Patents

Literature

39results about How to "Reduce interfacial internal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

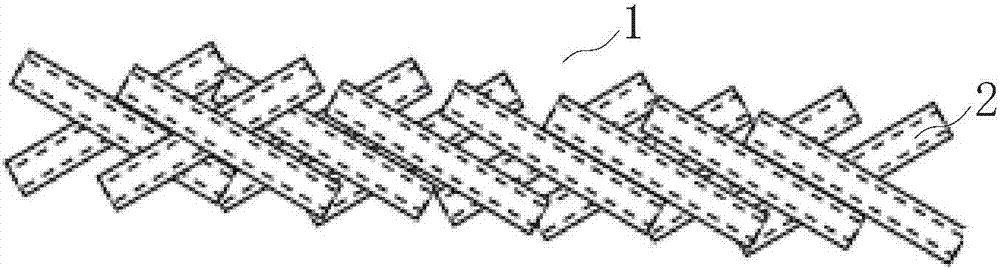

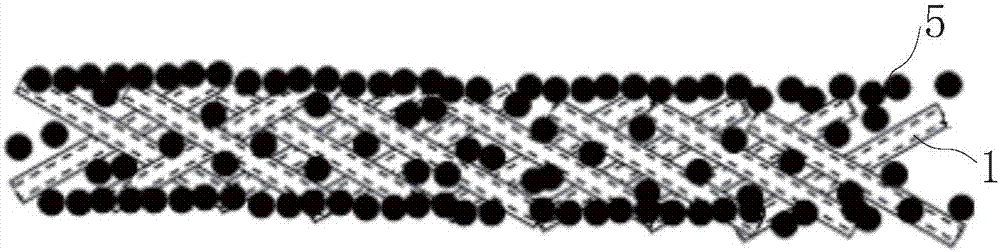

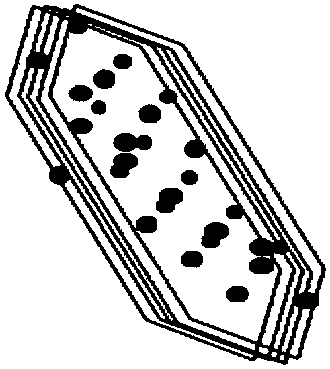

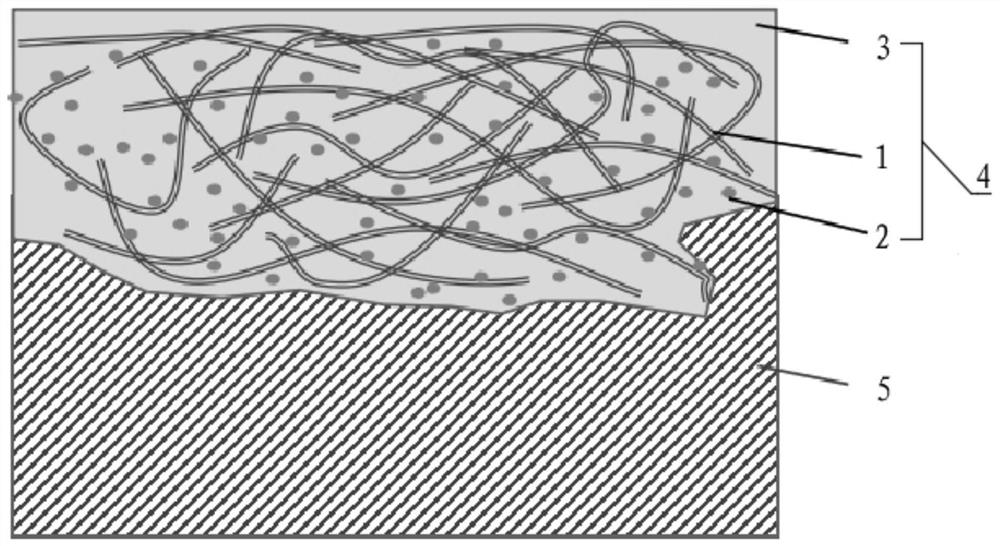

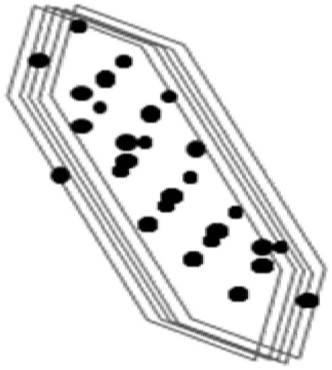

Flexible current collector, electrode containing flexible current collector, and battery

InactiveCN106898729AReduce interfacial internal resistanceIncrease productivityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesFiberInternal resistance

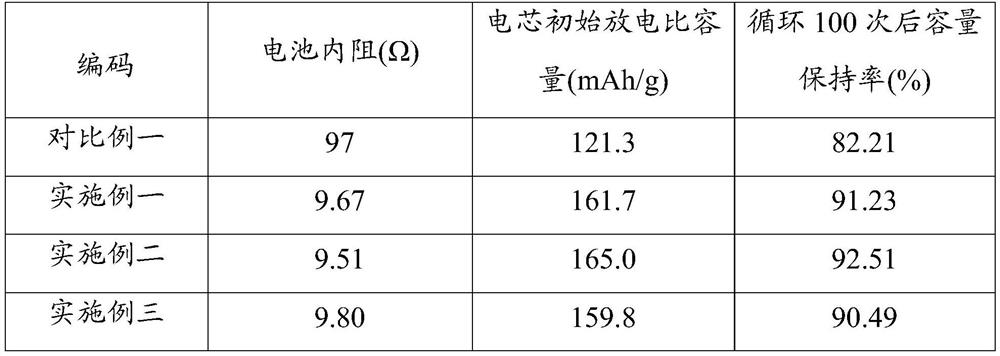

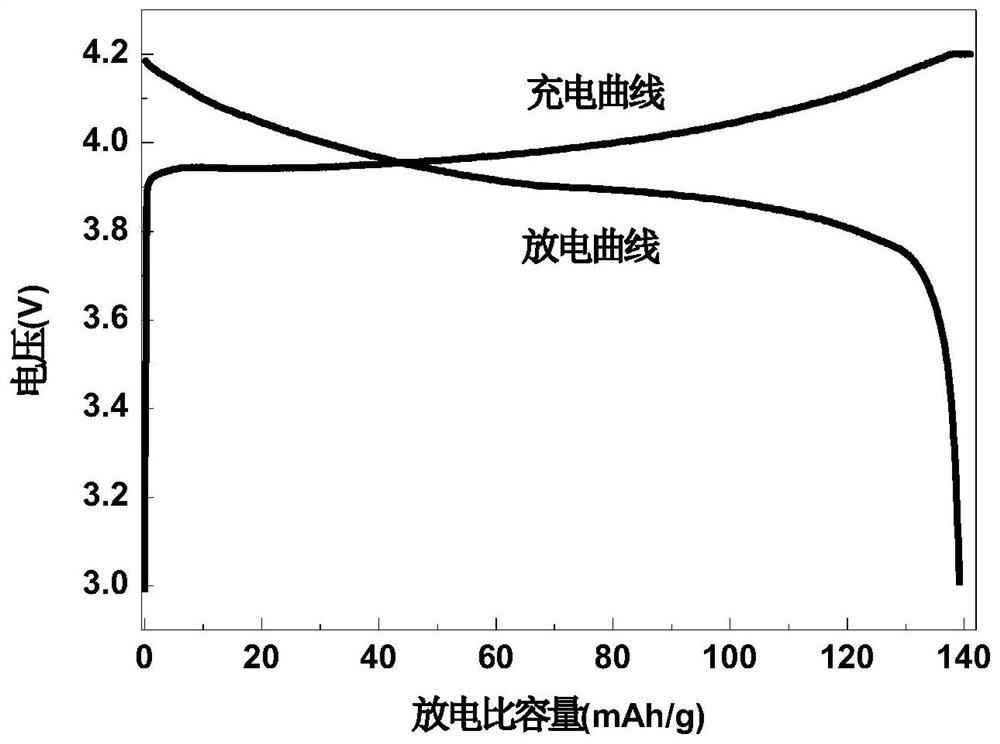

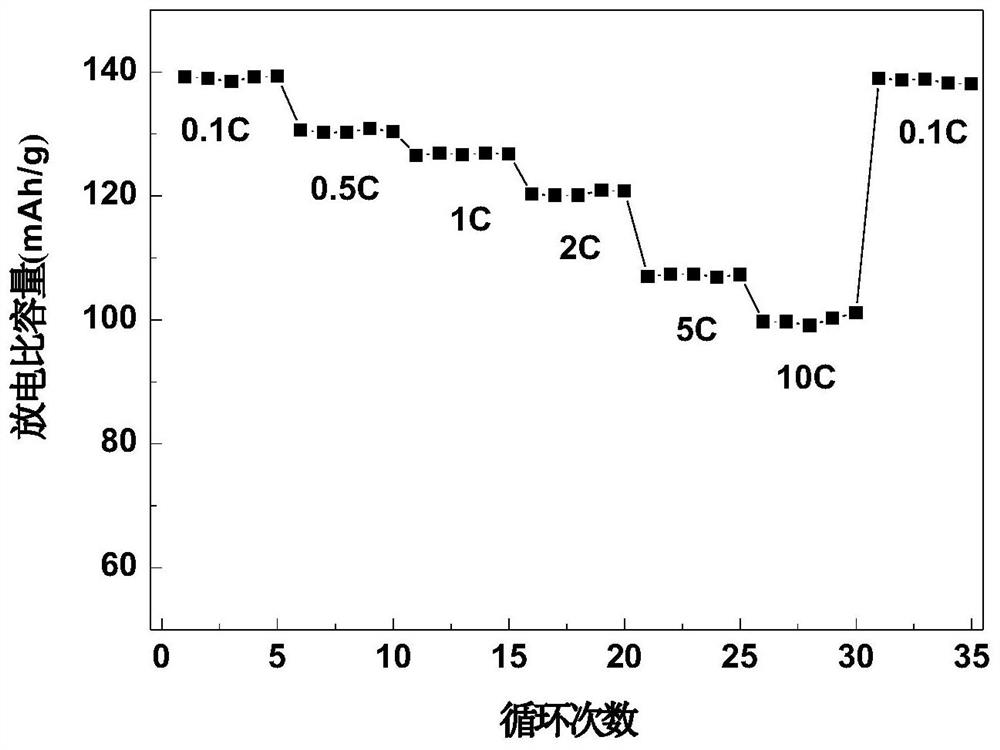

The invention discloses a flexible current collector, an electrode containing the flexible current collector, and a battery. The flexible current collector comprises a textile fabric base and a metal conductive coating; the fiber of the textile fabric is coated with the metal conductive coating; the thickness of the metal conductive coating is 200 nm to 5 microns. An electrode active material of the electrode containing the flexible current collector is loaded on the surface and / or in the hole of the flexible current collector. By adoption of the battery prepared from the electrode provided by the invention, the interface resistance of the battery can be effectively reduced, the electrode mass of unit area is reduced, and the mass energy density is improved; the flexible current collector provided by the invention has higher machining property relative to that of the traditional metal foil, so the production efficiency of the battery can be improved, and the production cost of the battery can be reduced; the current collector base is a macromolecular material and can be shrunk and fused at high temperature, so the safety performance of the battery is improved.

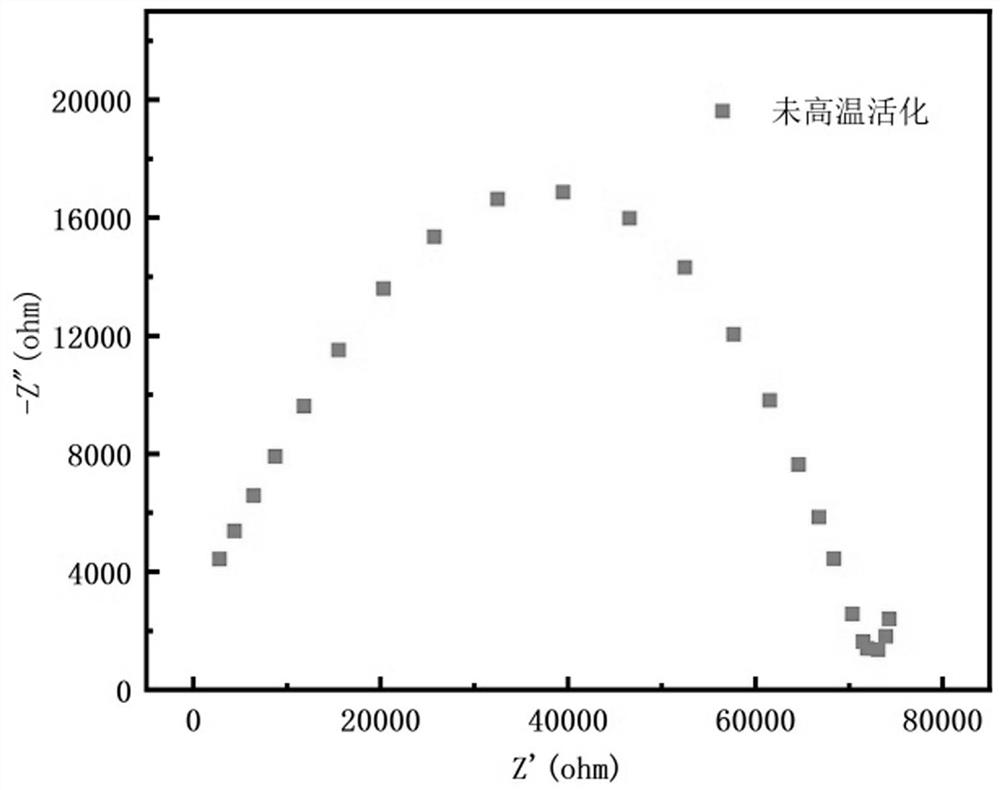

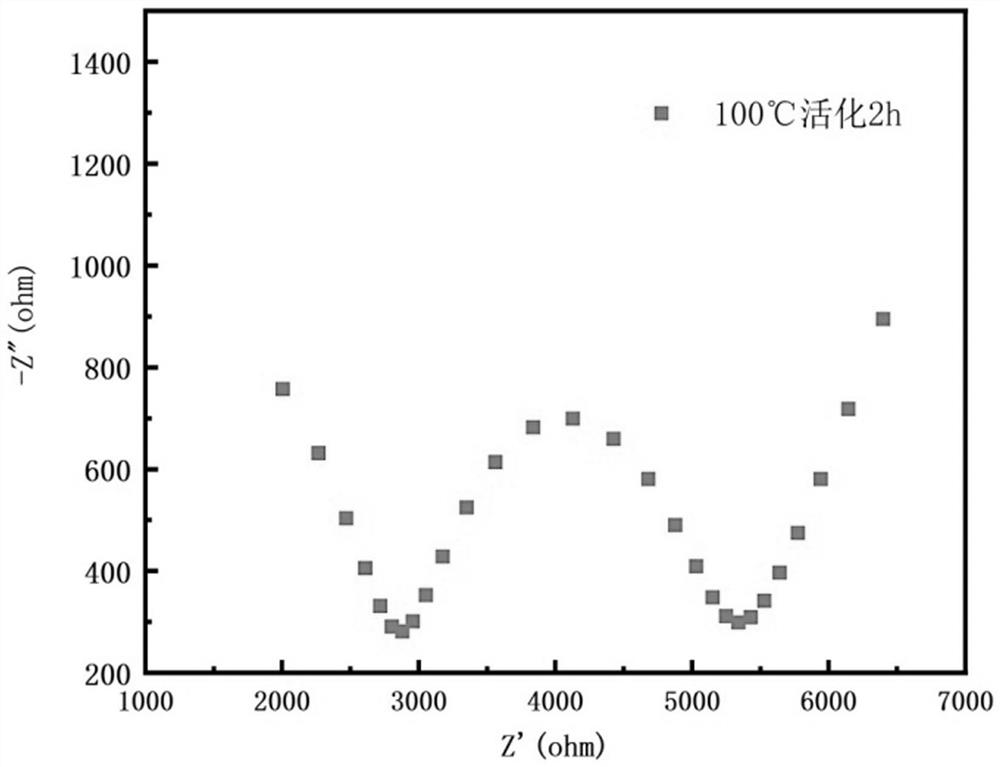

Preparation method of solid state lithium battery composite cathode film

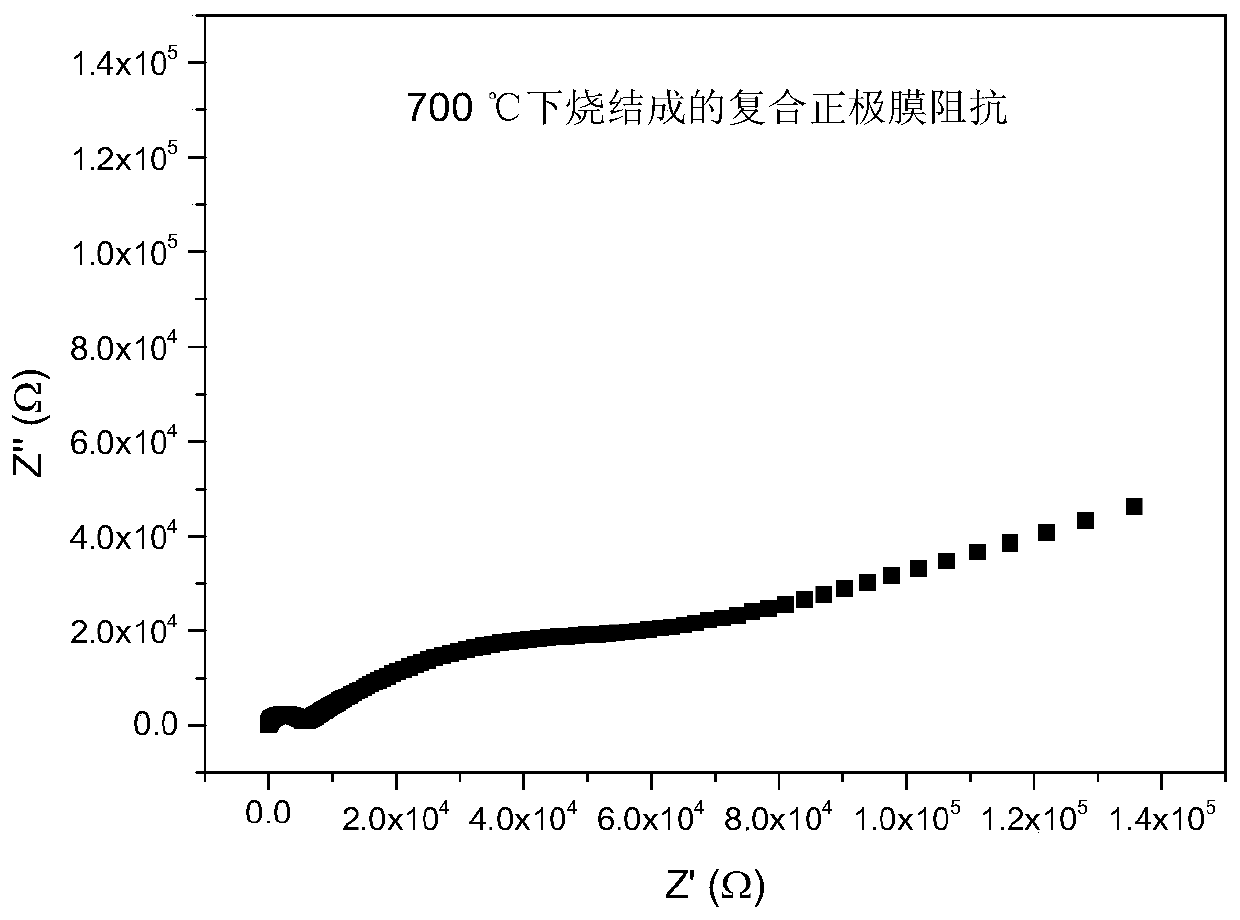

ActiveCN109860550AImprove compactnessReduce interfacial internal resistanceElectrode manufacturing processesLi-accumulatorsInterface impedanceAdhesive

