A kind of copper-aluminum composite material and preparation method thereof

A copper-aluminum composite material and copper ion technology, which is applied in the field of nanomaterials, can solve the problems of weak interface bonding strength, weakened bonding strength of copper-aluminum composite connectors, and difficult assembly and processing, and achieves reduction of rolling force and heat treatment annealing temperature. The effect of improving the interface bonding strength and mechanical properties, shortening the production cycle and energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

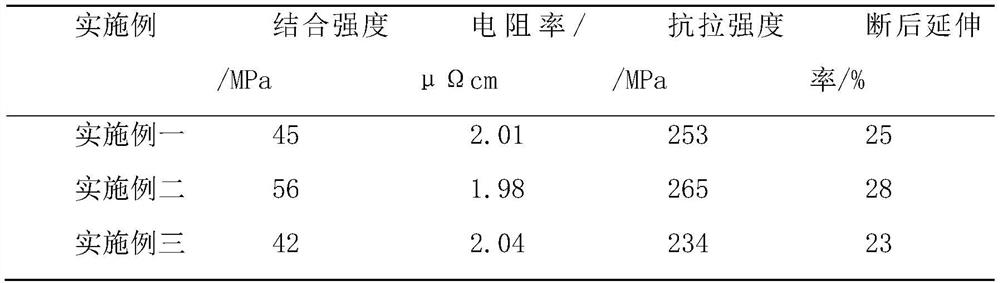

Embodiment 1

[0029] This embodiment provides a copper-aluminum composite material, including a Cu metal plate and an Al metal plate, and the Cu metal plate and the Al metal plate are combined into one body through cold rolling, wherein, before the cold rolling combination, the Cu metal plate and the Al metal plate are combined into one body. The surface of the metal plate is uniformly sprayed with Cu nanosol particles, and in-situ etching forms abundant active sites, and a three-dimensional rough structure is constructed on the surface of Cu and / or Al metal. Formation of Cu nanosol particles for etching-assisted solid-state connection of copper-aluminum composites.

[0030] In the above embodiment, the sol technology and surface nano-etching technology are introduced to controllably prepare Cu nano-sol particles with uniform size and controllable shape, and the Cu nano-sol particles are sprayed onto the surface of Cu and / or Al metal, and in-situ etching is performed. Erosion builds a three...

Embodiment 2

[0038] This embodiment provides a copper-aluminum composite material, a Cu metal plate and an Al metal plate, and the Cu metal plate and the Al metal plate are composited into one body through cold rolling, wherein, before the cold rolling composite, the surface of the Cu metal plate is uniformly sprayed Cu nano-sol particles are etched in-situ to form abundant active sites, and a three-dimensional rough structure is constructed on the surface of Cu metal to form Cu nano-sol particles assisted by solid-state connection of copper-aluminum composite materials. Promote the interlocking of the Cu metal surface, and form a dual high-strength metallurgical bond between the Cu / Al interface and the side through the atomic diffusion and migration through the abundant active sites in the interface under the action of lower stress, avoiding the formation of intermediate phases and reducing the composite material. Interface internal resistance; effectively improve the interface bonding str...

Embodiment 3

[0048] This embodiment provides a copper-aluminum composite material, including: a Cu metal plate and an Al metal plate, and the Cu metal plate and the Al metal plate are composited into one body by cold rolling, wherein, before the cold rolling composite, on the surface of the Al metal plate The Cu nano-sol particles are uniformly sprayed, and abundant active sites are formed by in-situ etching, and a three-dimensional rough structure is constructed on the surface of the Al metal to form a Cu nano-sol particle etching-assisted solid-state connection of copper-aluminum composite materials. Promote the interlocking of Cu and Al metal surfaces, and form a high-strength metallurgical bond between the Cu / Al interface and the side surfaces through atomic diffusion and migration through the abundant active sites at the interface under lower stress, avoiding the formation of intermediate phases and reducing the recombination. The interface internal resistance of the material; effectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com