Patents

Literature

135results about How to "Remove air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

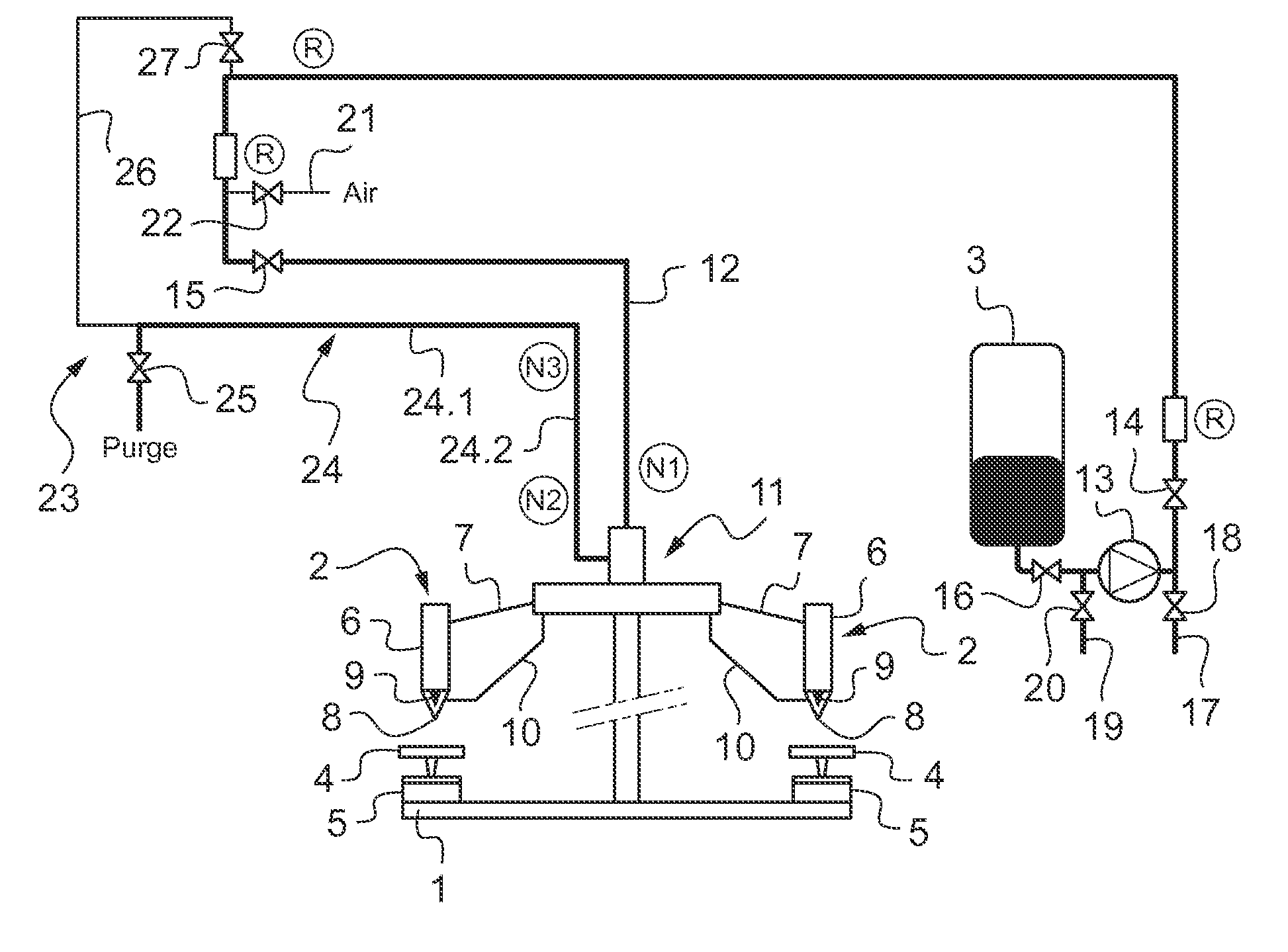

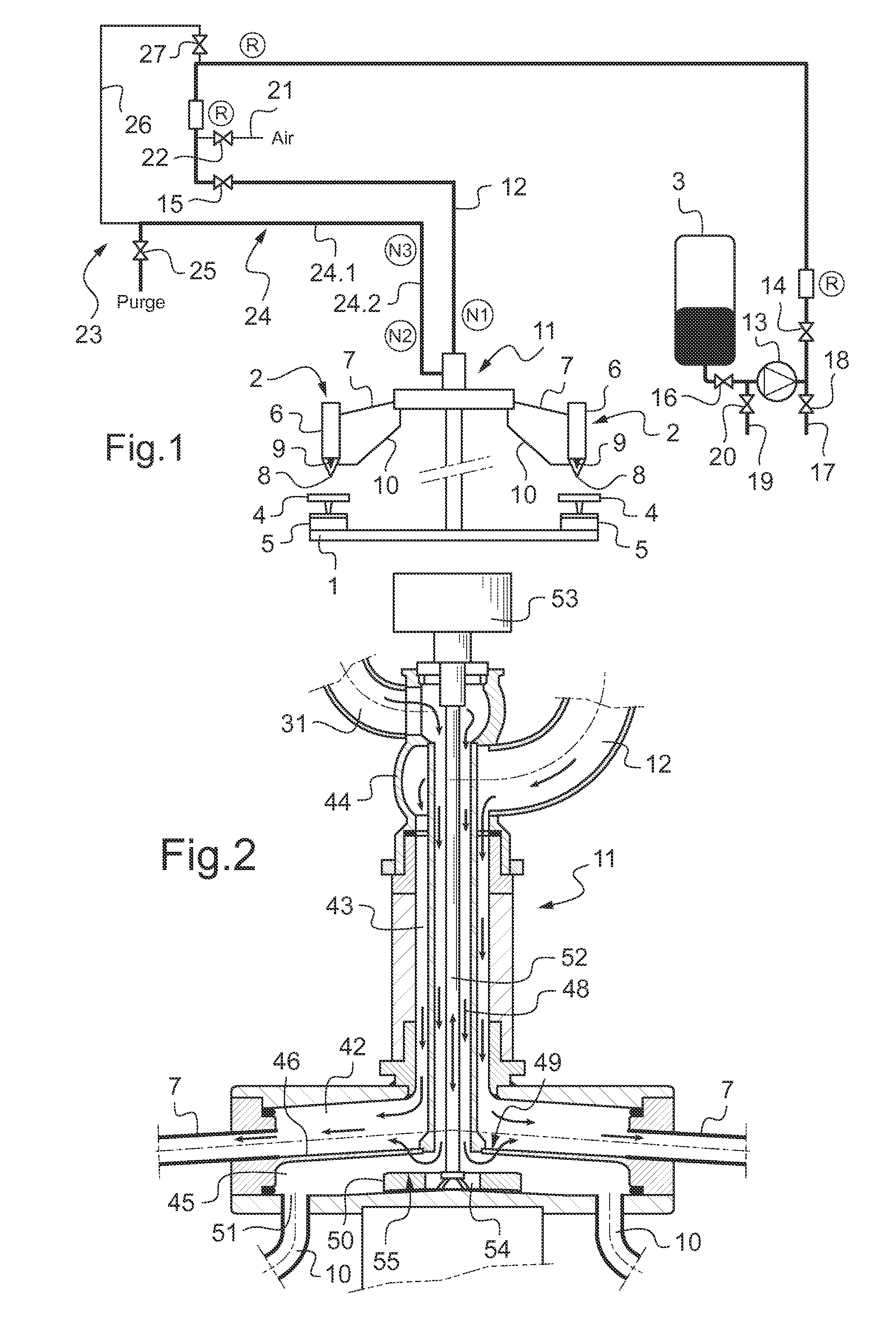

Infusion apparatus

ActiveUS20100280430A1Reduce need for interventionReduce riskMedical devicesPressure infusionEngineeringExpansion chamber

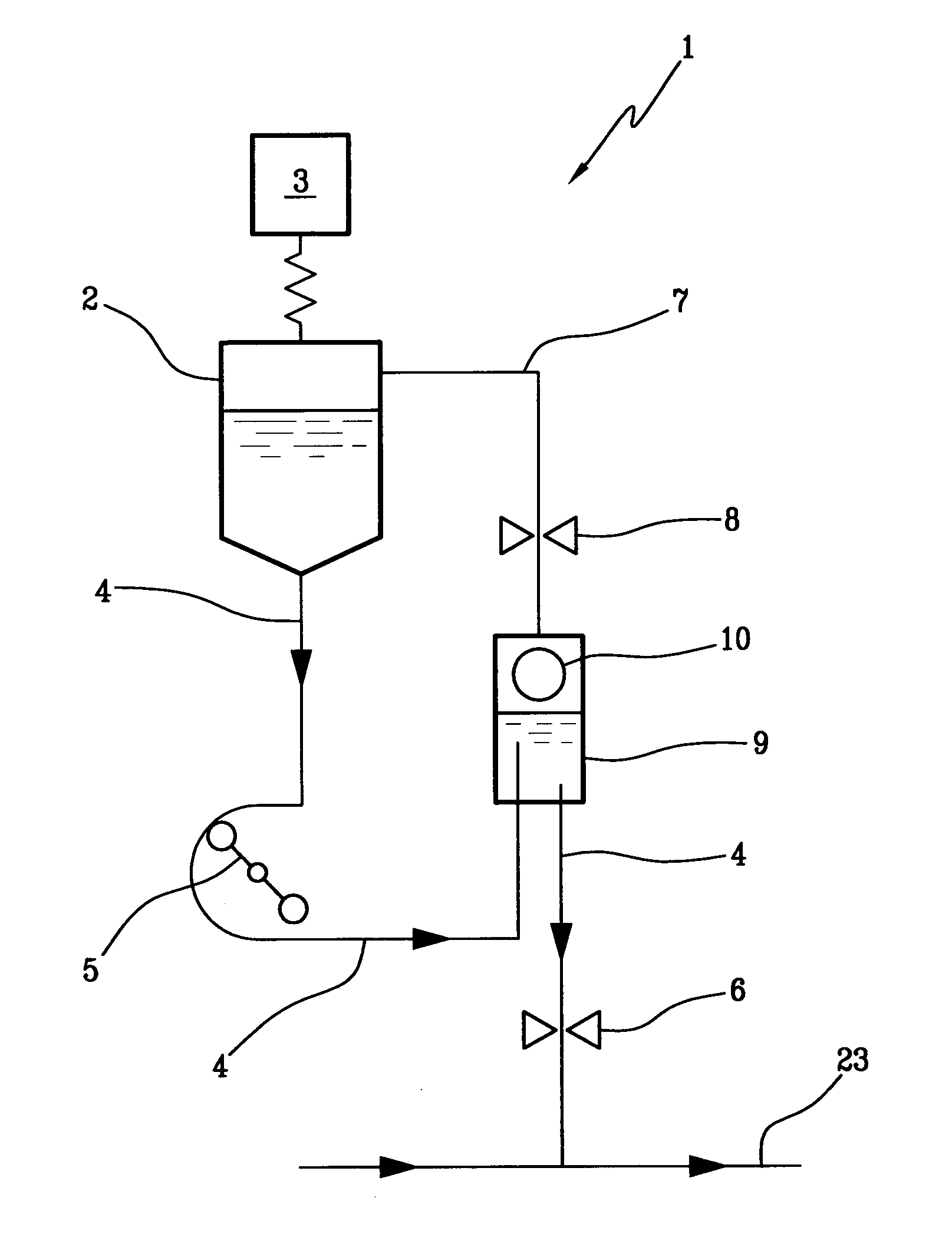

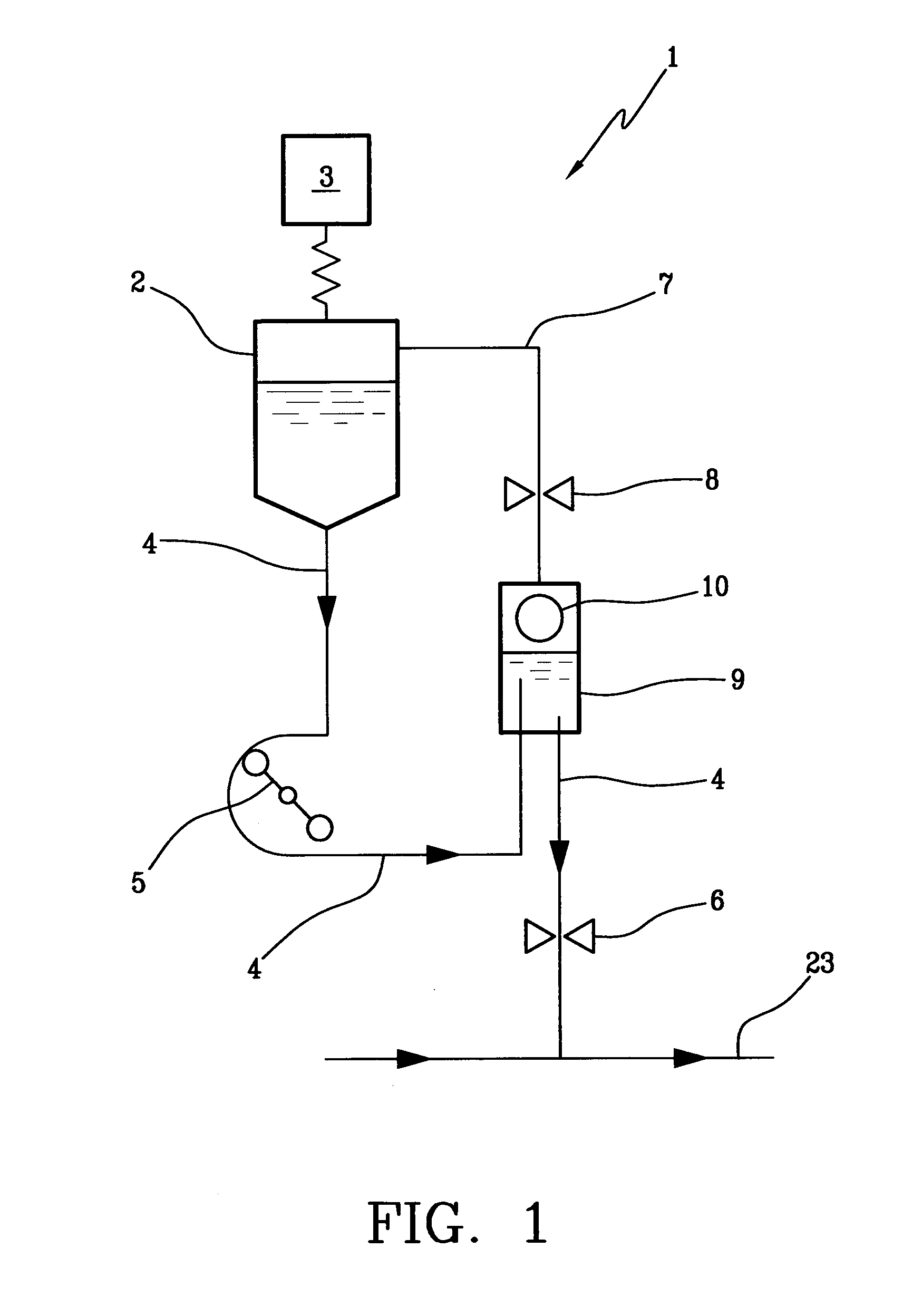

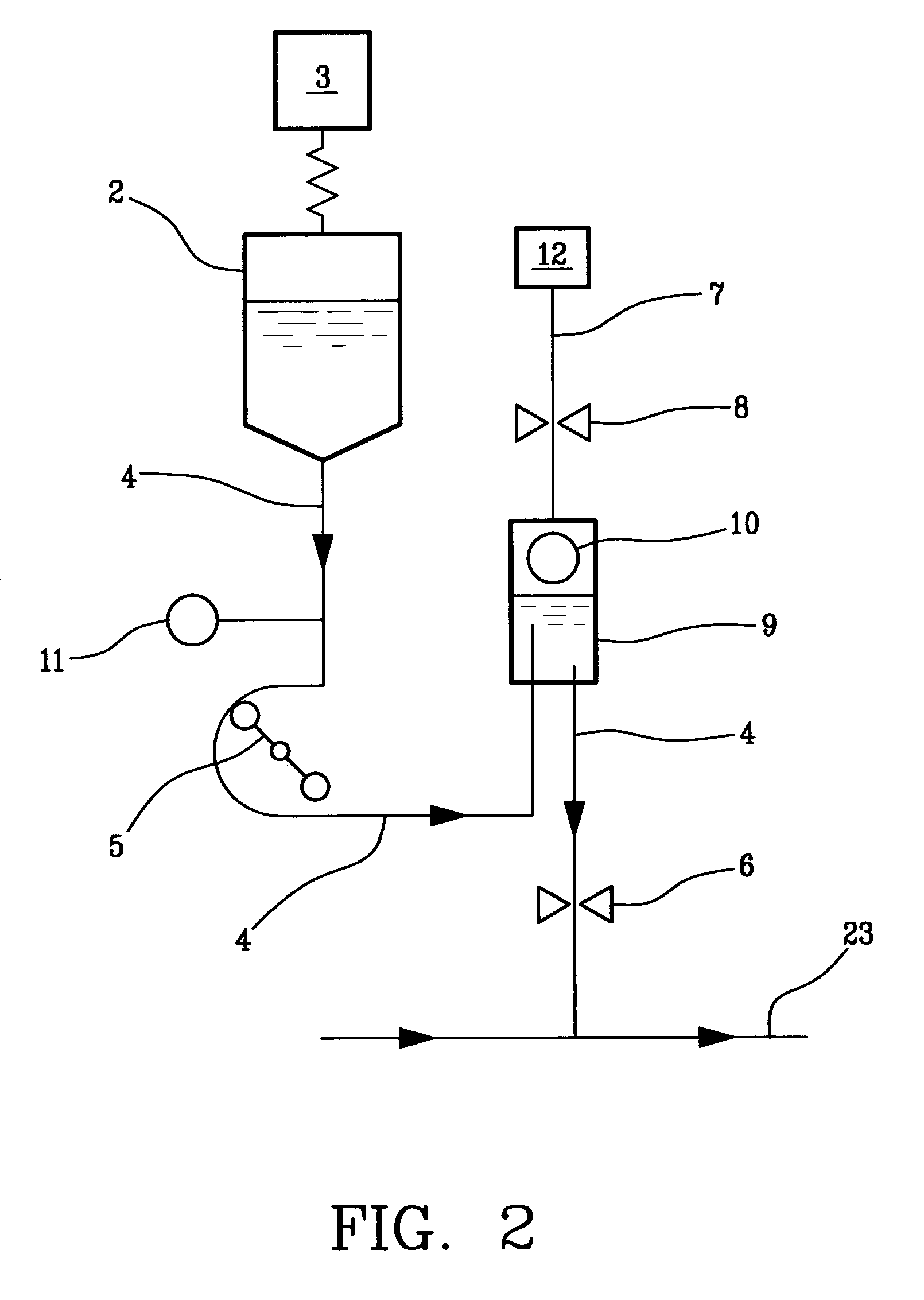

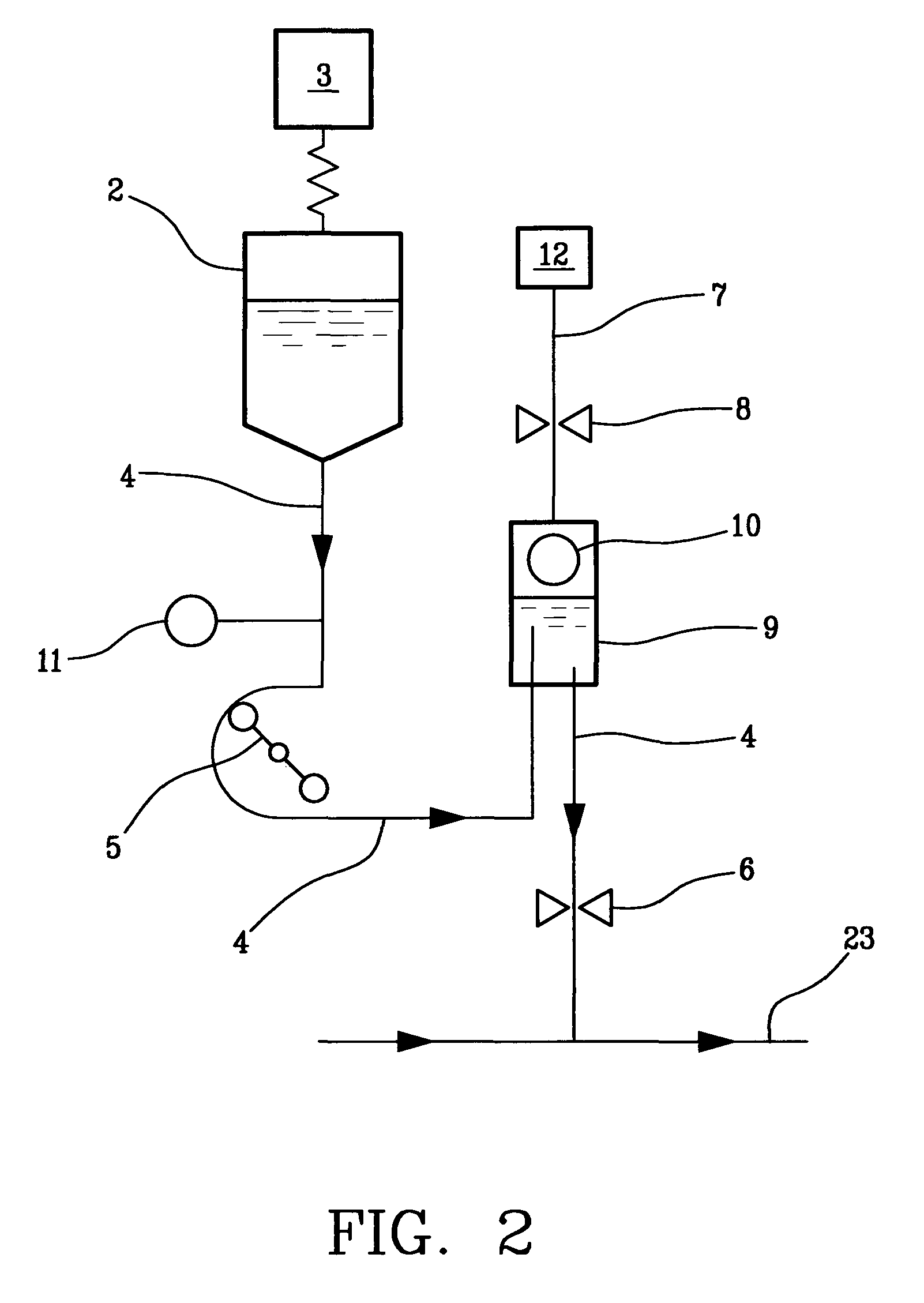

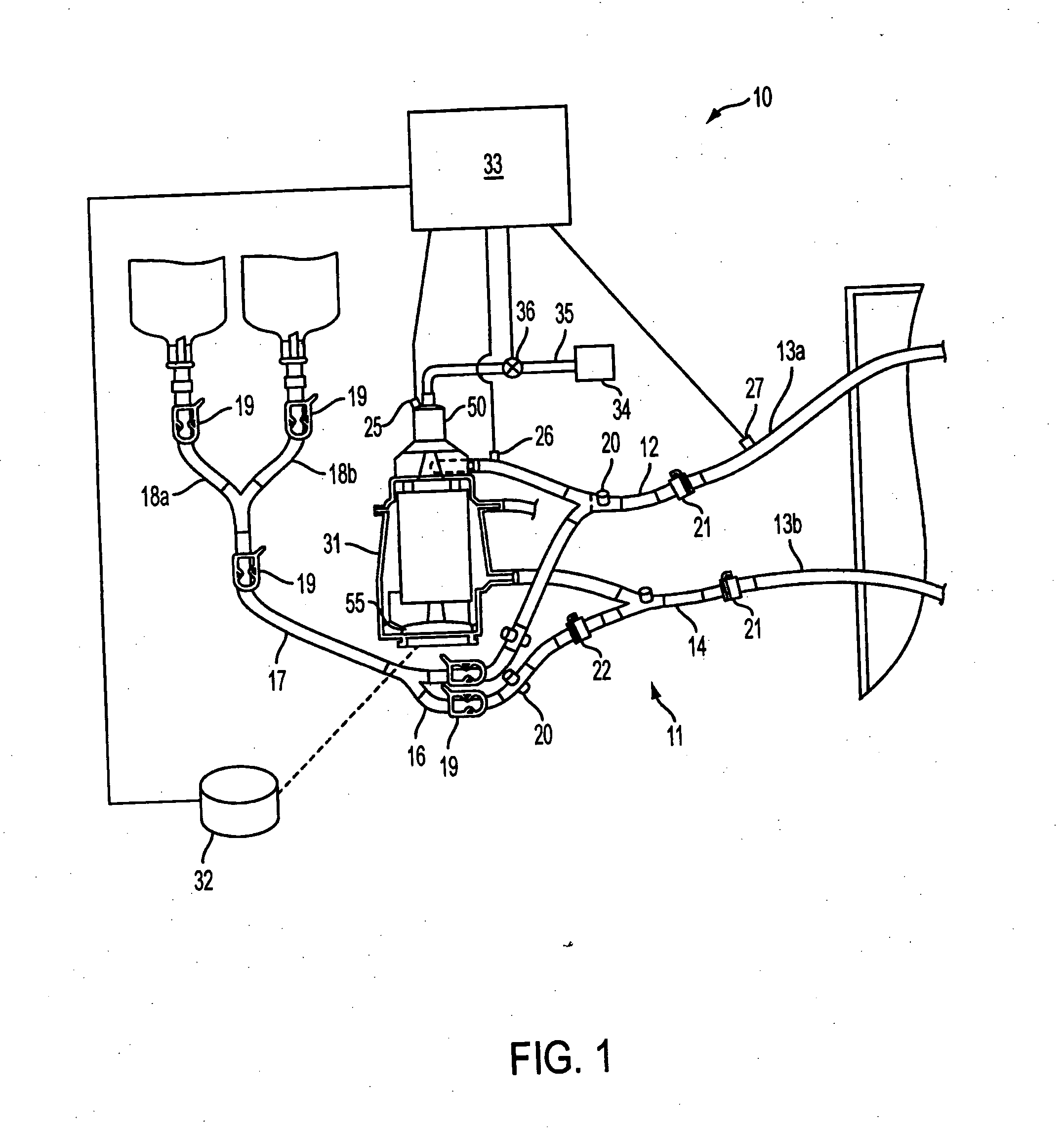

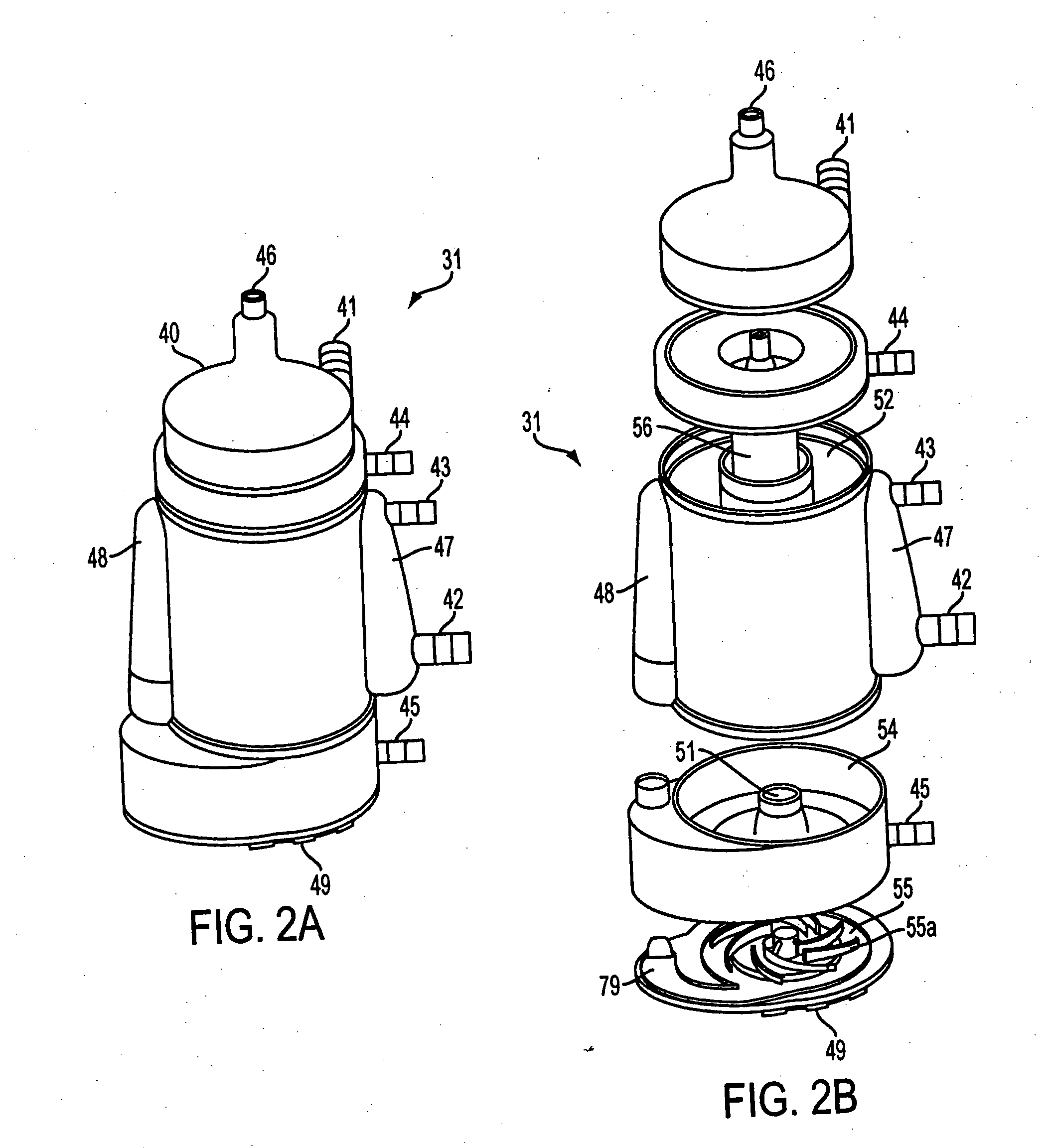

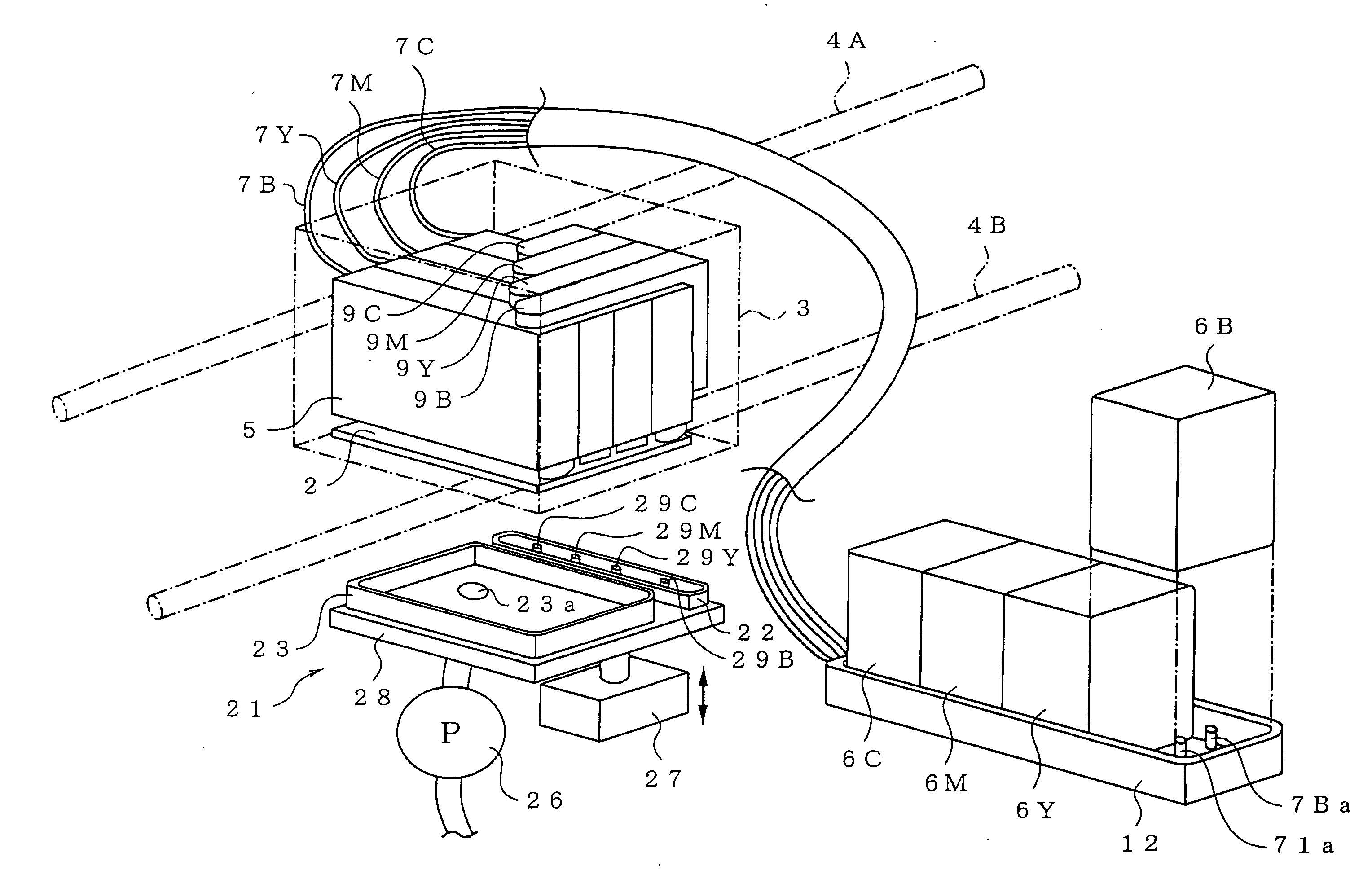

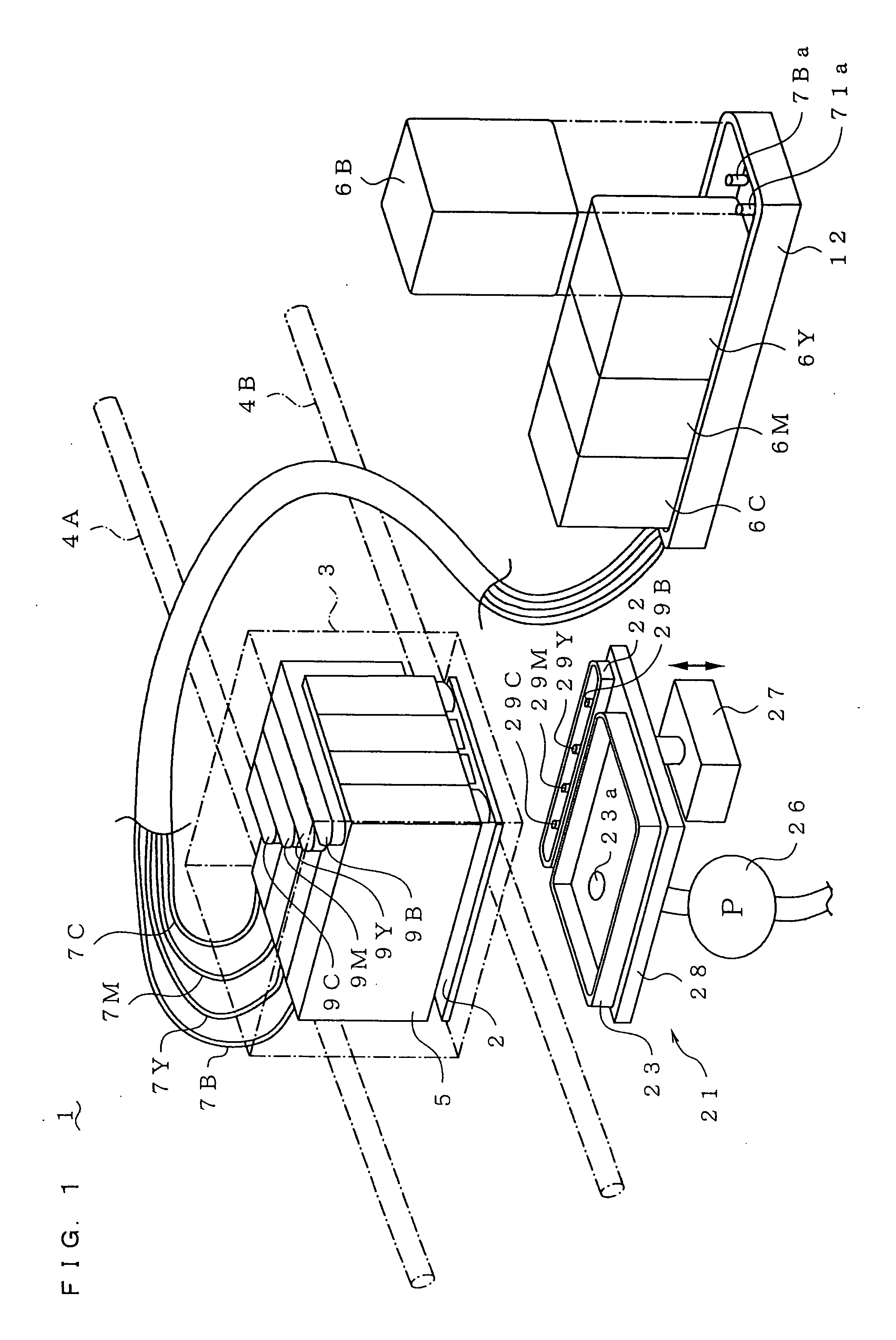

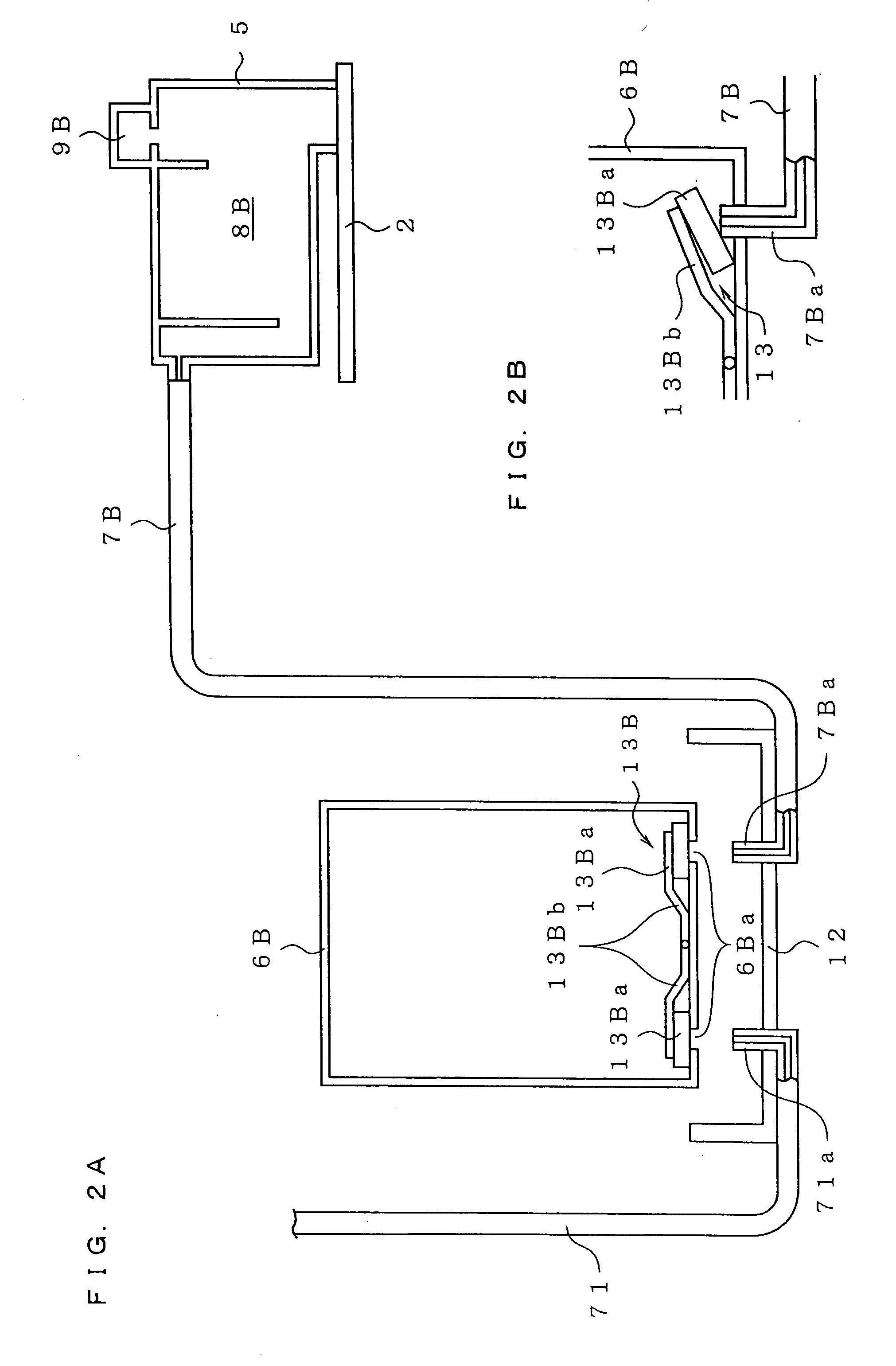

In an infusion apparatus, an infusion line (4) connects a container (2) of an infusion fluid to an extracorporeal blood circuit (23). A first valve (6) closes the infusion line downstream of an infusion pump (5). An expansion chamber (9), provided with a pressure sensor (10), is arranged between the infusion pump and the first valve. A second valve (8) closes a vent line (7) of the expansion chamber. The processor closes the first valve when the container is emptied. After replacement with a new and full container, the processor restarts the pump and selectively opens the first valve or the second valve according to the increase in pressure measured in the expansion chamber.