The present invention relates to a preparation method of a solid state lithium battery composite cathode film, belonging to the technical field of battery cathode materials. In order to solve the problems that sintering aids are required being added and the internal resistance of the interface is high in the prior art, the present invention provides a preparation method of a solid state lithium battery composite cathode film. The method comprises the steps of: performing uniform mixing and ball milling of active cathode particles and LLZO solid electrolyte particles in proportion, then dryingthe mixture to obtain composite cathode powder body particles, wherein the mass content of the LLZO solid electrolyte particles in the composite cathode powder body particles is 5.0-35wt%; mixing thecomposite cathode particles, a binder, adhesives, a dispersing agent, a plasticizer and a solvent to form a composite cathode slurry; and performing tape casting of the composite cathode slurry to prepare a composite cathode blank film, performing drying and rubber discharging of the composite cathode blank film, and performing low-temperature sintering processing at a temperature of 650-850 DEG Cto obtain a composite cathode film. The preparation method of the solid state lithium battery composite cathode film can effectively improve the interface densification, can reduce the interface impedance and can reduce the interface charge transfer resistance.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

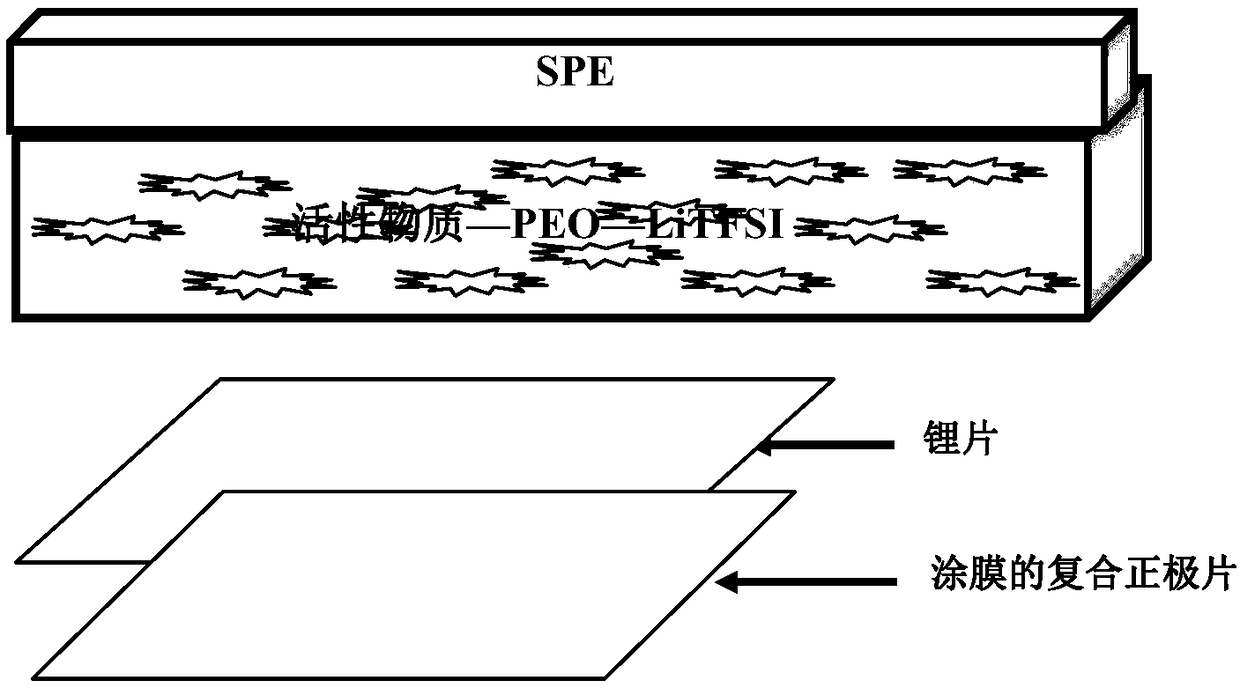

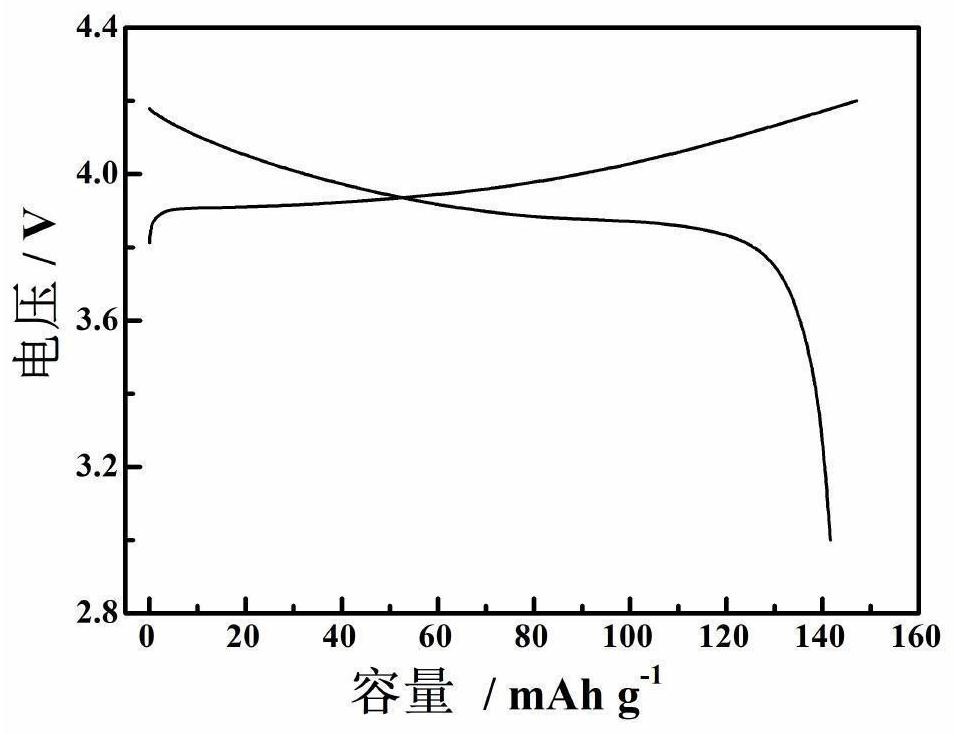

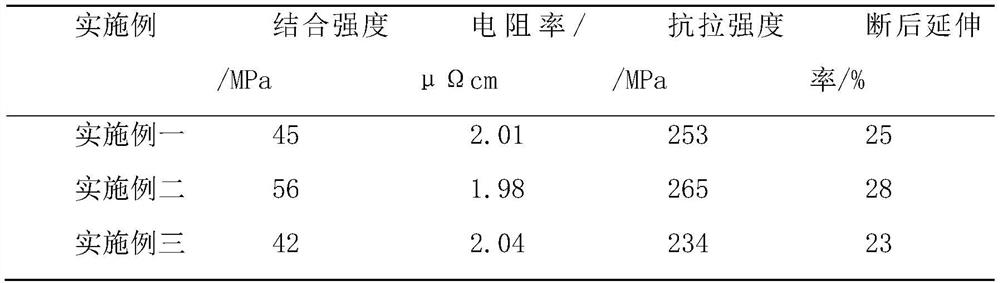

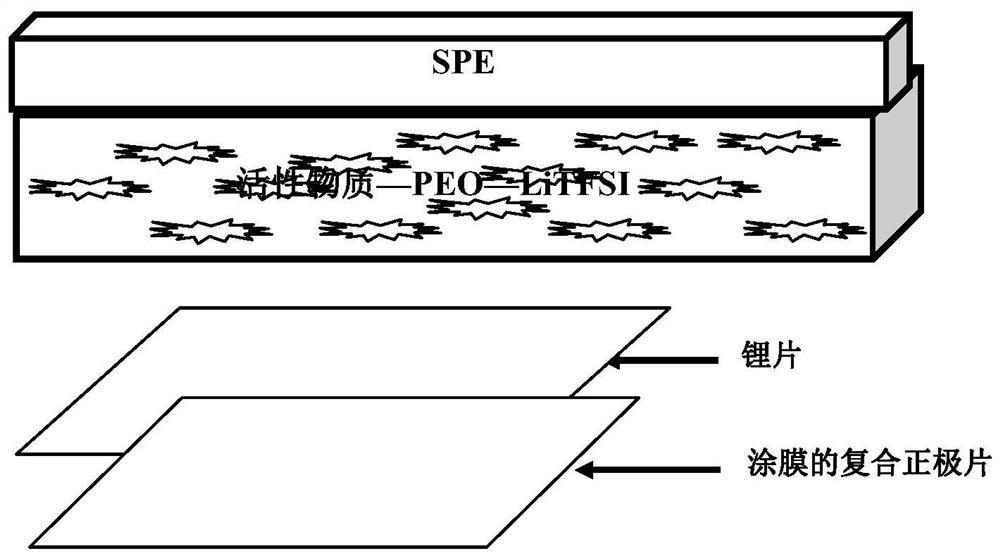

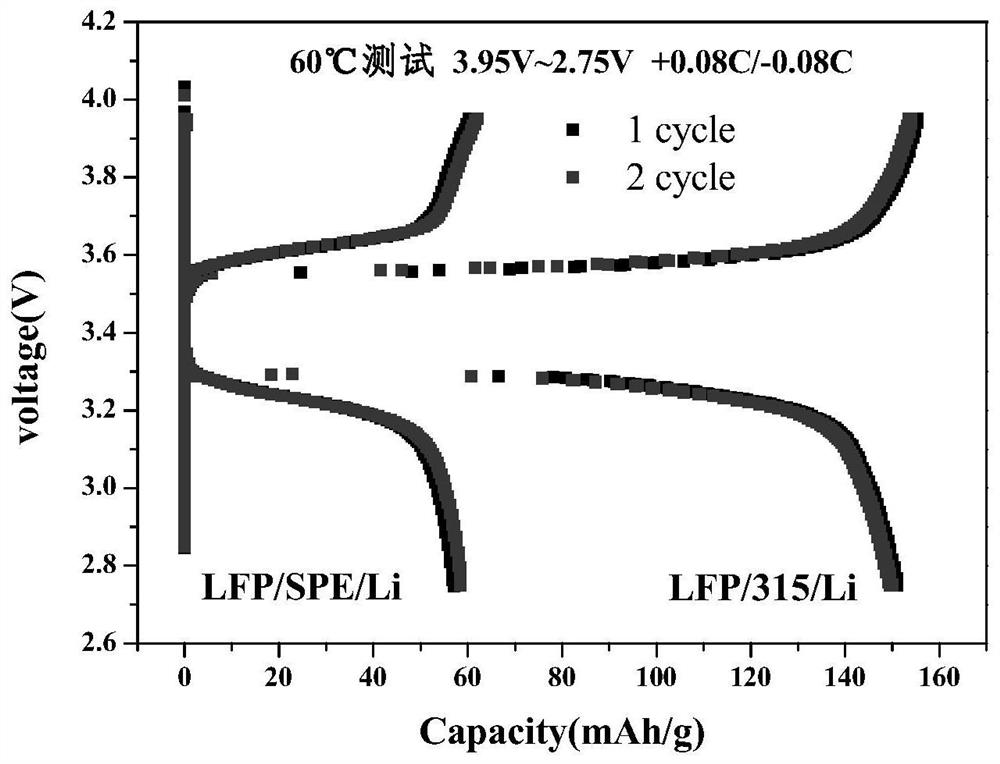

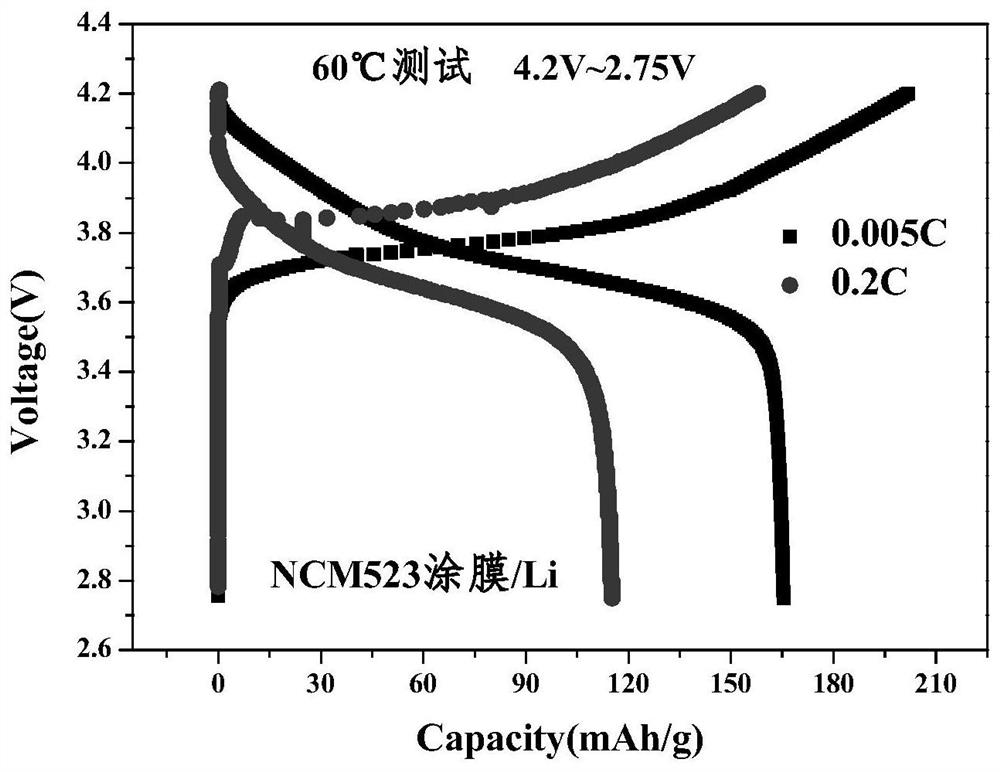

A composite cathode for a solid-state battery and a preparation method thereof

ActiveCN109119591AIncrease capacityImprove securityNon-aqueous electrolyte accumulator electrodesCurrent collectorComposite cathode

