Compound type light guiding module and manufacturing method thereof

A technology of a light guide module and a manufacturing method, which is applied in the directions of light guide, optics, optical components, etc., can solve the problems of low light utilization efficiency and loss of the light guide module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

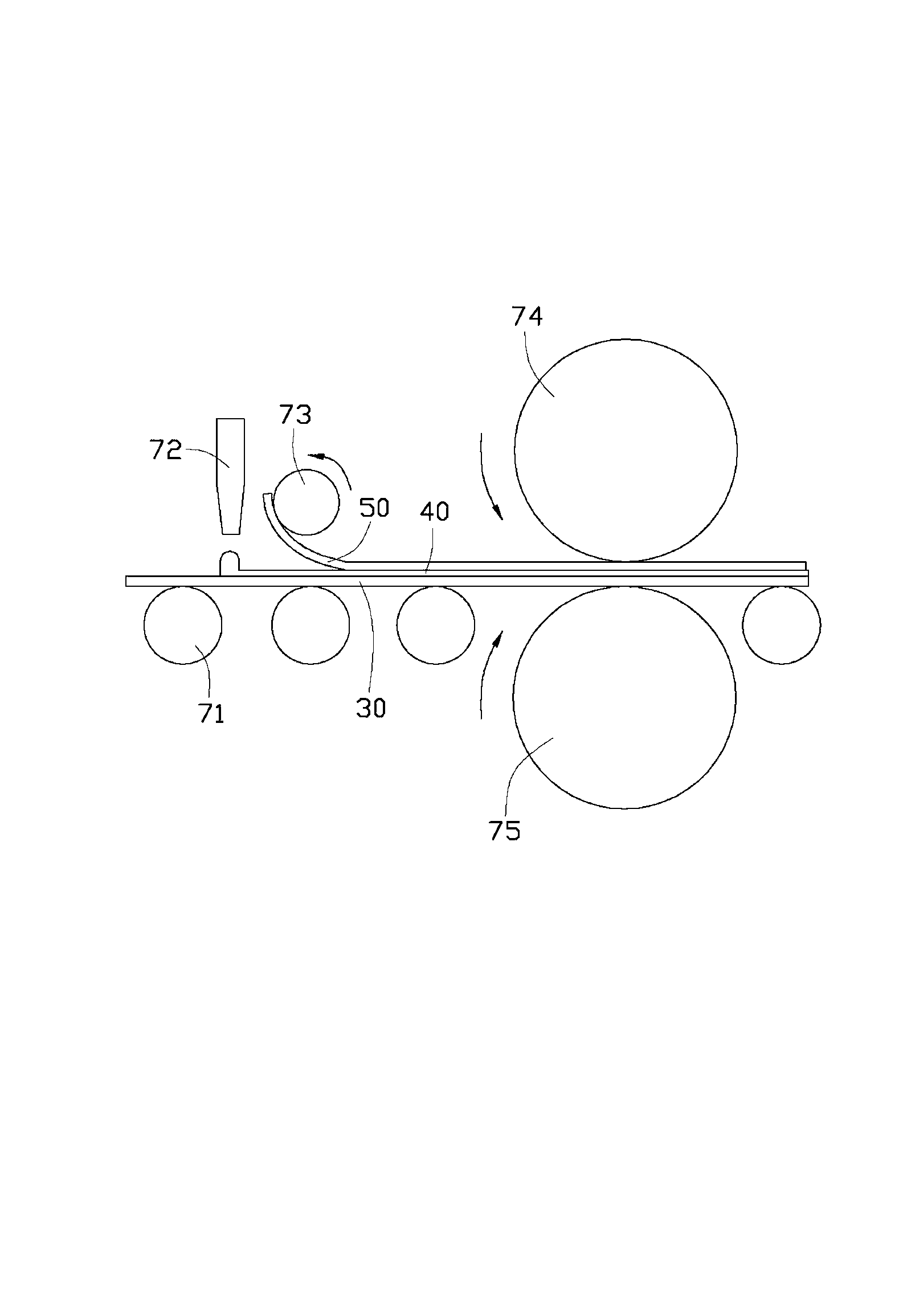

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings.