Owner:GAMBRO LUNDIA AB

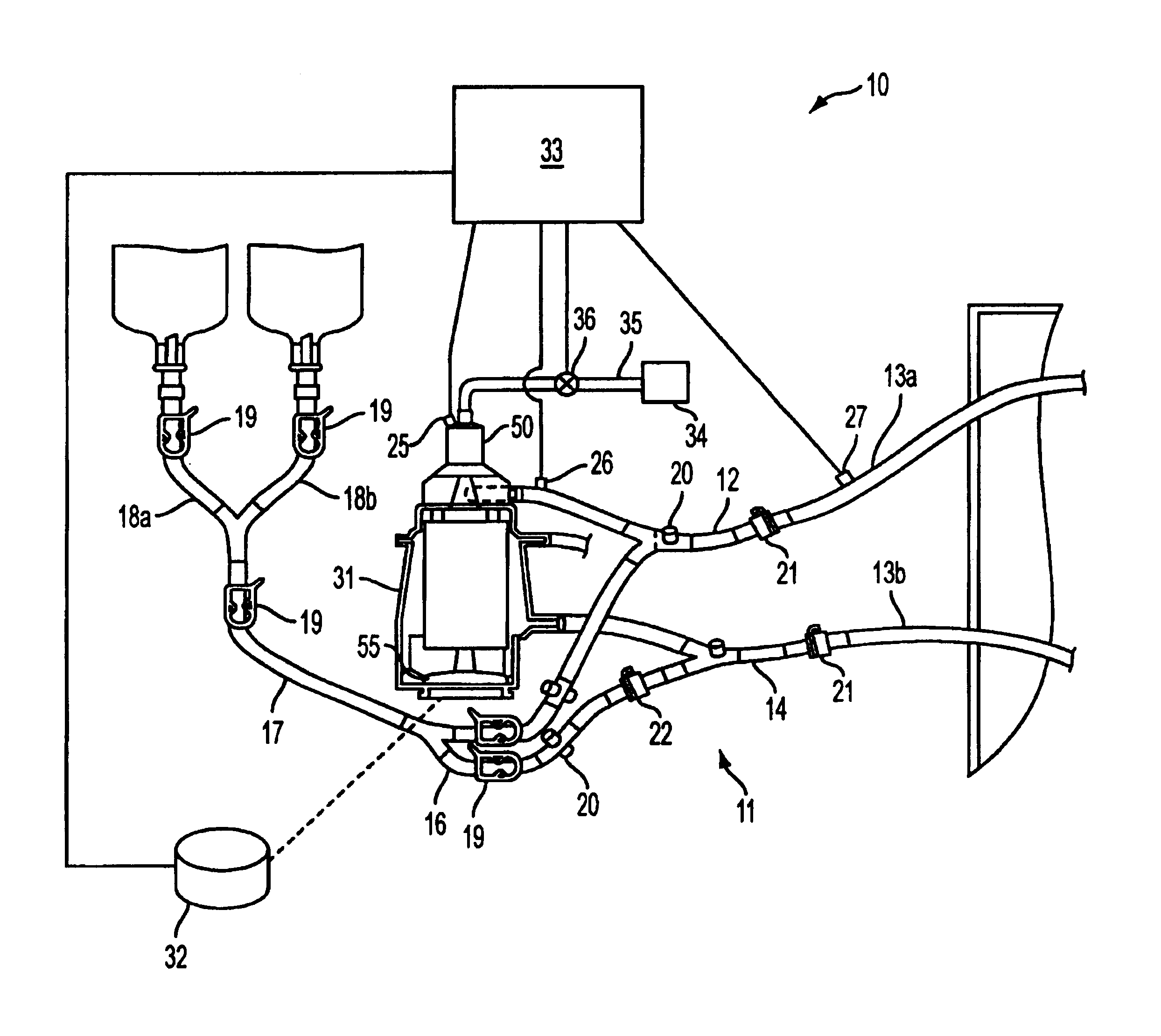

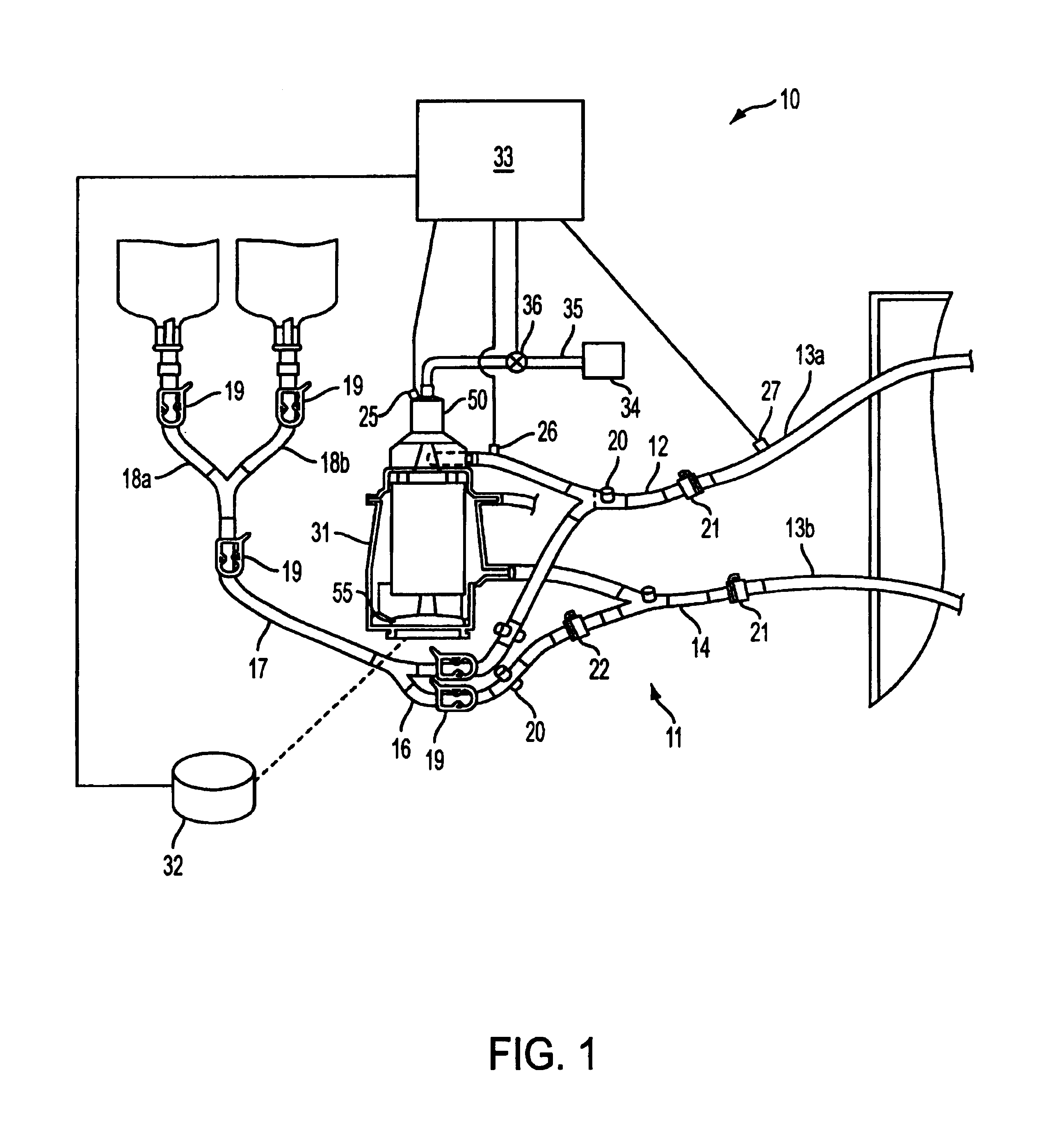

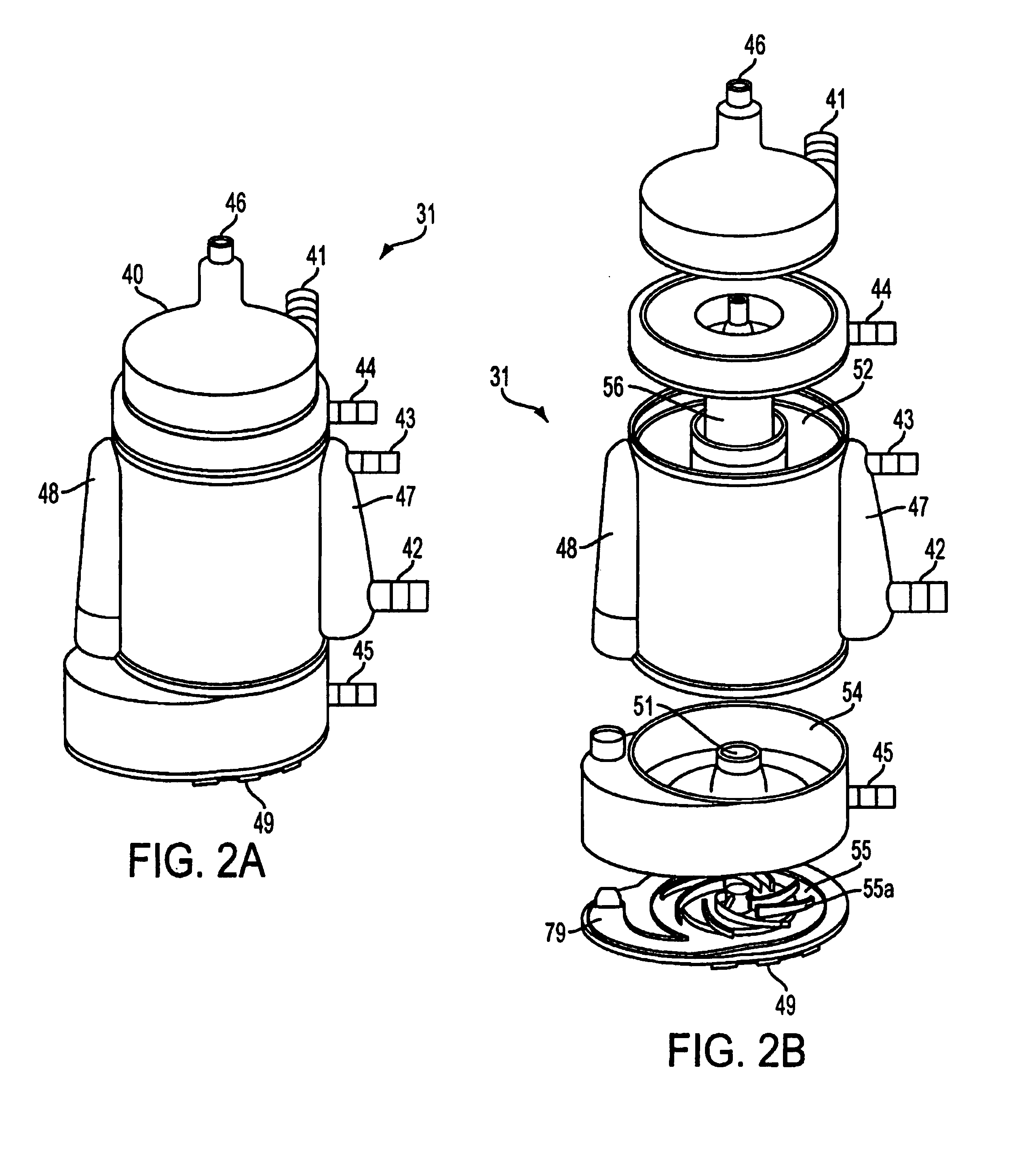

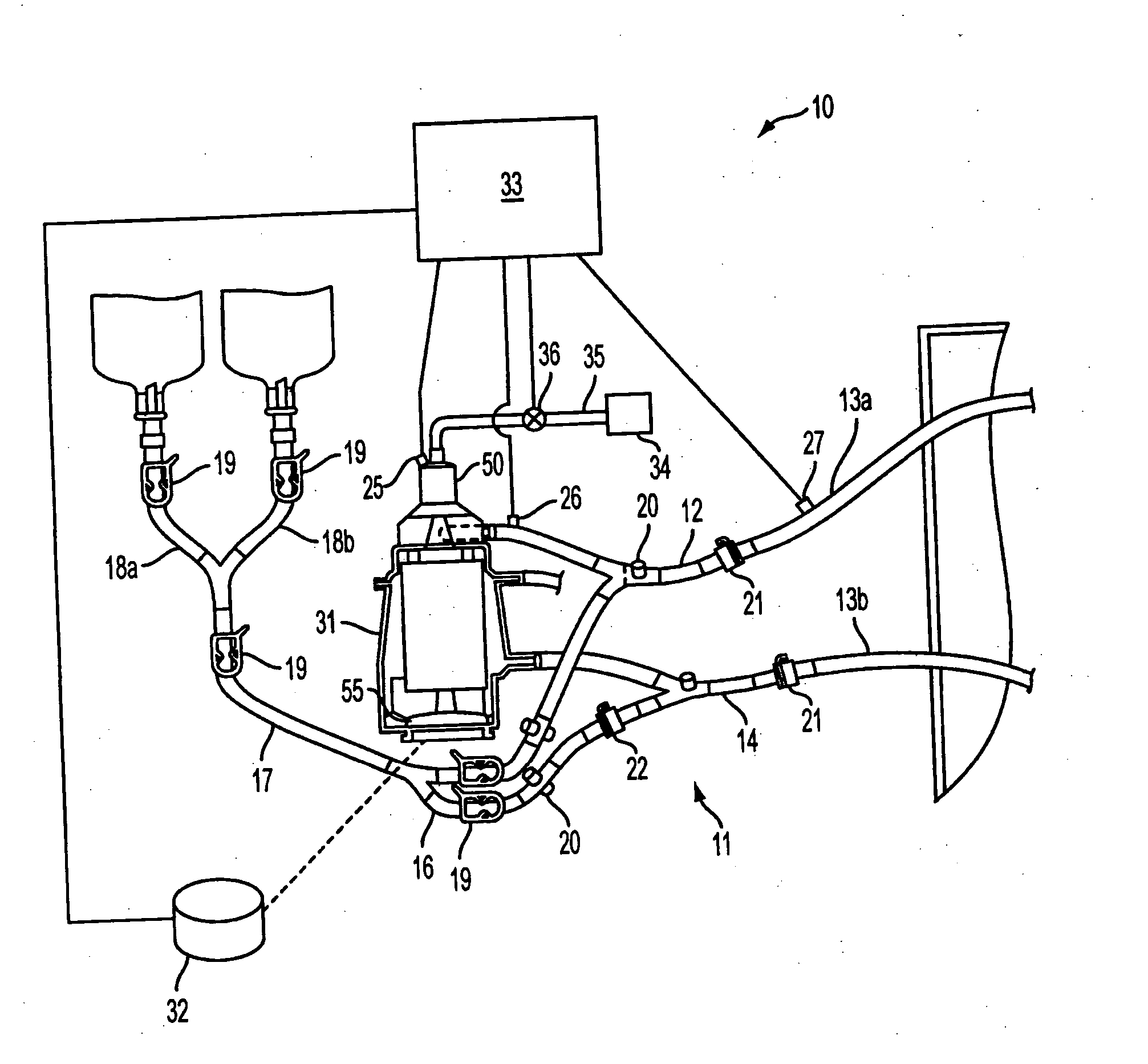

Extracorporeal blood handling system with automatic flow control and methods of use

InactiveUS7022099B2Extension of timeImprove abilitiesOther blood circulation devicesHaemofiltrationAutomatic controlHandling system

Apparatus for processing blood in an extracorporeal circuit with automatic flow control is provided in which error conditions are sensed and system operation is modulated responsive to the error conditions. The apparatus includes an extracorporeal blood processing system, at least one sensor that senses the presence or absence of gas or monitors venous pressure, and a controller operably coupled to the blood processing system to selectively reduce pump speed or to reconfigure flow paths within the blood processing system responsive to the sensor output.

Owner:TAIWAN IMAGINGTEK +1

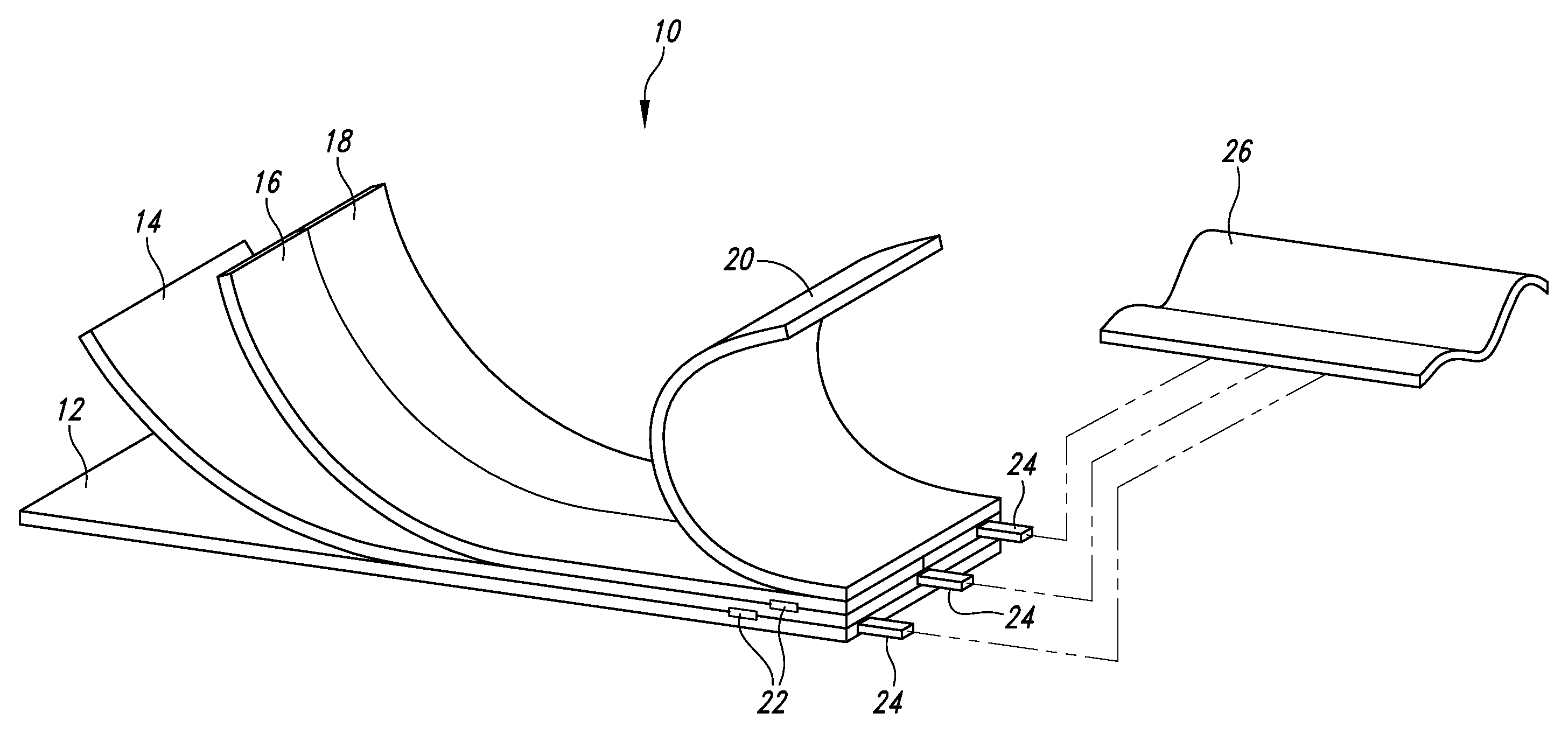

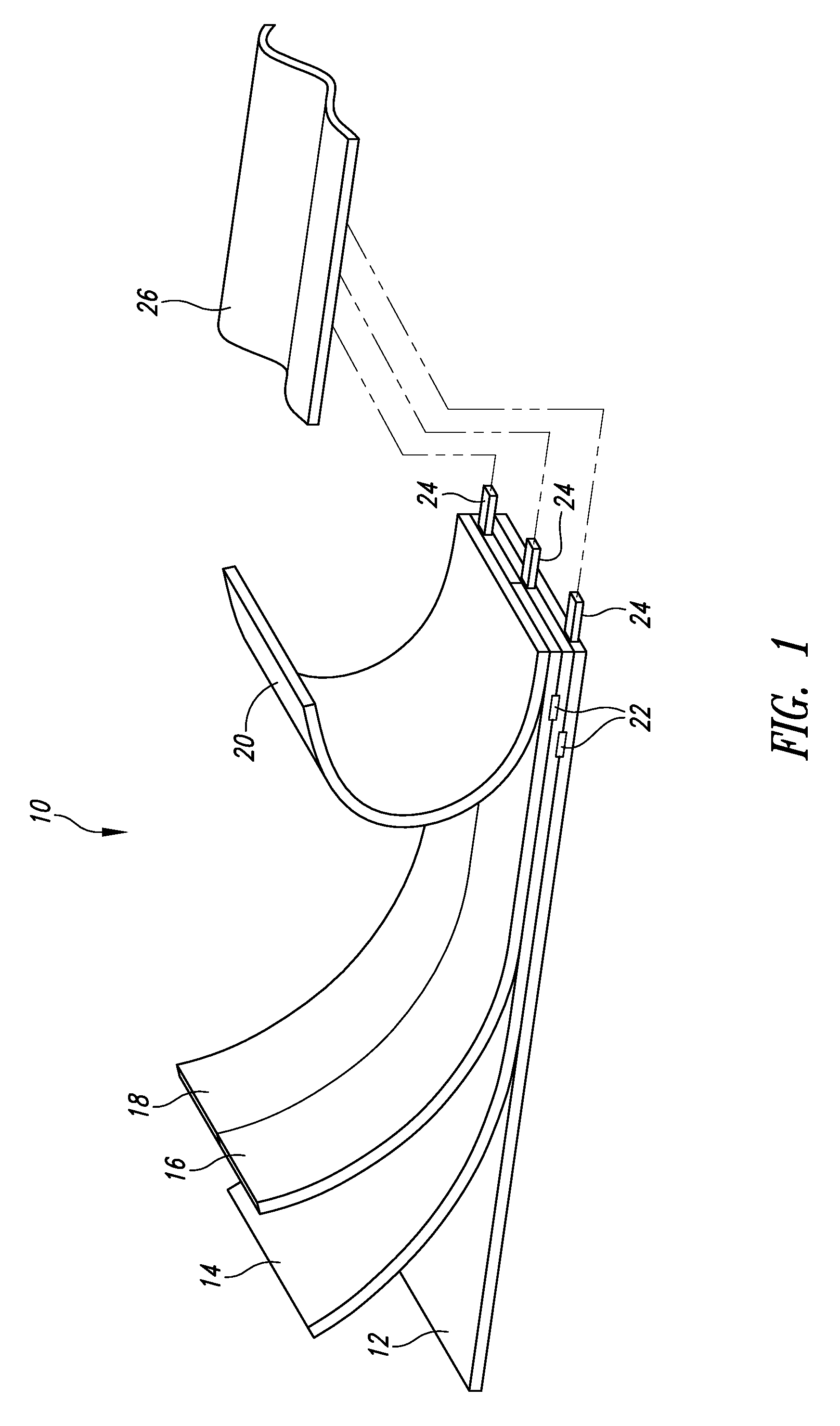

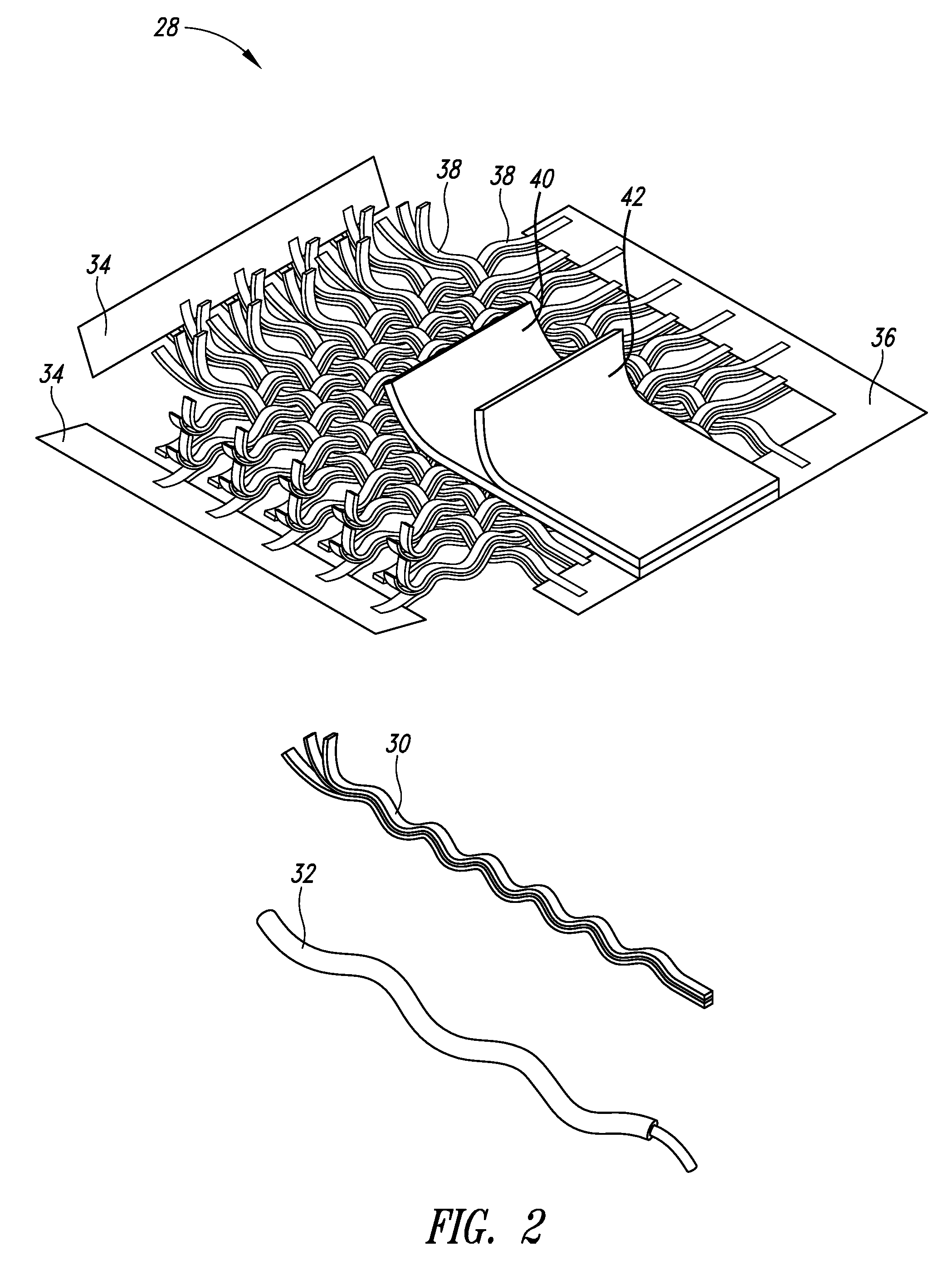

Thin film energy fabric integration, control and method of making

InactiveUS20080109941A1Remove airNot to damageLaminationLamination apparatusStored energyEngineering

A material that includes a first section for storing energy and a second section for collecting and converting energy for storage by the first section in which the stored energy is preferably electrical energy that is used for one from among heat dissipation, heat generation, light emission and powering of an electric circuit in a plurality of devices, ideally covered with a layer to form at least one self-contained panel for operation independently or with other panels to form a system. The material can be formed of layers having devices or components embedded therein, the layers preferably laminated together using a battened pattern of adhesion. A control bus system allows master or slave designation as well as power sharing to the individual panels in the garment as well as among garments.

Owner:ENERGY INTEGRATION TECH INC

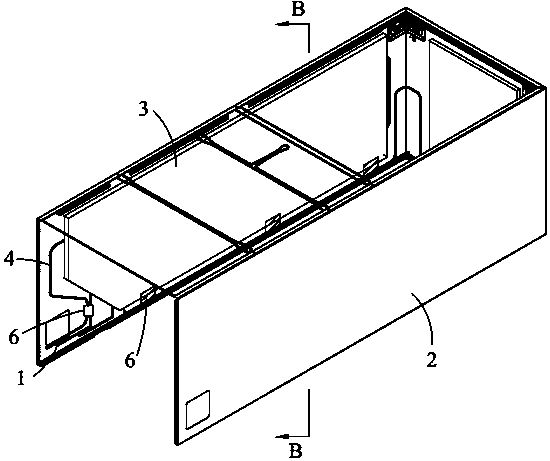

Refrigerator

InactiveCN104344653ARemove airAvoid separationLighting and heating apparatusInsulation for cooling apparatusPulp and paper industryRefrigerated temperature

The invention relates to a refrigerator which comprises a refrigerator shell, vacuum heat insulation plates arranged on the inner side of the refrigerator shell, an condensation pipe arranged between the vacuum heat insulation plates and the refrigerator shell and an exhaust part, wherein the condensation pipe is clung to the refrigerator shell; the exhaust part is provided with an air inlet; the air inlet is formed close to the condensation pipe to exhaust air around the condensation pipe out of the refrigerator. According to the refrigerator, the exhaust part is arranged, and the air inlet of the exhaust part is formed close to the condensation pipe, so that air around the condensation pipe can be effectively eliminated, and the refrigerator shell is further prevented from being separated from the vacuum heat insulation plates.