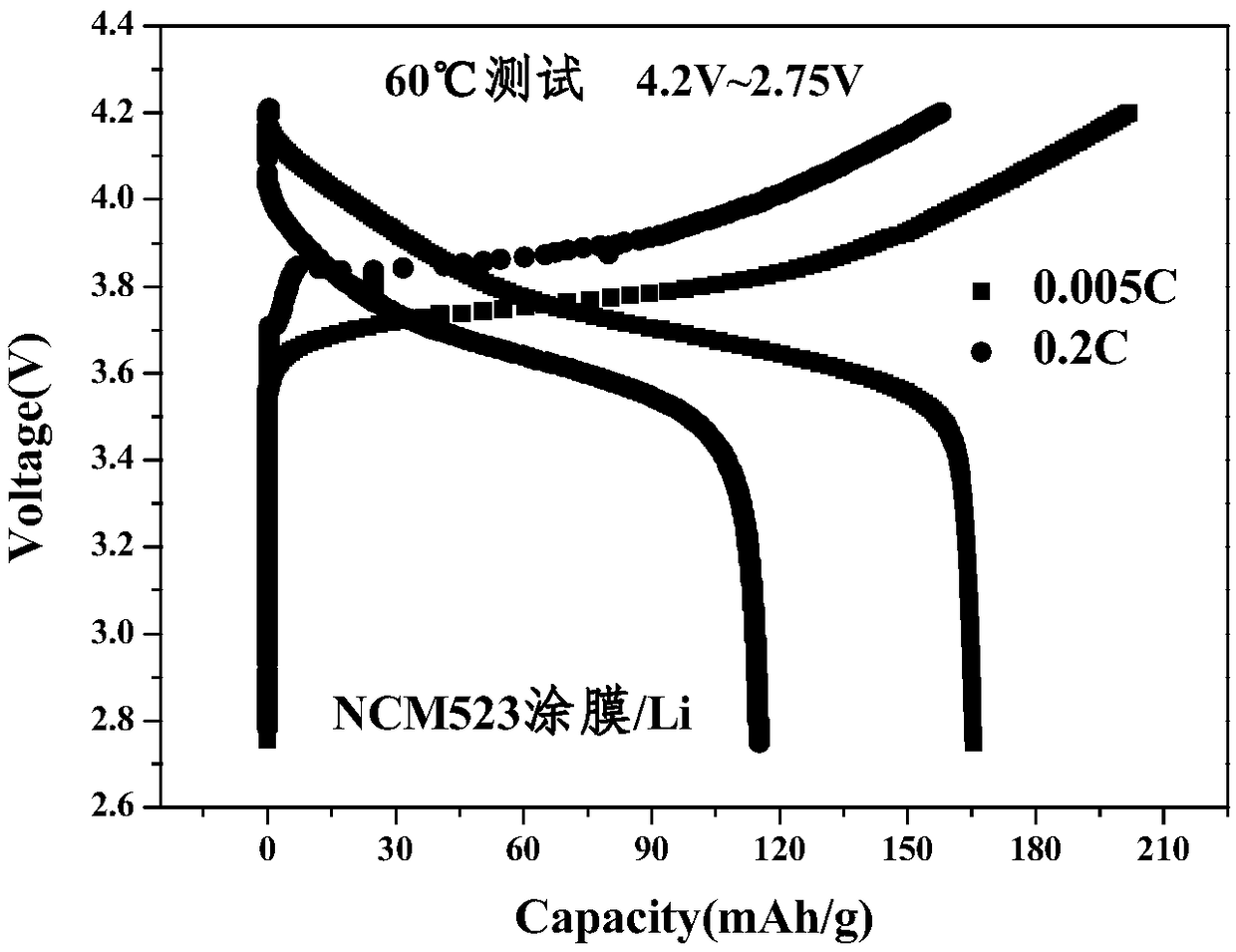

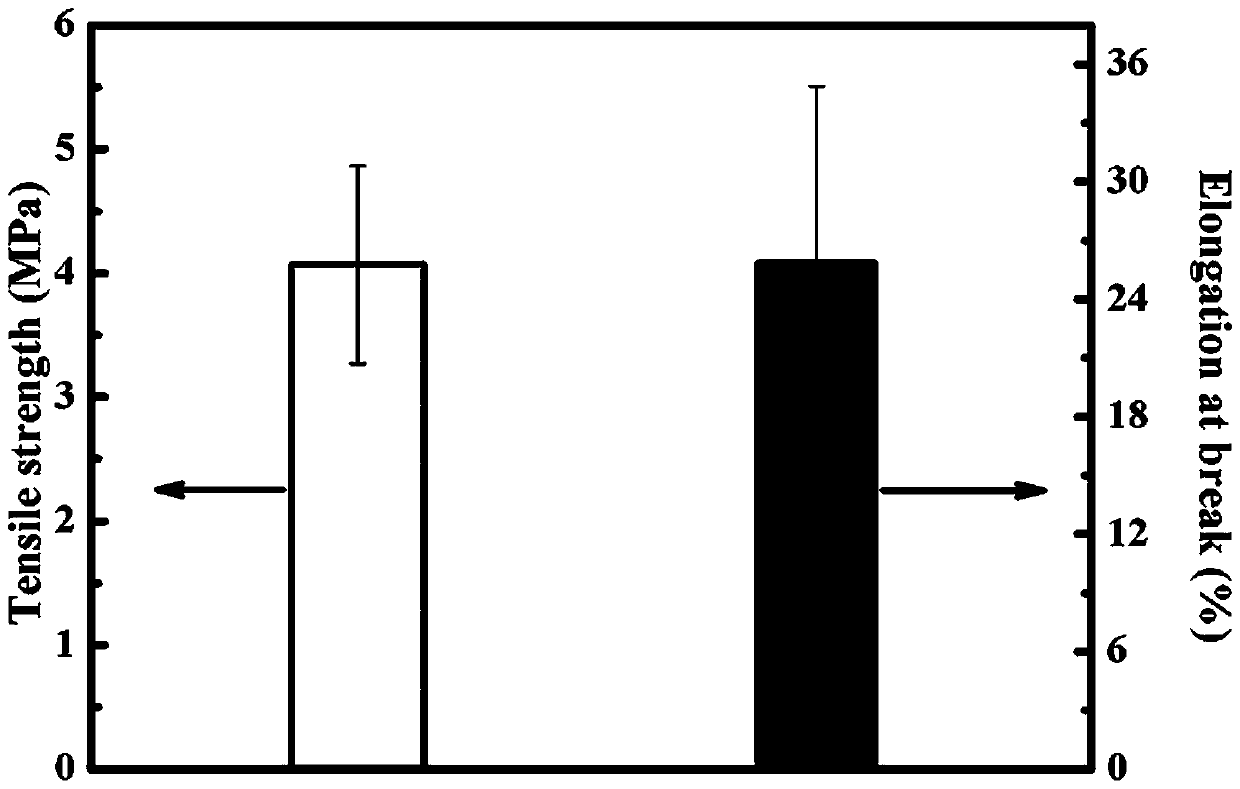

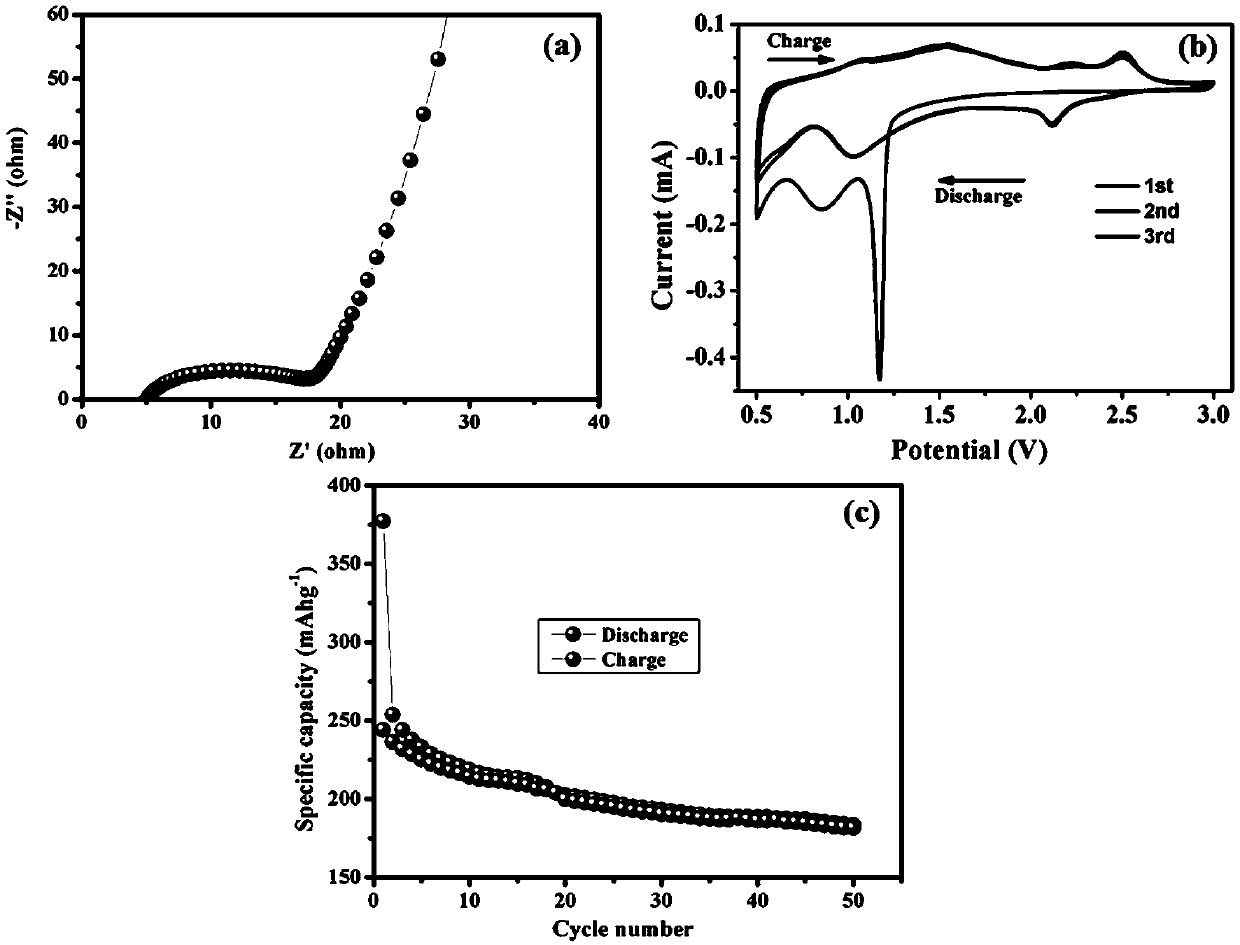

The invention relates to a composite cathode for a solid-state battery. The composite cathode comprises a composite cathode sheet and an electrolyte membrane formed by coating solid-state electrolyteslurry on the composite cathode sheet. The composite cathode sheet is formed by coating composite cathode slurry on a cathode current collector. The solid-state electrolyte slurry comprises a polymerand a lithium salt in a mass ratio of 1 to 5. The composite positive electrode slurry comprises a positive electrode active material, a conductive agent, a binder, a polymer and a lithium salt in a mass ratio of 250 - 350: 5 - 35: 5 - 35: 1 - 5: 1. The invention effectively reduces the internal resistance of the interface, improves the interface impedance, reduces the ion transmission distance, thereby improving the capacity of the solid-state battery, effectively improving the tensile strength, and thus improving the capacity and safety performance of the solid-state battery. In addition, thesolid-state battery of the present invention is used in a plurality of battery systems such as NCM111, NCM523, NCM622, NCM811, LFP, LCO, and the like, and has a wide application range.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

A method of inhibiting gas generation in battery formation and a lithium ion battery formed by adopting the method

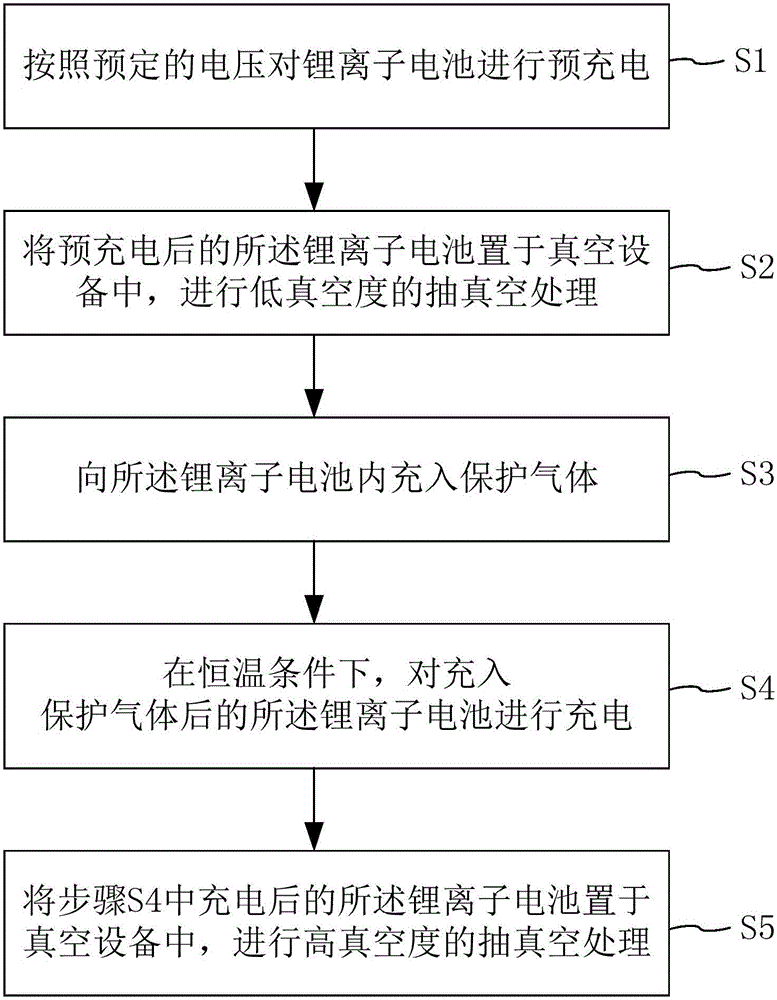

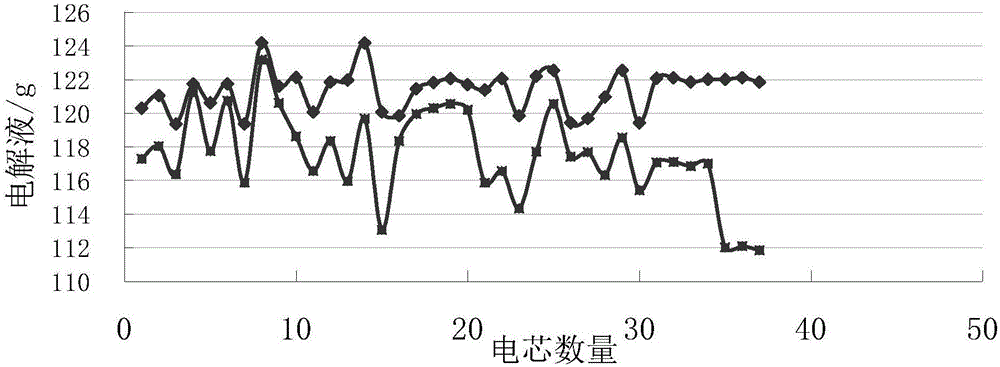

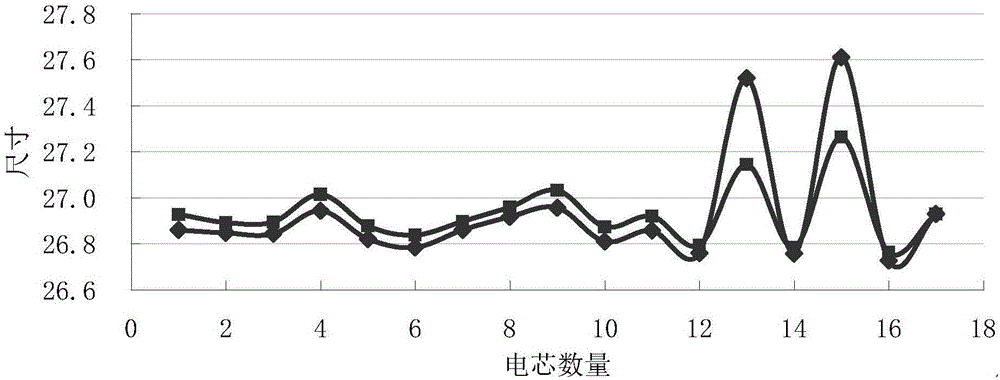

InactiveCN106505250AInhibit decomposition gas productionHigh initial capacityFinal product manufactureSecondary cells charging/dischargingDecompositionElectrochemistry

A method of inhibiting gas generation in battery formation and a lithium ion battery formed by adopting the method are disclosed. The method includes S1) pre-charging the lithium ion battery according to a preset voltage, S2) putting the pre-charged lithium ion battery into a vacuum device and performing vacuumizing treatment with a low vacuum degree, S3) feeding a protective gas into the lithium ion battery, S4) charging the lithium ion battery at a constant temperature after the protective gas is fed, and S5) putting the lithium ion battery charged in the step S4) into the vacuum device and performing vacuumizing treatment with a high vacuum degree. Gas generation due to electrolyte decomposition in a formation process of the lithium ion battery is effectively inhibited by the method, thus effectively avoiding a ballooning phenomenon, and providing safety for lithium ion battery production and application. In addition, the initial capacity of the battery is increased, the battery interface internal resistance is reduced, electrochemical performance stability of the battery is effectively improved and the cyclic life of the battery is greatly prolonged.

Owner:SHENZHEN TOPBAND

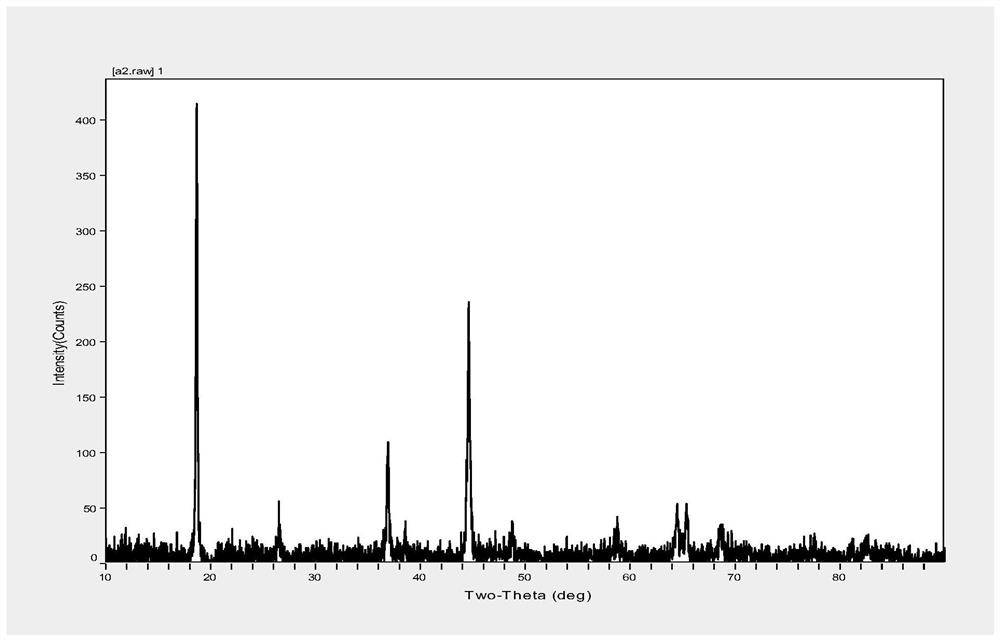

Positive electrode material precursor, preparation method thereof and positive electrode material

ActiveCN107706364AImprove cycle performanceThe distance between primary particle layers is reducedCell electrodesSecondary cellsManganeseNickel compounds

The invention provides a preparation method of a positive electrode material precursor. The preparation method comprises the following steps of A) mixing a nickel-containing compound, a cobalt-containing compound, a manganese-containing compound and water to obtain a mixed solution; B) mixing the mixed solution, a precipitant and a complexing agent, and performing co-precipitation reaction to obtain a Ni-Co-Mn precursor solution, wherein the Ni-Co-Mn precursor is shown in a general formula (I); and C) mixing an oxidization agent and the Ni-Co-Mn precursor solution during the co-precipitation reaction process, and performing partial oxidization reaction to obtain the positive electrode material precursor, wherein the positive electrode material precursor is a secondary spherical particle composite precursor formed by accumulating primary particles shown in the general formula (I) and a general formula (II), the general formula (I) is Ni<x>Co<y>Mn<1-x-y>CO<3>, the general formula (II) isNi<x>Co<y>Mn<1-x-y>O, 0<x<1, 0<y<1, and (x+y)<1.

