Flexible current collector, electrode containing flexible current collector, and battery

A flexible current collector and electrode technology, applied in the direction of electrode carrier/collector, battery electrode, non-aqueous electrolyte battery electrode, etc., can solve the problems affecting battery performance efficiency, poor machining performance, battery leakage current, etc., and achieve good electrical conductivity Performance, good machinability, and the effect of increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

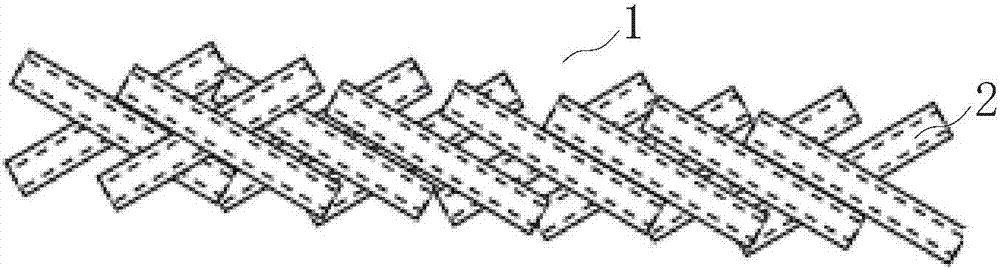

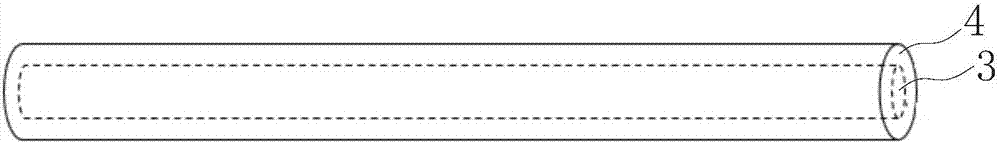

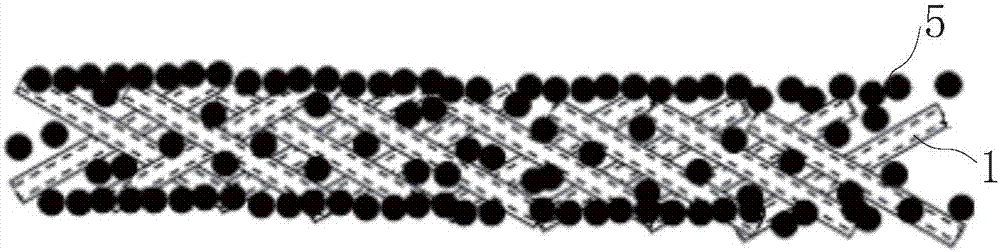

[0053] The total thickness of the prepared flexible current collector is 35 μm, the textile substrate has 4 layers, the material is polyester, the diameter of the polyester fiber is 7-10 μm, the material of the metal conductive plating layer is copper-nickel, and the total thickness is 2 μm.

[0054] It has been determined that the mass per unit area of the flexible current collector is 37g / m 2 , the surface resistance is ~35mΩ;

[0055] When baked at 120°C for 5 hours, the thermal shrinkage rate is less than 1%, and the resistance change is less than 2%; when the bending radius is 1em, it is bent 180° more than 20,000 times, and the resistance change is less than 2%.

Embodiment 2

[0057] The total thickness of the prepared flexible current collector is 45 μm, and the textile substrate has 5 layers, the material is polyester, the diameter of the polyester fiber is 7-10 μm, the material of the metal conductive plating layer is copper, and the total thickness is 2 μm.

[0058] It has been determined that the mass per unit area of the flexible current collector is 50g / m 2 , the surface resistance is ~25mΩ;

[0059] When baked at 120°C for 5 hours, the heat shrinkage rate is less than 1%, and the resistance change is less than 2%; when the bending radius is 1cm, it is bent 180° more than 20,000 times, and the resistance change is less than 2%.

Embodiment 3

[0061] The total thickness of the prepared flexible current collector is 35 μm. The textile substrate has 4 layers, the material is polyester, the diameter of the polyester fiber is 7-10 μm, the material of the metal conductive coating is aluminum, and the total thickness is 3 μm.

[0062] It has been determined that the mass per unit area of the flexible current collector is 23g / m 2 , the surface resistance is ~45mΩ;

[0063] When baked at 120°C for 5 hours, the heat shrinkage rate is less than 1%, and the resistance change is less than 2%; when the bending radius is 1cm, it is bent 180° more than 20,000 times, and the resistance change is less than 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com