Owner:HAIER GRP CORP +1

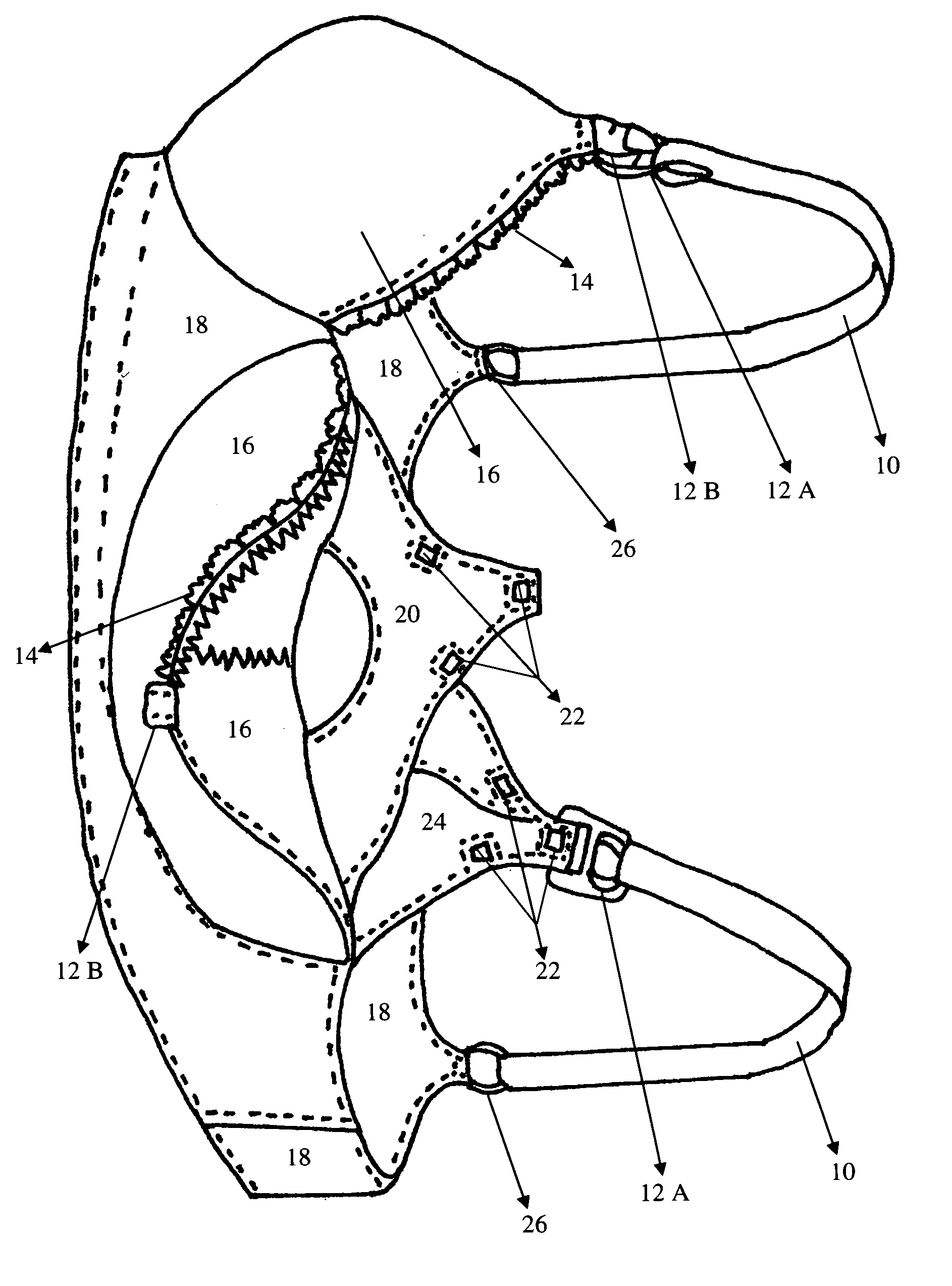

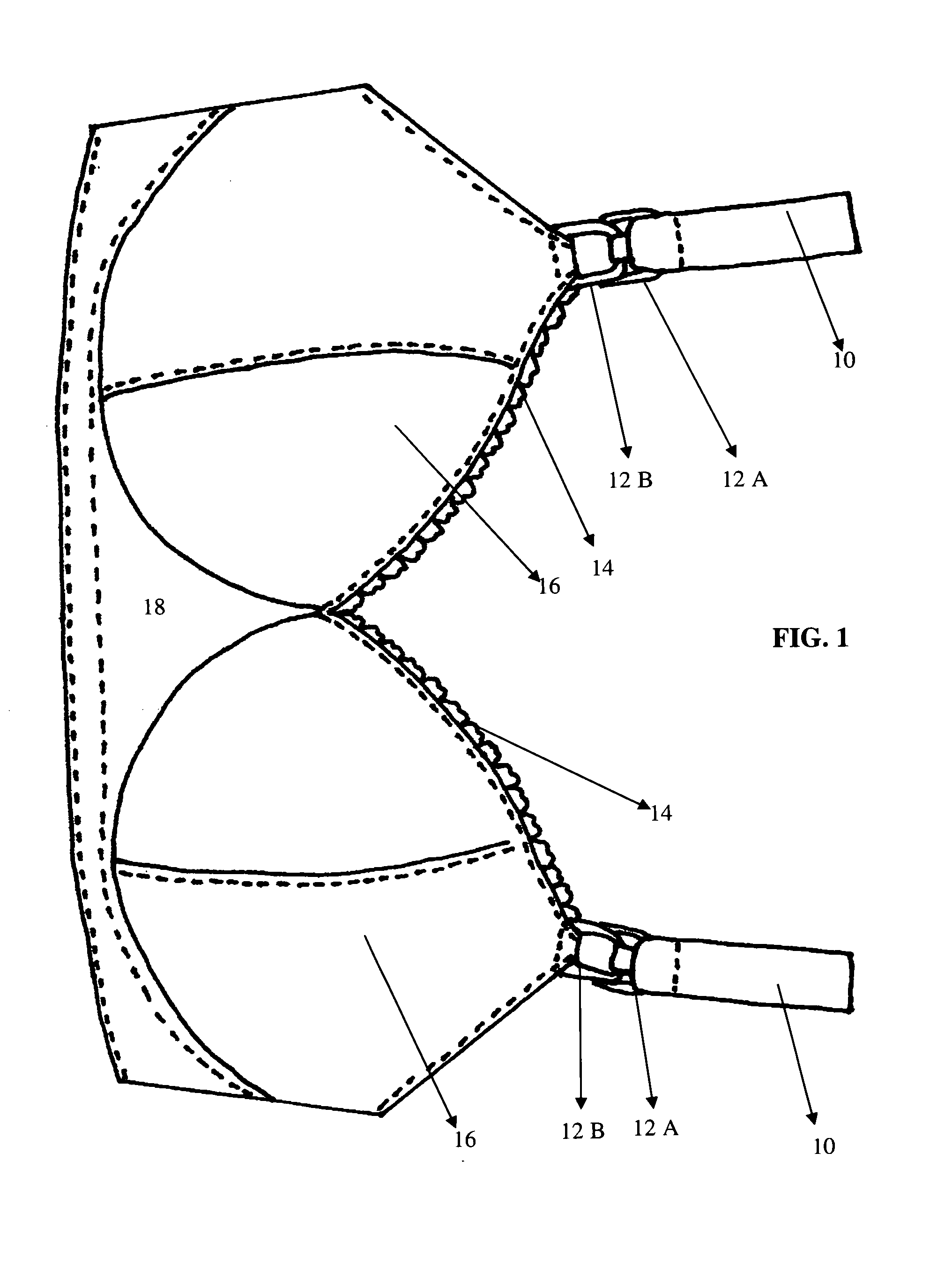

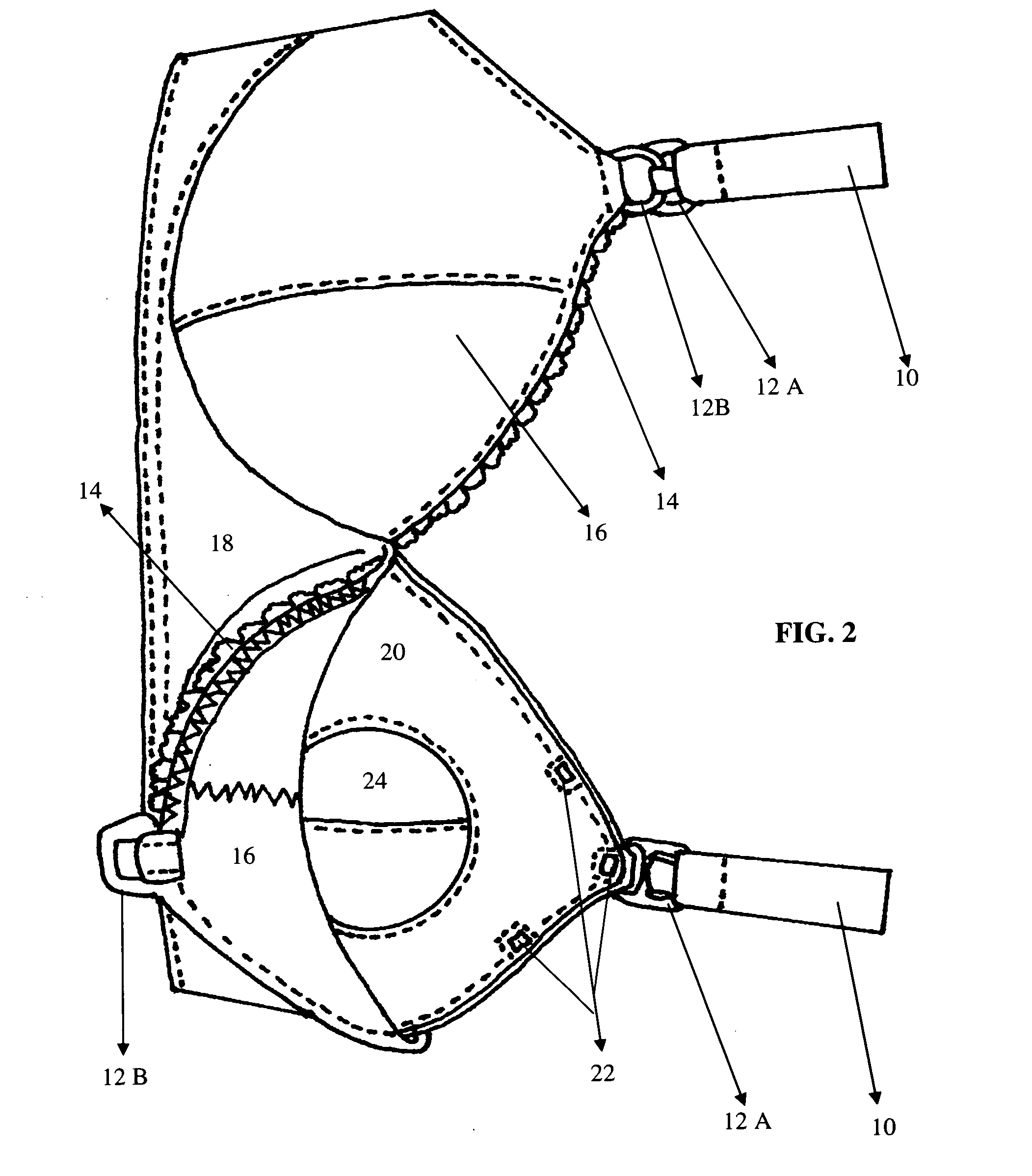

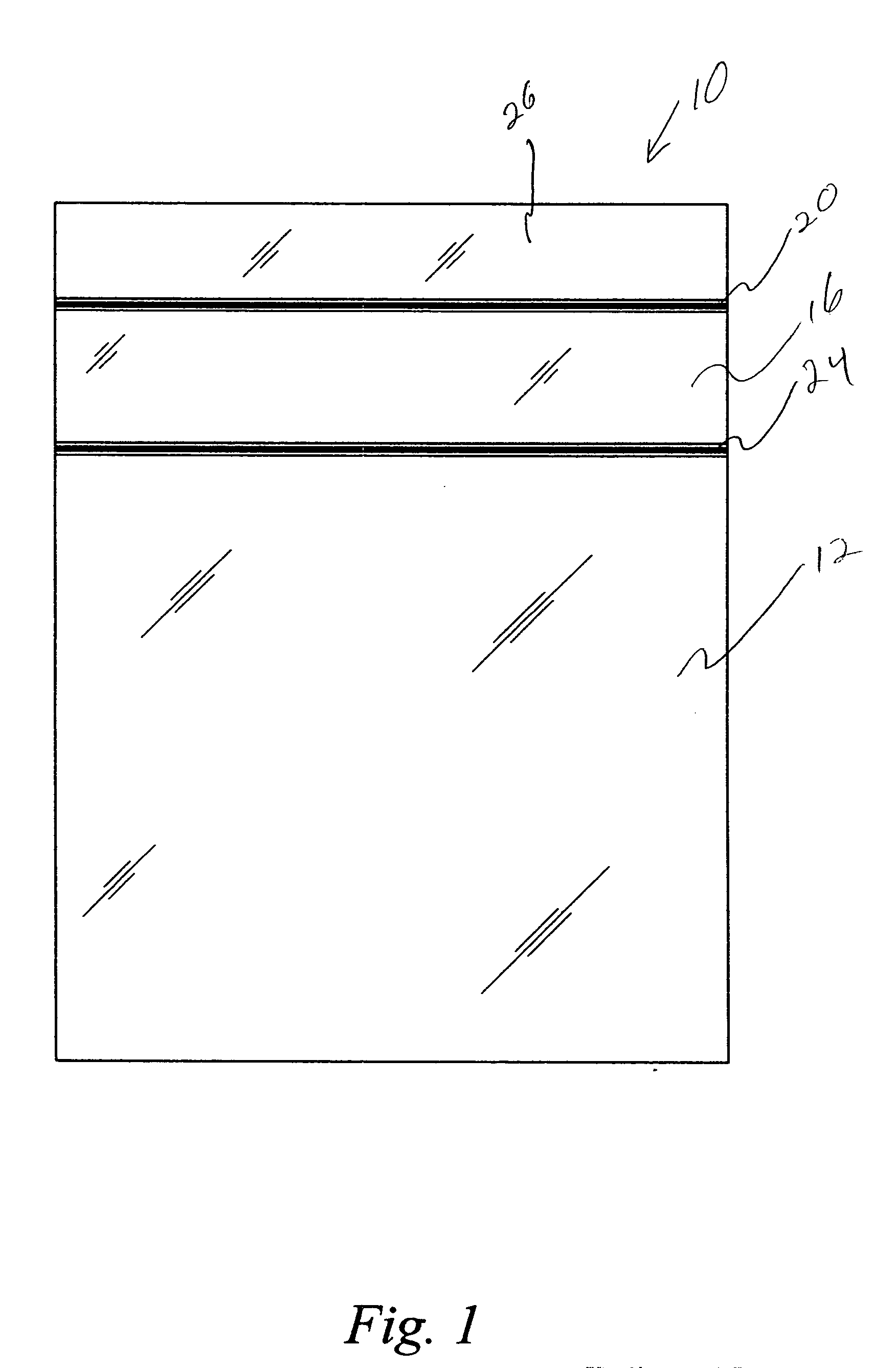

Next best nursing bra and nurser liner

A nursing bra with nurser liner pouch for simulating breastfeeding. The bra includes multiple layers. The first outer layer can be opened and flipped down by releasing the clasp at the bra strap. The second inner layer with circular opening can be opened by un-snapping the snaps that attach the second inner layer to the back third layer. The second inner layer and back third layer create a pocket for the nurser liner pouch. The nurser liner pouch can contain fluid while the threaded cap base attached is sized to be secured to a commercially available nipple and retainer ring and can be placed into the pocket into the nursing bra with nipple protruding through the circular opening in the second inner layer. The nursing bra with nurser liner pouch is expected to far more closely simulate the experience and project the appearance of natural breastfeeding.

Owner:BOELE ALMA LOUISE +1

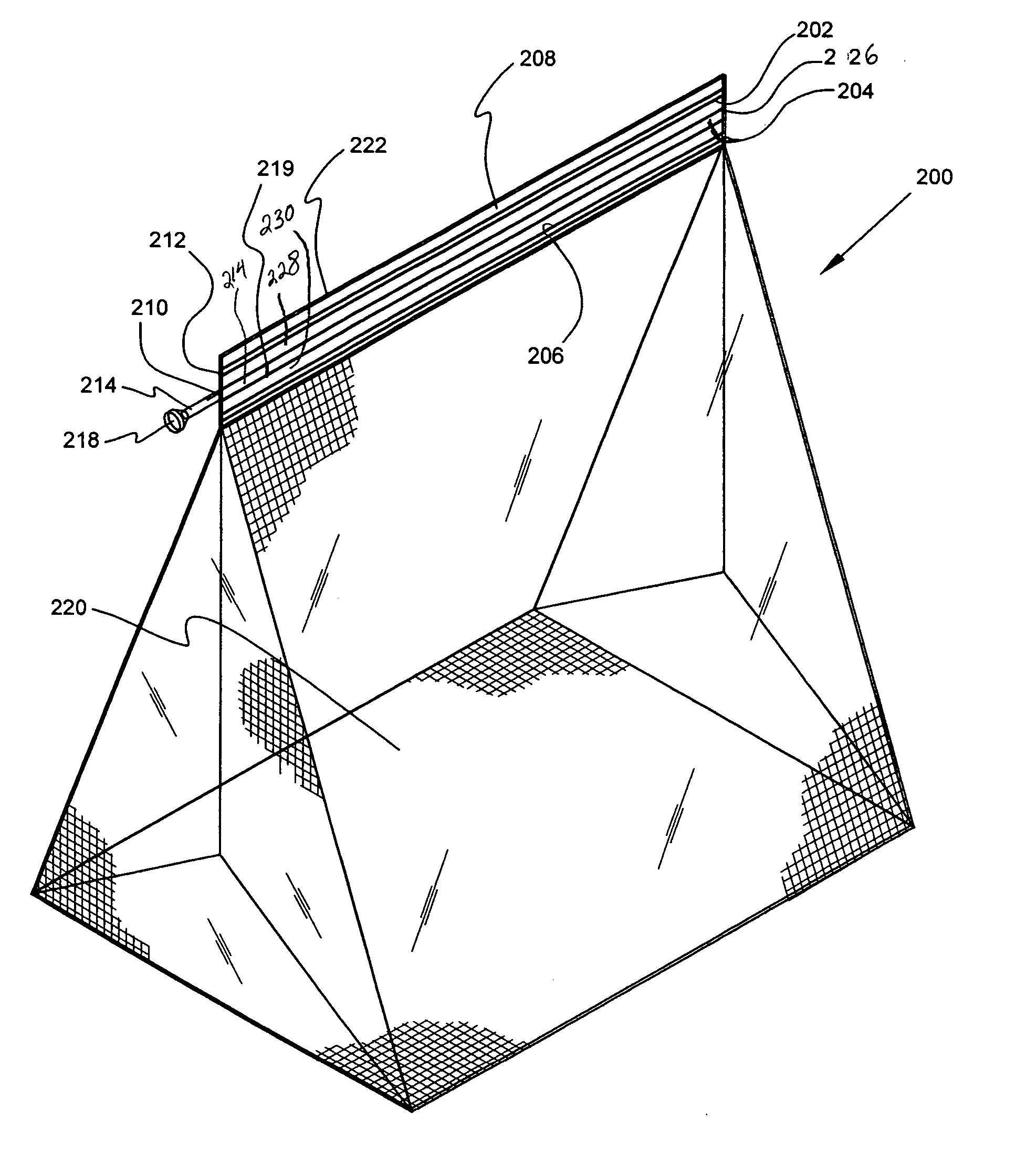

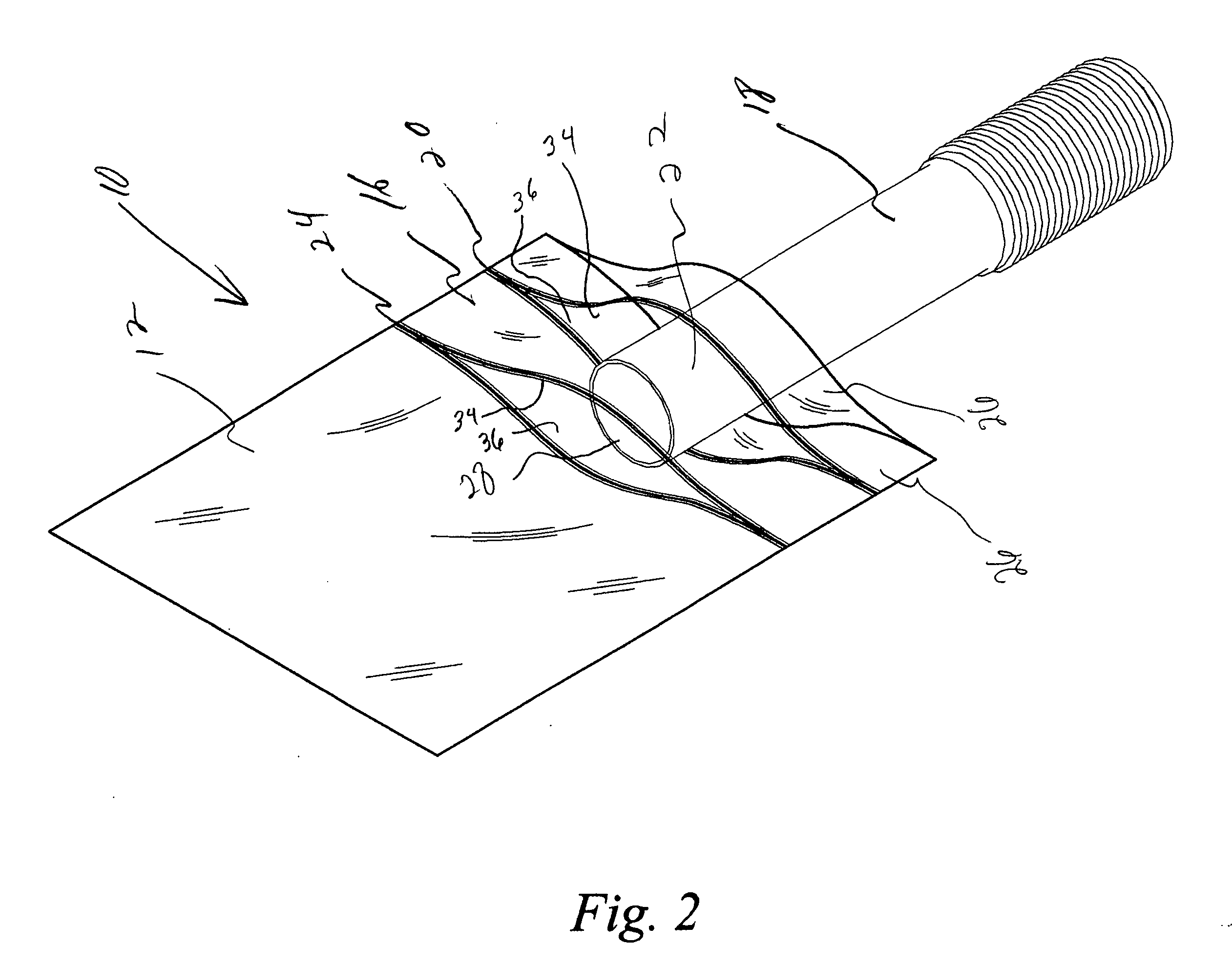

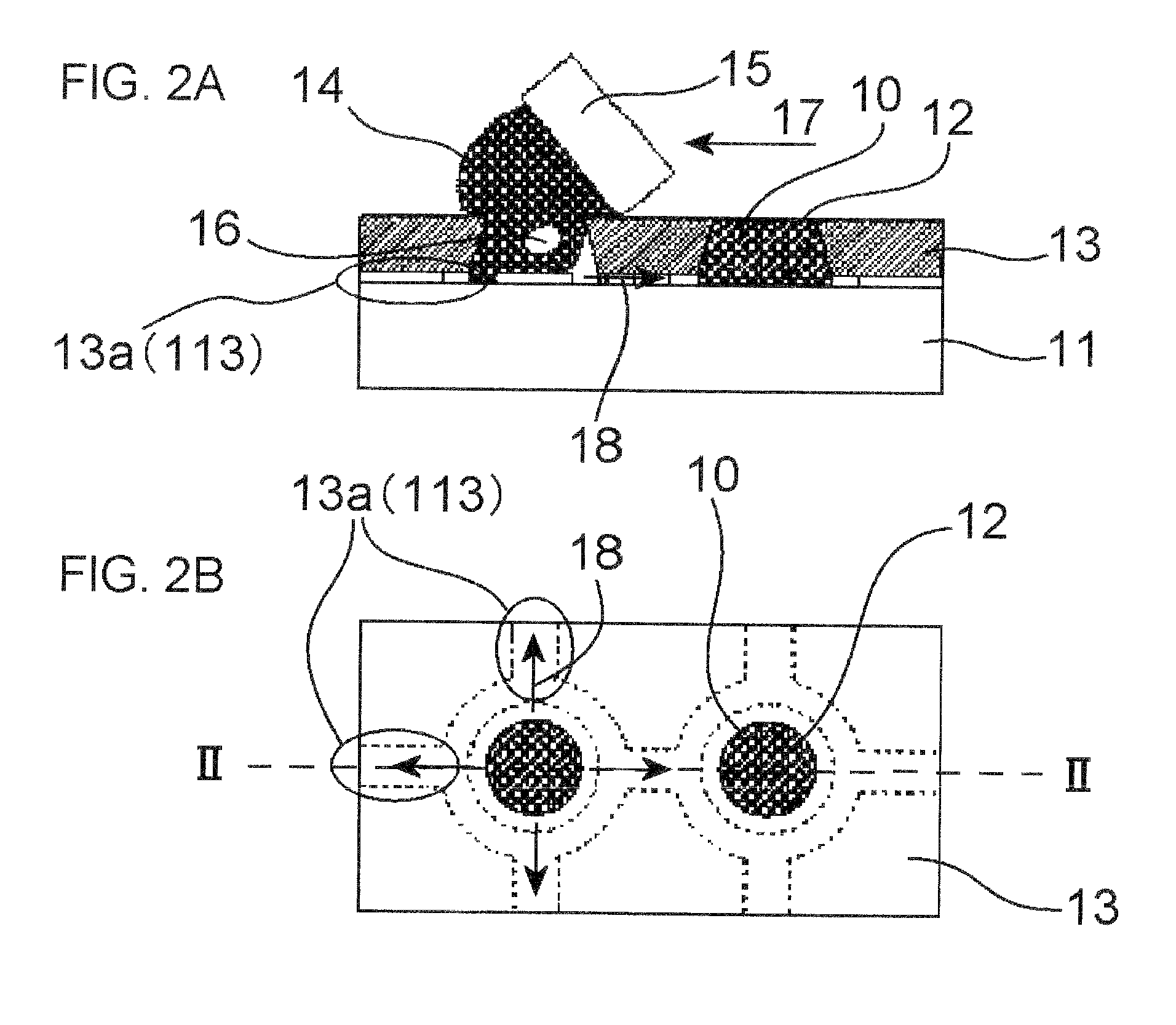

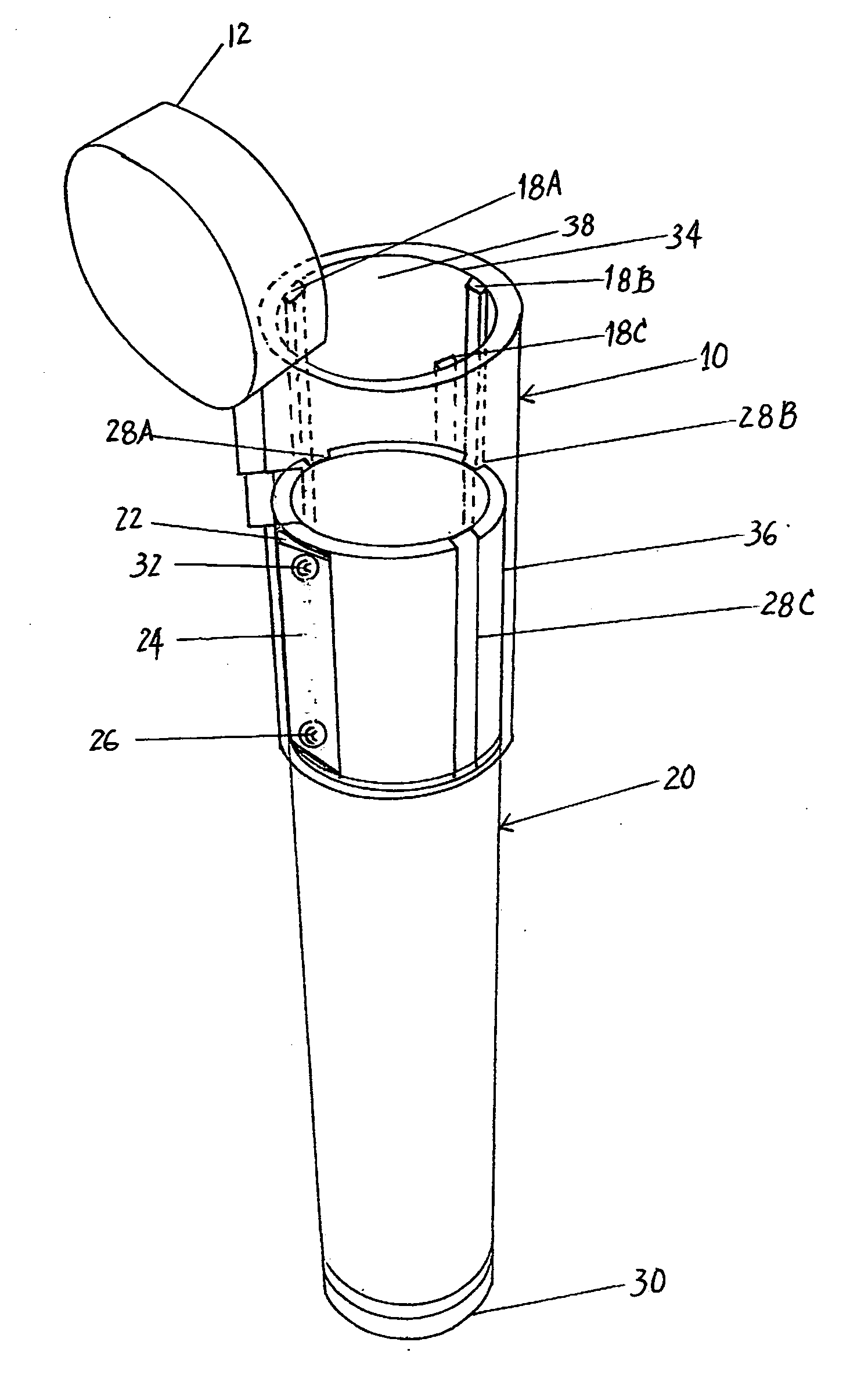

Enclosure for preserving perishable goods

An enclosure 10 for preserving perishable goods 14 includes an inner portion 12 for removably receiving perishable goods 14, an outer portion 16 that removably receives a vacuum device 18 such as a vacuum cleaner which removes air from the enclosure 10 after the goods 14 have been inserted into the inner portion 12, a sealable outer seal 20 that provides an air tight boundary between the enclosure 10 and an end portion 22 of the vacuum device 18 to promote the removal of air from the enclosure 10, and a sealable inner seal 24 that provides an air tight boundary for the inner portion 12 and the goods 14 therein after the removal of air from the enclosure 10 and while the vacuum device 18 remains engaged with the outer seal 20; the vacuum device 18 being separated from the outer seal 20 after the removal of air from the inner portion 12 and the air tight sealing of the inner seal 24 whereby the perishable goods 14 are encased in a vacuum sealed inner portion 12 of the enclosure 10 to preserve the perishable goods 14 after the goods 14 are frozen. An alternative enclosure 200 includes an opening 222, a first locking seal 202 disposed relatively close and substantially parallel to the opening 222, a second locking seal 204 disposed adjacent and parallel to the first locking seal 202, a third locking seal 206 disposed adjacent and parallel to the second locking seal 204, and an aperture 210 disposed in a first side portion 212 of the enclosure 200 adjacent to the second locking seal 204 to enable an air evacuation tube to snugly insert through the first side portion 212 of the enclosure 200.

Owner:KOZAK BURTON

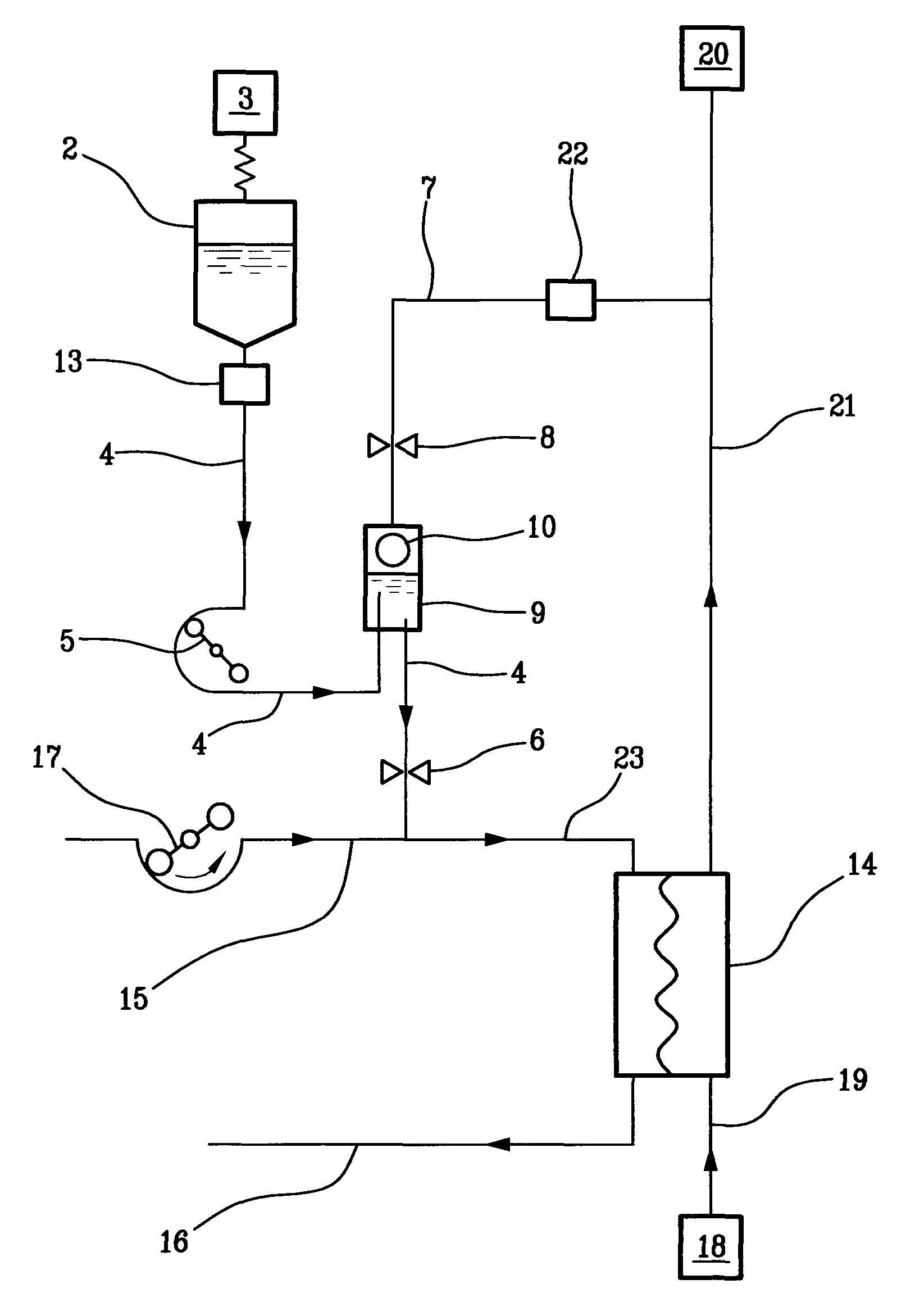

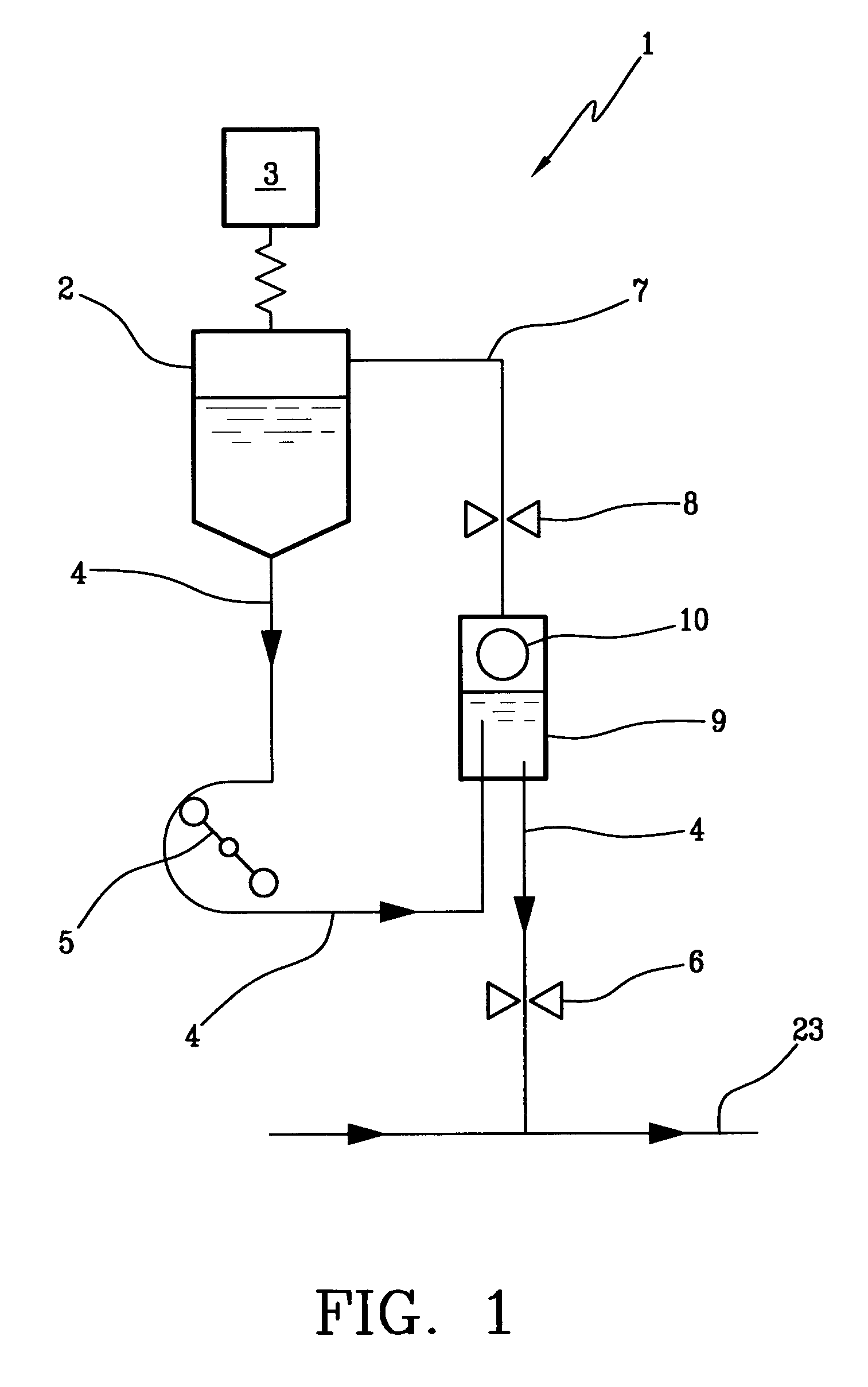

Infusion apparatus

ActiveUS8728020B2Reduce need for interventionReduce riskMedical devicesFlow monitorsEmergency medicineExpansion chamber

In an infusion apparatus, an infusion line (4) connects a container (2) of an infusion fluid to an extracorporeal blood circuit (23). A first valve (6) closes the infusion line downstream of an infusion pump (5). An expansion chamber (9), provided with a pressure sensor (10), is arranged between the infusion pump and the first valve. A second valve (8) closes a vent line (7) of the expansion chamber. The processor closes the first valve when the container is emptied. After replacement with a new and full container, the processor restarts the pump and selectively opens the first valve or the second valve according to the increase in pressure measured in the expansion chamber.

Owner:GAMBRO LUNDIA AB

Low speed vacuum squeeze casting technology

The invention provides a low speed vacuum extruding casting technique which comprises the steps of: (1) the design of dies, a vacuum system and a hot runner; (2) the installation, the preheating and the coating of the hot runner and the dies; (3) the pouring of molten metal into the hot runner, die matching and vacuum pumping; (4) low speed and vacuum filling; (5) extruding and solidifying; (6) the opening of the dies to take finished products. The technical effects of the technique are the improvement of a temperature field during the casting process and the realization of the casting method of injection at low speed, solidification under high pressure and hole shrinkage without vacuum. The low speed vacuum extruding casting technique can effectively reduce the probability of containing pores and shrinkage and loose defects, heat treatment can be carried out to die casts, and both the tensile strength and the percentage elongation of the die casts after the heat treatment are increased by 25 percent, thereby greatly improving the quality of the die casts.

