Patents

Literature

1966results about "Trucks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

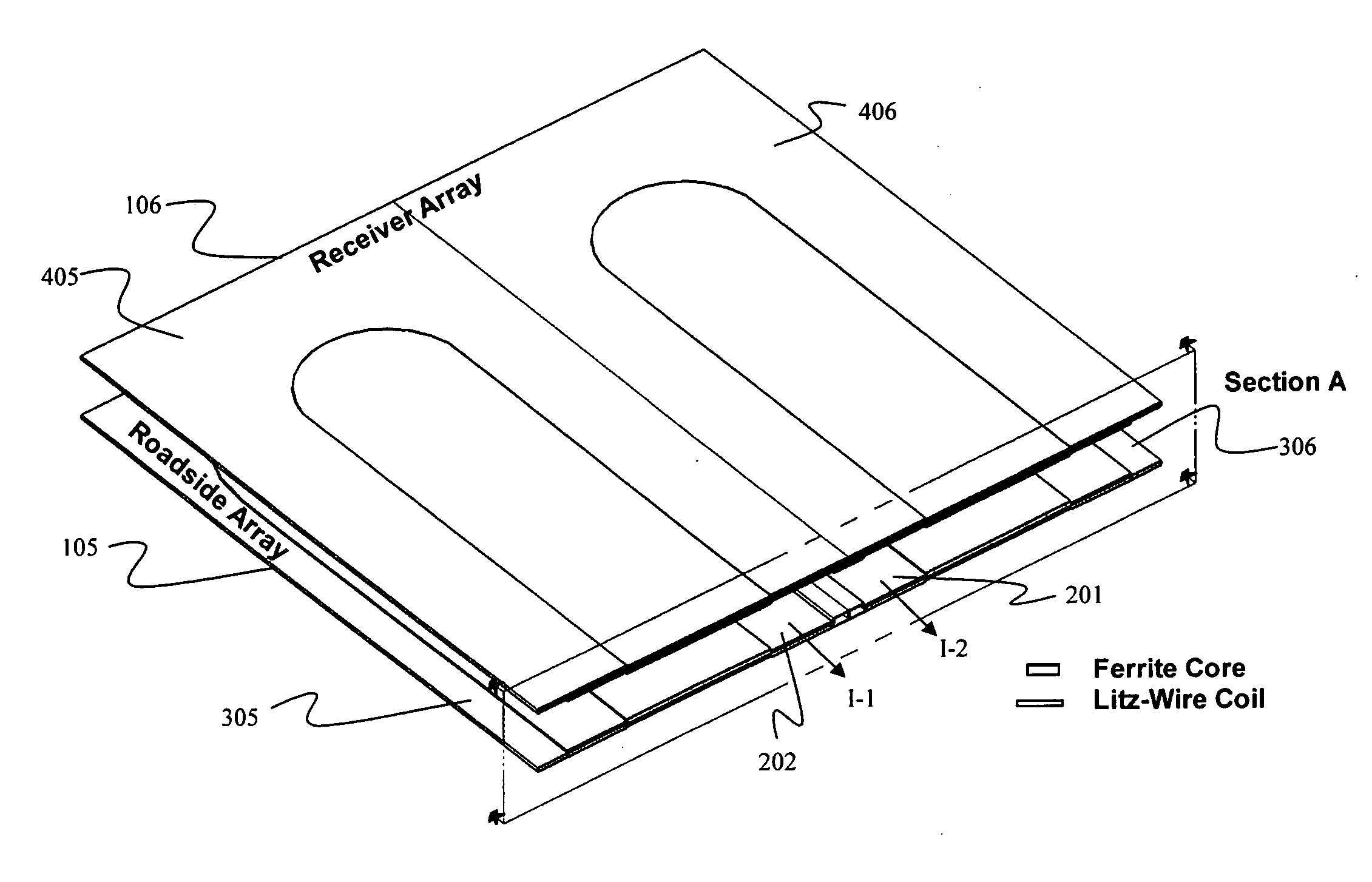

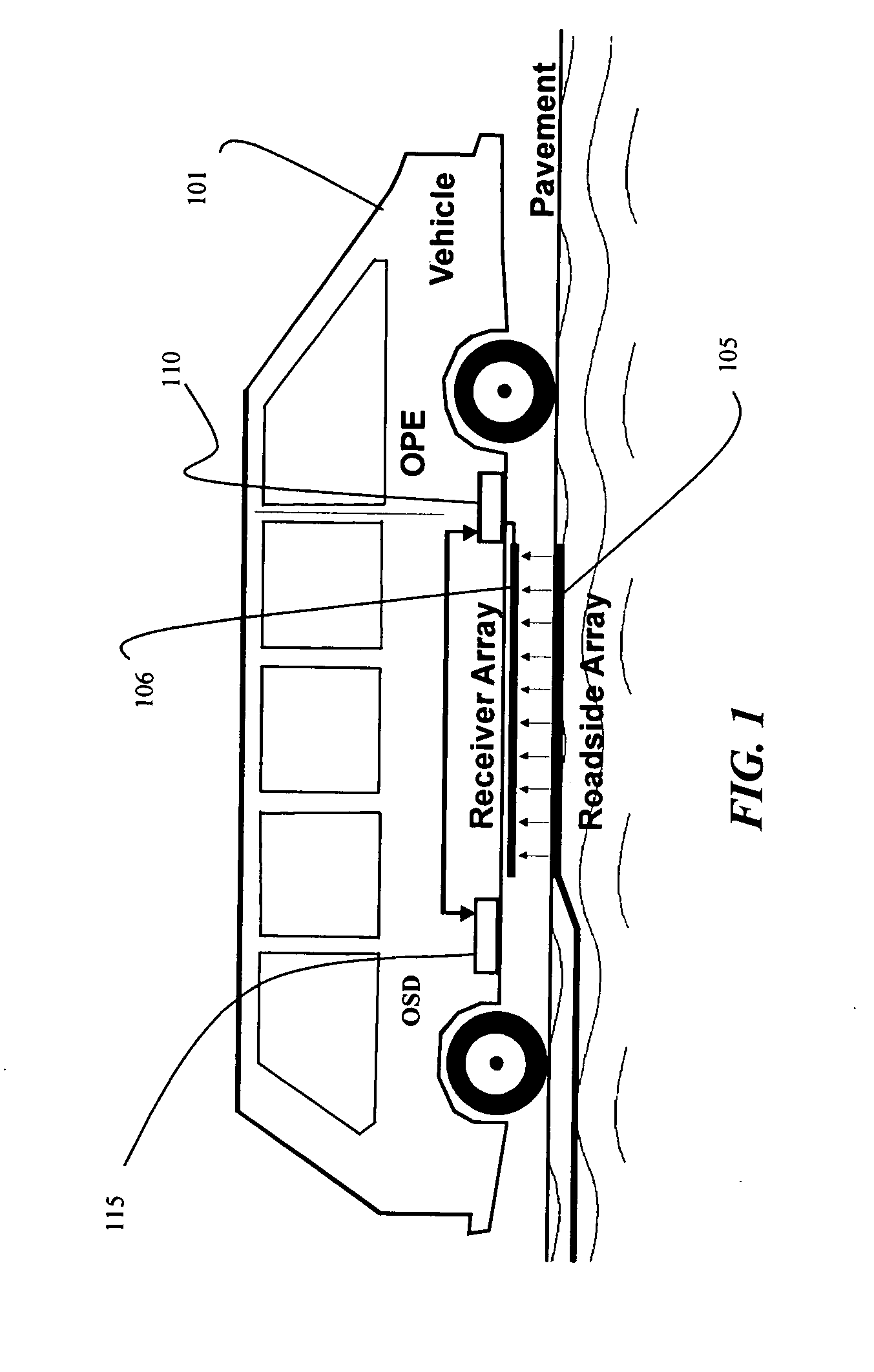

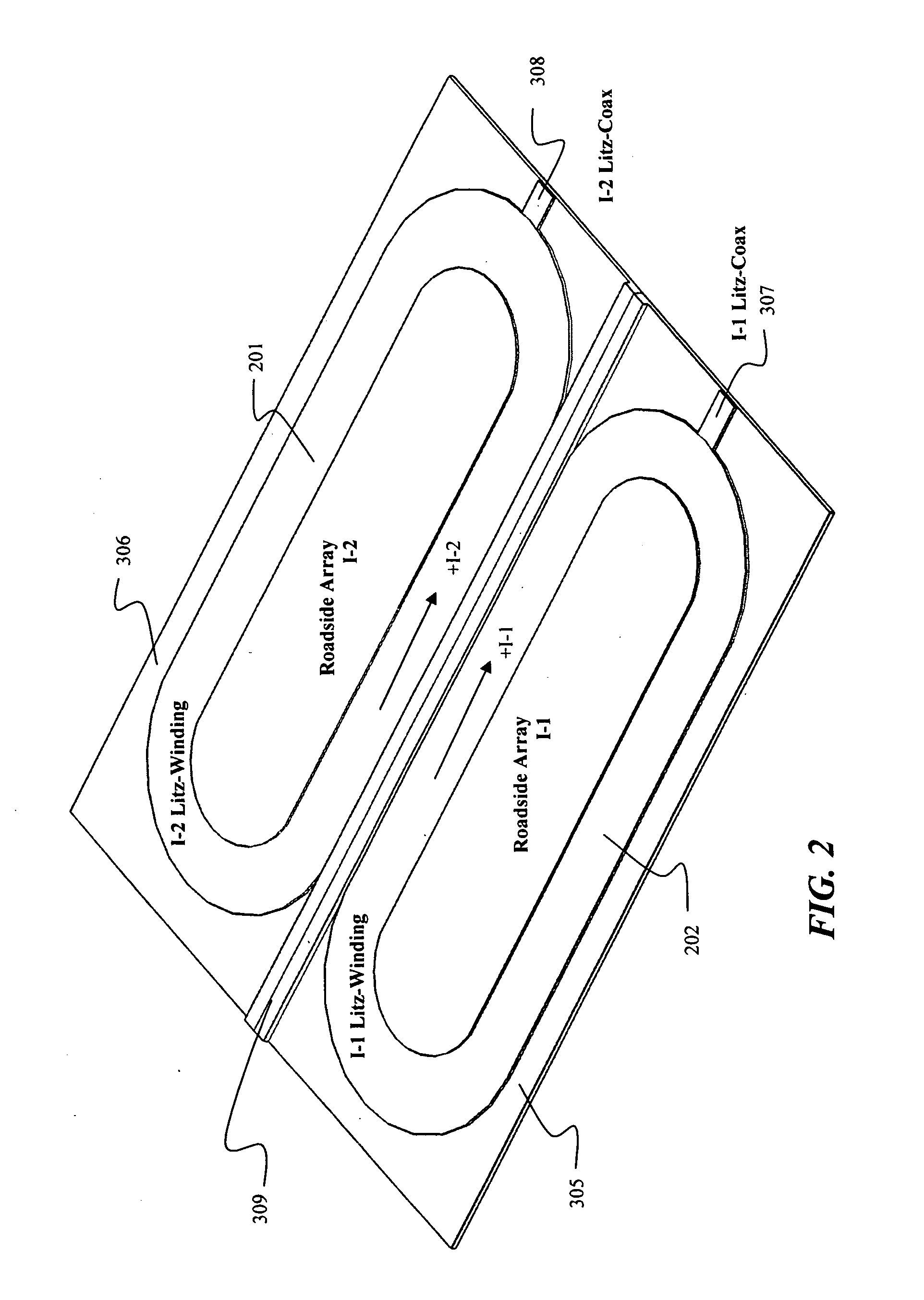

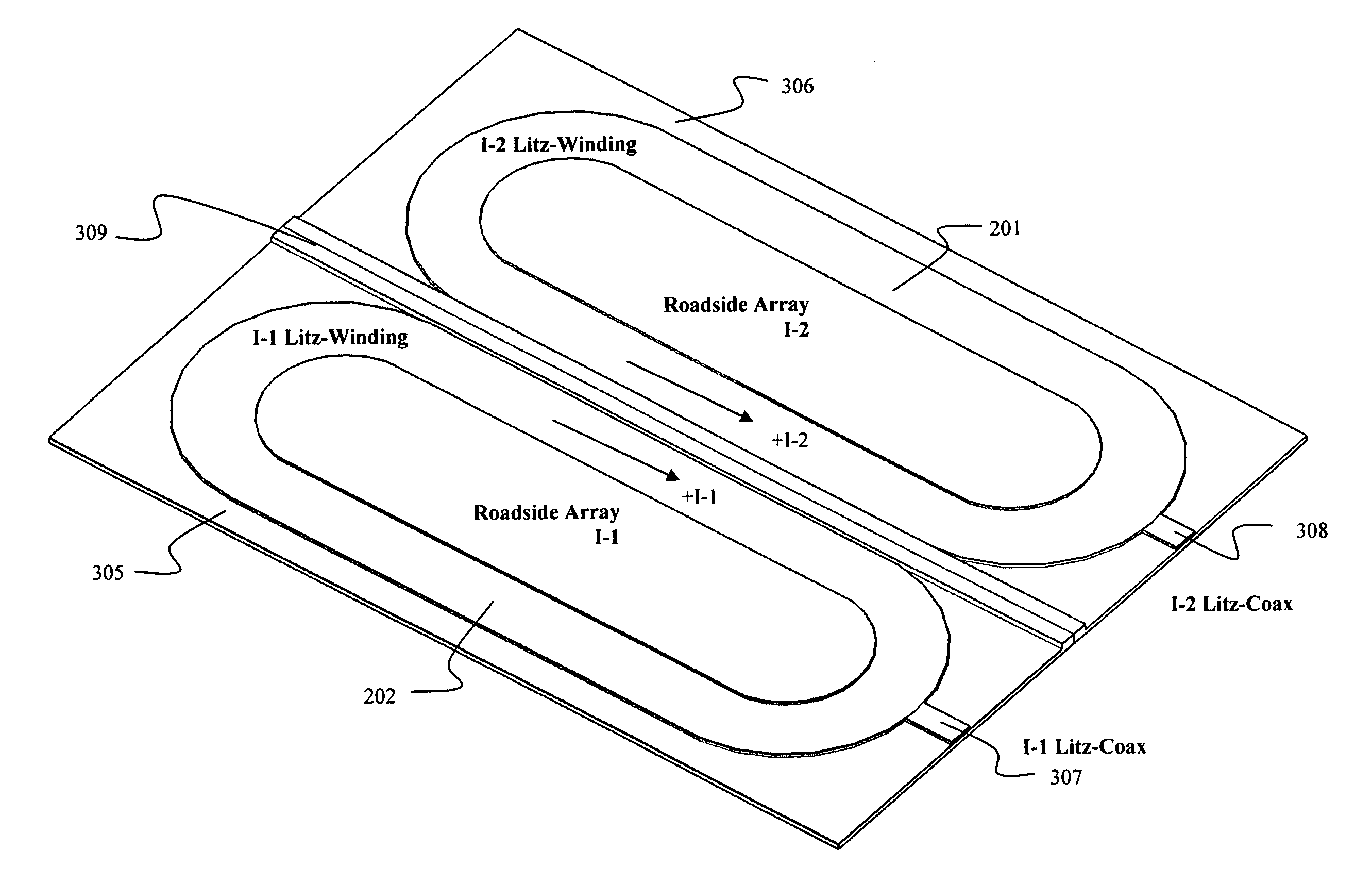

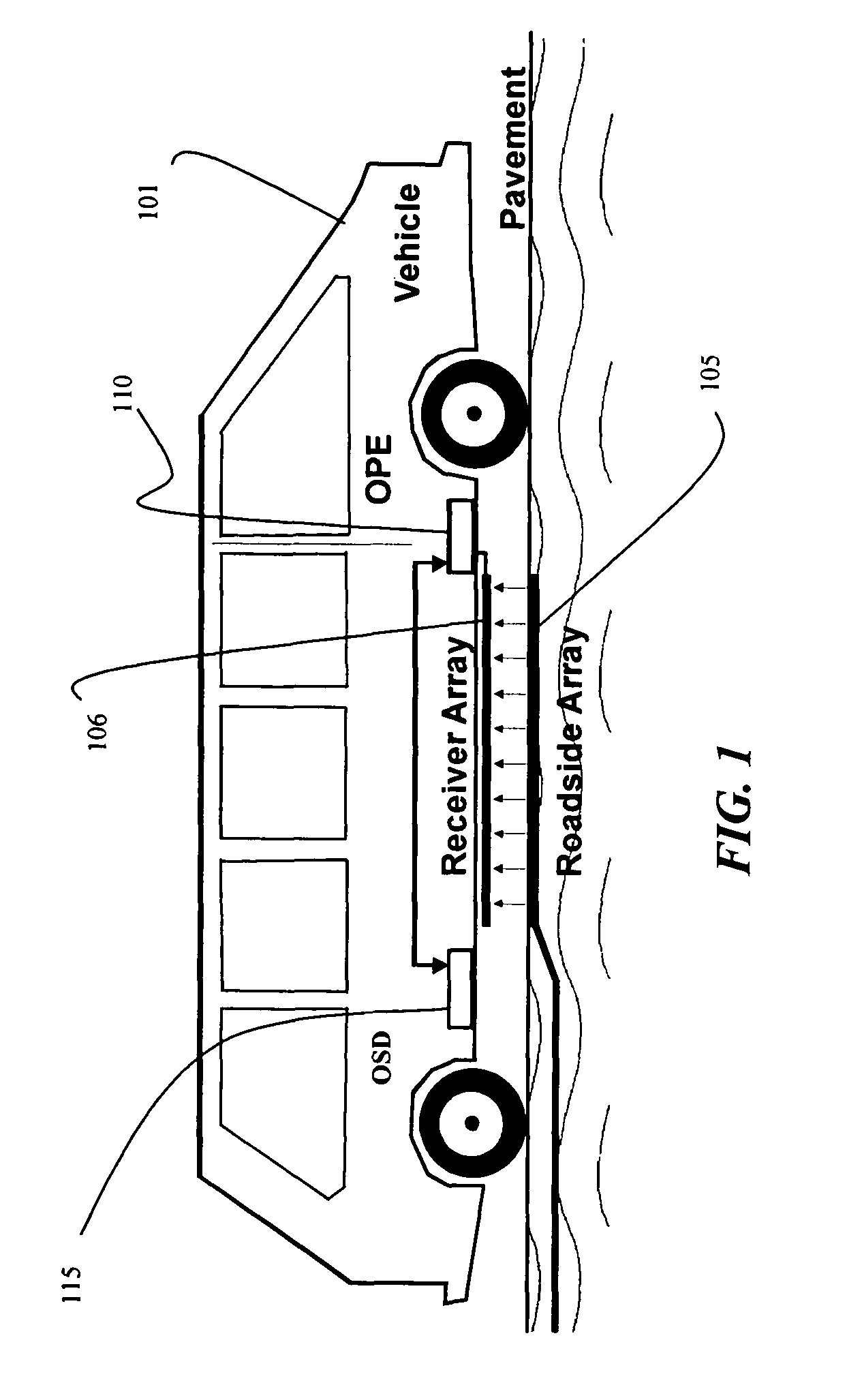

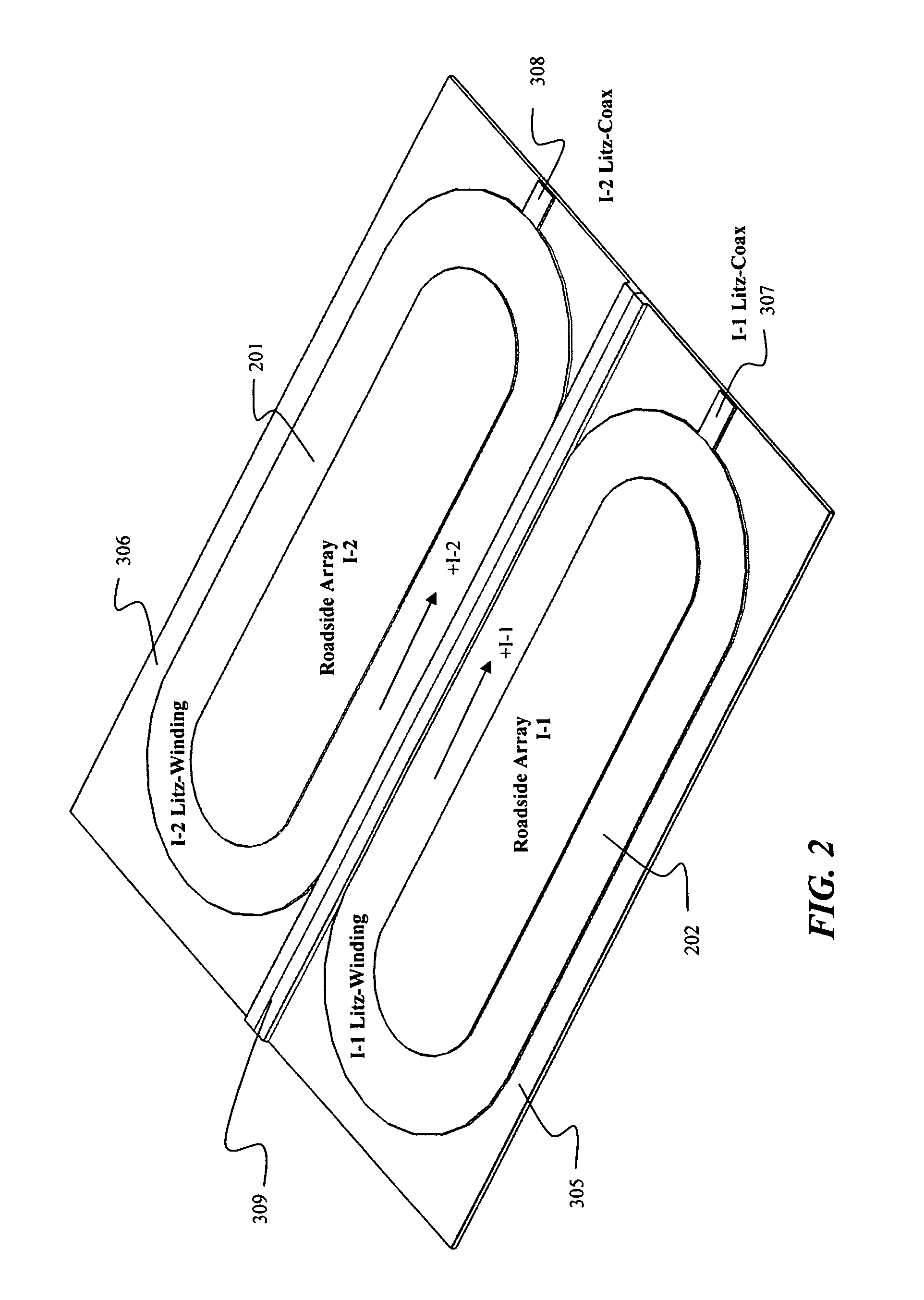

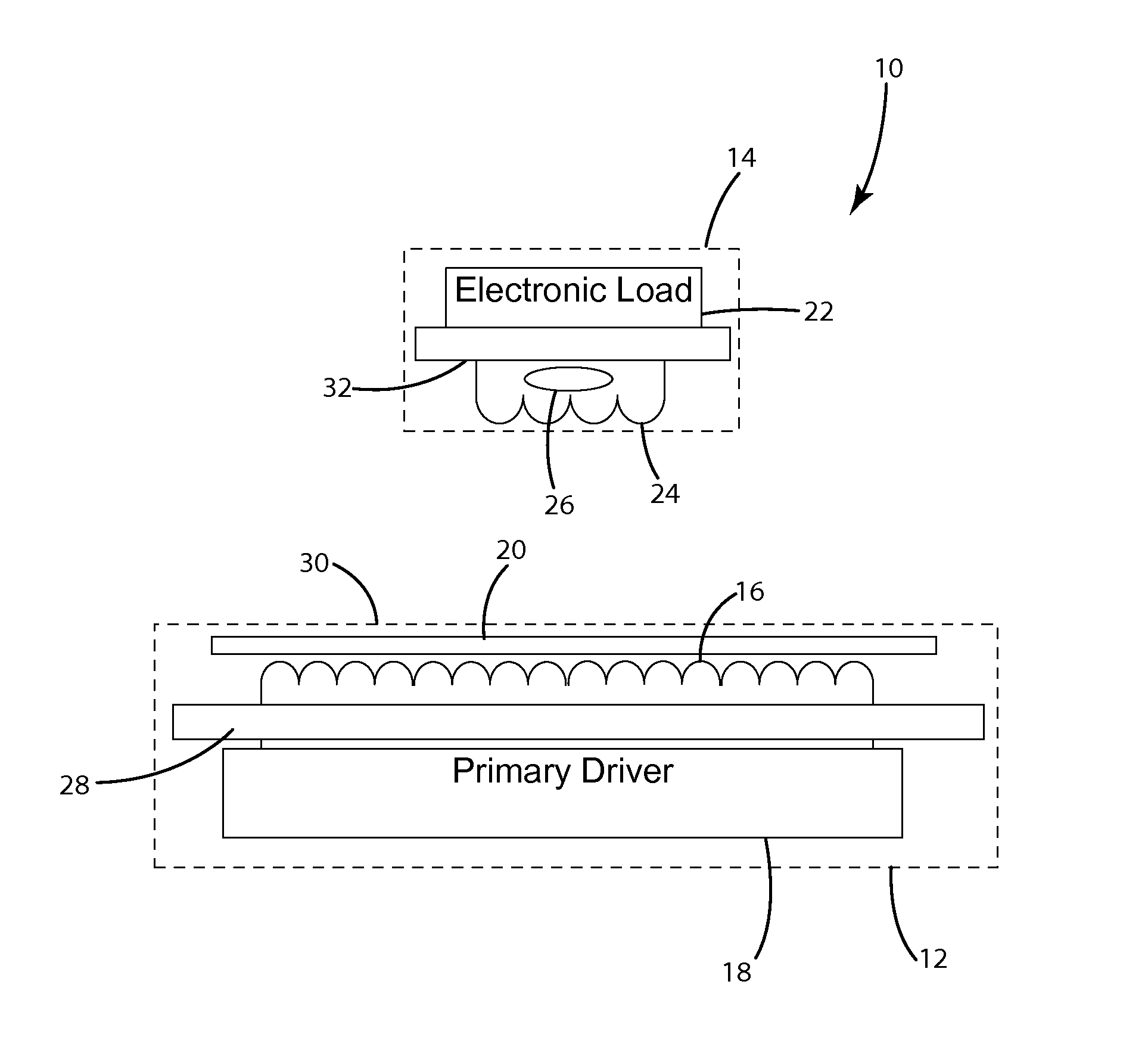

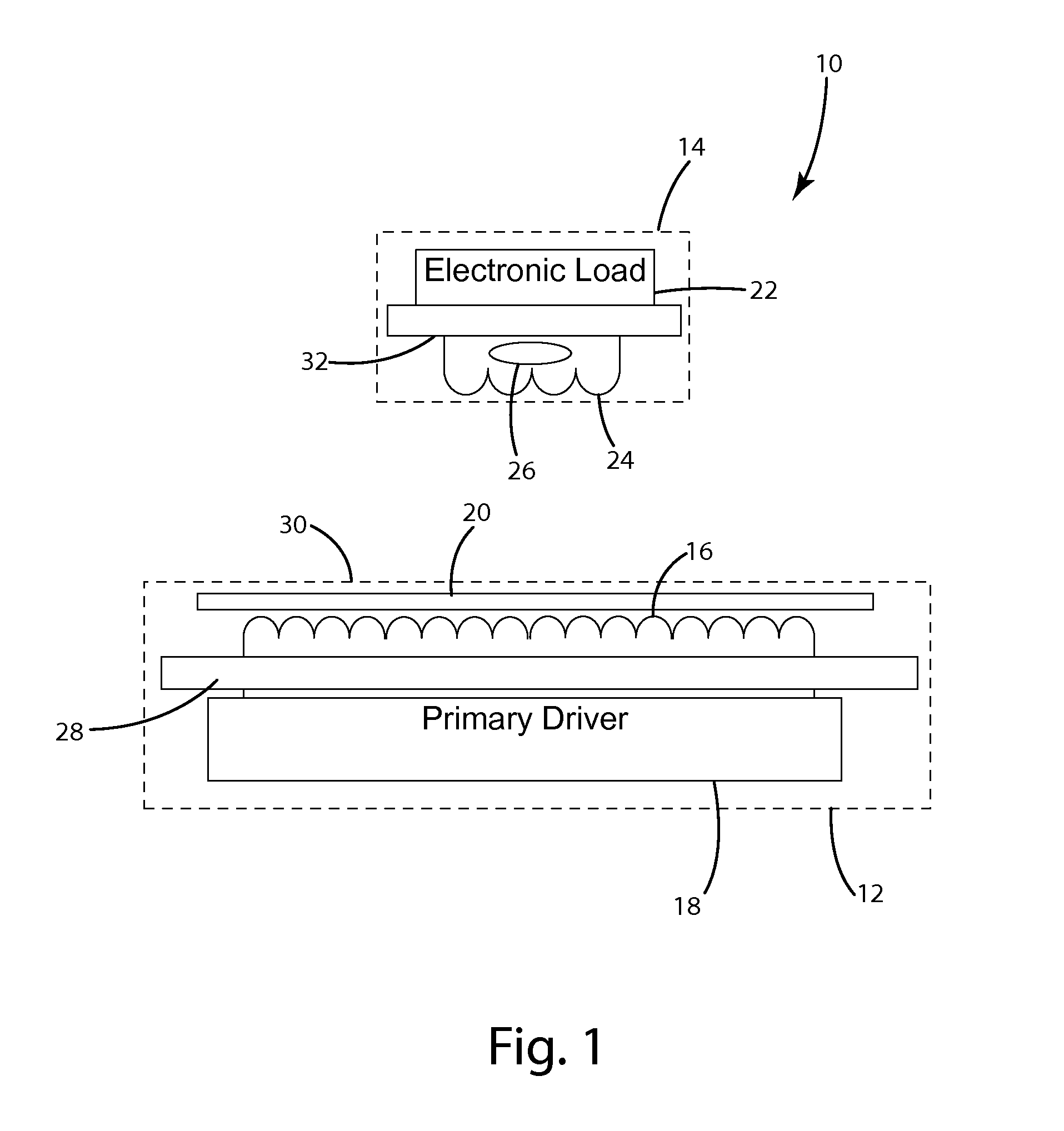

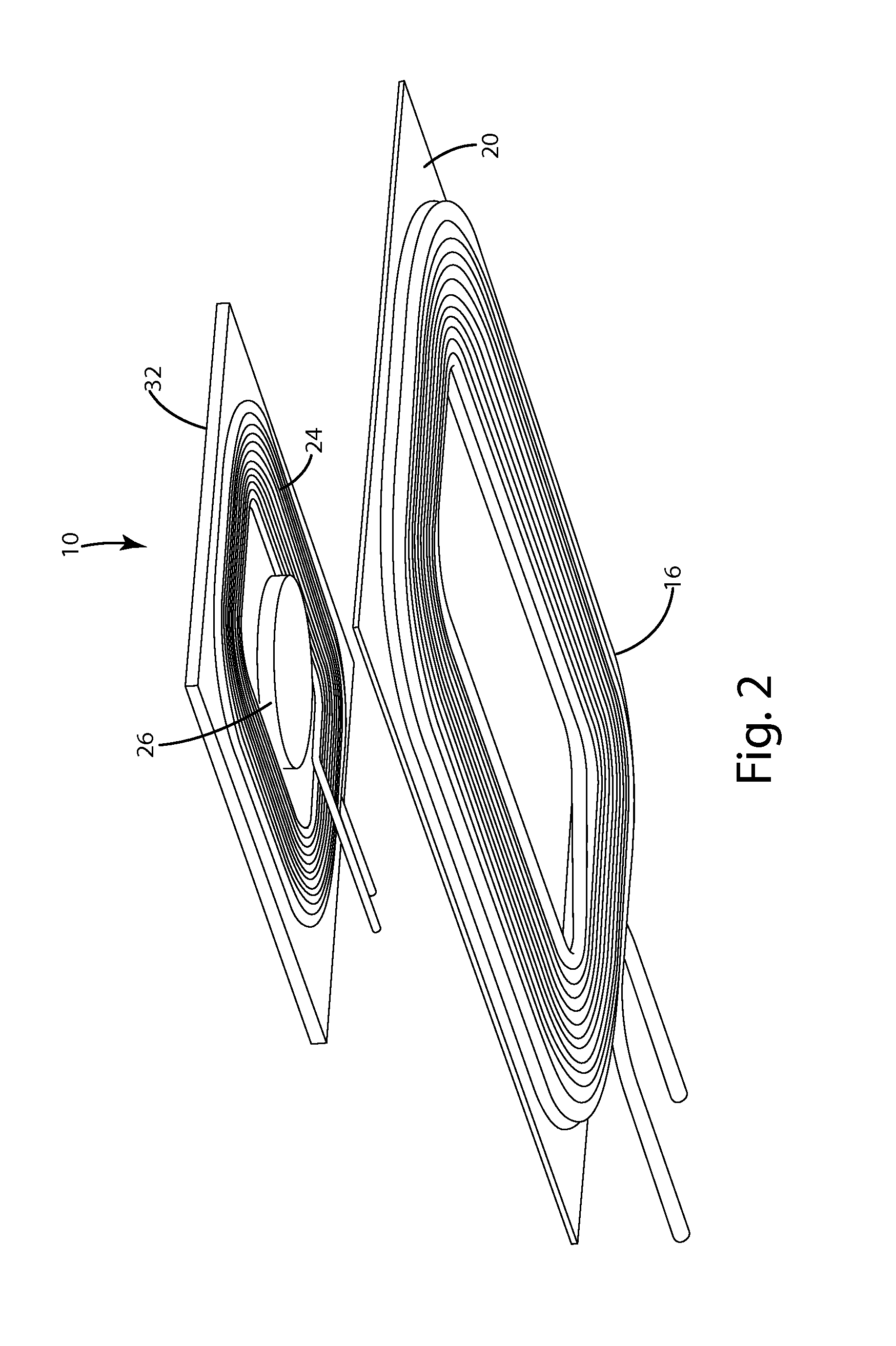

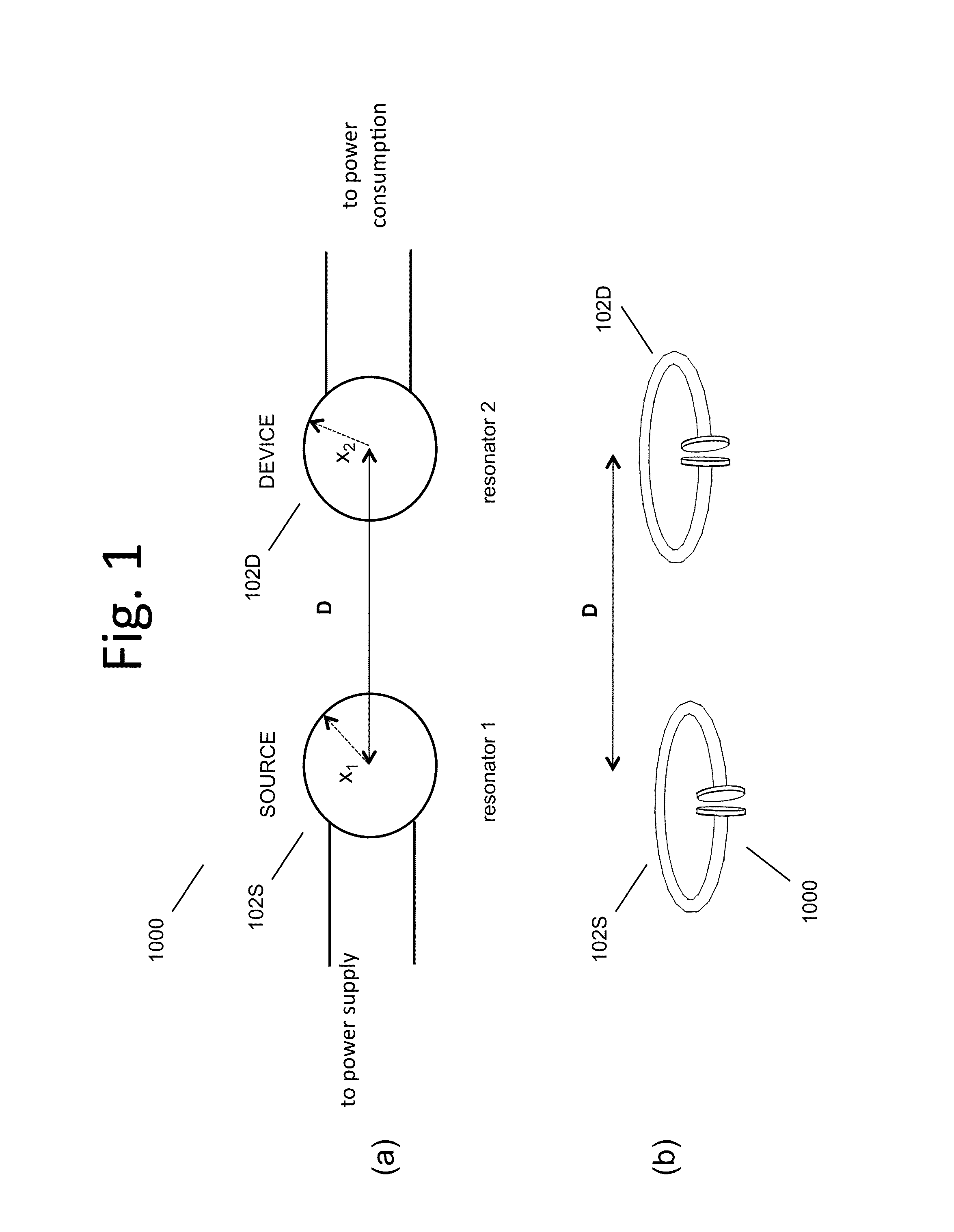

High power wireless resonant energy transfer system

InactiveUS20080265684A1Increase powerImprove distributionBatteries circuit arrangementsRailway vehiclesResonant energyTransfer system

