high-temperature flue gas ceramic filtering dedusting system. Then, the converter gas is conveyed to a CO2 absorption system, CO2 is absorbed and absorption liquid rich in CO2 is obtained, the CO2-removed converter gas is rich in CO which can be used as significant energy for metallurgy and can be used for hot blast heater waste heat air, coke oven, power station boiler, steel rolling heating furnace and the like, CO2-absorbed solution is desorbed by a CO2 separation system for CO2 separation, and the separated CO2 and external CO2 are circularly used for convertor slag splashing protection, bottom blowing and top blowing, recycling of the convertor gas in a workshop can be achieved, the utilization rate of the convertor gas can be improved, the emission of CO2 can be reduced, and significant social and environmental benefits can be obtained.

Owner:PEKING UNIV

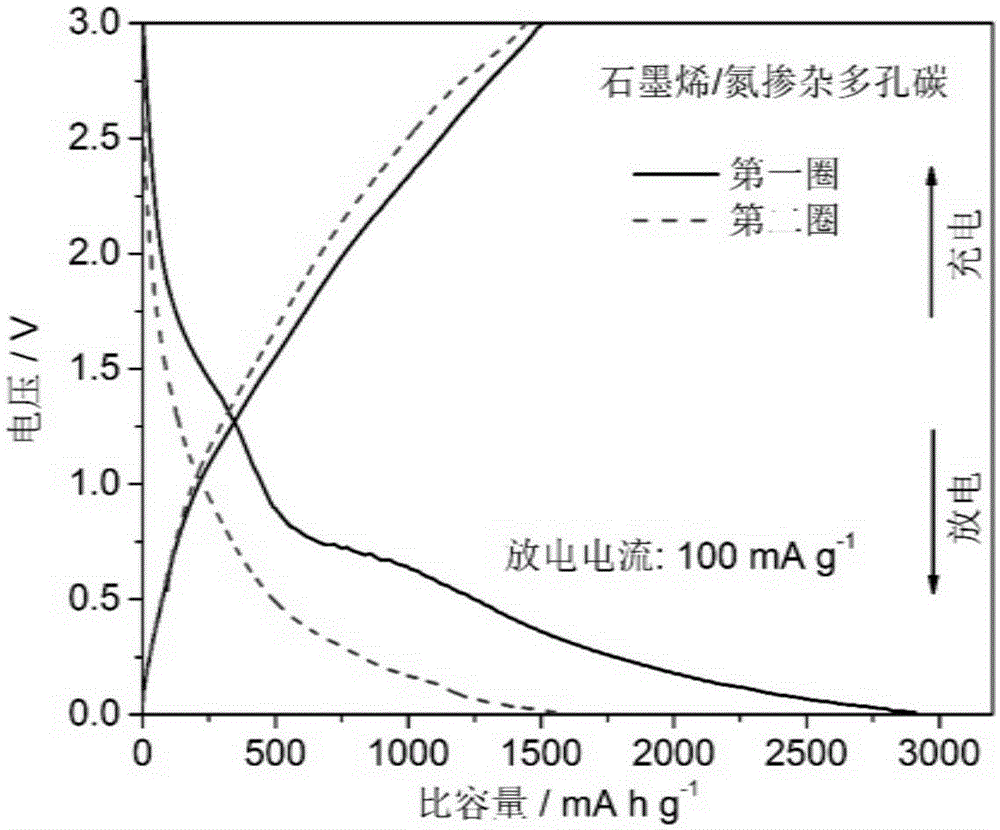

High-performance carbon-based negative electrode material of lithium ion battery and preparing method thereof

ActiveCN105185967AHigh theoretical capacityThe preparation technology is simpleSecondary cellsNegative electrodesPower flowPorous carbon

The invention provides a high-performance carbon-based negative electrode material suitable for a lithium ion battery and a preparing method thereof. An improved fused salt heating method is used as the preparing method, a three-dimensional structure carbon material having the high specific surface and microtopography at the same time is obtained. The morphology structure is characterized in that a conductive one-dimensional linear carbon material or a conductive two-dimensional sheet-shaped carbon material serves as a framework, and the outer surface of the framework is evenly coated with porous carbon particles. The carbon material serves as the high-performance negative electrode material of the lithium ion battery and has the advantages of being high in mass energy density, good in large-current discharging capacity, long in service life, environmentally friendly and free of heavy metal elements. The preparing method is simple, low in requirement for reaction devices and suitable for industrial production.