Owner:NANCHANG HANGKONG UNIVERSITY

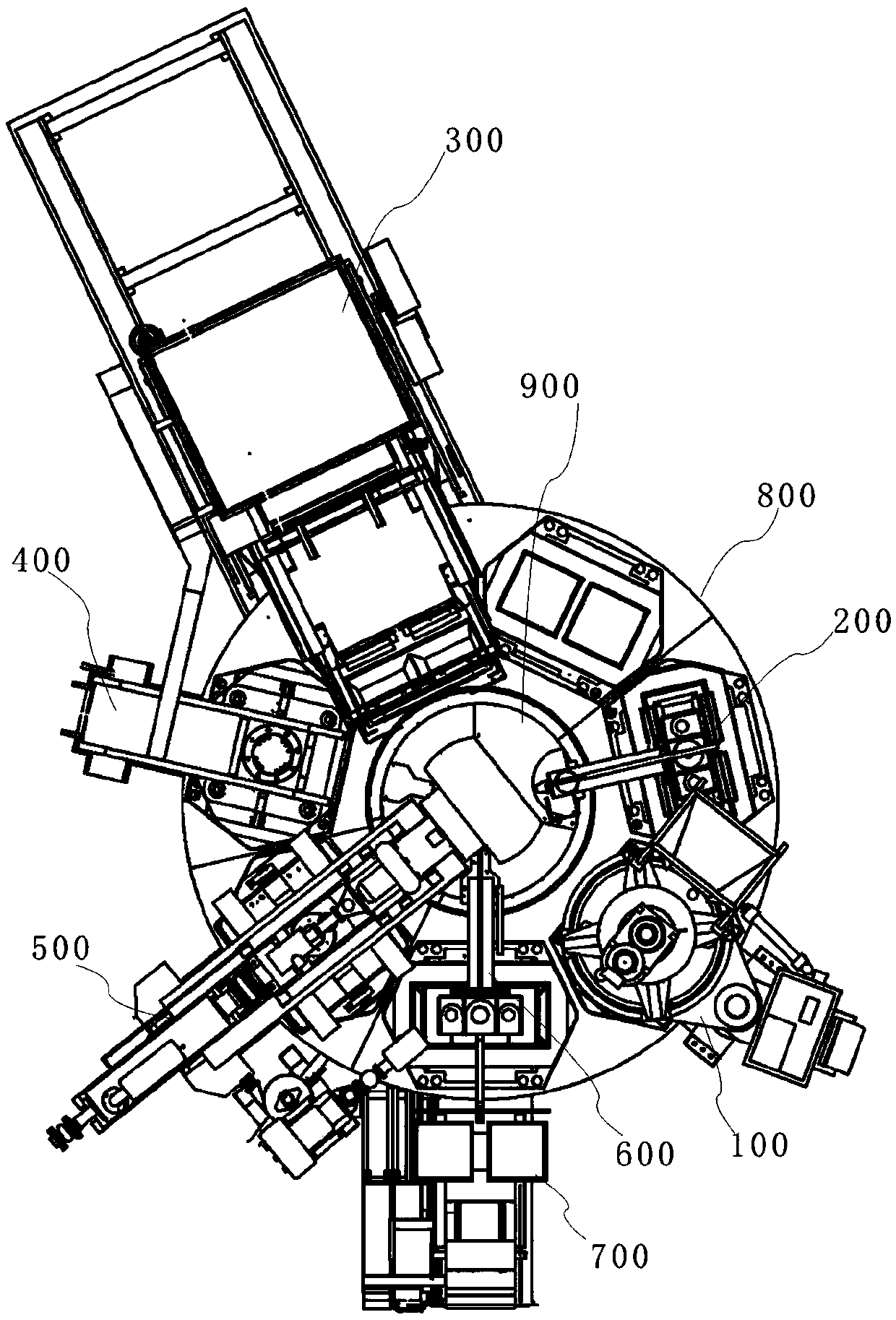

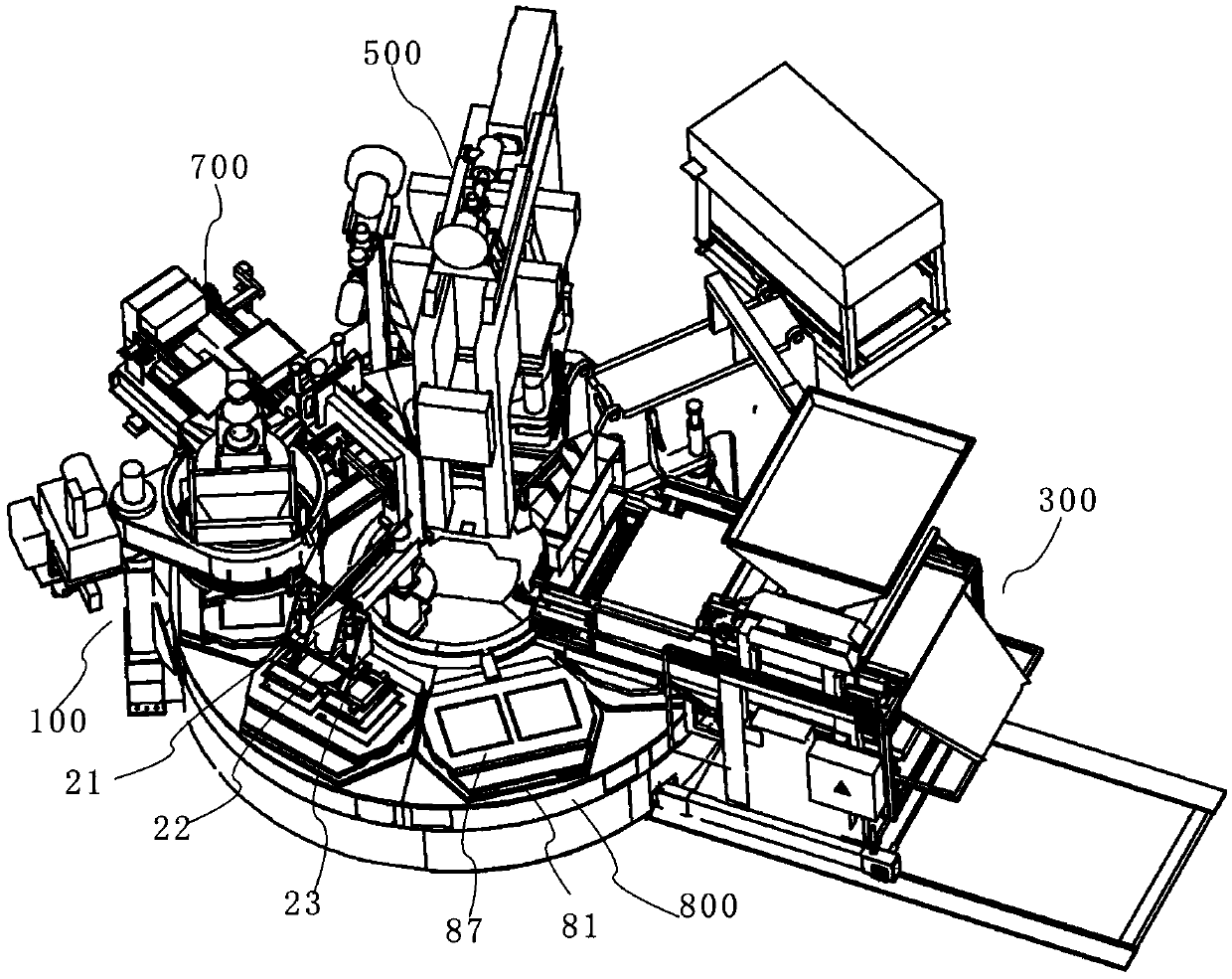

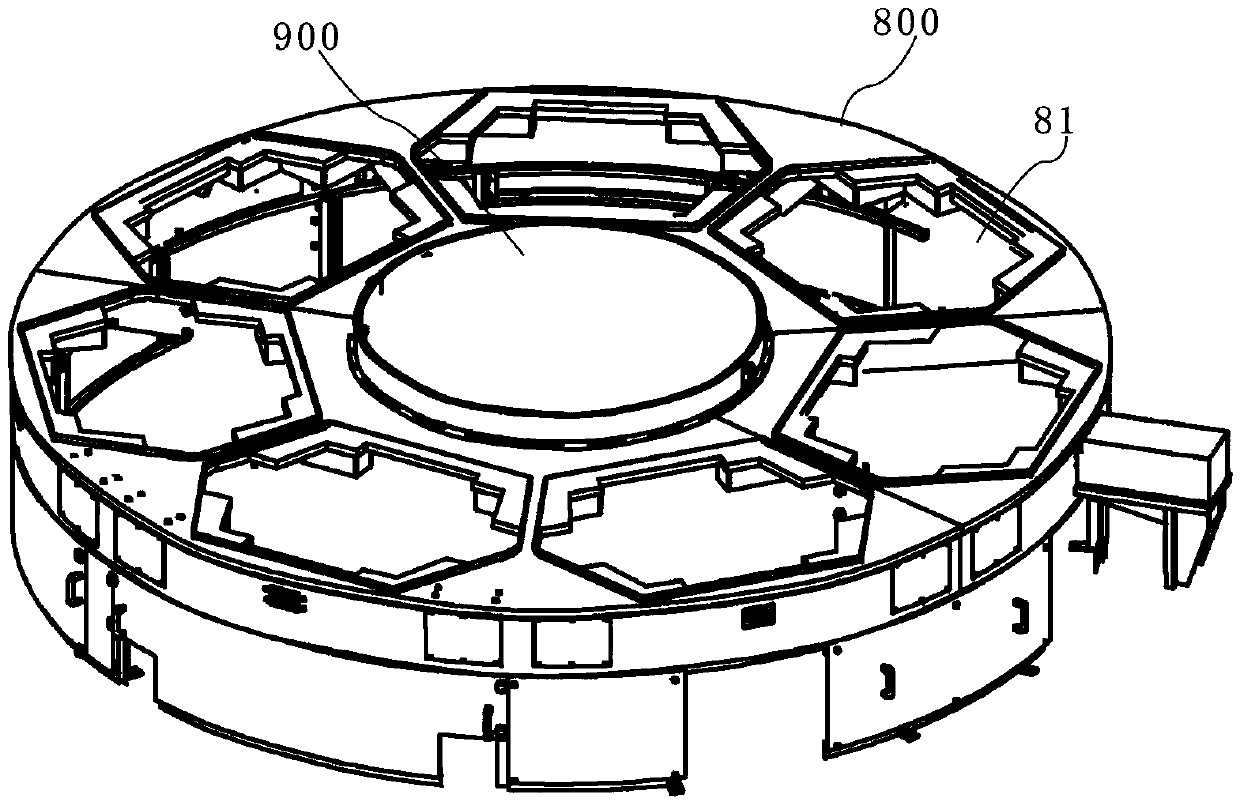

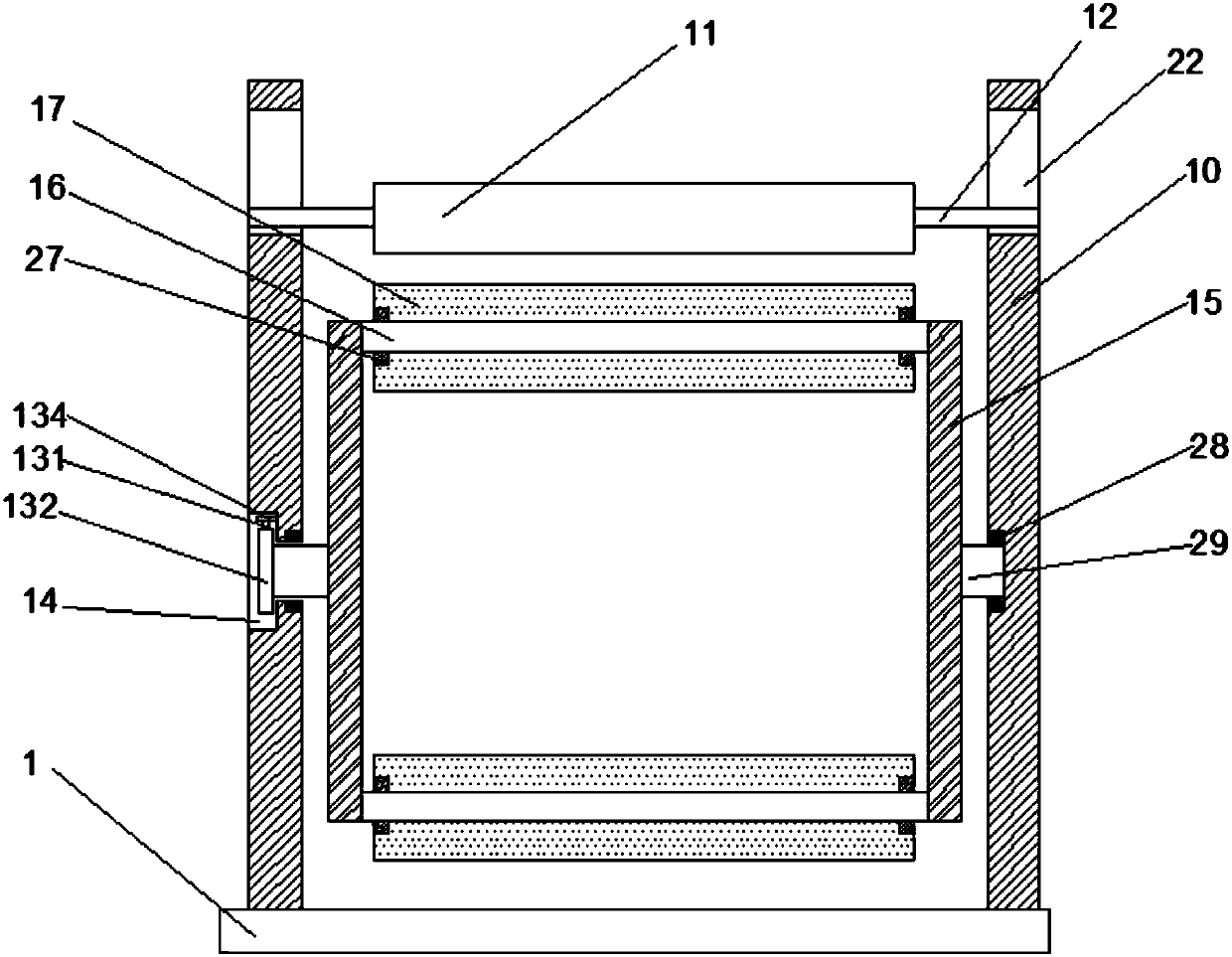

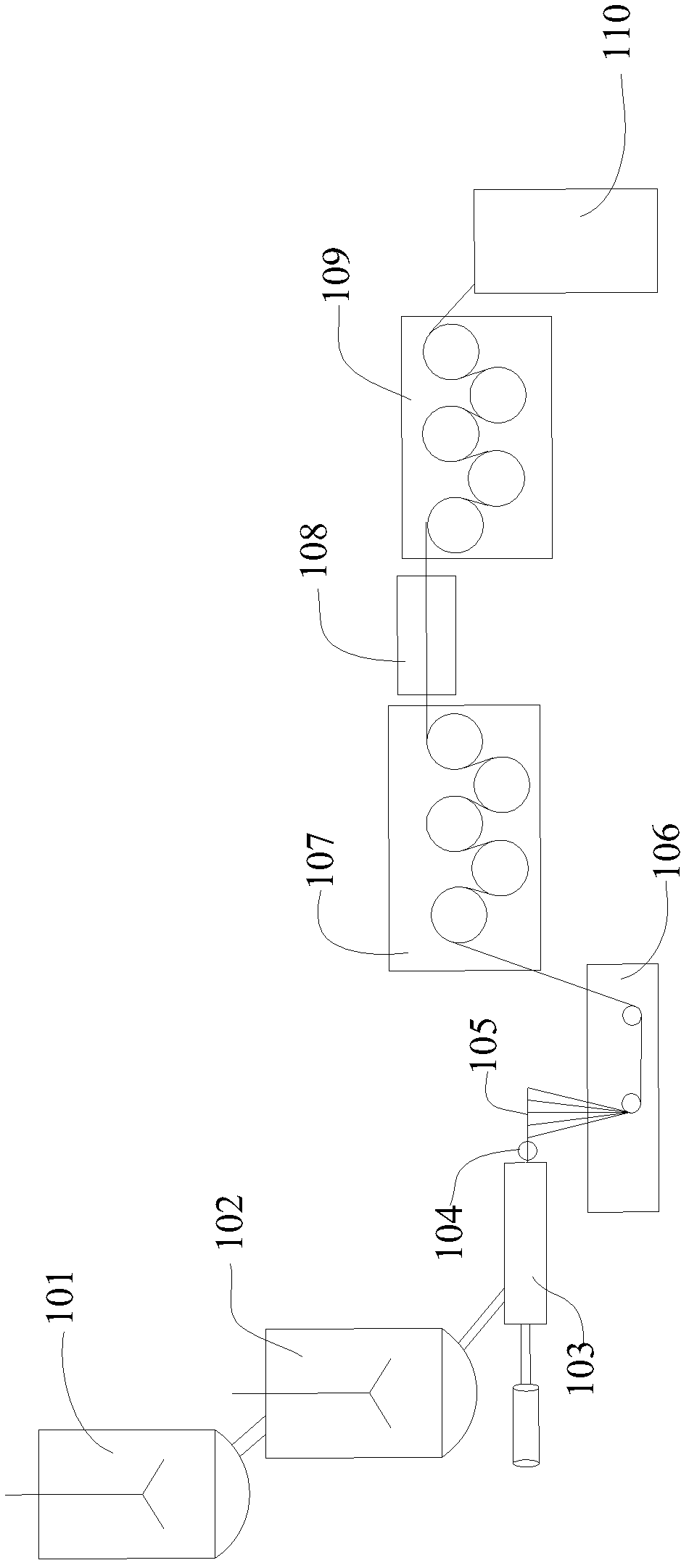

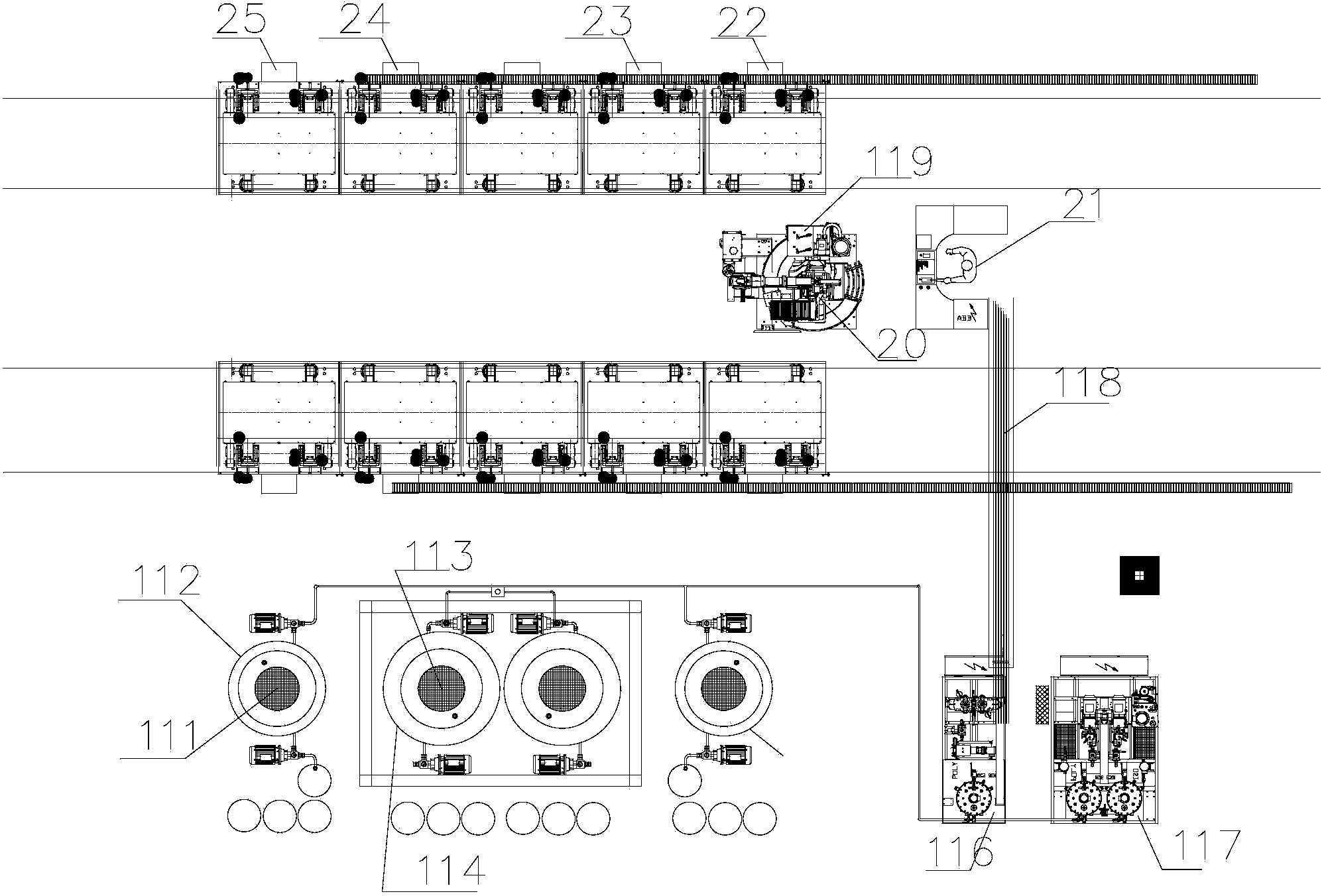

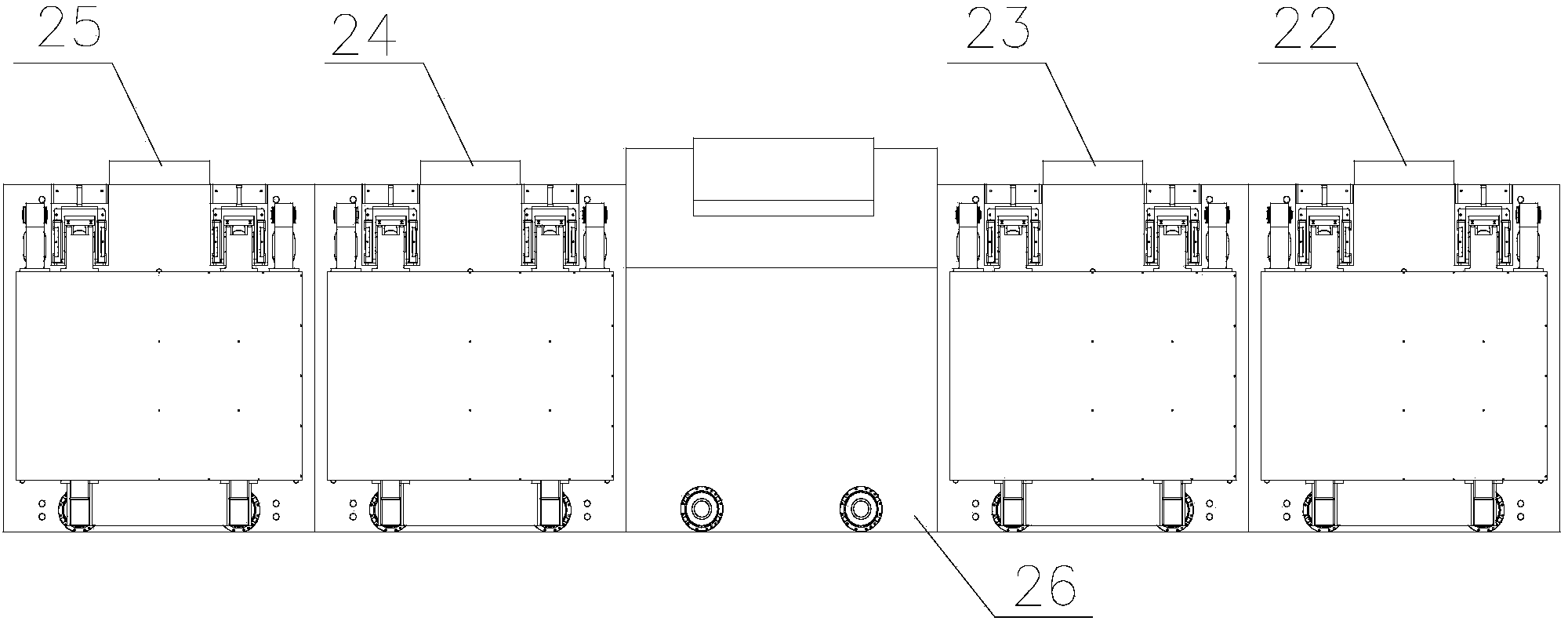

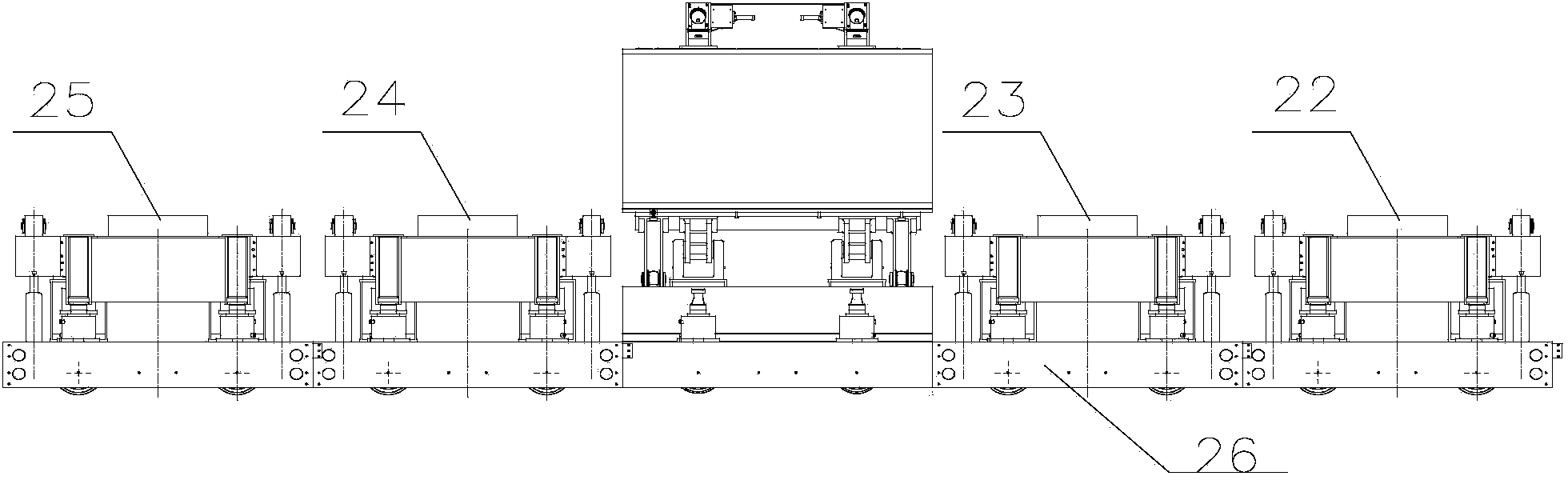

Full-automatic stone-like brick making machine and brick making method

PendingCN109676750ALower requirementReduce consumptionDischarging arrangementFeeding arrangmentsBrickSurface layer

The invention relates to a full-automatic stone-like brick making machine and a brick making method. The stone-like brick making machine comprises a center seat and a rotary disc, a plurality of moldpositions are uniformly distributed on the rotary disc in the circumferential direction, a vibration box body is fixedly mounted at each mold position through a rubber cushion block, a vibration motoris mounted on the bottom of each vibration box body and is hidden in the vibration box body, lifting oil cylinders are respectively mounted on two symmetrical sides of each vibration box body, and apiston rod of each lifting oil cylinder is connected with a connecting block; and a fabric distributing machine, a vibrating press, a prepressing machine, a main press unit and a demolding and brick discharging unit are sequentially arranged at each mold position correspondingly in the rotating direction of the rotary disc, and 0-2 transition positions are reserved between the vibrating press andthe prepressing machine. According to the invention, brick making processes are innovatively separated and arranged into an annular layout, the occupied area is small, the various processes can act simultaneously, the production period is shortened, the surface of a surface layer is compact, the requirement on raw materials is reduced, produced bricks can be maintained in a maintenance kiln or ina manner of standing and drying in the shade, the production period can be greatly shortened, and the energy consumption is reduced.

Owner:QUANGONG MACHINERY

Bottling installation including filler spouts fitted with feed-back ducts from the spout bodies

ActiveUS20130000779A1Reliable bottling installationMinimize of amountLiquid fillingSolid materialEngineeringControl valves

Owner:SERAC GROUP

Extracorporeal blood handling system with automatic flow control and methods of use

InactiveUS20060009728A1Extension of timeImprove abilitiesOther blood circulation devicesControl devicesAutomatic controlHandling system

Apparatus for processing blood in an extracorporeal circuit with automatic flow control is provided in which error conditions are sensed and system operation is modulated responsive to the error conditions. The apparatus includes an extracorporeal blood processing system, at least one sensor that senses the presence or absence of gas or monitors venous pressure, and a controller operably coupled to the blood processing system to selectively reduce pump speed or to reconfigure flow paths within the blood processing system responsive to the sensor output.

Owner:CARDIOVENTION

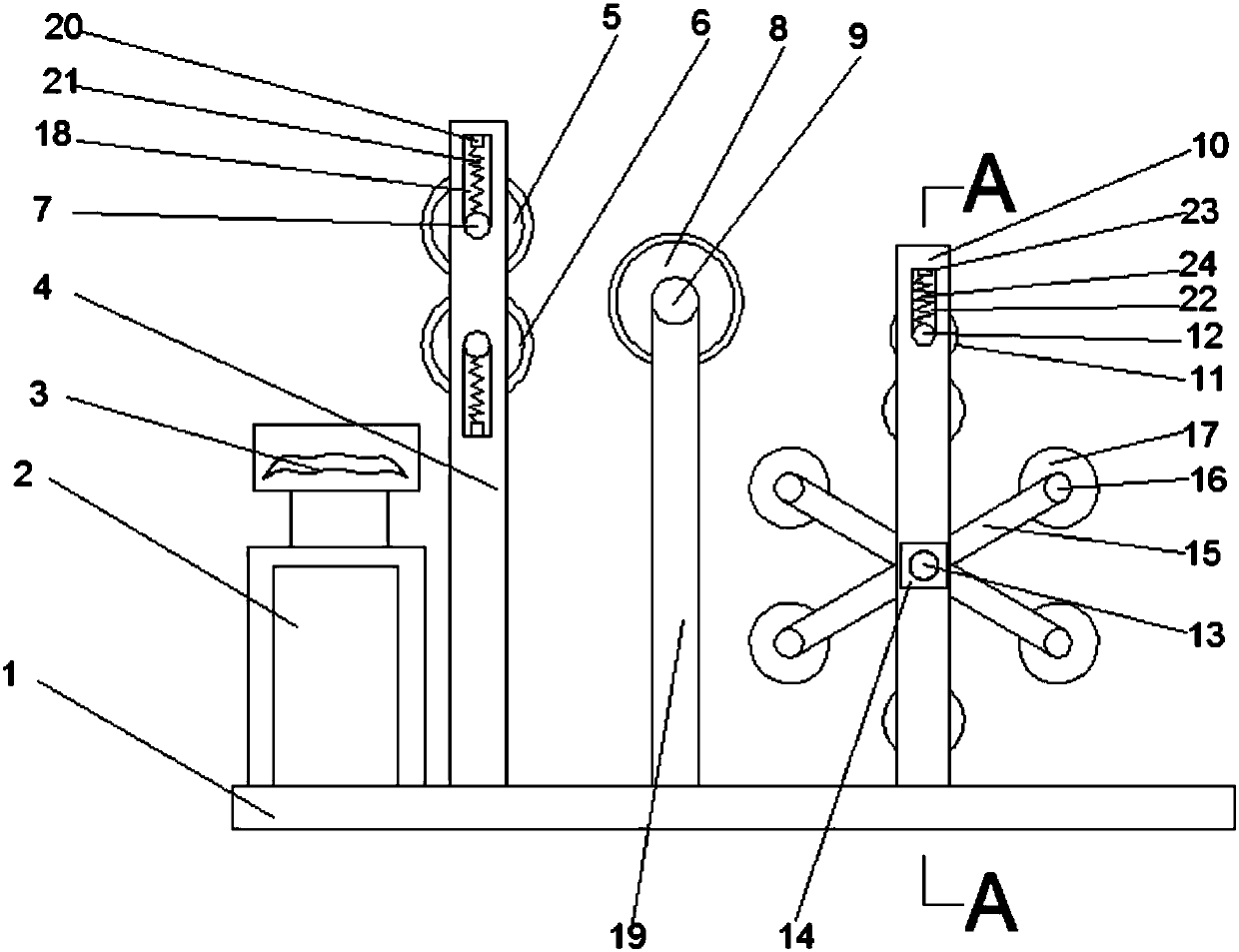

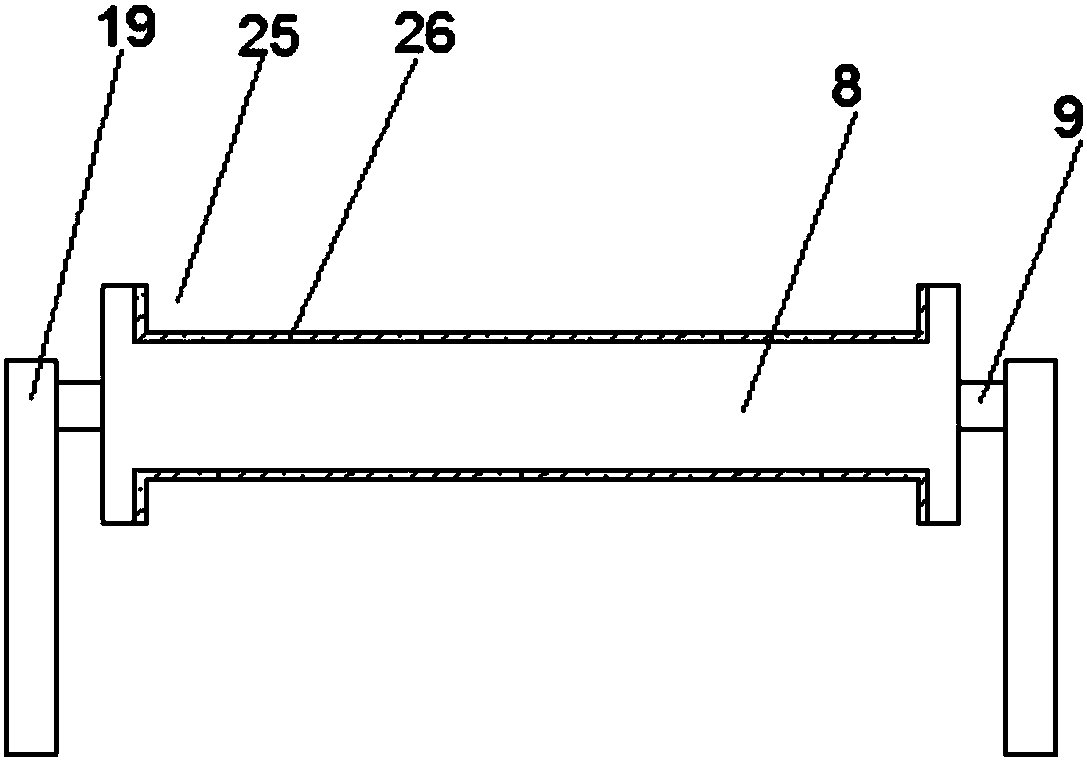

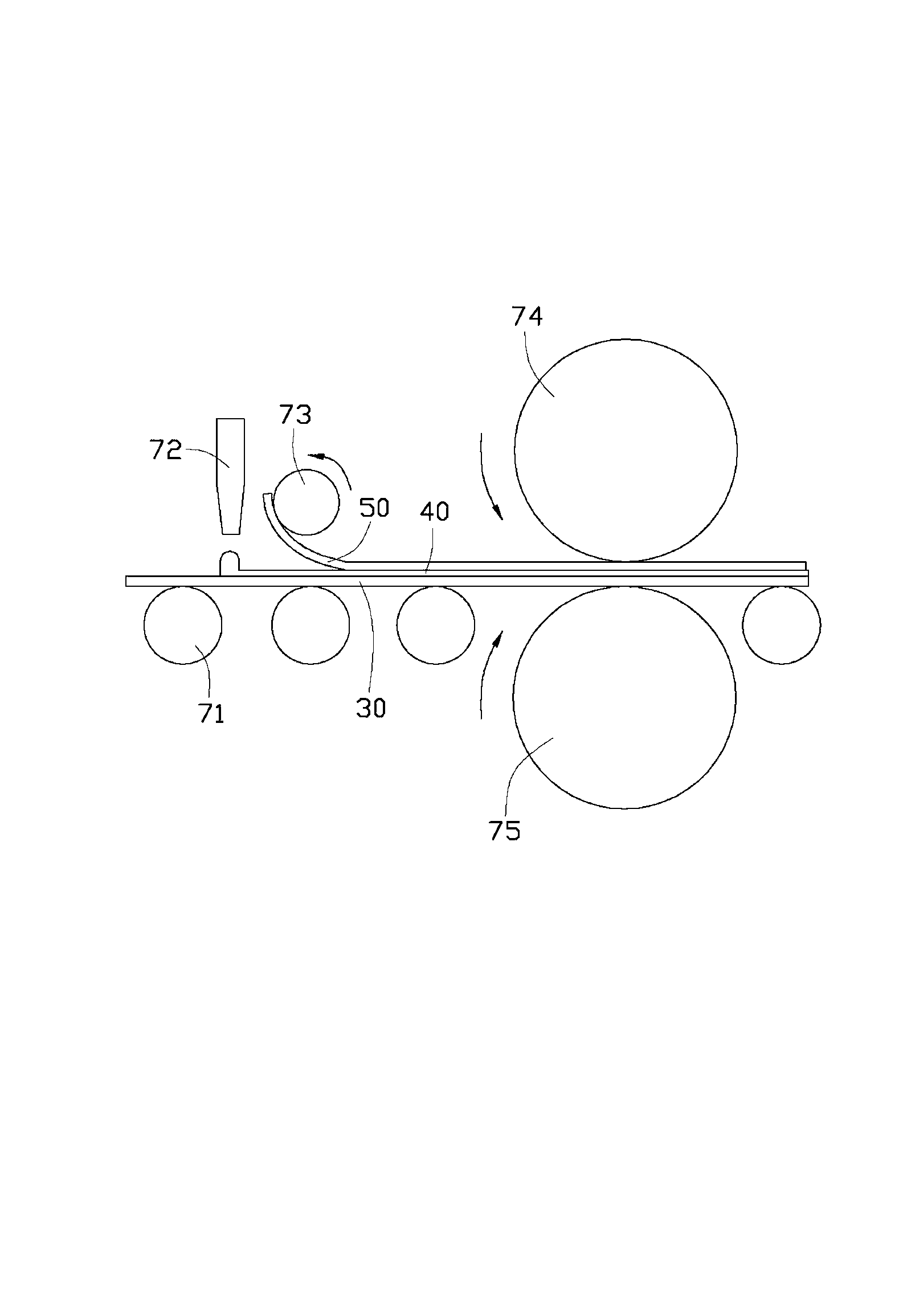

Isolation type non-woven fabric textile winding machine and application method

The invention discloses an isolation type non-woven fabric textile winding machine which belongs to the technical field of textile winding. A cooling fan is arranged at the top of a fixed bracket; anupper flattening roller and a lower flattening roller are arranged at the top of a first bracket in sequence from top to bottom; a tensioning roller is arranged at the top of a third bracket; the tensioning roller is connected onto the third bracket through a second connecting shaft; a second through hole is formed in the top of a side wall of a second bracket; a second fixed block is arranged atthe top of the second through hole; a second rigid spring is arranged at the bottom of the second fixed block; a third connecting shaft is provided with a tracking roller; six groups of winding rollers with the same structure are arranged below the tracking roller; the winding rollers are connected with a connecting frame through a fourth connecting shaft; a ratchet wheel mechanism which is matched with a mounting groove is arranged at the left end of a fifth connecting shaft. The winding machine disclosed by the invention is reasonable in structural design and high in automation degree; simple and convenient textile winding work can be ensured and the winding effect of the fabric is remarkable.