Owner:FARKAS

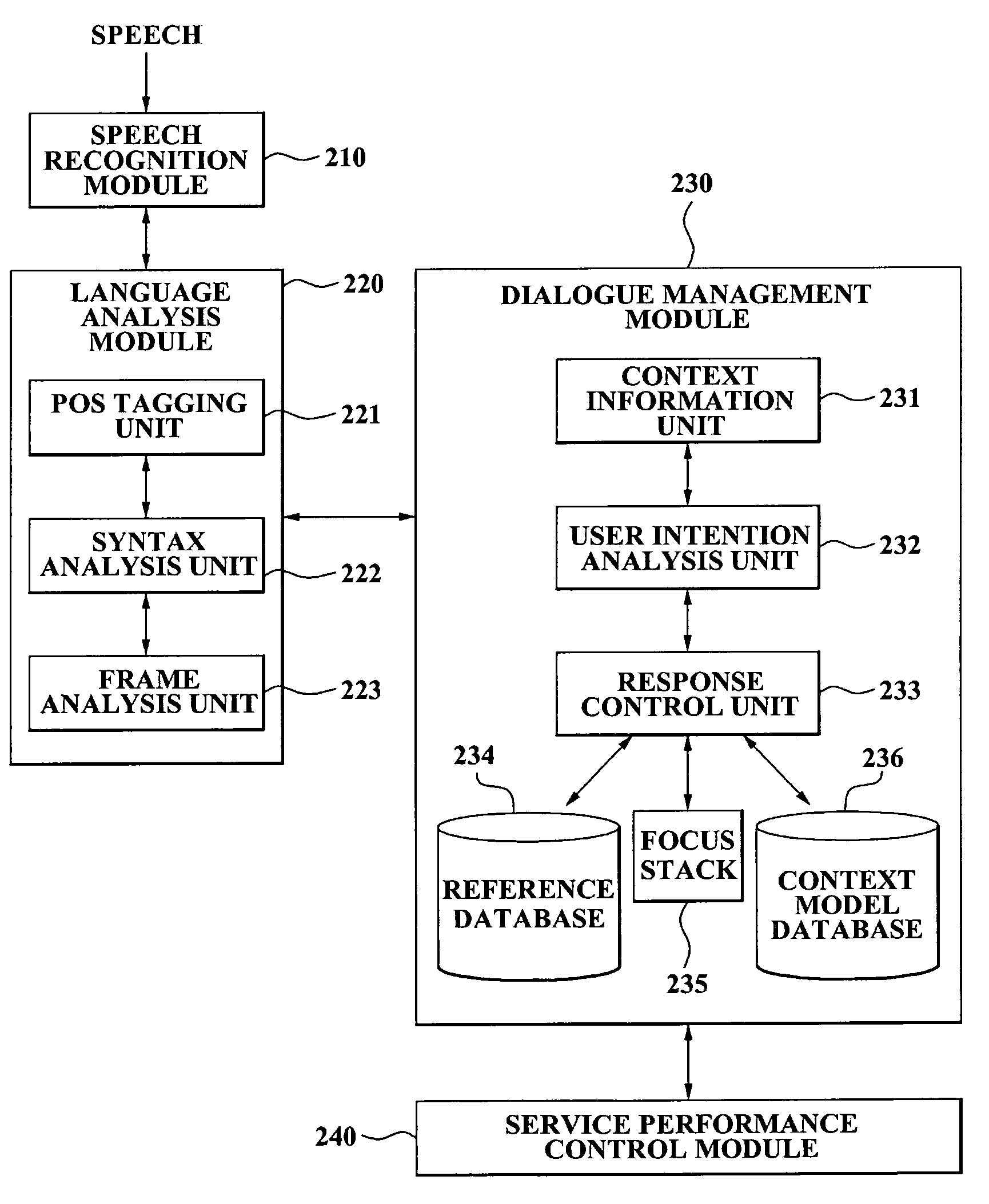

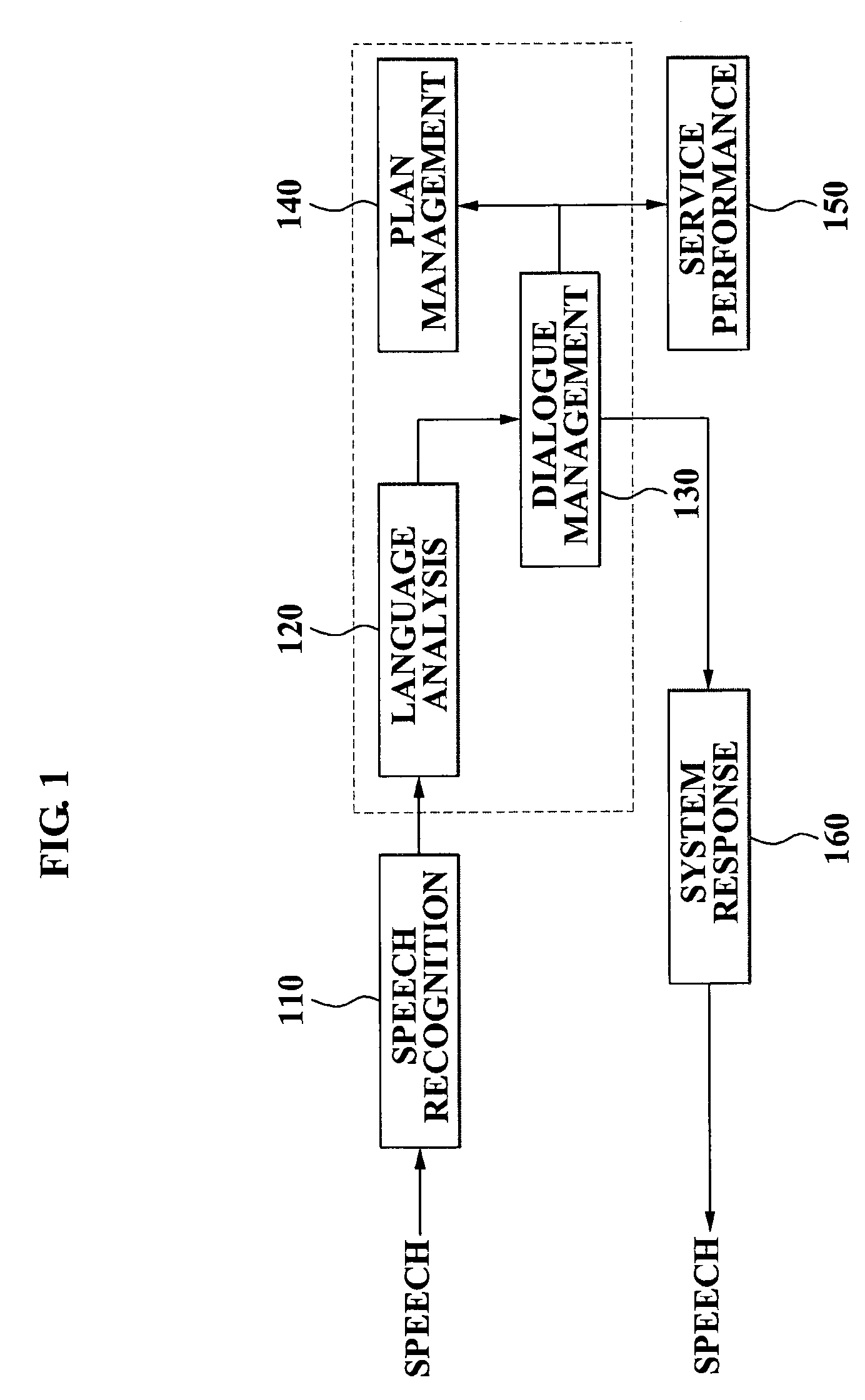

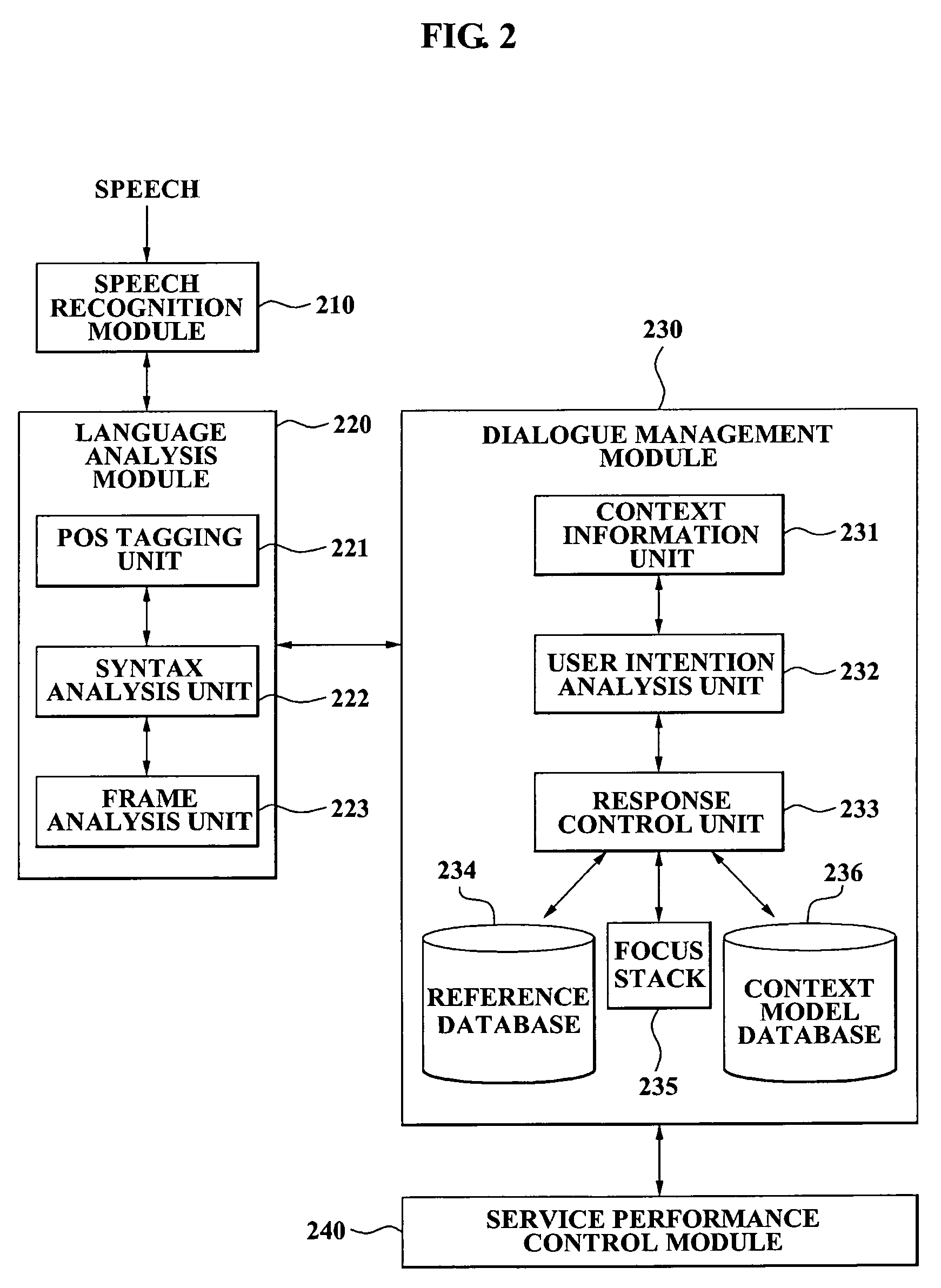

Apparatus for providing voice dialogue service and method of operating the same

InactiveUS7734461B2Accurate analysisAccurate contentSemantic analysisSpeech recognitionPart of speechSyntax

A speech dialogue service apparatus including: a language analysis module tagging a part of speech (POS) of each respective word included in a sentence recorded in a predetermined text, syntactically analyzing the sentence by classifying a meaning of each respective word, and generating at least one semantic frame corresponding to the sentence according to a result of the syntactical analysis; and a dialogue management module analyzing an intention of the sentence corresponding to the at least one respective semantic frame, and generating a system response corresponding to the sentence intention by selecting a predetermined sentence intention according to whether an action corresponding to the intention of the respective sentence can be performed.

Owner:SAMSUNG ELECTRONICS CO LTD

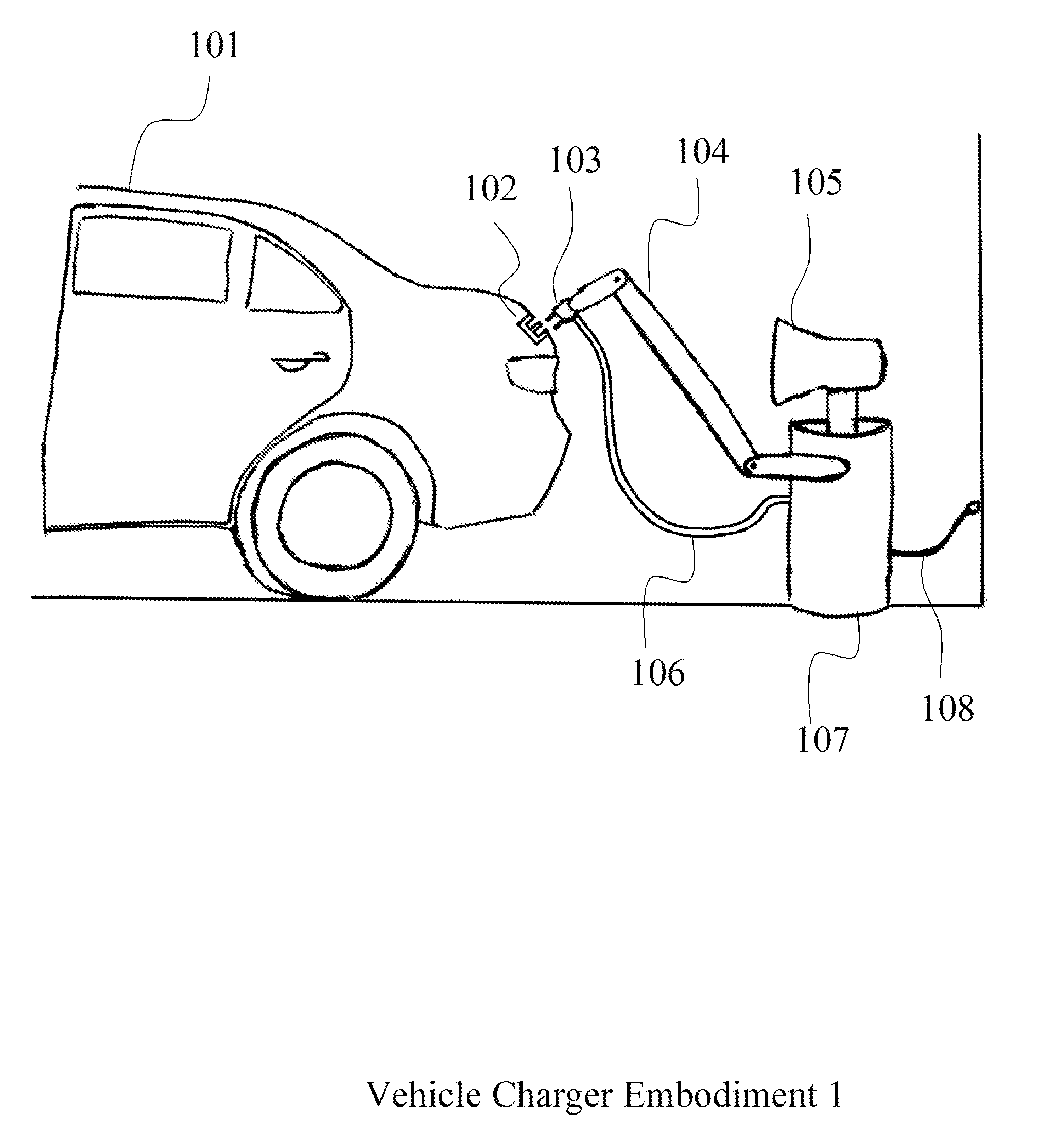

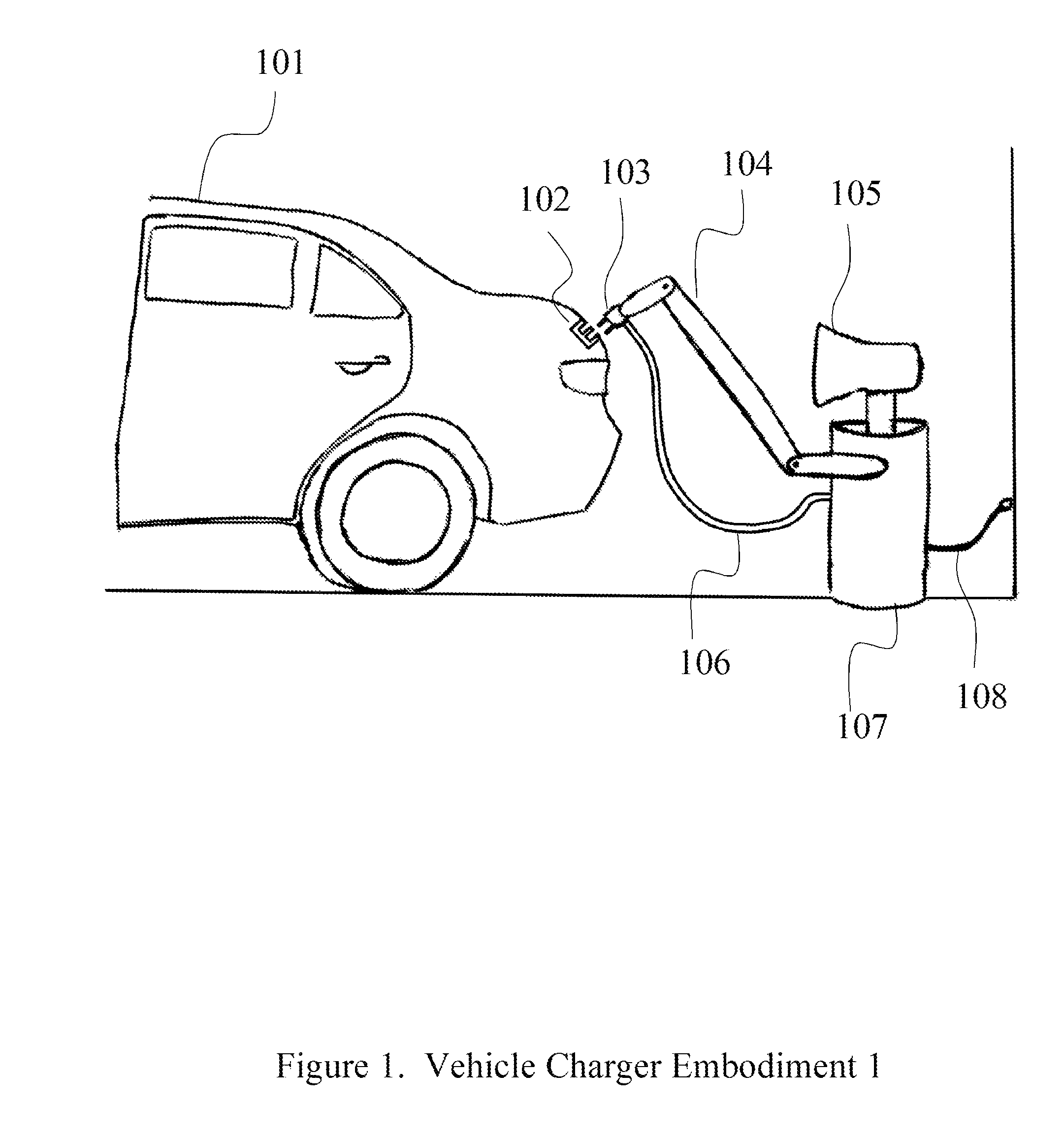

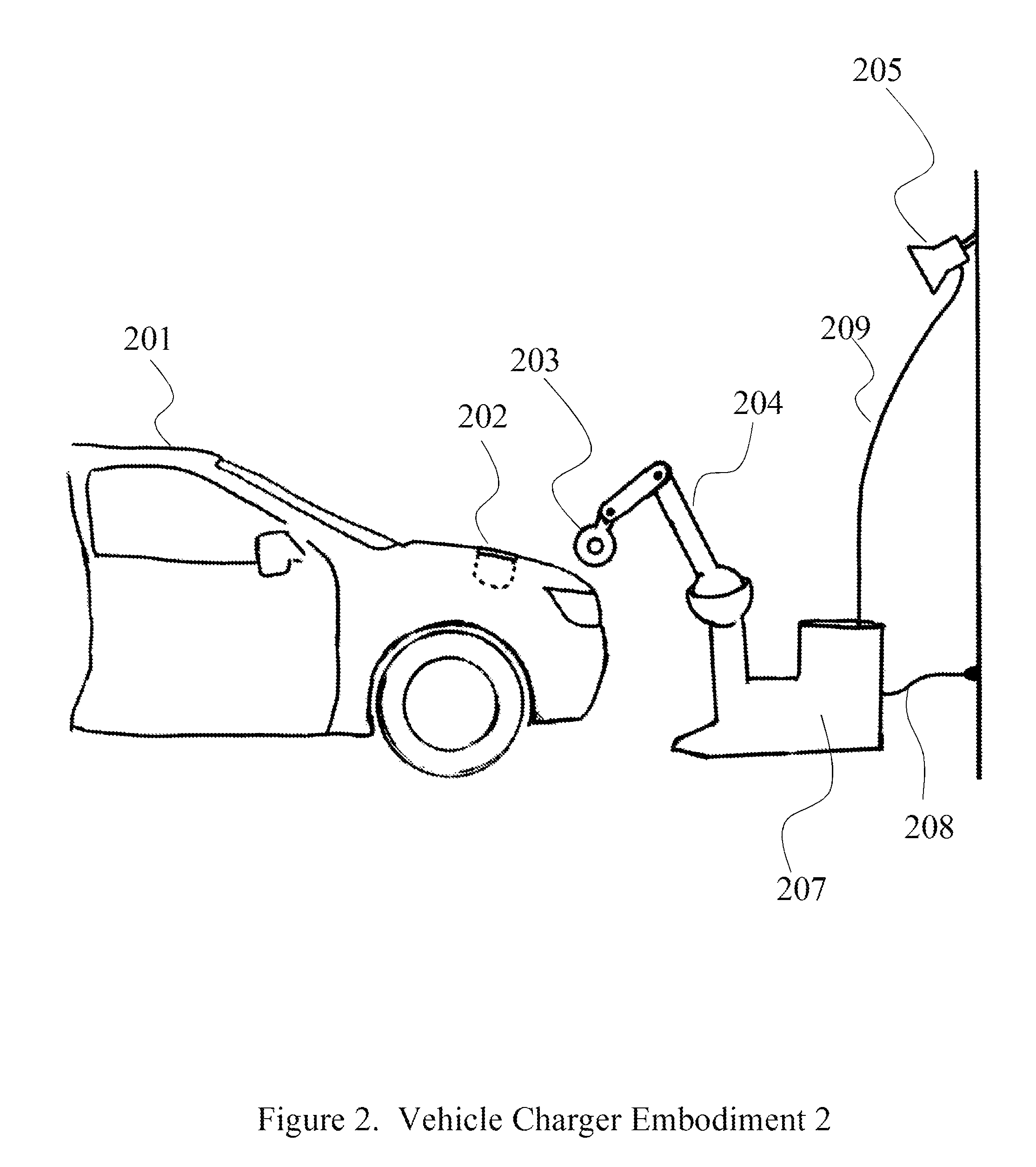

System to automatically recharge vehicles with batteries

A plug-in hybrid electric vehicle (PHEV) is an automobile which can use either electricity or gasoline. With high gasoline prices, electricity is becoming a promising alternative to power next generation automobiles. One advantage of the PHEV and the BEV (battery electric vehicle) is that charging can be done at home. However, the small battery capacity of PHEV's may require recharging the batteries almost daily. It would be convenient for an owner of a car with batteries to not have to plug in the battery each and every day that charging is required. Our invention is a system that plugs the power automatically into the vehicle with minimal human intervention using an automated docking system. The system is composed of a robotic manipulator with a camera and a processing unit. The system uses the camera and vision processing to identify the vehicle's position, and consequently, the location of the vehicle's charging receptacle. The robotic manipulator then directs the charging cord's plug into the receptacle of the vehicle. Once charging is complete, the robotic manipulator removes the plug from the vehicle.

Owner:SEVENTHDIGIT CORP

Charging Service Vehicle Network

InactiveUS20120303397A1Increase capacityEfficient redeploymentBatteries circuit arrangementsCharging stationsEngineeringSystem controller

Charging service vehicle networks are among the embodiments disclosed herein, including battery module-powered EV charging roadside service vehicles. Battery modules are removably mounted to the service vehicles and manually exchanged within a system of battery module storage locations. Some embodiments provide resupply vehicles for delivering battery modules between storage locations and / or service vehicles, and may be used to exchange battery modules. Controllers are used to reserve battery modules at the storage locations to ensure availability for high priority activities. Some storage locations have charging apparatus to recharge battery modules stored there, and some storage locations are repositionable mobile units. Multiple tiers or levels of system controllers used by service vehicles to control centers are implemented to manage operations and optimize usage of battery modules and charging services across wide areas, including providing additional service vehicles to supply temporary needs for charging services.

Owner:GREEN CHARGE NETWORKS

High power wireless resonant energy transfer system

InactiveUS7880337B2Batteries circuit arrangementsLoad balancing in dc networkResonant energyTransfer system

Owner:FARKAS

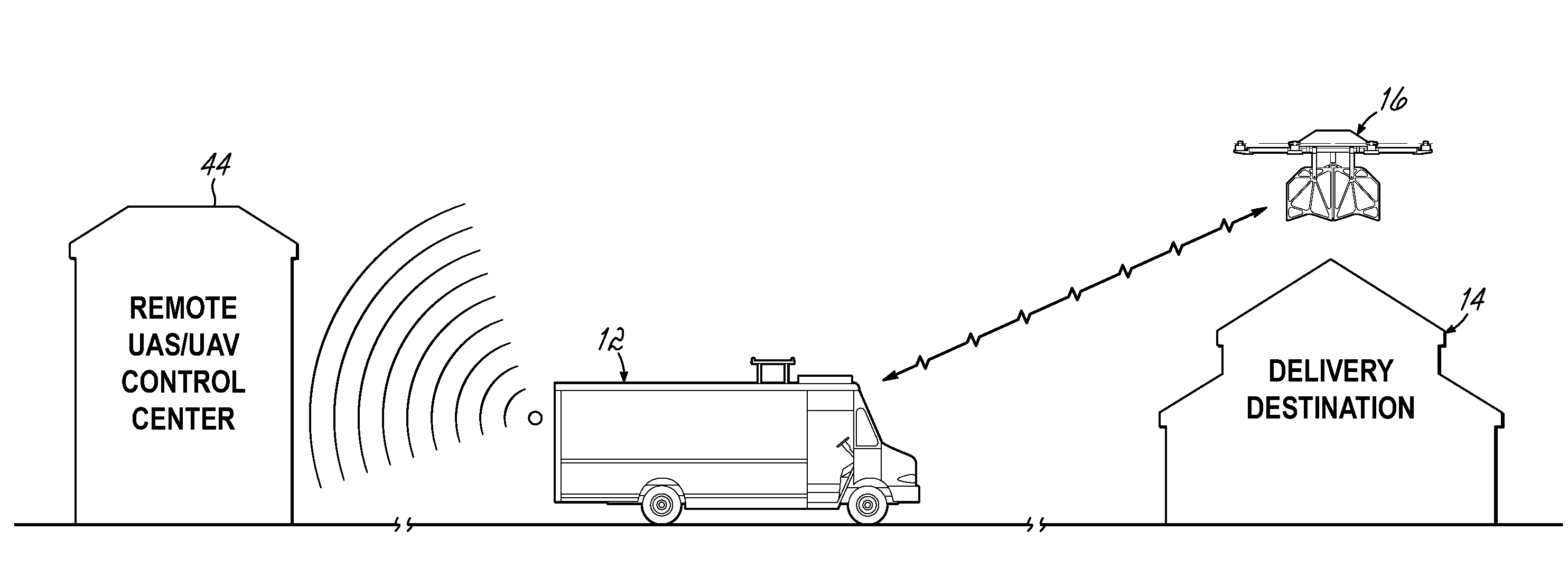

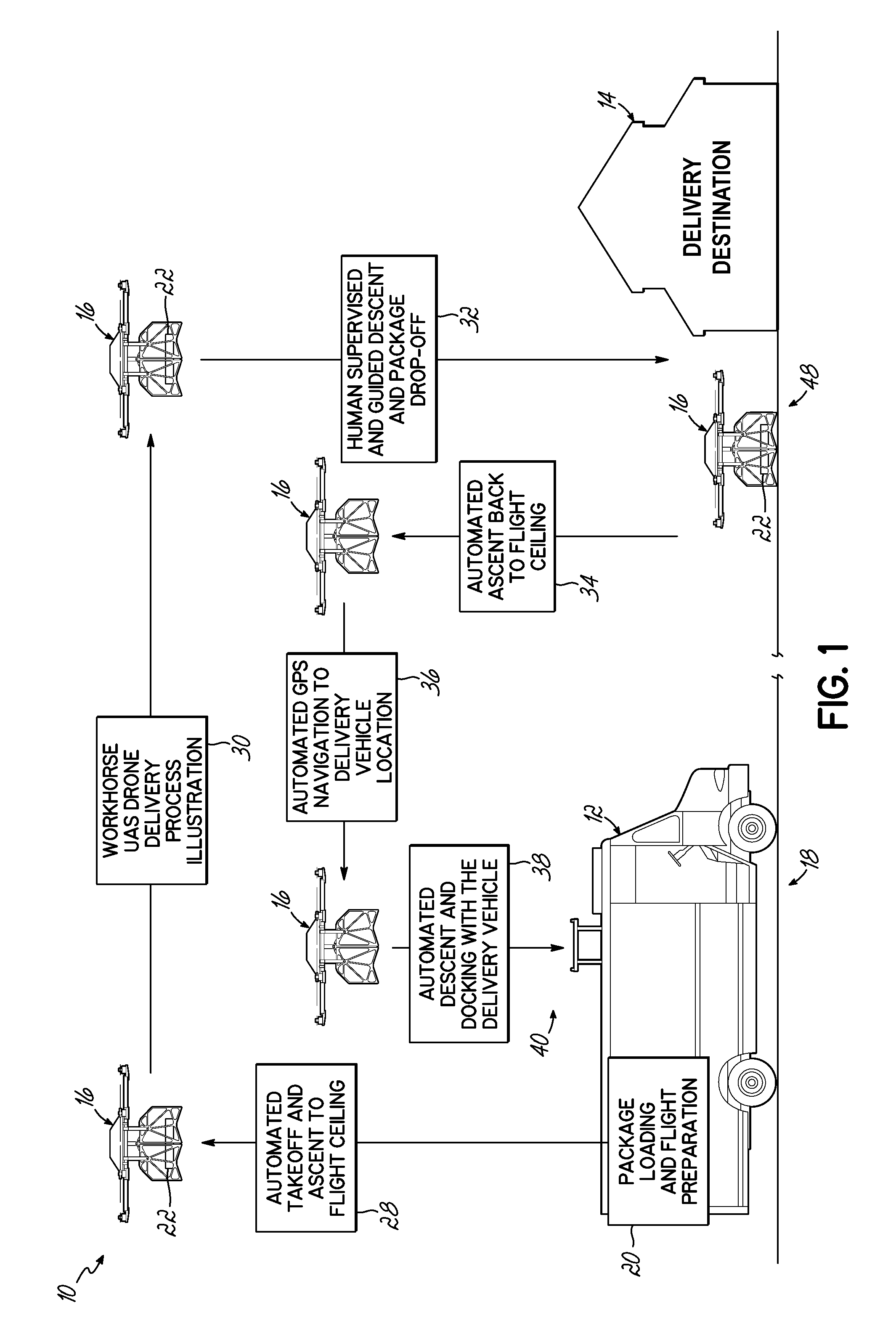

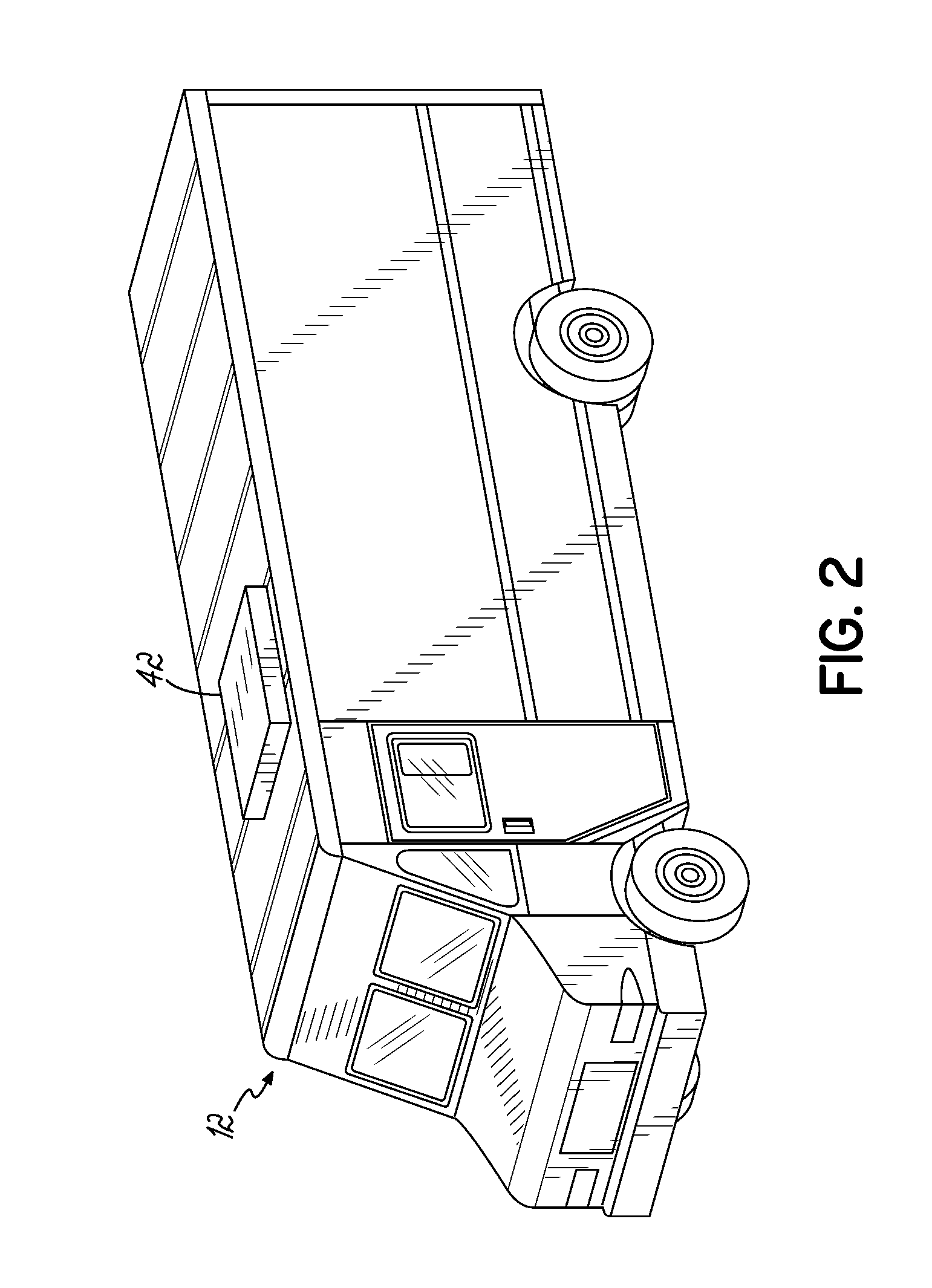

Package delivery by means of an automated multi-copter uas/uav dispatched from a conventional delivery vehicle

ActiveUS20160200438A1Substantial fuel savingReduce operating costsRemote controlled aircraftVehicular energy storageDocking stationDelivery vehicle

Methods and associated systems for autonomous package delivery utilize a UAS / UAV, an infrared positioning senor, and a docking station integrated with a package delivery vehicle. The UAS / UAV accepts a package for delivery from the docking station on the delivery vehicle and uploads the delivery destination. The UAS / UAV autonomously launches from its docked position on the delivery vehicle. The UAS / UAV autonomously flies to the delivery destination by means of GPS navigation. The UAS / UAV is guided in final delivery by means of a human supervised live video feed from the UAS / UAV. The UAS / UAV is assisted in the descent and delivery of the parcel by precision sensors and if necessary by means of remote human control. The UAS / UAV autonomously returns to the delivery vehicle by means of GPS navigation and precision sensors. The UAS / UAV autonomously docks with the delivery vehicle for recharging and preparation for the next delivery sequence.

Owner:WORKHORSE GRP INC

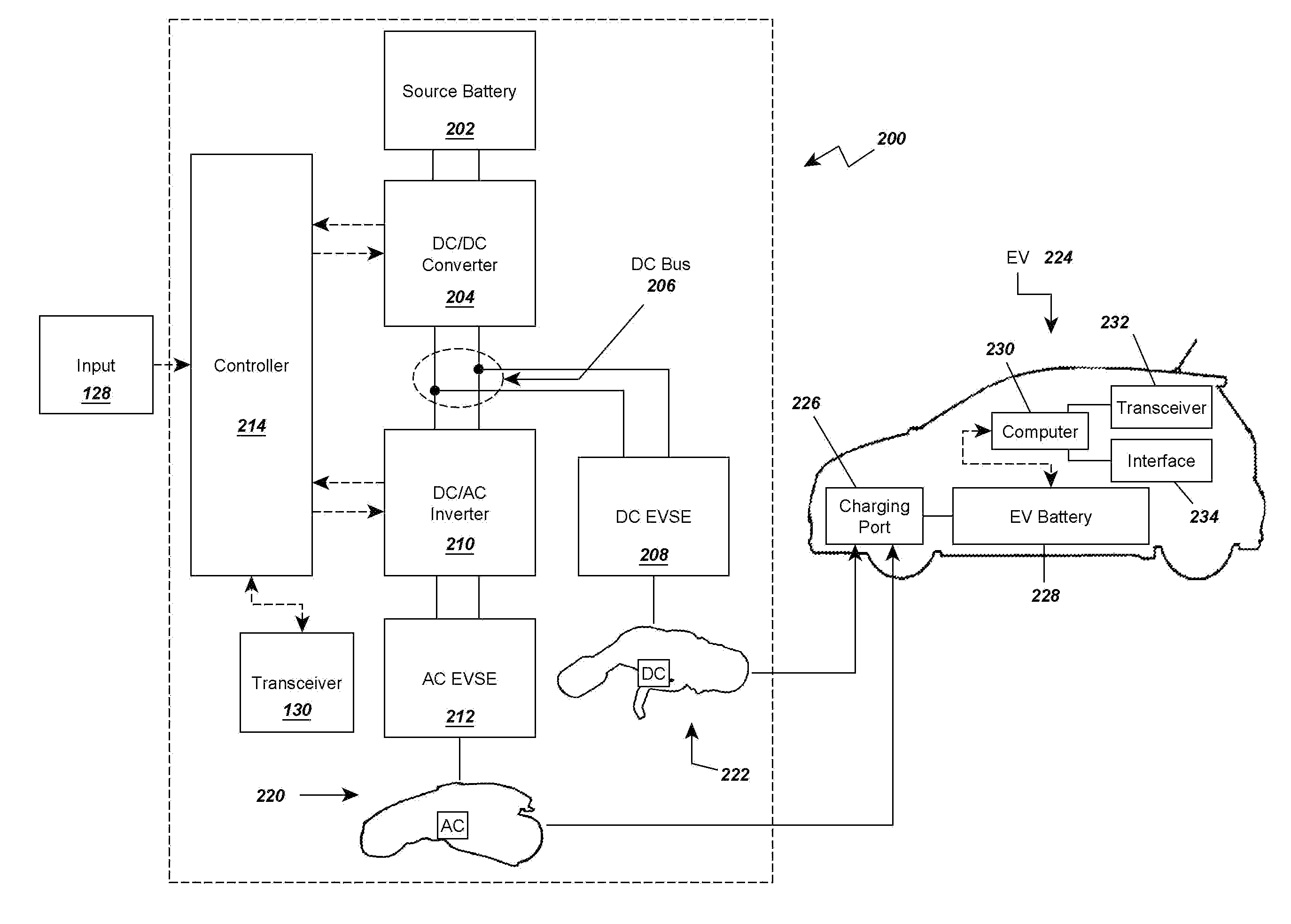

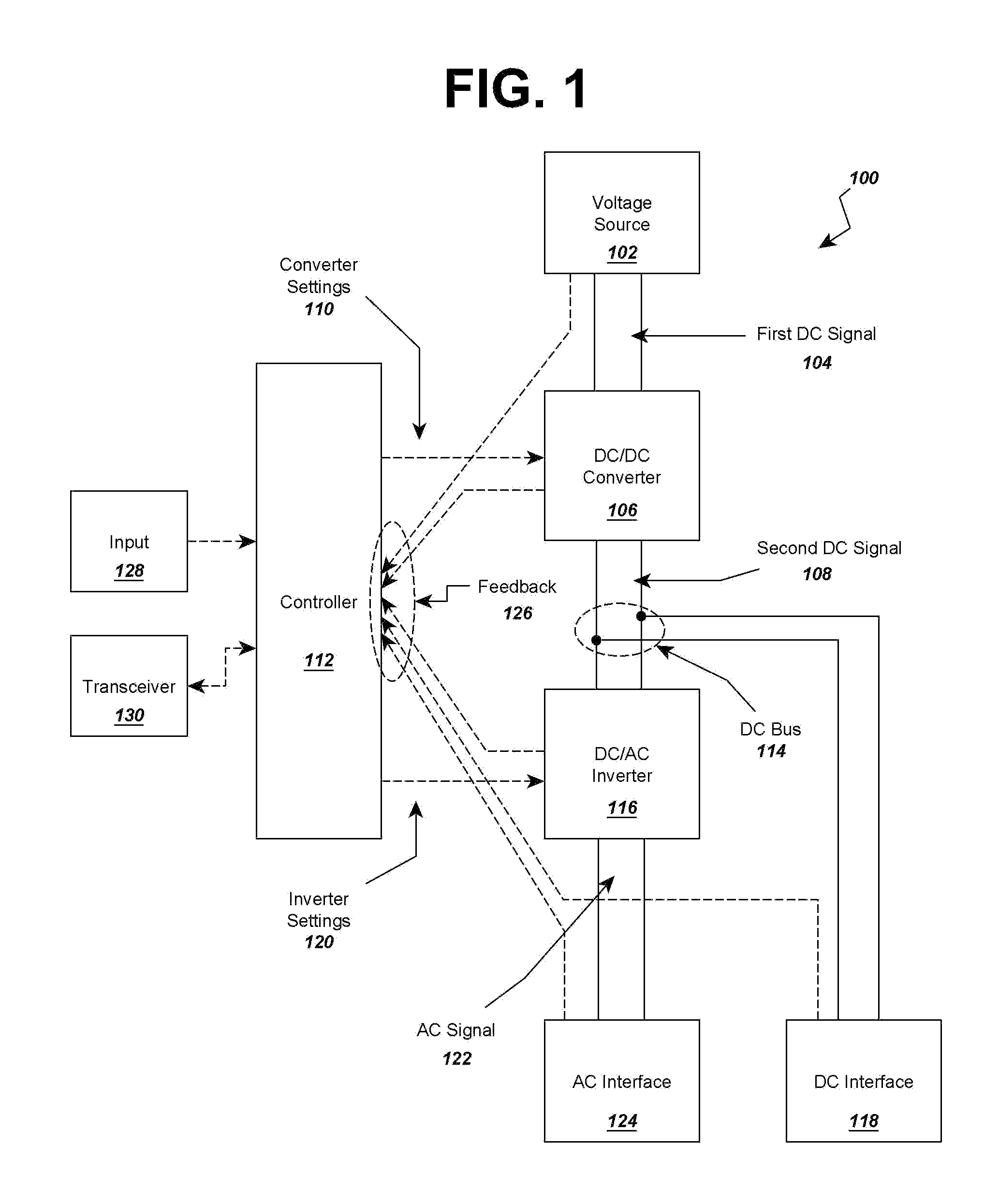

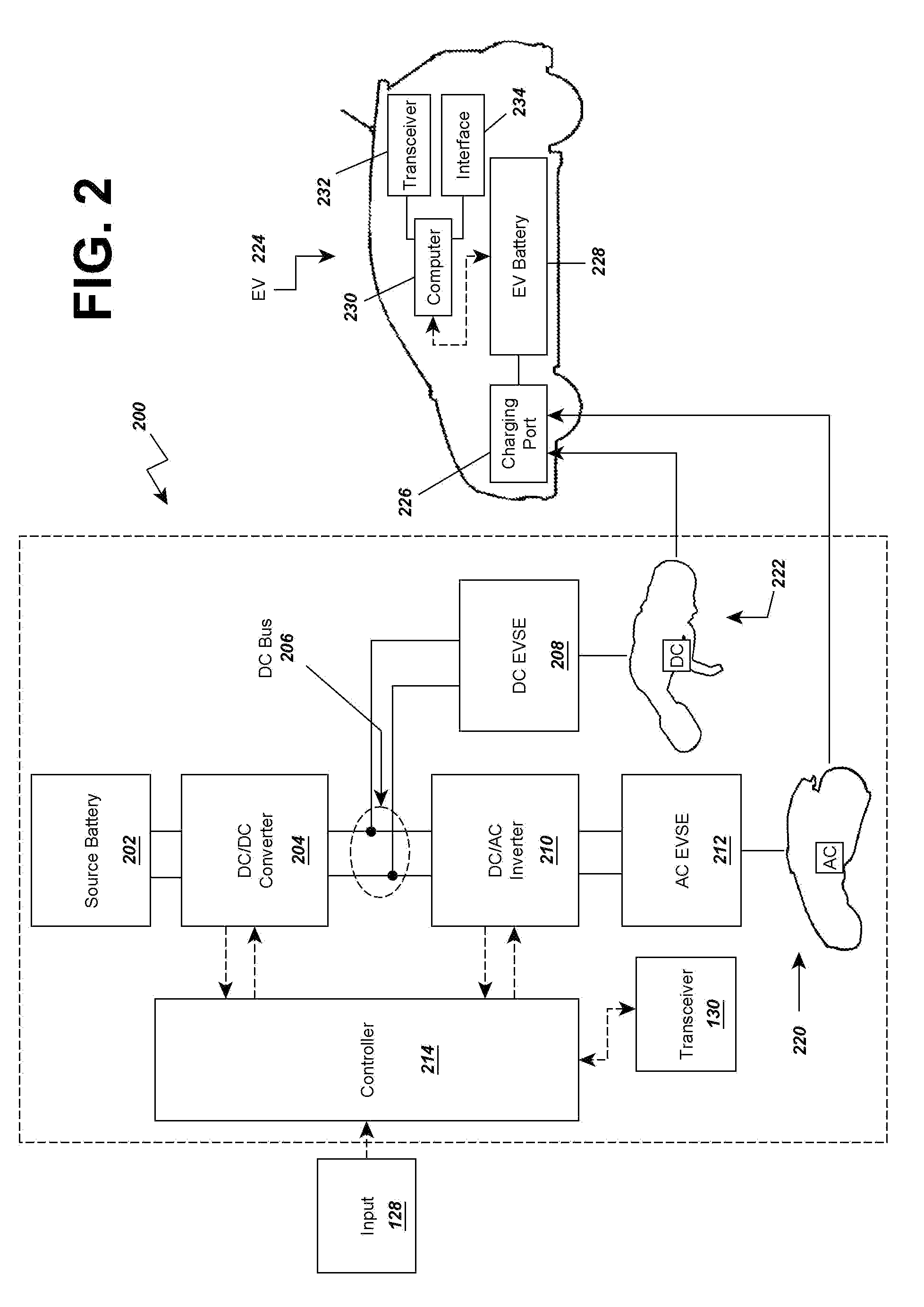

Multi-Mode Electric Vehicle Charging Station

InactiveUS20130020993A1Low costReduce equipment costsCircuit authenticationCharging stationsElectricityReduced size

A reduced size and complexity multi-mode electric vehicle charging station is provided which allows a user to select AC and DC powerform output and may provide those outputs to connectors for charging electric vehicles. A voltage source is provided to a DC converter that then outputs to a DC bus or electrical connection. The DC bus may be accessed by DC charging equipment or a DC-AC inverter that is connected to AC charging equipment, thereby providing DC and AC charging ability. In one aspect, the multi-mode electric vehicle charging station is used in a rescue vehicle for charging stranded EVs via multiple charging standards without requiring the rescue vehicle to carry independent charging systems for each charging standard. In another aspect, the charging station is used in a stationary charging station to reduce cost and complexity of using multiple independent charging systems.

