Battery Power System for Plug In Hybrid Tractor Trailers

a hybrid and battery power technology, applied in the field of plug-in hybrid and electric tractor trailers, can solve the problems of large size and bulk of battery power packs, and the use of battery power for the principal motive force of heavy duty transportation, such as tractor trailers, is much more problematic, and achieves the effect of increasing the capacity of large-capacity battery sources, efficient charging, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

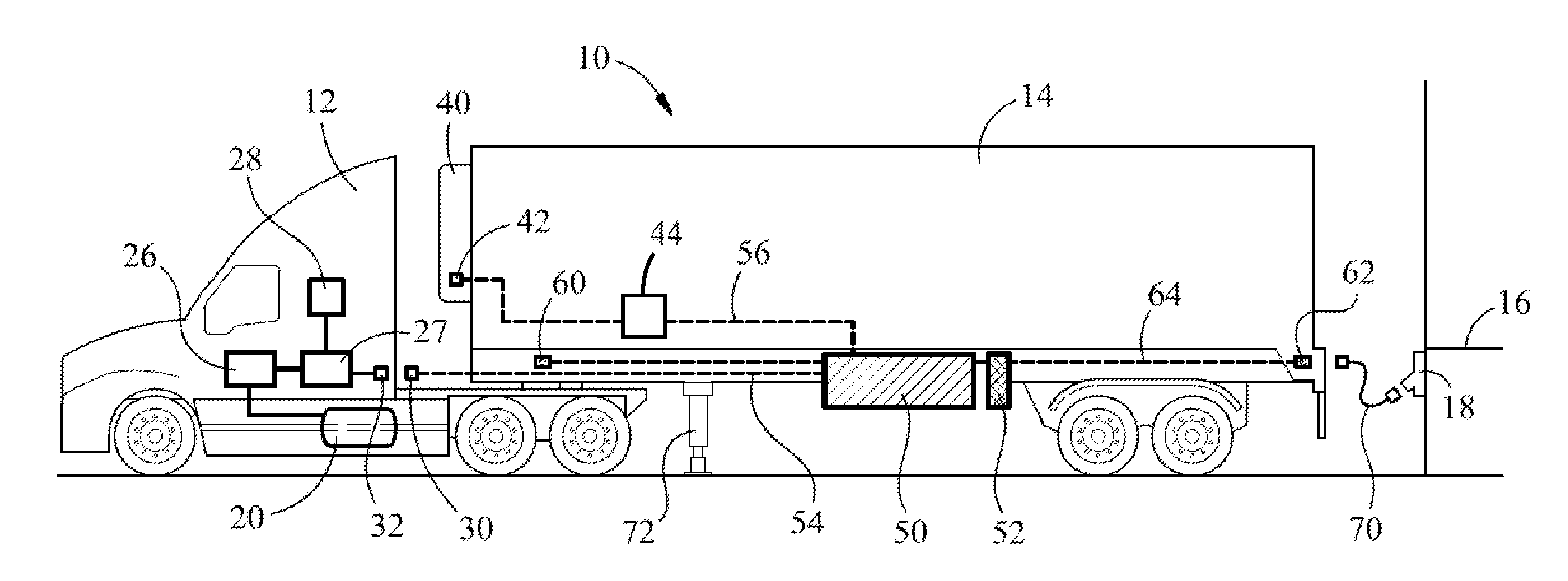