Owner:宁波富理电池材料科技有限公司

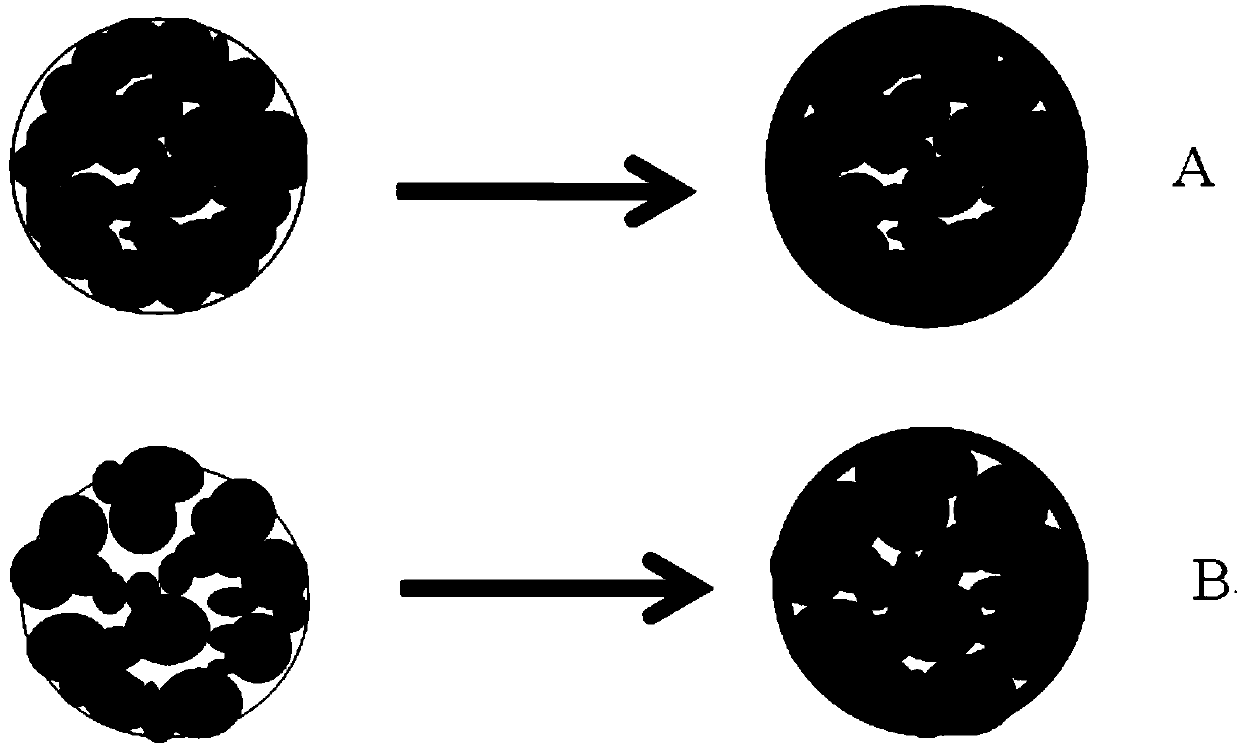

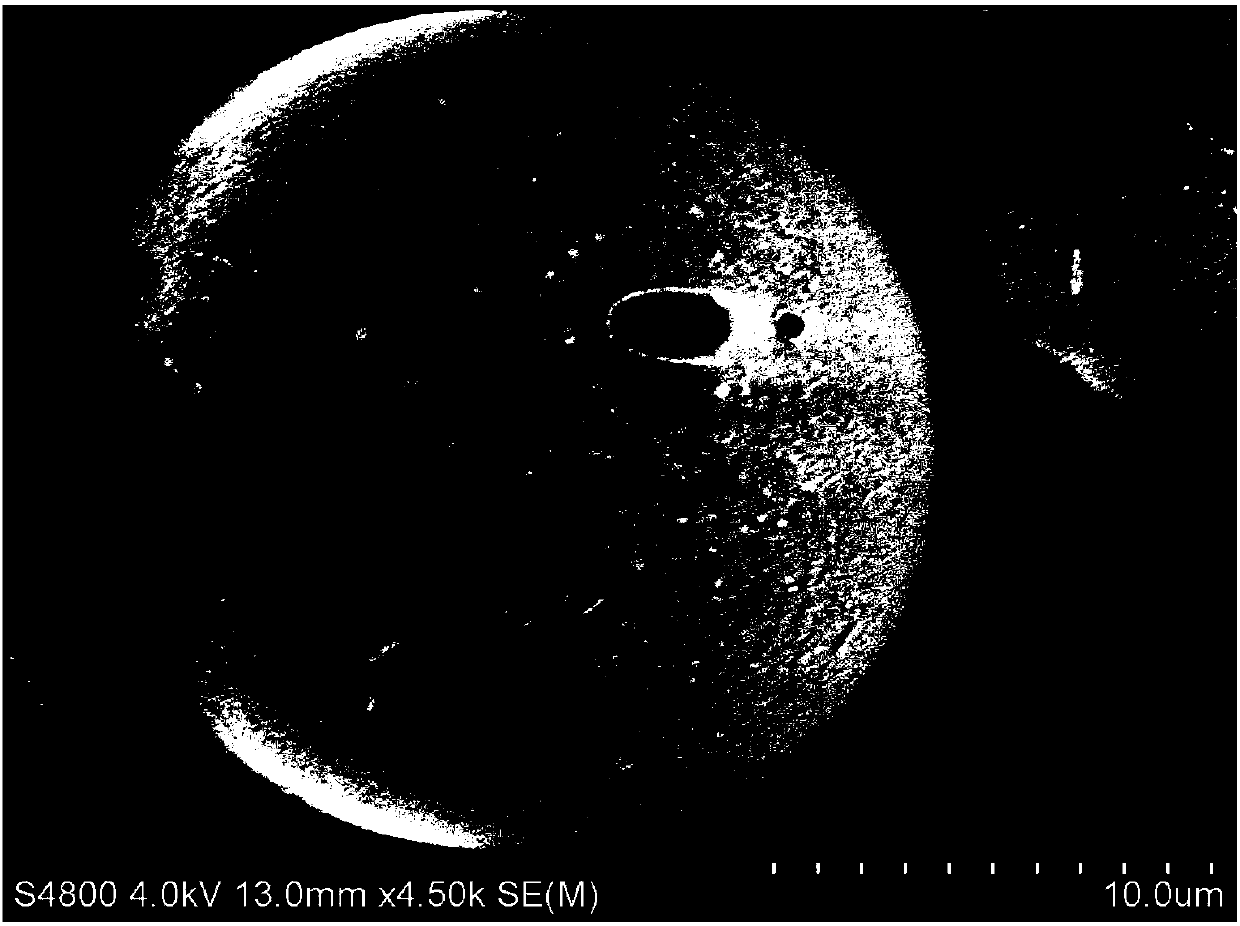

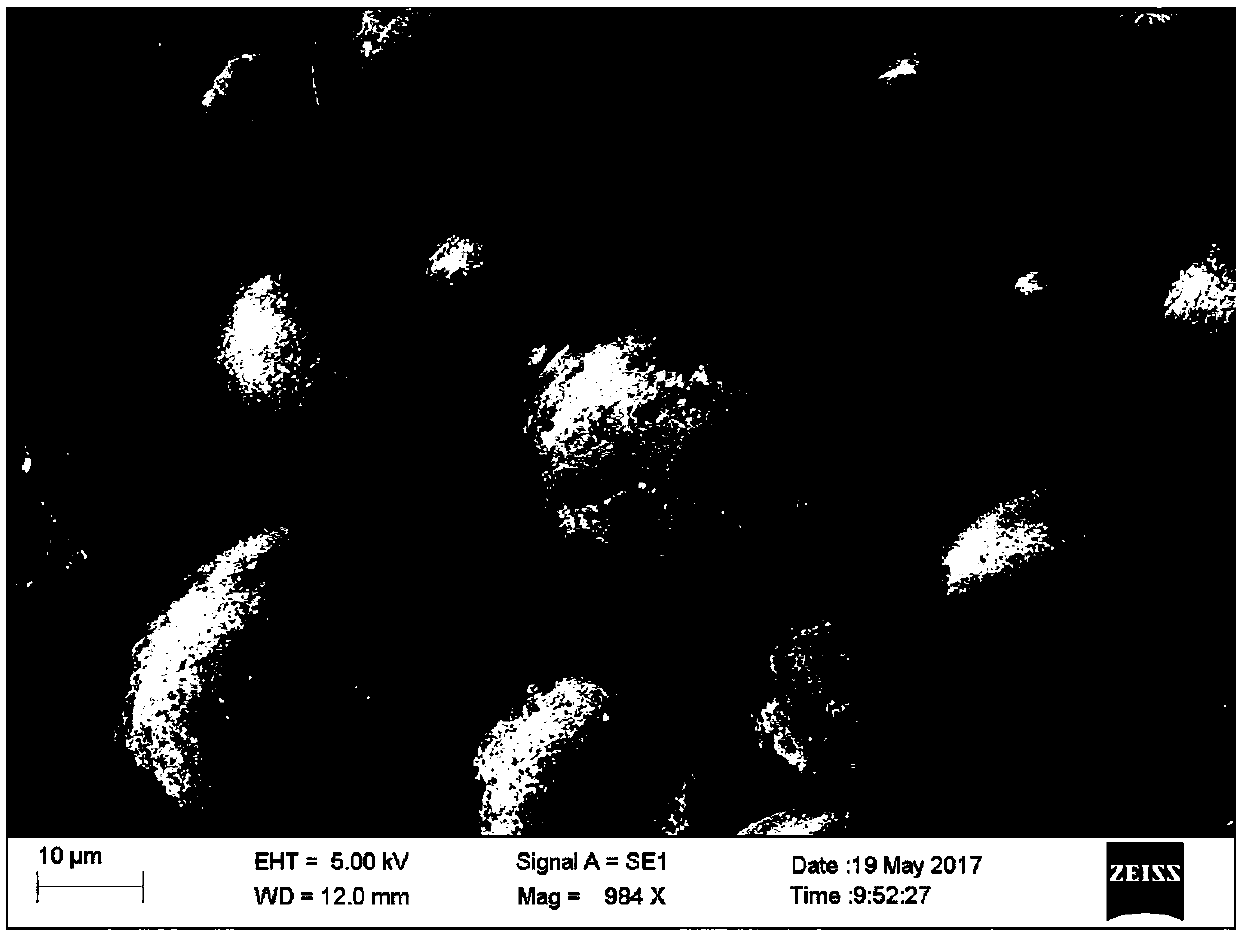

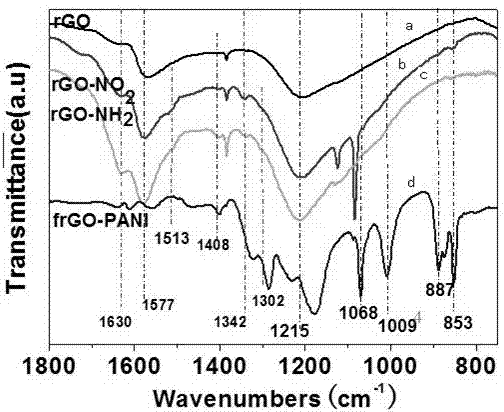

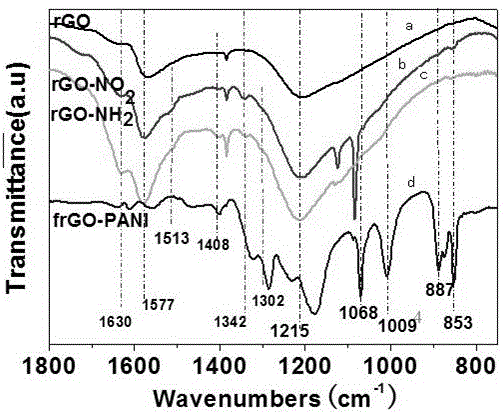

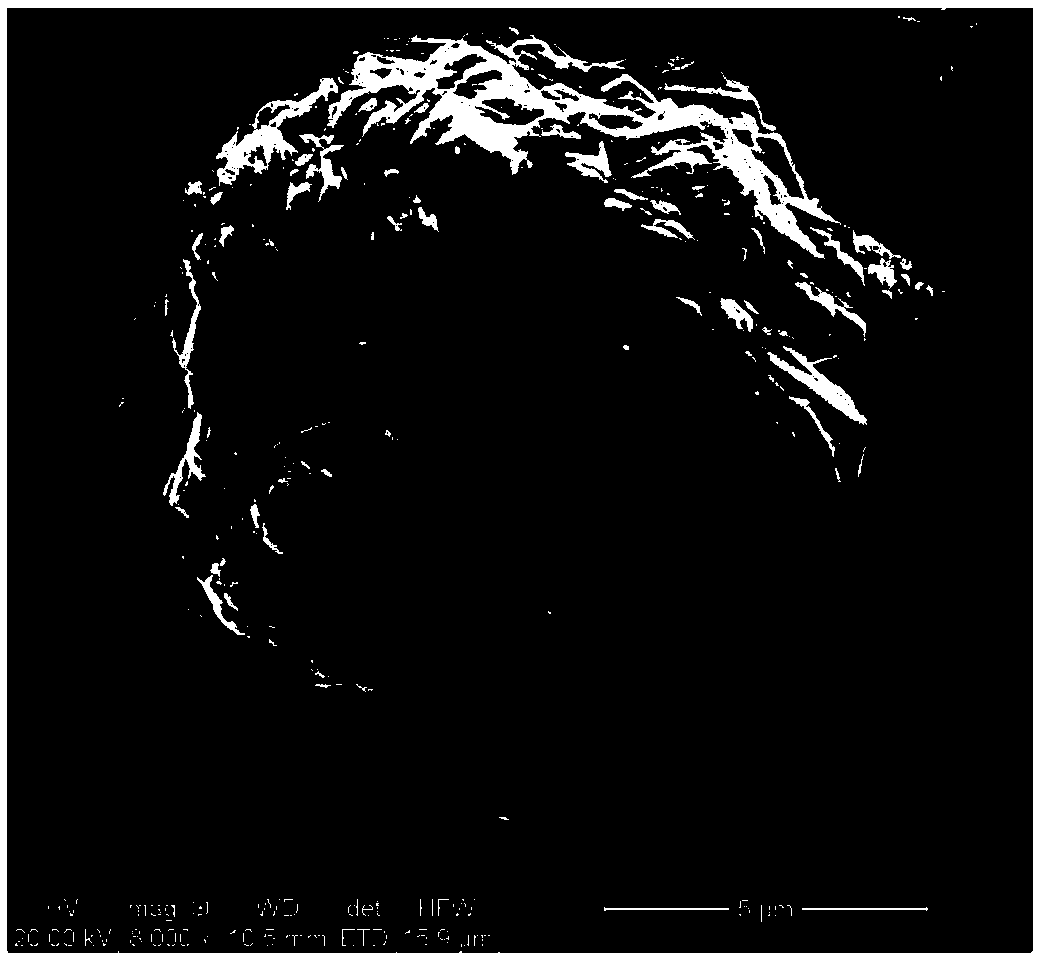

Synthetic method for graphene-based three-dimensional polyaniline array nanocomposite

The invention discloses a synthetic method for graphene-based three-dimensional polyaniline array nanocomposite, which is different from the previously reported methods. In the synthetic method, graphene and polyaniline are connected by chemical bonds rather by physical acting force. The graphene-based three-dimensional polyaniline array is a nanocomposite with an array structure. The invention further provides a synthetic method of the nanocomposite. The synthetic method comprises the following steps: finally adding aminobenzene monomer and an oxidant under acidic conditions so as to initiate in-situ polymerization to obtain the graphene polyaniline array. Different from the graphene-based three-dimensional polyaniline composite connected through physical adsorption, the nanocomposite has the advantages of being good in thermal stability, small in resistance, good in electric chemical property and the like.

Owner:JIANGXI NORMAL UNIV

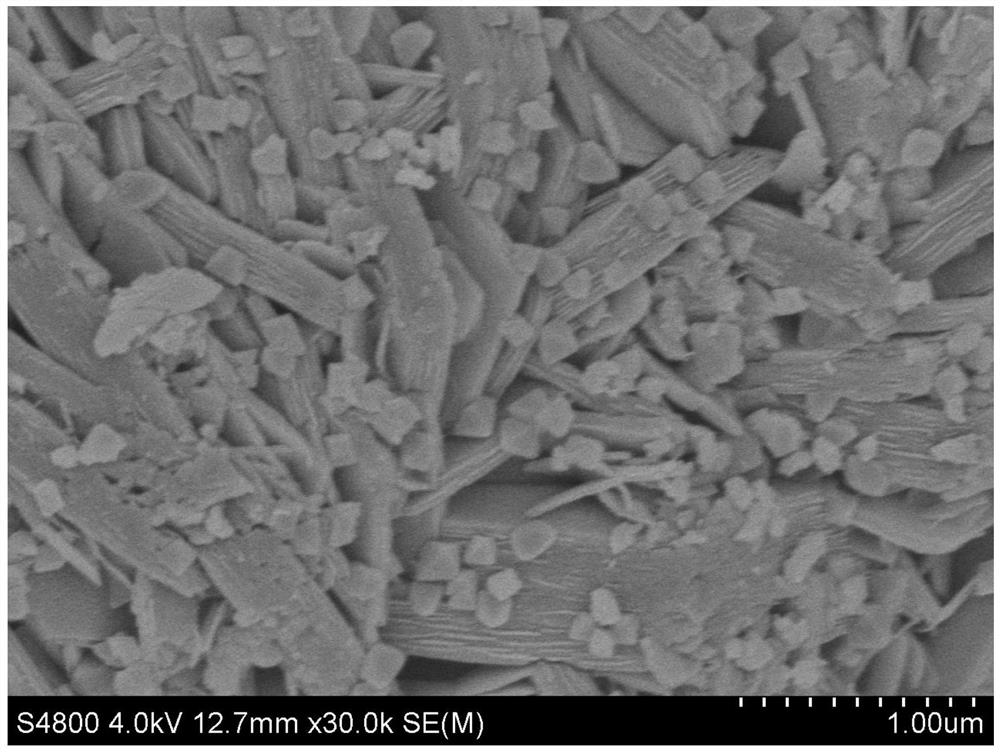

Positive electrode material precursor and preparation method thereof, positive electrode material and lithium ion battery

ActiveCN109994726AImproved magnification performanceUniform materialCell electrodesSecondary cellsNanoparticleInternal resistance

The invention provides a positive electrode material precursor. The positive electrode material precursor has the general formula shown as formula (I): NixCoyMnzAl1-x-y-z (OH)2 (I), wherein the positive electrode material precursor is spherical particles composed of positive electrode material precursor hexagonal sheets, and positive electrode material precursor nano particles are compounded on the positive electrode material precursor hexagonal sheets. According to the method, the precursor of a ternary or quaternary positive electrode material is obtained, and the spherical particles are formed by the hexagonal sheets; the precursor hexagonal sheets are further compounded with the precursor nano particles, and the multi-layer hexagonal sheets and the nano particles on the surfaces thereof form spherical particles, so that the structure is complete and uniform, the processing performance of the positive electrode material can be effectively improved by virtue of the nano particles onthe surfaces of the hexagonal sheets, the structural stability of the positive electrode material is improved, and the cycling performance of the positive electrode material is improved; and the specific surface area of the material is increased by virtue of the nano particles on the surfaces of the hexagonal sheets, the internal resistance of the material in the circulation process is lowered, and the rate performance of the material is improved.

Owner:HUBEI JIUBANG NEW ENERGY TECH

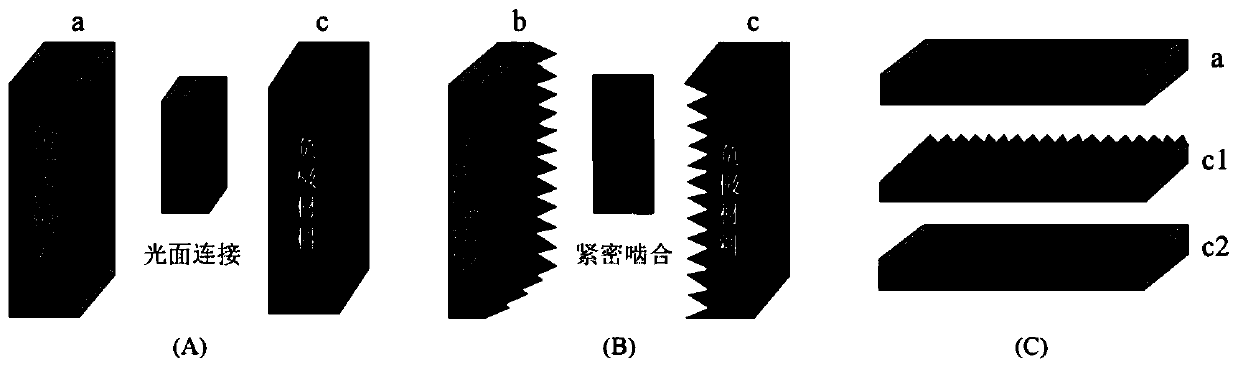

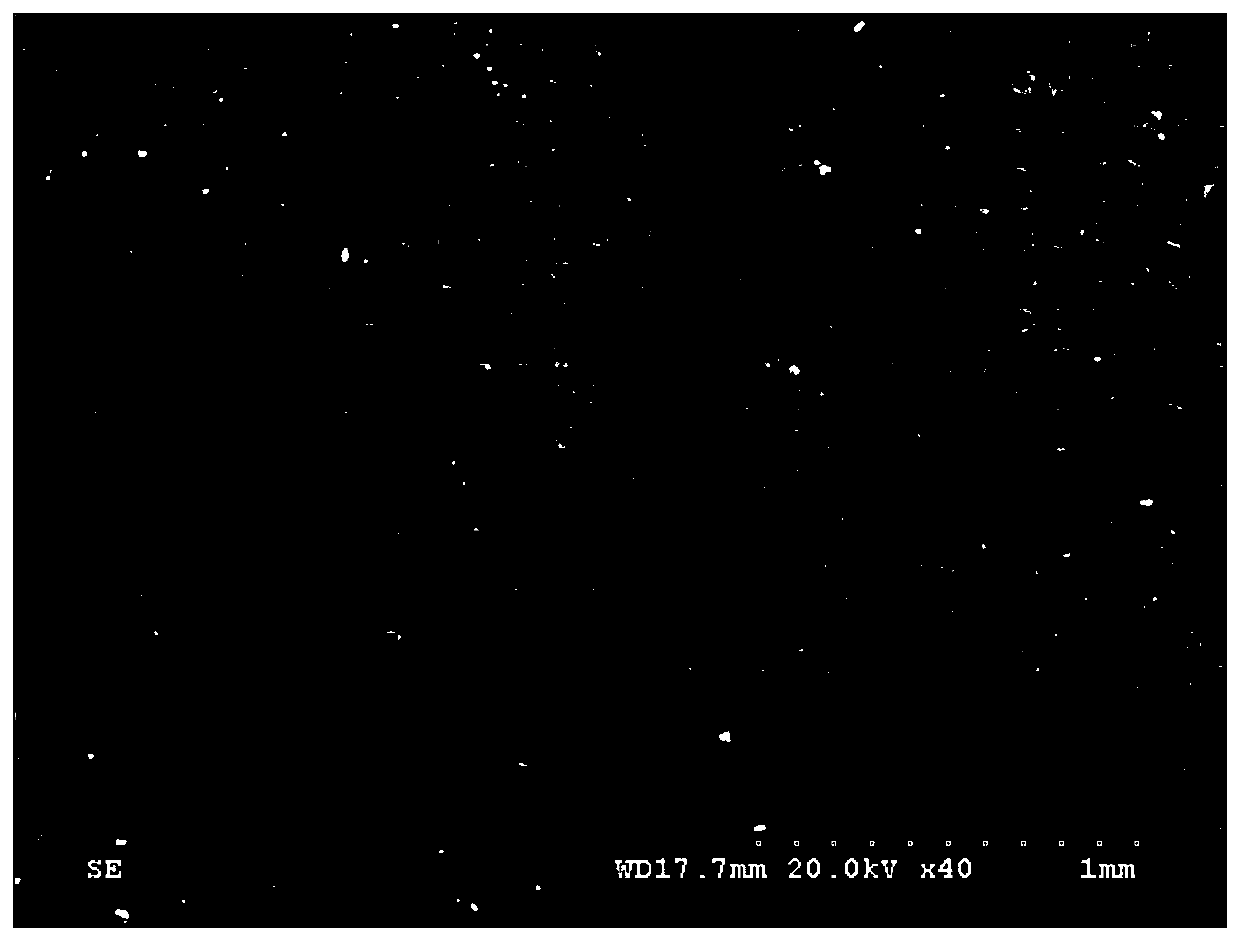

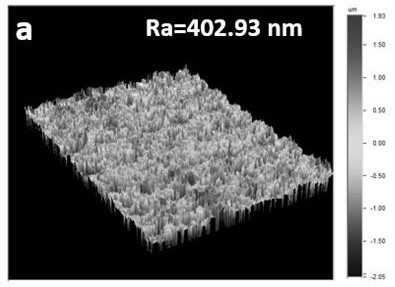

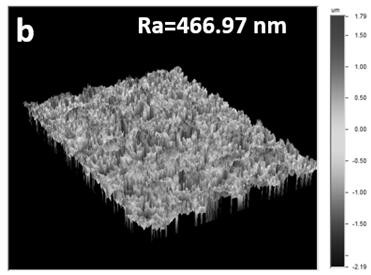

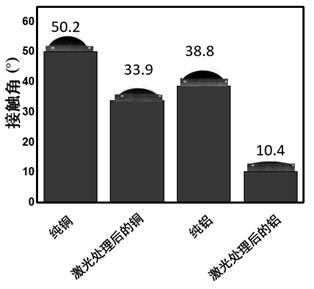

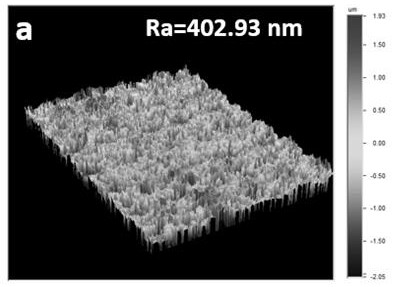

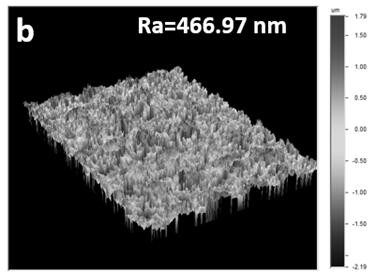

Ultrafast laser three-dimensional micro-nanometer texturing method for surfaces of copper foil current collectors on negative poles of lithium ion batteries