Owner:宁夏中恒创越新材料科技有限公司

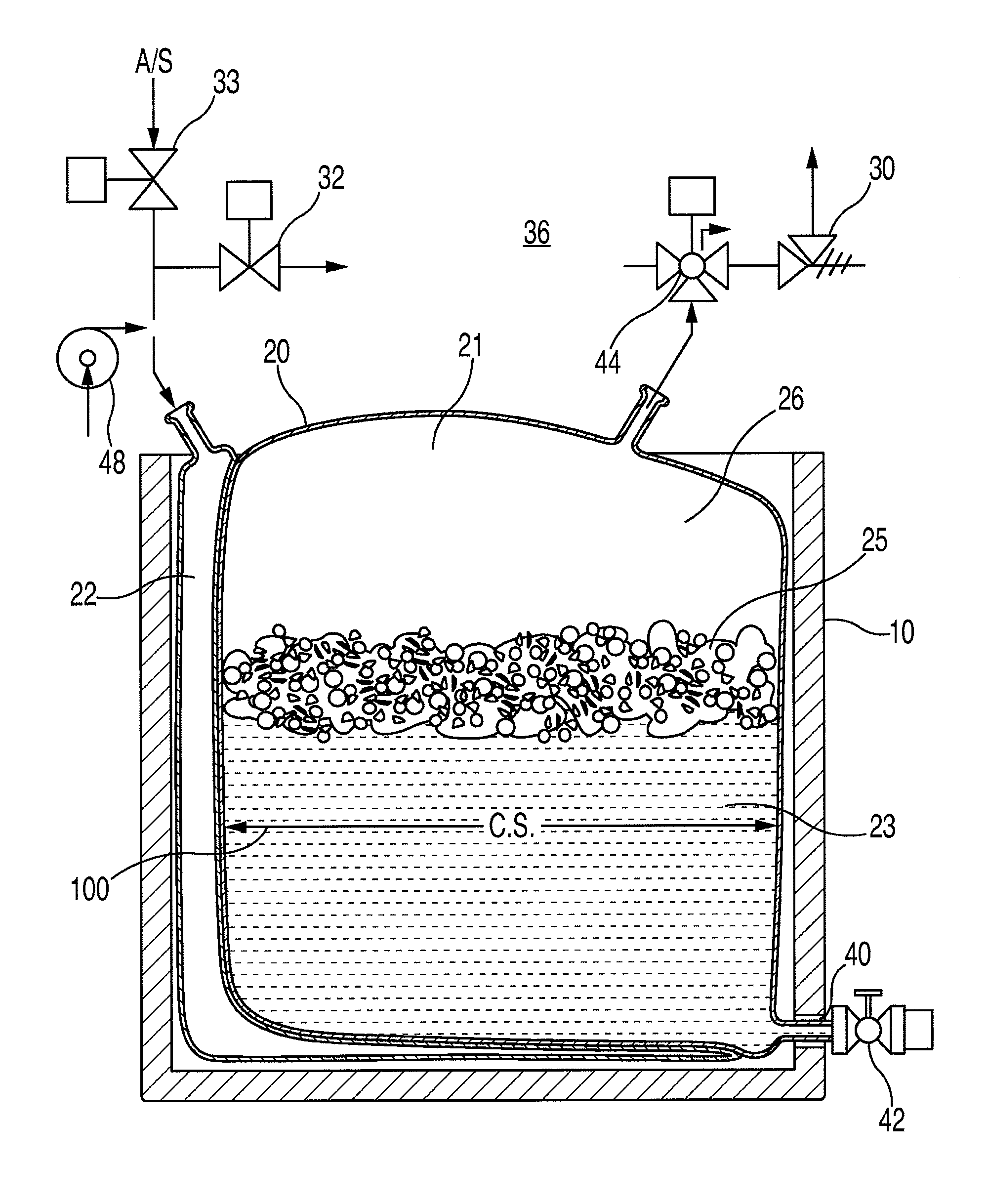

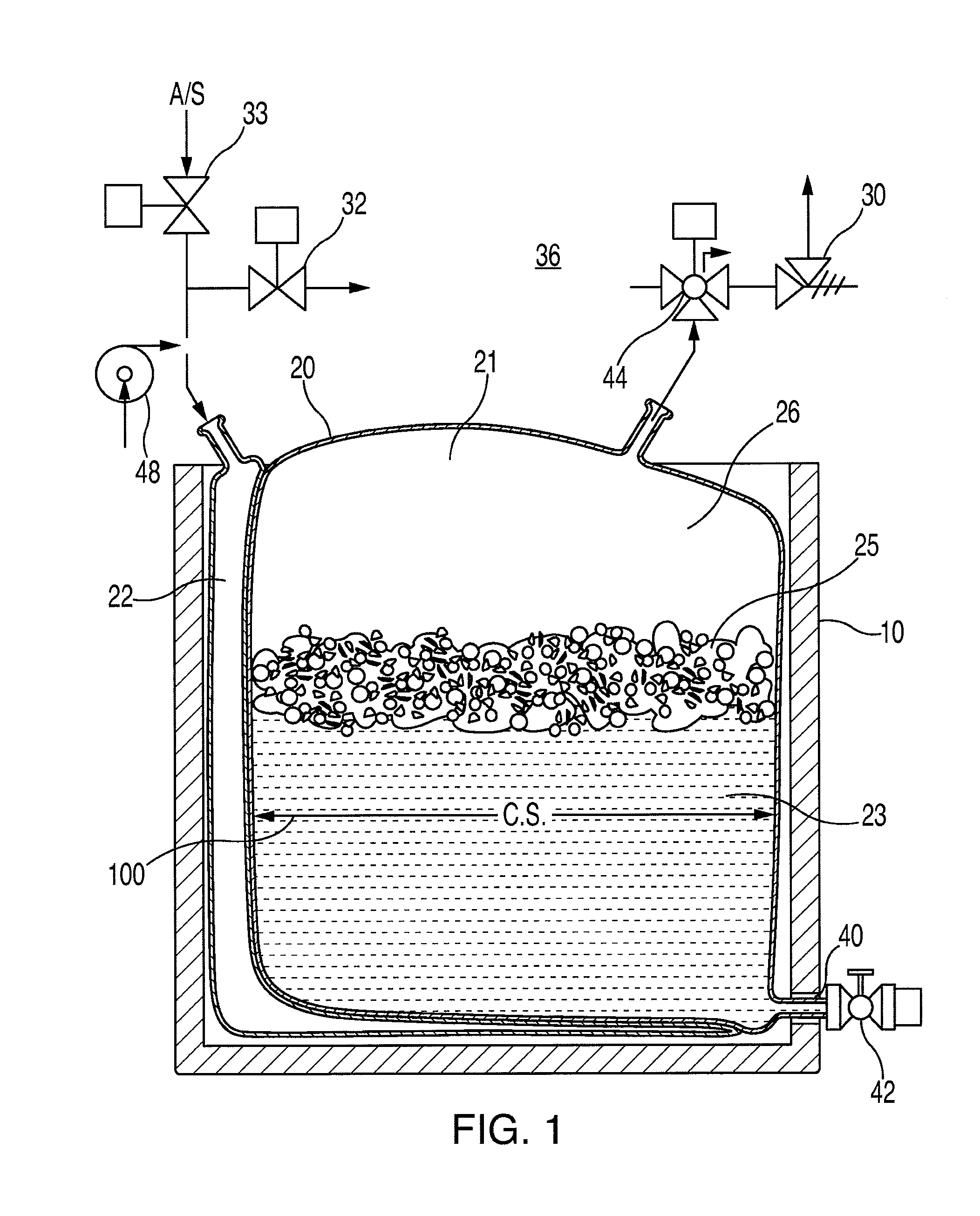

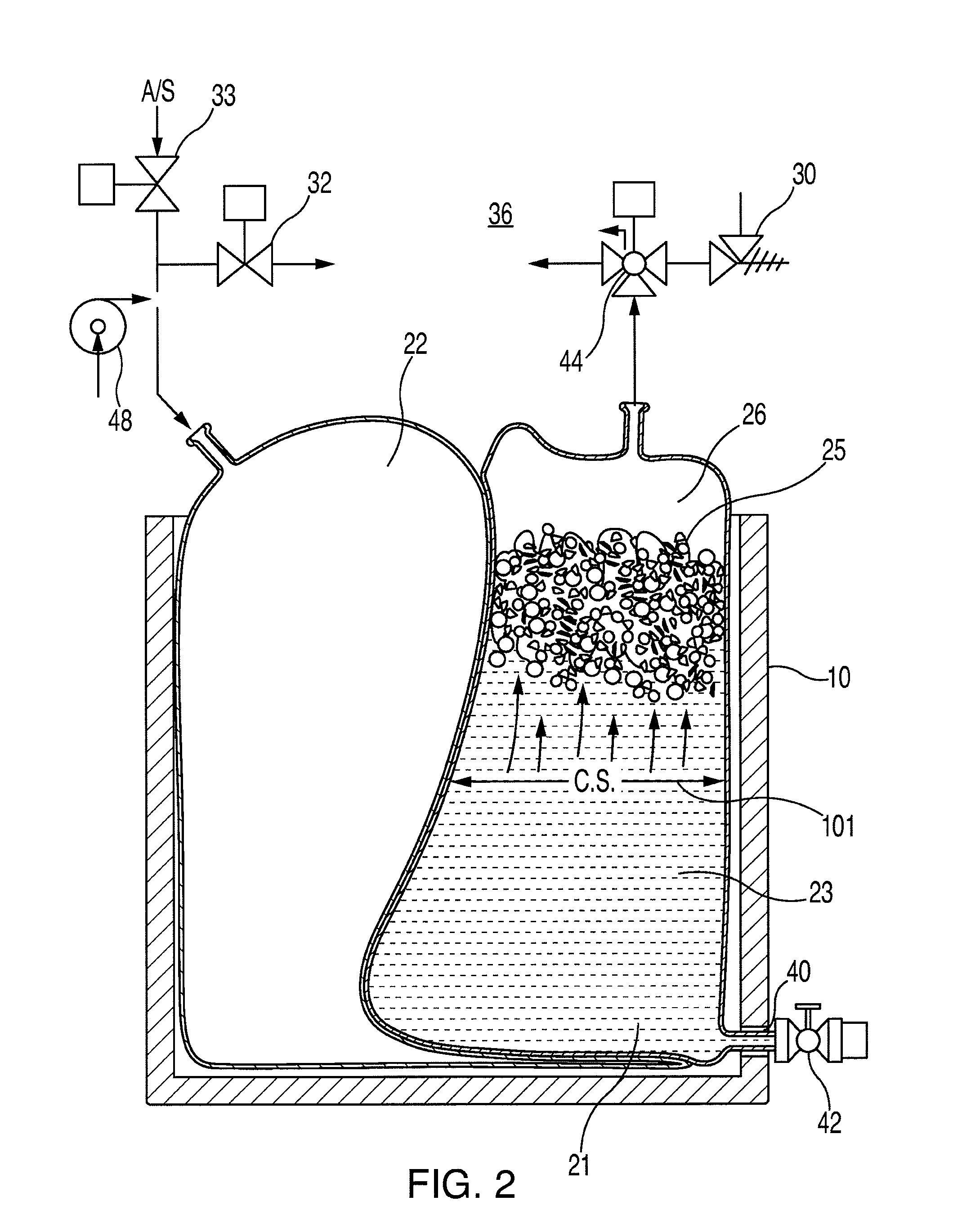

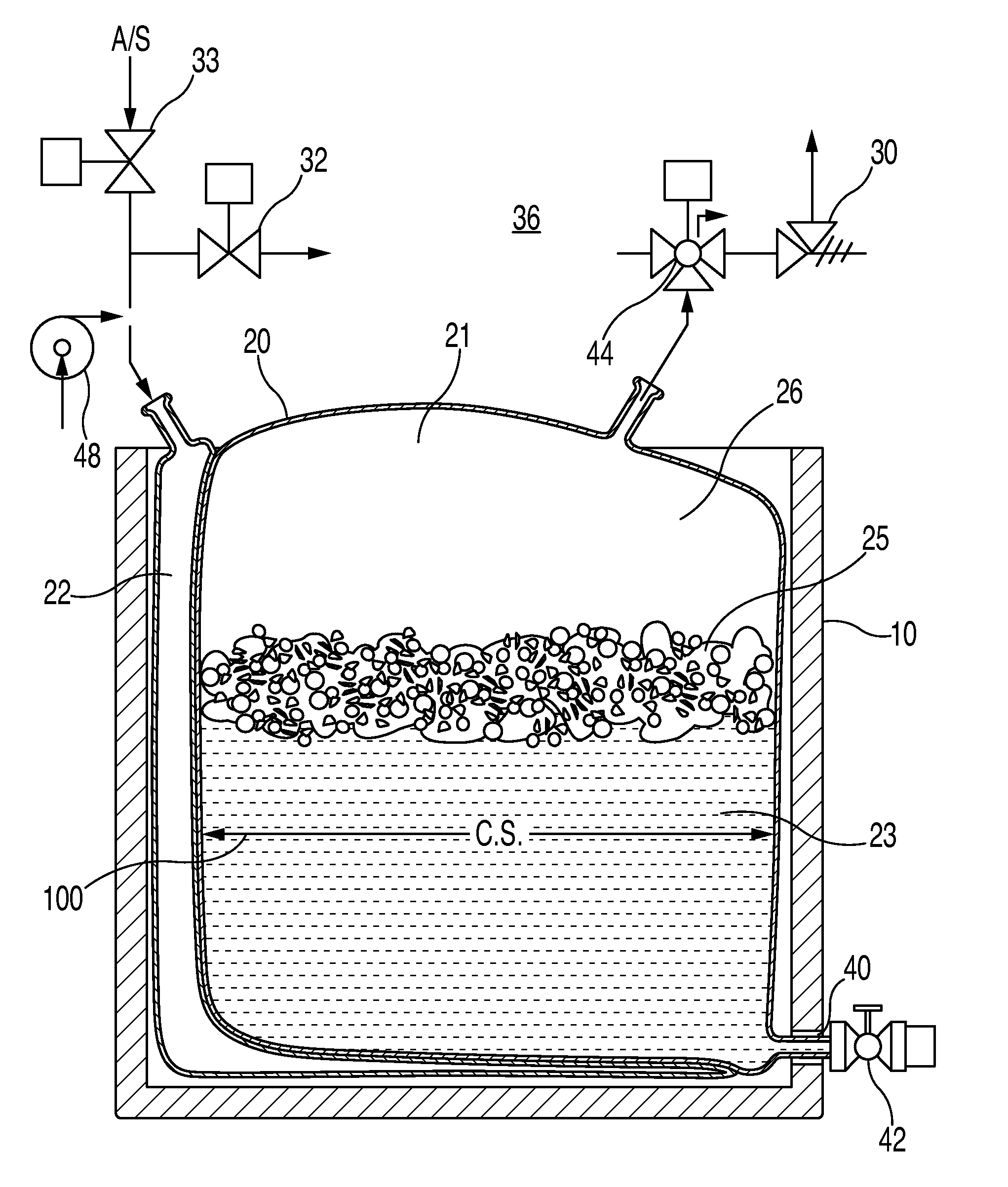

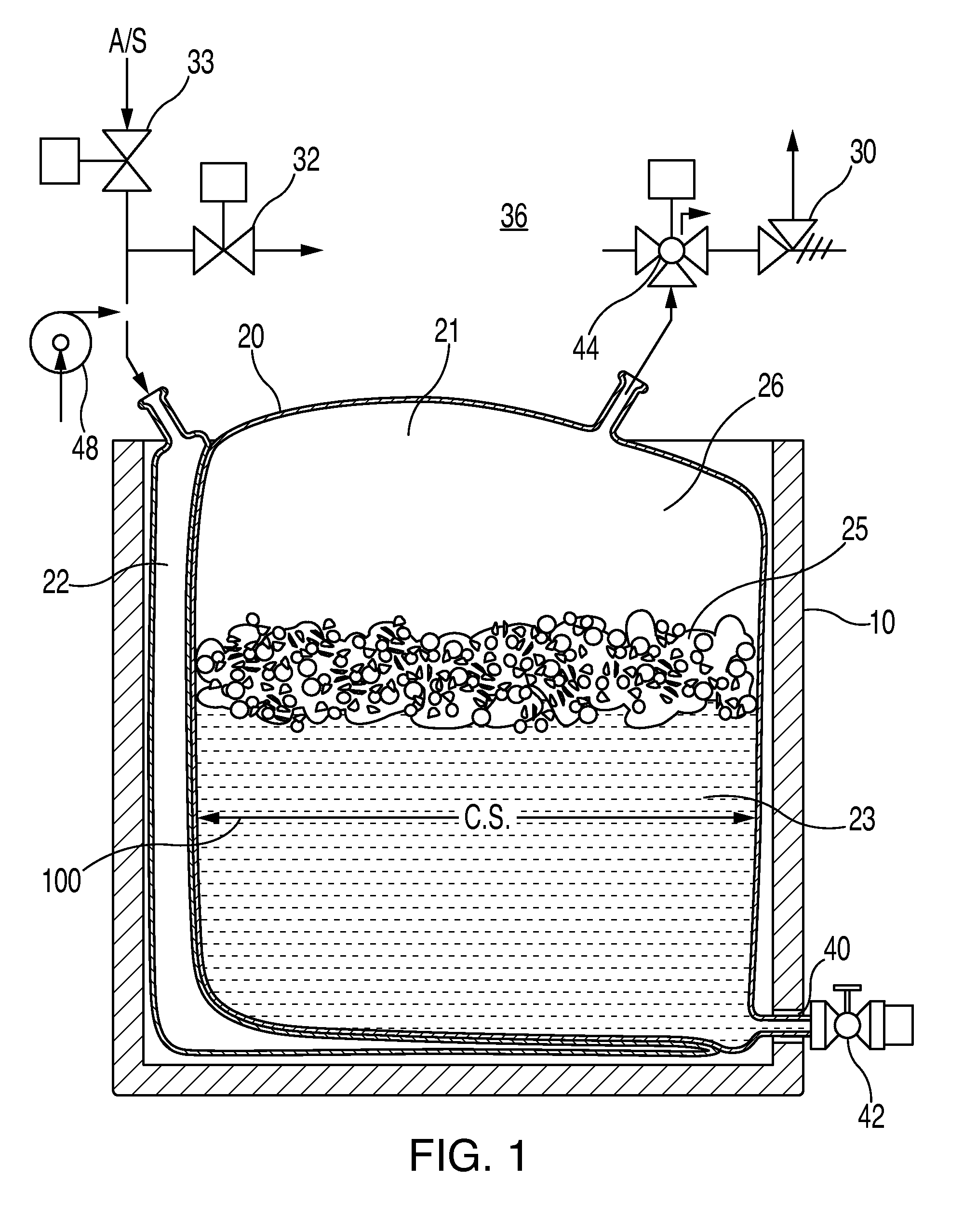

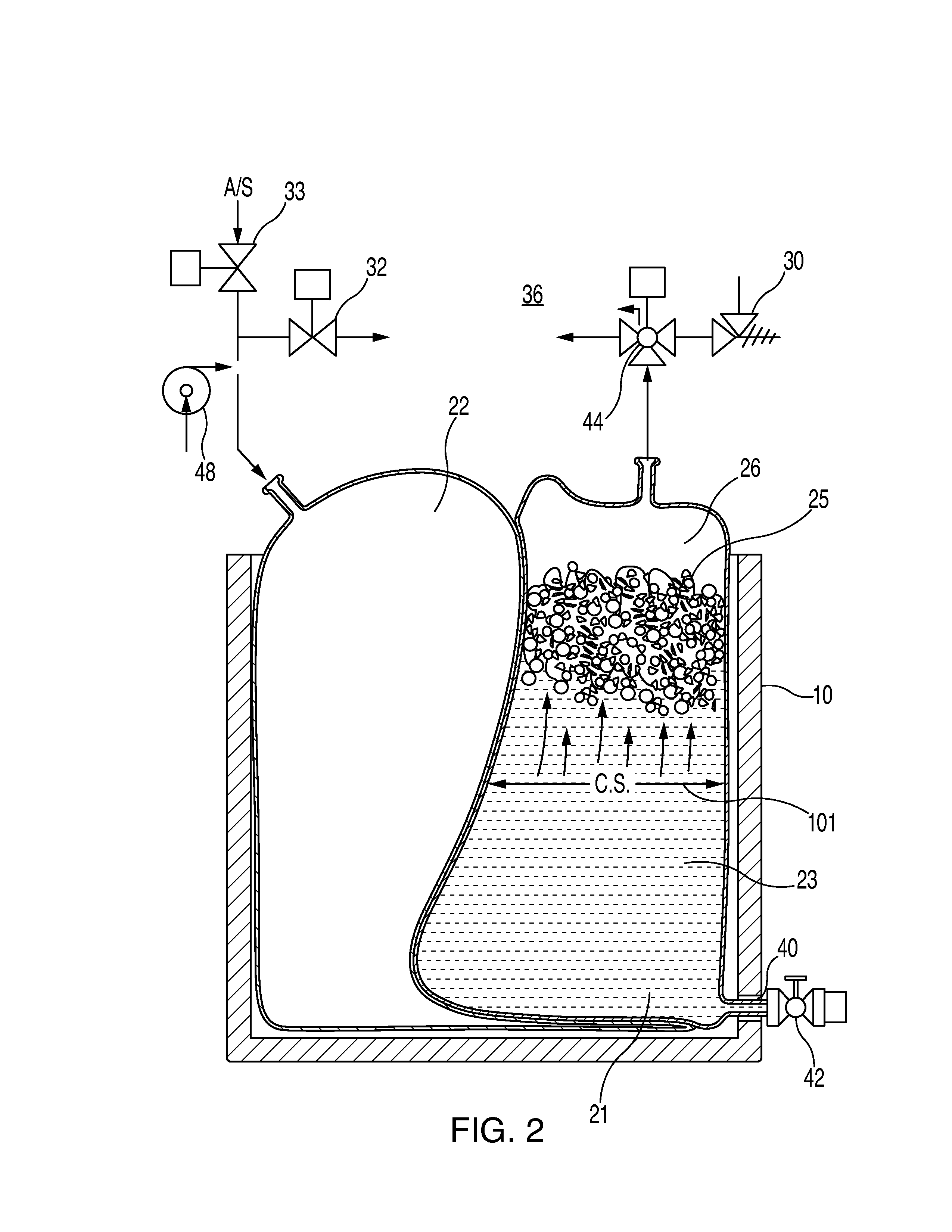

Disposable wine fermentaton vessel with cap management and integral press

ActiveUS20160002578A1Facilitate agitationEasy to manageShaking/oscillating/vibrating mixersTransportation and packagingFlavorFruit juice

A disposable winemaking apparatus for fermenting wine containing skins, seeds, and stems that form a cap includes a single-use, dual chamber plastic bag that incorporates a mechanism to agitate and disperse the cap in order to maximize extraction of color and flavor. It also includes an integral press mechanism to squeeze out the fermented juice through a strainer, retaining the pomace in the disposable bag. The device may also be used for racking and transfer of wine during aging.

Owner:SINGH VIJAY

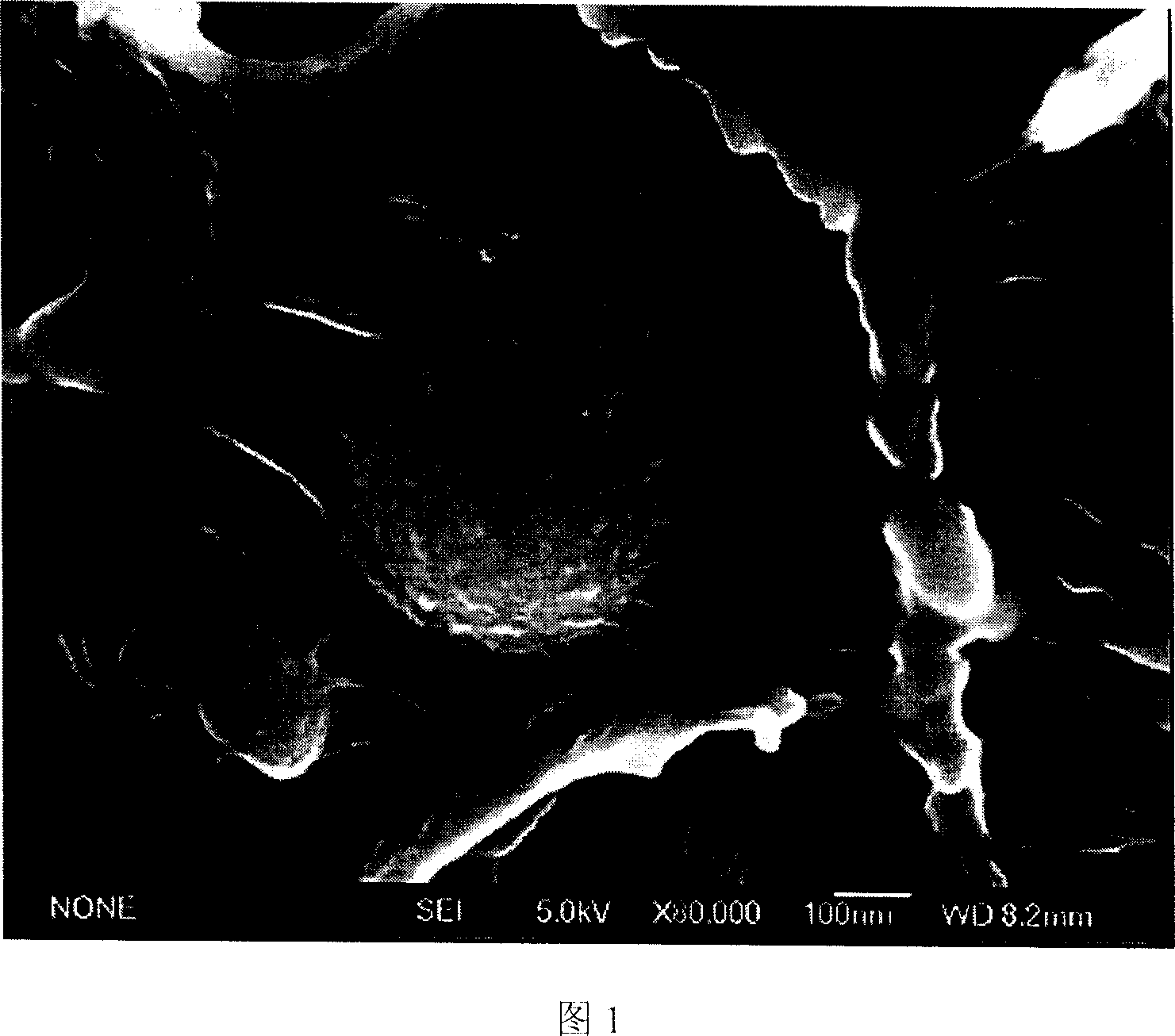

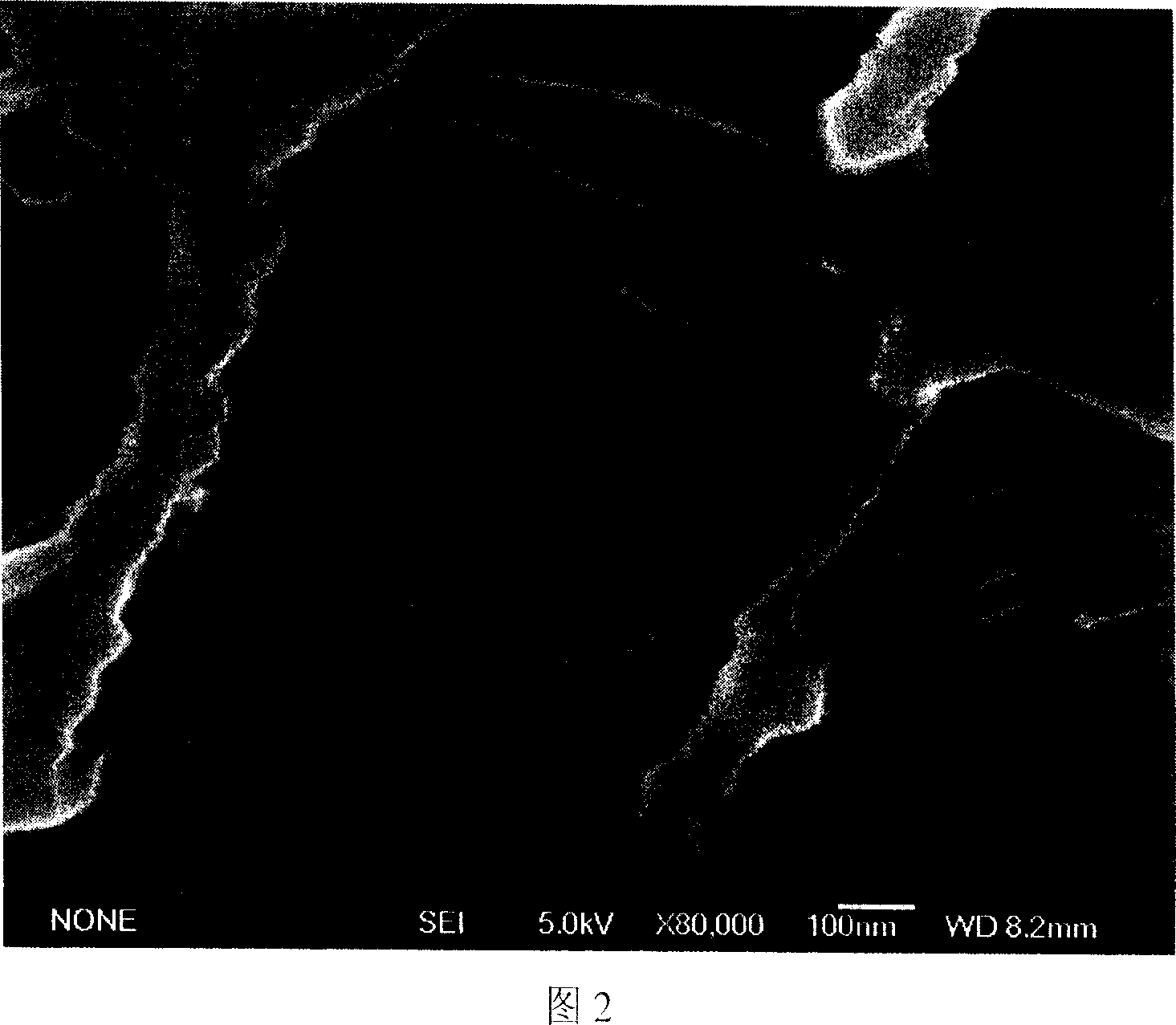

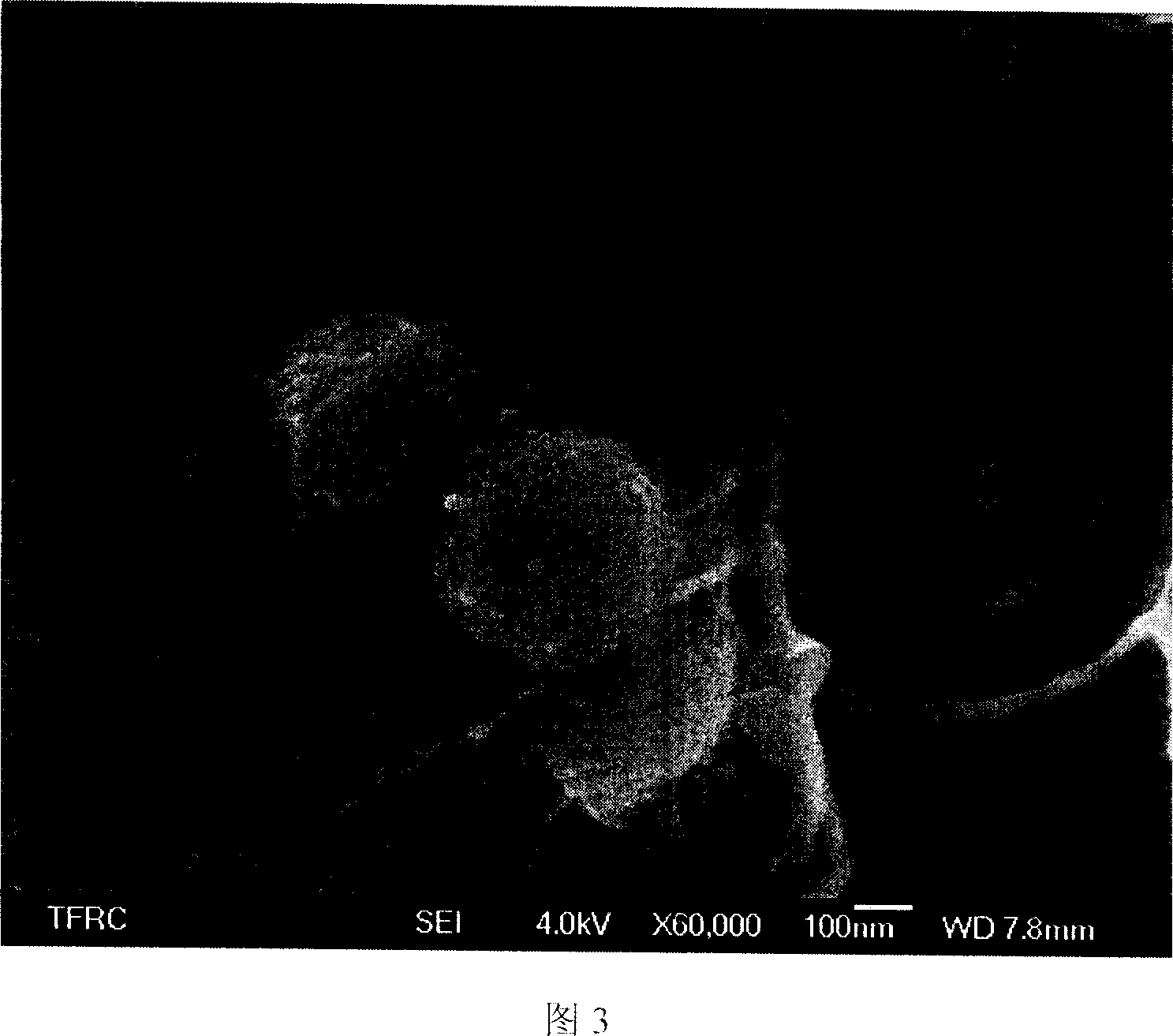

Composite material formed of organic polymer and mesoporous molecular sieve and its interface structure and preparation method thereof

InactiveCN101062958ALarge specific surface areaMesoporous channels are regular and orderlyMolecular sievePolymer resin

The invention discloses a composite material and interface structure and preparing method, which comprises the following steps: choosing medium hole polymer molecule organic monomer and reaction aids as raw material; adding the medium hole molecular screen into liquid organic monomer dissolved with reaction aids; generating organic polymer molecule in the pore path of the medium hole molecular screen; projecting along pore path to outside under proper polymeric condition; forming organic-inorganic interconnected network hybridization particle; merging the organic polymer molecule in molecular screen and homopolymer molecule out of the molecular screen tightly; forming the product. The interface structure of this composite material likes 'rambutan' appearance, which hot property and dynamic property possesses bigger improvement.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