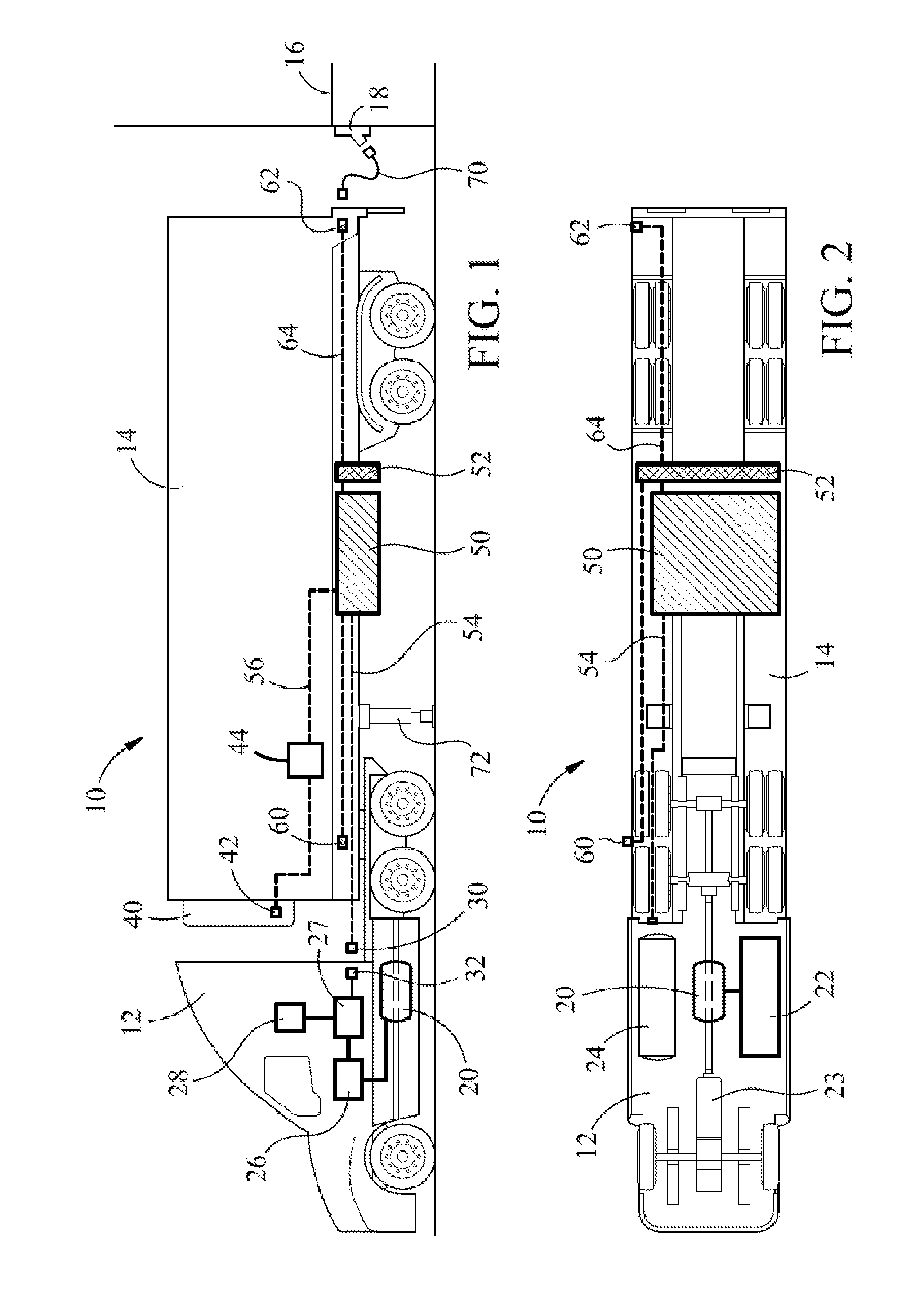

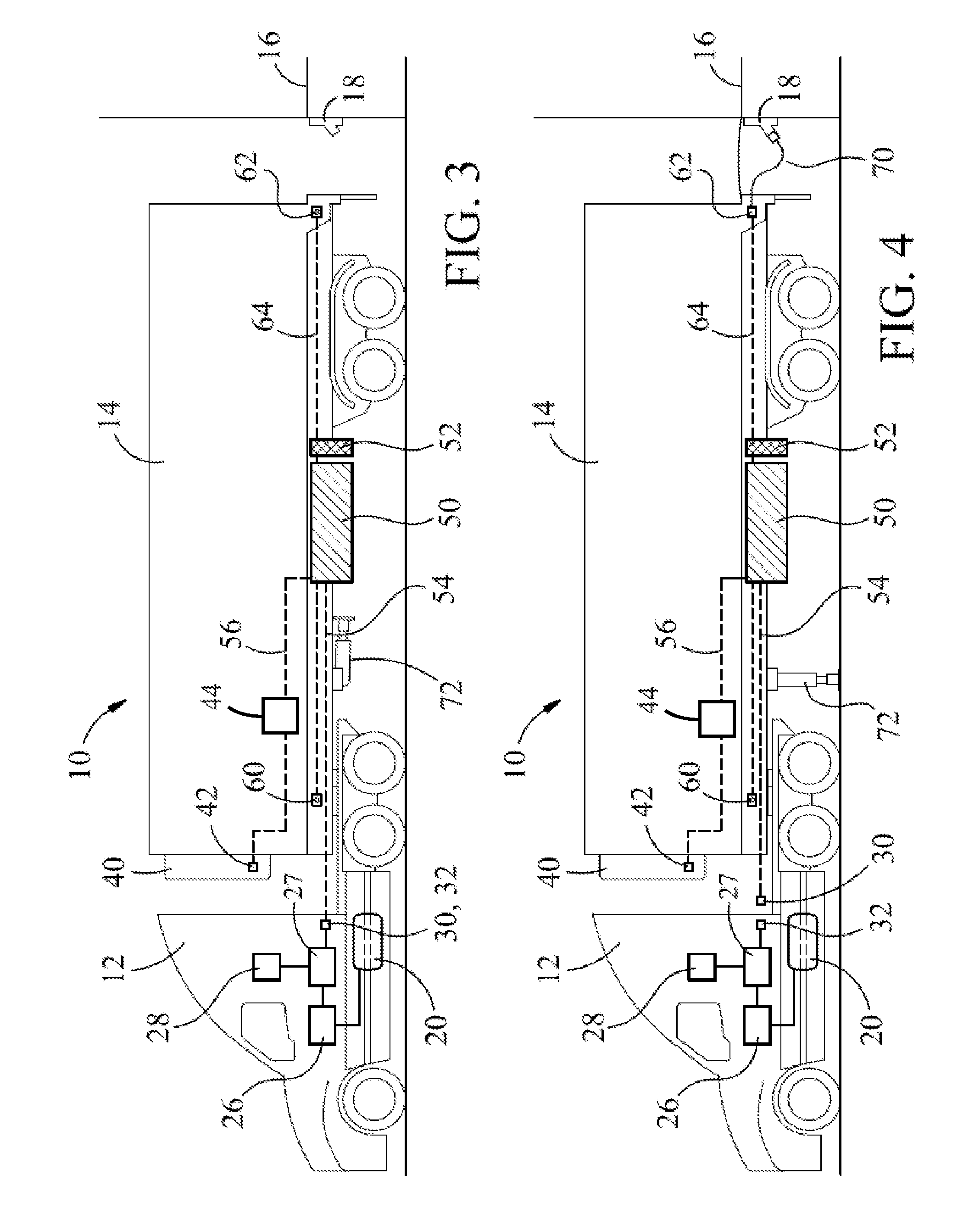

With reference to the drawings wherein like numerals represent like parts throughout the several figures, a plug in hybrid tractor trailer which employs battery power as well as an internal combustion engine for the motive power is generally designated by the numeral 10. The plug in hybrid tractor trailer comprises a plug in hybrid tractor or cab 12 which couples with the trailer 14. In FIG. 1, the tractor trailer is illustrated as parked at a loading dock 16 which also has a power outlet 18. It should be appreciated that the cab 12 and trailer 14 are intended to be representative of various possible types and configurations. The cab 12, in some embodiments, may be powered solely by electricity and not employ an internal combustion engine.

The plug in hybrid cab 12 employs an induction drive motor 20 which obtains power from an onboard battery module 22. In one embodiment, the battery module is disposed opposite the fuel tank 24 for the internal combustion engine. A voltage converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com