InactiveCN110102901AImprove scienceIncrease capacityElectrode manufacturing processesElectrode carriers/collectorsCopper foilCurrent collector

The invention belongs to the field of laser processing, and relates to an ultrafast laser three-dimensional micro-nanometer texturing method for the surfaces of copper foil current collectors on negative poles of lithium ion batteries. Ultrafast laser is adopted for three-dimensional micro-nanometer texturing of the surfaces of the copper foil current collectors; the screening process comprises the following steps: glaze copper foil current collectors and characteristic-different three-dimensional micro-nanometer textured copper foil current collectors are assembled with batteries; the performances of the batteries are tested to build a relation between the different three-dimensional micro-nanometer texturing characteristics and the performances of the batteries; and the three-dimensionalmicro-nanometer texturing characteristics for improving the performances of the batteries are screened, and are textured on the surfaces of the copper foil current collectors. The method is used formicro-nanometer texturing of the copper foil current collectors by the ultrafast laser to form functional surface microstructures on the surfaces of the current collectors; the characteristics and thefunctions thereof are improved; the copper foil current collectors and electrode materials are tightly engaged, so that the interface internal resistance and the volume change degree of the electrodematerials are reduced, the specific surface area of the current collectors and the adhesion quantity of the electrode materials are improved, the corrosion of the current collectors by electrolyte isreduced, and the performances of the batteries are improved; and the method is scientific and reasonable, and is accurate and reliable in result.

Owner:SHANGHAI UNIV OF ENG SCI +3

Solid-state lithium battery and production method thereof

PendingCN113054241ASimple manufacturing processEasy to mass produceSolid electrolytesSecondary cells servicing/maintenanceSolid state electrolyteInternal resistance

The invention discloses a solid-state lithium battery and a production method thereof.The solid-state lithium battery comprises a positive plate, a negative plate and a solid-state electrolyte, and the solid-state electrolyte is arranged between the positive plate and the negative plate; a polymer gel electrolyte is also arranged in at least one of the inside of the negative plate, between the negative plate and the solid electrolyte, the inside of the solid electrolyte, between the solid electrolyte and the positive plate, and the inside of the positive plate; and the polymer gel electrolyte in the solid battery can inhibit an interface reaction between the solid electrolyte and the positive and negative electrodes, and also can improve the mechanical toughness of the solid electrolyte and reduce the interface internal resistance among ceramic particles. The battery design can effectively reduce the internal resistance of the solid-state lithium battery and improve the safety and electrochemical performance of the battery.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

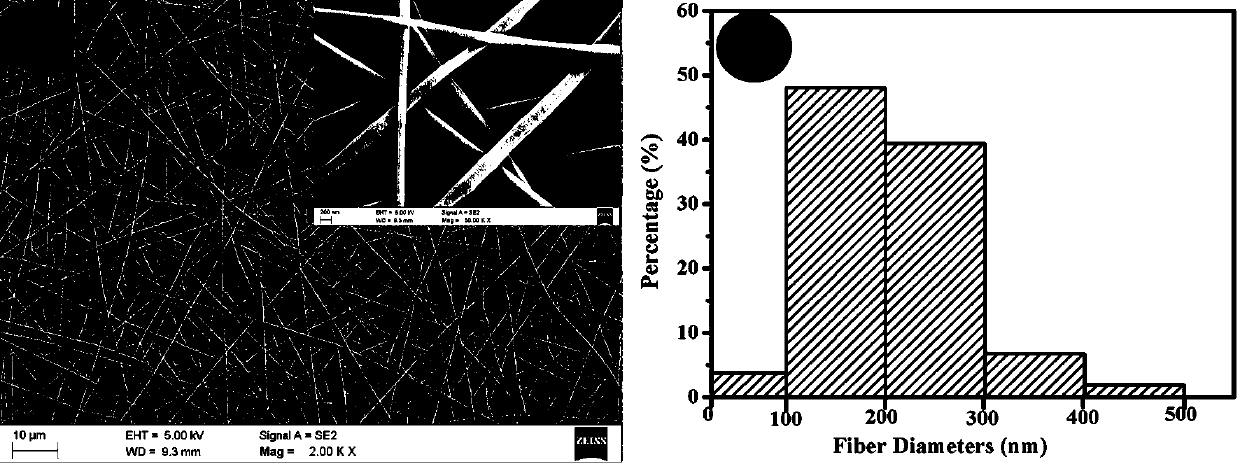

Sodium-ion battery diaphragm and preparation method thereof

InactiveCN110120483AHigh dielectric constantImprove electrochemical stabilityElectro-spinningCell component detailsPorosityMass ratio

The invention discloses a sodium-ion battery diaphragm and a preparation method thereof. The specific method comprises the following steps: adding a certain amount of mixed powder of PVDF and PAN (indifferent mass ratios) into an appropriate solvent; placing the mixture on a constant-temperature magnetic stirrer at a certain temperature, stirring the mixture for 2 hours to completely dissolve PVDF and PAN, then performing stirring at normal temperature for 12 hours to obtain uniform spinning solution with a certain concentration, placing the uniform spinning solution silently in a vacuum environment for a period of time, and removing bubbles in the spinning solution; and then sucking the spinning solution into an injector after standing and defoaming, preparing a PVDF / PAN composite nano-microporous diaphragm by utilizing an electrostatic spinning technology, and then drying and storing the prepared diaphragm for later use. The preparation method is simple in process and low in cost, and the prepared PVDF / PAN composite nano-diaphragm has the advantages of high ionic conductivity, high porosity, uniform pore size distribution, good electrolyte wettability, good cycle performance andthe like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of integrated all-solid-state lithium ion battery

InactiveCN112054159AIncreased active contact sitesDeepening of mutual infiltrationSolid electrolytesElectrode thermal treatmentSolid state electrolyteAll solid state

The invention discloses a preparation method of an integrated all-solid-state lithium ion battery. The preparation method comprises the following steps: preparation of a solid-state inorganic electrolyte, preparation of an organic-inorganic hybrid electrolyte and preparation of the all-solid-state lithium ion battery. The method has the advantages that a certain amount of electrolyte is added intothe electrode, and the electrode is artificially infiltrated into the electrolyte, so that the active contact sites of the electrode and the electrolyte are increased, and the mutual infiltration degree of the interface of the electrode and the solid electrolyte of the all-solid-state lithium ion battery after annealing treatment is deepened; more channels are provided for lithium ion conduction,and the interface internal resistance between the prepared all-solid-state lithium ion battery electrode and the electrolyte is reduced.

Owner:LANZHOU UNIVERSITY

Graphene-modified copper foil electrode used for power battery with silica-based cathode

ActiveCN108288714AIncrease contact areaLower migration barrierElectrode carriers/collectorsSecondary cellsPower batteryInternal resistance

The invention discloses a graphene-modified copper foil electrode used for a power battery with a silica-based cathode. The copper foil electrode includes a copper foil base body, and the copper foilbase body is sequentially provided with a graphene buffering layer and an active material layer; the graphene buffering layer is formed on the copper foil base body and forms a flow gathering layer along with the copper foil base body; the active material layer is a silica-based alloy cathode coating layer, and the silica-based alloy cathode coating layer includes compound ingredients including C,Si, GeP5 and GeS, wherein the mass ratio of the compound ingredients including C, Si, GeP5 and GeS is (1-10):(1-10):(1-10):(1-10). The graphene-modified copper foil electrode has the advantages thatthe contact area between the flow gathering layer and the active materials is enlarged, and electronic migration potential barriers and interface internal resistance are reduced; the compatibility andbonding strength between the active materials and flow gathering bodies are enhanced; the physical, chemical and electrochemical properties are stable, and the stability of copper foil under an electrochemical condition and the battery safety are improved.

Owner:深圳名飞远科技有限公司

Low-internal-resistance all-solid-state battery and preparation method thereof

ActiveCN112652815AInhibit swellingIncrease contactSolid electrolytesFinal product manufactureSolid state electrolyteAll solid state

The invention provides a low-internal-resistance all-solid-state battery and a preparation method thereof. The low-internal-resistance all-solid-state battery comprises a positive electrode layer and a composite negative electrode layer, a solid electrolyte layer is arranged between the positive electrode layer and the composite negative electrode layer, the solid electrolyte layer and the positive electrode layer are integrally prepared through solidification, and the composite negative electrode layer comprises a negative electrode layer and a buffer layer; the buffer layer is composed of hard carbon and a conductive polymer, and the buffer layer and the negative electrode layer are integrally prepared. The hard carbon and the conductive polymer are used as the buffer layer, so that the problem of pole piece expansion in the charging and discharging process of the negative electrode is inhibited, the negative electrode is in good interface contact with the solid electrolyte, the interface stability between the solid electrolyte and the negative electrode is improved, and the interface internal resistance is reduced.

Owner:郑州中科新兴产业技术研究院

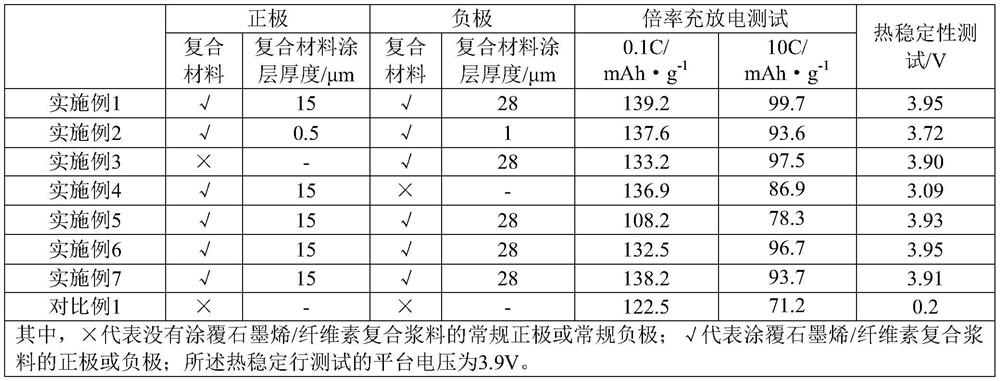

Lithium ion battery containing graphene/cellulose composite material, and preparation method thereof

ActiveCN108933236AEasy to prepareMild reaction conditionsCell electrodesSecondary cellsGrapheneLithium-ion battery

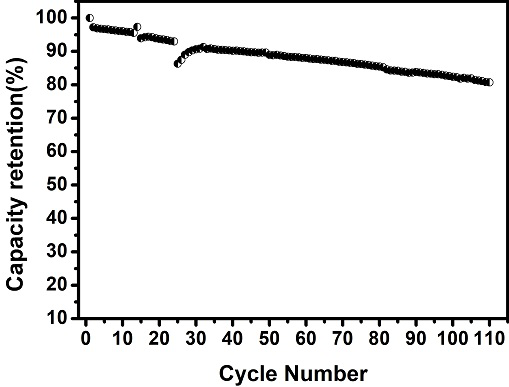

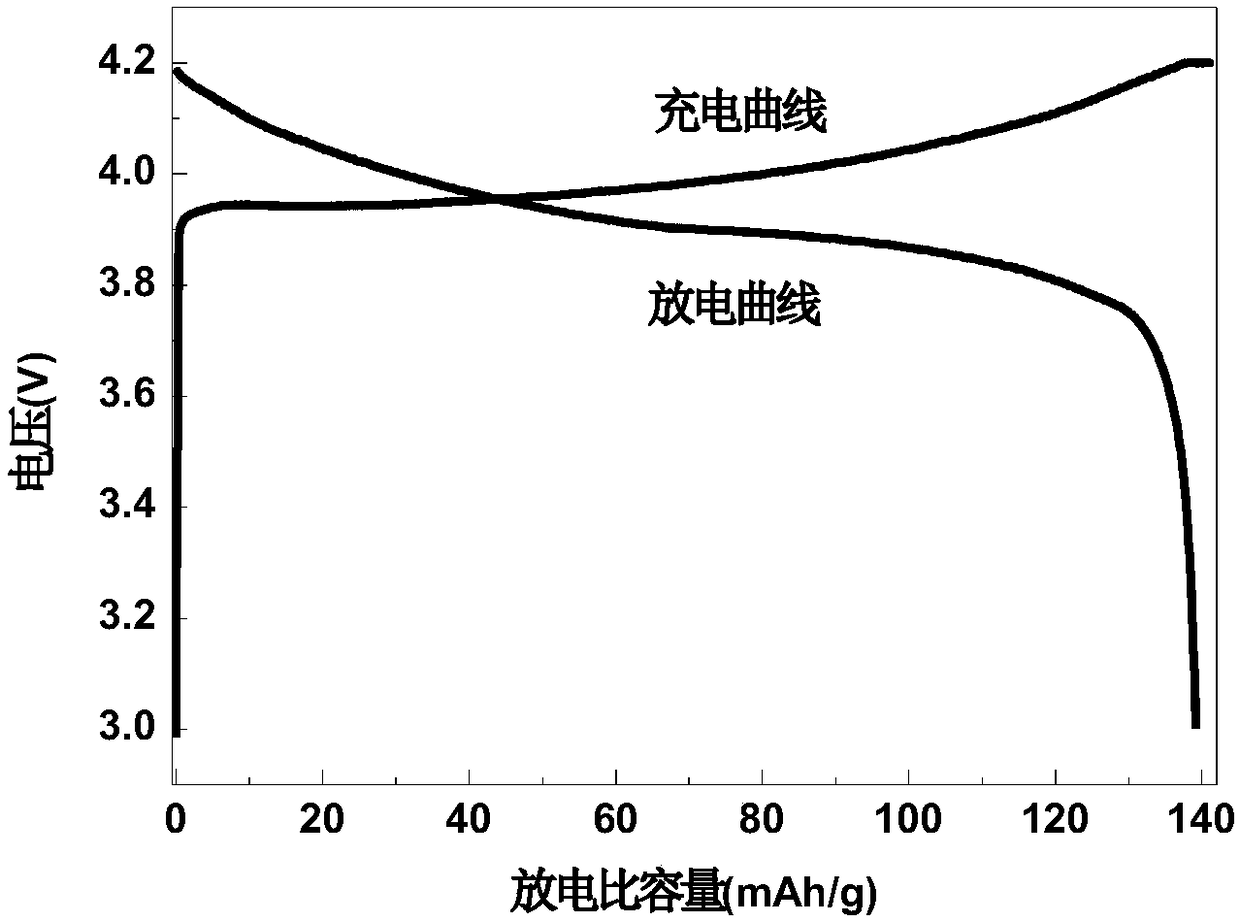

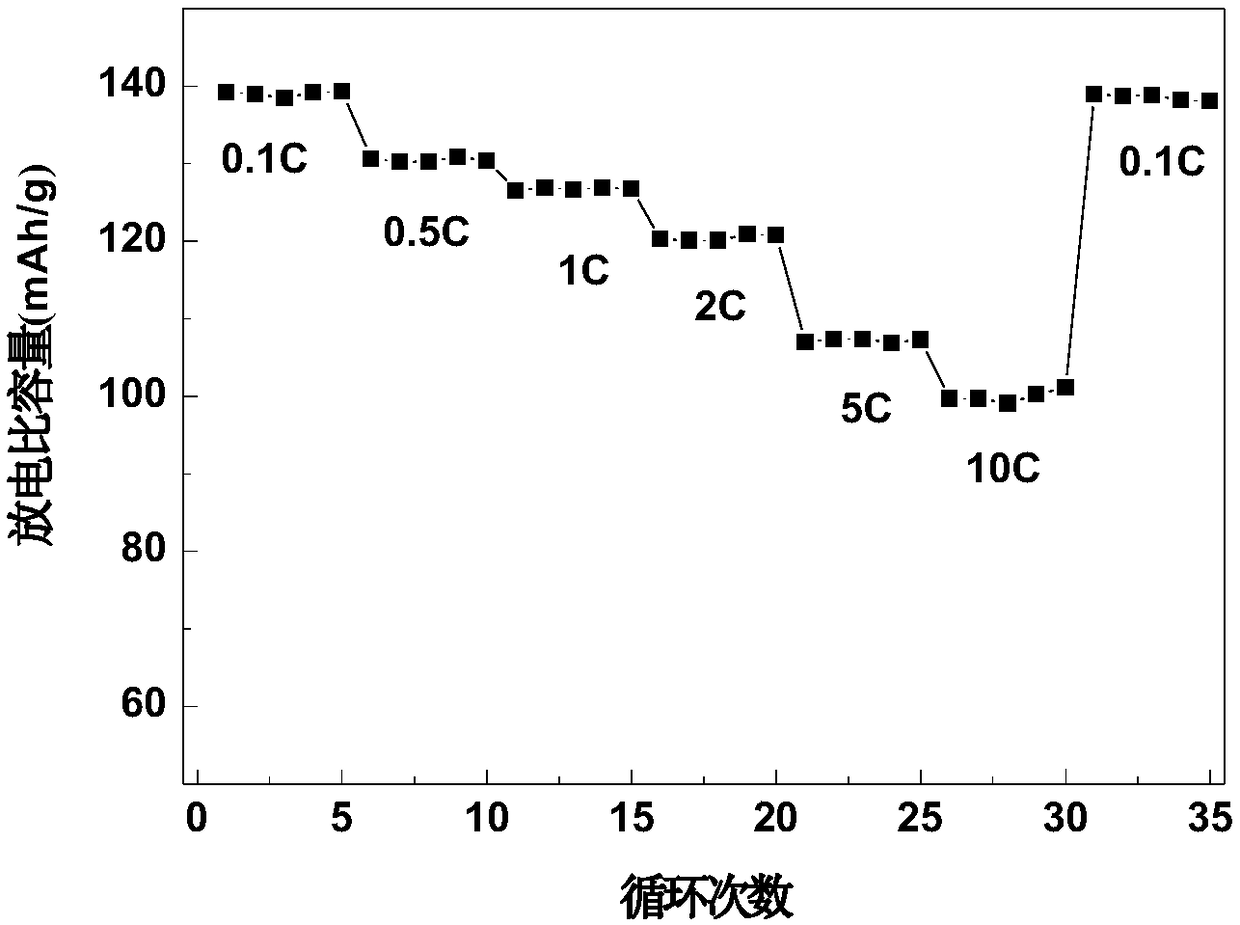

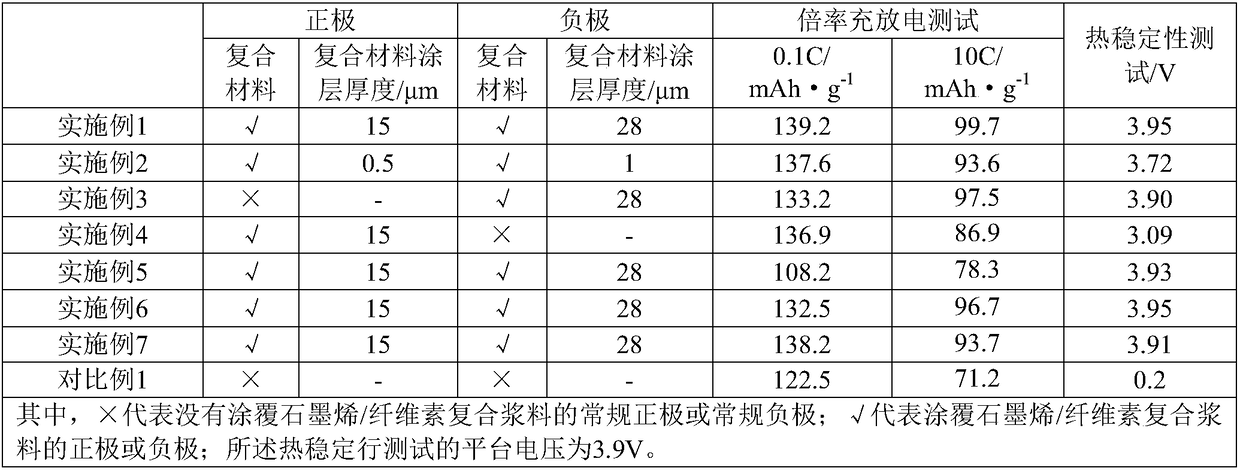

The invention discloses a negative electrode and a positive electrode for a lithium ion battery, and the lithium ion battery and a preparation method thereof. The negative electrode comprises a negative plate and a graphene / cellulose composite material layer on one side surface of the negative plate. The positive electrode comprises a positive plate and a graphene / cellulose composite material layer on one side surface of the positive plate. The graphene / cellulose composite material layer comprises graphene and cellulose. A coating can effectively inhibit the growth of dendritic crystals on thesurface of the negative plate so as to improve the cycle performance and safety performance of the battery; and the coating can effectively reduce the direct internal interface resistance of the surface of the positive and negative plates and an electrolyte so as to enhance the capacity of the corresponding battery. The lithium ion battery prepared by using the negative electrode and / or the positive electrode has high cycle capacity and cycle stability and good cycle safety. The preparation method for the lithium ion battery is simple in process, mild in reaction conditions, short in production cycle, and capable of realizing large-scale industrial production.