Owner:GREEN CHARGE NETWORKS

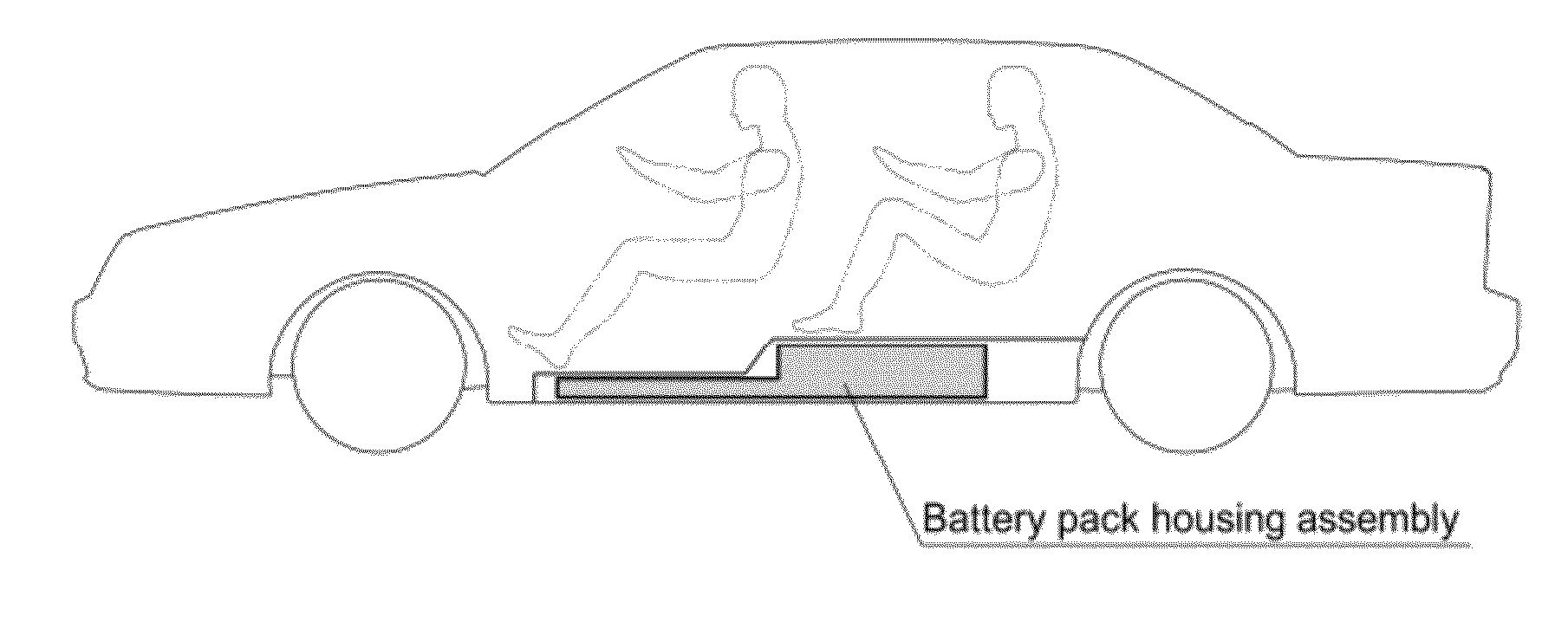

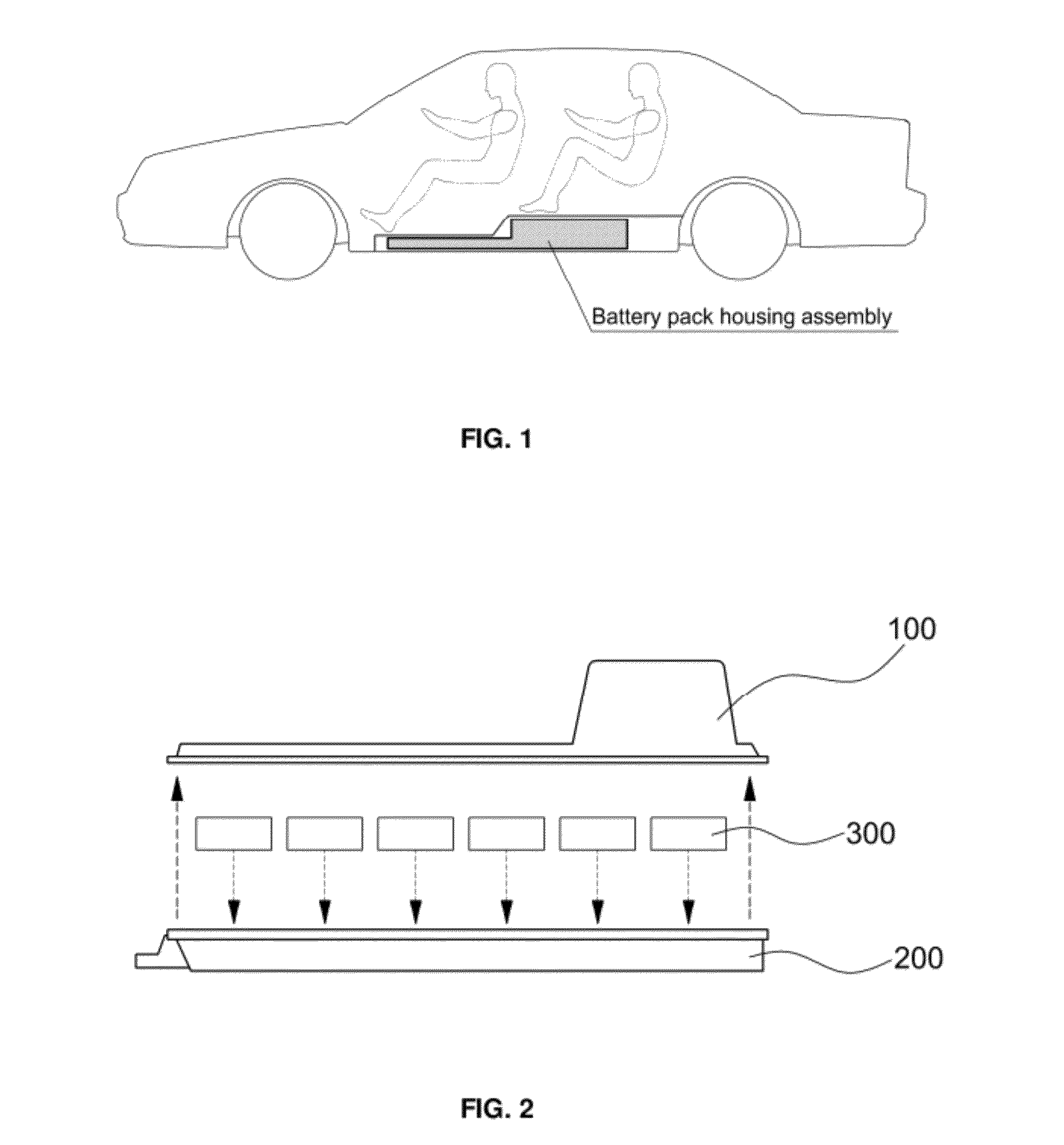

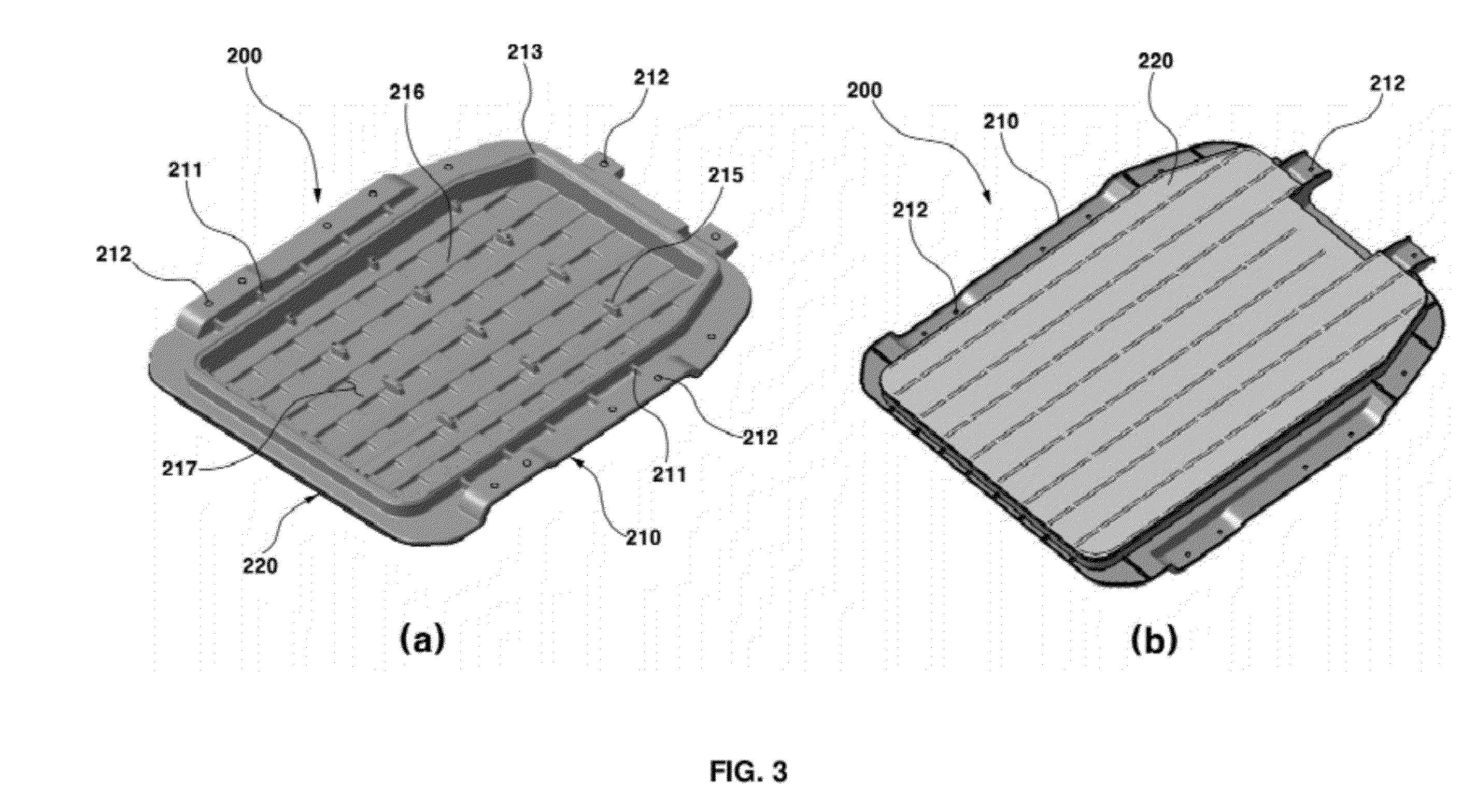

Battery pack housing assembly for electric vehicle using plastic composite material

InactiveUS20120103714A1Reduce vehicle weightImprove structural rigiditySuperstructure subunitsPropulsion by batteries/cellsFiberElectric vehicle

The present invention provides a battery pack housing assembly for an electric vehicle, which is formed of a lightweight composite material to reduce the weight and configured to have a dual laminated structure with a closed cross-sectional area formed by composite molding to absorb impact energy. For this purpose, the present invention provides battery pack housing assembly for an electric vehicle using a plastic composite material, the battery pack housing assembly having an upper cover mounted at the bottom of a vehicle body, a lower housing, and a battery pack received and mounted in the lower housing, wherein the lower housing has a dual laminated structure with a closed cross-sectional area formed by bonding an upper plate and a lower plate, each composed of a fiber reinforced plastic composite material, to absorb impact energy, thus increasing structural stiffness.

Owner:HYUNDAI MOTOR CO LTD +1

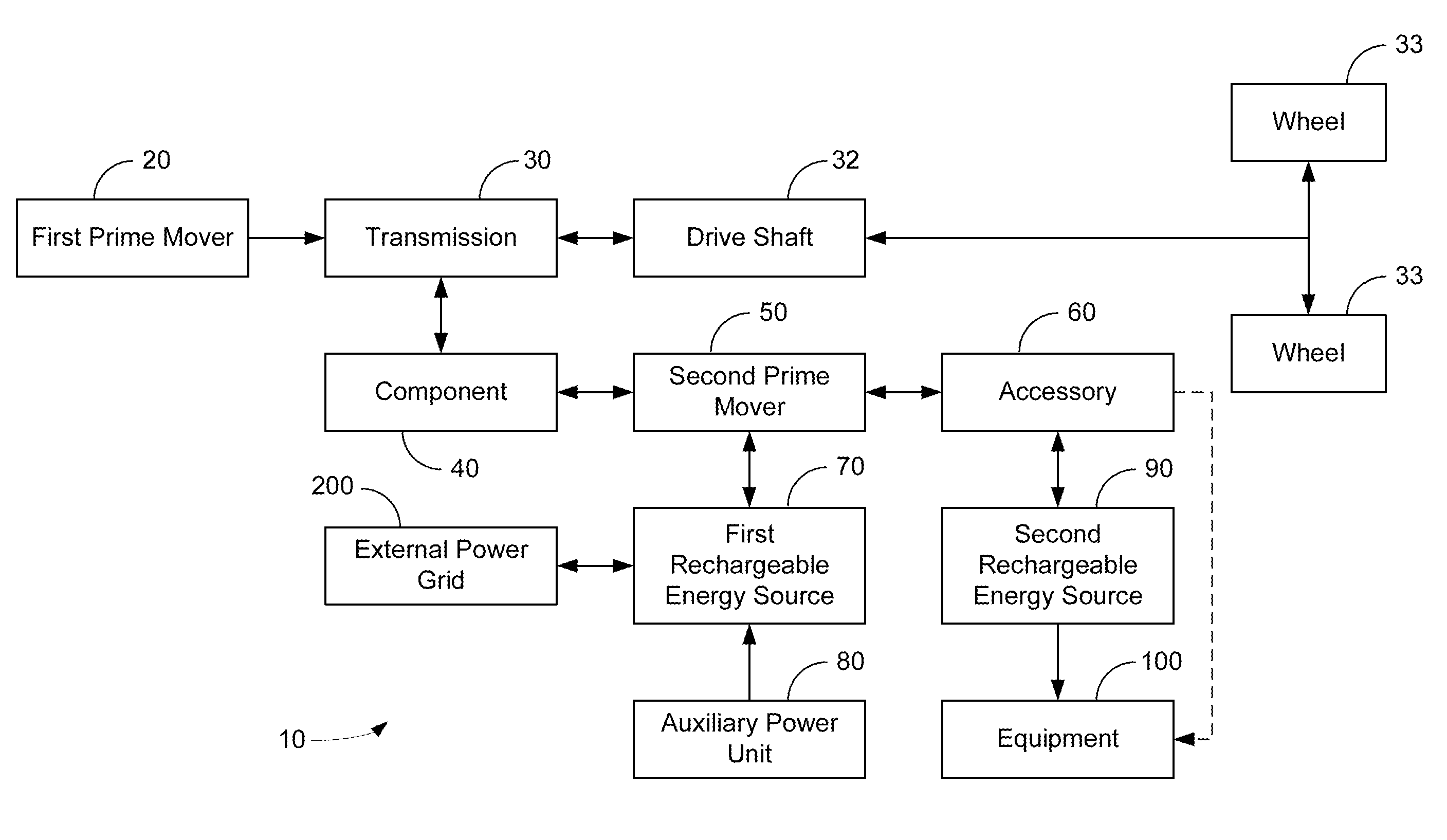

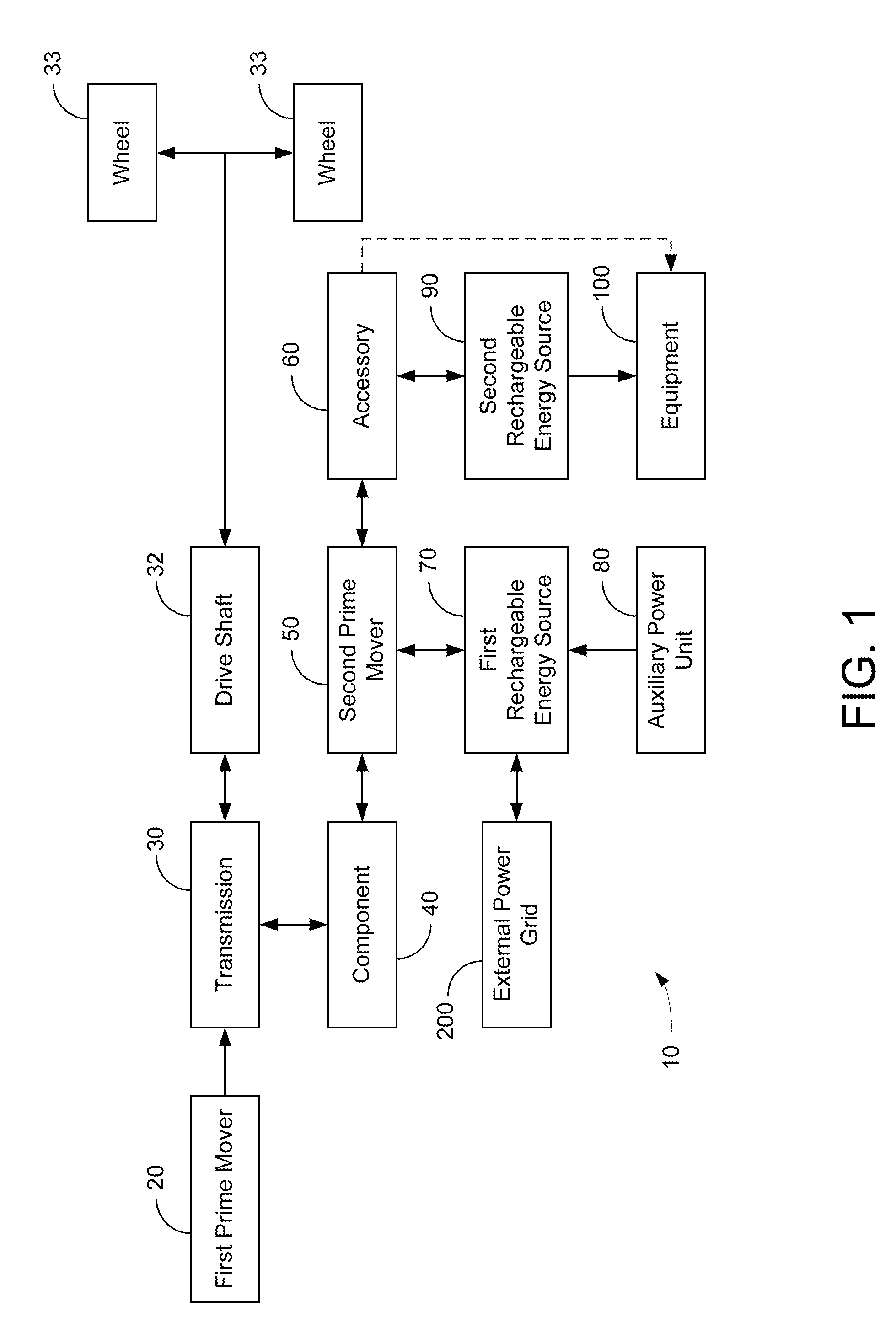

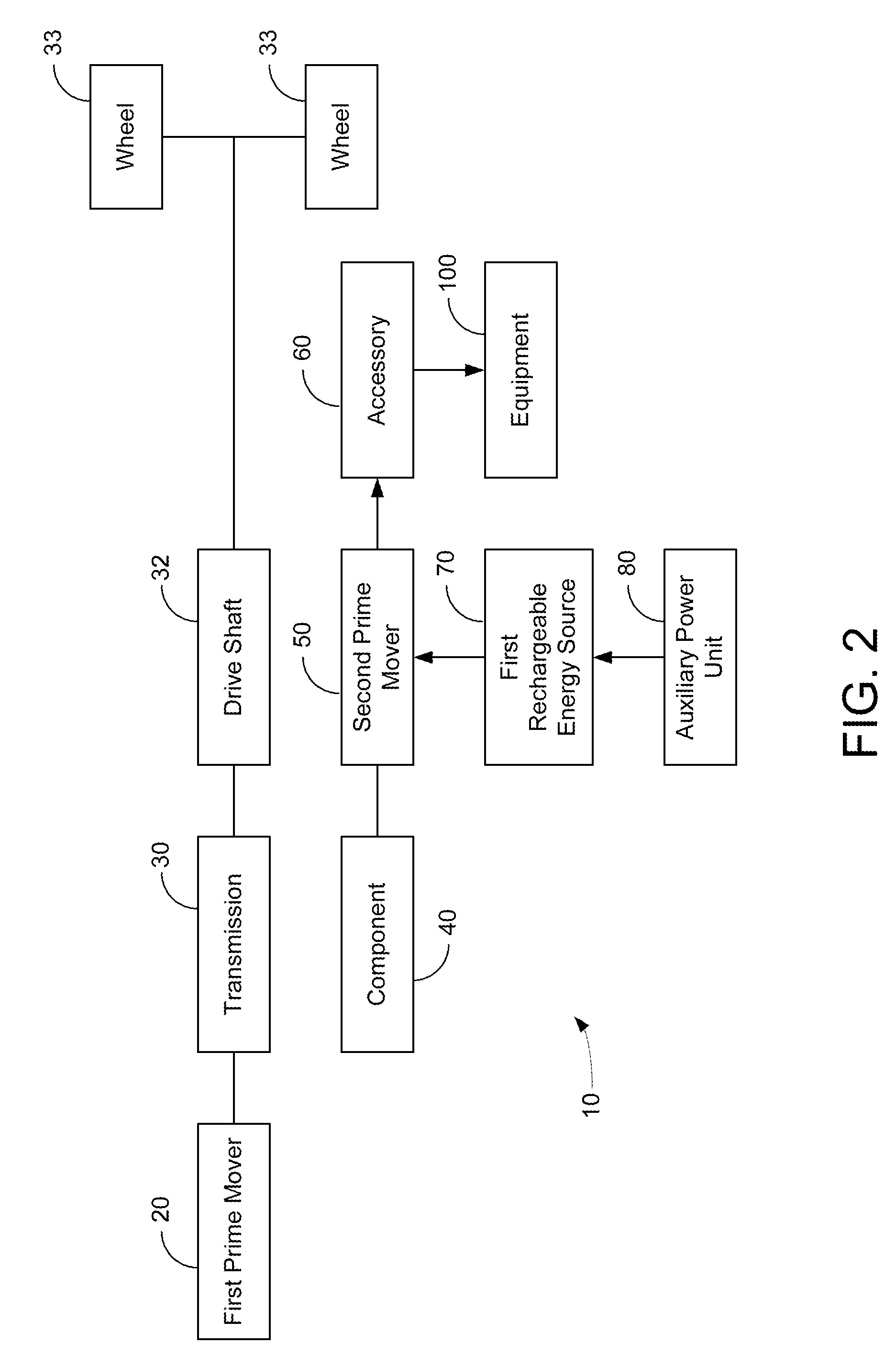

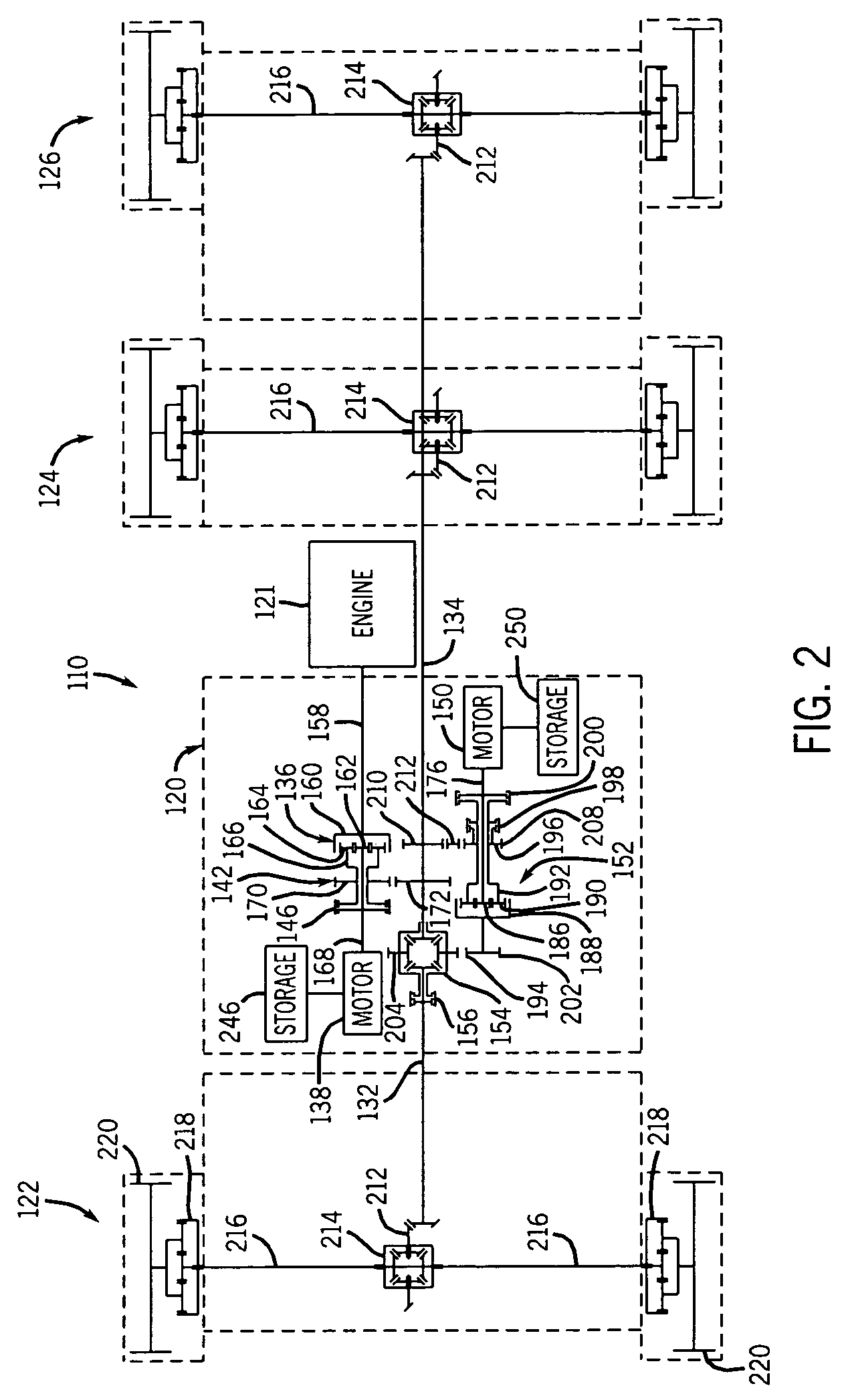

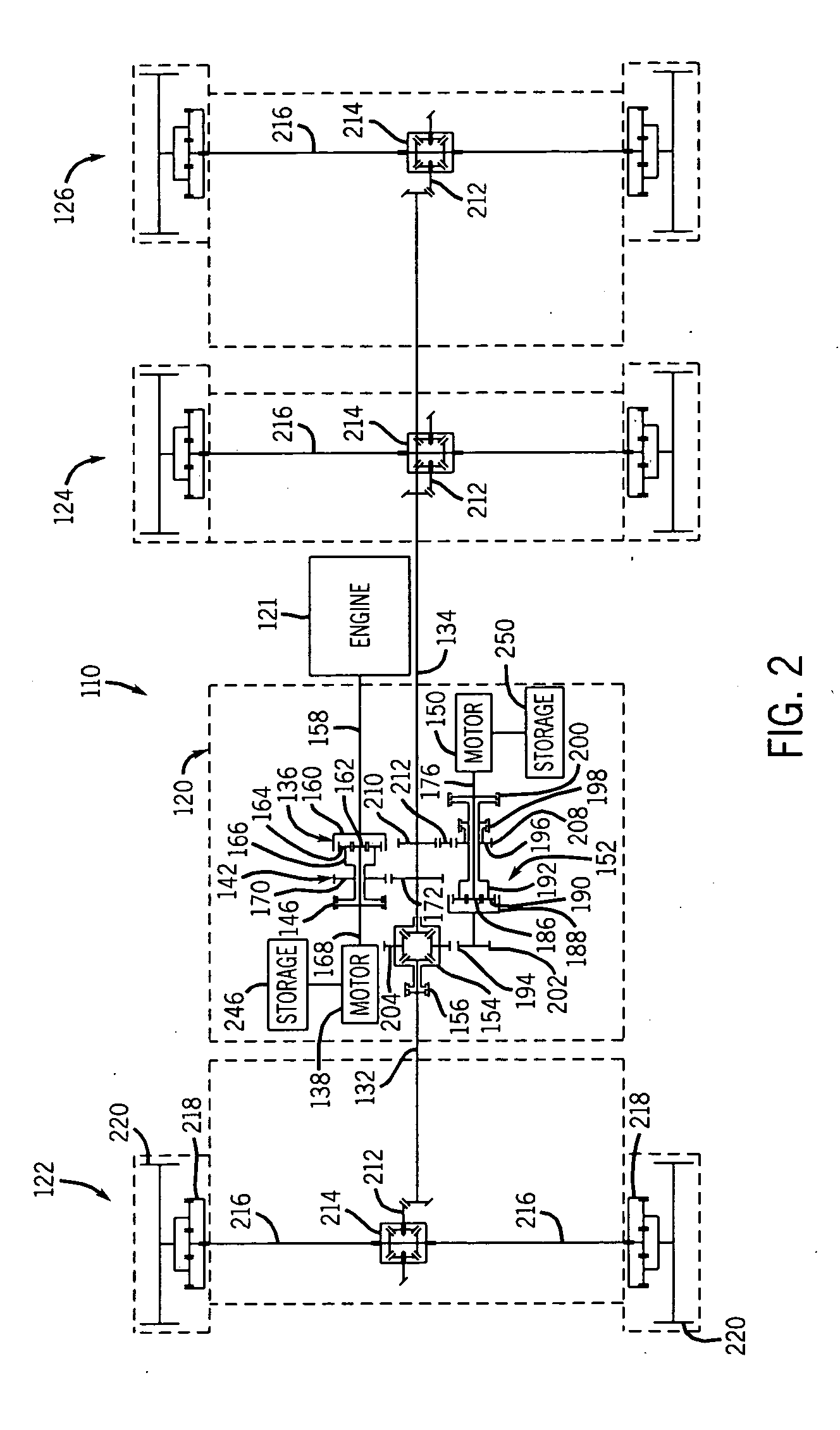

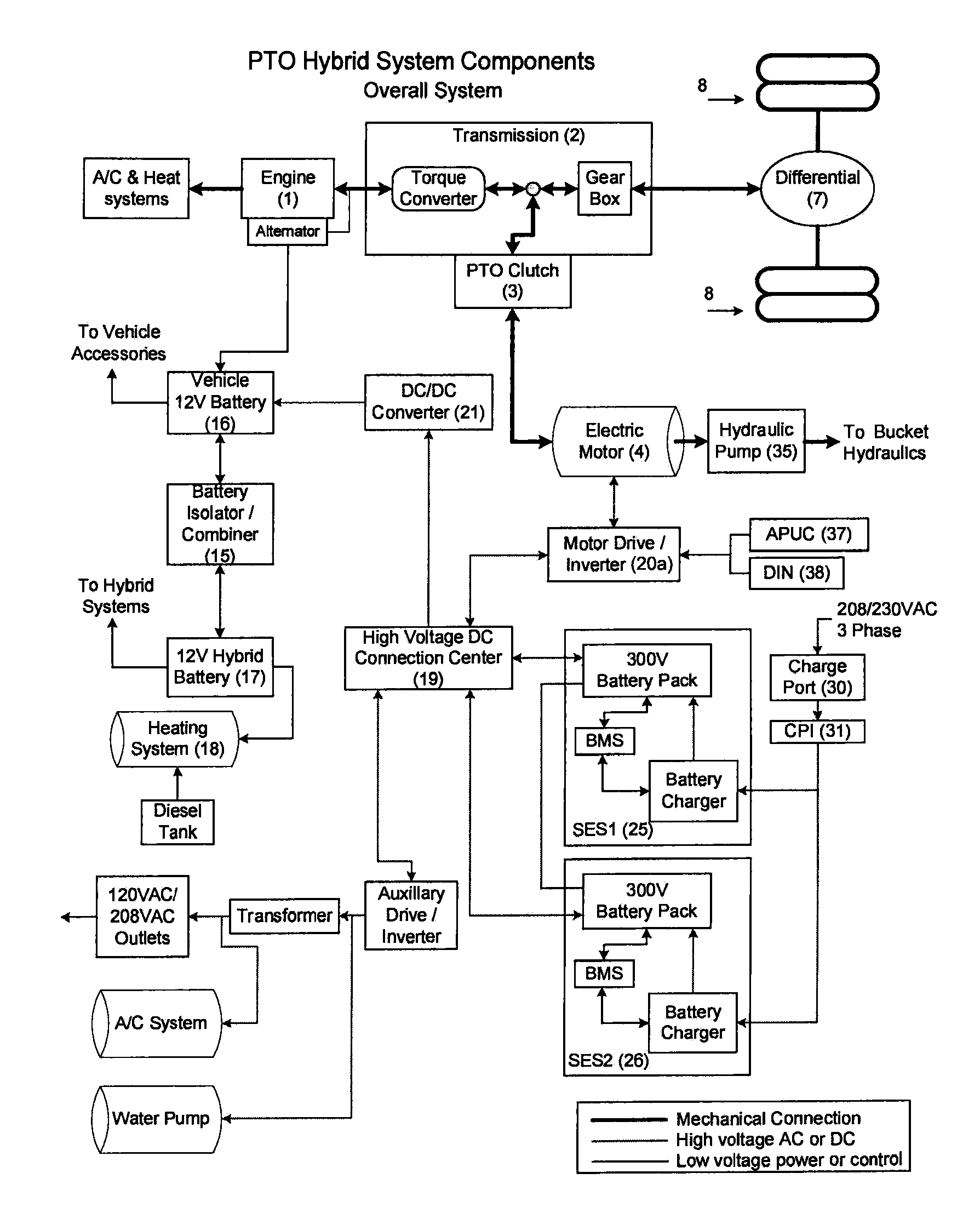

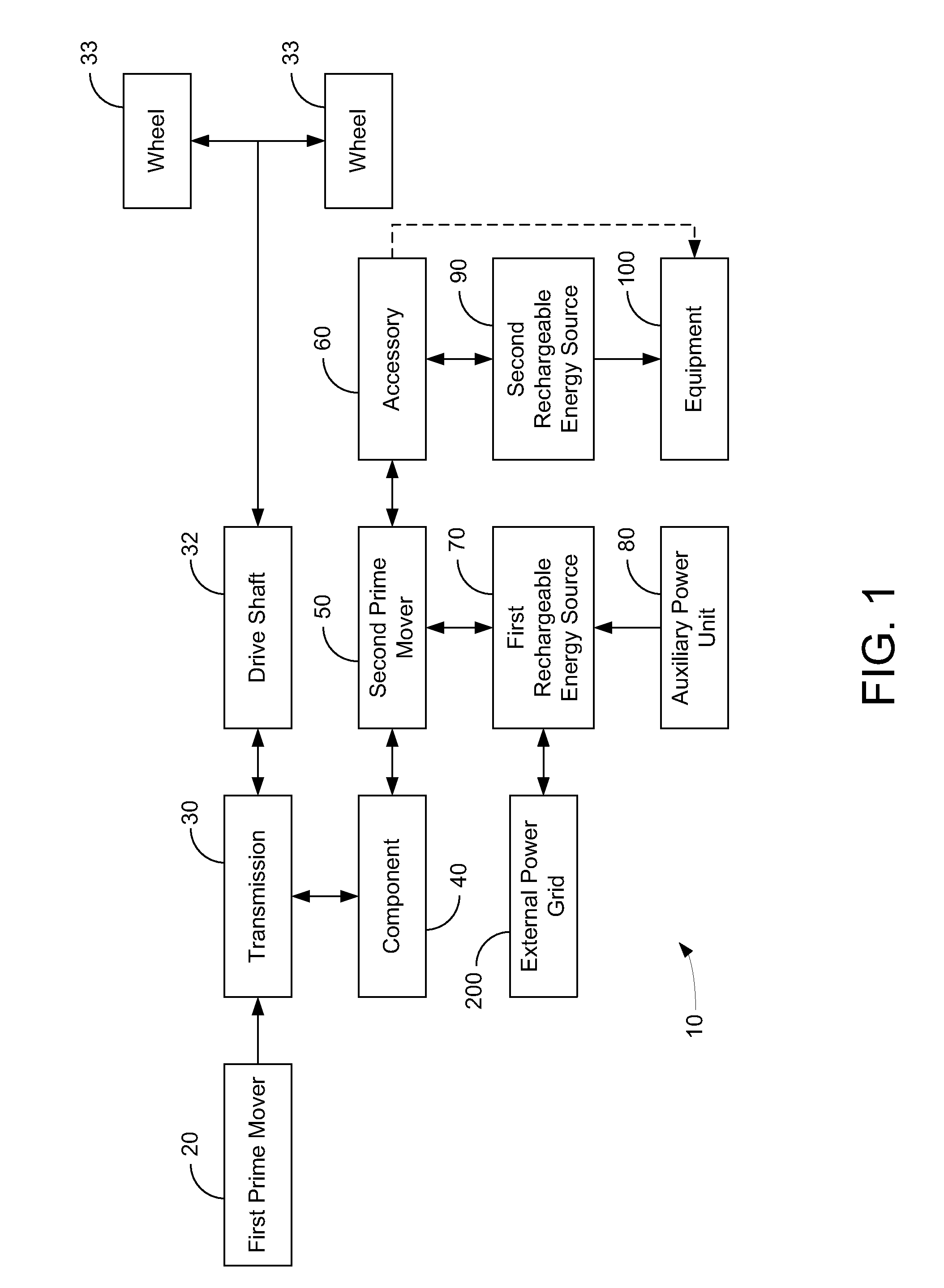

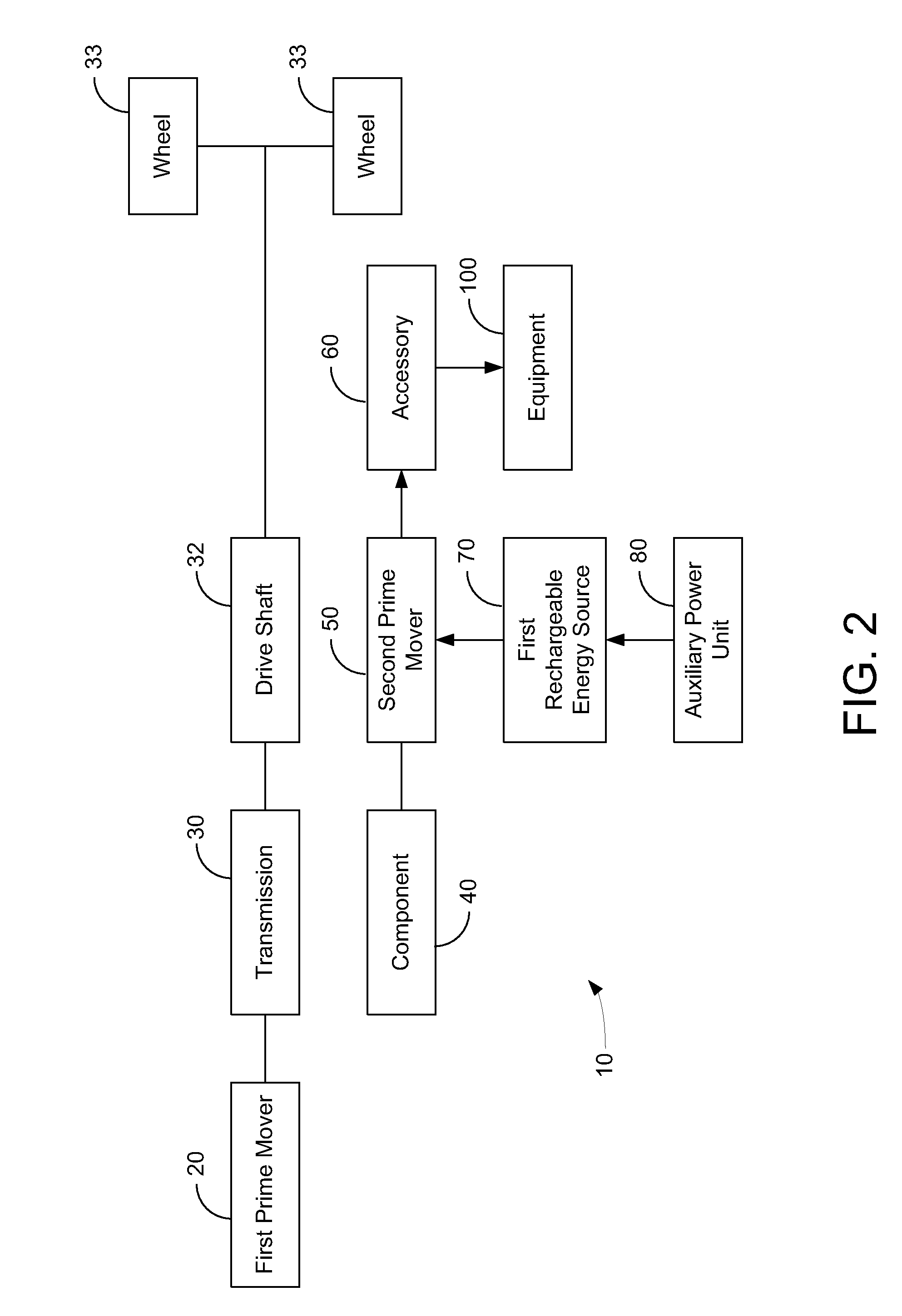

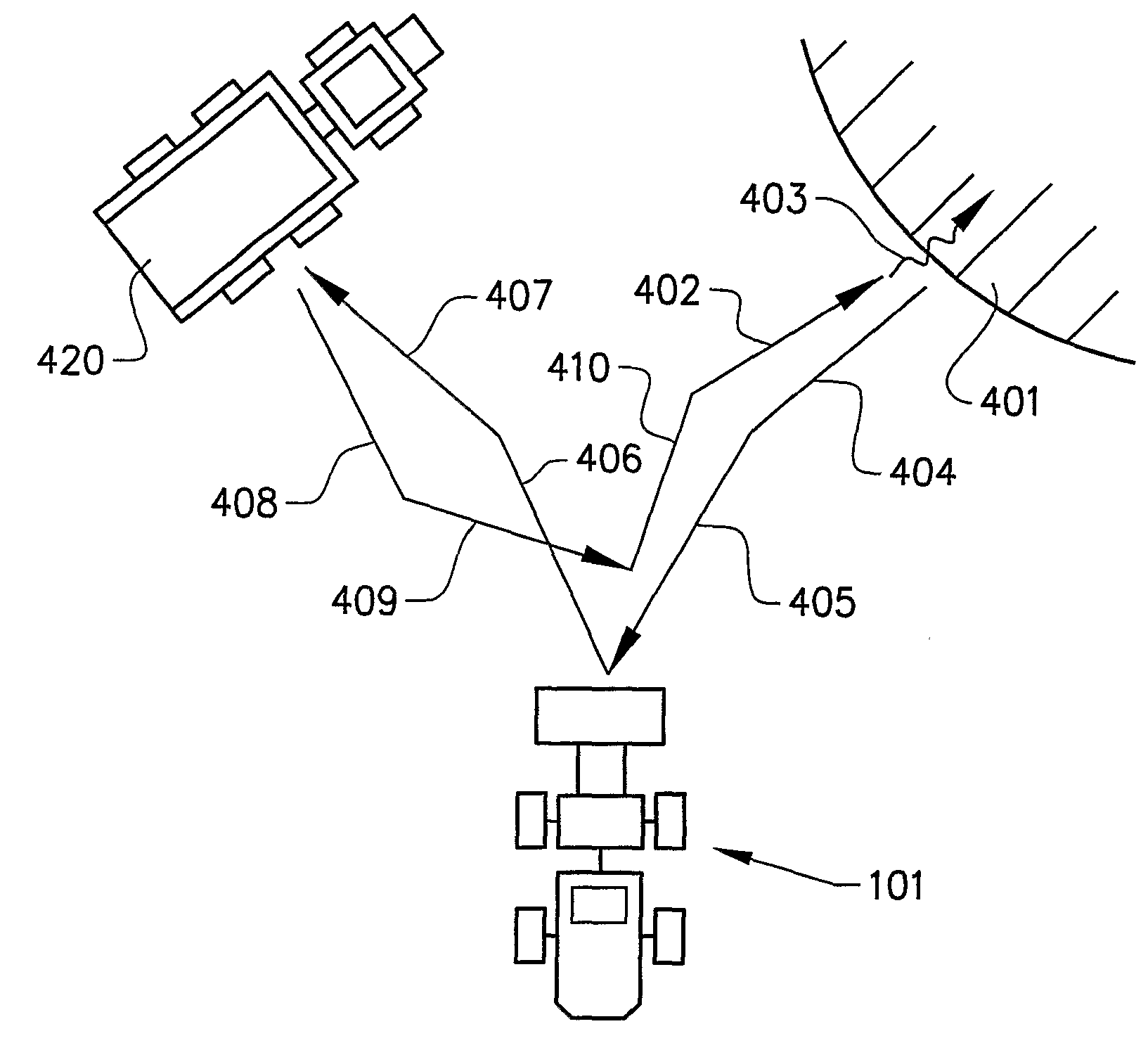

Hybrid vehicle drive system and method and idle reduction system and method

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:POWER TECH HLDG LLC

Selectively controllable electromagnetic shielding

ActiveUS20120112552A1High strengthImprove permeabilityLocalised screeningNear-field transmissionEngineeringMagnetic shield

A selectively controllable electromagnetic shield having an electromagnetic shielding material and a mechanism for selectively generating an aperture in the shield. The mechanism for selectively generating an aperture may be a magnetic field source that generates a magnetic field of sufficient strength to substantially saturate all or a portion of the shielding material. For example, a permanent magnet or DC electromagnet may be used to selectively saturate the shield. In its un-saturated state, the magnetic shield has a high permeability and functions as a flux path for the magnetic field. Once saturated, the permeability of the shield is substantially reduced so that the magnetic field lines are no longer drawn into the shield to the same degree. As a result, once saturated, a substantially greater amount of the electromagnetic field may flow through or around the shield in the saturated region.