Owner:NANJING UNIV OF TECH

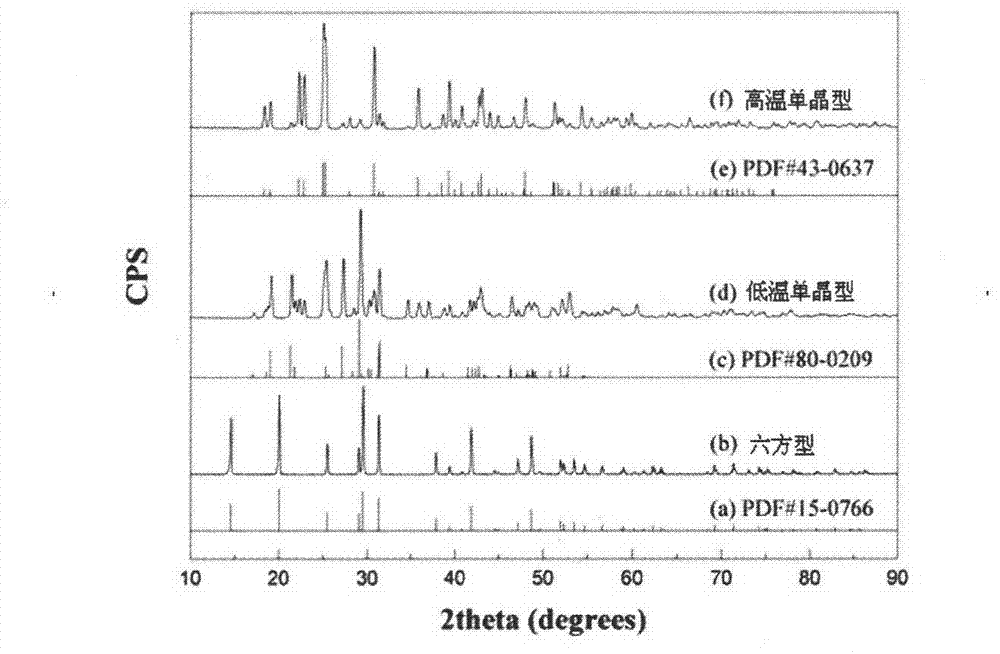

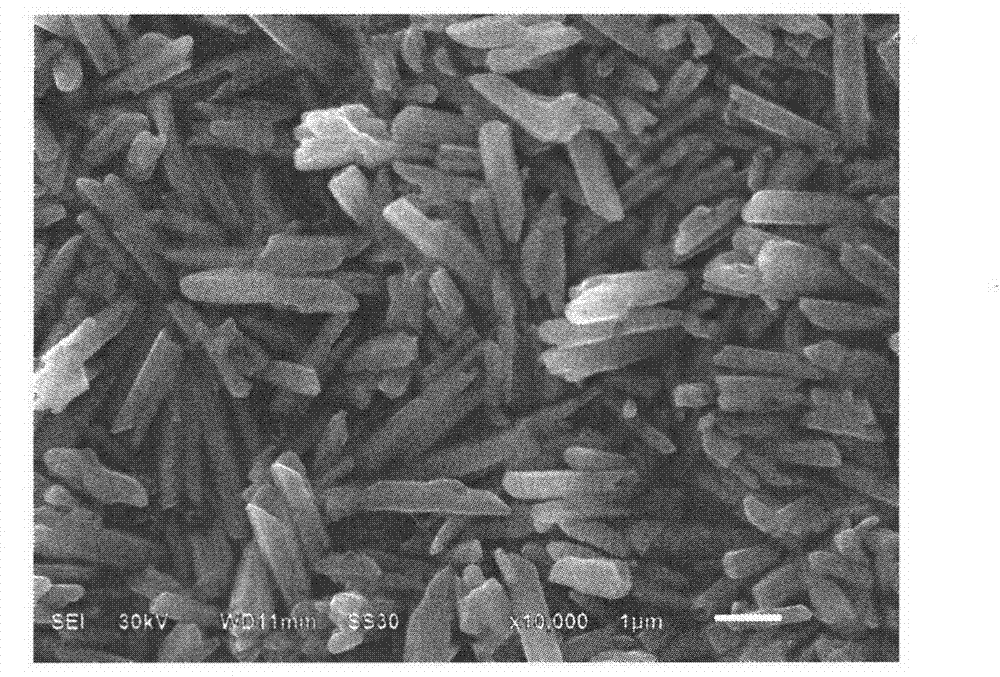

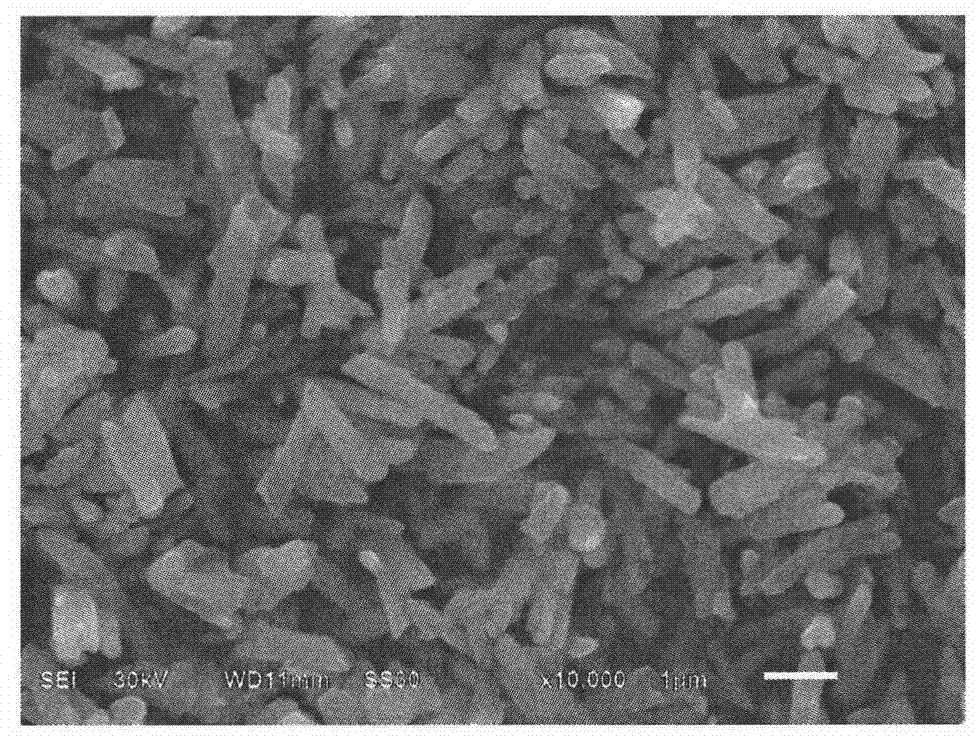

Preparation method of lithium ion battery anode materials BiPO4 based on chemical conversion reaction and lithium ion battery for manufacturing

InactiveCN102862967ALow costThe preparation process is simple and controllableCell electrodesSecondary cellsElectrical batterySingle crystal

The invention discloses a preparation method of lithium ion battery anode materials BiPO4 based on a chemical conversion reaction and a lithium ion battery for manufacturing. The invention has the technical effects that a preparation method of lithium ion battery anode materials BiPO4 based on a chemical conversion reaction and a lithium ion battery for manufacturing are provided, wherein the anode materials BiPO4 include a hexagonal crystal type containing crystal water, a low-temperature single crystal type without crystal water, and a high-temperature single crystal type. The anode materials BiPO4 have a theoretical output voltage of about 3.1V, a theoretical specific discharge capacity of 265.5mAh g<-1>, a theoretical mass energy density of 830.5Whkg<-1>, and a volume energy density of 5253.1Wh L<-1>; and all first specific discharge capacities under the multiplying power of 0.1C are greater than 240mAhg<-1>. According to the preparation method of lithium ion battery anode materials BiPO4 based on a chemical conversion reaction, the preparation process is simple and easy to control, the raw materials are low in cost, and the anode materials are environment-friendly, can be produced industrially on a large scale, and are potential novel anode materials. The prepared three different crystal types of anode materials BiPO4 can be applied to lithium ion batteries, thereby having an excellent application prospect.

Owner:XIANGTAN UNIV

Composite current collector and lithium ion battery

ActiveCN112751038ALow costReduce weightElectrode carriers/collectorsSecondary cellsLithium-ion batteryBattery cell

The invention provides a composite current collector which comprises at least two composite layers and a splicing fixing layer, the two composite layers are respectively a conductive layer containing a carbon material and a carrier layer containing a non-metallic material with holes, the conductive layer is connected with the carrier layer, and the edges of the conductive layer and the carrier layer are spliced and fixed through the splicing fixing layer. The weight of the current collector is reduced, so that the mass energy density of a battery is improved, the cycle life of the battery is prolonged, the overall structural stability of the current collector is improved, the cost is low, the lithium ion battery comprises a shell and a battery cell, the battery cell is arranged in the shell, and the battery cell comprises a positive electrode, a negative electrode and an isolating membrane between the positive electrode and the negative electrode; the positive electrode and the negative electrode of the lithium battery comprise the composite current collectors, the positive electrode and the negative electrode of the lithium battery are made of the composite current collectors, the mass energy density of the lithium battery is improved, the cycle life of the lithium battery is prolonged, and the production cost is reduced.

Owner:蜻蜓实验室(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com