Owner:BEIJING NORMAL UNIVERSITY

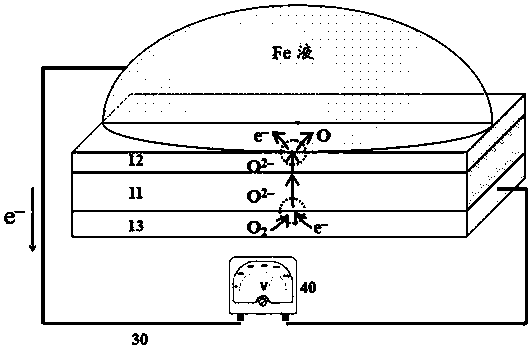

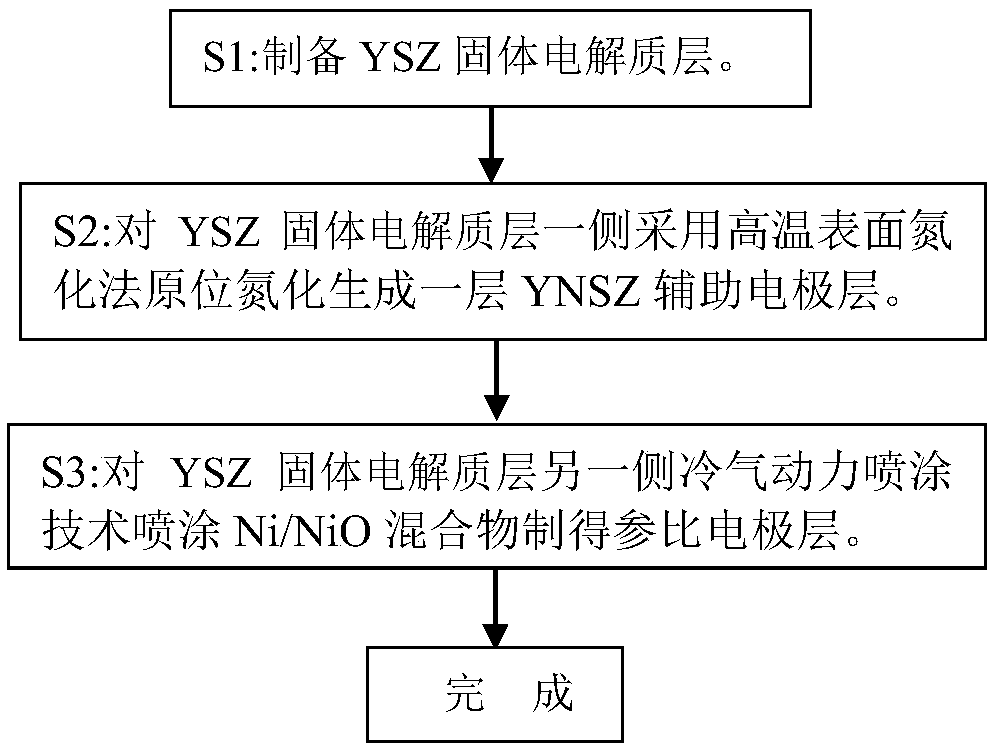

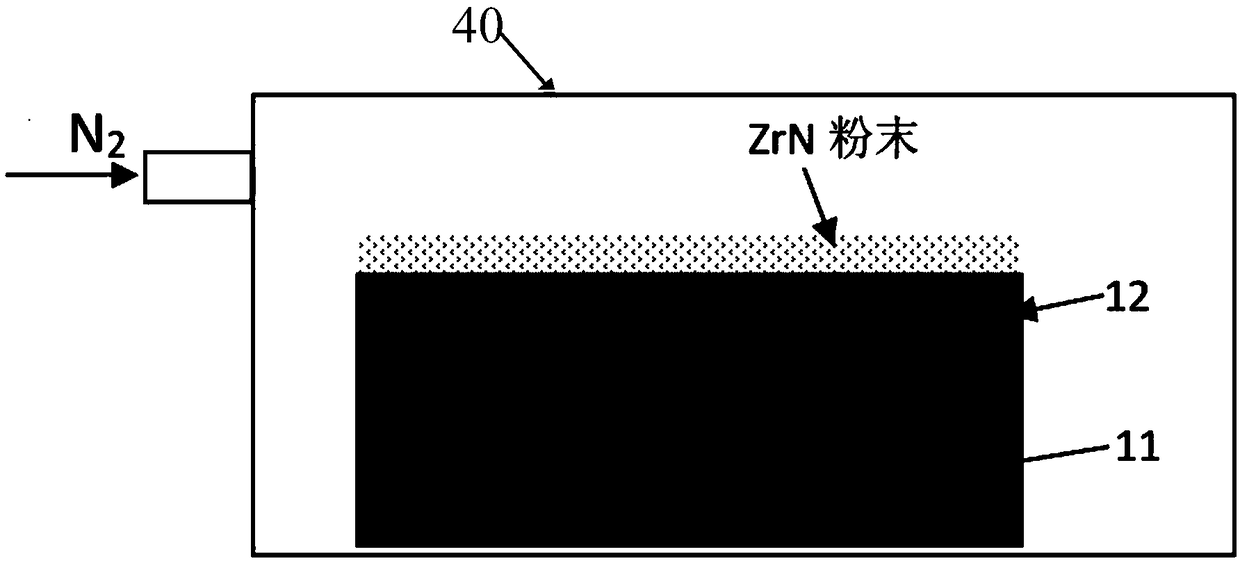

Electrochemical sensor for monitoring nitrogen content, and manufacturing method for sensor

ActiveCN109239149AImprove thermal shock resistanceImprove performanceMaterial electrochemical variablesElectrochemical gas sensorOptoelectronics

The invention relates to an electrochemical sensor for monitoring the nitrogen content. The sensor comprises a solid electrolyte layer which takes Y2O3-doped zirconia (YSZ) as a matrix material, and an auxiliary electrode layer which takes nitrogen-doped Y2O3 stabilized zirconia (YNSZ) formed by replacing partial oxygen ions in the YSZ with nitrogen ions as a matrix material. The invention furtherprovides a manufacturing method for the electrochemical sensor. A high-temperature surface nitriding treatment method is used for generating the YNSZ auxiliary electrode layer with a certain thickness in situ on the surface of the prepared YSZ solid electrolyte, so that the process is rapid and simple, the YNSZ auxiliary electrode layer is compact and pore-free and is tightly and firmly combinedwith the matrix of the YSZ solid electrolyte, the compatibility is good, and the interface resistance is small; and therefore, the nitrogen content electrochemical sensor with the excellent performance can be further obtained by means of the manufacturing method.

Owner:NORTHEASTERN UNIV

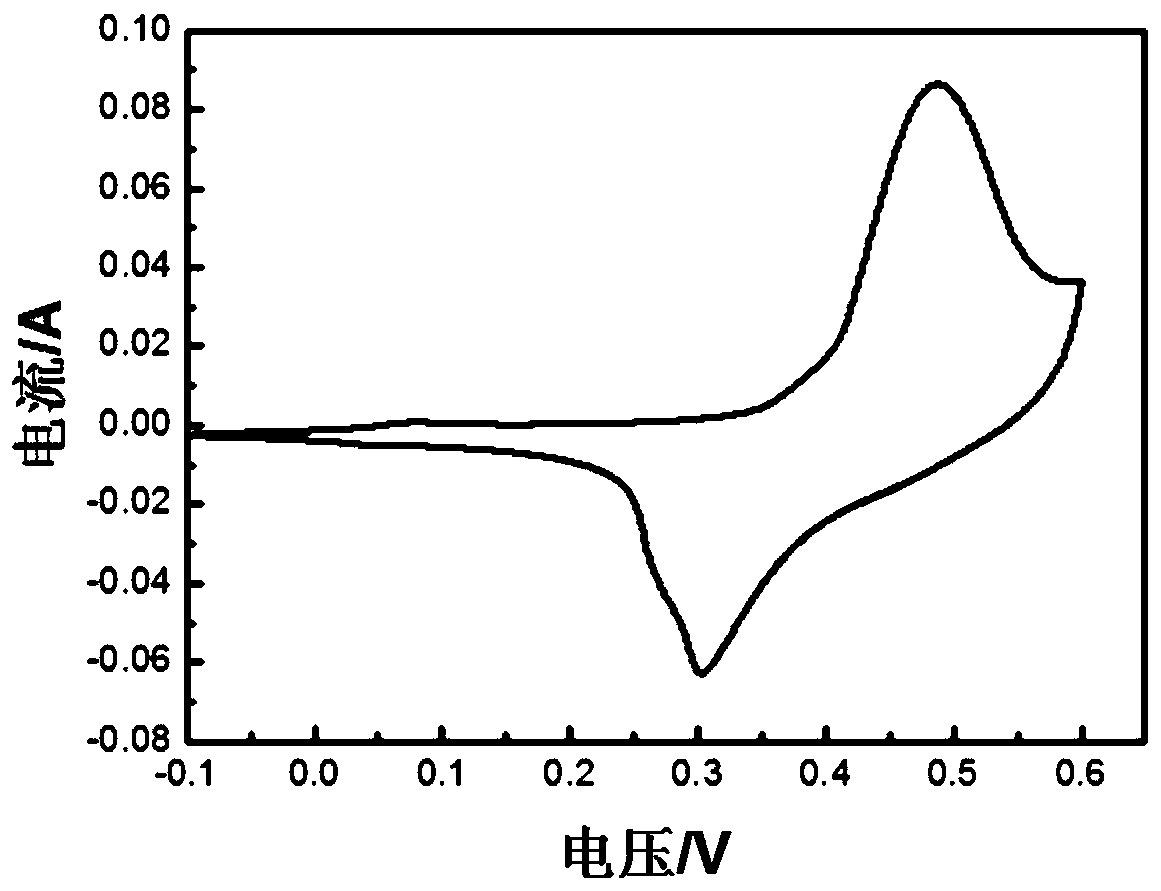

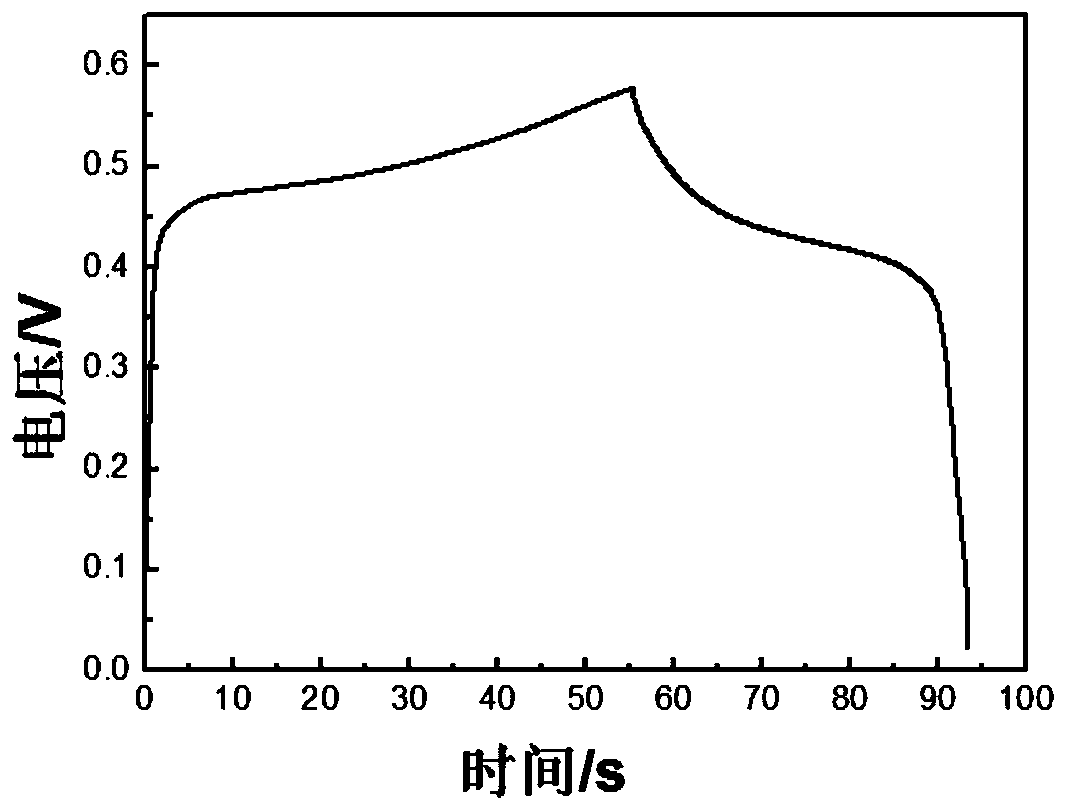

Synthesis of graphene-based three-dimensional polyaniline array nanocomposites

ActiveCN103172856BEasy transferShorten the diffusion pathElectrical resistance and conductanceIn situ polymerization

The invention discloses a synthetic method for graphene-based three-dimensional polyaniline array nanocomposite, which is different from the previously reported methods. In the synthetic method, graphene and polyaniline are connected by chemical bonds rather by physical acting force. The graphene-based three-dimensional polyaniline array is a nanocomposite with an array structure. The invention further provides a synthetic method of the nanocomposite. The synthetic method comprises the following steps: finally adding aminobenzene monomer and an oxidant under acidic conditions so as to initiate in-situ polymerization to obtain the graphene polyaniline array. Different from the graphene-based three-dimensional polyaniline composite connected through physical adsorption, the nanocomposite has the advantages of being good in thermal stability, small in resistance, good in electric chemical property and the like.