Owner:PHILIPS IP VENTURES BV

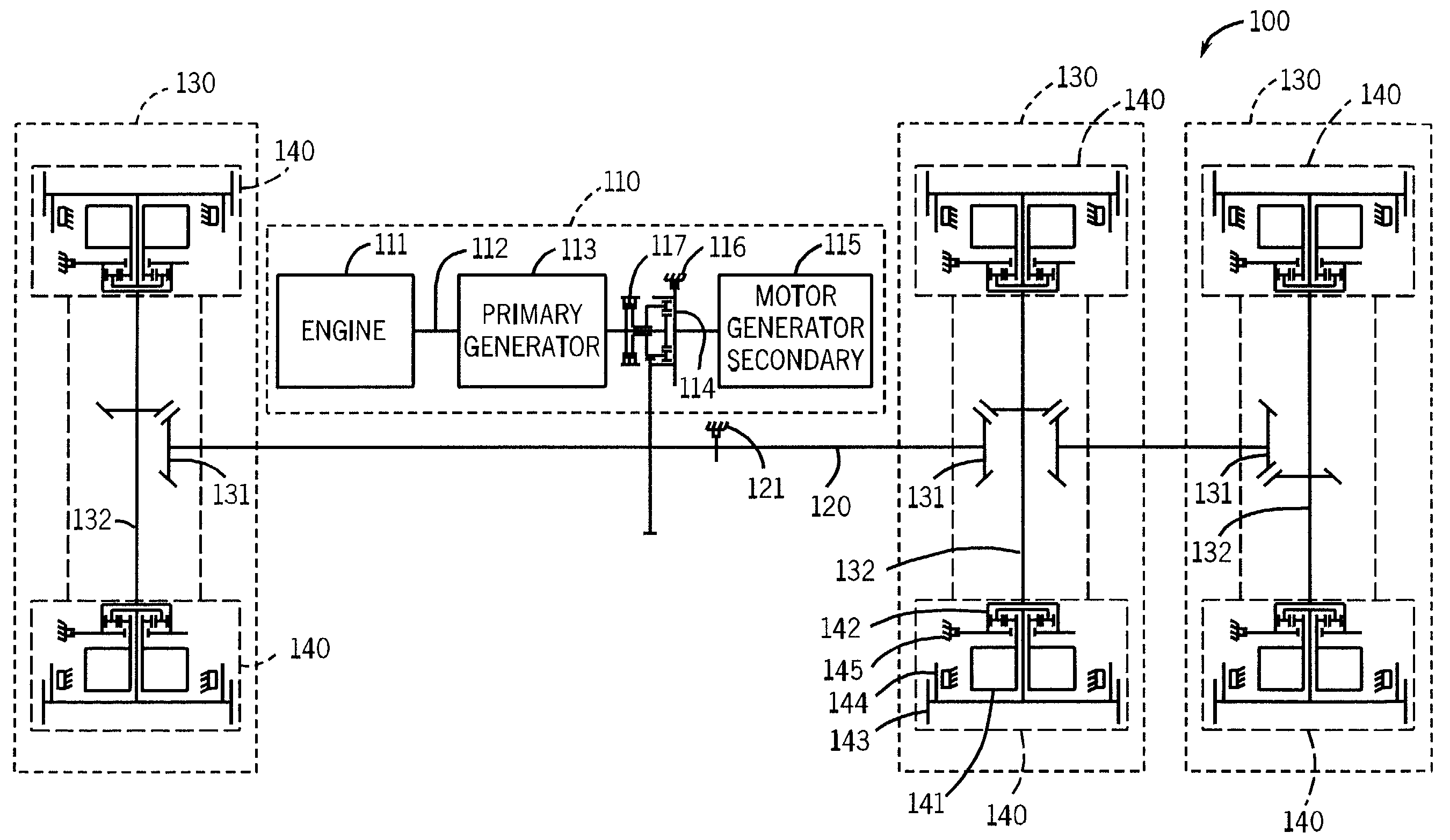

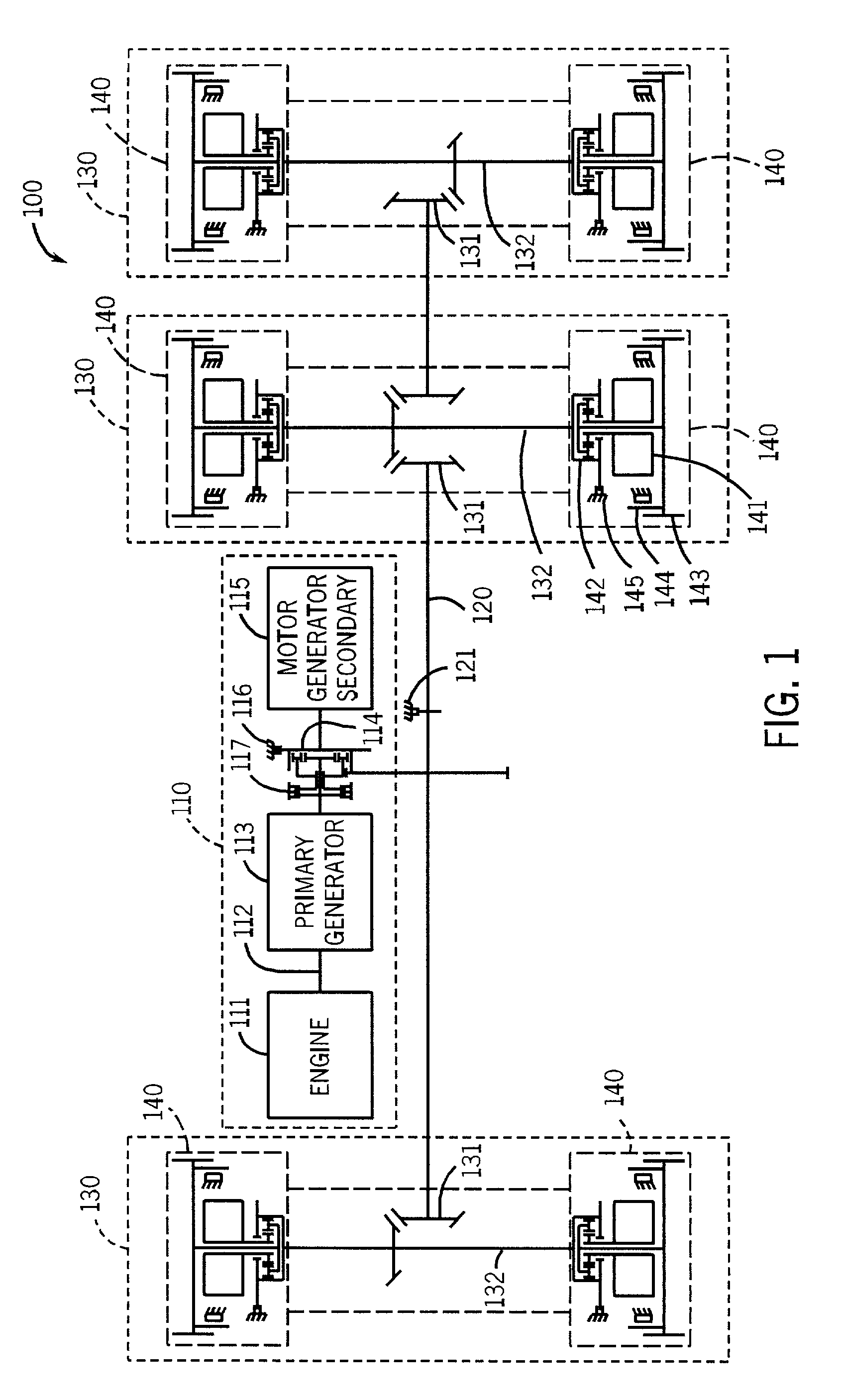

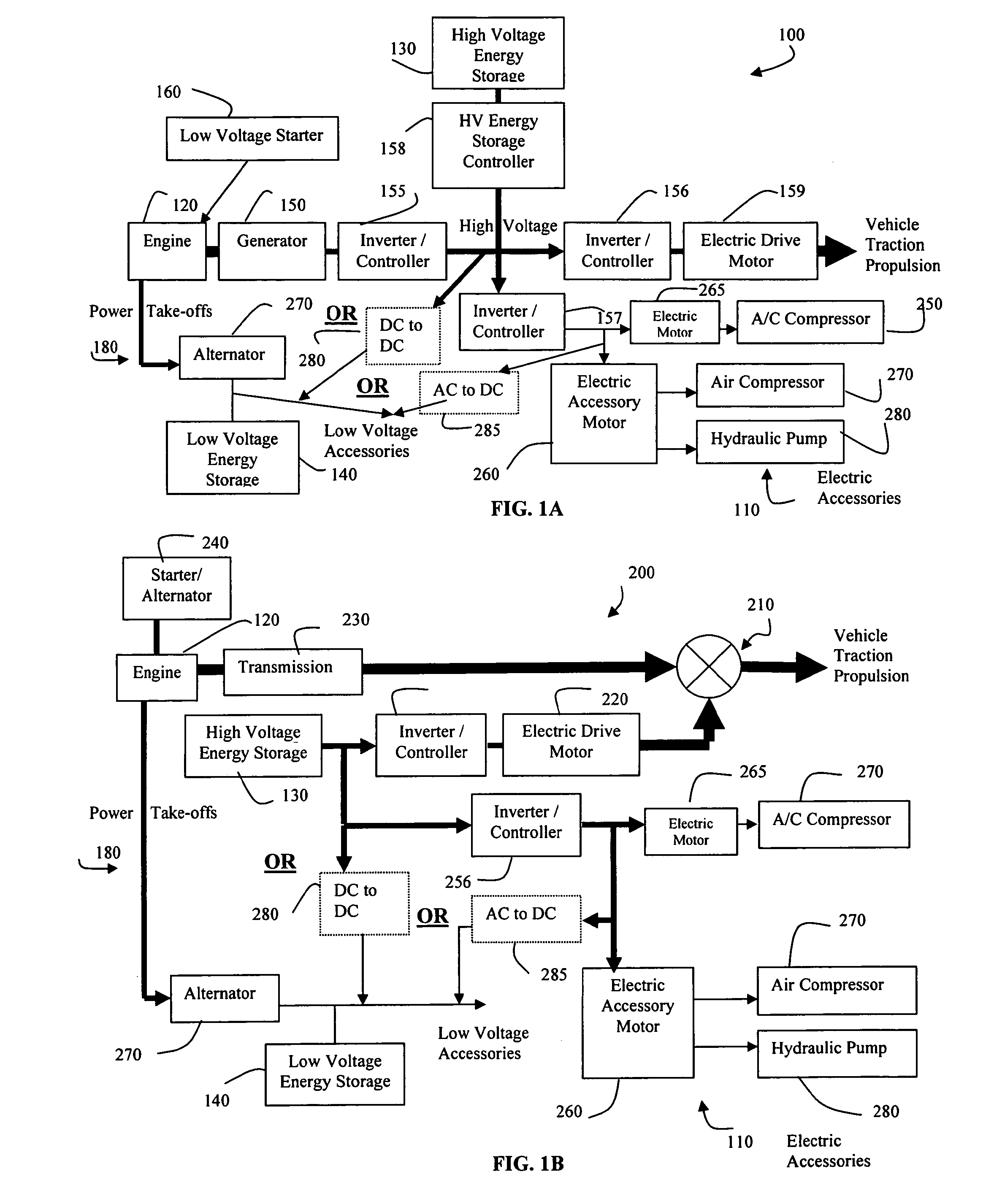

Hybrid vehicle with combustion engine/electric motor drive

A vehicle including a prime mover, a generator mechanically coupled to the prime mover, a first multi-input drive unit having at least first and second rotational inputs and at least one rotational output wherein the first rotational input is coupled to the prime mover, a first electric motor mechanically coupled to the second rotational input and electrically coupled to the generator and a first pair of vehicle drive wheels coupled to the rotational output.

Owner:OSHKOSH CORPORATION

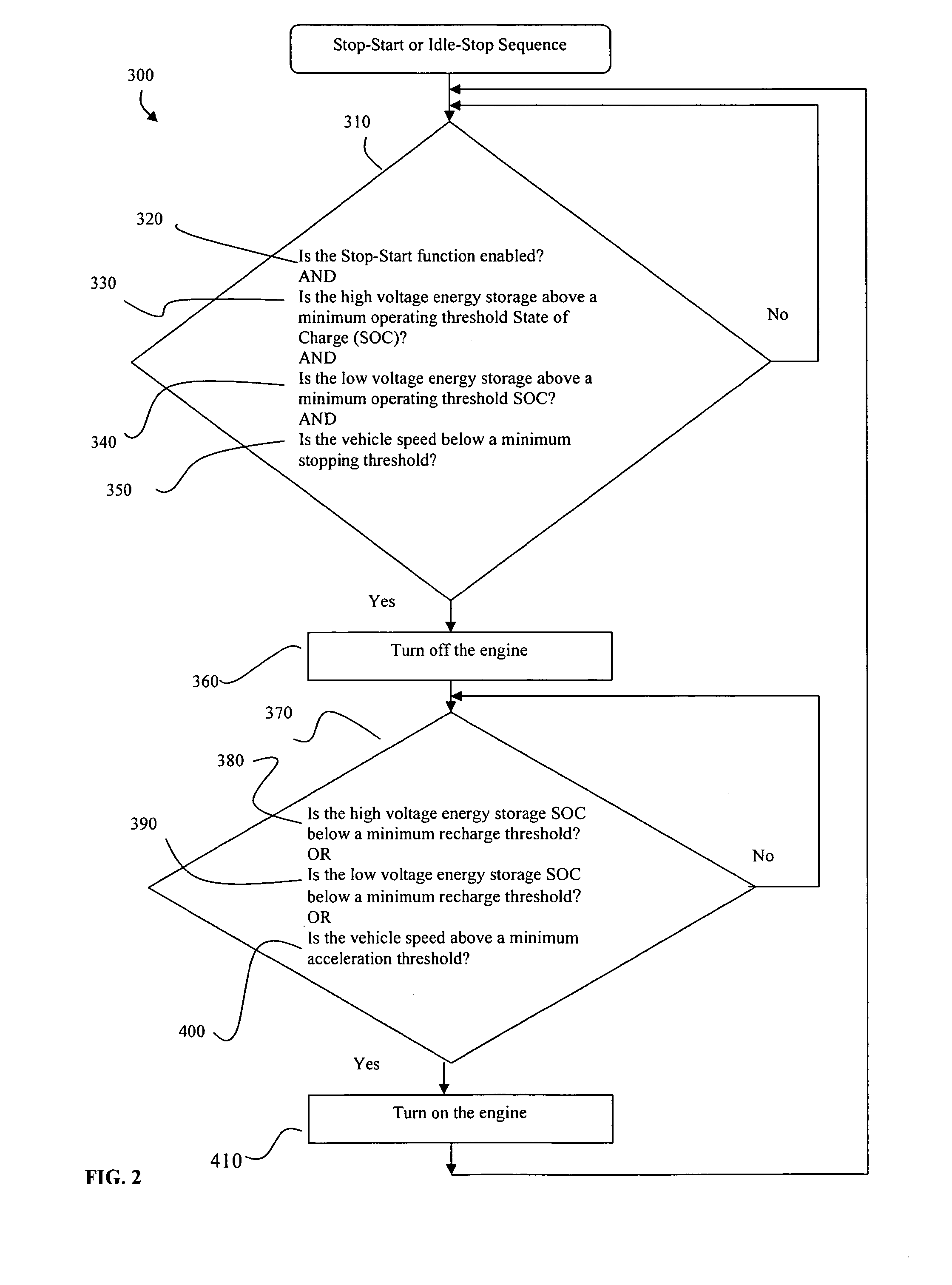

Method of Controlling Engine Stop-Start Operation for Heavy-Duty Hybrid-Electric Vehicles

InactiveUS20100145562A1Noise minimizationHybrid vehiclesInternal combustion piston enginesElectric vehicleInternal combustion engine

A start-stop or idle-stop method for a heavy-duty hybrid vehicle that turns off the fuel supply while maintaining the crankshaft rotation of the internal combustion engine when the vehicle stops or, optionally, when the vehicle travels downhill, travels in a noise sensitive location, travels in an exhaust emissions sensitive location, or operates in an emergency situation. The stop-start or idle-stop method automatically turns on the engine fuel supply to restart combustion when the vehicle starts accelerating, is no longer traveling downhill, is no longer traveling in a noise sensitive or exhaust sensitive location, is no longer in an emergency situation, or has dropped below the minimum energy storage restart level. The stop-start or idle-stop may be inhibited upon certain override conditions.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

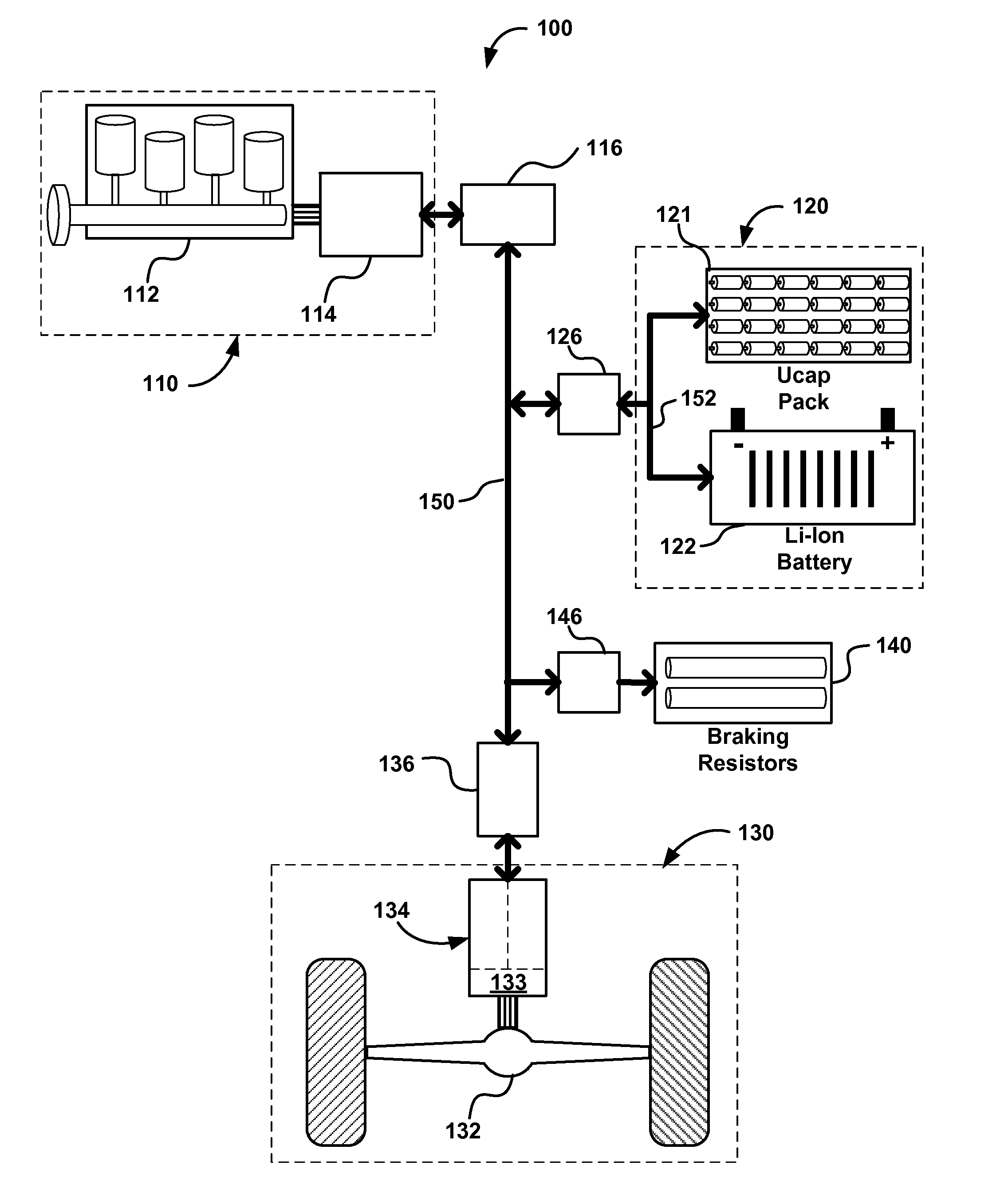

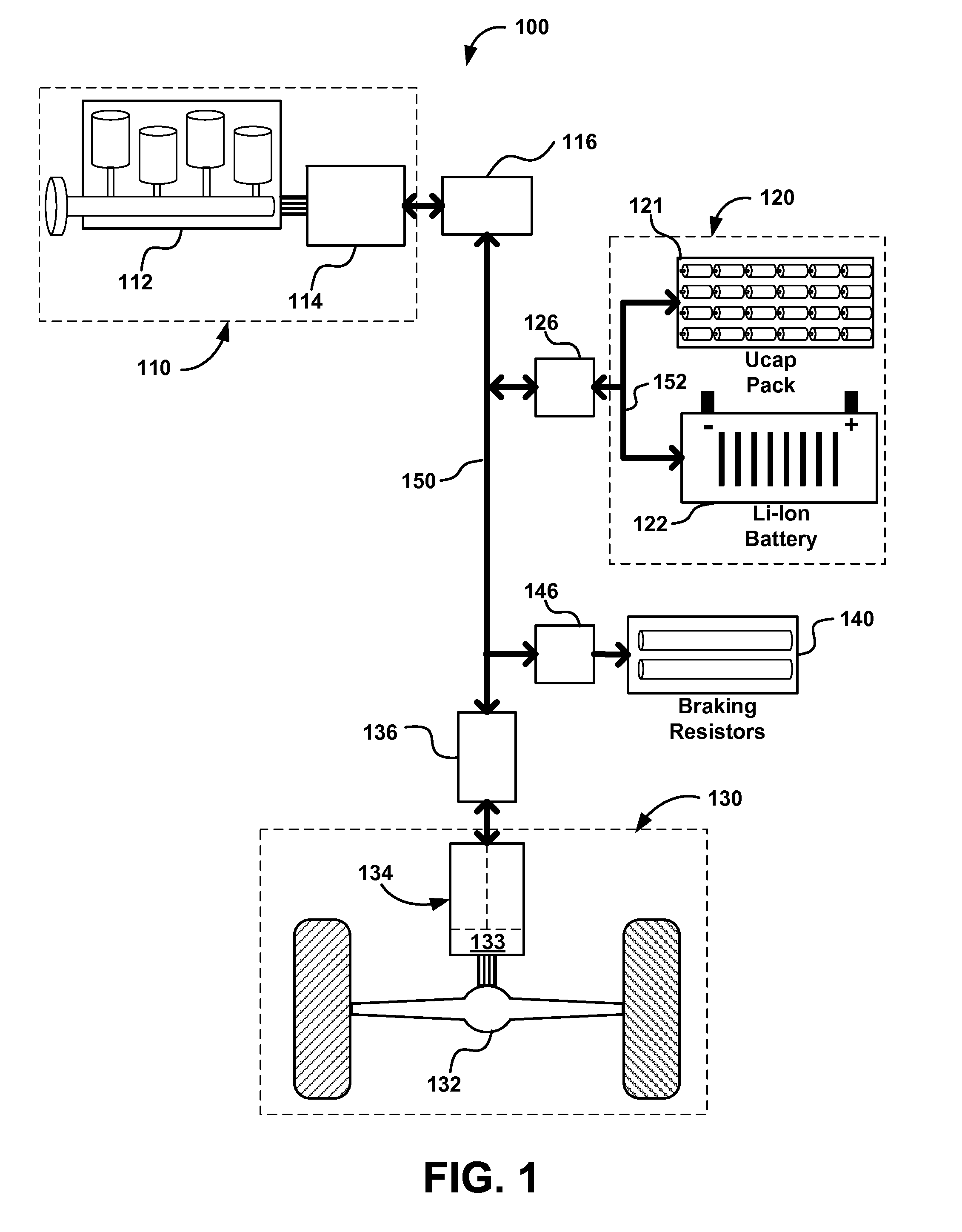

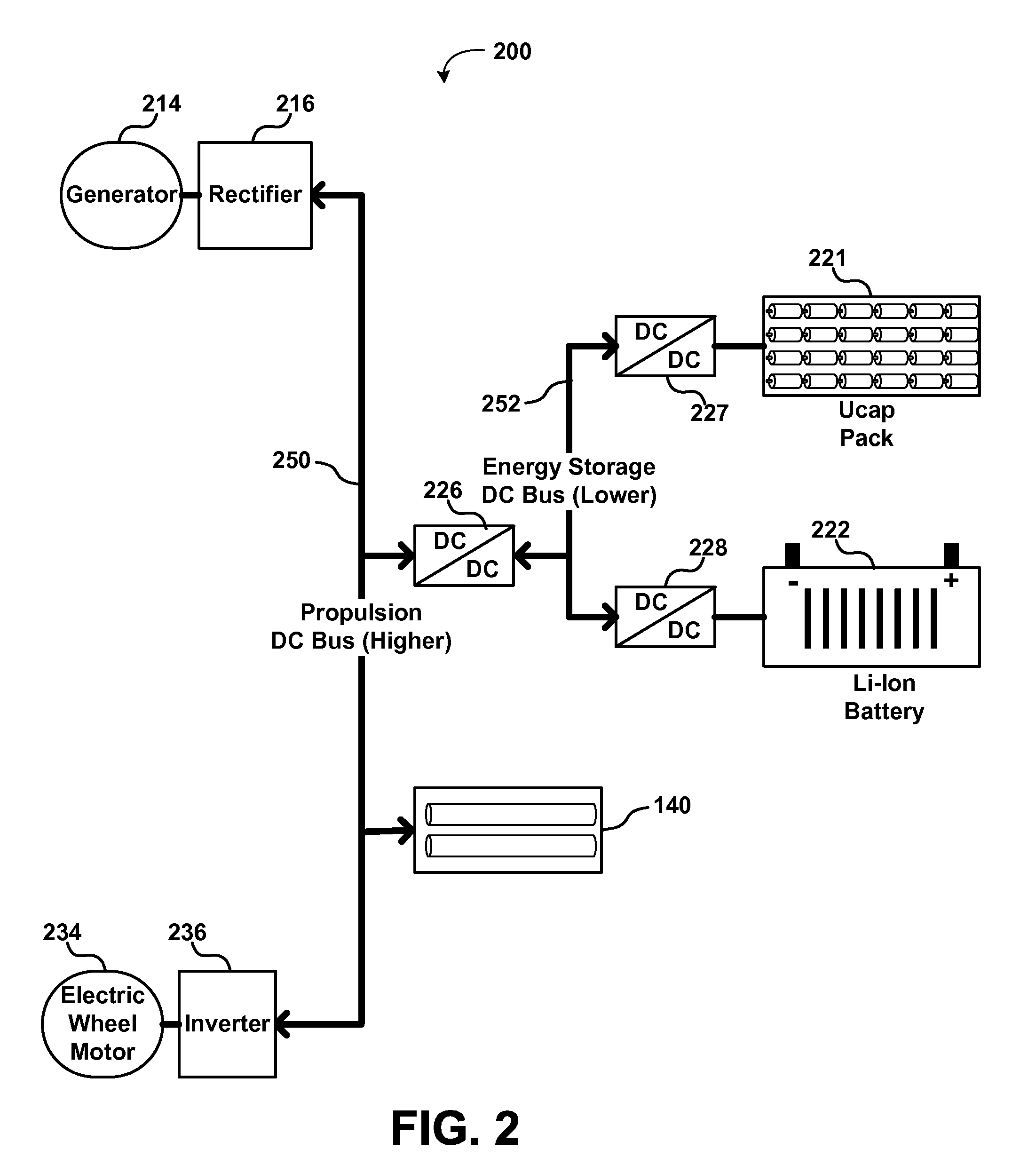

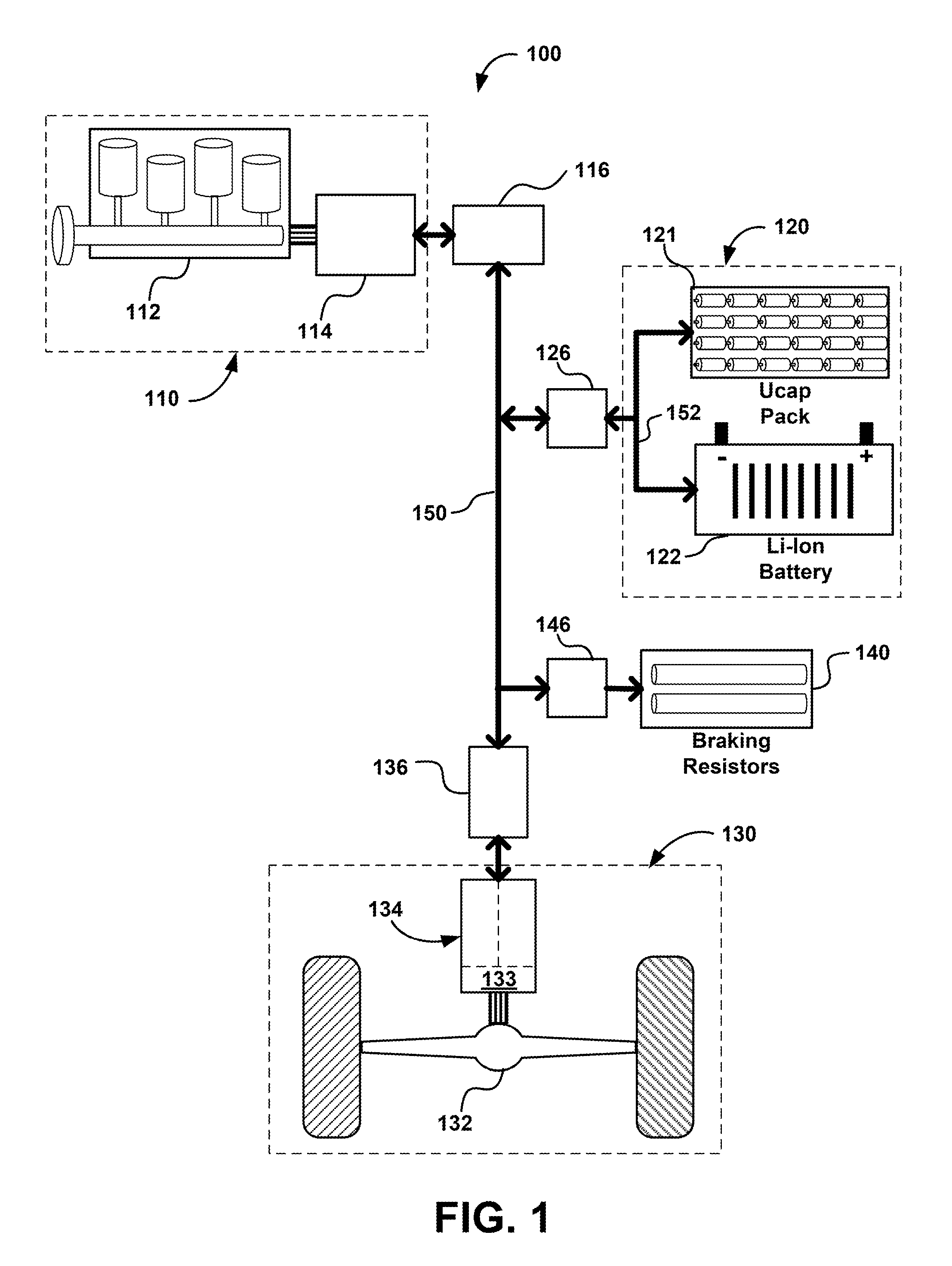

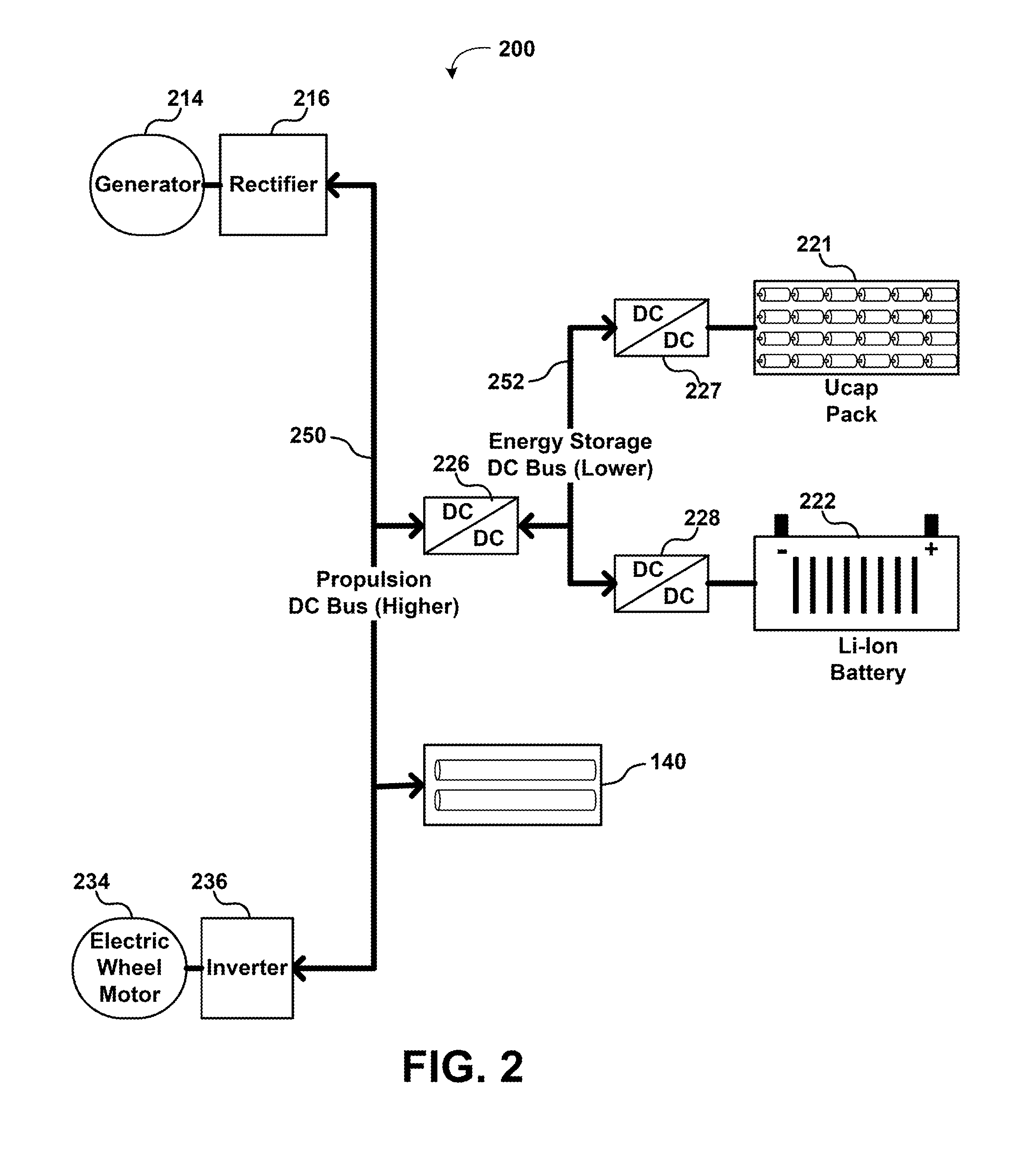

Propulsion Energy Storage Control System and Method of Control

InactiveUS20110100735A1Efficient and inexpensive and reliableElectrodynamic brake systemsPropulsion using engine-driven generatorsElectricityControl system

A propulsion energy storage control system and method of control interspersed between a heavy duty hybrid-electric drive system and its propulsion energy storage. The control system having an energy storage DC bus, electrical interfaces to the drive system and a plurality of propulsion energy storage subsystems, DC-to-DC converters at each interface, and a controller configured to operate each DC-to-DC converter independently such that power flow may charge, discharge, and shuttle between the plurality of propulsion energy storage subsystems.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