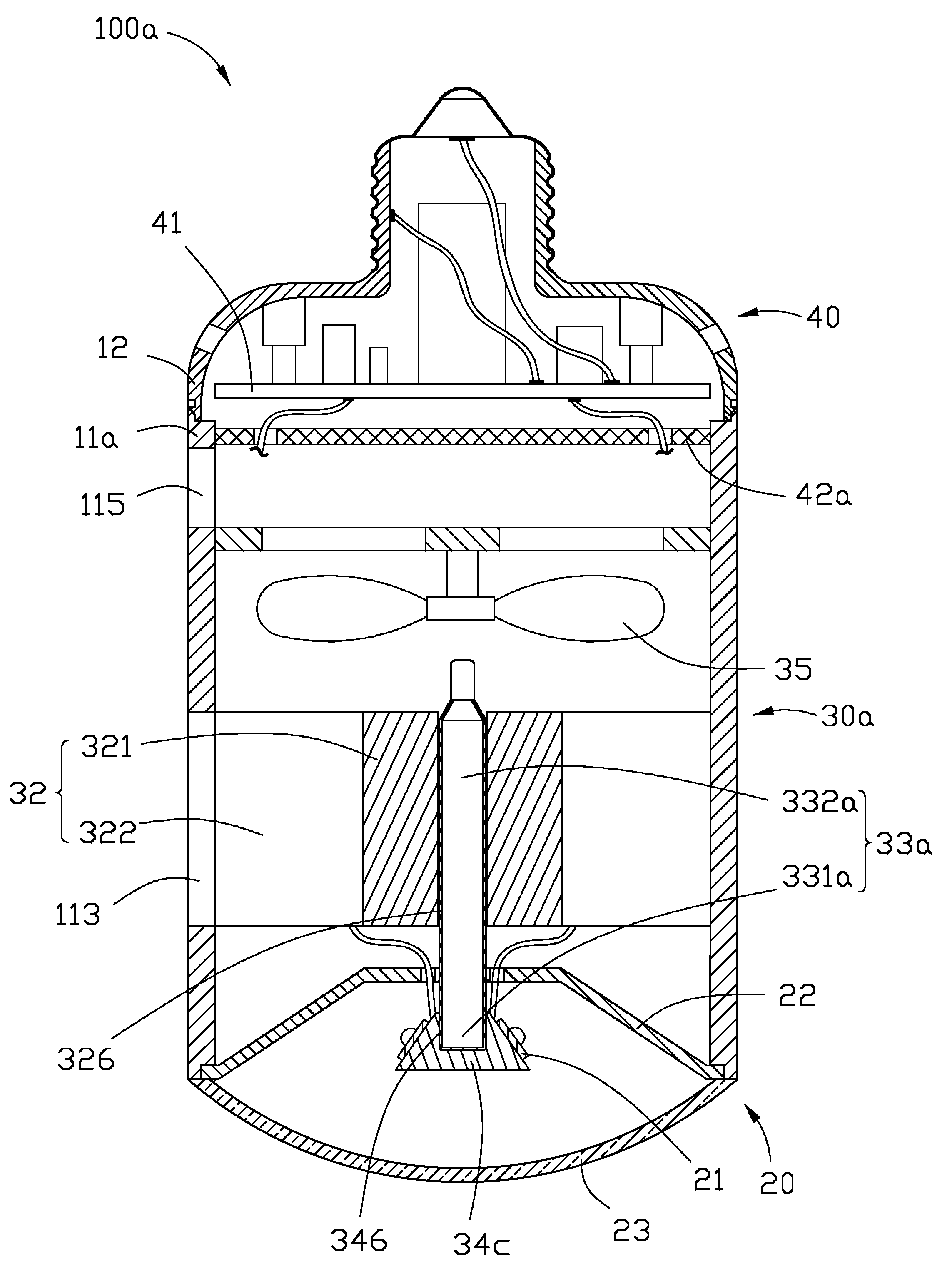

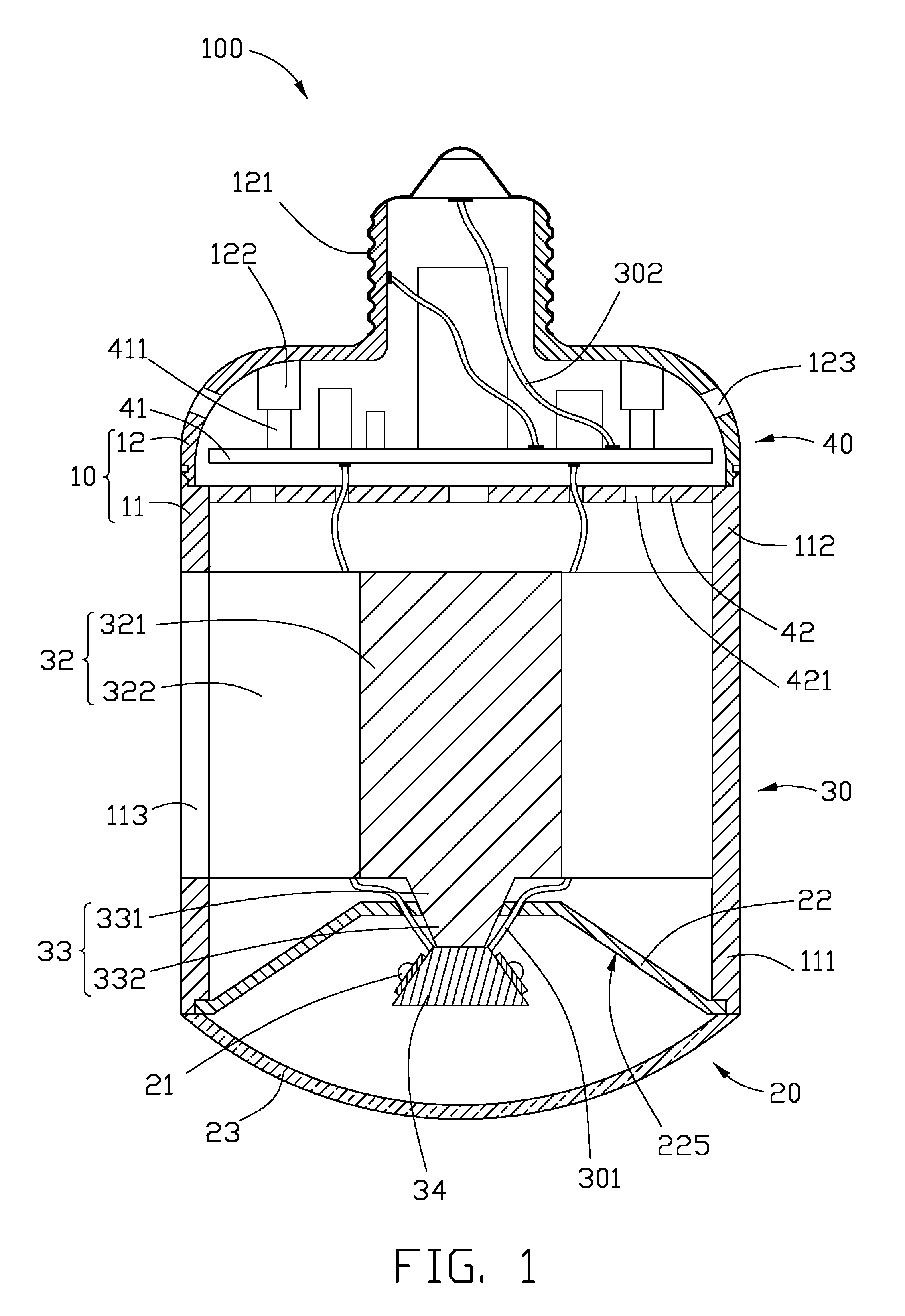

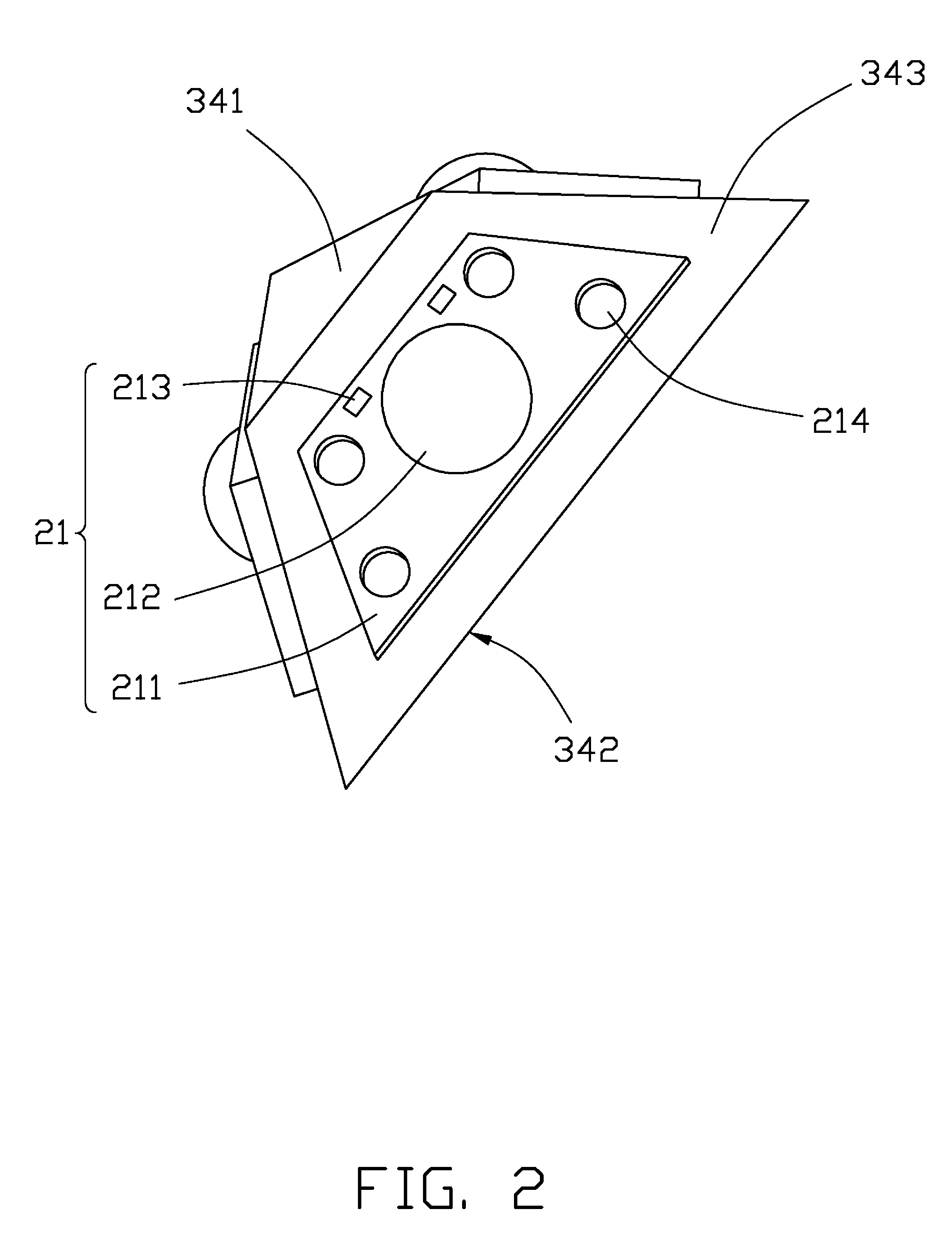

LED lamp

InactiveUS7847471B2Remove airSolve the low heat dissipation efficiencyPoint-like light sourceSolid-state devicesHeat conductingEngineering

An LED lamp includes a hollow lamp housing, a front optical part, a rear electrical part, and a middle heat dissipation part. The heat dissipation part includes a heat sink, a mounting seat in front of the heat sink, and a heat conducting member connecting the mounting seat with the heat sink. The lamp housing defines a plurality of air exchanging holes corresponding to the fins. The mounting seat includes a small top surface, an opposite large bottom surface, and a plurality of sloping heat absorbing surfaces between the top surface and the bottom surface. The optical part includes a plurality of light sources arranged on the heat absorbing surfaces, a light reflector located between the heat sink and the mounting seat and surrounding the heat conducting member, an optical lens located in front of the light reflector and the mounting seat.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Method for producing alumina homogenization material

ActiveCN101121604AImprove high temperature corrosion resistanceImprove fire resistanceGrain growthMaterials science

The present invention discloses a preparation method for bauxite material; which uses the aluminium bauxite mineral with loose structure and incapable of baking directly, and is formed through the following steps including matching, grilling, de-iron, filtering, molding and drying and baking. The main crystal phase of the bauxite material is Alpha- Al2O3, whose section is caesious with compact texture and inerratic crystal grain growth; most of the material is more than 15um; each physical index reaches or even exceeds the bauxite material produced in domestic; compared with the existing technology, the material has the advantages of lower baking temperature and shorter baking time and so on.

Owner:PUYANG REFRACTORIES GRP CO LTD

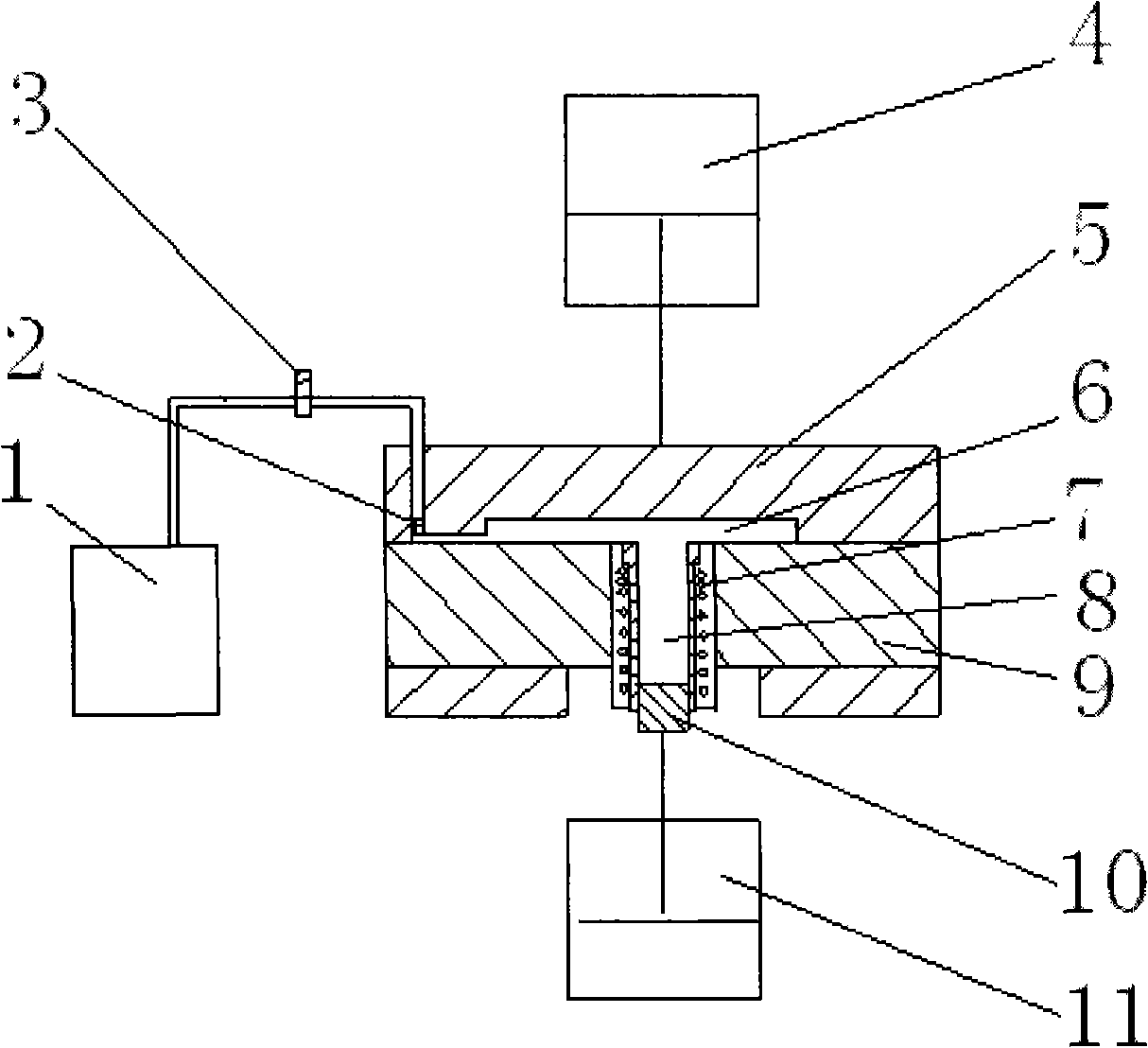

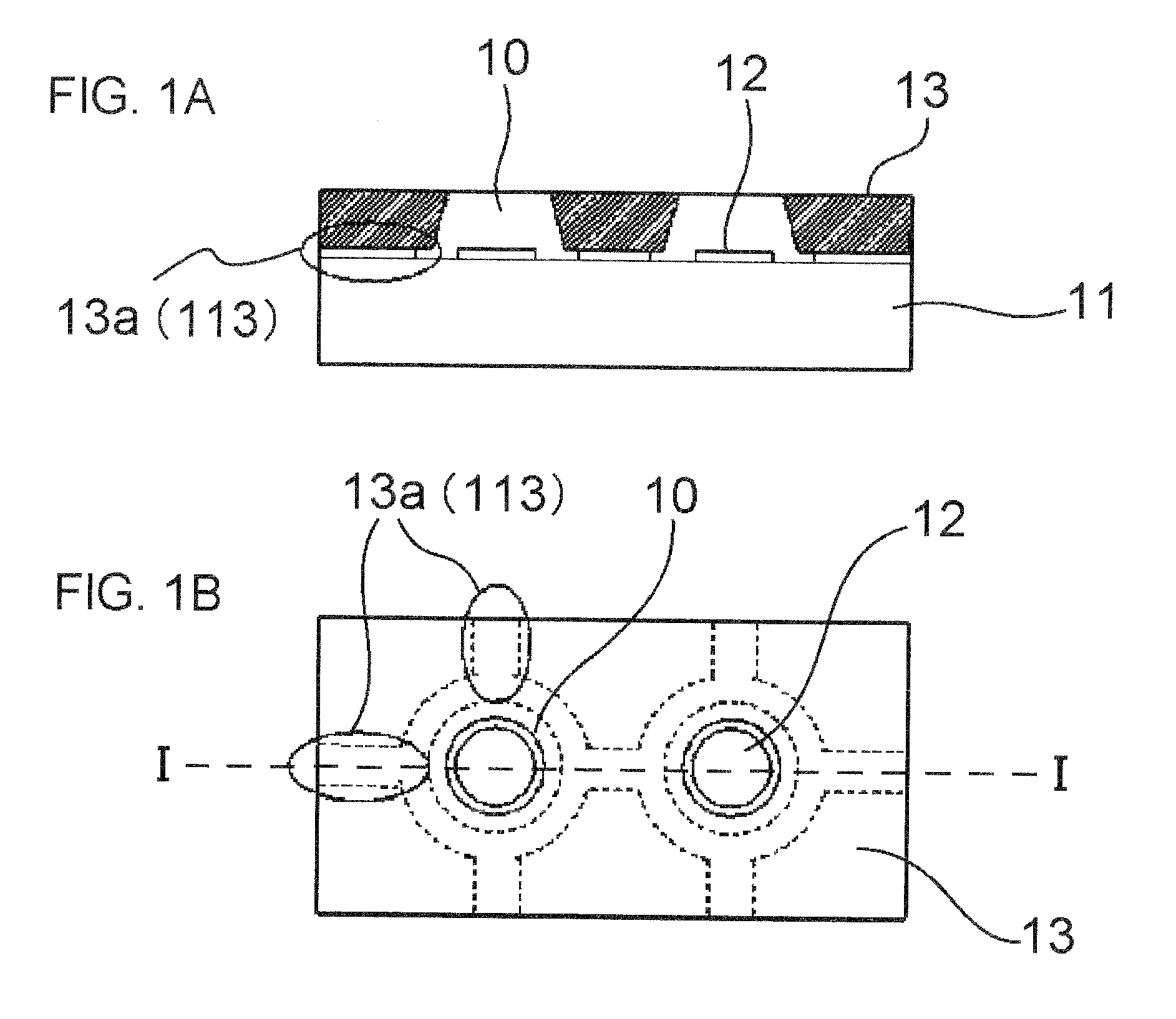

Method for printing a metal paste, metal mask, and bump forming method

InactiveUS20090239091A1Improve fill rateRemove airPattern printingPrinted circuit manufactureFiller metalMetal

A method for printing a metal paste includes the step of arranging, to locate a through hole of a metal mask having the through hole on an electrode, a metal mask on a substrate and forming a gap portion communicating with the through hole in an interface between the substrate and the metal mask. According to this method, in filling of a metal paste, a flux oozing on a surface of the metal paste can be moved to the gap portion. In other words, a deaeration path for residual air in the metal paste clogged by the flux can be secured by removing the flux. In this manner, in the through hole, the remaining air in the metal paste can be removed, and a filling rate of the metal paste can be increased.

Owner:RENESAS ELECTRONICS CORP

Inkjet recording apparatus and air removal method therefor

ActiveUS20080007605A1Remove airHigh viscosityOther printing apparatusHead holderElectrical and Electronics engineering

There is provides an inkjet recording apparatus comprising: an inkjet head held in a head holder; and an ink tank mounted on the head holder. The ink tank has an ink chamber, a path for communicating the chamber with atmosphere, and an exit valve to open and close the path. The apparatus further comprises: an ink cartridge arranged below the ink tank for supplying the ink to the ink chamber through a channel; an operating member for opening and closing the exit valve; a ink transfer device; and a controller. The controller performs controls of causing the operating member to open the exit valve such that an atmosphere pressure affects an inside of the ink chamber, and such that the ink both in the chamber and in the channel returns to the ink cartridge through the channel; and causing the device to fill the chamber.

Owner:BROTHER KOGYO KK

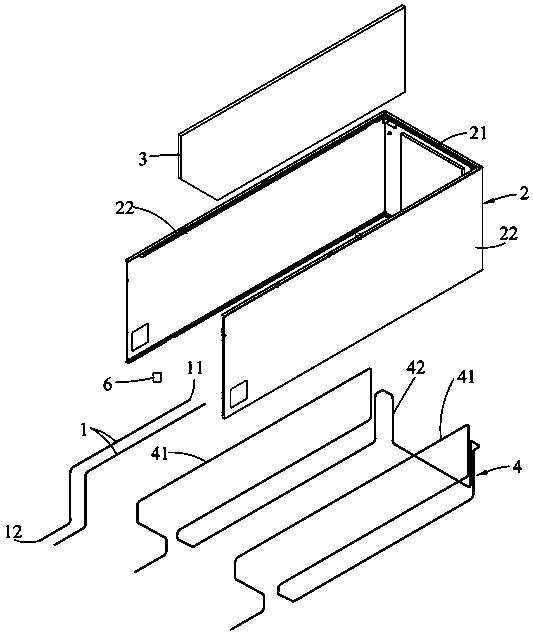

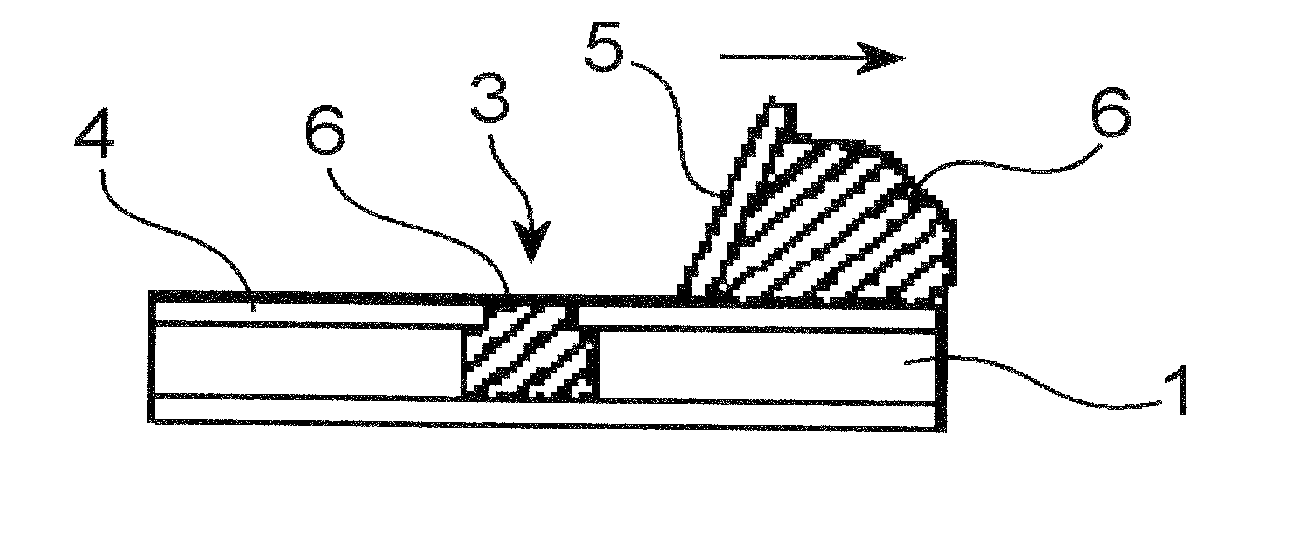

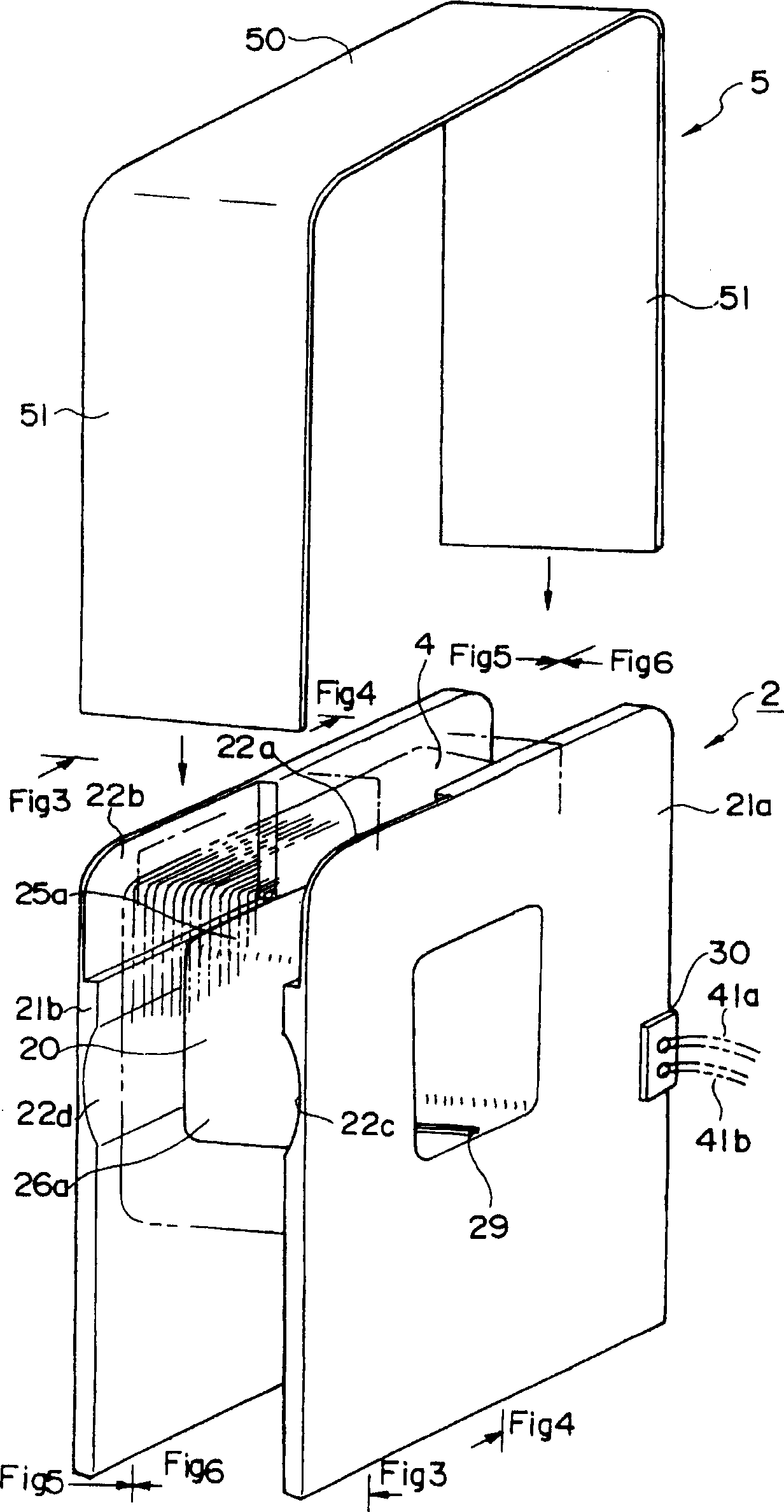

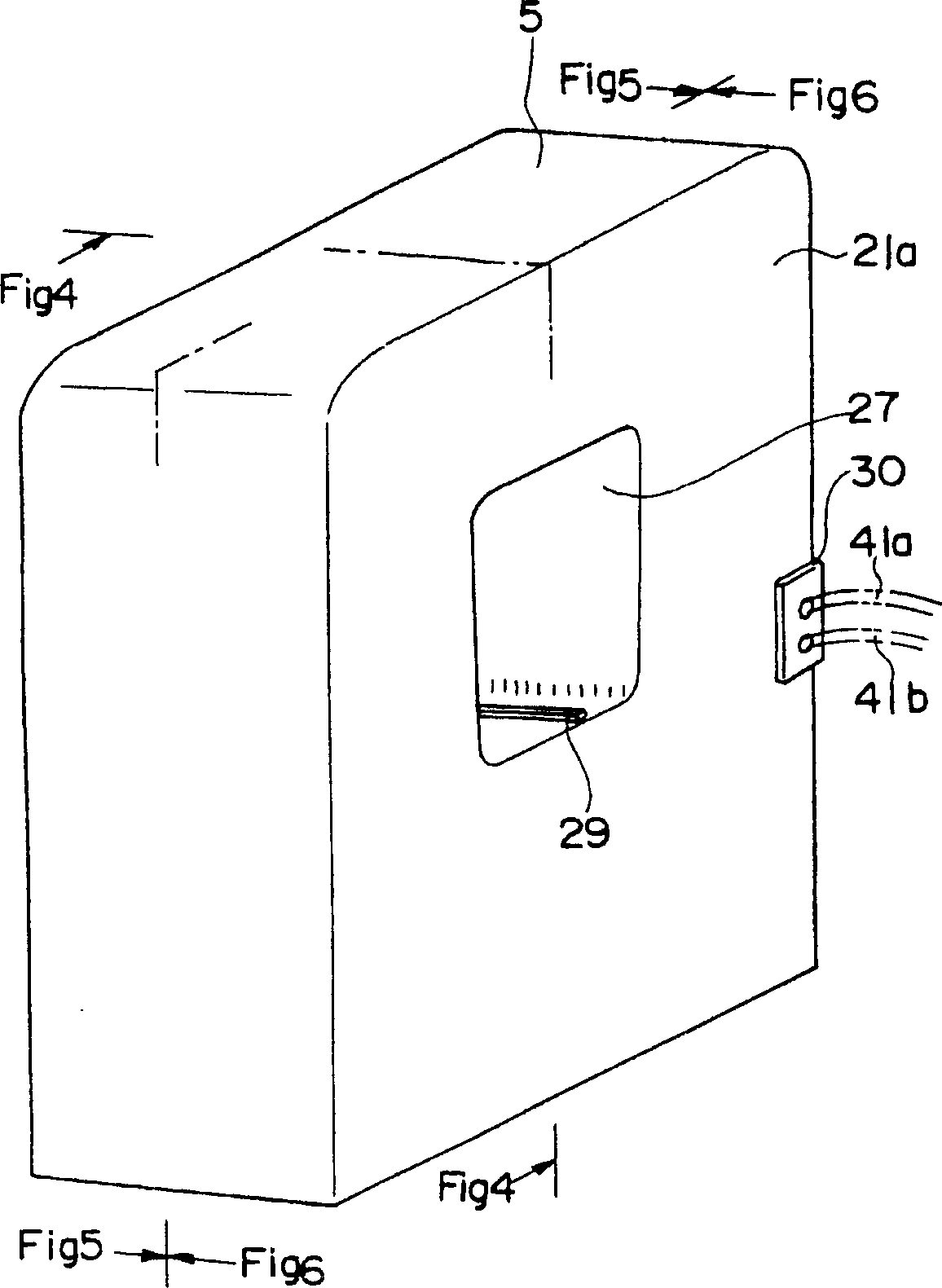

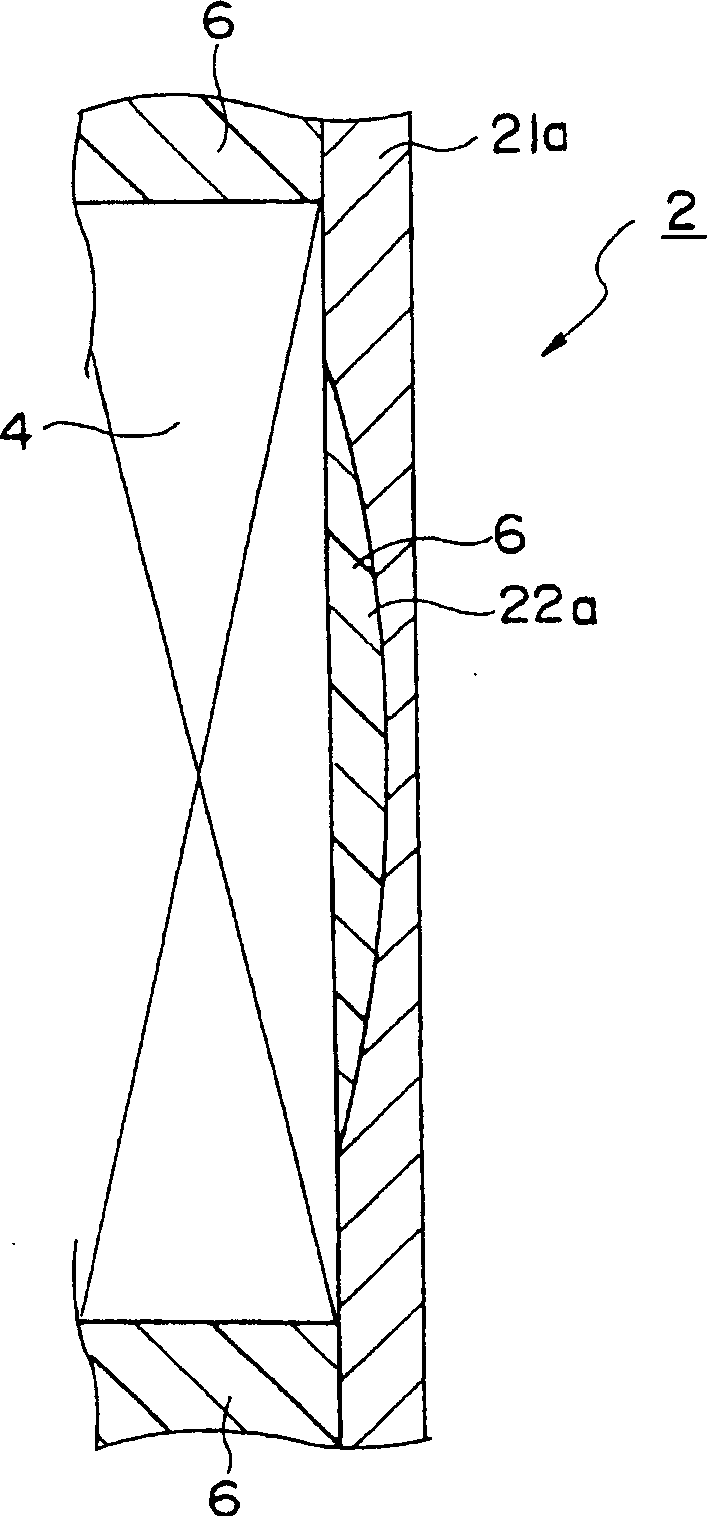

Electromagnetic coil and its manufacturing method and coil form

InactiveCN1412790ARemove airOperating means/releasing devices for valvesTransformers/inductances coils/windings/connectionsBobbinTreatment use

To provide an electromagnetic coil that can be used for a long period in an electric motor, solenoid-controlled valve, electromagnetic actuator, etc. This electromagnetic coil is composed of a coil bobbin 3, a coil 4, and a coil case 5. The coil 4 is sealed with a molding resin. Recessed sections 22a, 22b, 22c, 22d, etc., up to the outer peripheral surfaces 25a, 26a, etc., of a core 20 are formed on the internal side faces of the flanges 21a and 21b of the coil bobbin 2. In addition, the molding resin 6 which seals the periphery of the winding 4 is packed in the internal space between the flanges 21a and 21b of the bobbin 2 and the coil case 5, recessed sections 22a, 22b, 22c, 22d, etc., of the flanges 21a and 21b, and the space (not shown in the picture.) formed between the outer peripheral surfaces 25a, 26a, etc., of the core 20 and the coil 4 through vacuum defoaming treatment using the casting method.

Owner:FUJIKOKI MFG CO LTD

Ultrahigh molecular weight polyethylene bulletproof plate

InactiveCN102538589AThe overall thickness is thinReduce usageSynthetic resin layered productsLaminationFiberPolymer science

The invention provides an ultrahigh molecular weight polyethylene bulletproof plate which comprises a plurality of ultrahigh molecular weight polyethylene weftless fabrics with the density of above 135g / cm<2>. The fiber filaments in adjacent two polyethylene weftless fabrics are arranged at angles of 0 / 90-45 / 45 degrees. The ultrahigh molecular weight polyethylene bulletproof plate provided by the invention has light weight, high strength and high modulus.

Owner:杨珍芬

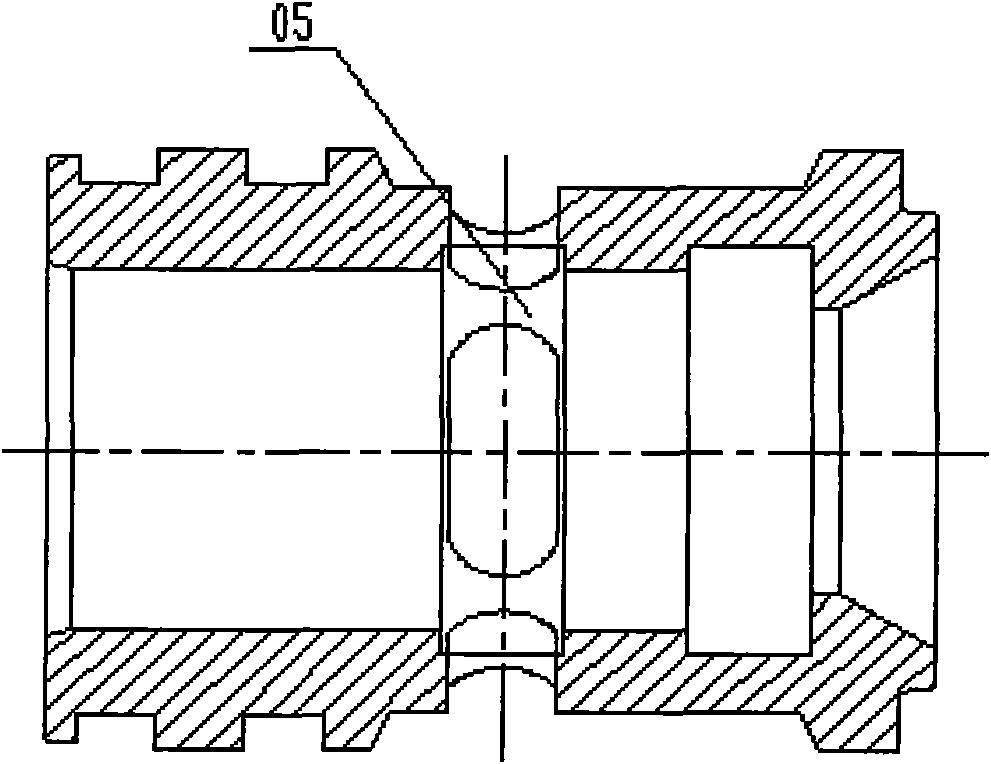

Hydraulic control flow valve

ActiveCN102313044ACompact structureEasy to processOperating means/releasing devices for valvesValve members for absorbing fluid energyExhaust valveControl engineering

The invention discloses a hydraulic control flow valve, which comprises a main valve core and a main valve body, wherein the main valve core is arranged in a main valve sleeve; the main valve sleeve is arranged in a main valve body stepped hole; an oil outlet sleeve is arranged in the main valve body stepped hole below the main valve sleeve; seal rings are arranged between the oil outlet sleeve and the main valve sleeve as well as between the oil outlet sleeve and the main valve body; a sealing member is also arranged between the main valve core and the main valve sleeve; an overflow valve insert and a pressure compensation insert are assembled on the main valve body through threads in a matching way; a cover plate is arranged above the main valve sleeve and is provided with a pressure gauge and an exhaust valve; and seal rings are arranged between the cover plate and the main valve sleeve and at the junction of the cover plate and a main valve body control oil path hole. The hydraulic control flow valve has the advantages of simple structure, convenience in processing, repair and replacement, stable and reliable speed adjustment, good sealing property, simple pipeline connection,small occupied space, convenience in observation and control of pressure and flow, small squeal during work and small jitter of the main valve core. The hydraulic control flow valve is mainly appliedto a drainage system of a liquid cargo ship and the like.