Owner:JIANGXI NORMAL UNIV

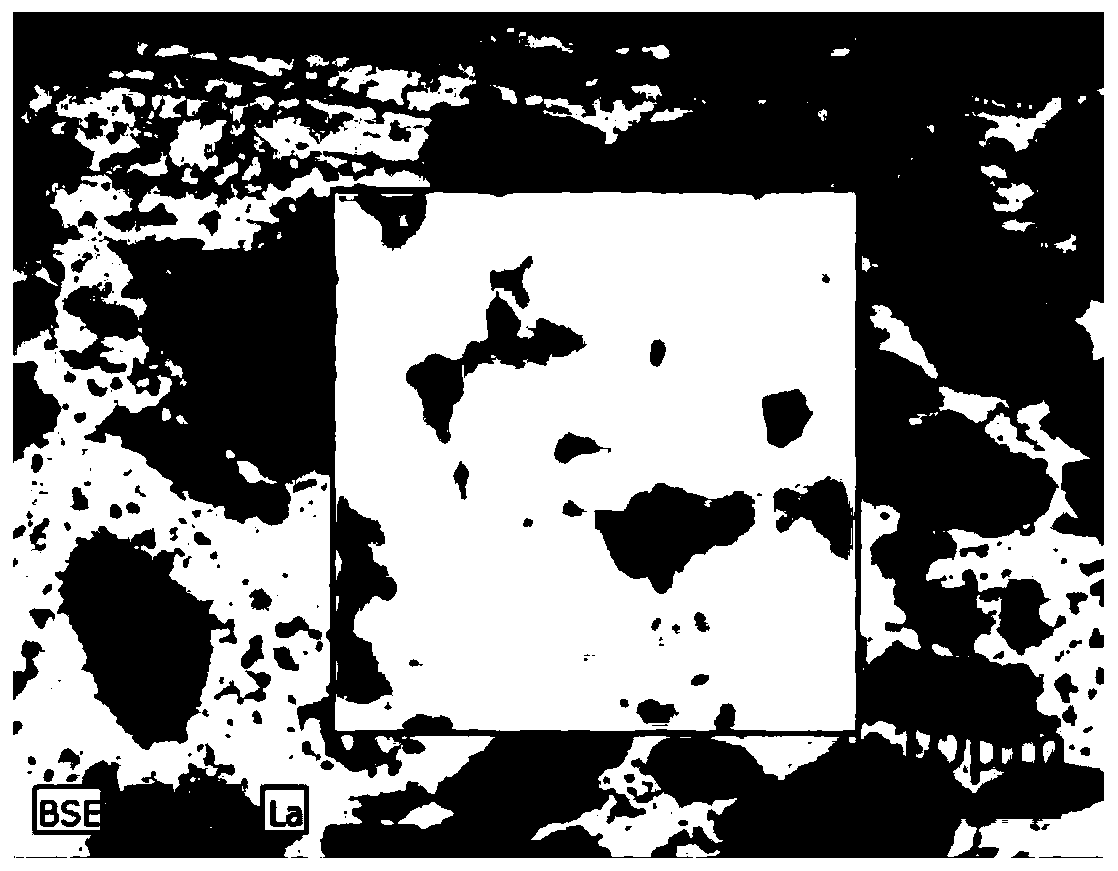

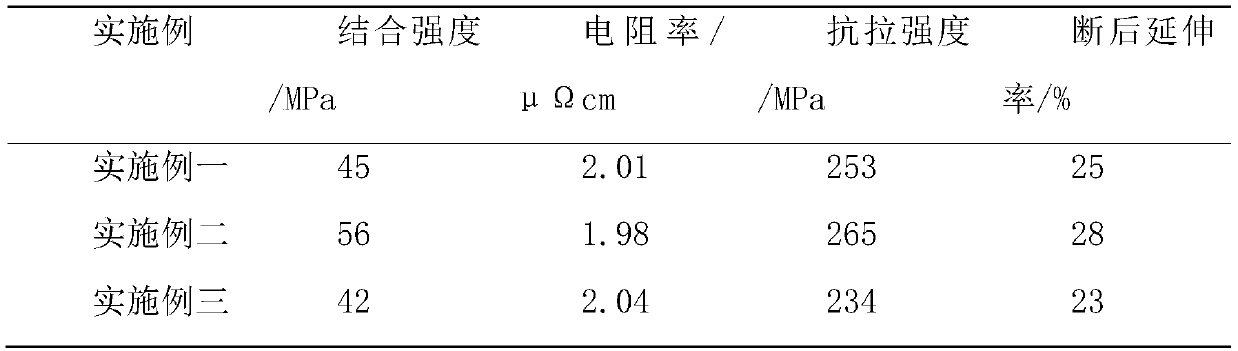

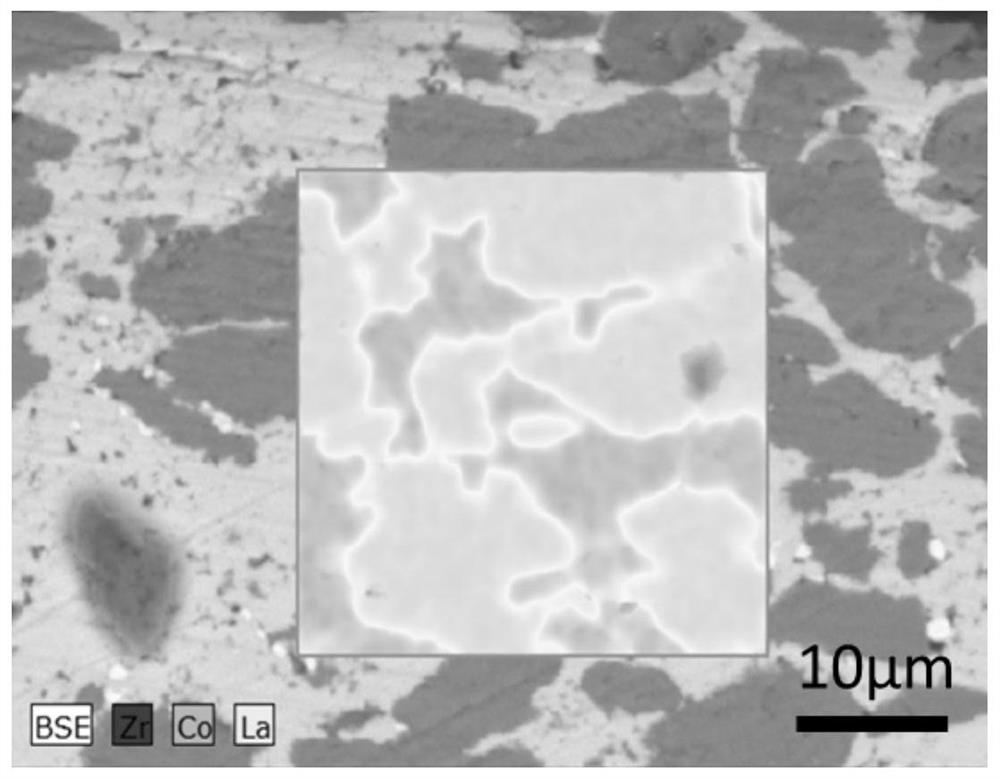

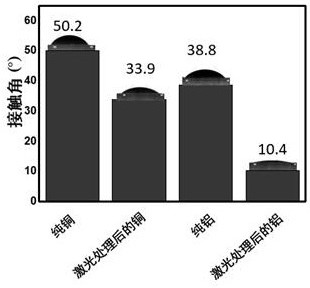

Copper-aluminum composite material and preparation method thereof

ActiveCN111424274AAchieve interlockReduce interfacial internal resistanceMaterial nanotechnologyRoll force/gap control deviceEtchingAluminum composites

The invention provides a copper-aluminum composite material and a preparation method thereof. The copper-aluminum composite material comprises a Cu metal plate and an Al metal plate which are compounded into a whole through cold rolling. Before cold rolling compounding, Cu nano sol particles are evenly sprayed to the surfaces of the metal plates, rich active sites are formed through in-situ etching, a three-dimensional rough structure is constructed on the Cu and / or Al metal surface, and the copper-aluminum composite material is formed. The method comprises the steps that the Cu nano sol particles are synthesized through a sol-gel method; the Cu nano sol particles are evenly sprayed to the surfaces of the Cu and / or Al metal plates, rich active sites are formed through in-situ etching, thethree-dimensional rough structure is constructed on the Cu and / or Al metal surface, and the Cu and / or Al metal plates with the surfaces subjected to in-situ activation etching are obtained; and then the Cu and Al metal plates with the surfaces subjected to in-situ activation etching are subjected to cold rolling compounding solid state connection, and the copper-aluminum composite material is obtained. The copper-aluminum composite material and the preparation method thereof are simple in process, high in production efficiency and low in manufacturing cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

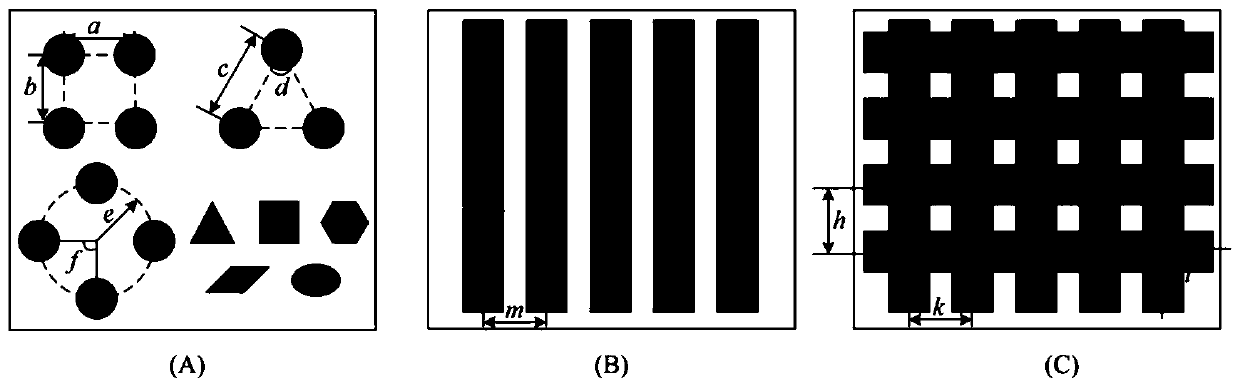

Lithium ion battery electrode and preparation method thereof and lithium ion battery

ActiveCN111710833AIncrease roughnessIncrease contact areaElectrode carriers/collectorsSecondary cellsInterface impedanceInternal resistance

The invention provides a lithium ion battery electrode and a preparation method thereof and a lithium ion battery. The preparation method of the lithium ion battery electrode comprises the following steps: carrying out pattern engraving treatment on the surface of a current collector by adopting a laser device; spraying an electrode material slurry on the surface of the current collector subjectedto pattern engraving treatment; and drying the current collector sprayed with the electrode material slurry to obtain the lithium ion battery electrode, wherein in the step 1, when the laser device is adopted to perform pattern engraving treatment on the surface of the current collector, an included angle between the laser head of the laser device and the surface of the current collector is 30-60degrees. According to the invention, laser treatment enables a current collector to generate a groove forming an angle with the surface of the current collector, and an electrode material can be fully embedded into the designed groove, so that the electrode material is difficult to fall off from the surface of the current collector; and according to the electrode prepared by the method, the contact area of the current collector and the electrode material is greatly increased, the resistance interface impedance is reduced, and the assembled battery is low in interface internal resistance and high in cycling stability.

Owner:HUNAN UNIV

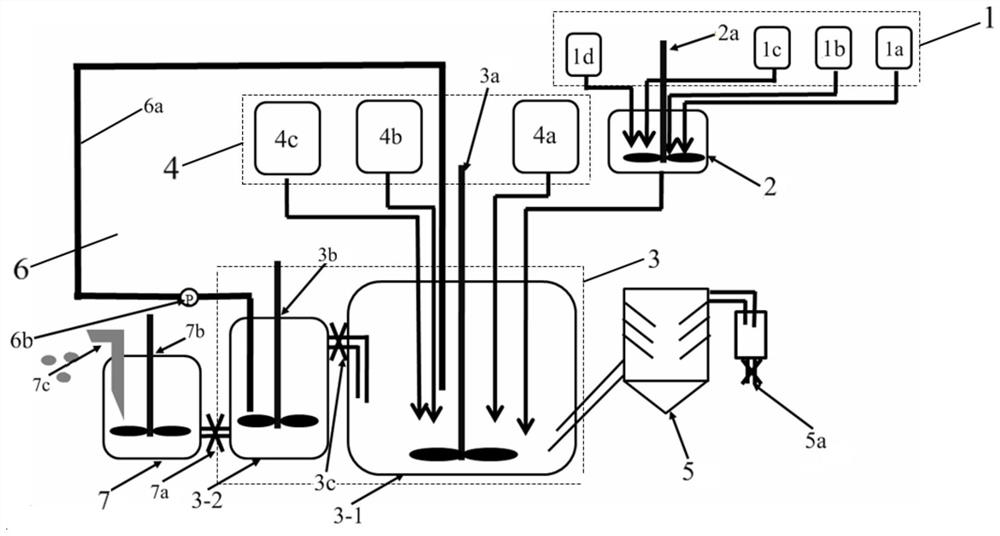

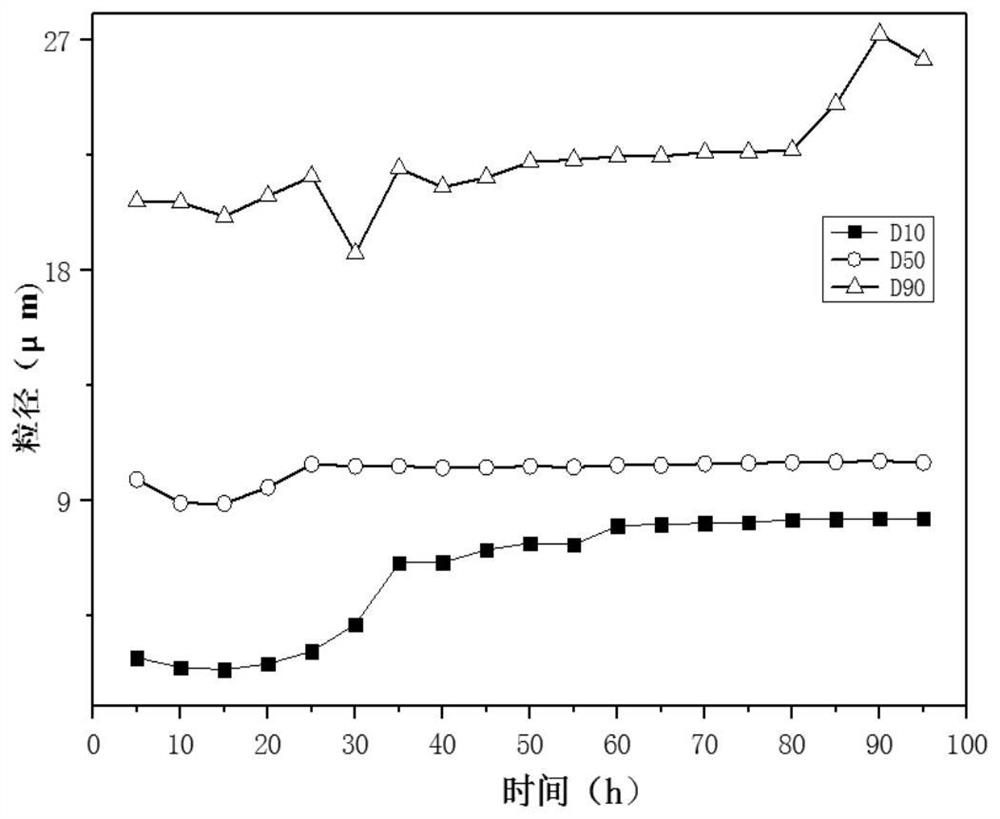

Multistage reaction system, lithium ion multi-element positive electrode material precursor, preparation method of lithium ion multi-element positive electrode material precursor and preparation method of lithium ion multi-element positive electrode material

ActiveCN112209451AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsChemical physicsElectrical battery

The invention provides a multistage reaction system, a lithium ion multi-element positive electrode material precursor, a preparation method of the lithium ion multi-element positive electrode material precursor and a preparation method of a lithium ion multi-element positive electrode material. According to the multi-stage reaction system provided by the invention, two stages of reaction kettlesare arranged, a circulating device is arranged between the two stages of reaction kettles, the multi-element positive electrode material precursor prepared by the system and the preparation method iscontrollable and uniform in particle size, regular in morphology and high in tap density, and the structural stability of the positive electrode material can be improved; the primary particle interlayer spacing of the positive electrode material precursor is reduced, the specific surface area of the material is increased, and the tap density of the material is improved; and meanwhile, the processreduces the interface internal resistance of the positive electrode material in the circulation process, so that the electrochemical performance, especially the circulation performance and the rate capability, of the material are improved, the energy density of the lithium ion battery is improved, and the process is suitable for industrial batch production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

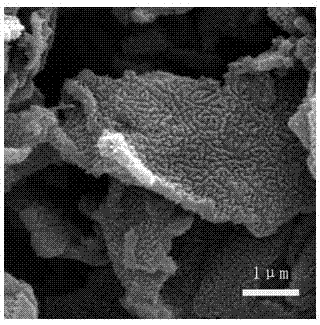

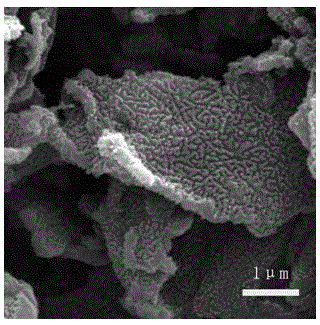

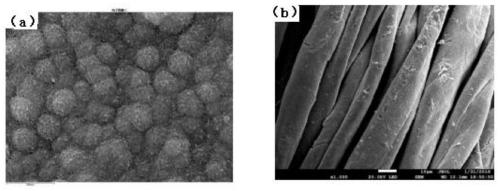

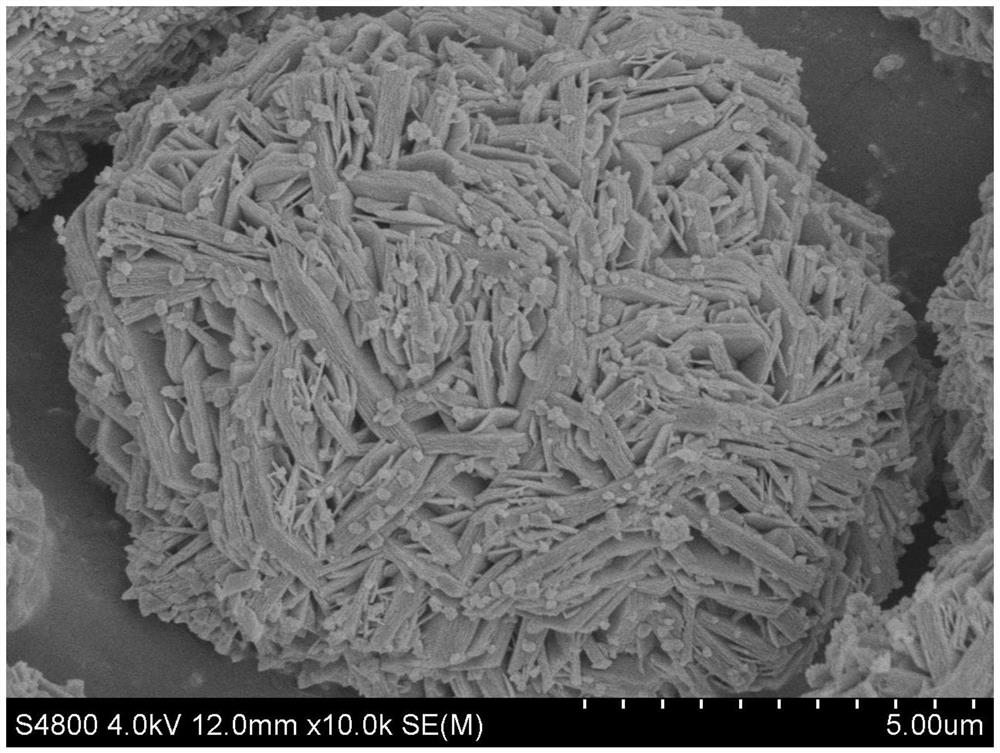

A kind of preparation method and application of nickel cloth current collector

ActiveCN108400339BSimplify operating proceduresLow costElectrode carriers/collectorsSecondary cellsFiberCapacitance

The invention relates to fabrication method and application of a nickel-fabric current collector, and belongs to the technical field of a flexible current collector. The fabrication method comprises the steps of taking gauze as a substrate, and sequentially performing roughing, sensitization, activation, reduction, chemical nickel plating and post-treatment process on the substrate so that a metalconductive nickel layer is uniformly coated on fiber of the substrate and the nickel-fabric current collector is fabricated. The pure-cotton absorbent gauze is sensitized and activated by a one-stepmethod, the operation program can be greatly simplified, and the qualified rate of a product is improved; a normal-temperature alkali chemical plating liquid is employed, the problem of plating liquidwaste caused by instability of the plating liquid under a high-temperature condition is prevented, the maintenance of a solution is facilitated, and operation is facilitated; and moreover, a lithiumion battery and a supercapacitor which are fabricated by employing the nickel-fabric current collector have the advantages of small interface internal resistance, high energy density and high pseudo capacitance, the production efficiency of the battery is greatly improved, the production cost is reduced, and the fabrication method is suitable for industrial production on a large scale.

