Electric refrigerated truck power supply system and control method thereof, electric refrigerated truck

A technology for power supply systems and refrigerated vehicles, applied to the power supply of electric heating circuits, motor vehicles, trucks, etc., can solve the problems that relays cannot be detected and processed in time, the status is not monitored and fed back in time, and there is no emergency measure for backup power schemes, etc. To achieve double protection, reduce the connection of pipelines, and reduce the effect of cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

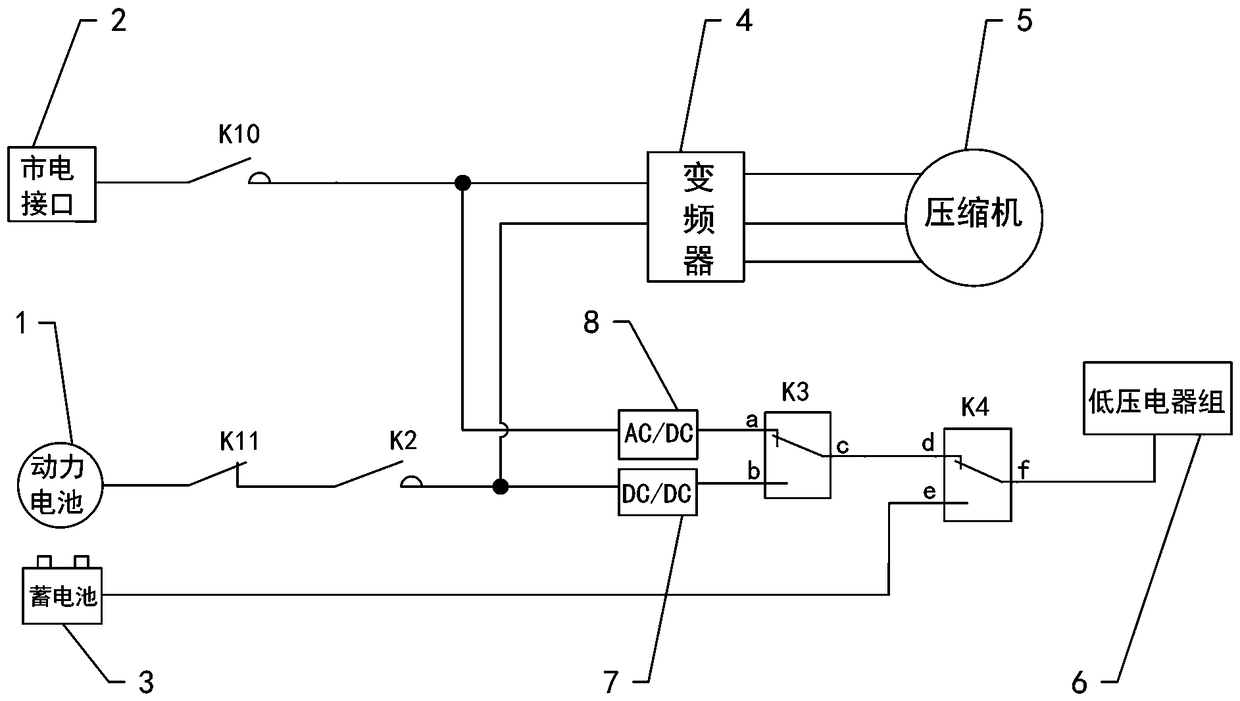

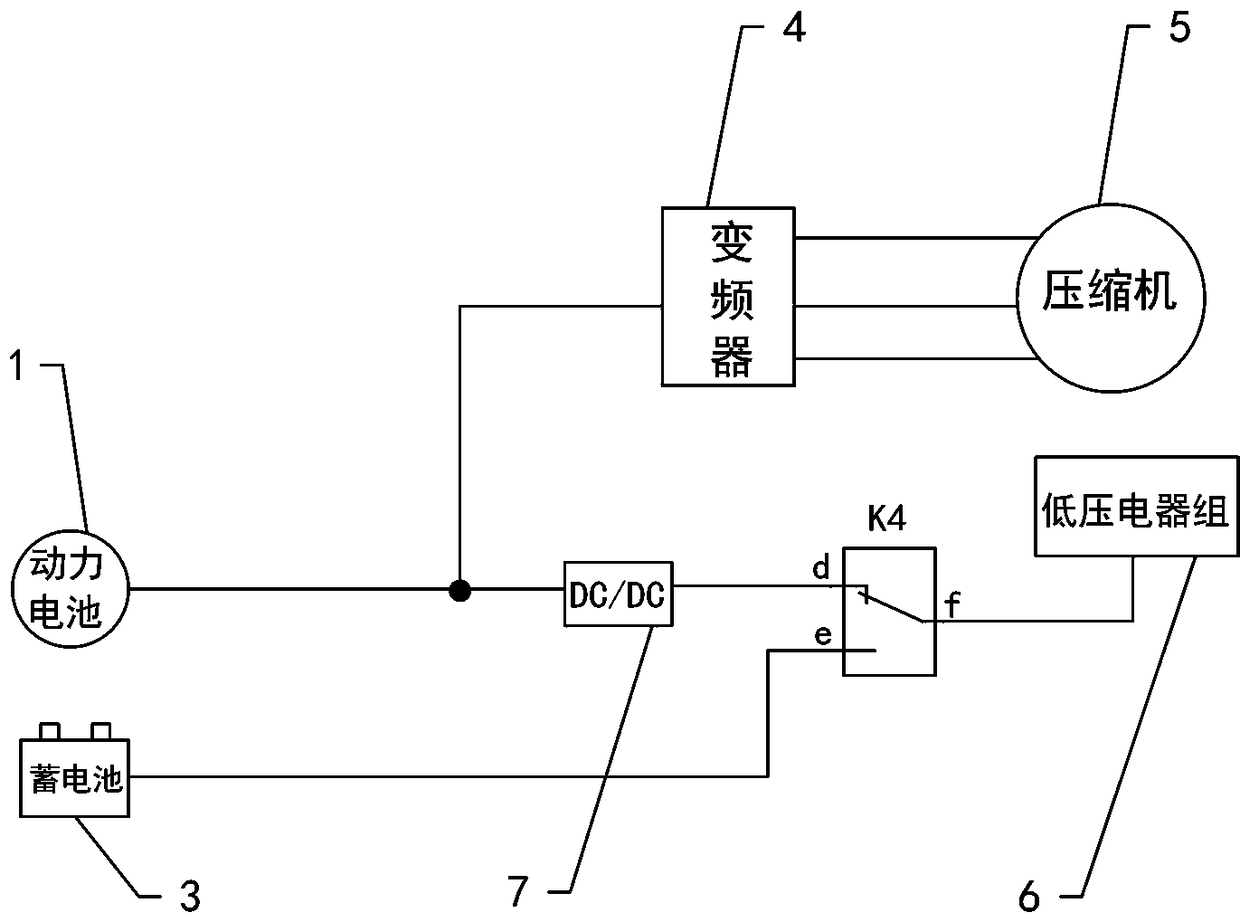

[0048] Such as figure 1 As shown, this embodiment discloses a power supply system for an electric refrigerated vehicle, which includes:

[0049] Power battery 1, which can output 540V DC, and power battery 1 can provide DC high voltage for the refrigeration unit;

[0050] Mains power interface 2, which can be connected to the mains, which can output 380V alternating current, and the mains can provide AC high-voltage power for the refrigeration unit;

[0051] Battery 3, which can provide 24V low-voltage electricity;

[0052] A first-level switch group, which is a double-throw switch K4, the double-throw switch K4 is provided with a moving end d, a moving end e, and a non-moving end f, and the double-throw switch K4 is normally closed to the moving end d;

[0053] A secondary switch group, which is a double-throw switch K3, the double-throw switch K3 is provided with a moving end a, a moving end b, and a non-moving end c, and the double-throw switch K3 is normally closed to th...