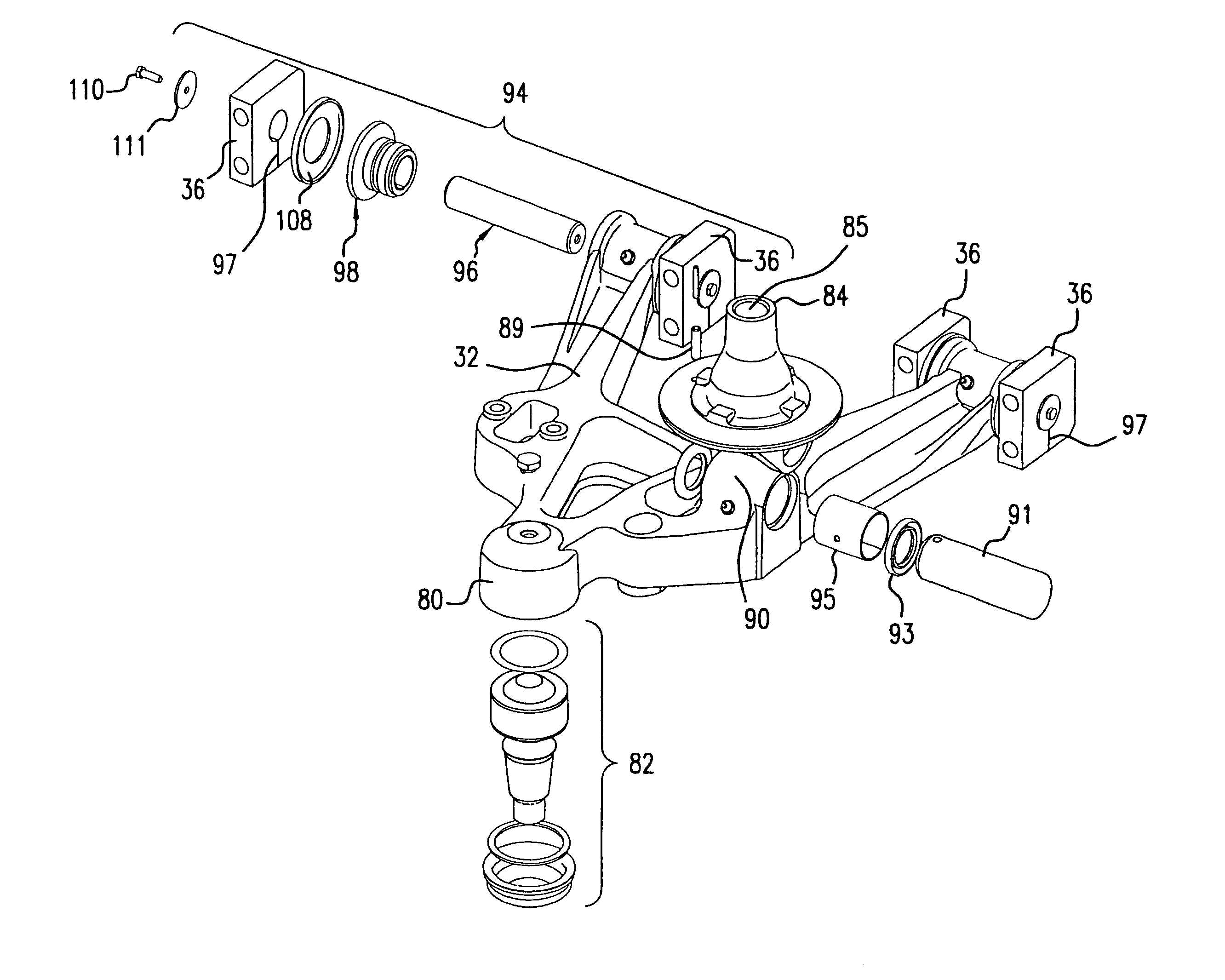

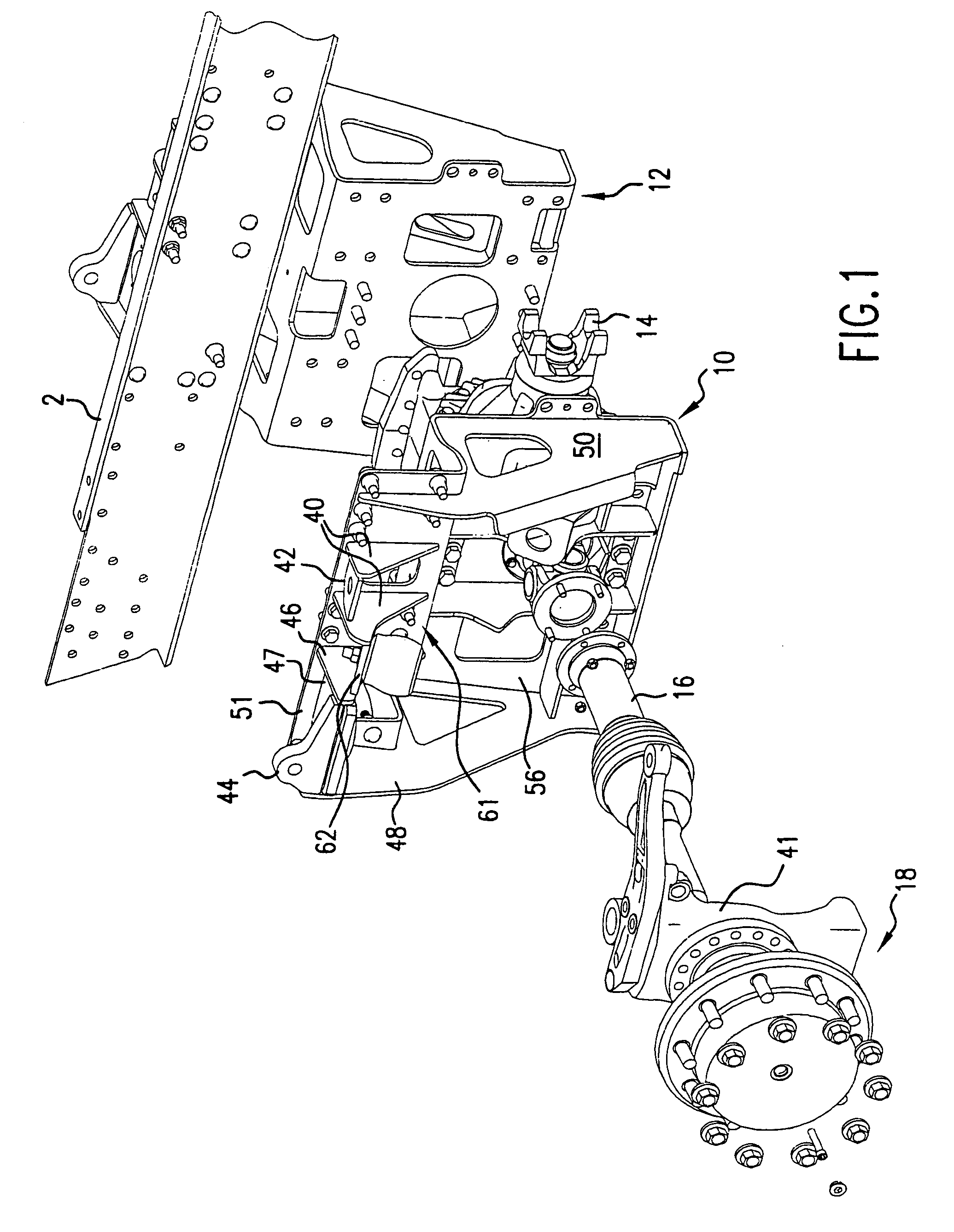

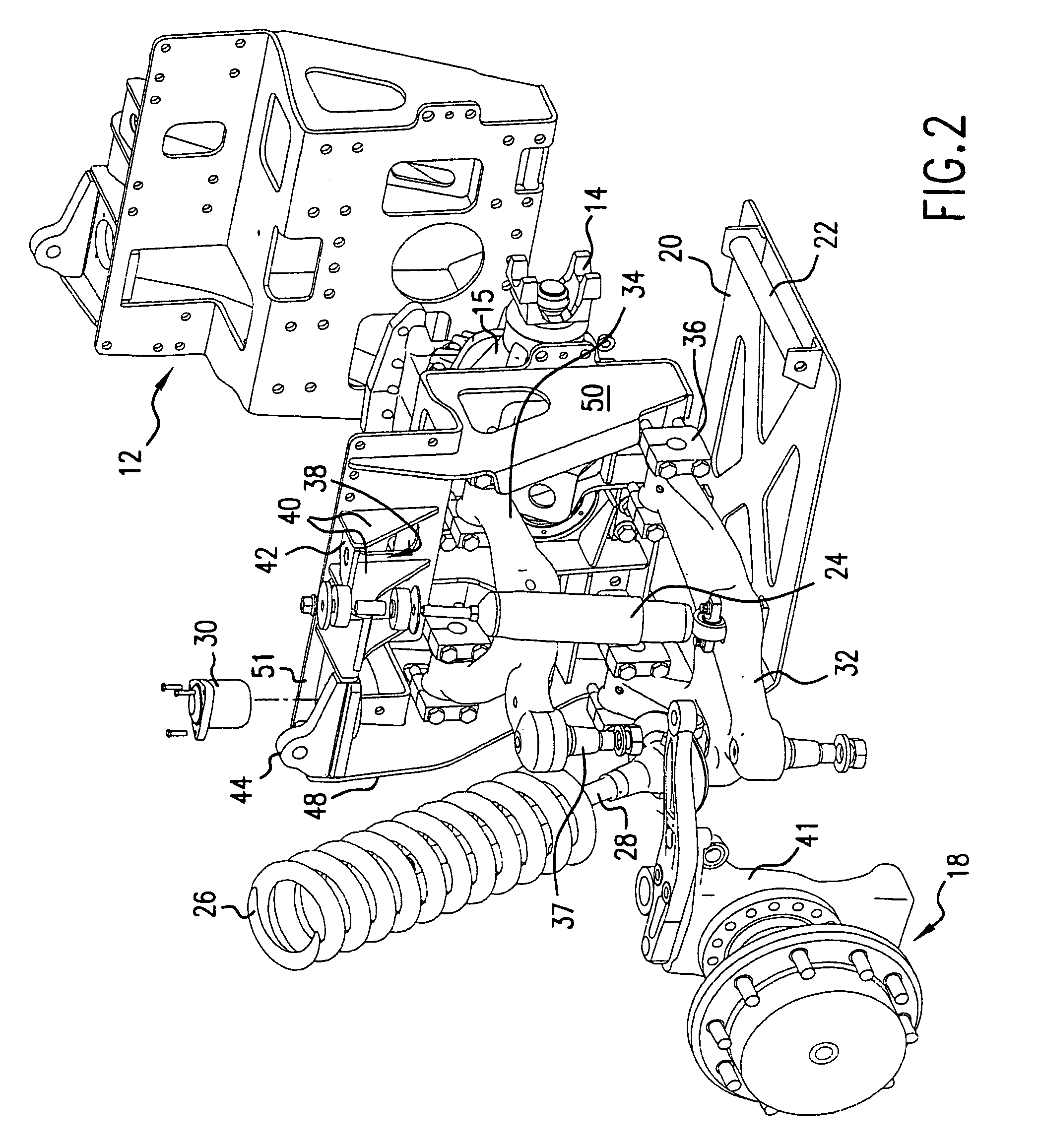

Mounting assembly for a vehicle suspension arm

A mounting assembly for use with a mounting surface includes an arm, a pin, a pair of clamping blocks and a fastener. The arm has a cylindrical bore at one end. The pin extends through the bore. Each block of the pair of clamping blocks includes a central opening and is circumferentially discontinuous about the central opening. Each clamping block further includes a slot defined by portions of the block. The slot is dimensioned to allow the pin to pass through the slot when the block is in an unclamped position and to tightly grip the pin when the block is in a clamped position. The fasteners extend across the slots and are configured to engage the mounting surface to mount the blocks to the mounting surface.

Owner:OSHKOSH CORPORATION

Series relayed wireless power transfer in a vehicle

InactiveUS20140265555A1Efficient deliveryEfficient energy transferElectromagnetic wave systemRailway vehiclesElectric power transmissionEnergy transfer

Described herein are improved capabilities for a system and method for wireless energy distribution across a vehicle compartment of defined area, comprising a source resonator coupled to an energy source of a vehicle and generating an oscillating magnetic field with a frequency, and at least one repeater resonator positioned along the vehicle compartment, the at least one repeater resonator positioned in proximity to the source resonator, the at least one repeater resonator having a resonant frequency and comprising a high-conductivity material adapted and located between the at least one repeater resonator and a vehicle surface to direct the oscillating magnetic field away from the vehicle surface, wherein the at least one repeater resonator provides an effective wireless energy transfer area within the defined area.

Owner:WITRICITY CORP

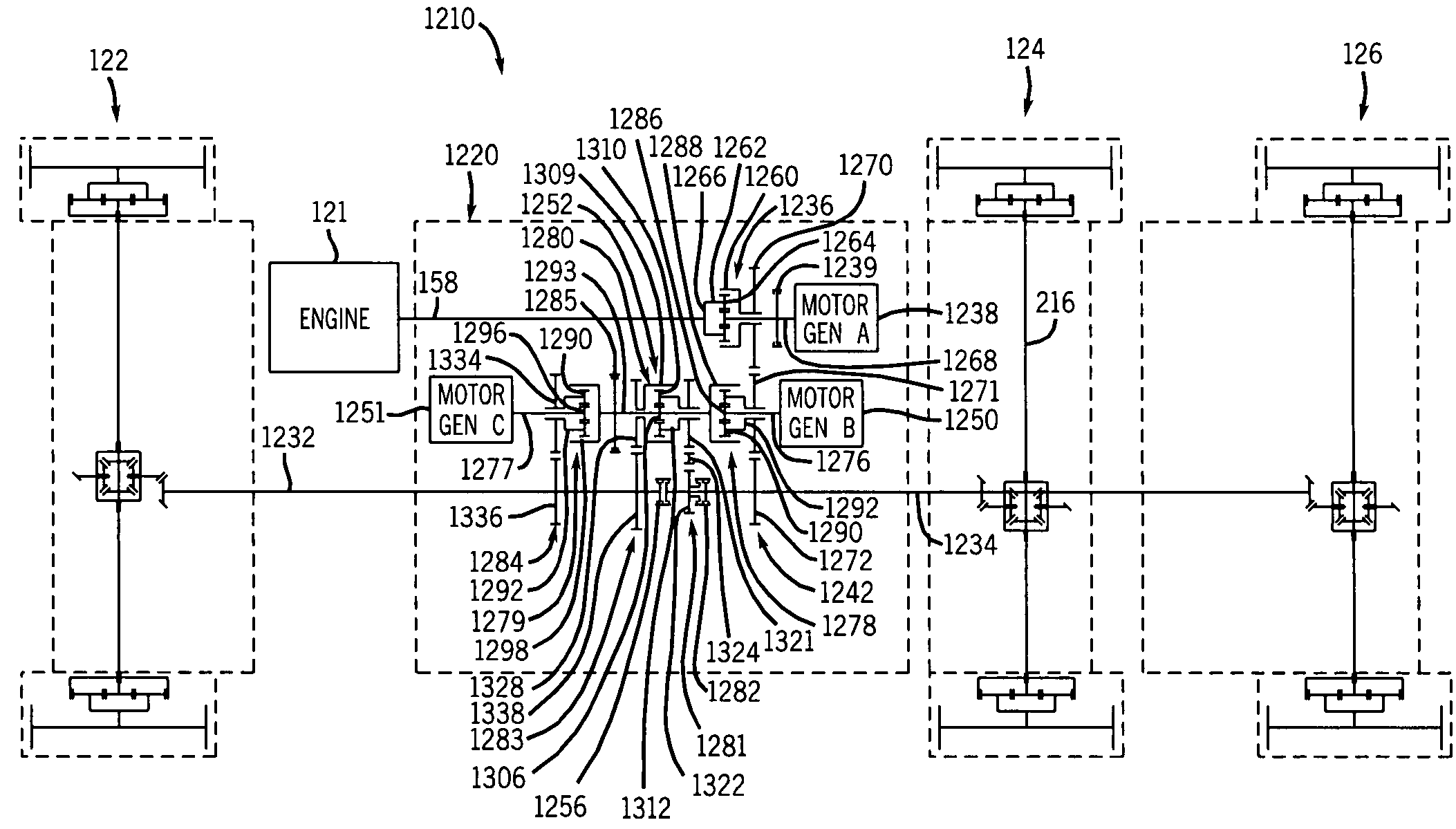

Next generation hybrid III parallel/series hybrid system

InactiveUS20080185198A1Maximize fuel economyExtended service lifeHybrid vehiclesElectric propulsion mountingHybrid systemCost effectiveness

This Next Generation Heavy Hybrid Propulsion System III was specifically designed to use mainly all off the components. This facilitates in the rapid deployment to market with minimum increased purchasing price to the truck over conventional propulsion systems.By designing a cost effective no frills hybrid system, allows more trucks to be equipped with this technology and reap the rewards of higher fuel economy. There is minimum research and development funds needed to place this technology on line. This technology can be used in small cars to large vehicles with similar results, increased fuel economy.

Owner:JONES STEVEN MARK

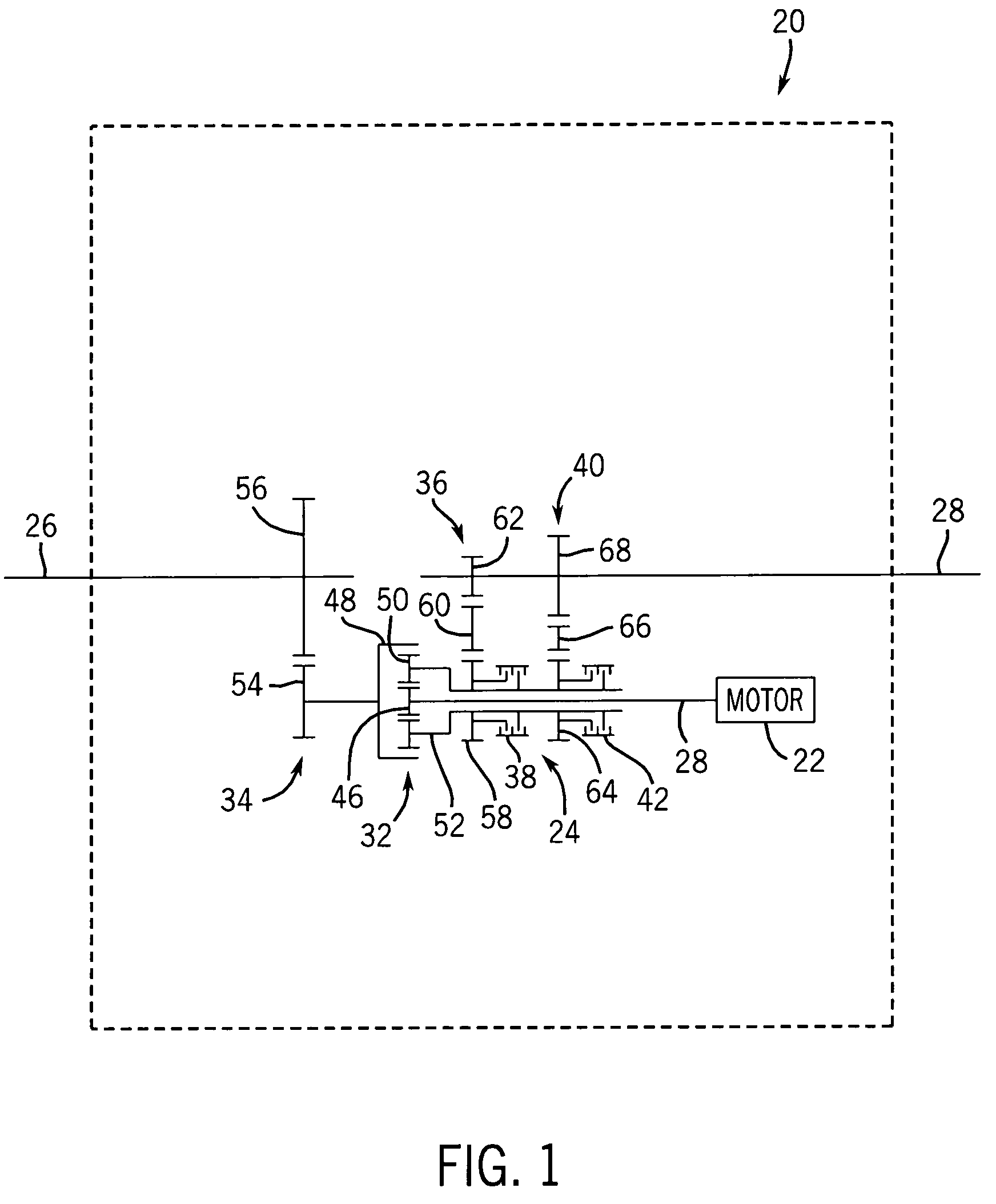

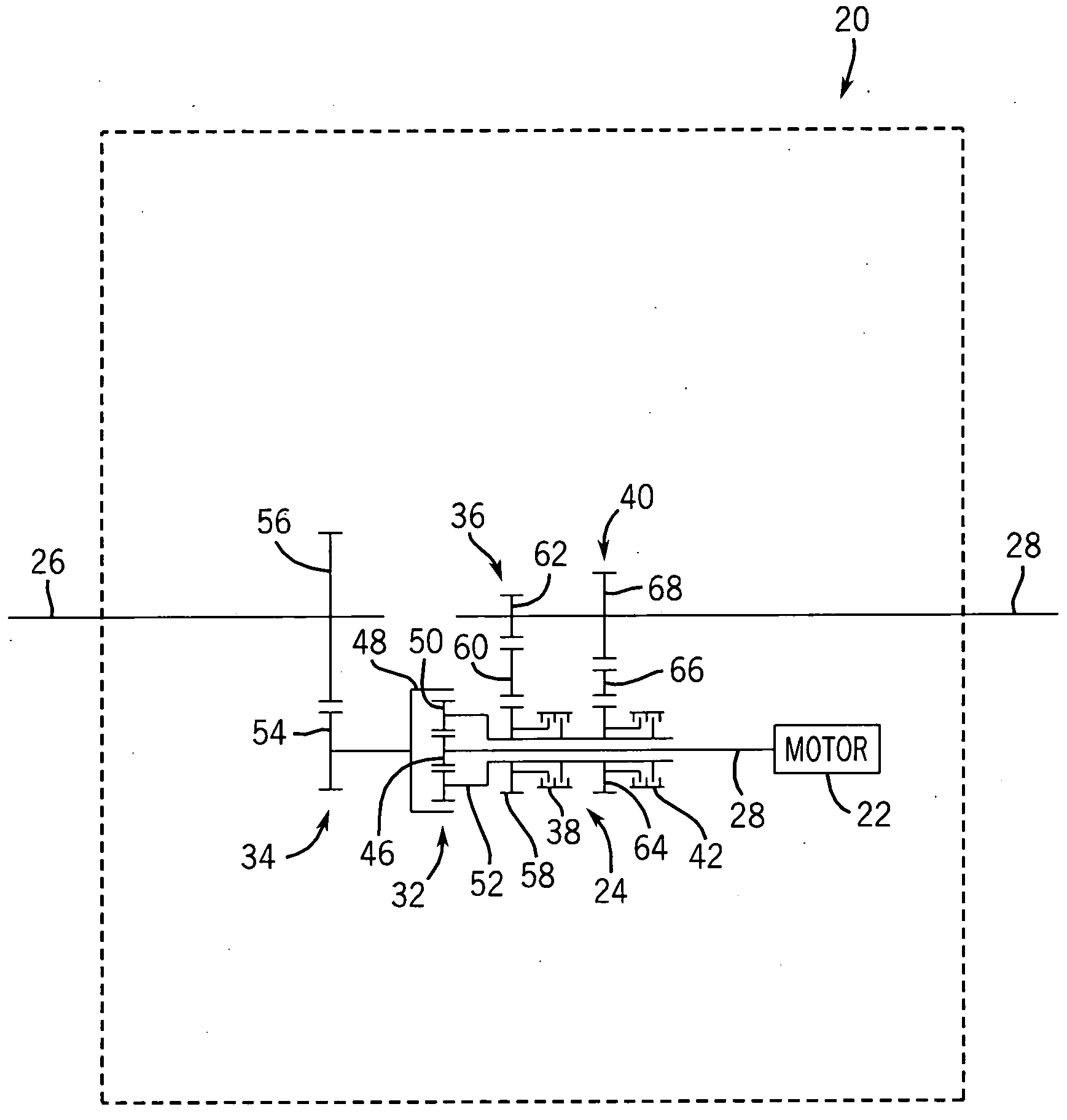

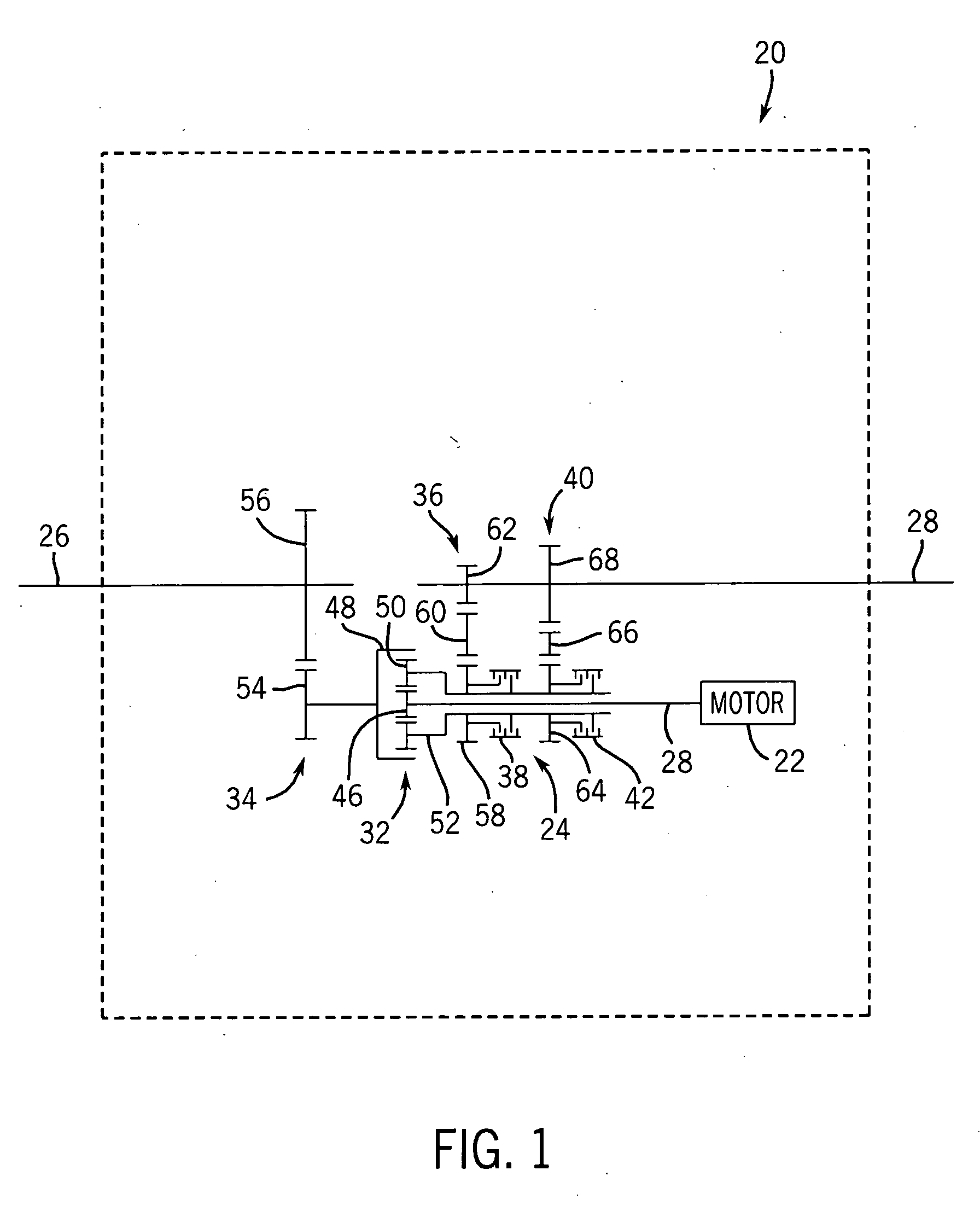

Power splitting vehicle drive system

A vehicle includes a prime mover, a first output shaft, a second output shaft and a planetary gear assembly. The planetary gear assembly includes a sun gear, a ring gear and a plurality of planetary gears supported between the ring gear and the sun gear by a carrier. One of the sun gear and the ring gear is coupled to the prime mover. The other of the ring gear and the sun gear is coupled to the first output shaft. The first carrier is coupled to the second output shaft.

Owner:OSHKOSH CORPORATION

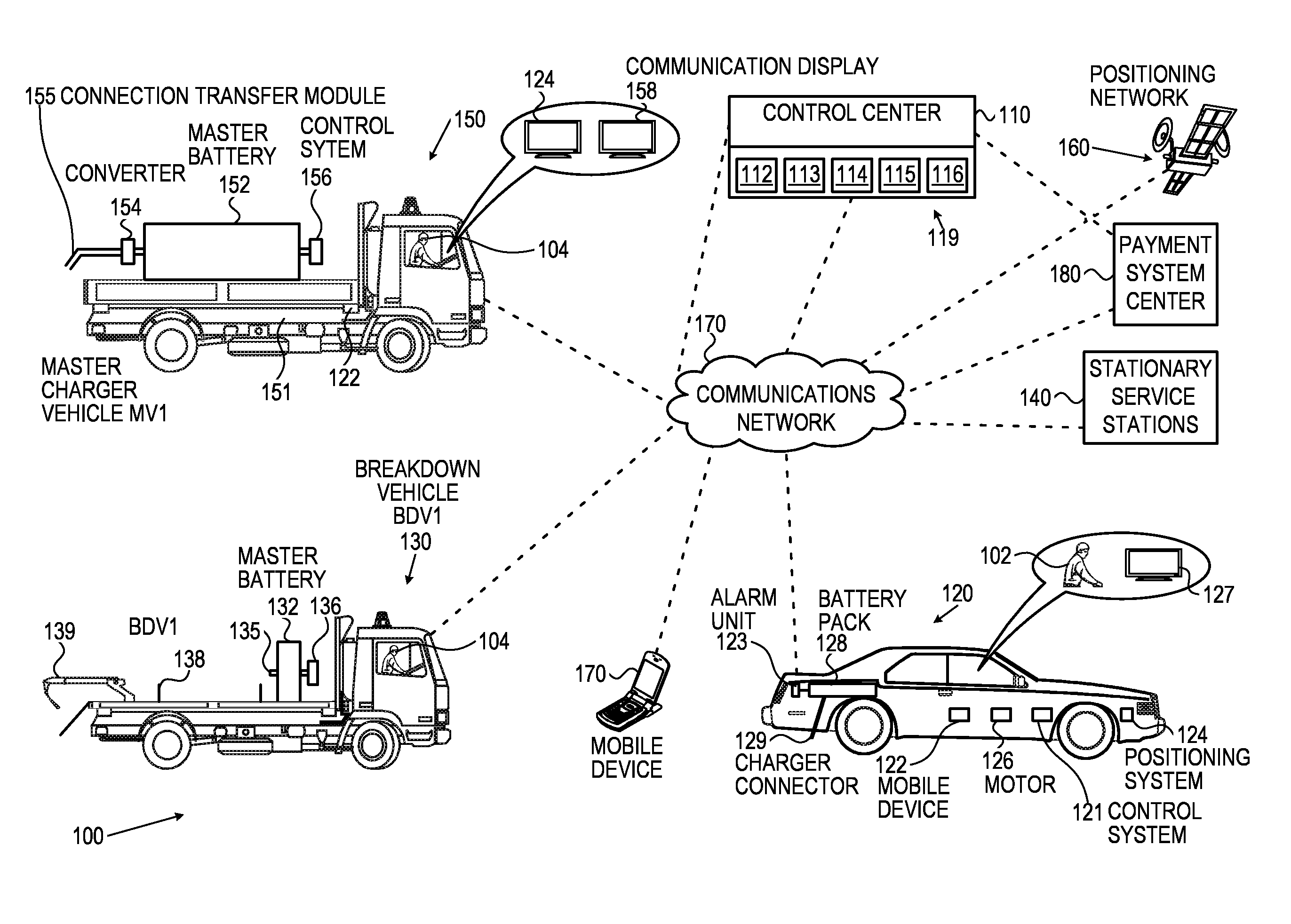

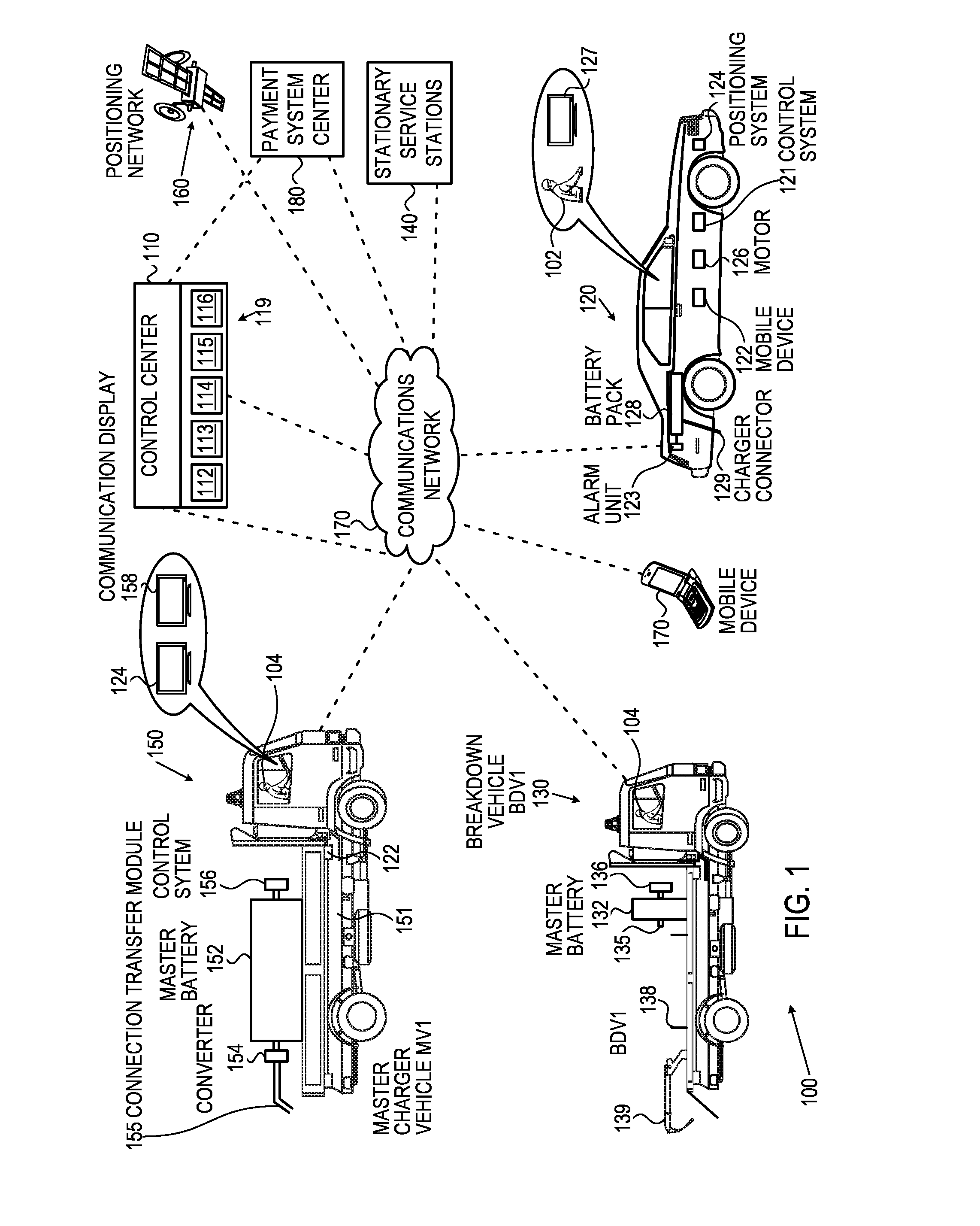

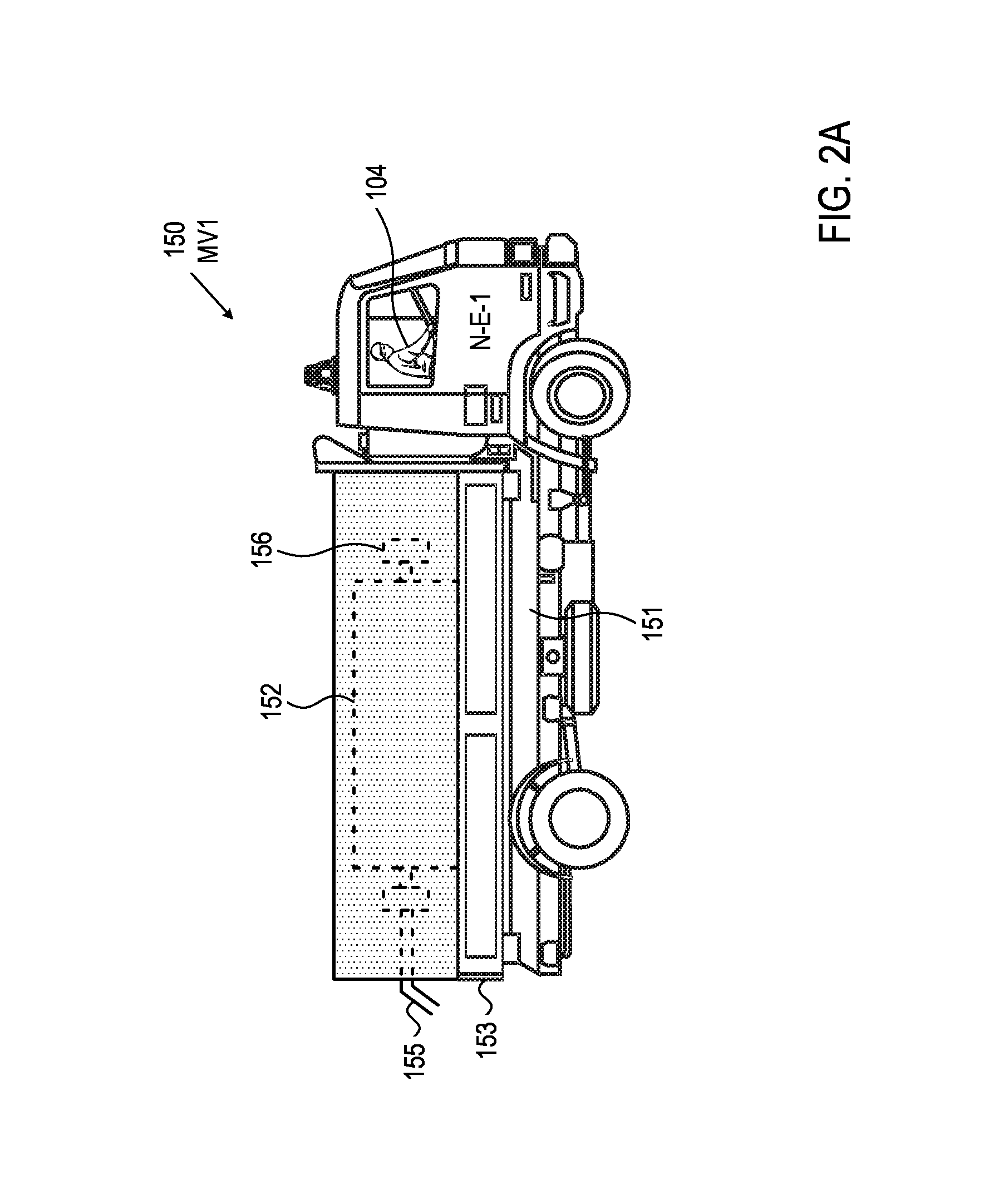

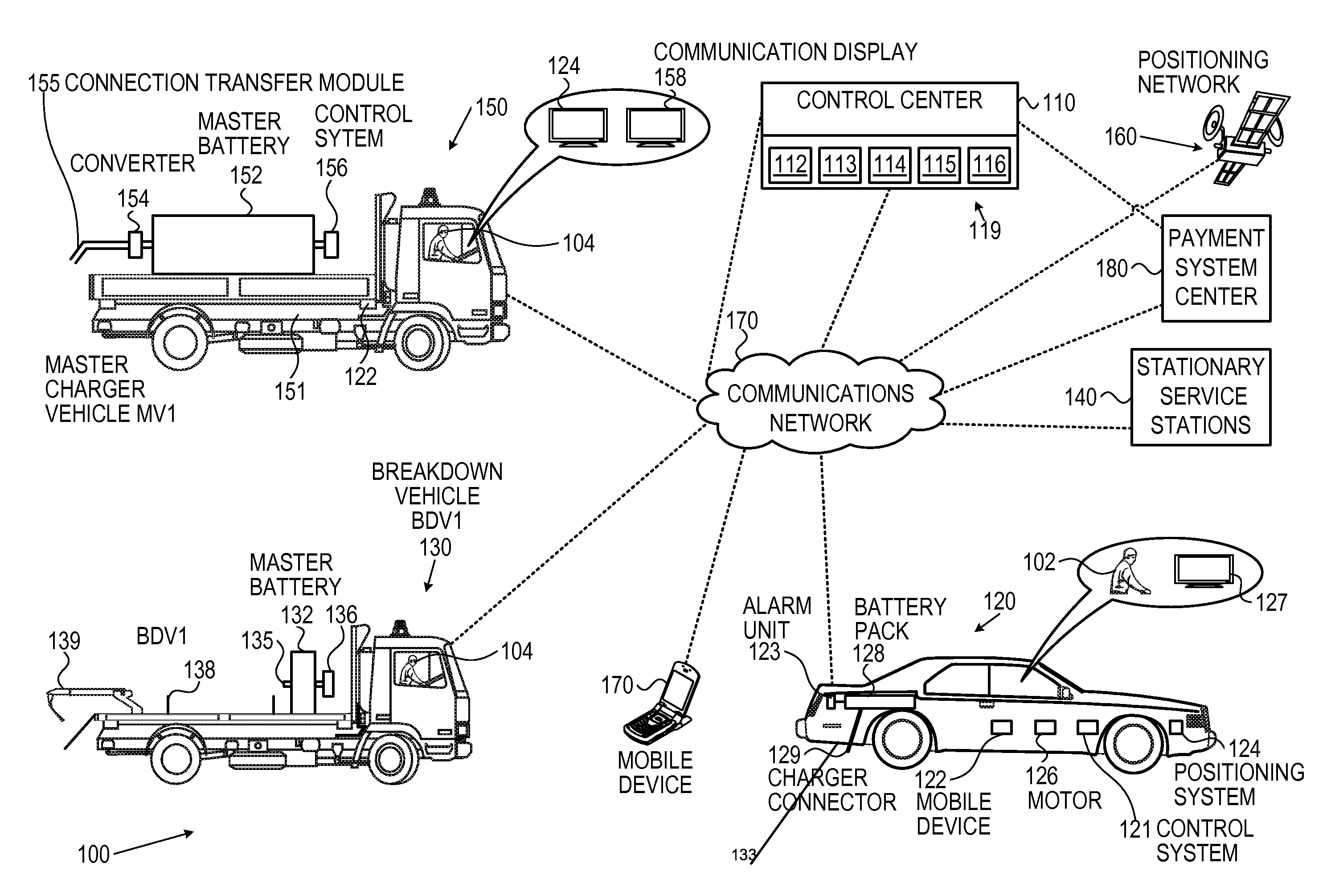

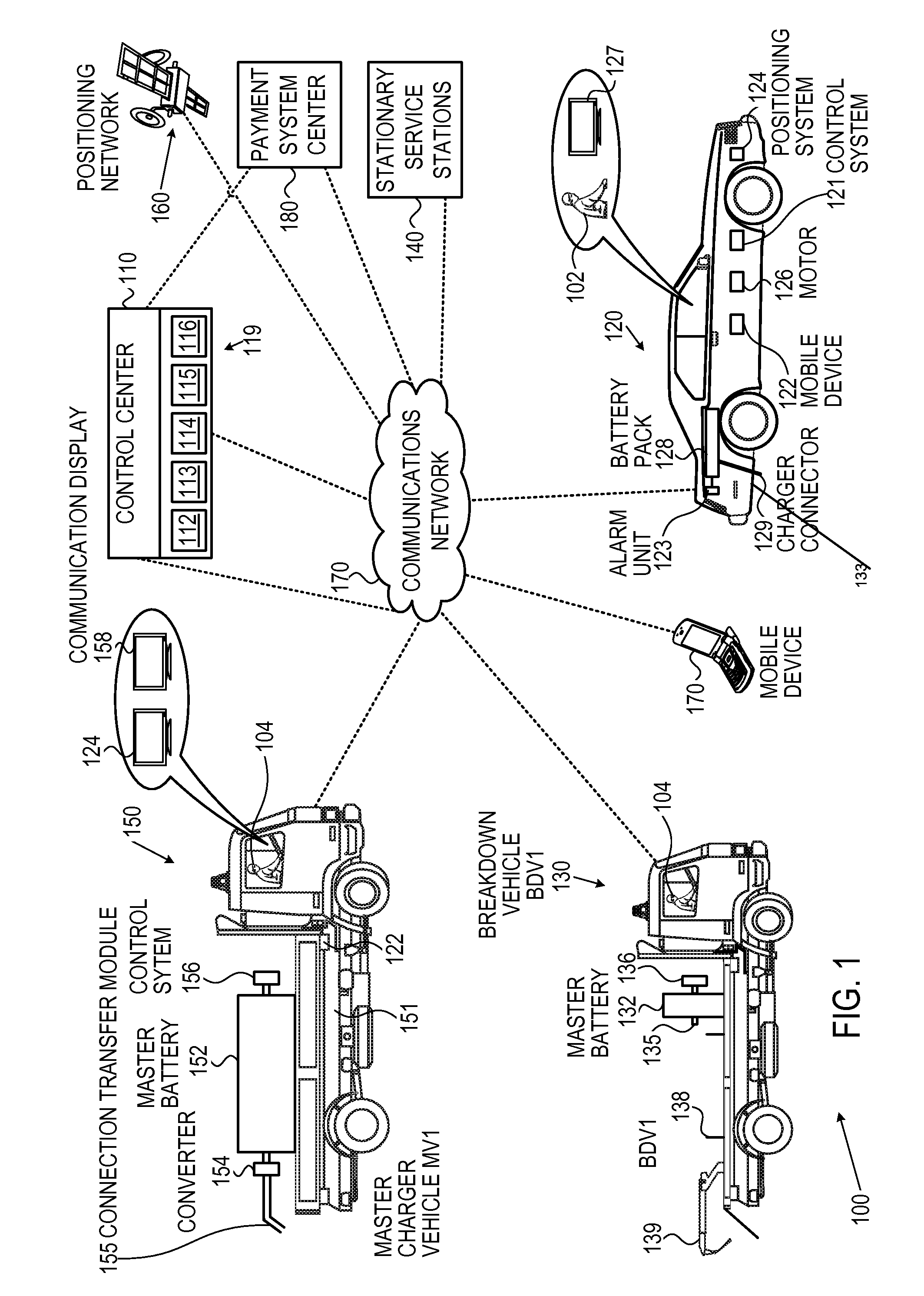

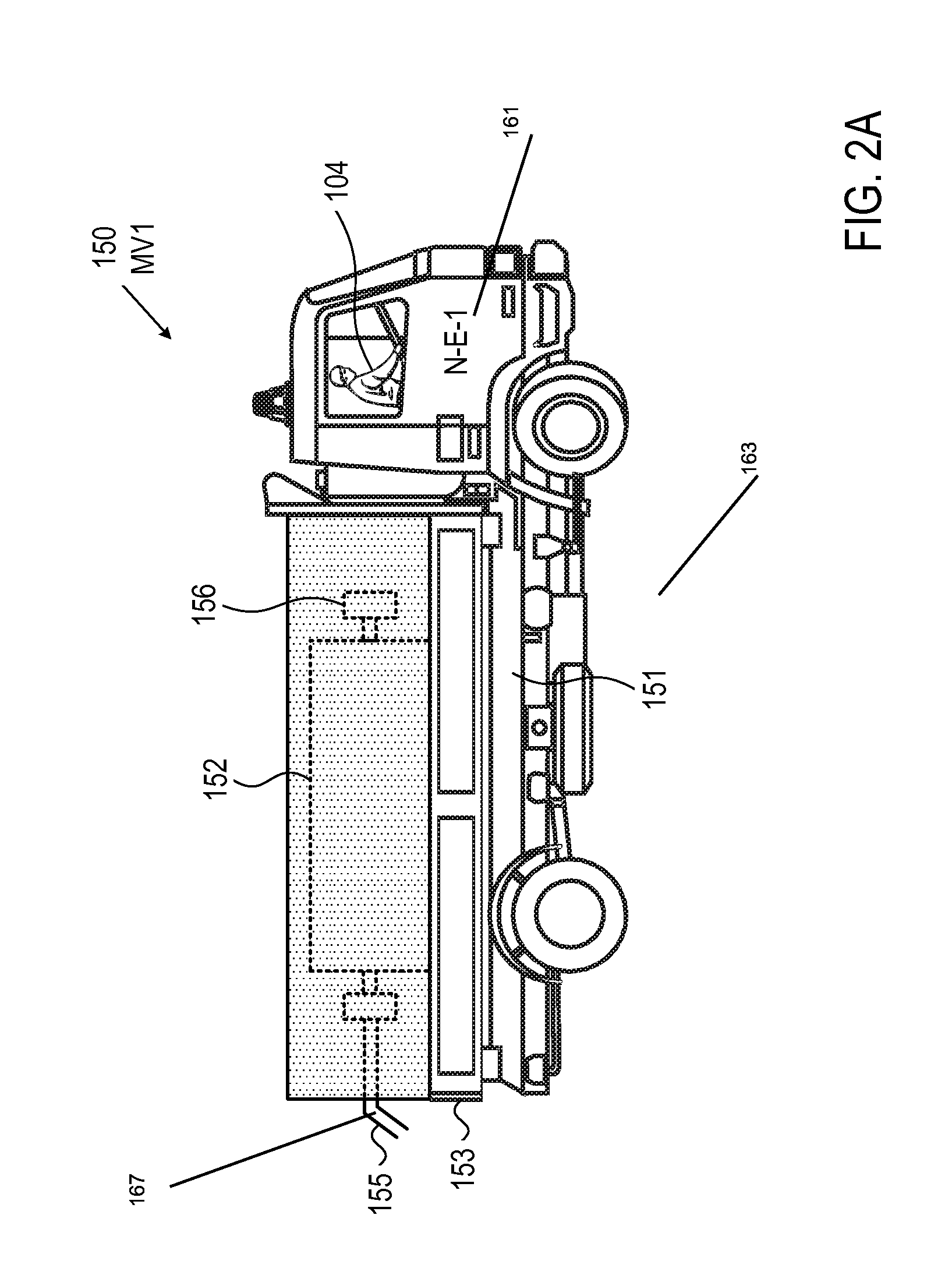

Real-time system and method for tracking, locating and recharging electric vehicles in transit

InactiveUS20120005031A1Batteries circuit arrangementsSpecial tariff metersBattery chargeControl system

The present invention provides computer-controlled electric battery charging systems and methods for charging a battery of a roaming electric vehicle, the system comprising an electric vehicle comprising at least one battery, a master charger vehicle comprising a master battery module and a control system in communication with the at least one electric vehicle and the master charger vehicle to enable the master charger vehicles to reach the electric vehicle, wherein the master battery module is adapted to charge the at least one battery.