Owner:HUBEI UNIV

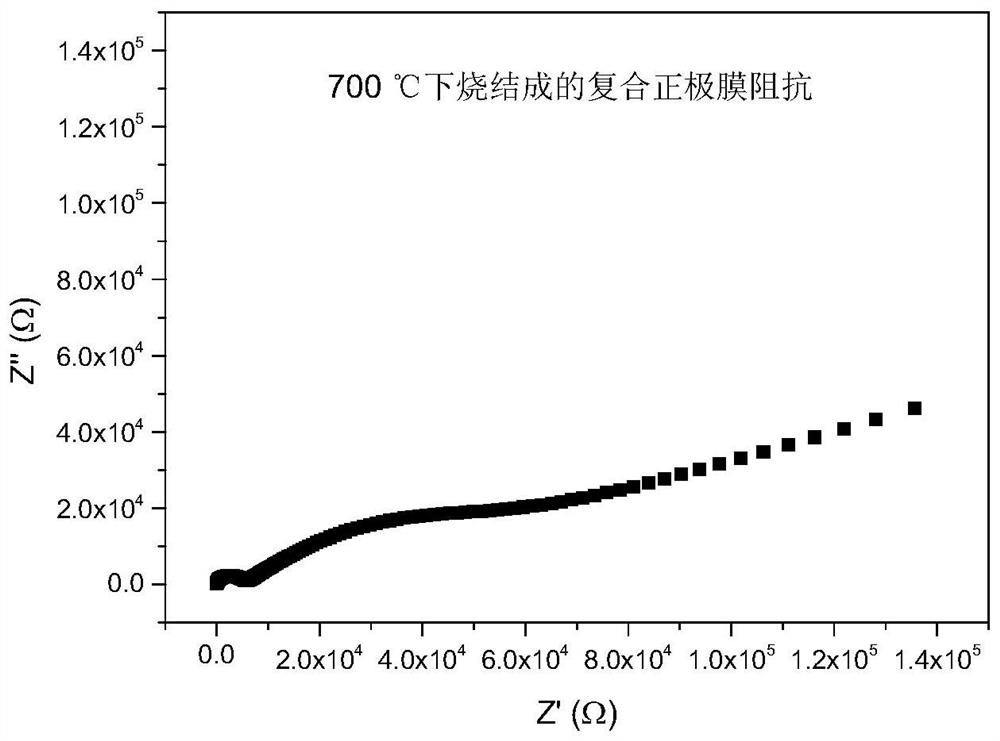

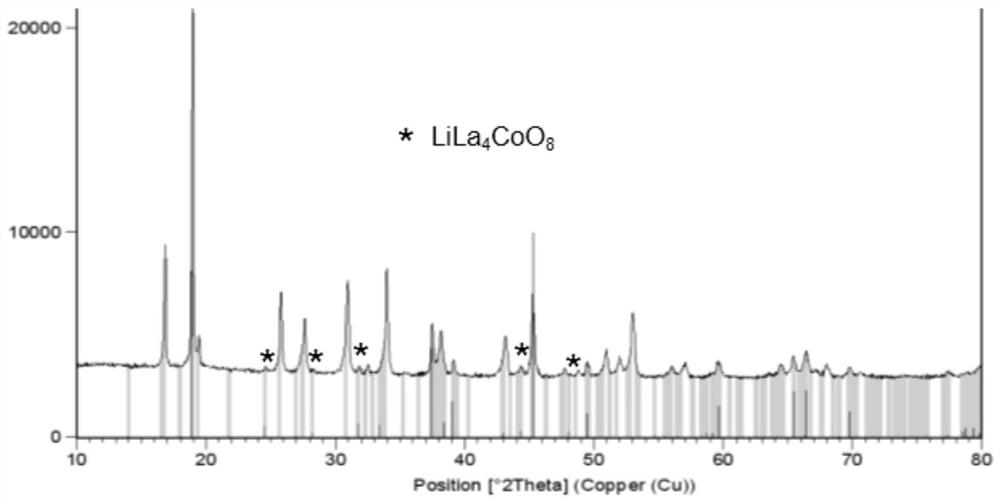

A kind of preparation method of solid-state lithium battery composite positive electrode film

ActiveCN109860550BImprove compactnessReduce interfacial internal resistanceElectrode manufacturing processesLi-accumulatorsSolid state electrolyteInterface impedance

The present invention relates to a preparation method of a solid state lithium battery composite cathode film, belonging to the technical field of battery cathode materials. In order to solve the problems that sintering aids are required being added and the internal resistance of the interface is high in the prior art, the present invention provides a preparation method of a solid state lithium battery composite cathode film. The method comprises the steps of: performing uniform mixing and ball milling of active cathode particles and LLZO solid electrolyte particles in proportion, then dryingthe mixture to obtain composite cathode powder body particles, wherein the mass content of the LLZO solid electrolyte particles in the composite cathode powder body particles is 5.0-35wt%; mixing thecomposite cathode particles, a binder, adhesives, a dispersing agent, a plasticizer and a solvent to form a composite cathode slurry; and performing tape casting of the composite cathode slurry to prepare a composite cathode blank film, performing drying and rubber discharging of the composite cathode blank film, and performing low-temperature sintering processing at a temperature of 650-850 DEG Cto obtain a composite cathode film. The preparation method of the solid state lithium battery composite cathode film can effectively improve the interface densification, can reduce the interface impedance and can reduce the interface charge transfer resistance.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

Graphene substrate and thin film lithium battery with same

PendingCN114050272AImprove conductivityHigh mechanical strengthFinal product manufactureElectrode carriers/collectorsSolid state electrolyteElectrical battery

The invention discloses a graphene substrate and a thin film lithium battery with the same. The thickness of the graphene substrate is 0.5-10 [mu]m, and the square resistance value of the graphene substrate is 0.1-2 ohm / sq. As the graphene substrate has extremely high conductivity, excellent mechanical strength and mechanical property, excellent thermal stability and super chemical stability, when the graphene substrate is applied to the thin-film lithium battery, perfect matching with a solid positive electrode material and a solid negative electrode material can be realized at the same time; therefore, the electrochemical corrosion defect of other metal collectors in the multiple charging and discharging processes of the battery can be avoided. As an excellent adhesion substrate of a solid positive electrode material and a solid negative electrode material, the graphene substrate provided by the invention can provide super-strong binding force between the positive electrode material and the negative electrode material, and does not generate any influence on normal vapor deposition of the positive electrode material, a solid electrolyte material and the negative electrode material of the thin-film lithium battery.

Owner:鄂尔多斯市紫荆创新研究院

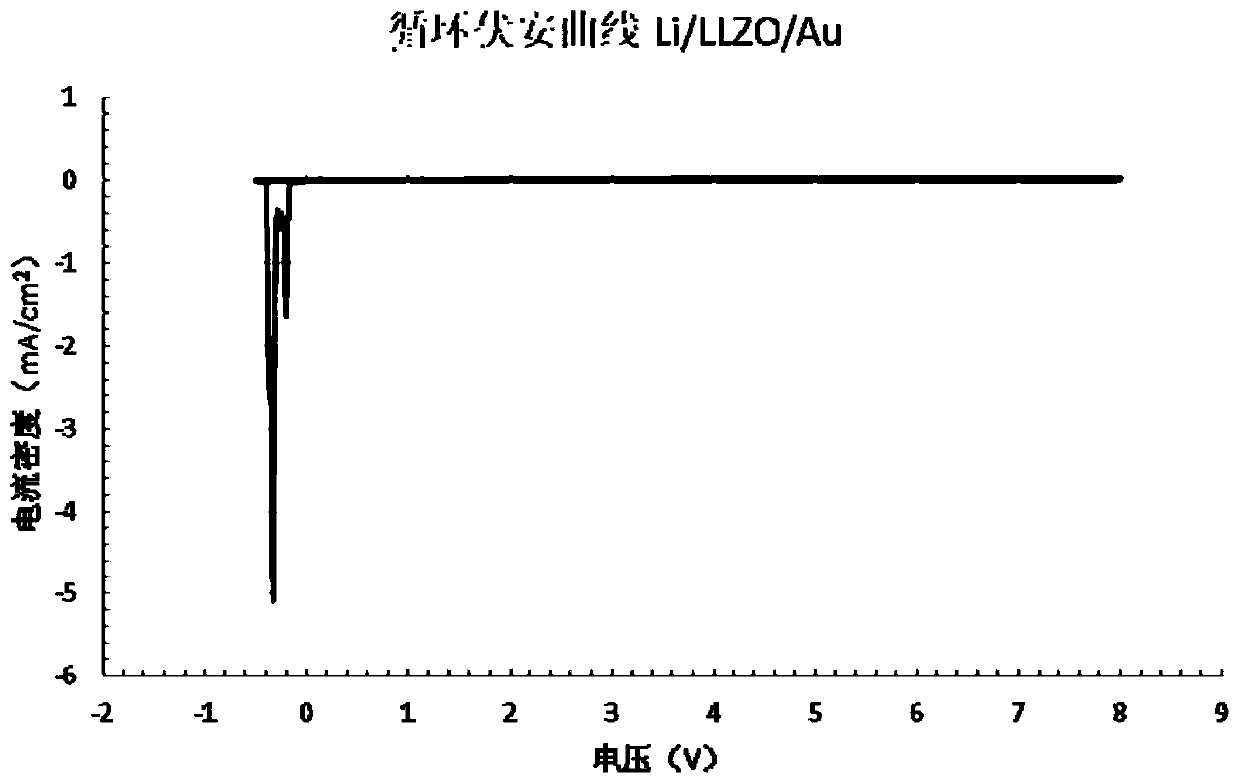

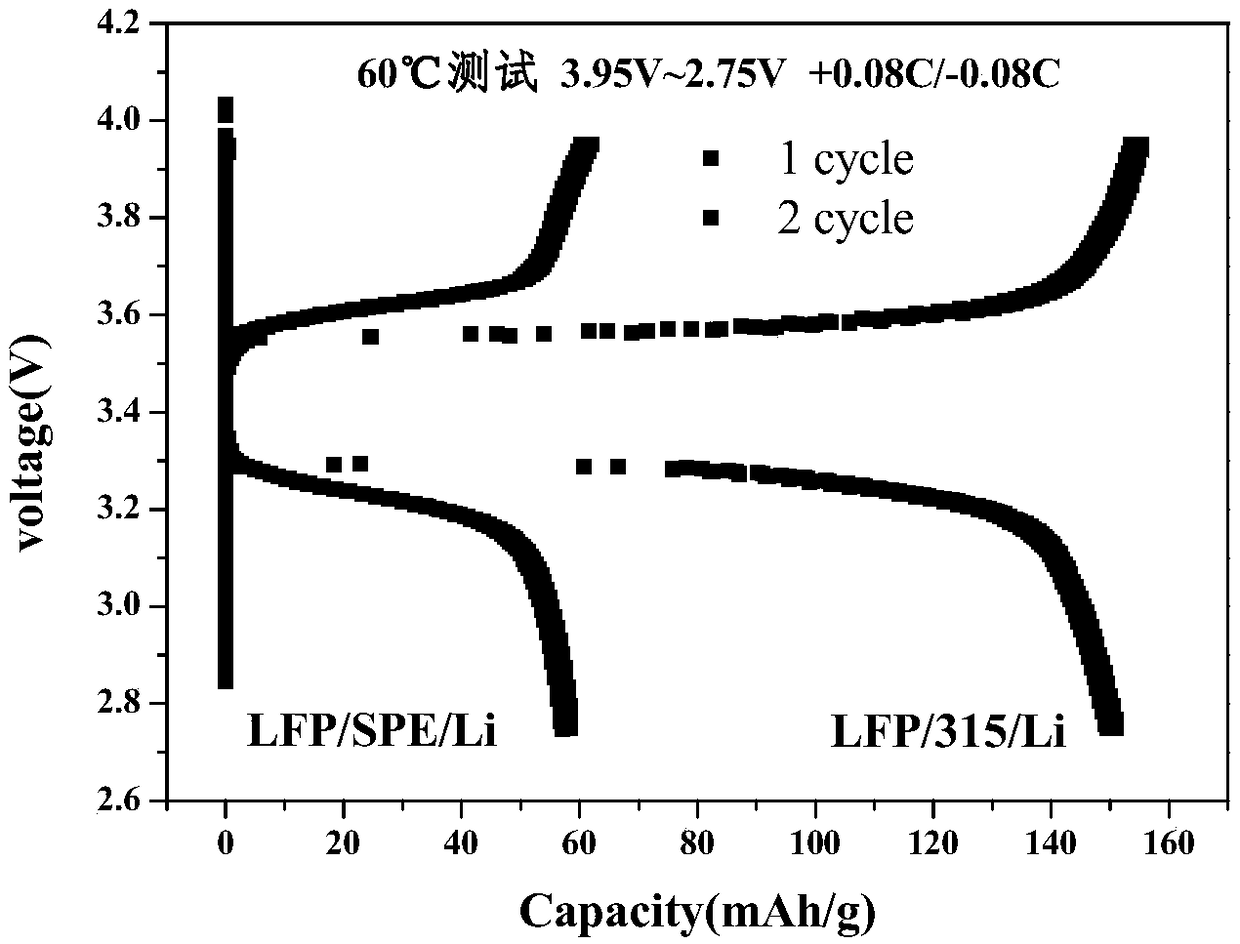

A kind of preparation method of all-solid-state battery

ActiveCN110265723BIncrease energy densityImprove cycle stabilityFinal product manufactureLi-accumulatorsSolid state electrolyteElectrical battery

An embodiment of the present invention provides a method for preparing an all-solid-state battery, which relates to the technical field of batteries. The method comprises: pressing the solid electrolyte powder into an electrolyte sheet, mixing lithium cobaltate, polyvinylidene fluoride, carbon nanotubes and N-methyl-2-pyrrolidone in a mass ratio of 40:9:8:6, and configuring the Mixed solution, the mixed solution according to 0.1mg / cm 2 The amount of the electrolyte sheet was dropped on the surface of the electrolyte sheet, dried, sprayed gold on the surface of the electrolyte sheet, and sintered at 700°C for 0.5h to obtain the target electrolyte sheet, and assembled the battery with the target electrolyte sheet. By covering the cathode material gold film on the surface of the electrolyte, and then heat treatment, the contact gap between the active material and the electrolyte in the assembled battery can be greatly reduced, and the discharge of organic matter in the battery can reduce the internal resistance of the interface and avoid falling off. problems, improving the energy density and cycle stability of all-solid-state batteries.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of composite negative electrode of lithium battery

ActiveCN113809390AImprove interface compatibilityHigh mechanical strengthSolid electrolytesFinal product manufactureMetallic lithiumSolid state electrolyte

The invention discloses a preparation method of a composite negative electrode of a lithium battery. The preparation method comprises the following steps: S1, preparing an inorganic solid electrolyte through an electrostatic spinning method; S2, compounding zinc oxide, an organic solid electrolyte and a lithium salt to the surface of the inorganic solid electrolyte through a solution casting method to obtain a composite solid electrolyte; and S3, casting metal lithium in a molten state on one side of the composite solid electrolyte, and performing cold press molding to obtain the composite solid electrolyte-metal lithium composite negative electrode. The lithium battery negative electrode prepared by the invention has good conductivity and good flexibility.

Owner:福建巨电新能源股份有限公司

A kind of lithium ion battery comprising graphene/cellulose composite material and preparation method thereof

ActiveCN108933236BEasy to prepareMild reaction conditionsCell electrodesSecondary cellsElectrical batteryGraphite

Owner:BEIJING NORMAL UNIVERSITY

A kind of lithium ion battery electrode and preparation method thereof, lithium ion battery

ActiveCN111710833BIncrease roughnessIncrease contact areaElectrode carriers/collectorsSecondary cellsInterface impedanceInternal resistance

The invention provides a lithium ion battery electrode and a preparation method thereof and a lithium ion battery. The preparation method of the lithium ion battery electrode comprises the following steps: carrying out pattern engraving treatment on the surface of a current collector by adopting a laser device; spraying an electrode material slurry on the surface of the current collector subjectedto pattern engraving treatment; and drying the current collector sprayed with the electrode material slurry to obtain the lithium ion battery electrode, wherein in the step 1, when the laser device is adopted to perform pattern engraving treatment on the surface of the current collector, an included angle between the laser head of the laser device and the surface of the current collector is 30-60degrees. According to the invention, laser treatment enables a current collector to generate a groove forming an angle with the surface of the current collector, and an electrode material can be fully embedded into the designed groove, so that the electrode material is difficult to fall off from the surface of the current collector; and according to the electrode prepared by the method, the contact area of the current collector and the electrode material is greatly increased, the resistance interface impedance is reduced, and the assembled battery is low in interface internal resistance and high in cycling stability.

Owner:HUNAN UNIV

A kind of copper-aluminum composite material and preparation method thereof

ActiveCN111424274BAchieve interlockReduce interfacial internal resistanceMaterial nanotechnologyRoll force/gap control deviceEtchingAluminum composites

The invention provides a copper-aluminum composite material and a preparation method thereof, comprising a Cu metal plate and an Al metal plate, the two are combined into one body through cold rolling, and before the cold rolling and compounding, Cu nano-sol is uniformly sprayed on the surface of the metal plate Particles are etched in situ to form abundant active sites, and a three-dimensional rough structure is constructed on the surface of Cu and / or Al metal to form a copper-aluminum composite material. The method comprises synthesizing Cu nano sol particles by a sol-gel method; uniformly spraying the Cu nano sol particles onto the surface of Cu and / or Al metal sheets, forming abundant active sites through in-situ etching, and forming a rich active site on the Cu and / or Al metal surface Construct a three-dimensional rough structure to obtain Cu and / or Al metal sheets with in-situ active etching on the surface; then connect the Cu and Al metal sheets after in-situ active etching on the surface to obtain copper-aluminum composite through cold rolling composite solid-state connection Material. The invention has the advantages of simple process, high production efficiency and low production cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

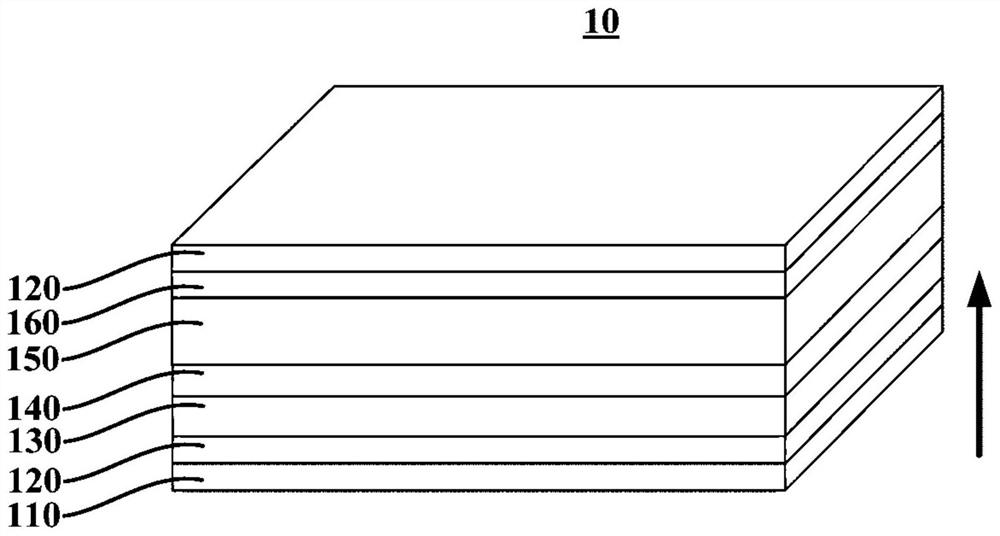

Composite positive electrode for solid-state battery and preparation method thereof

ActiveCN109119591BIncrease capacityImprove securityNon-aqueous electrolyte accumulator electrodesSolid state electrolyteElectrical battery

The invention relates to a composite positive electrode for a solid-state battery. The composite positive electrode includes a composite positive electrode sheet and an electrolyte membrane formed by coating the composite positive electrode sheet with a solid electrolyte slurry. The composite positive electrode sheet is formed by coating the composite positive electrode slurry on the positive electrode current collector. , the solid electrolyte slurry includes a polymer and lithium salt with a mass ratio of 1 to 5:1; the composite positive electrode slurry includes a positive electrode active material with a mass ratio of 250 to 350:5 to 35:5 to 35:1 to 5:1 , conductive agents, binders, polymers and lithium salts. The invention effectively reduces the interface internal resistance, improves the interface impedance, and reduces the ion transmission distance, thereby increasing the capacity of the solid-state battery, effectively increasing its tensile strength, thereby improving the capacity and safety performance of the solid-state battery. In addition, the solid-state battery of the present invention is used in multiple battery systems such as NCM111, NCM523, NCM622, NCM811, LFP, and LCO, and has a wide range of applications.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

A kind of cathode material precursor and preparation method thereof, cathode material and lithium ion battery

ActiveCN109994726BImproved magnification performanceUniform materialCell electrodesSecondary cellsNanoparticleInternal resistance

The present invention provides a kind of cathode material precursor, has the general formula as shown in formula (I): Ni x co y mn z Al 1‑x‑y‑z (OH) 2 (1); The positive electrode material precursor is a spherical particle composed of a positive electrode material precursor hexagonal sheet, and the positive electrode material precursor nanoparticle is compounded on the positive electrode material precursor hexagonal sheet. The present invention obtains the precursor of the ternary or quaternary positive electrode material, which consists of spherical particles composed of hexagonal sheets, and the hexagonal sheets of the precursor are also compounded with nanoparticles of the precursor. These multi-layered hexagonal sheets and the nanoparticles on the surface Spherical particles with a complete and uniform structure. Nanoparticles on the hexagonal sheet surface can effectively improve the processing performance of the positive electrode material, improve the structural stability of the positive electrode material, and improve the cycle performance of the positive electrode material. The nanoparticles on the hexagonal sheet surface also increase the material The specific surface area reduces the internal resistance during the material cycle and improves the rate performance of the material.

Owner:HUBEI JIUBANG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com