Lithium ion battery electrode and preparation method thereof and lithium ion battery

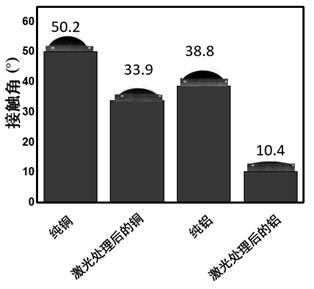

A lithium-ion battery and electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode carriers/current collectors, etc., can solve the problems of limited improvement, failure to integrate current collectors and electrode materials, etc., to reduce impedance , the effect of increasing the roughness and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: (positive electrode: laser treatment + vibration treatment)

[0038] A preparation method for a positive electrode of a lithium ion battery, specifically comprising the following steps:

[0039] Step 1: Select a commercially available aluminum foil (thickness is preferably 12 µm) as the current collector of the positive electrode of the lithium-ion battery, thoroughly clean the aluminum foil with ethanol, dry it, and press it flat with mechanical force. Among them, the purchased aluminum foil is called pure aluminum.

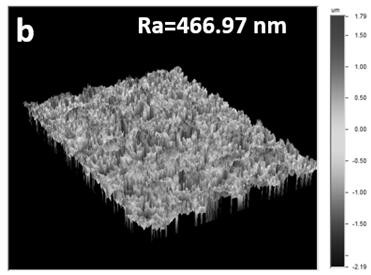

[0040] Step 2, using a laser to engrave a pattern on the surface of the current collector. Preferably, a femtosecond laser is used for laser patterning, and the specific process is: use a spherical lens (the focal length is preferably 170 mm) to focus the laser beam process into a point shape, and use a computer-controlled two-axis (x and y) array lens The composition process is executed in the system. The pattern of this example on the surf...

Embodiment 2

[0047] Example 2: (negative electrode: laser treatment + vibration treatment)

[0048]A preparation method of a lithium ion battery negative electrode, specifically comprising the following steps:

[0049] Step 1: Select a commercially available copper foil (thickness is preferably 12 µm) as the current collector of the positive electrode of the lithium-ion battery, thoroughly clean the copper foil with ethanol, dry it, and press it flat with mechanical force. Among them, the purchased copper foil is called pure copper.

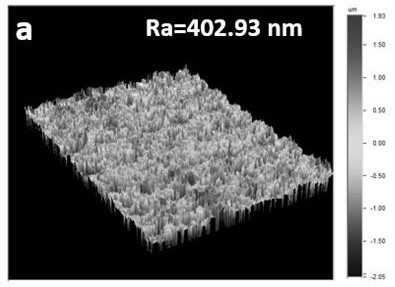

[0050] Step 2, using a laser to engrave a pattern on the surface of the current collector. Preferably, a femtosecond laser is used for laser patterning, and the specific process is: use a spherical lens (the focal length is preferably 170 mm) to focus the laser beam process into a point shape, and use a computer-controlled two-axis (x and y) array lens The composition process is executed in the system. The pattern of this example on the copper foil surface...

Embodiment 3

[0057] Example 3: (positive electrode: laser treatment only)

[0058] The difference between Example 3 and Example 1 is that only the laser is used to engrave the pattern on the surface of the aluminum foil, and the acoustic wave generator is not used for vibration treatment, and the current collector after scraping the positive electrode material is directly placed in a vacuum at 80 ° C. Dry for 24 hours to obtain the lithium ion battery positive electrode. Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com