Owner:NATION-E

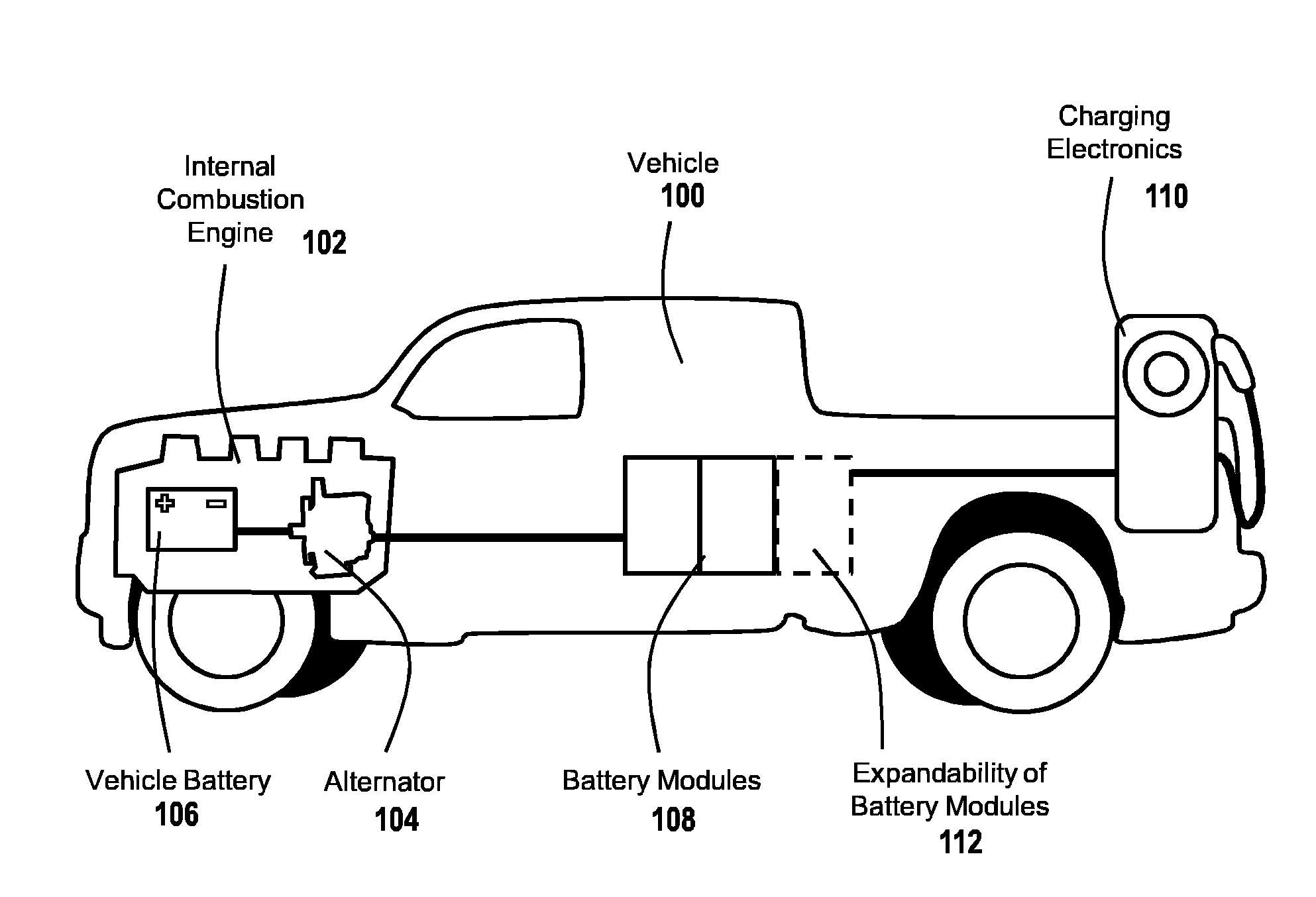

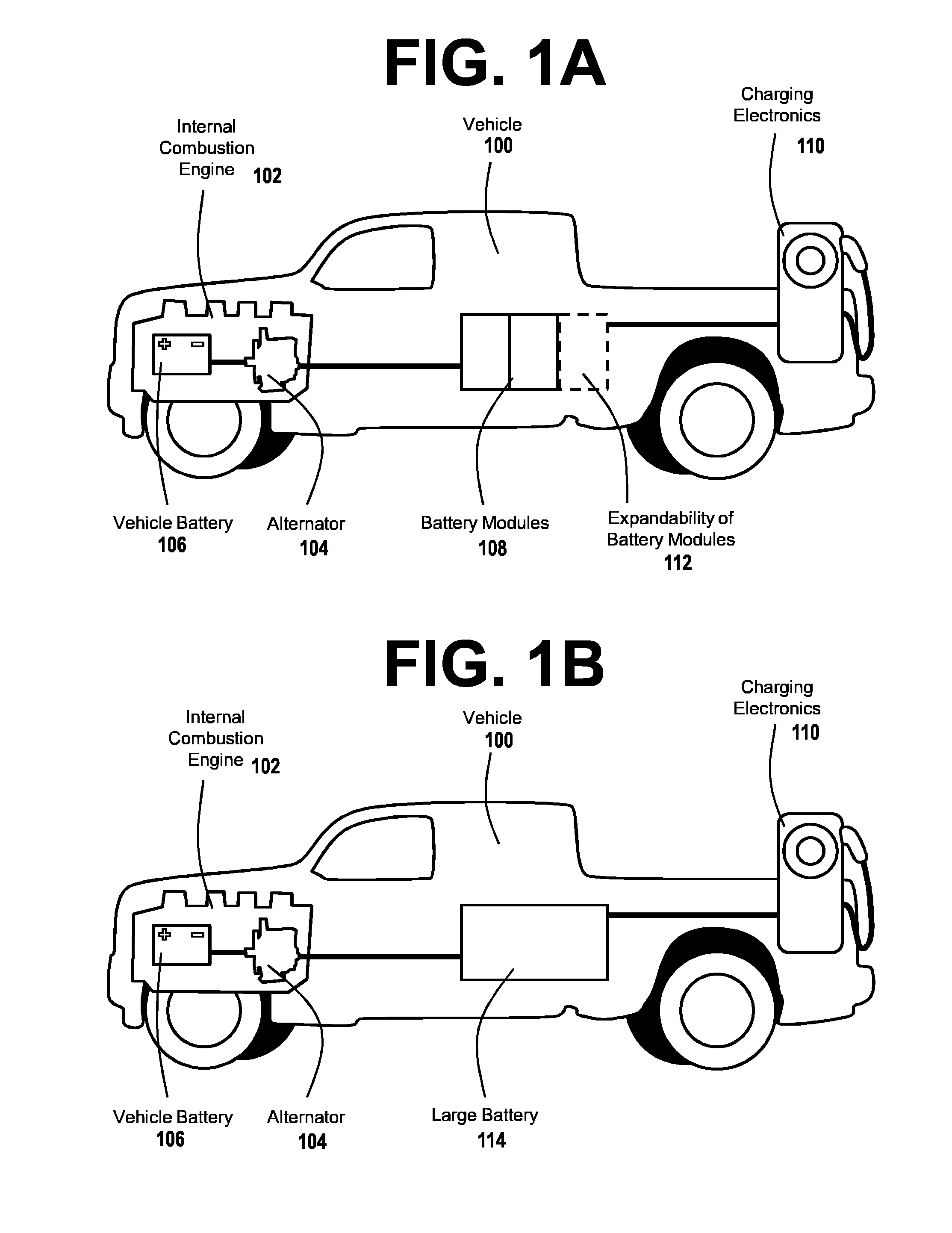

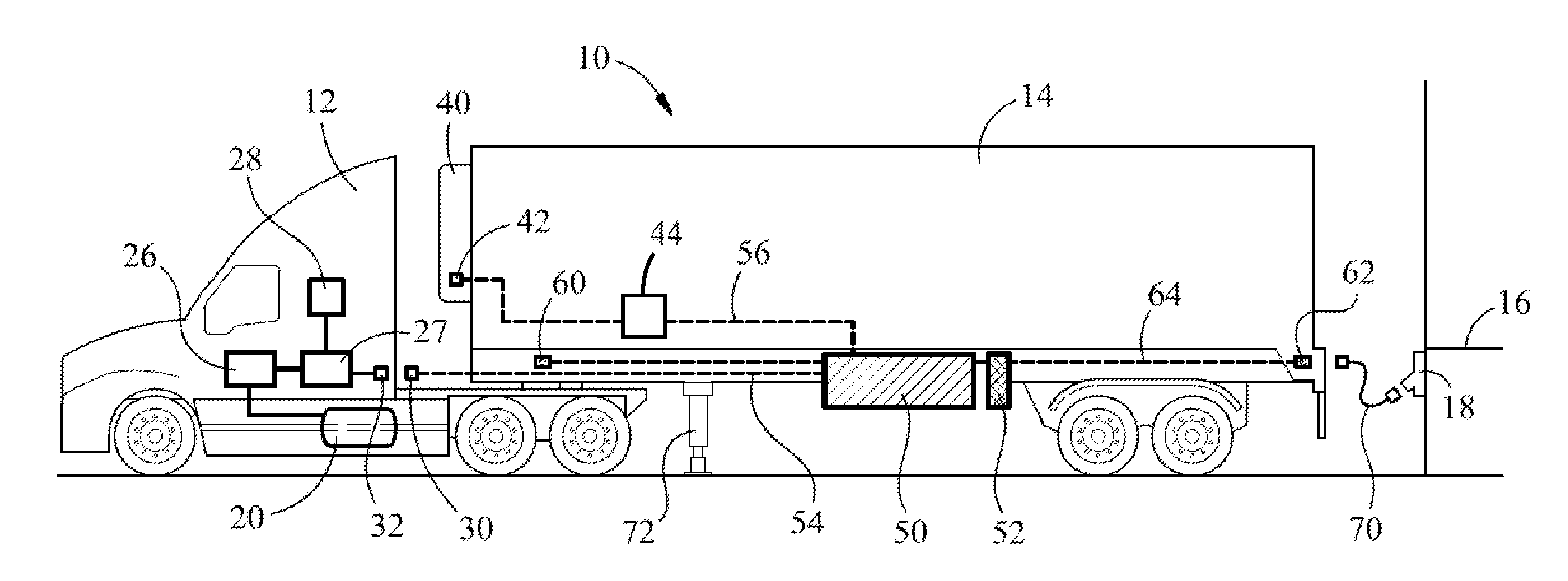

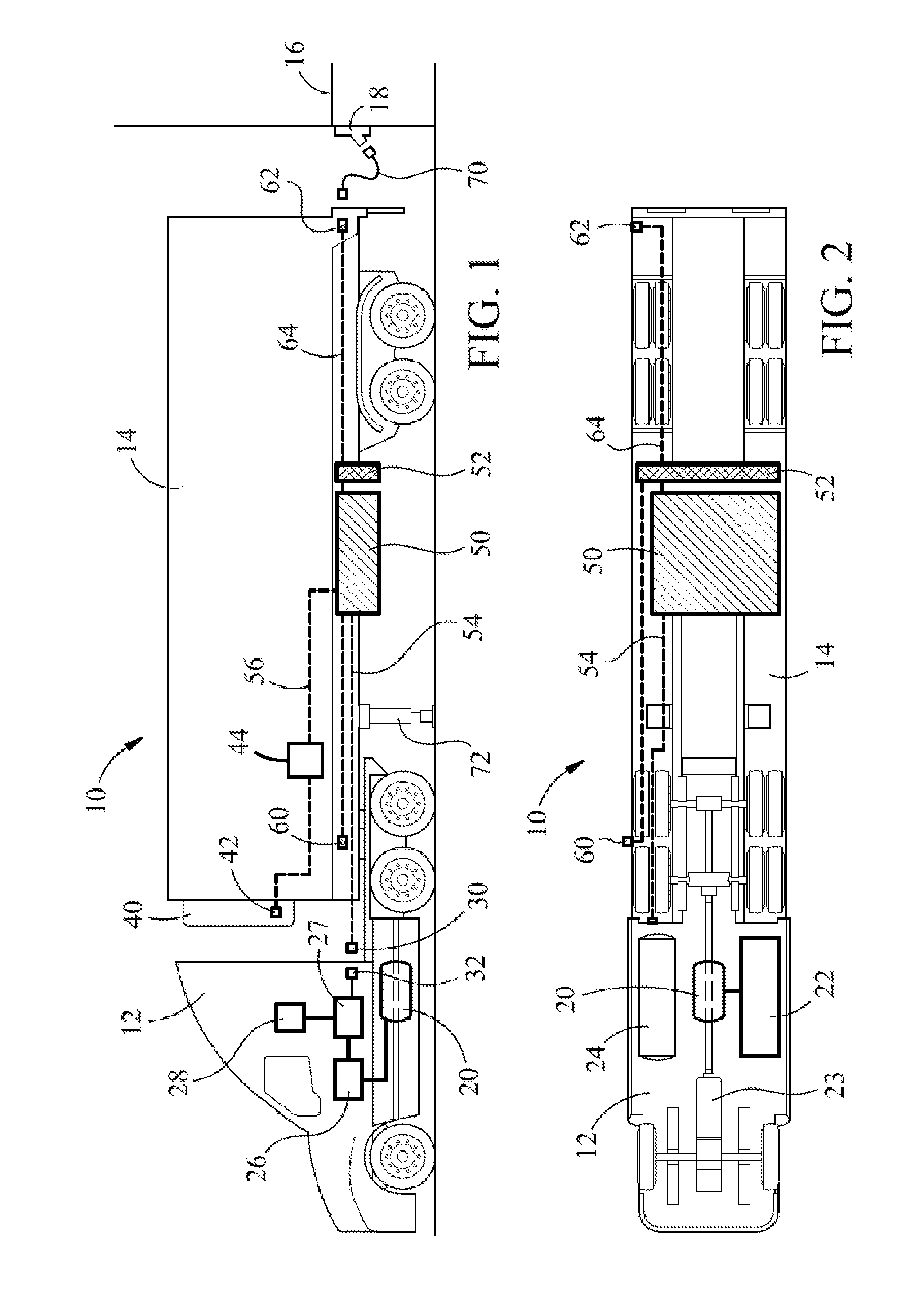

Battery Power System for Plug In Hybrid Tractor Trailers

InactiveUS20110114398A1Improve abilitiesLarge capacityHybrid vehiclesBatteries circuit arrangementsTractor trailerHybrid power

A battery power system for a plug-in hybrid or electric tractor trailer employs a battery module which is carried by the trailer. A cable communicates with the battery module and connects with a connector on the cab for supplying power to power the electric motor of the cab. The cab can be disconnected from the trailer while the battery module on the trailer is charged. The cab can then be driven by the electric motor powered by the battery supply of the cab.

Owner:CONTROL MODULE INDUSTRIES

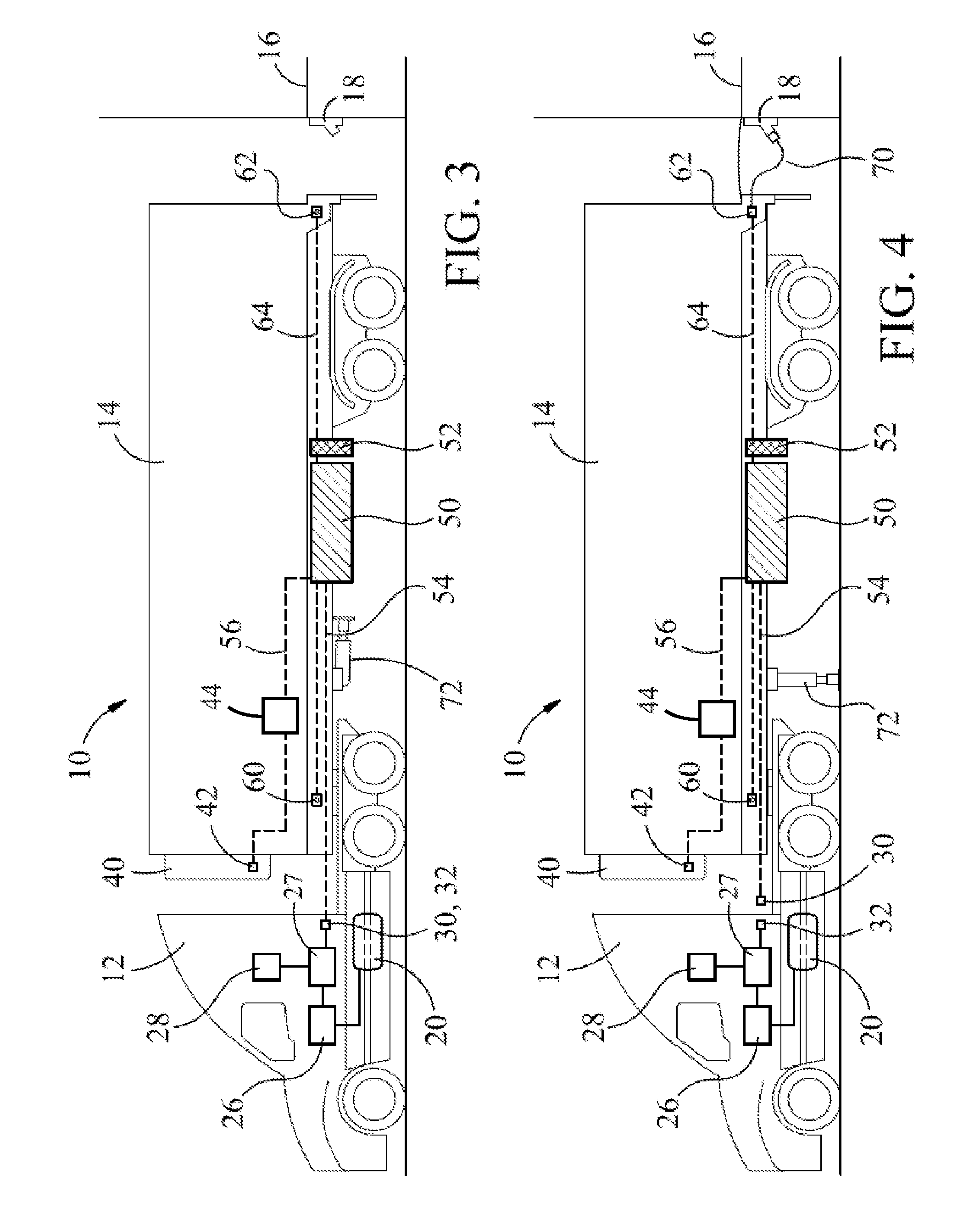

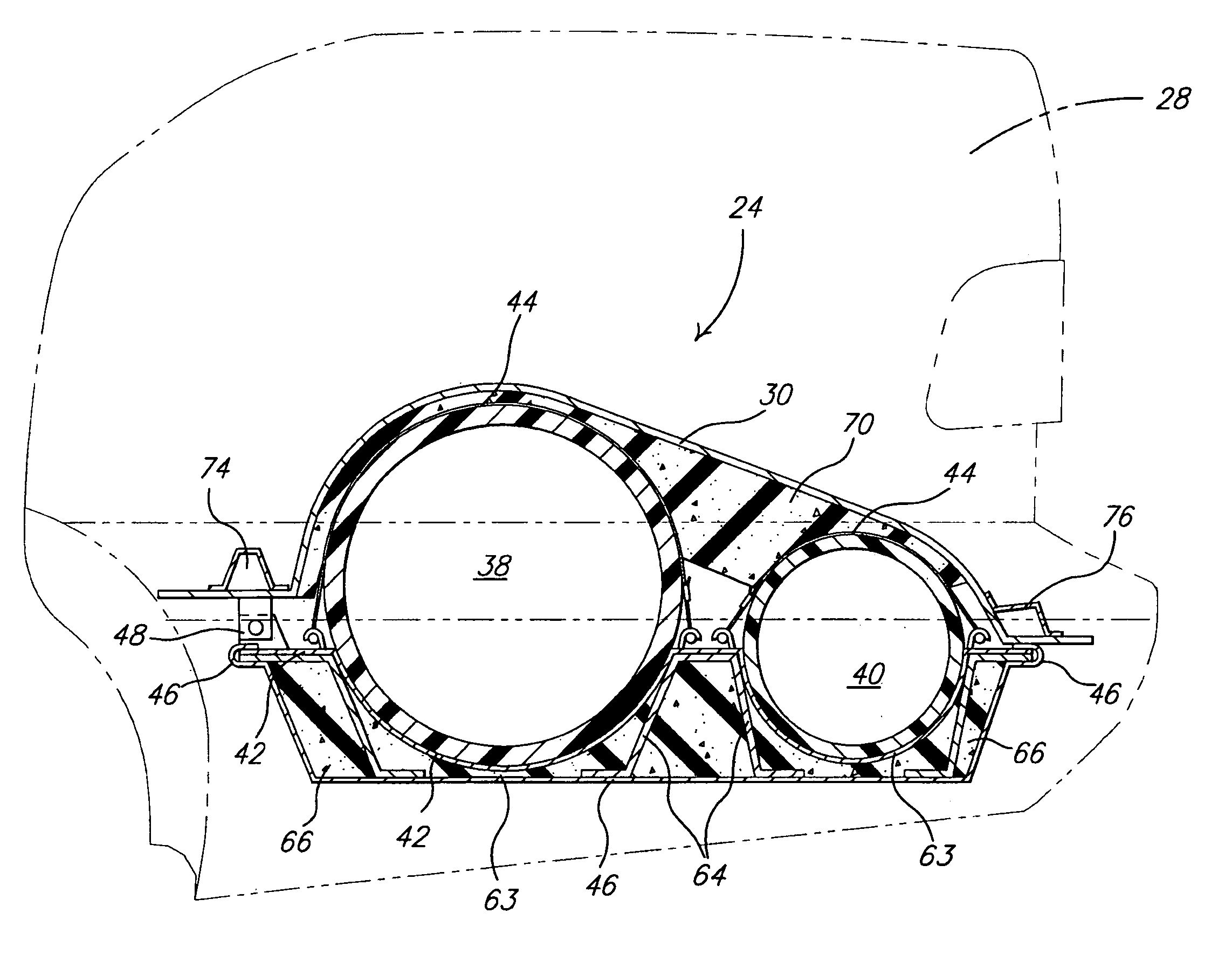

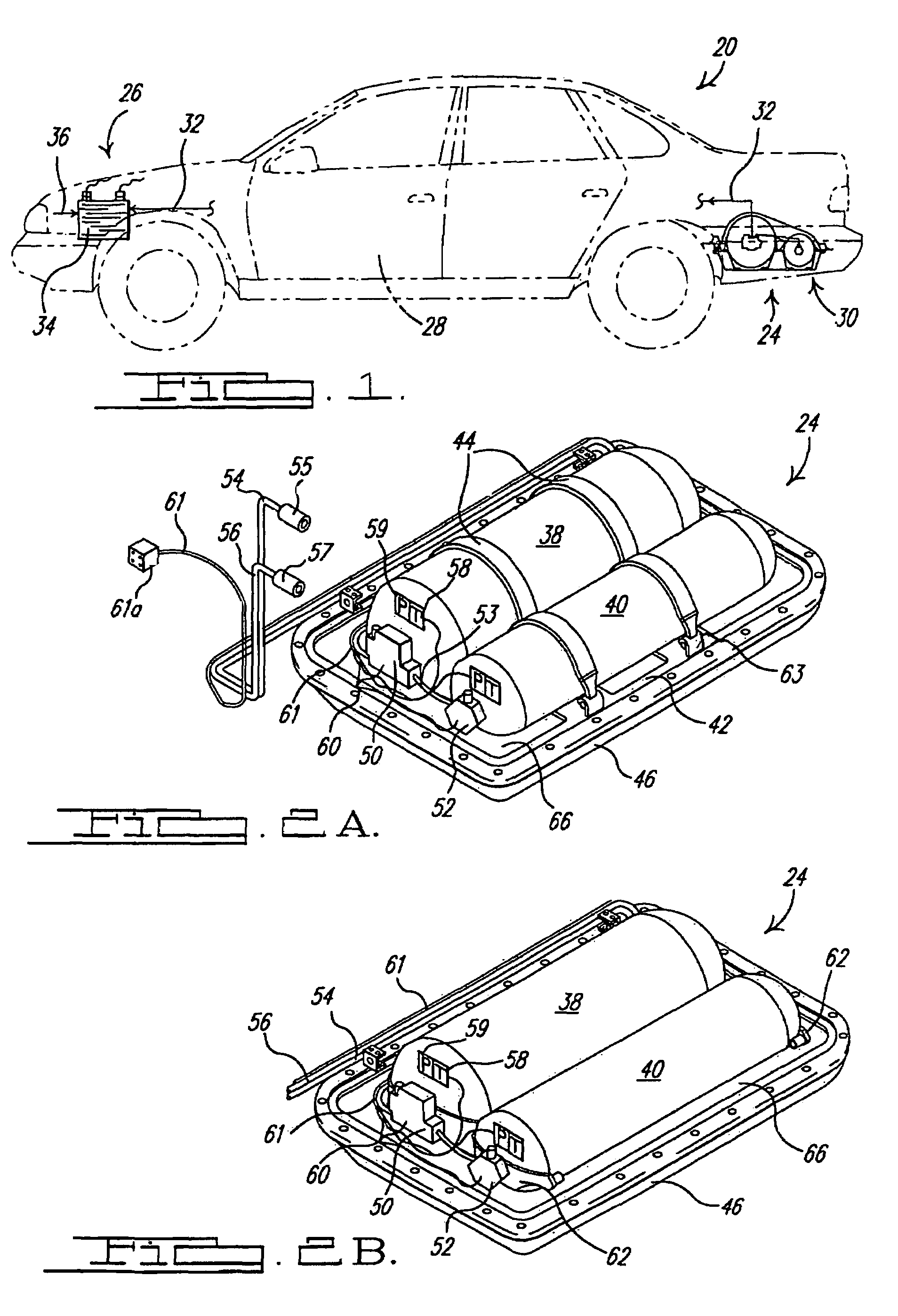

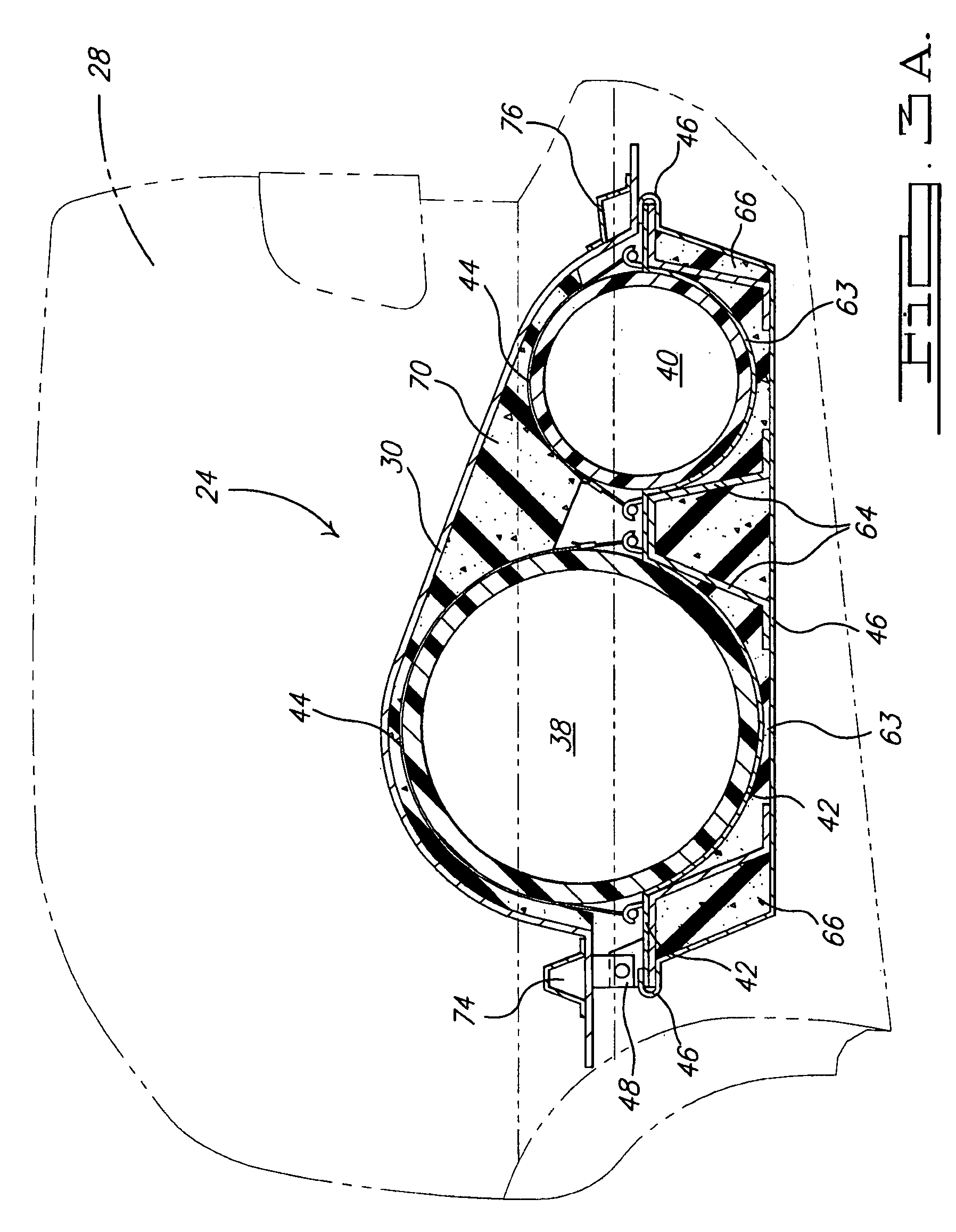

Modular fuel storage system for a vehicle

A gaseous fuel storage system for a vehicle is disclosed. The fuel storage system can be installed as a modular unit in the vehicle. The fuel storage system is pivotable relative to the vehicle to allow easy accessibility to the storage tanks without requiring the storage tanks to be unmounted from the vehicle. The fuel storage system also provides protection for the storage tanks through the use of shielding and energy absorbing material.

Owner:GM GLOBAL TECH OPERATIONS LLC

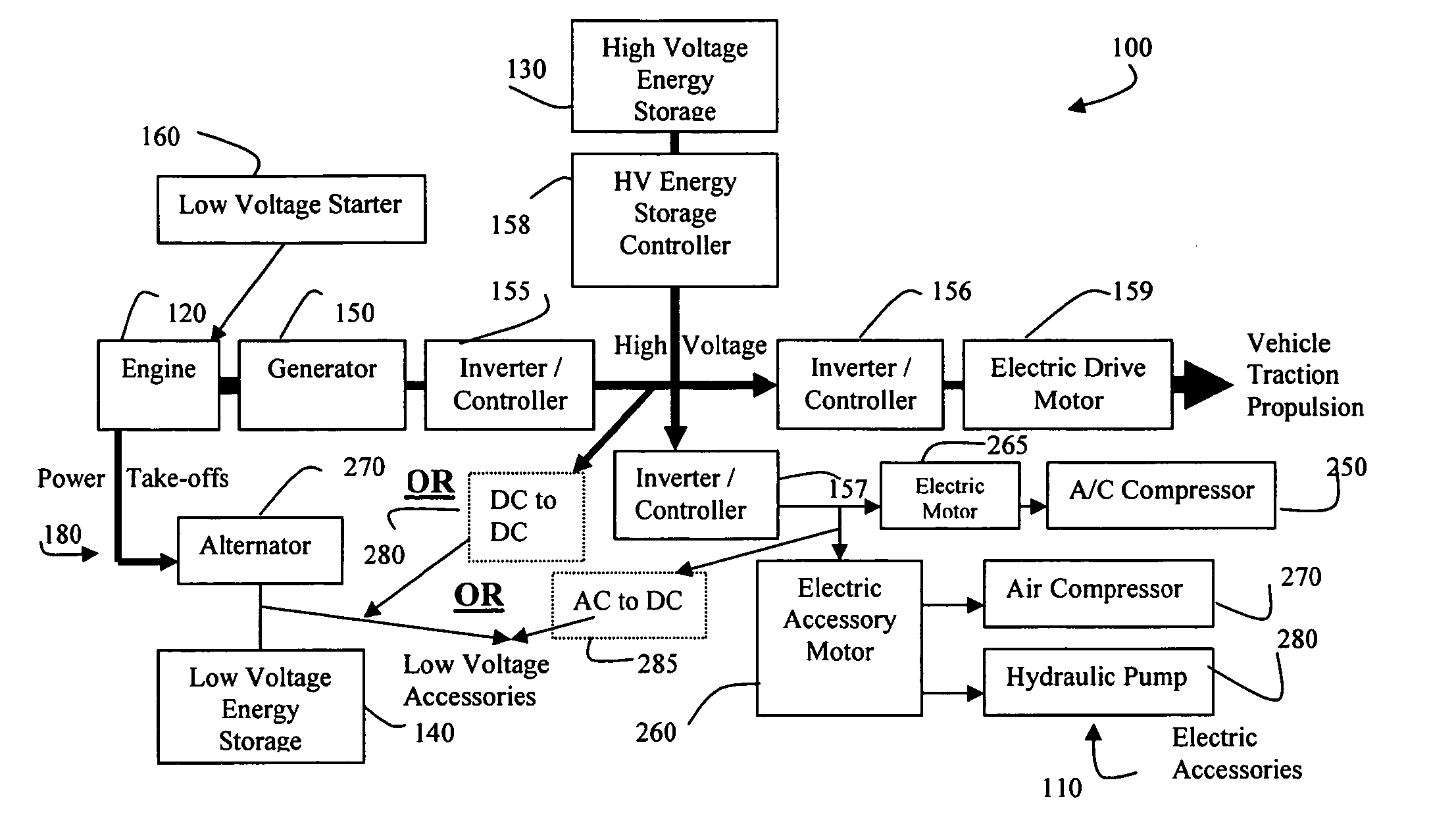

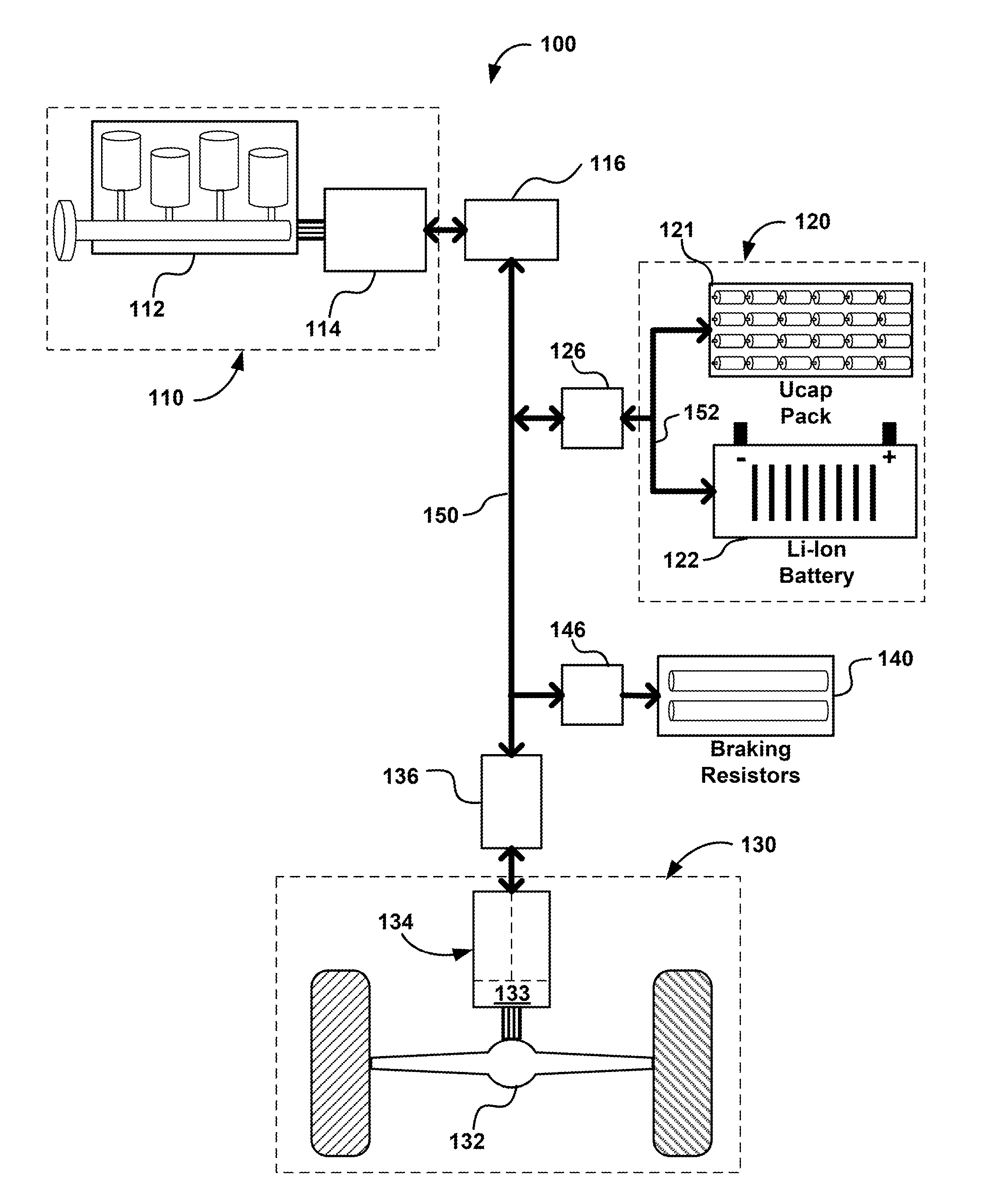

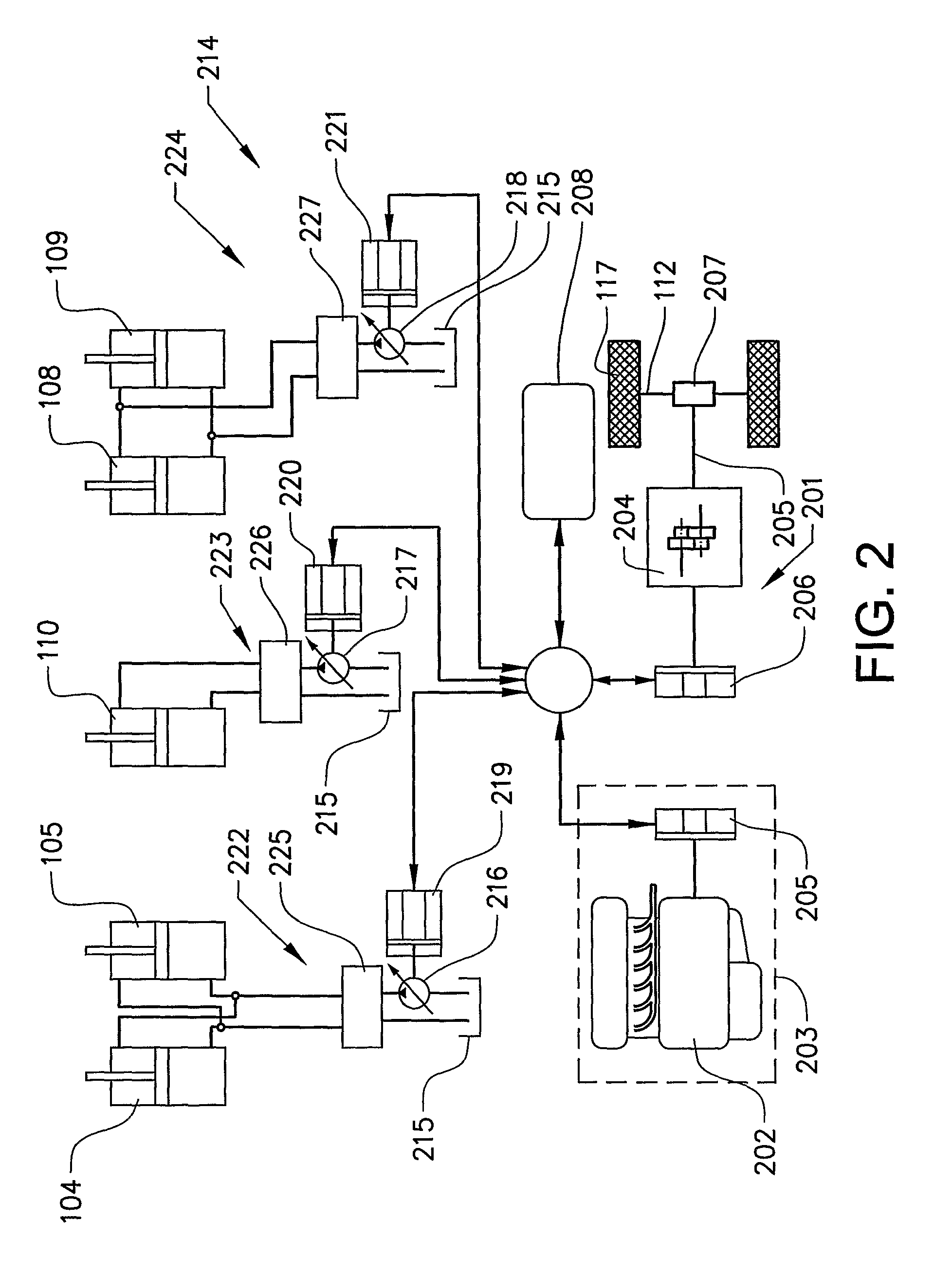

Expandable Energy Storage Control System Architecture

InactiveUS20100133025A1Efficient and inexpensive and reliableAuxillary drivesBatteries circuit arrangementsElectricityDrive wheel

A hybrid electric vehicle drive system comprises a first power bus electrically coupled to a motive power subsystem and a drive wheel propulsion assembly; a second power bus electrically coupled to the first power bus and a plurality of energy storage subsystems, wherein the first power bus is configured to allow electrical power to be transmitted among the motive power subsystem, the drive wheel propulsion assembly, and the second power bus, and wherein the second power bus is configured to allow electrical power to be transmitted among the plurality of energy storage subsystems and the first power bus.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

Real-time system and method for tracking, locating and recharging electric vehicles in transit

ActiveUS20120271758A1Batteries circuit arrangementsDigital data processing detailsBattery chargeControl system

The present invention provides computer-controlled electric battery charging systems and methods for charging a battery of a roaming electric vehicle, the system comprising an electric vehicle comprising at least one battery, a master charger vehicle comprising a master battery module and a control system in communication with the at least one electric vehicle and the master charger vehicle to enable the master charger vehicles to reach the electric vehicle, wherein the master battery module is adapted to charge the at least one battery.