Owner:SHANGHAI LIXIN HYDRAULIC

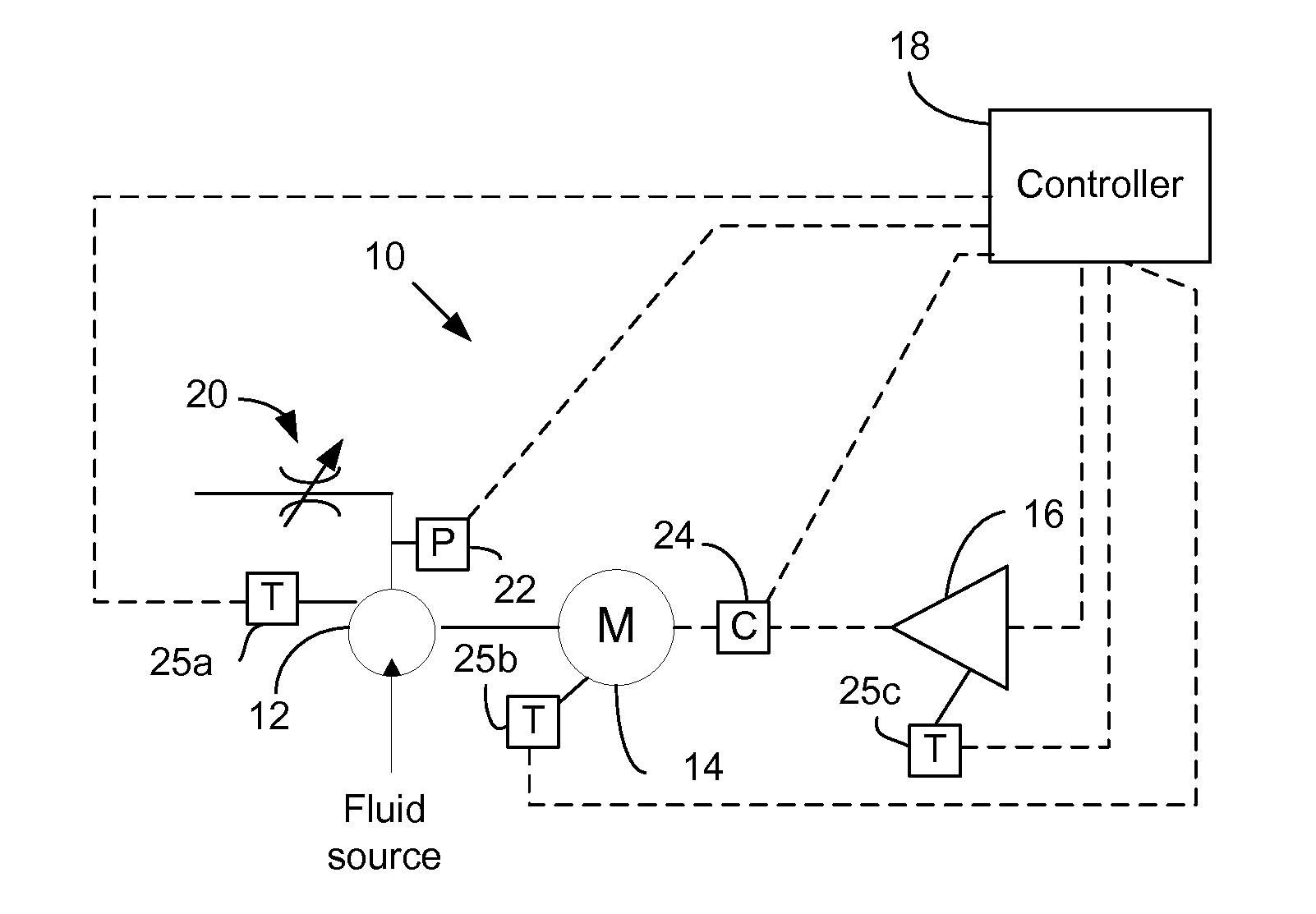

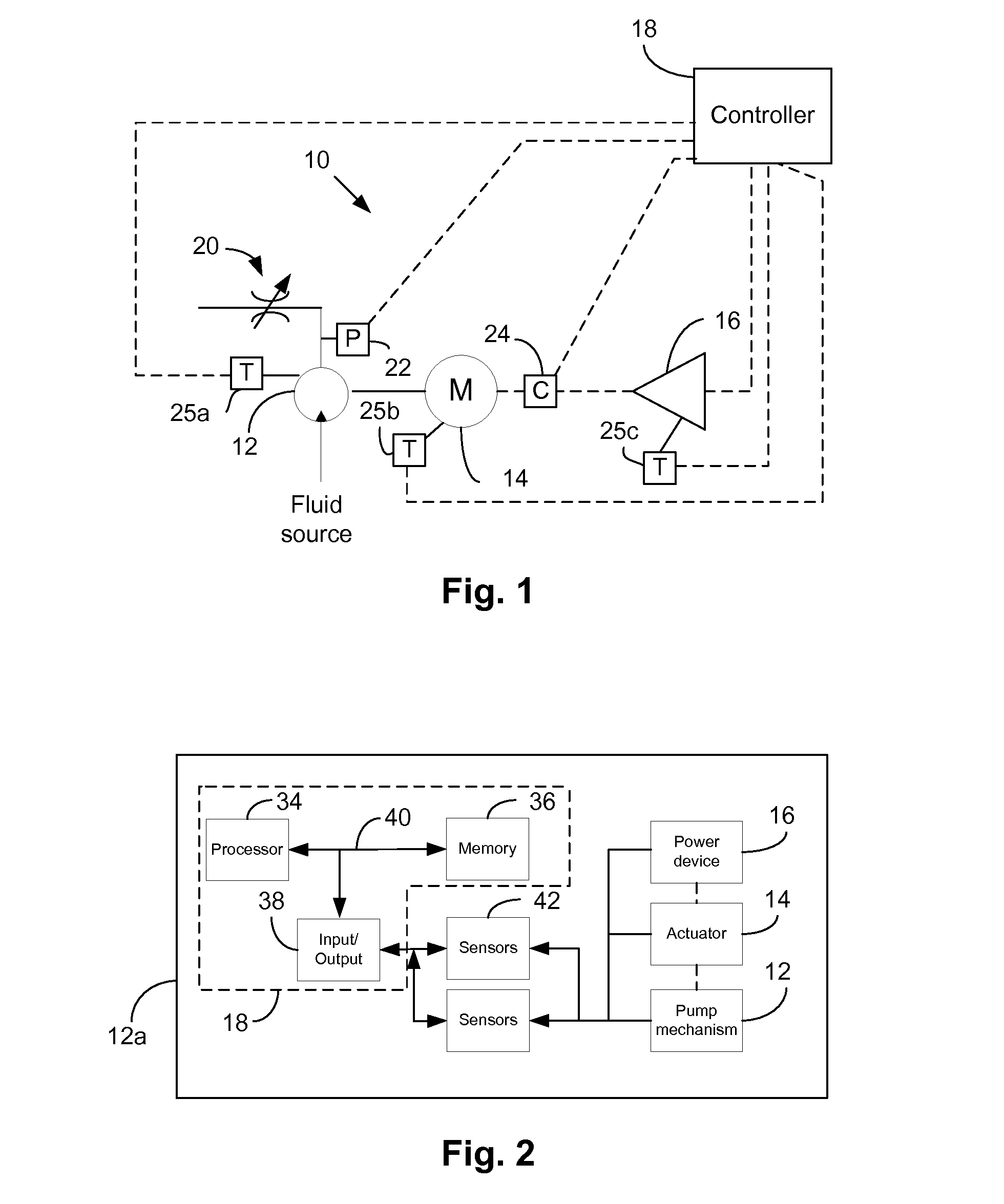

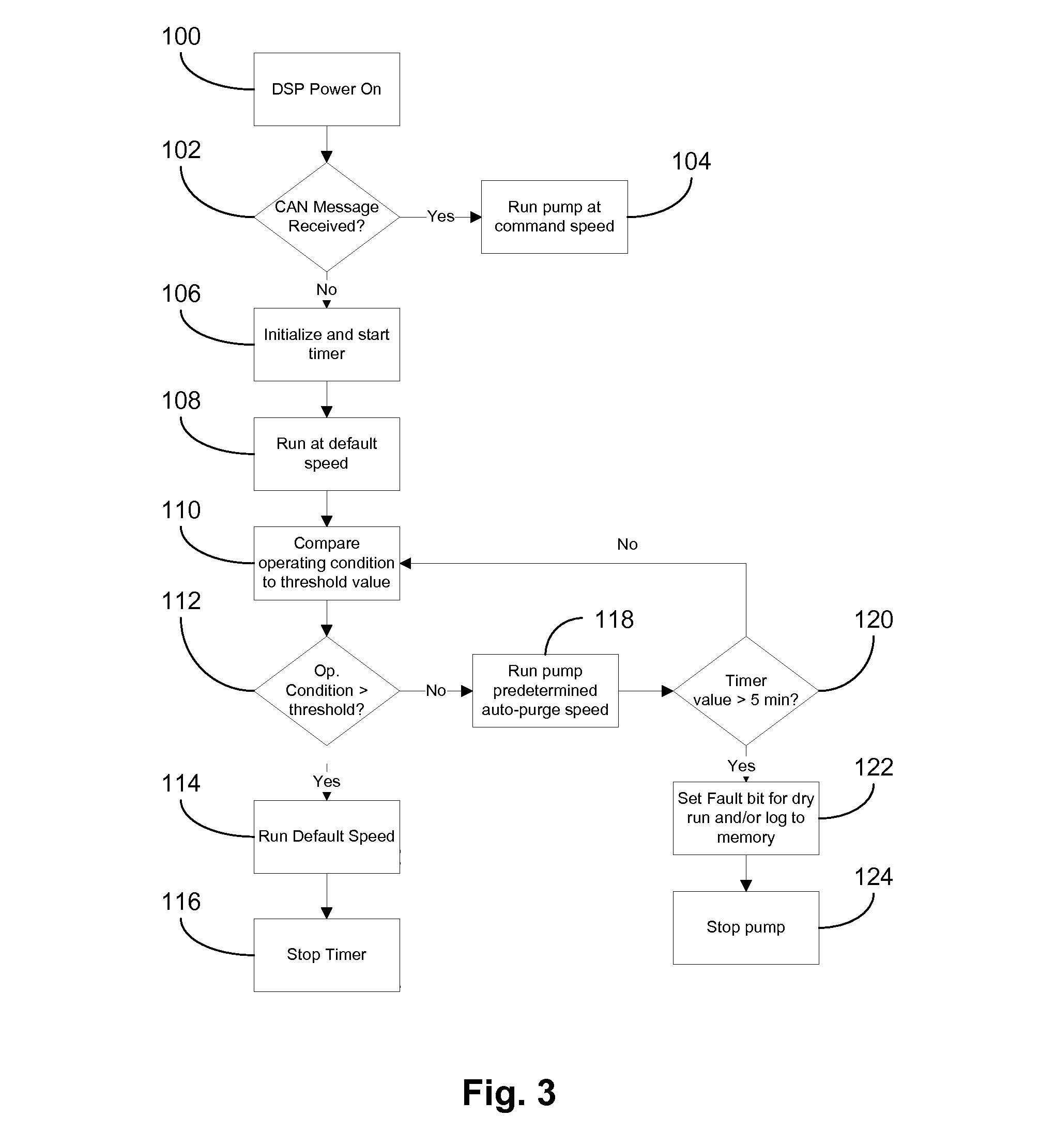

Pump condition monitoring and recovery

InactiveUS20150152860A1Preventing a system shutdownReduced availabilityMotor parameterPump parameterActuatorControl theory

A fluid pumping system includes a fluid pump, an actuator coupled to said fluid pump, and a controller operatively coupled to the actuator. The controller is configured to detect an irregular condition of at least one of the fluid pump, the actuator or the controller, and upon detecting the irregular condition, modify at least one operating parameter of the actuator to prevent the irregular condition from transitioning to a fault condition.

Owner:NICHOLS PORTLAND LLC

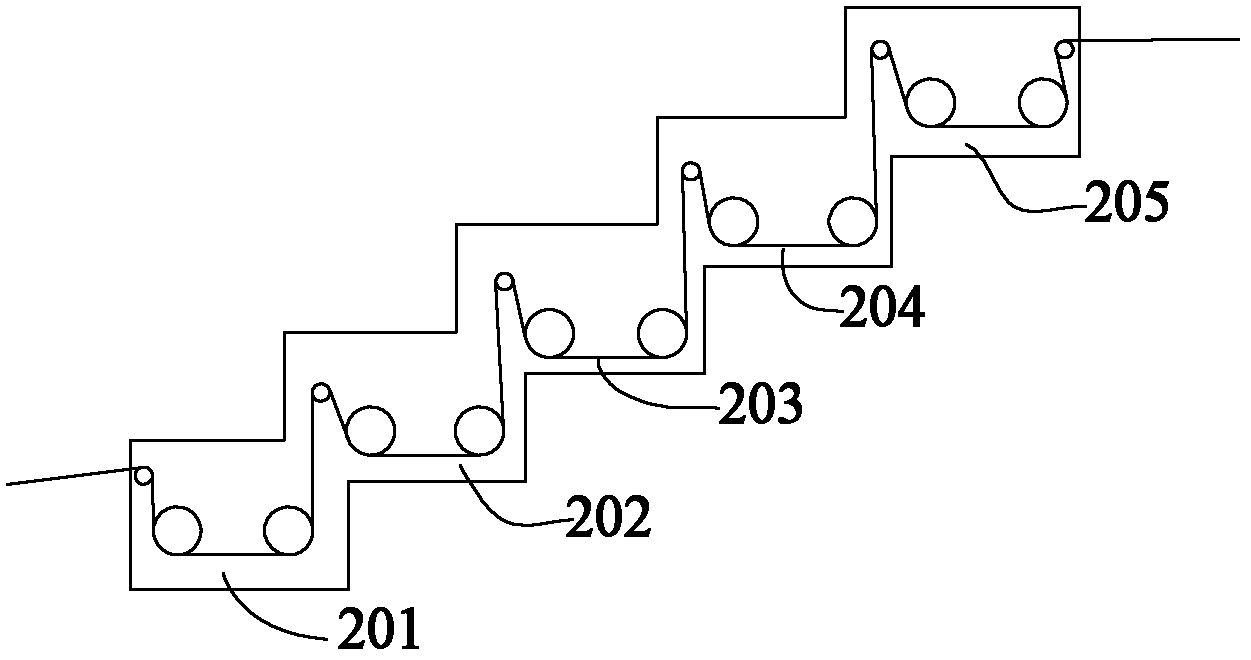

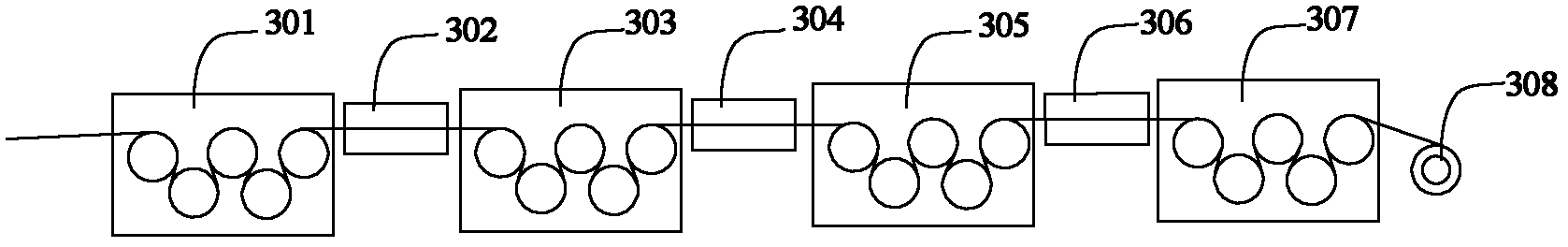

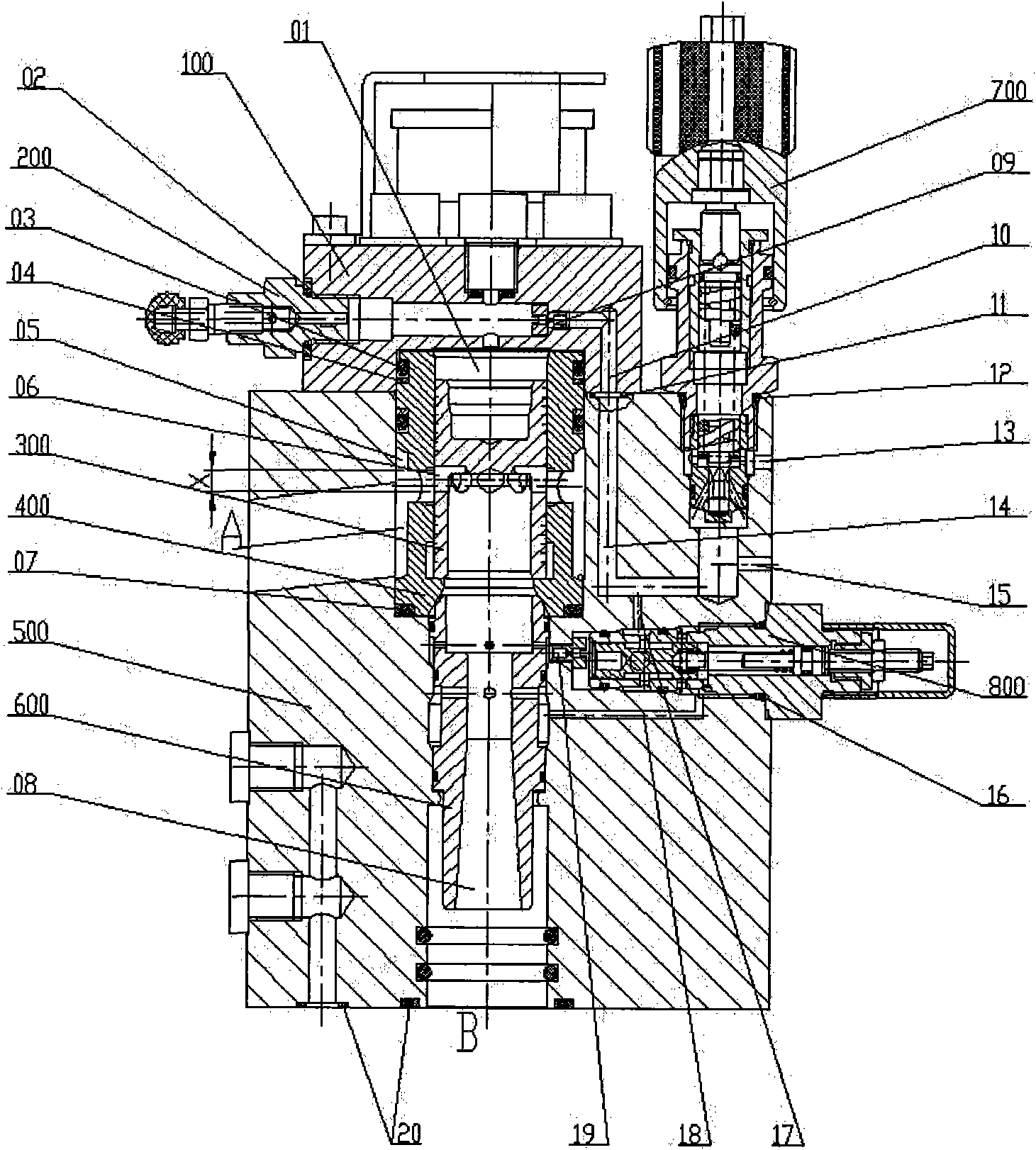

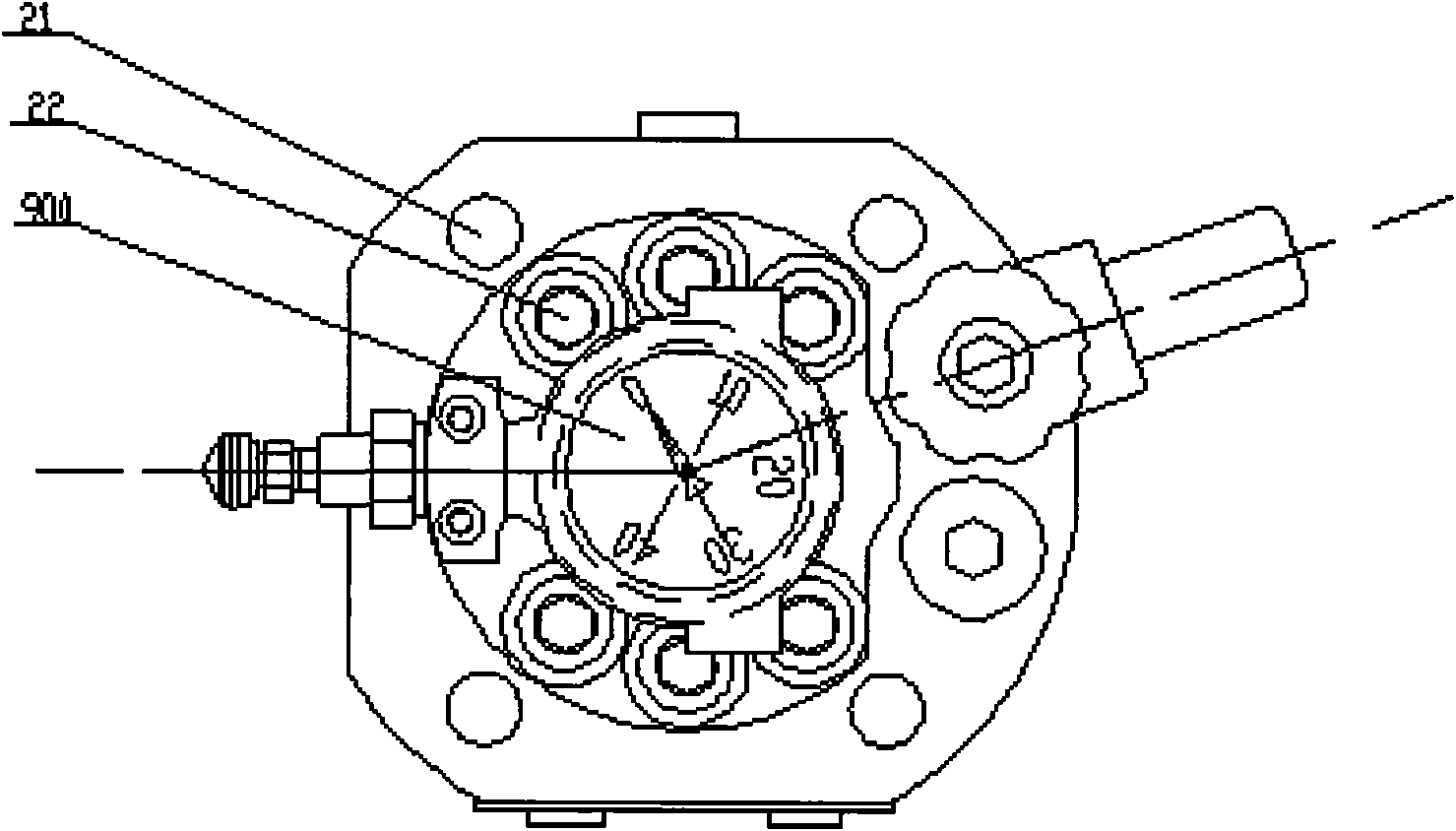

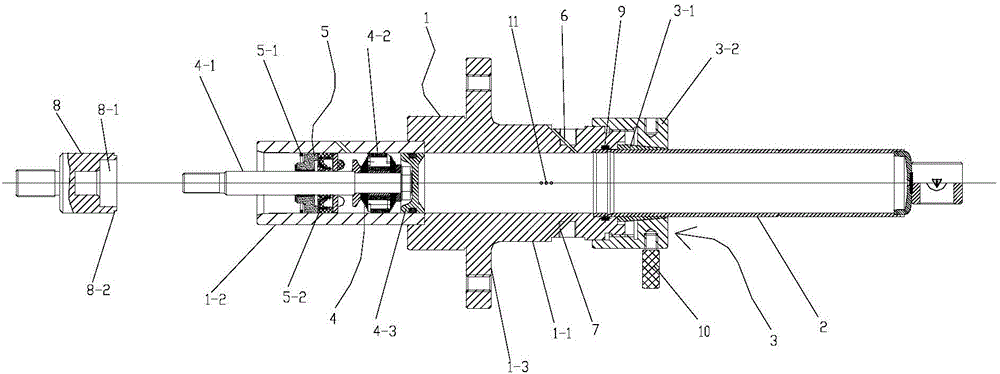

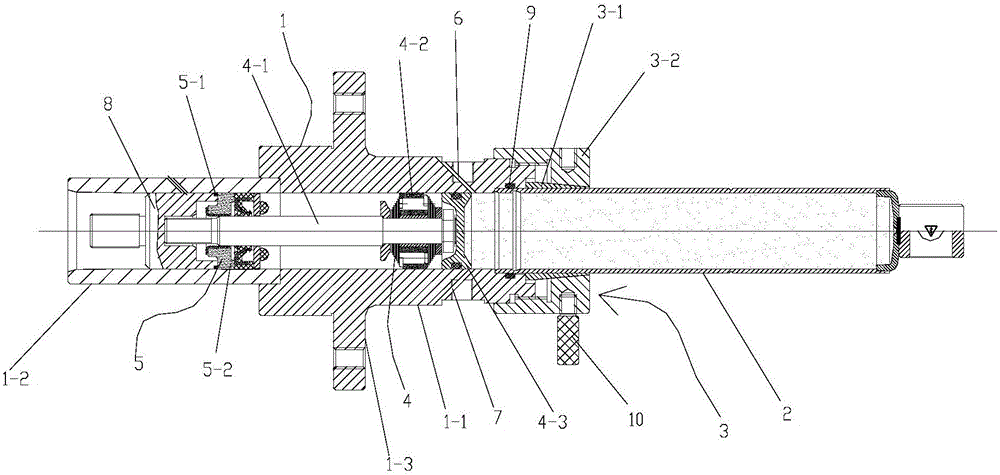

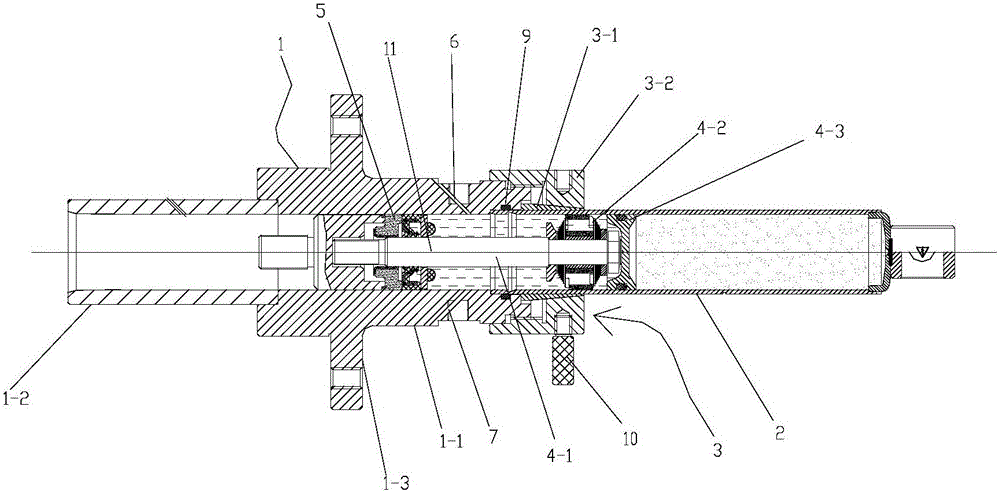

Tool and method for assembling shock absorber

The invention discloses a tool and a method for assembling a shock absorber. The tool comprises a guiding sleeve and a centering locking component which is used for coaxially communicating a barrel of the shock absorber with the guiding sleeve and connecting the barrel of the shock absorber with the guiding sleeve in a sealed manner; the tool further comprises a press head which is used for pushing a piston component and an oil seal assembly of the shock absorber to axially move along the inside of the guiding sleeve and enabling the piston component and the oil seal assembly to be press-fitted in the barrel finally; and a gas inflation hole for introducing gas and an oil injection hole for injecting hole are formed in the guiding sleeve. Air in a liquid chamber of the barrel of the product can be exhausted in the assembling process, the indication idle stroke can be eliminated, the performance of the product can be improved, the structure of the product can be optimized, the machining difficulty of parts can be reduced, the machining efficiency can be improved, meanwhile, the product is not required to be circulated back and forth, and the transport cost is reduced while the production cycle is shortened.

Owner:重庆渝安智能悬架有限公司

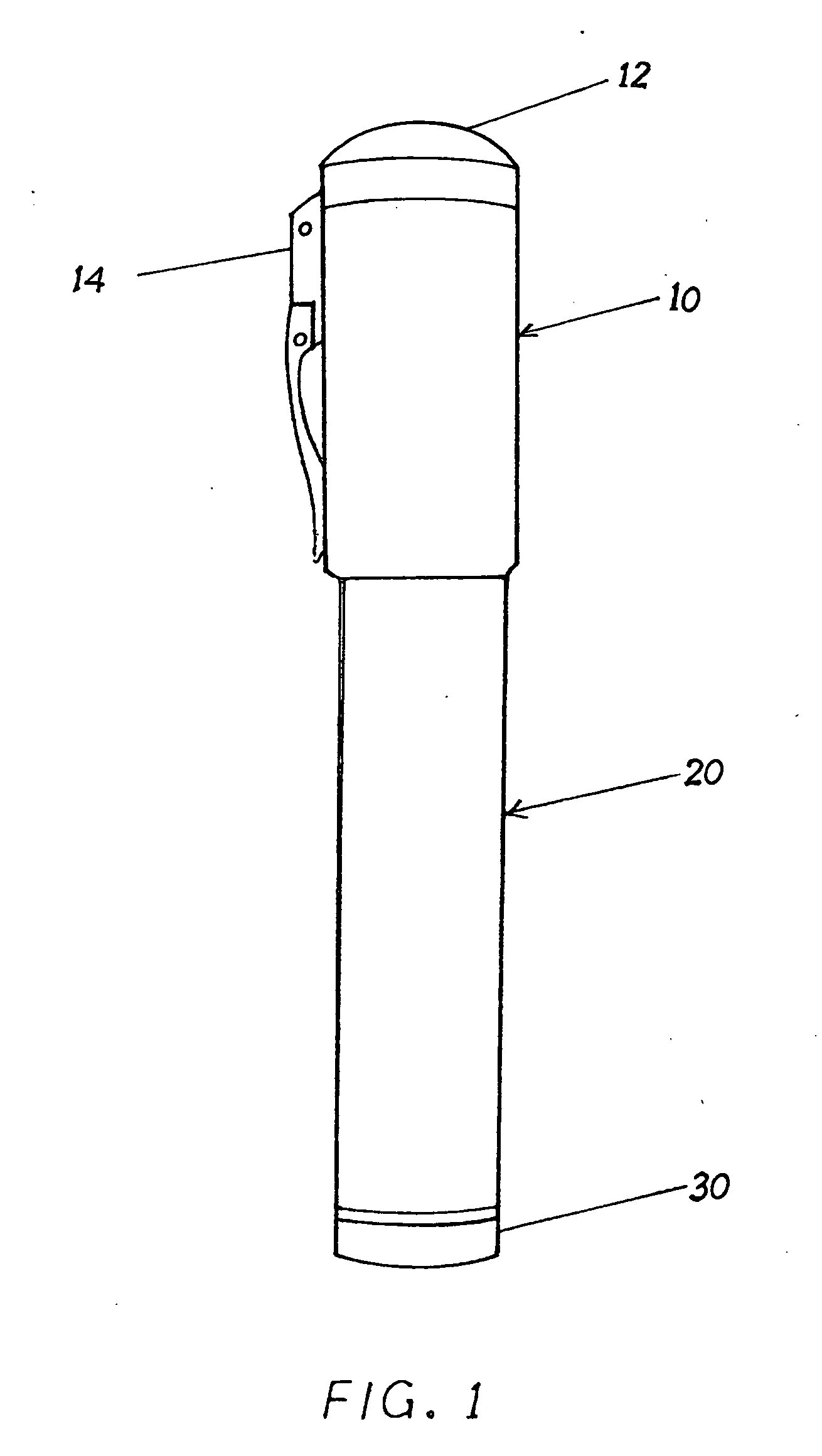

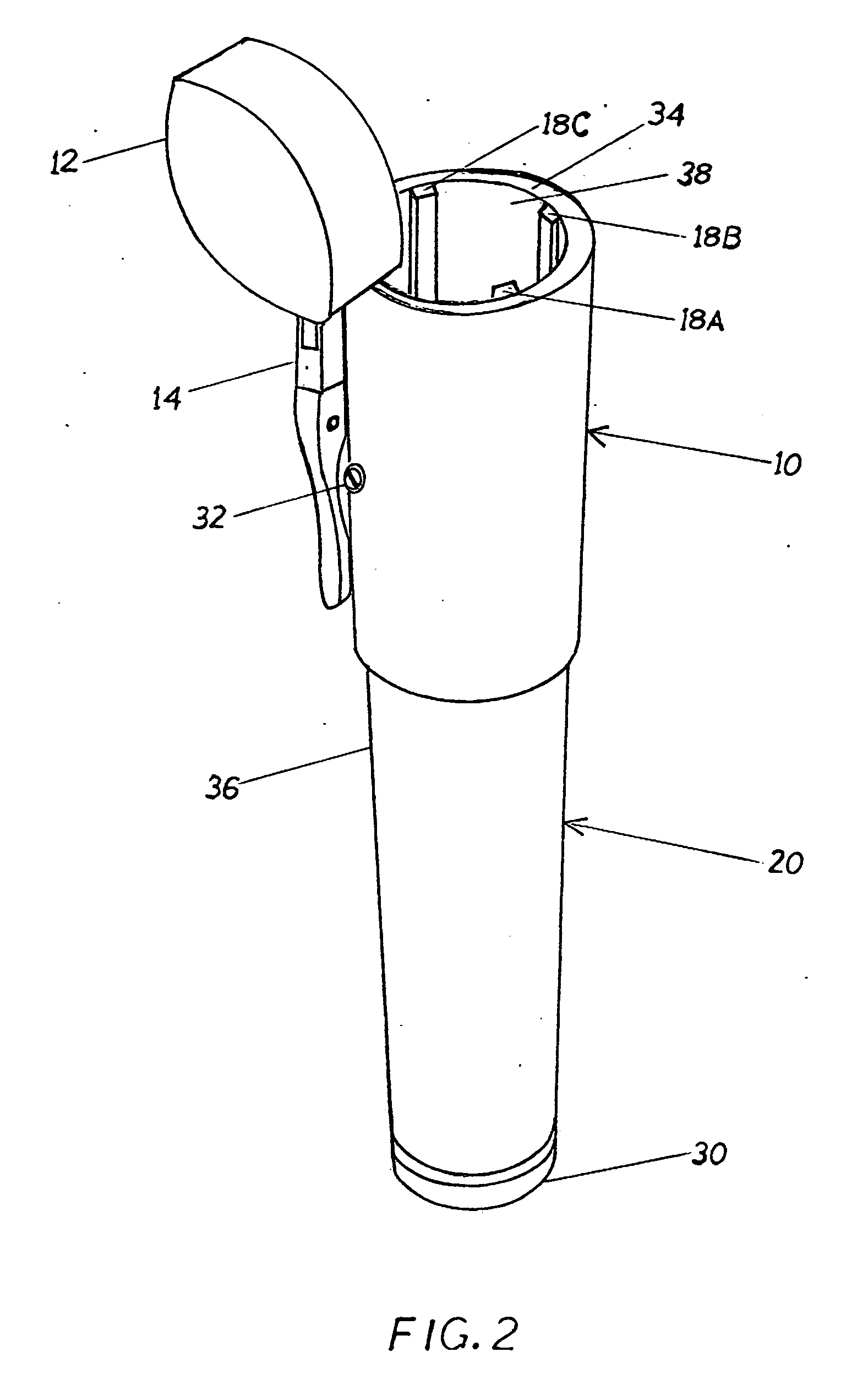

Cigar extinguisher & saver device

InactiveUS20070034216A1Facilitates snuffingExtinguished quickly and efficientlyTobacco pipesTobacco devicesCigar smokersTop cap

An improved portable cigar extinguisher and saver device consisting of an assembly of two hollow, cylindrical tube sections coupled together in a slidable, telescopic manner capable of being hermetically sealed by a movable top cap attached to the top tube section and a detachable bottom cap on the bottom tube section. The device can be sealed airtight and shortened or lengthened telescopically, thereby eliminating the space and air within to quickly extinguish a lit cigar and preserve it for later consumption, or to carry a fresh, unsmoked cigar. The device provides cigar smokers with a convenient, socially and environmentally friendly device for extinguishing and carrying a partially consumed cigar.