Embodiment 2

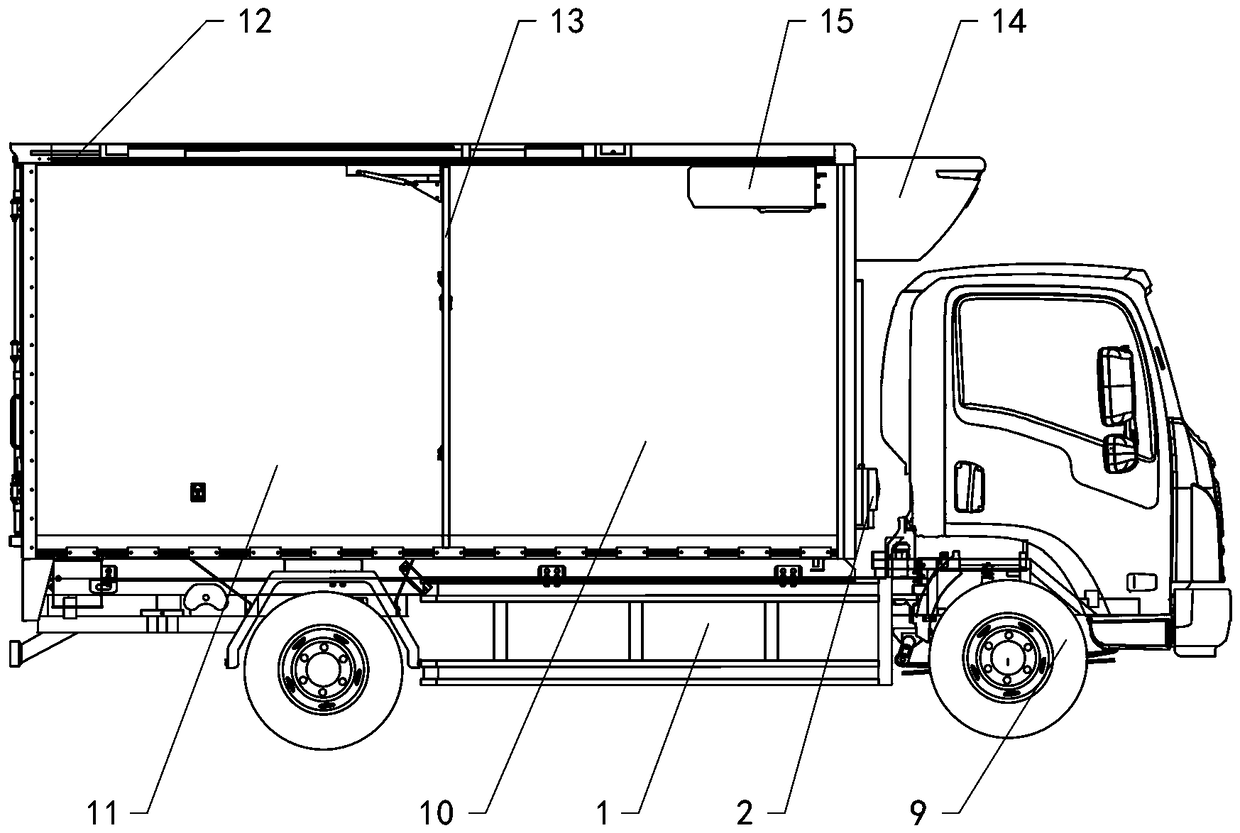

[0065] Such as image 3 The present embodiment shown provides an electric refrigerated vehicle, which includes an operation panel, a chassis 9, a condenser 14, an evaporator 15, a partition 13, a refrigerated compartment 12, and the power supply system for an electric refrigerated vehicle described in Embodiment 1. The device 14 is arranged outside the refrigerated compartment 12, the evaporator 15 is arranged inside the refrigerated compartment 12, the refrigerated compartment 12 is fixed on the chassis 9, and the refrigerated compartment 12 is divided into a refrigerated compartment 11 and a frozen compartment 10 by a partition 13.

[0066] Wherein, the temperature of the refrigerating compartment 11 can be set at 0-20°C, and the temperature of the freezing compartment 10 can be set at -30-0°C. The electronic fan and temperature sensor are arranged inside the refrigerated compartment 12 , and the partition 13 is provided with a square air duct, and the electronic fan is used...

Embodiment 3

[0069] This embodiment provides a control method for a power supply system of an electric refrigerated vehicle, which is applied to the power supply system of an electric refrigerated vehicle described in Embodiment 1.

[0070] Such as Figure 4 As shown, the main flow of the control method of the electric refrigerated vehicle power supply system includes the following steps:

[0071] Step S1 is to detect whether there is mains access, specifically, the control module detects whether the mains interface is connected to the mains, if the mains interface is connected to the mains, then perform step S3, if the mains interface is not connected to the mains, Then step S2 is executed.

[0072] Step S2 is to enter the vehicle power mode, specifically, the power battery supplies power to the refrigeration unit.

[0073] Step S3 is to enter the mains power mode, specifically, the mains supplies power to the refrigeration unit through the mains interface.

[0074] Step S4 is to detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com