Owner:NATION E

Power splitting vehicle drive system

ActiveUS20050109549A1Electric propulsion mountingGas pressure propulsion mountingEngineeringMechanical engineering

A vehicle includes a prime mover, a first output shaft, a second output shaft and a planetary gear assembly. The planetary gear assembly includes a sun gear, a ring gear and a plurality of planetary gears supported between the ring gear and the sun gear by a carrier. One of the sun gear and the ring gear is coupled to the prime mover. The other of the ring gear and the sun gear is coupled to the first output shaft. The first carrier is coupled to the second output shaft.

Owner:OSHKOSH CORPORATION

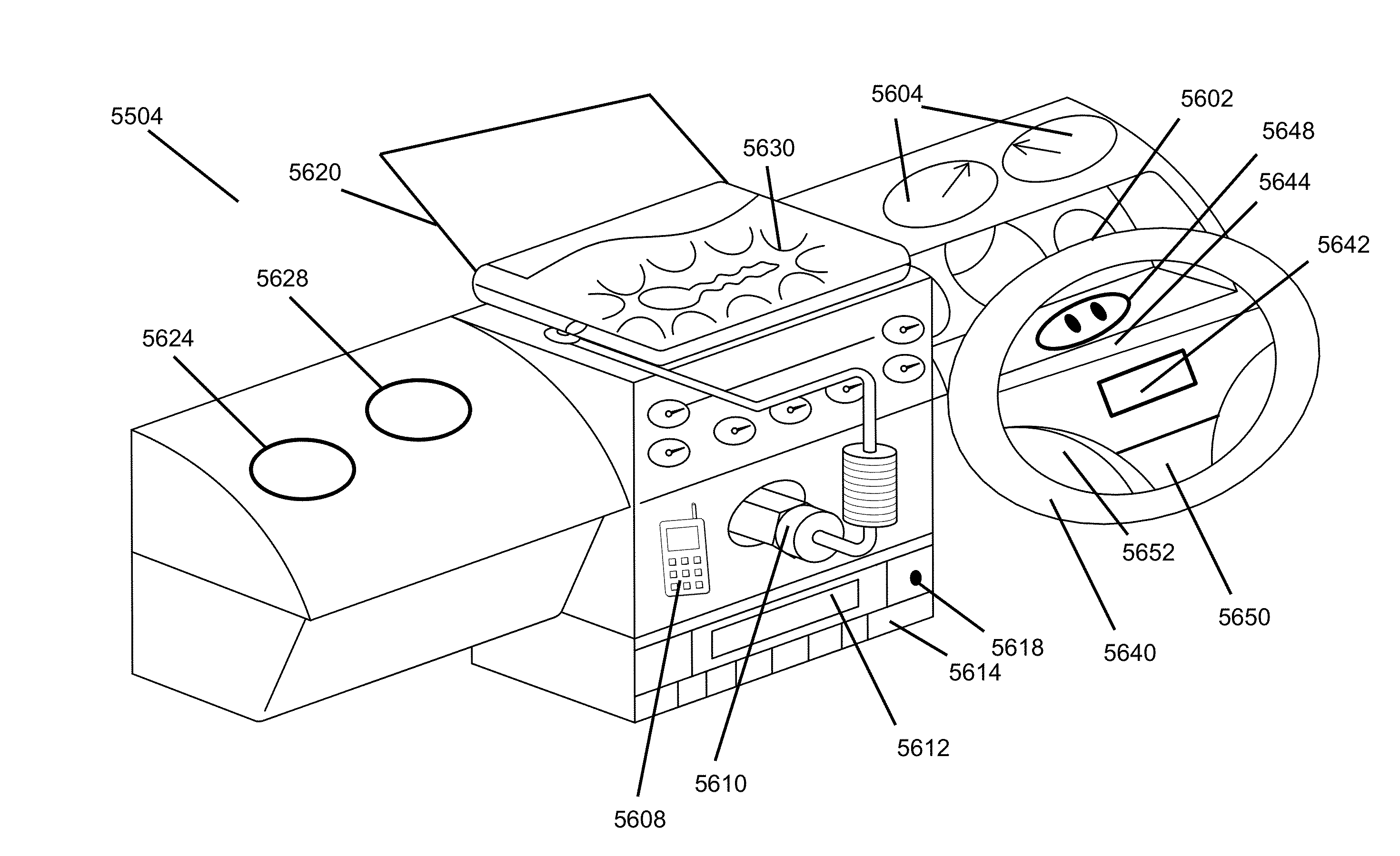

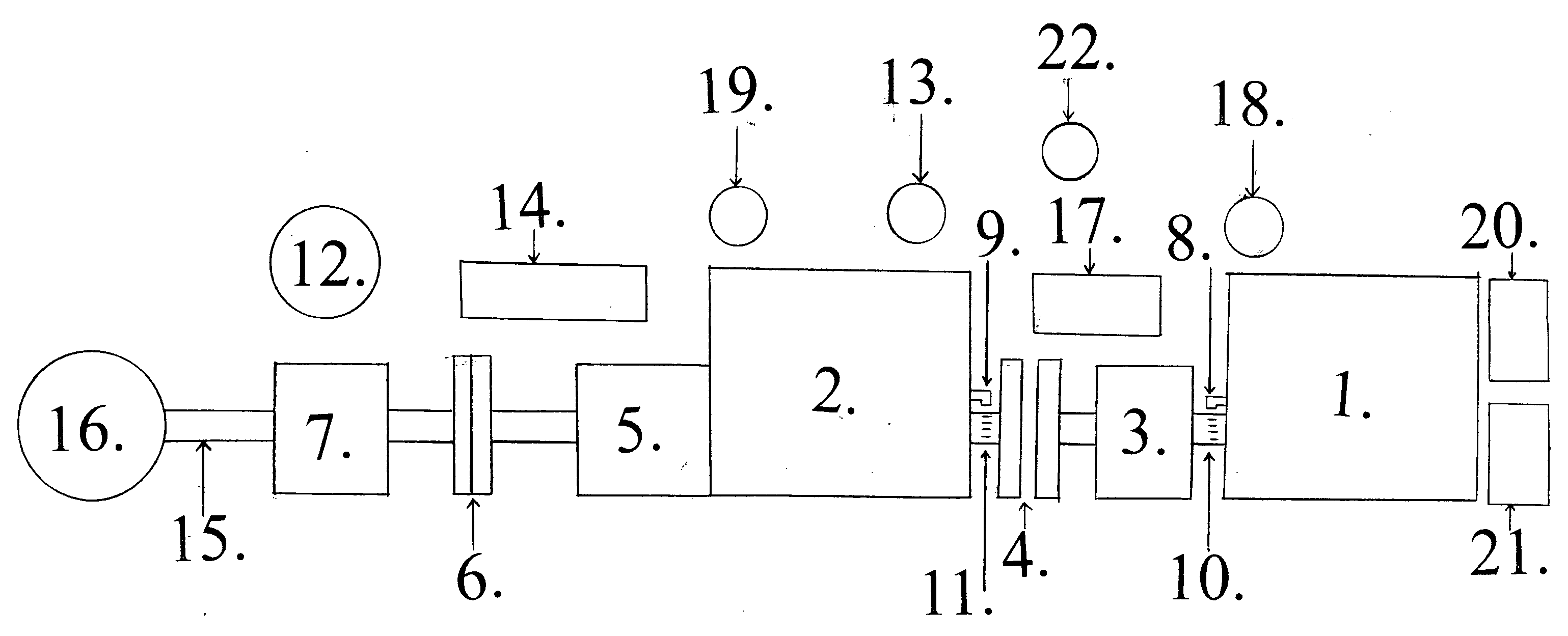

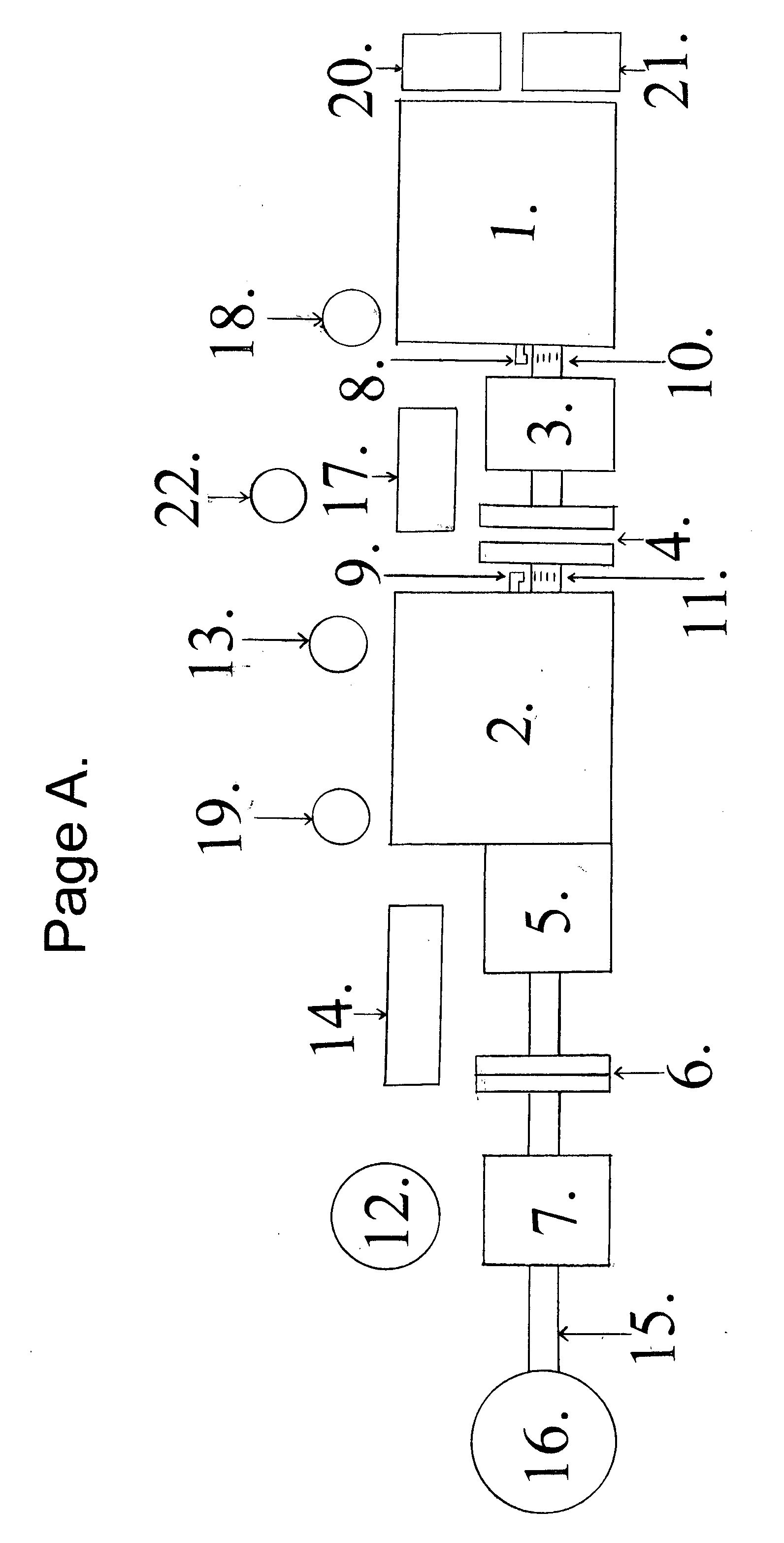

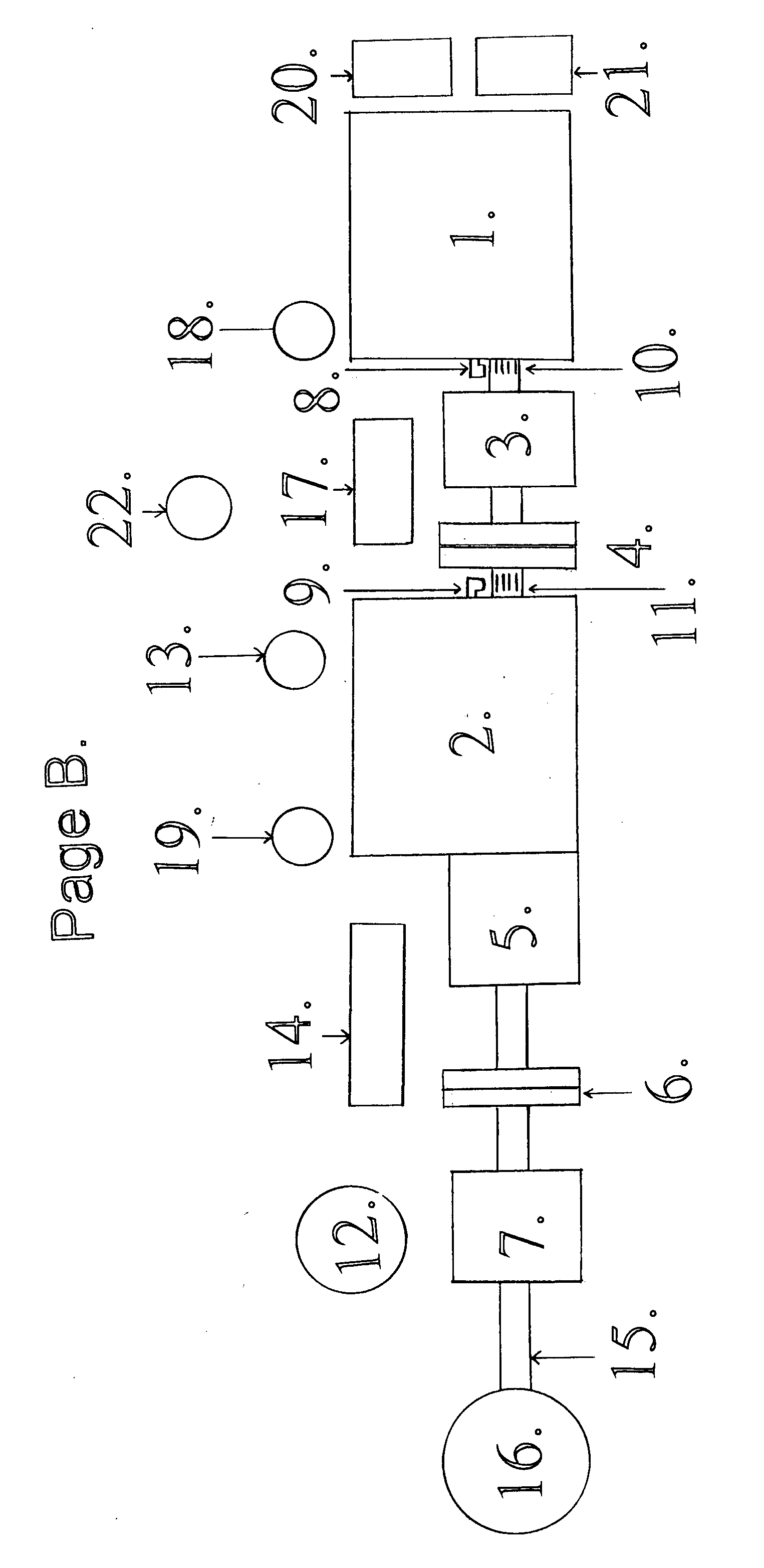

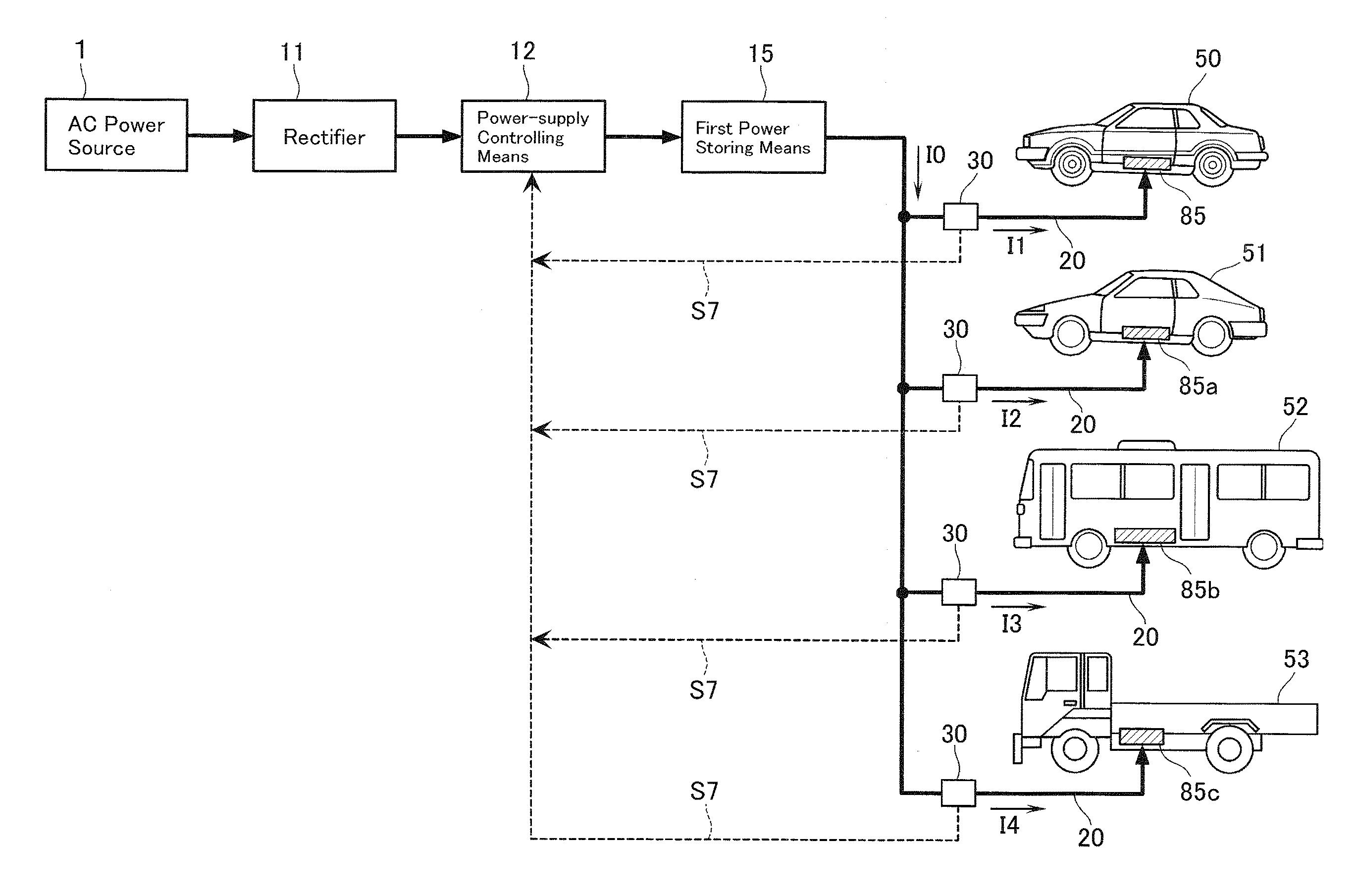

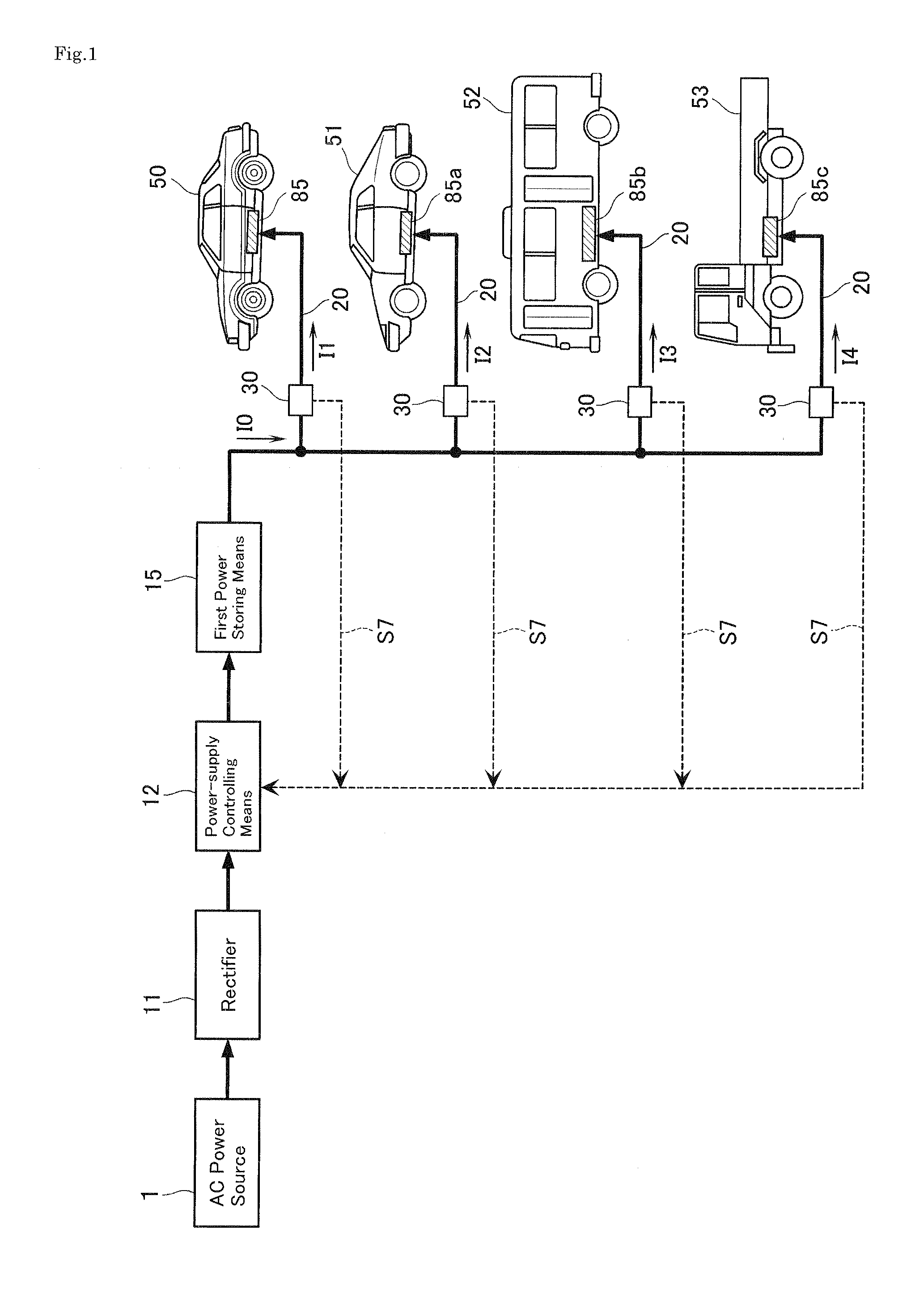

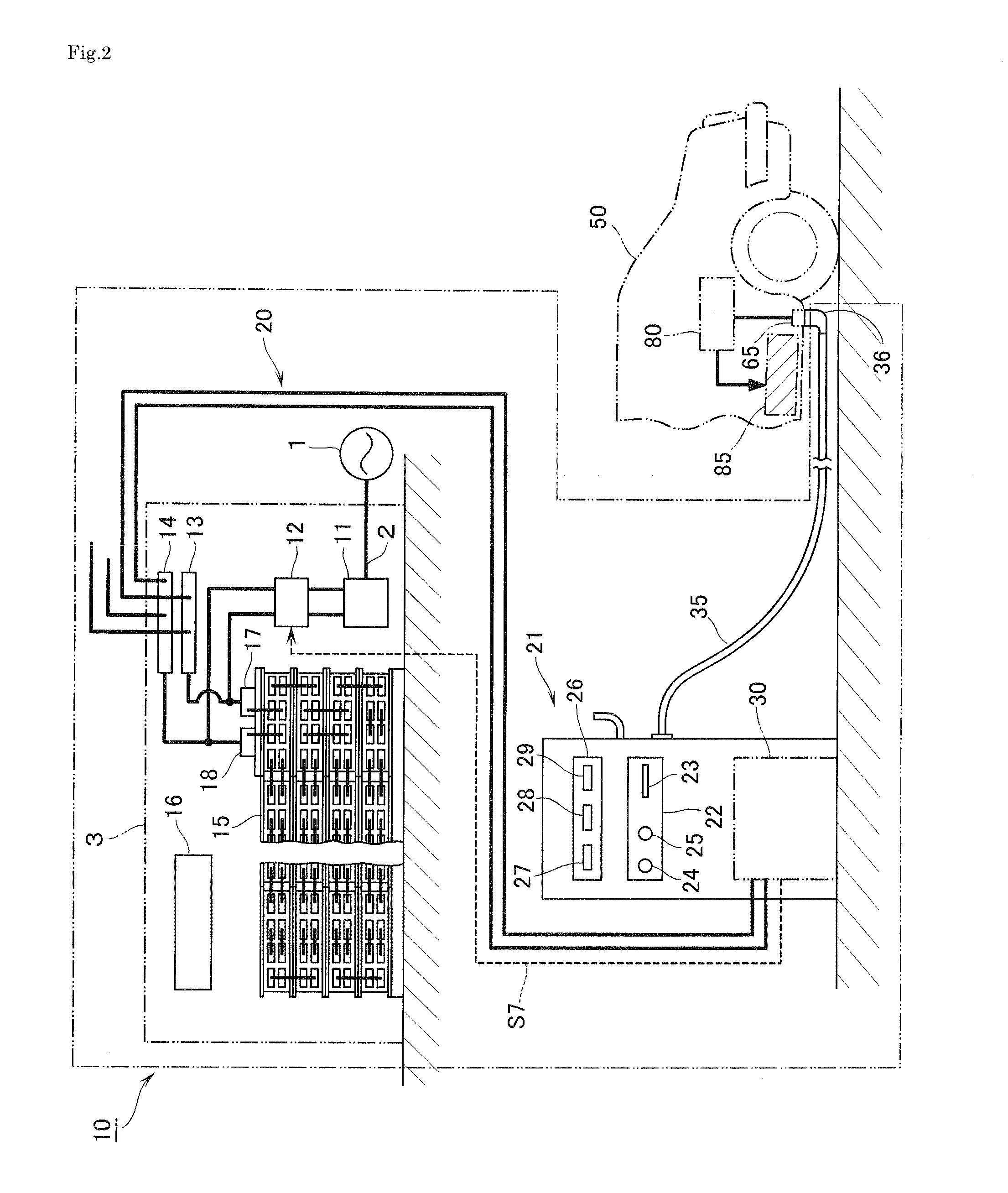

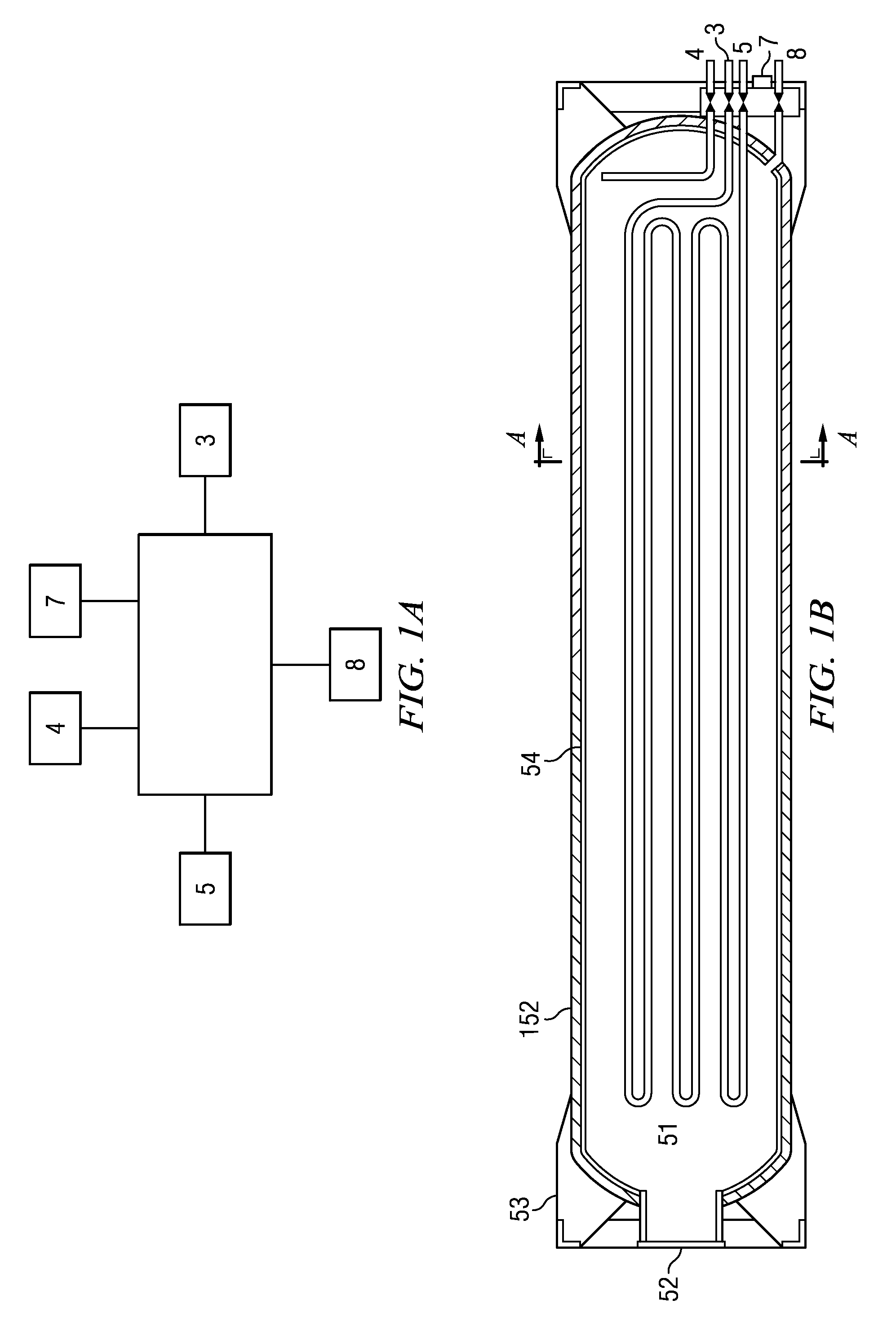

High-speed charging power supply device and high-speed charging power supply method

InactiveUS20110266996A1Improve performanceImprove mobilityCell temperature controlRailway vehiclesCharge controlExecution control

A boosting-charge power supply apparatus and a boosting-charge power supply method are capable of supplying electric power for boosting charge to a variety of mobile bodies using a single apparatus and supplying high-quality electric power to the mobile bodies.A boosting-charge power supply apparatus 10 which supplies electric power for boosting charge to a mobile body having a boosting-charge control function includes: a rectifier 11 for supplying DC power; a first power storing means 15 for storing DC power from the rectifier 11 and outputting pure DC power; a charging circuit 20 which sends pure DC power from the first power storing means 15 directly to a vehicle 50 including a second power storing means 85 for storing DC power from the first power storing means 15; and a power-supply controlling means 12 for stopping the rectifier 11 from supplying electric power to the first power storing means 15 while the first power storing means 15 is supplying electric power to charge the second power storing means 85. Control is executed in such a way that pure DC power supplied from the first power storing means 15 becomes electric power suitable for charging conditions of the second power storing means 85 on the vehicle 50 side, thereby enabling the same boosting-charge power supply apparatus 10 to supply electric power and give a boosting charge to a different type of vehicle. Further, the vehicle 50 can be supplied with high-quality electric power equivalent to pure DC power, thereby almost saving considering a noise, a surge or the like in designing electric circuits of the vehicle 50, so that the electric circuits of the vehicle 50 can be more easily designed.

Owner:INST FOR ENERGY APPL TECH

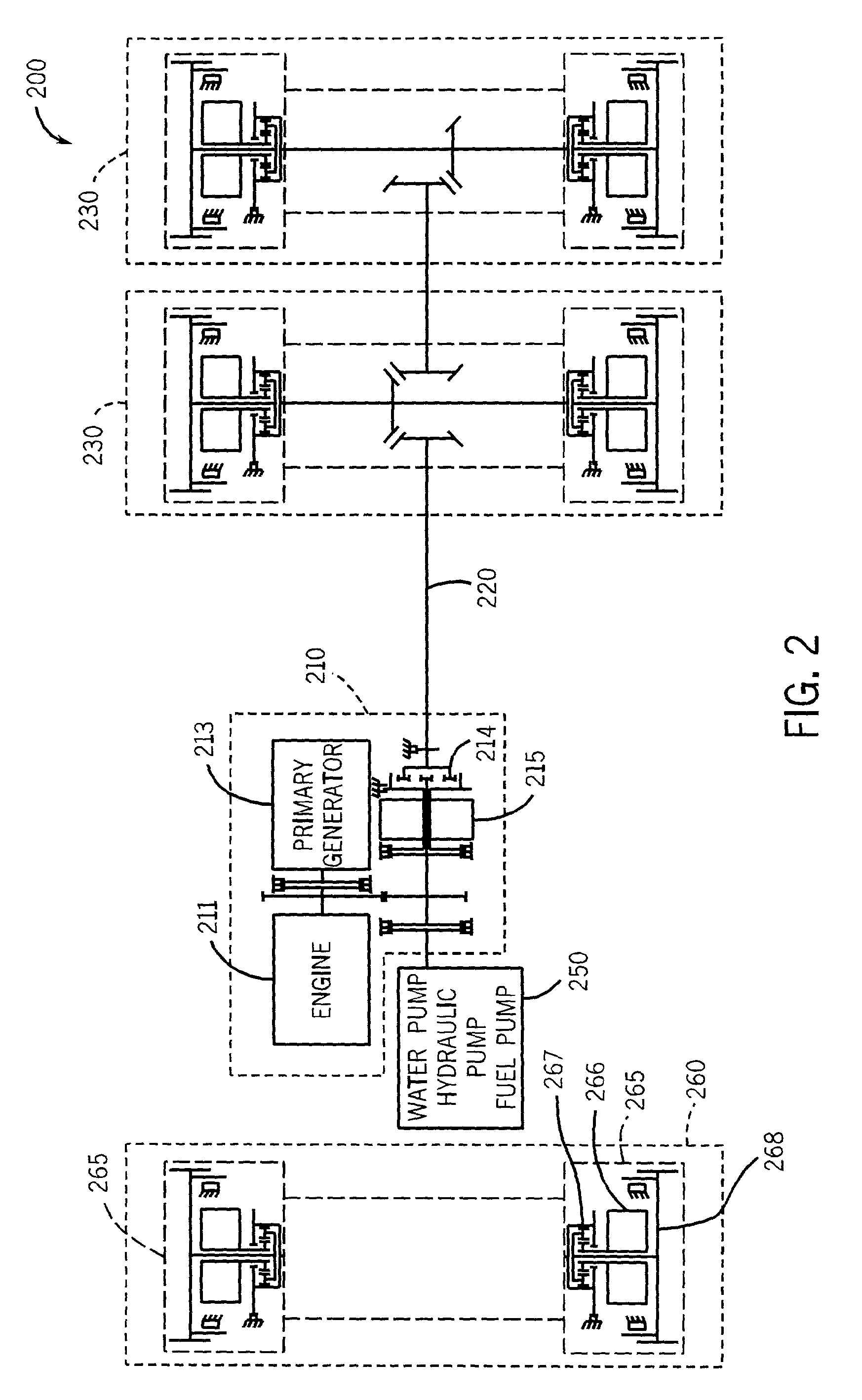

Hybrid vehicle drive system and method and idle reduction system and method

InactiveUS20120207620A1Auxillary drivesPlural diverse prime-mover propulsion mountingHydraulic motorIdle reduction

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:ODYNE SYST

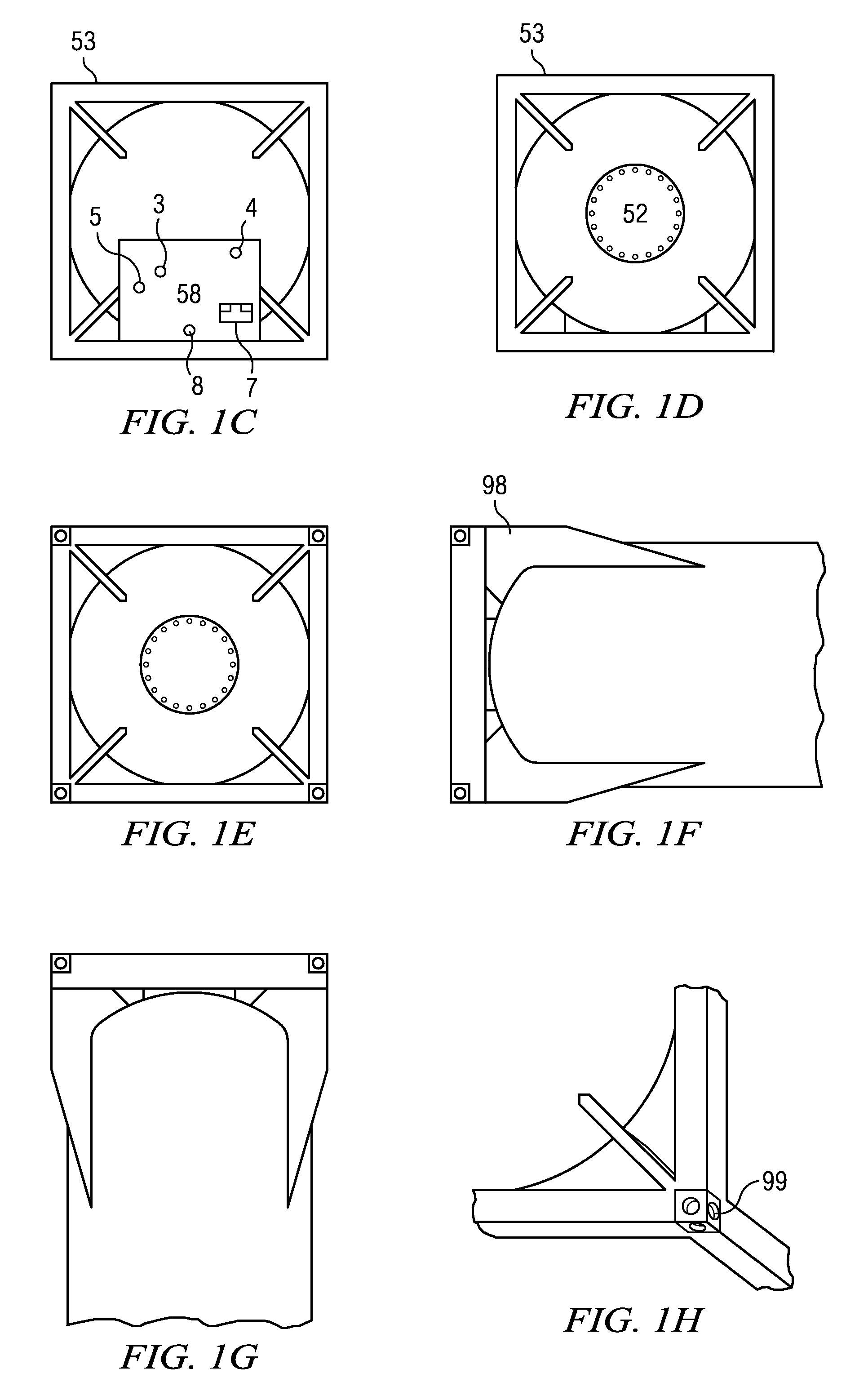

Clathrate hydrate modular storage, applications and utilization processes

Methods, apparatuses and systems directed to clathrate hydrate modular storage, applications and utilization processes. In one implementation, the present invention provides a method of creating scalable, easily deployable storage of natural gas and thermal energy by assembling an array of interconnecting, modular gas clathrate hydrate storage units.