Owner:LIU LILY +1

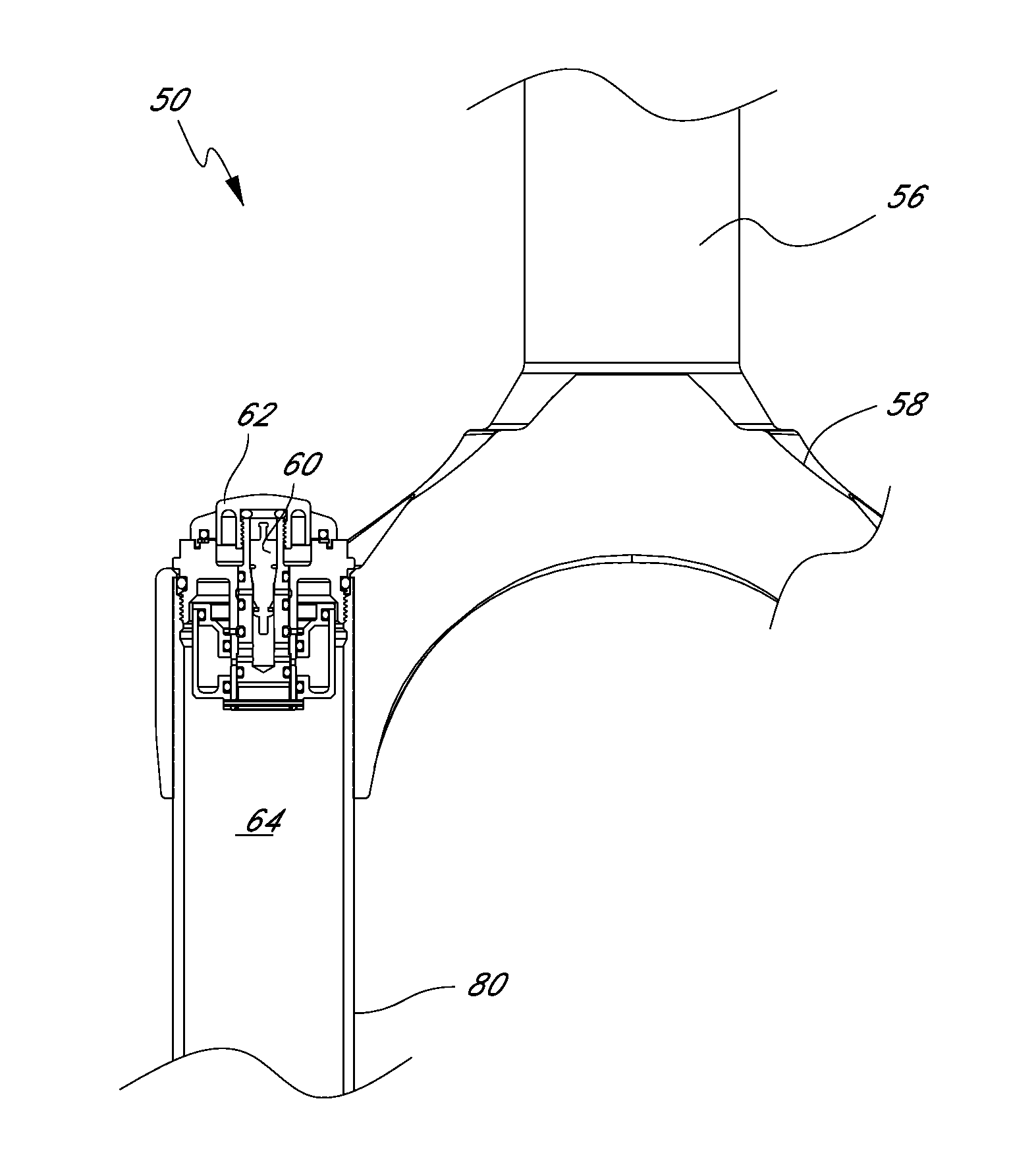

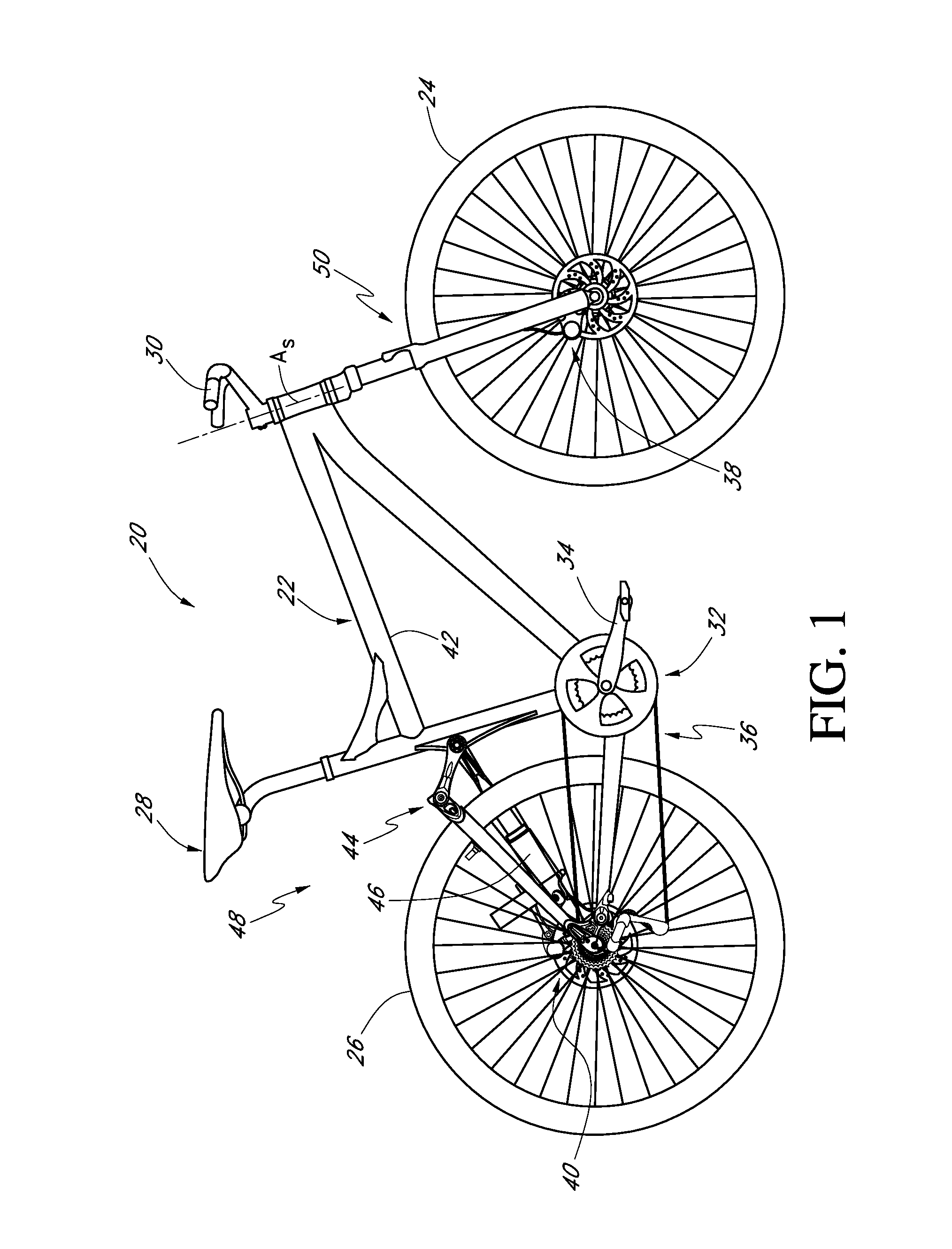

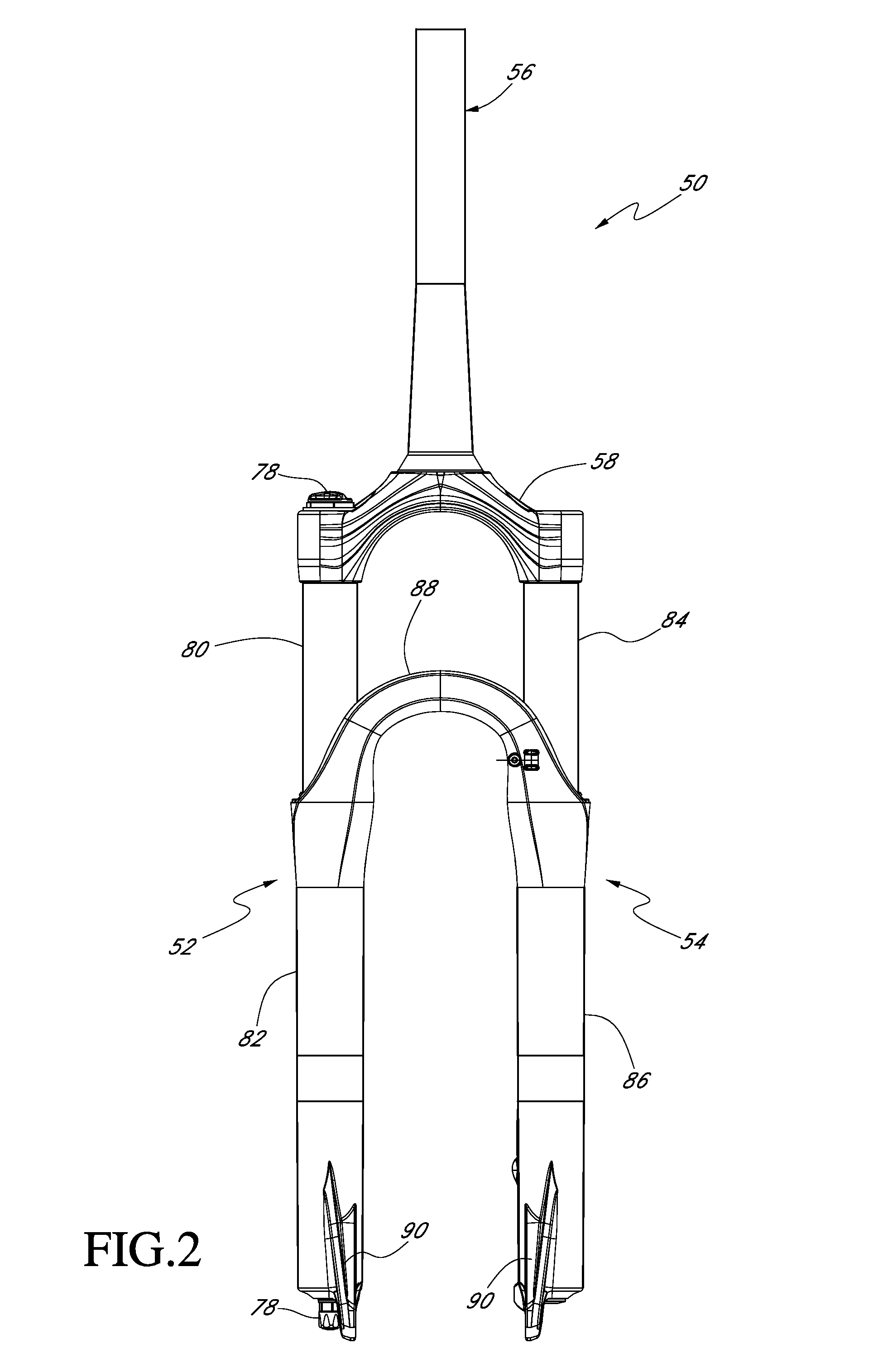

Bicycle with suspension

ActiveUS20130075998A1Reduce pressureRemove airPassenger cyclesWheel based transmissionAir springAtmosphere

A bicycle assembly can include a front or rear suspension system with a shock absorber. A front suspension system can be a suspension fork. A rear suspension system can include a rear shock absorber. The shock can have a shock body and a pressurized main air chamber within the shock body to act as an air spring. The shock can also have a valve configured to receive a pump for adding air to the main air chamber. A secondary air chamber and a control member can be used to reduce the pressure within the main air chamber by venting the secondary air chamber to the atmosphere.

Owner:SPECIALIZED BICYCLE COMPONENTS INC

Processing method for large-scale foaming decorating part

The invention discloses a processing method for a large-scale foaming decorating part. The method comprises the following steps: the material in a mixing and batching system is conveyed to a robot casting system via a foaming system; the material is continuously cast into lower molds of a combined mold vehicle through the robot system; according to program instructions, the upper mold set of the combined mold vehicle automatically complete the actions of turning over molds, closing molds and locking molds of the upper mold set; after the polyurethane product in the mold cavity is subjected to precuring operation, according to the program control instructions, the upper mold set automatically opens the molds, and at least completes exhaust action once; after the exhaust time controlled by the program is over, the upper mold set automatically closes and locks the molds, and locks the molds according to the program until the product is completely cured. The processing method for the large-scale foaming decorating part has the advantages that the exhaust working procedure is realized, the traveling and positioning of the mold vehicle are accurate, the void fraction of the formed product is low, the manufacturing precision of the formed product is high, the foaming density fluctuation of the product is low, and the physical index is high.

Owner:湖南亚太实业有限公司

Disposable wine fermentation vessel with cap management and integral press

ActiveUS20150147433A1Facilitate agitationWell managementShaking/oscillating/vibrating mixersBeer fermentationSingle useFlavor

A disposable winemaking apparatus for fermenting wine containing skins, seeds, and stems that form a cap includes a single-use, dual chamber plastic bag that incorporates a mechanism to agitate and disperse the cap in order to maximize extraction of color and flavor. It also includes an integral press mechanism to squeeze out the fermented juice through a strainer, retaining the pomace in the disposable bag. The device may also be used for racking and transfer of wine during aging.

Owner:SINGH VIJAY

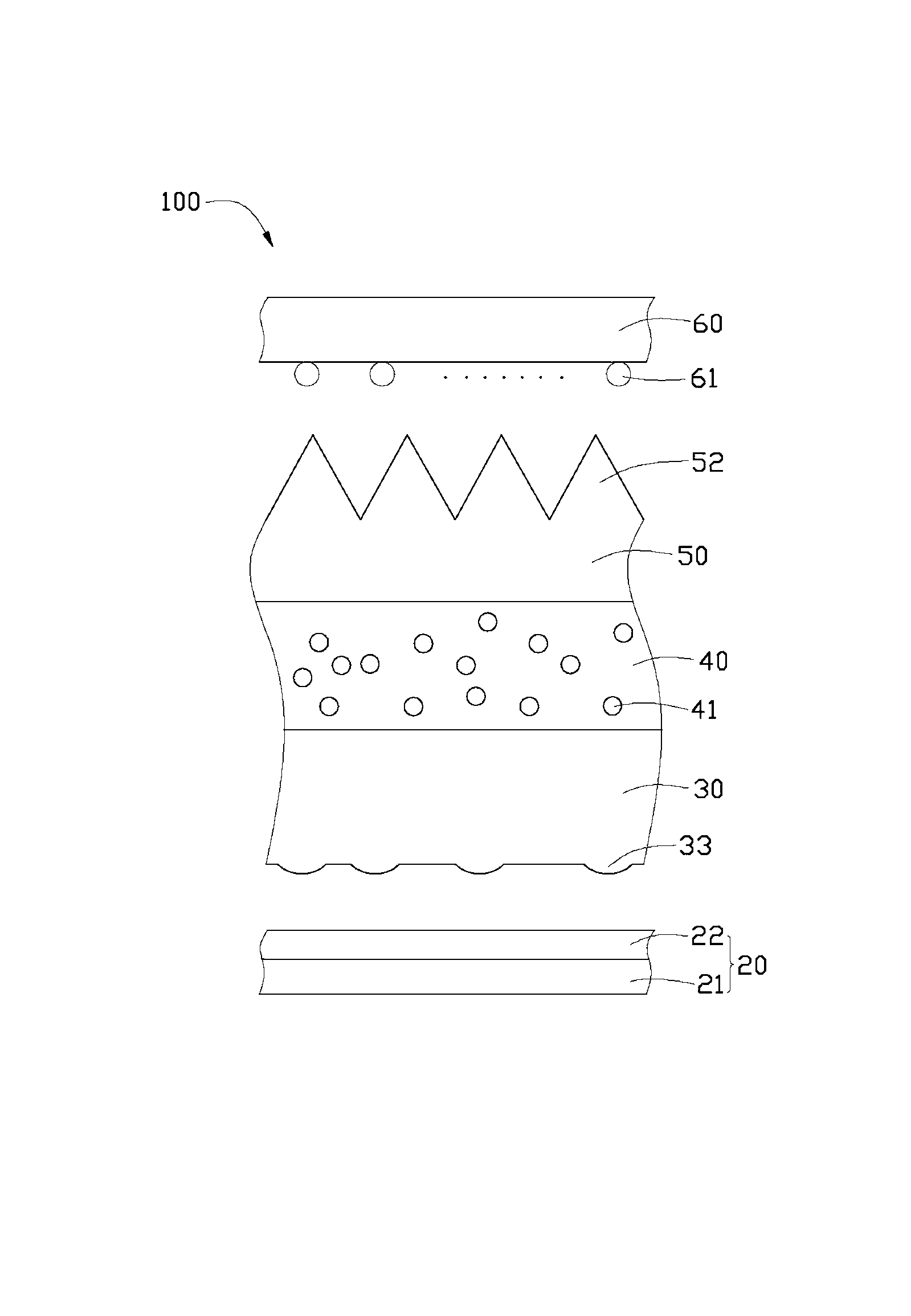

Compound type light guiding module and manufacturing method thereof

InactiveCN103163585AReduce thicknessReduce light lossPrismsDiffusing elementsOptoelectronicsLight guide

The invention provides a compound type light guiding module which comprises a light guiding plate, a diffusion layer and a brightening layer, wherein the light guiding plate, the diffusion layer and the brightening layer are stacked in sequence, the diffusion layer is connected on the light guide plate in an adhesive mode, and the brightening layer is connected on the diffusion layer in an adhesive mode. Scattering points are formed on the surface, opposite to the diffusion layer, of the light guiding plate, the diffusion layer comprises a transparent colloid and scattering particles distributed in the transparent colloid, and a micro-structure used for brightening is formed on the surface, opposite to the diffusion layer, of the brightening layer. According to the compound type light guiding module, the light loss rate of light when the light passes through the light guiding module can be reduced. The invention meanwhile provides a manufacturing method of the light guiding module.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

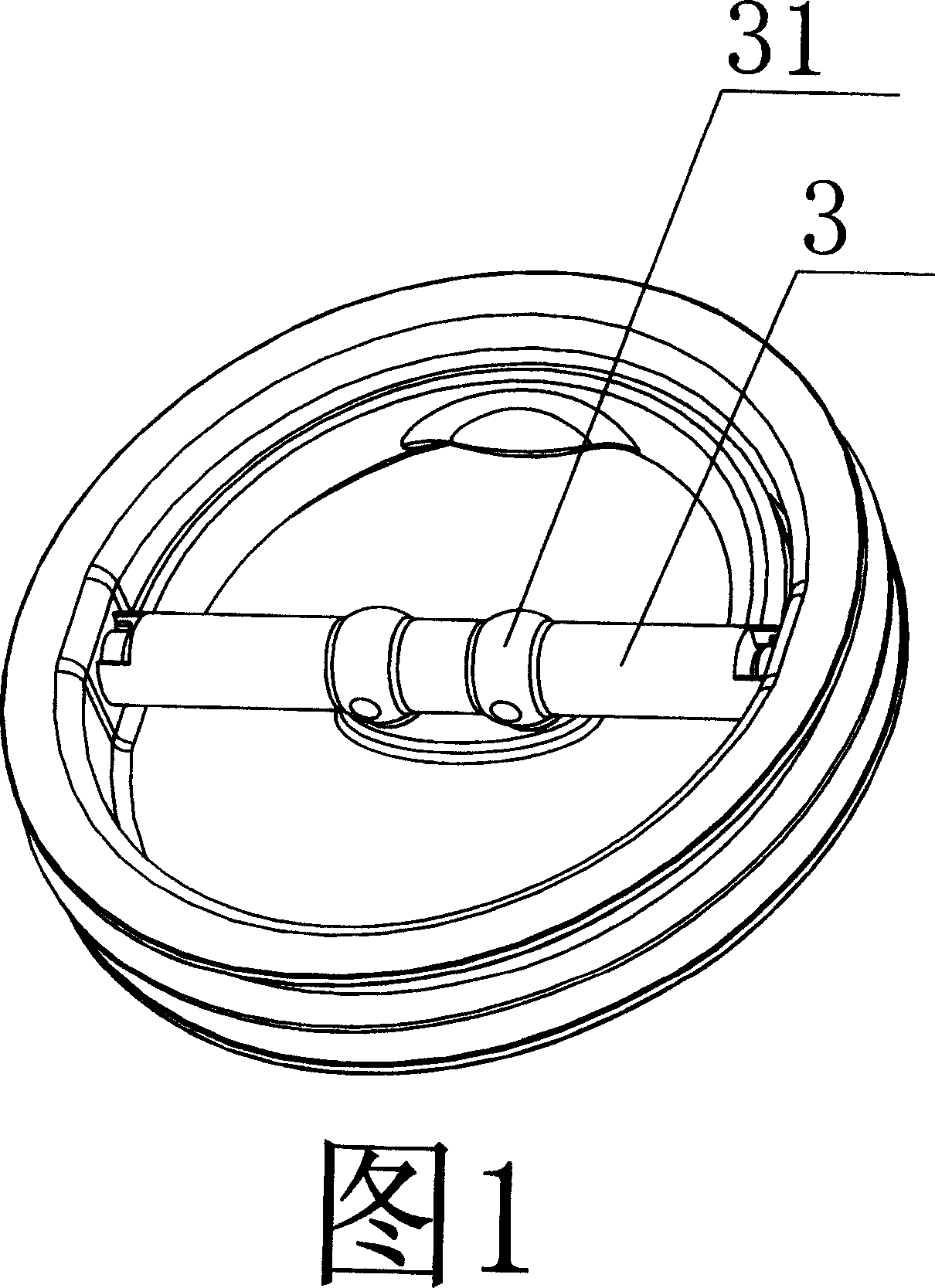

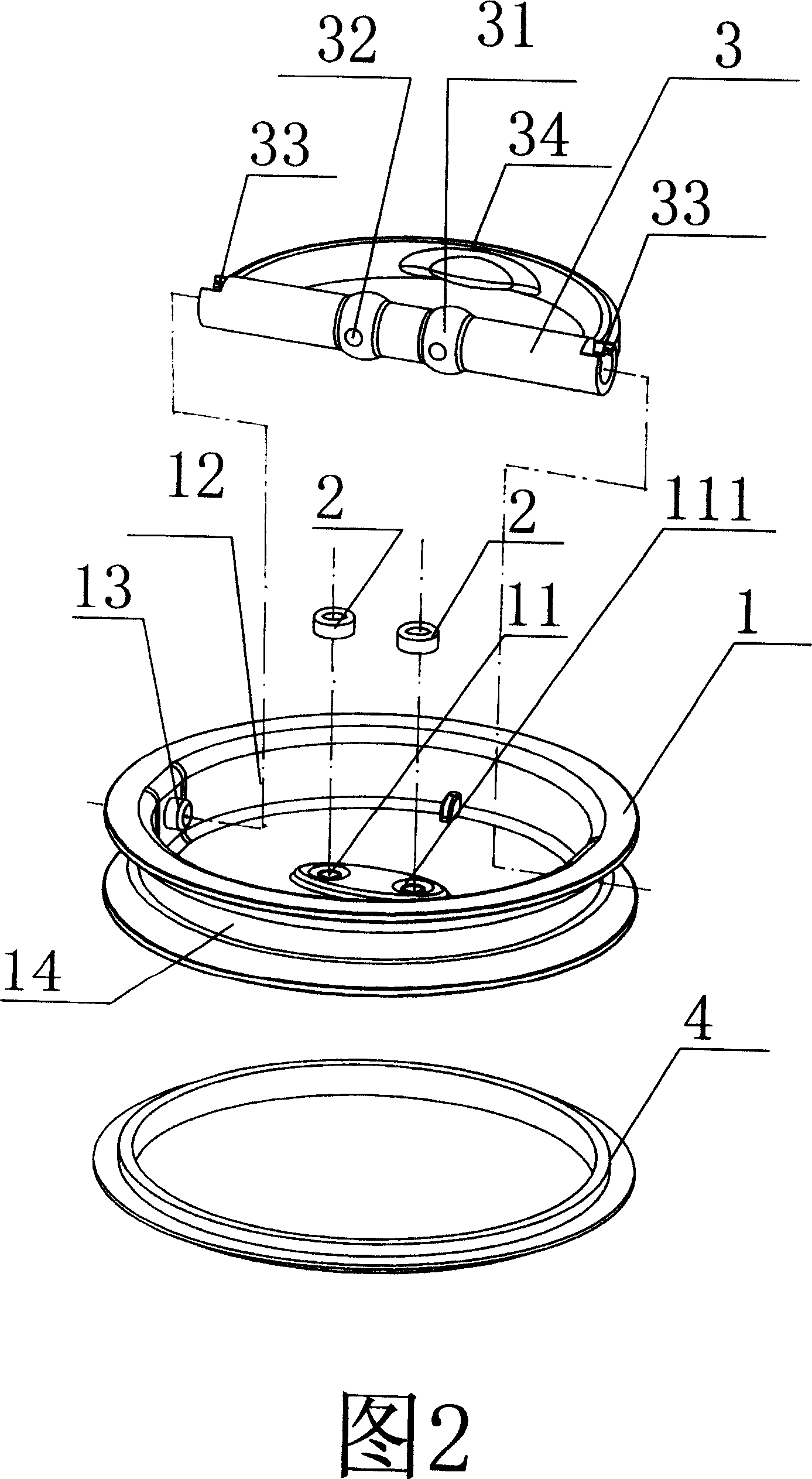

Sealed tank gas-discharging lid

The invention relates to a sealing pot exhaust cover. Wherein, it has a main body whose circumference has sealing ring to clamp it in the inner ring of pot; the cover has radial at least one exhaust hole whose upper part has concentric groove with damping rubber ring; the upper part of cover has rotation axle, while the rotation axle is fixed at the protrusion ring to compress the damp rubber ring; the protrusion ring has radial ventilate hole; when the rotation rotates, and the ventilate hole is through to the exhaust hole, the exhaust cover is clamped into the pot and the left air of pot is exhausted; when two holes are disconnected, the exhaust cover is clamped into the pot to be sealed; the cover has annular wall with radial coupled posts; two ends of rotation axle have grooves two clamp said posts, to fix the rotation axle on the cover; two ends of rotation axle are extended outward to form D-shape switch handle.

Owner:昆山富隆不锈钢制品有限公司

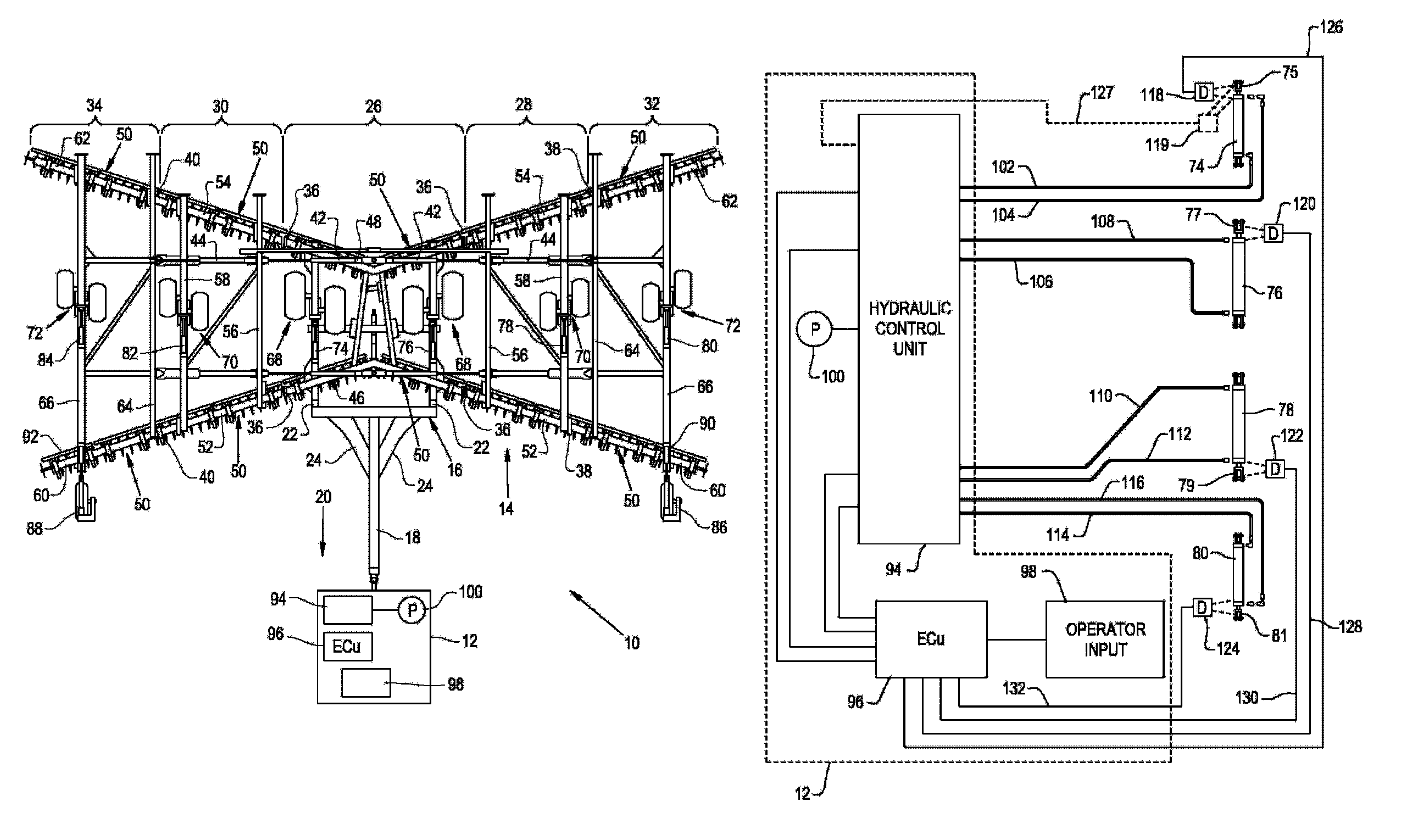

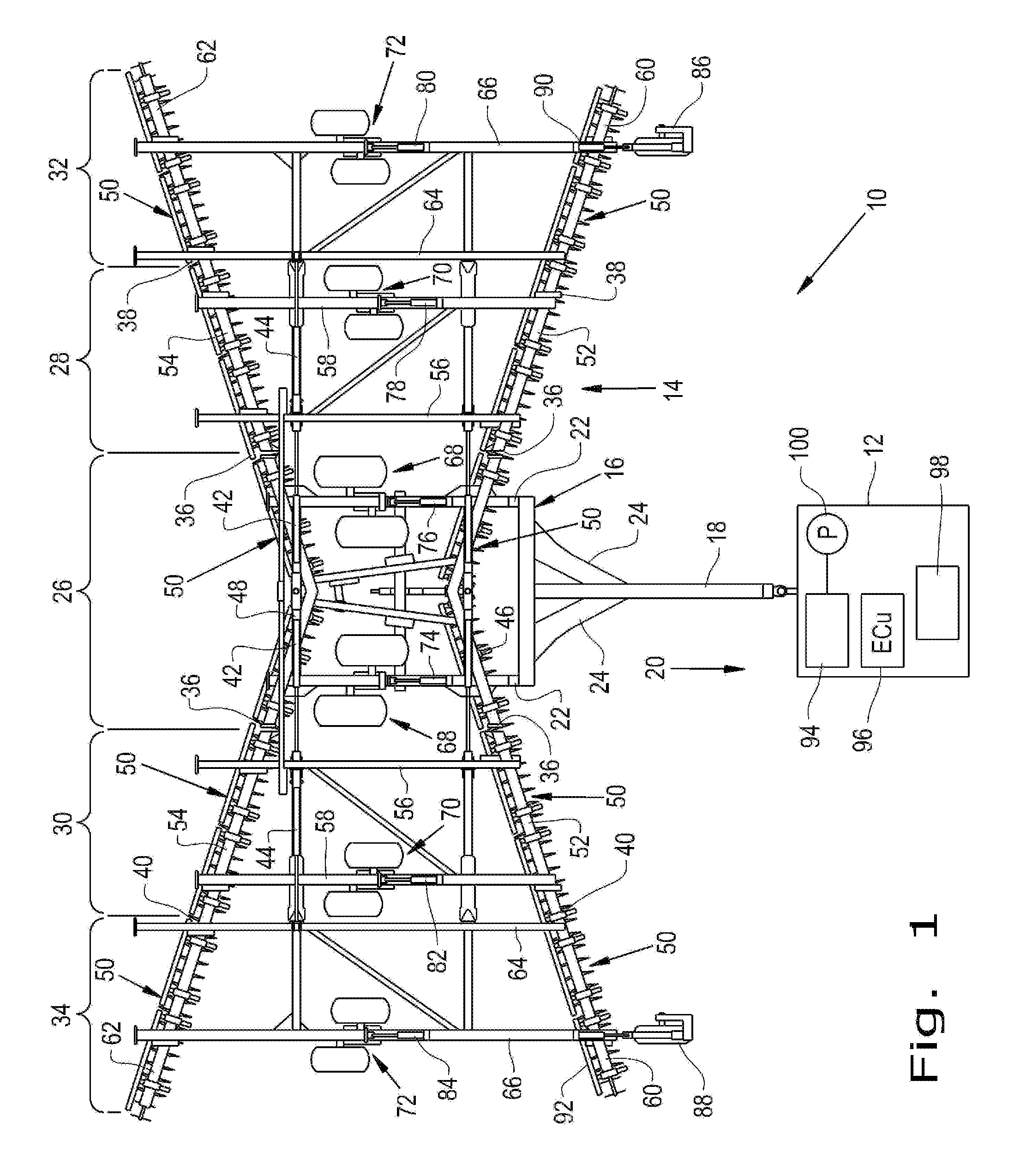

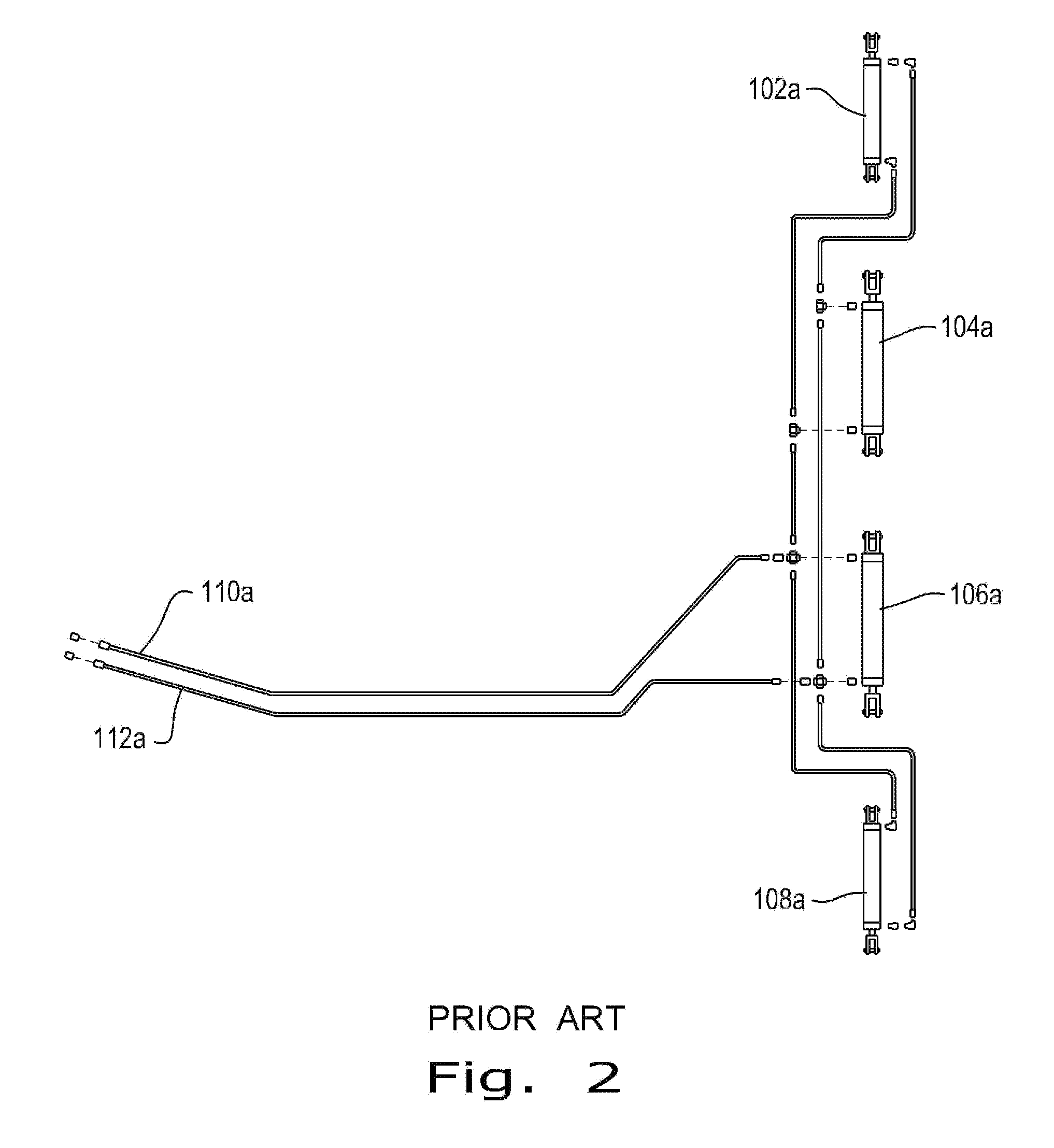

Apparatus and method for air removal in tillage implements using three way valves

ActiveUS9363939B2Efficient removalRemove airAgricultural machinesHarrowsHydraulic control unitHydraulic fluid

Air is removed from an hydraulic system for an agricultural implement supporting a plurality of gangs of disk blades extending generally laterally relative to a forward travel direction. The implement has carrier frames pivotally connected to wheel assemblies for controlling the height of the carrier frames relative to the ground through hydraulic actuators acting on the wheel assemblies. The hydraulic control unit enables independent and individual control of each actuator. An electronic control unit (ECU) controls three way valves associated with each actuator so that they may be operated in unison or individually. Hydraulic fluid is passed through the most remote actuator first and then actuators closer to the hydraulic control unit to remove air.

Owner:CNH IND CANADA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com