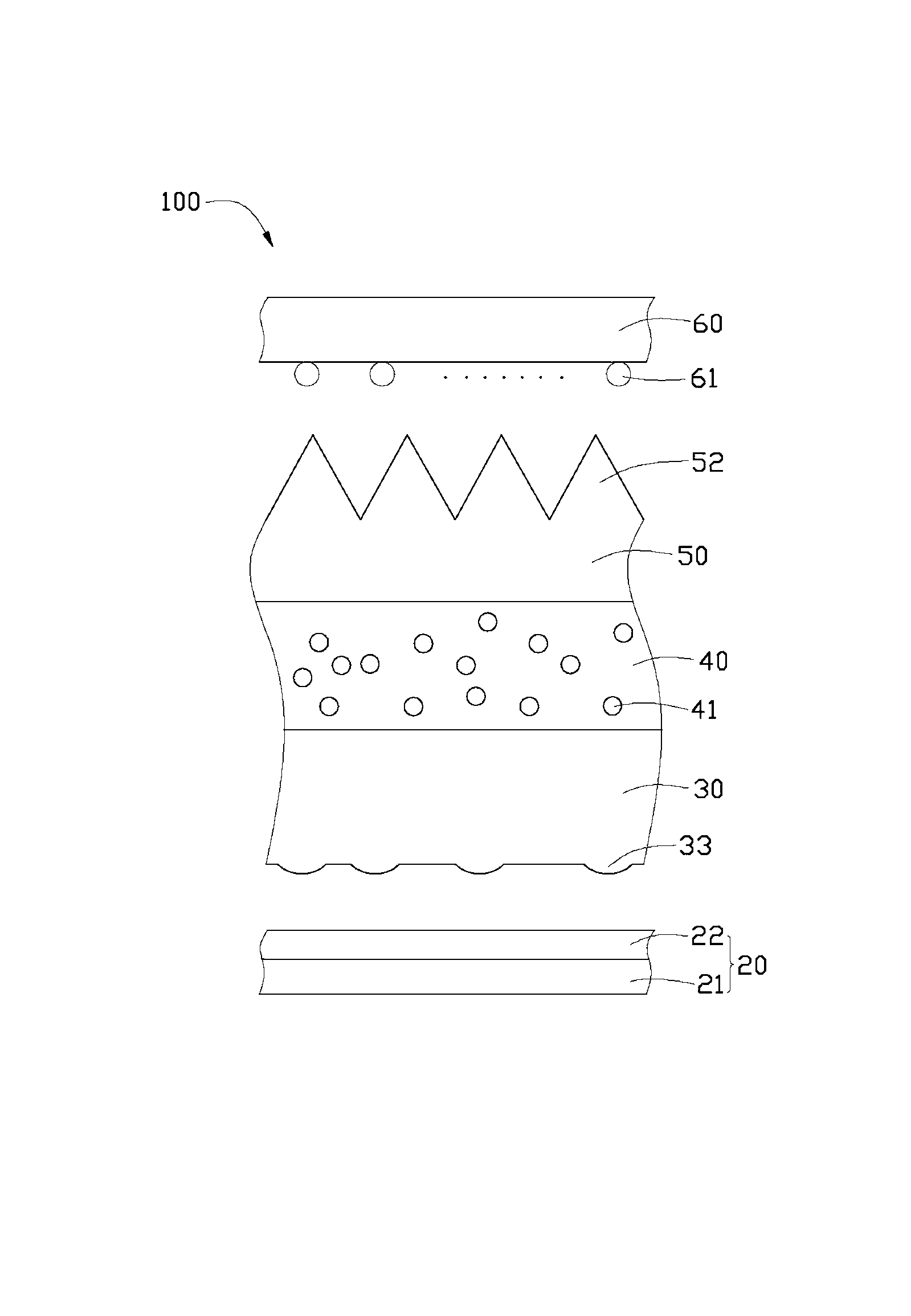

[0010] see figure 1 , which discloses a light guide module 100 according to an embodiment of the present invention, the light guide module 100 includes a reflective sheet 20 , a light guide plate 30 , a diffusion layer 40 , a brightness enhancement layer 50 , and a diffusion film 60 stacked together.

[0011] The reflective sheet 20 includes a transparent substrate 21 and a reflective film 22 coated on the transparent substrate 21. The material of the transparent substrate 21 is, for example, polyester carbonate (PC), and the material of the reflective film 22 is a highly reflective material such as aluminum or sulfuric acid. barium. The diffusion film 60 is a transparent film, and the surface of the transparent film is coated with diffusion particles 61. The material of the transparent film is, for example, polyethylene terephthalate (PET), and the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com