Owner:SOLID GAS TECH

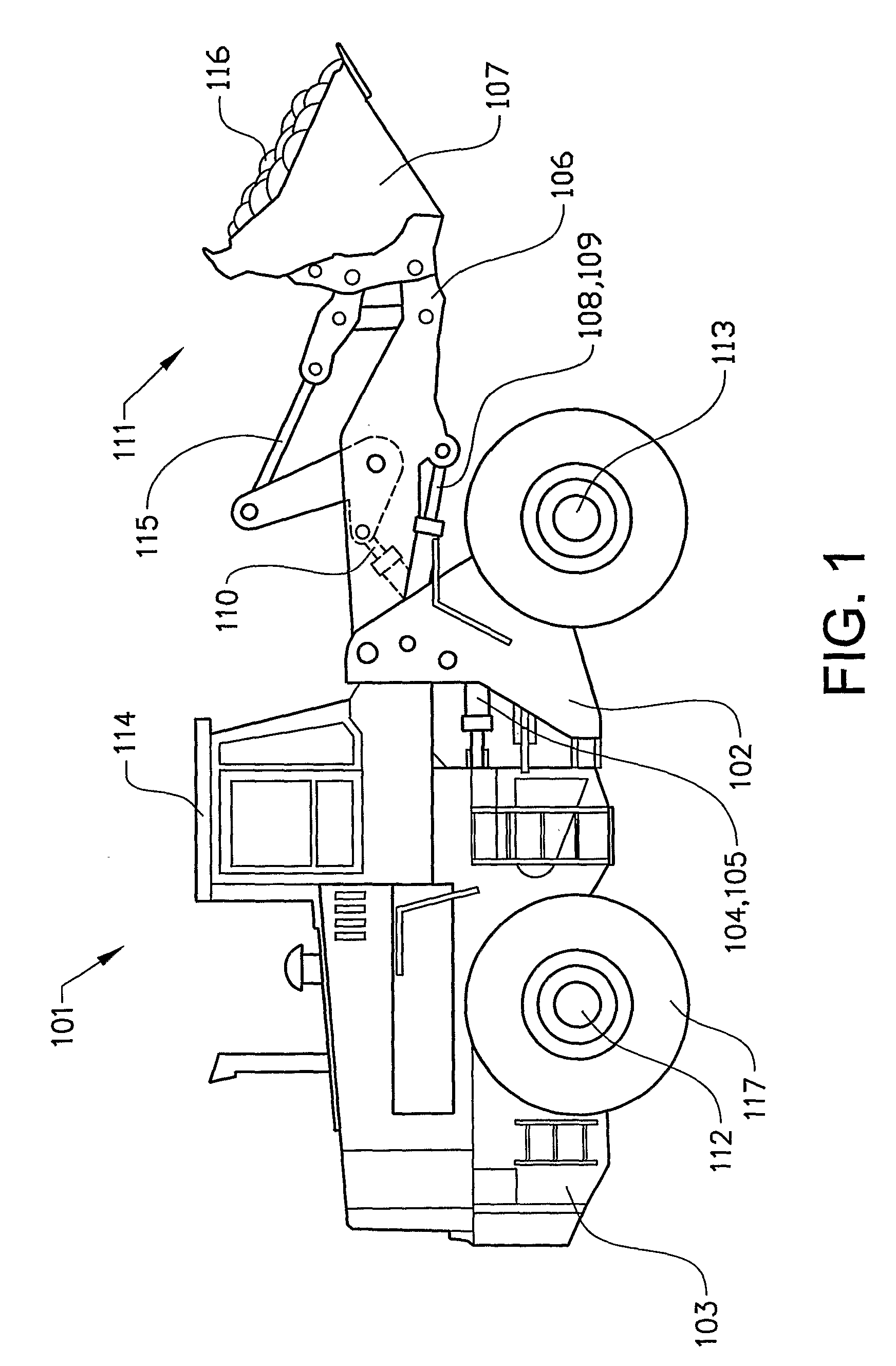

Method and a control system for controlling a work machine

ActiveUS20100332061A1Facilitate energy recoveryReduce fuel consumptionAnalogue computers for trafficSoil-shifting machines/dredgersElectric power transmissionControl system

A method is provided for controlling a work machine during operation in a repeated work cycle including controlling transfer of power to and from an energy storage arrangement in the work machine according to a predetermined control strategy, which is adapted for the characteristics of the work cycle.

Owner:VOLVO CONSTR EQUIP

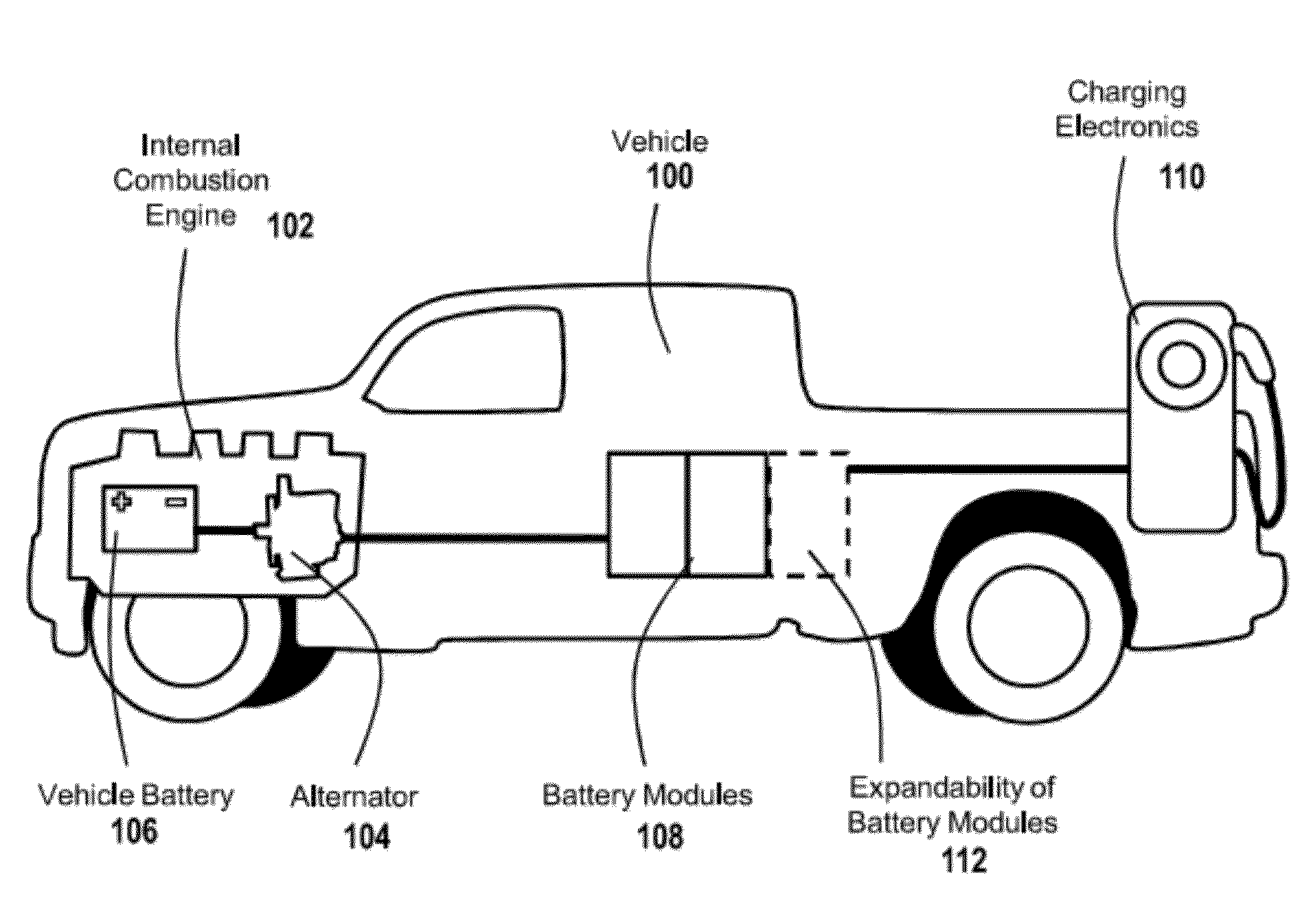

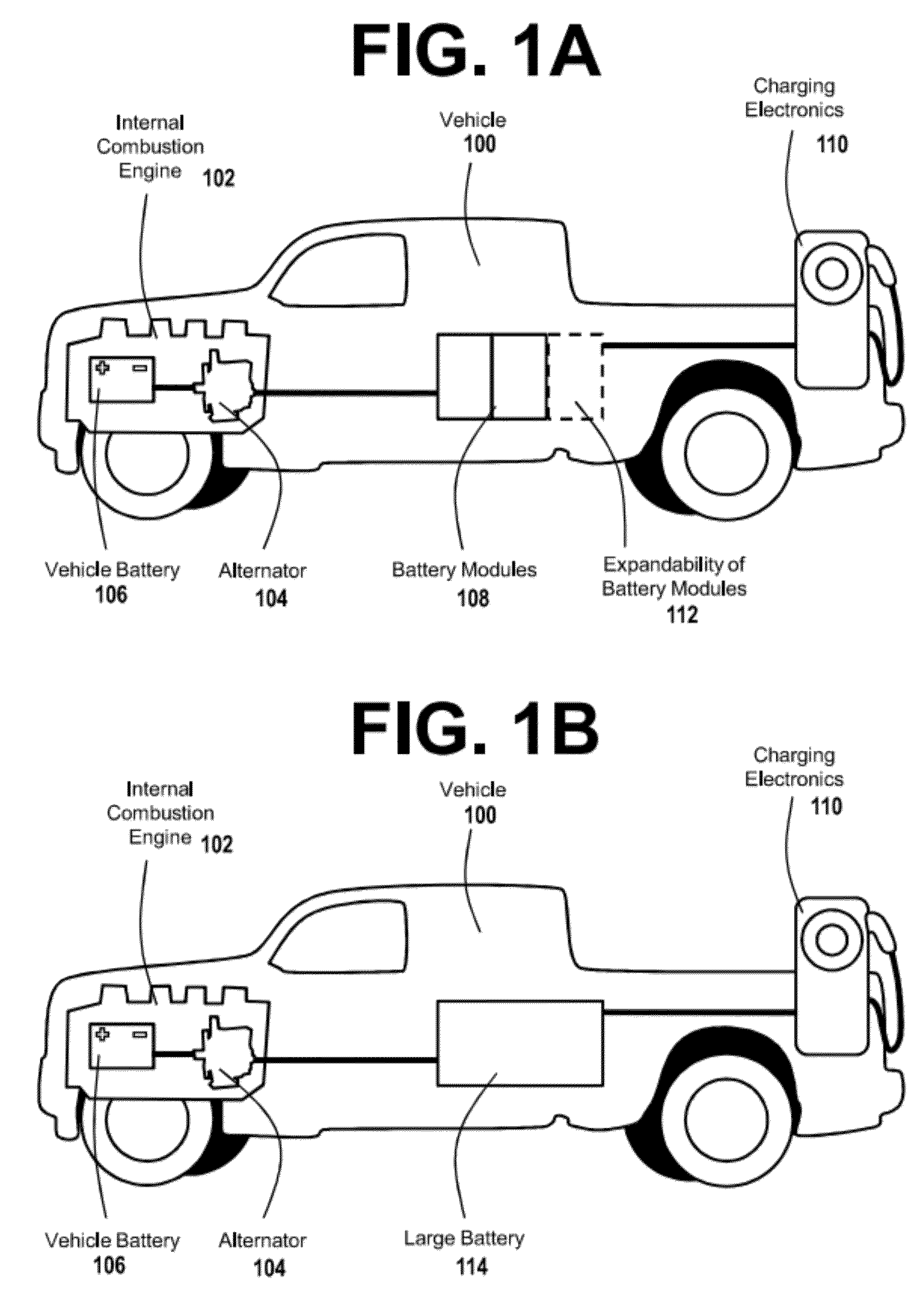

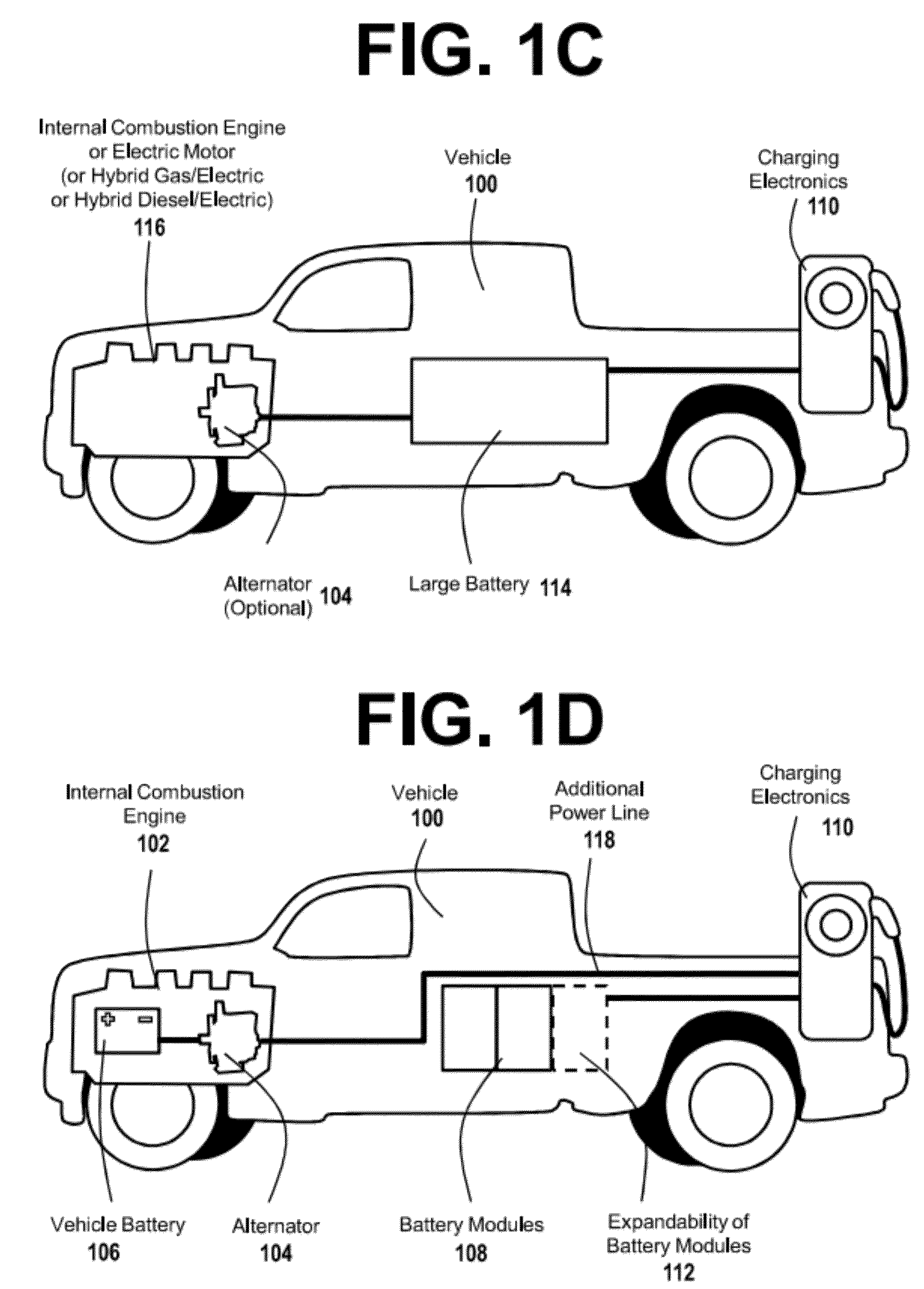

Charging Service Vehicles and Methods Using Modular Batteries

InactiveUS20120299531A1Turnover can be maximisedReduce stepsBatteries circuit arrangementsCharging stationsBattery chargeElectrical battery

Charging service vehicles and methods using modular batteries are disclosed. The service vehicles are vehicles having electric vehicle (EV) charging equipment, and removably mounted battery modules or battery module connection points. The battery modules are connected to the EV charging equipment as a source of electrical energy. Some embodiments disclose integrating the EV charging equipment with the vehicle, recharging modules through a distribution grid connection, the manner of discharging the batteries, modes of connecting and disconnecting the modules, the size and weight of the modules, quick-disconnectability of modules, control and monitoring of the modules and charging equipment, and / or ways of connecting modules to the vehicle. These features are beneficial to efficiently keep service vehicles available for EV charging through exchanging battery modules or providing additional battery modules when necessary, and may keep operators safe through de-energization of connectors and other precautions inherent in these designs.

Owner:ENGIE STORAGE SERVICES NA LLC

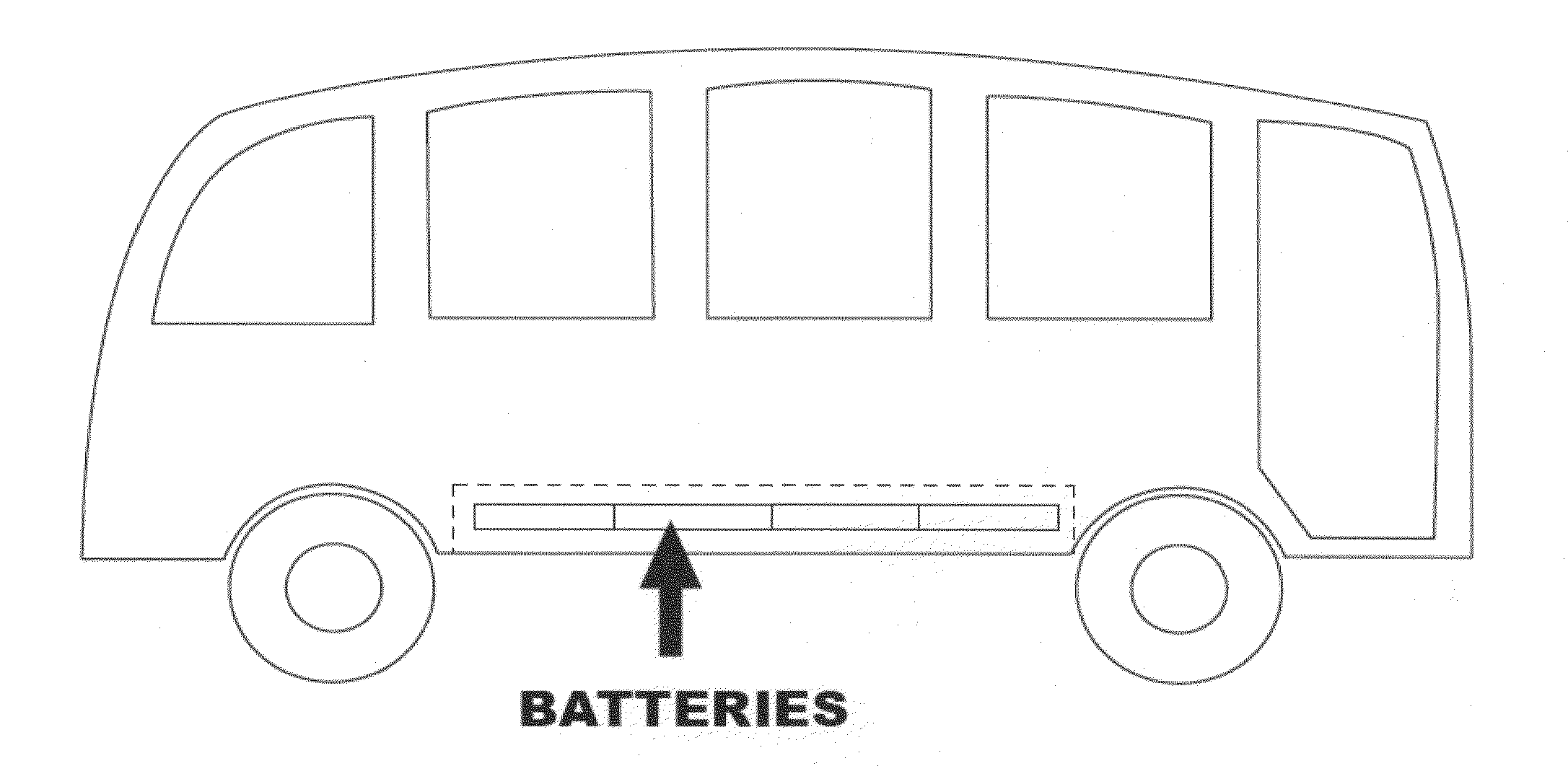

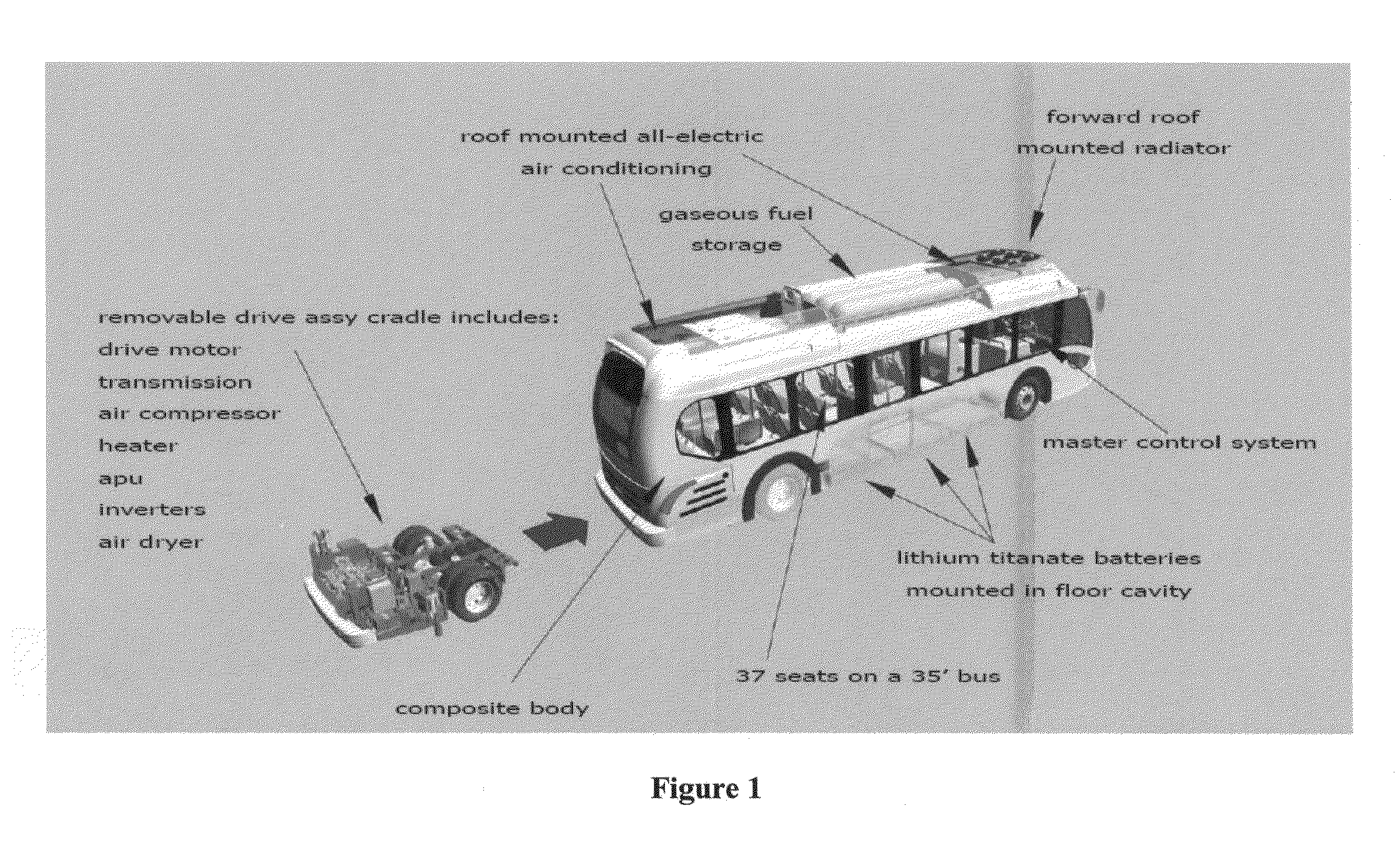

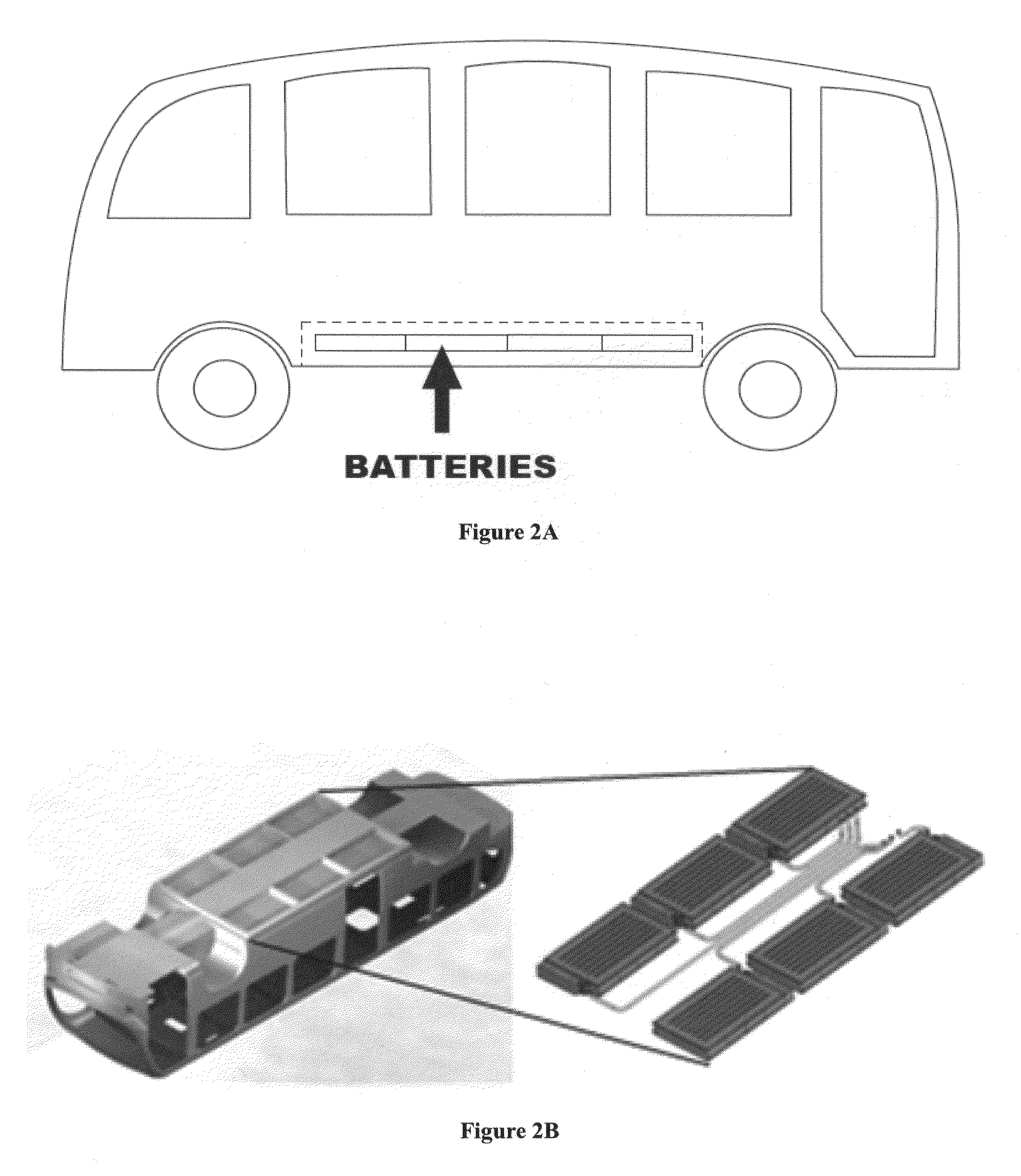

Vehicle battery systems and methods

The invention provides for a high occupancy or heavy-duty vehicle with a battery propulsion power source, which may include lithium titanate batteries. The vehicle may be all-battery or may be a hybrid, and may have a composite body. The vehicle battery system may be housed within the floor of the vehicle and may have different groupings and arrangements.

Owner:PROTERRA OPERATING CO INC

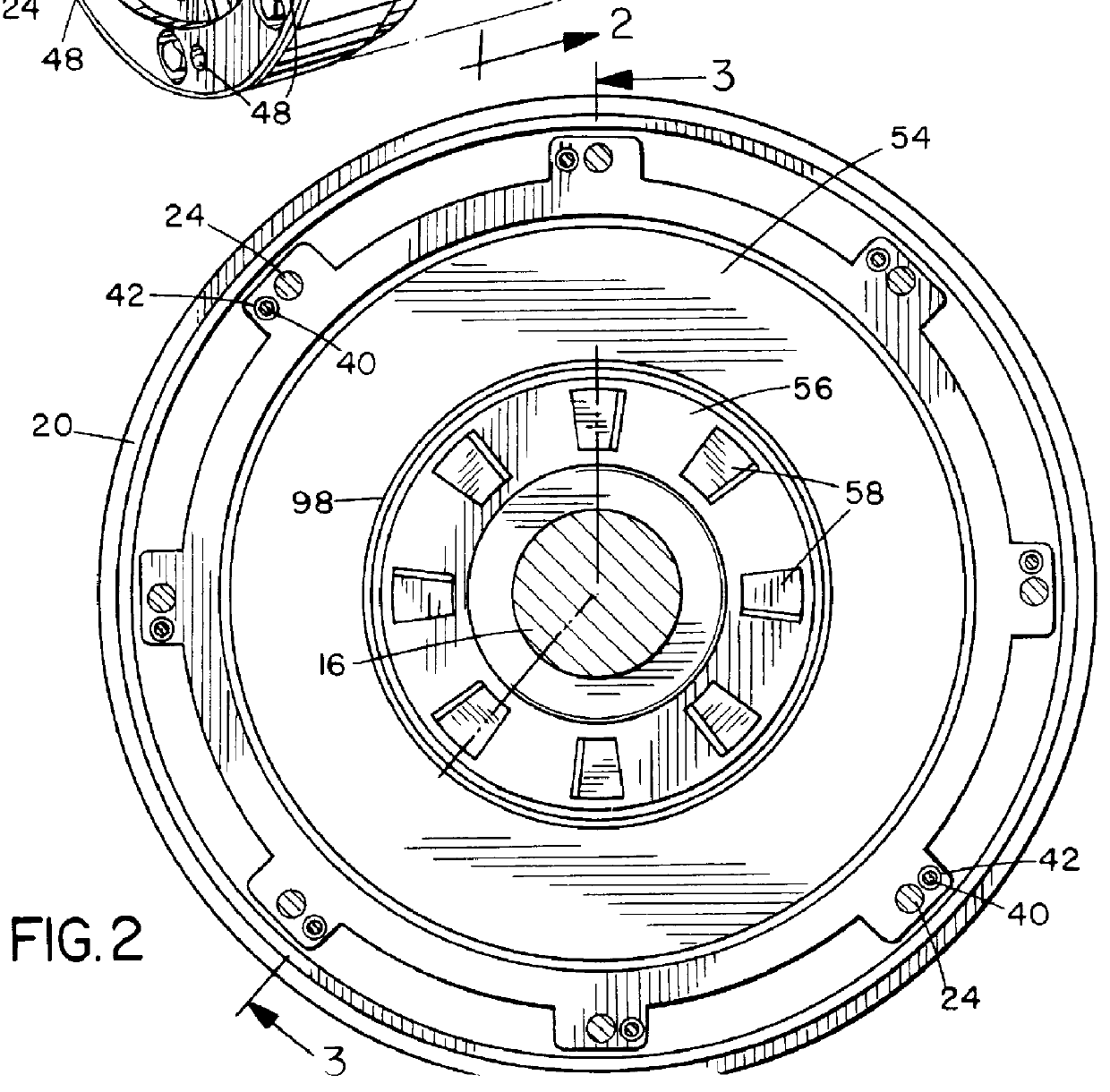

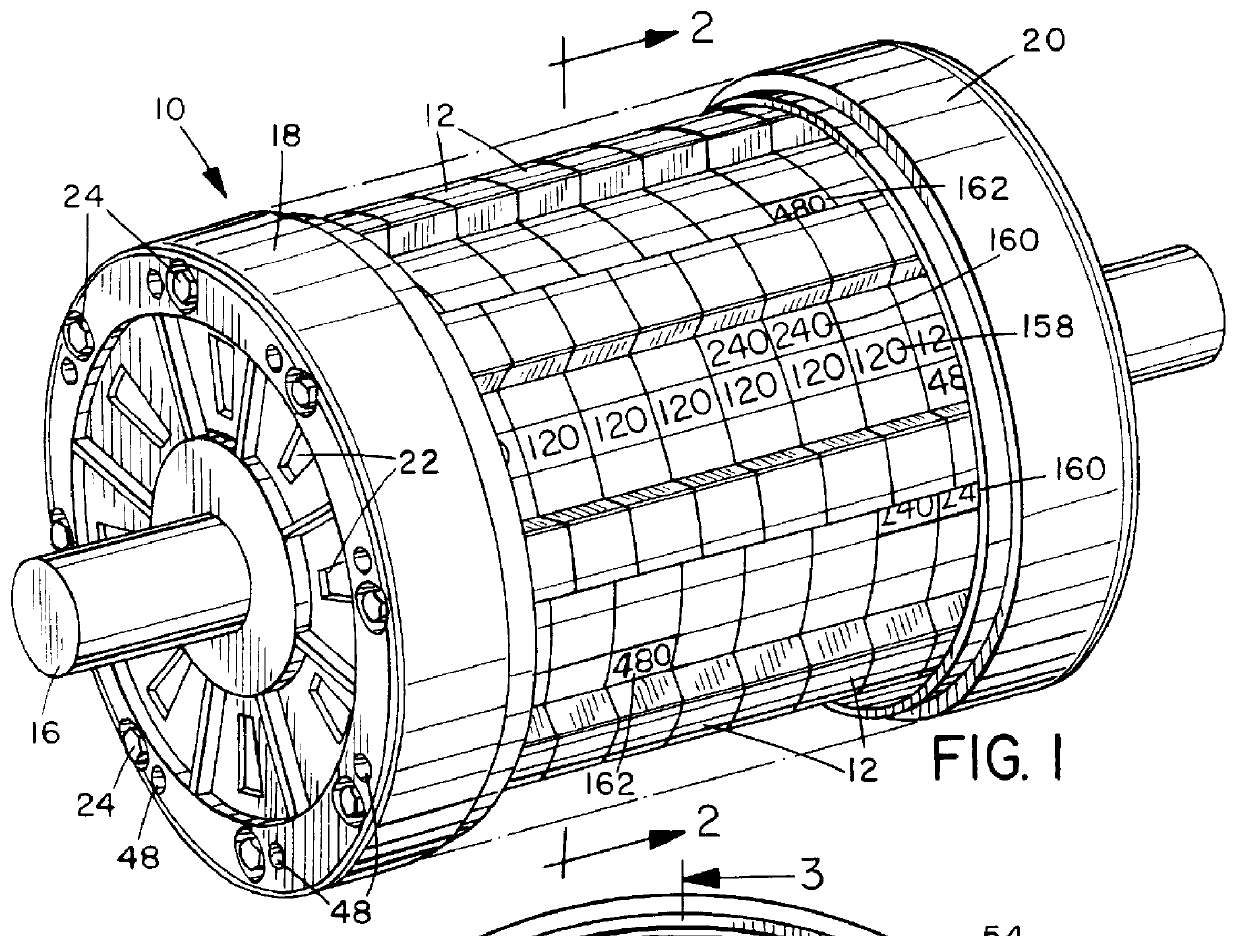

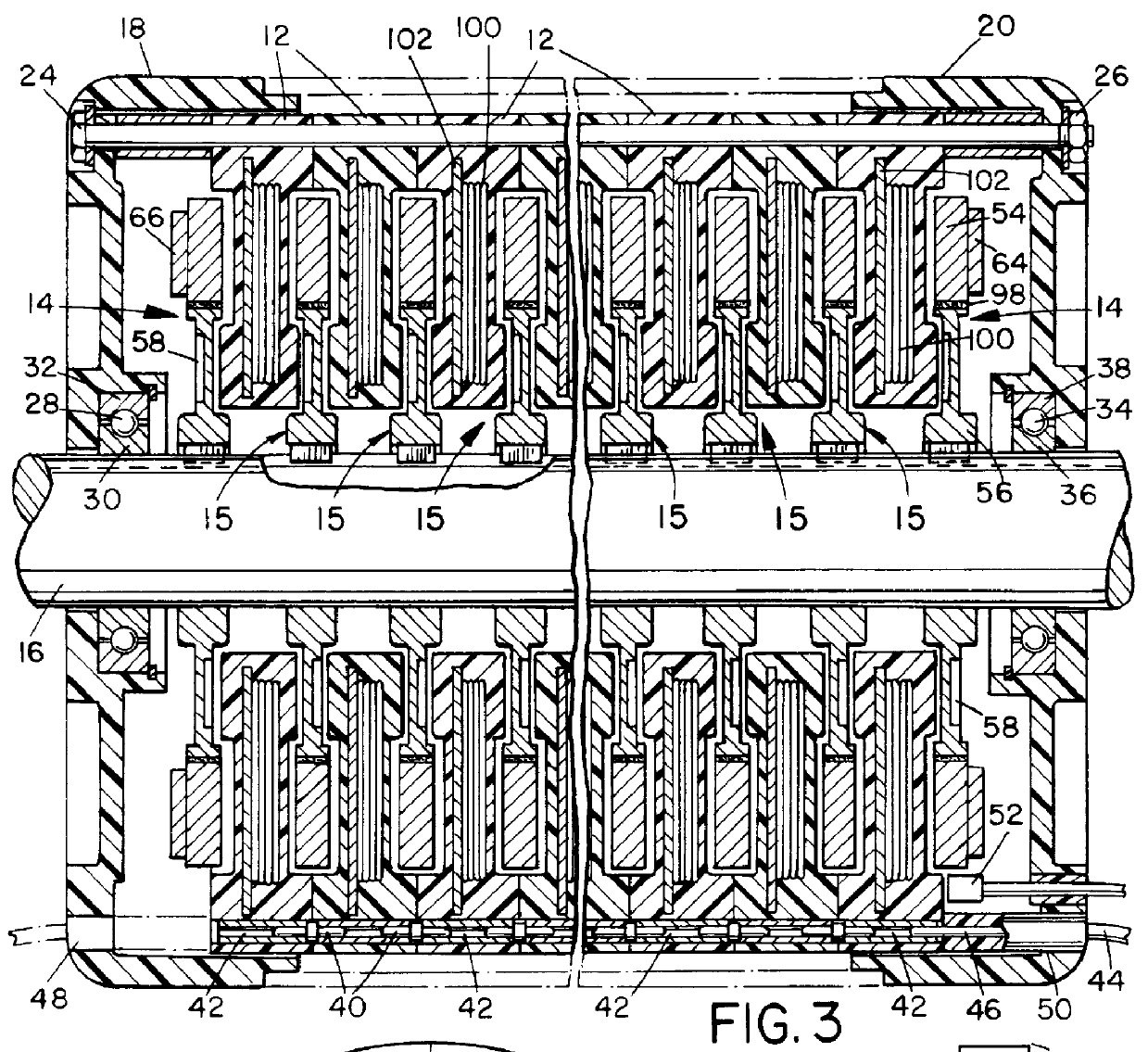

Motor generator including interconnected stators and stator laminations

InactiveUS6163097AMaximization of overall densityShort gapWindings insulation shape/form/constructionAsynchronous induction motorsCross-linkElectrical conductor

An axial field motor / generator having a rotor that includes at least three annular discs magnetized to provide multiple sector-shaped poles. Each sector has a polarity opposite that of an adjacent sector, and each sector is polarized through the thickness of the disc. The poles of each magnet are aligned with opposite poles of each adjacent magnet. Metal members adjacent the outermost two magnets contain the flux. The motor / generator also has a stator that includes a stator assembly between each two adjacent magnets. Each stator assembly includes one or more conductors or windings. Although the conductors may be formed of wire having a round, uniform cross-section, they may alternatively be formed of conductors having a tapered cross-section that corresponds to the taper of the sectors in order to maximize the density of the conductor in the gap between axially adjacent poles. The conductors may also alternatively be formed of traces in a printed circuit, which may have one or more layers. Each stator assembly may be removably connectable to another stator assembly to provide modularity in manufacturing and to facilitate selection of the voltage at which the motor / generator is to operate. Electrical contacts, such as pins extending from the casing, may removably connect the conductors of adjacent stator assemblies. A magnet may be dynamically balanced on the shaft by hardening a thin ring of cross-linked resin between the magnet and the shaft while the shaft is spun, using ultraviolet light to polymerize the resin.

Owner:SMITH TECH DEV LLC +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com