Electromagnetic coil and its manufacturing method and coil form

A coil bobbin and electromagnetic coil technology, applied in the direction of inductance/transformer/magnet manufacturing, electromagnet, transformer/inductor coil/winding/connection, etc., can solve problems such as short circuit and partial short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

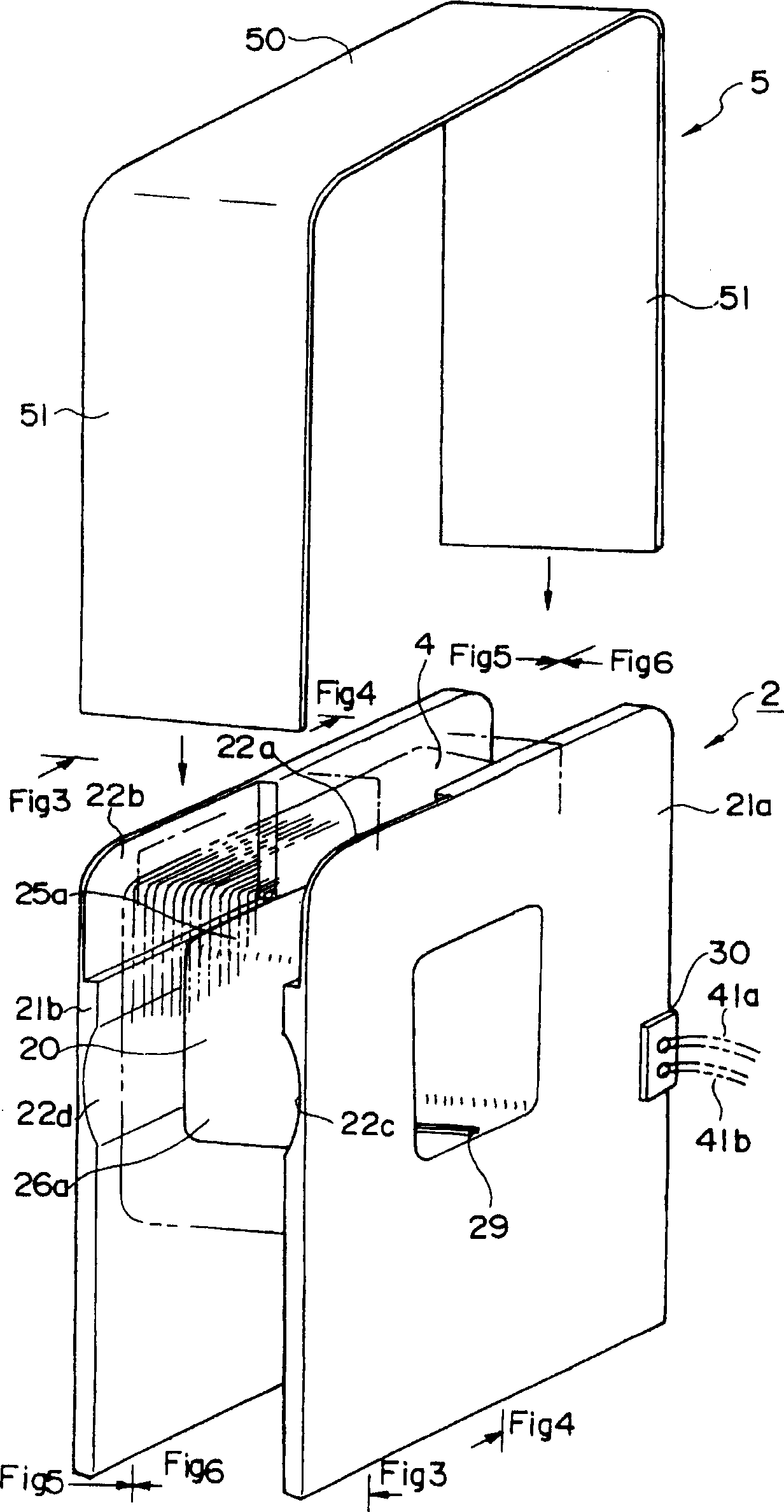

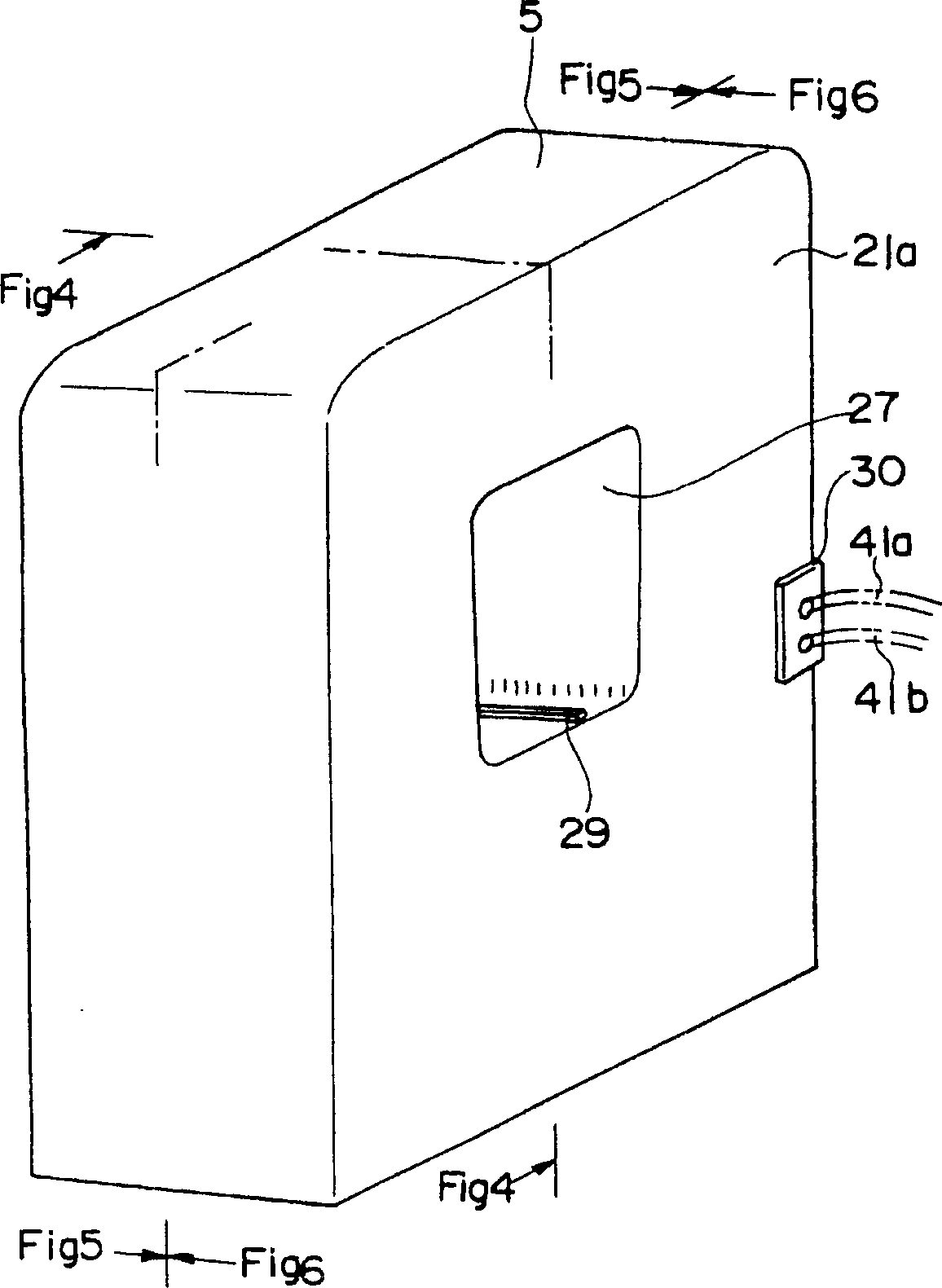

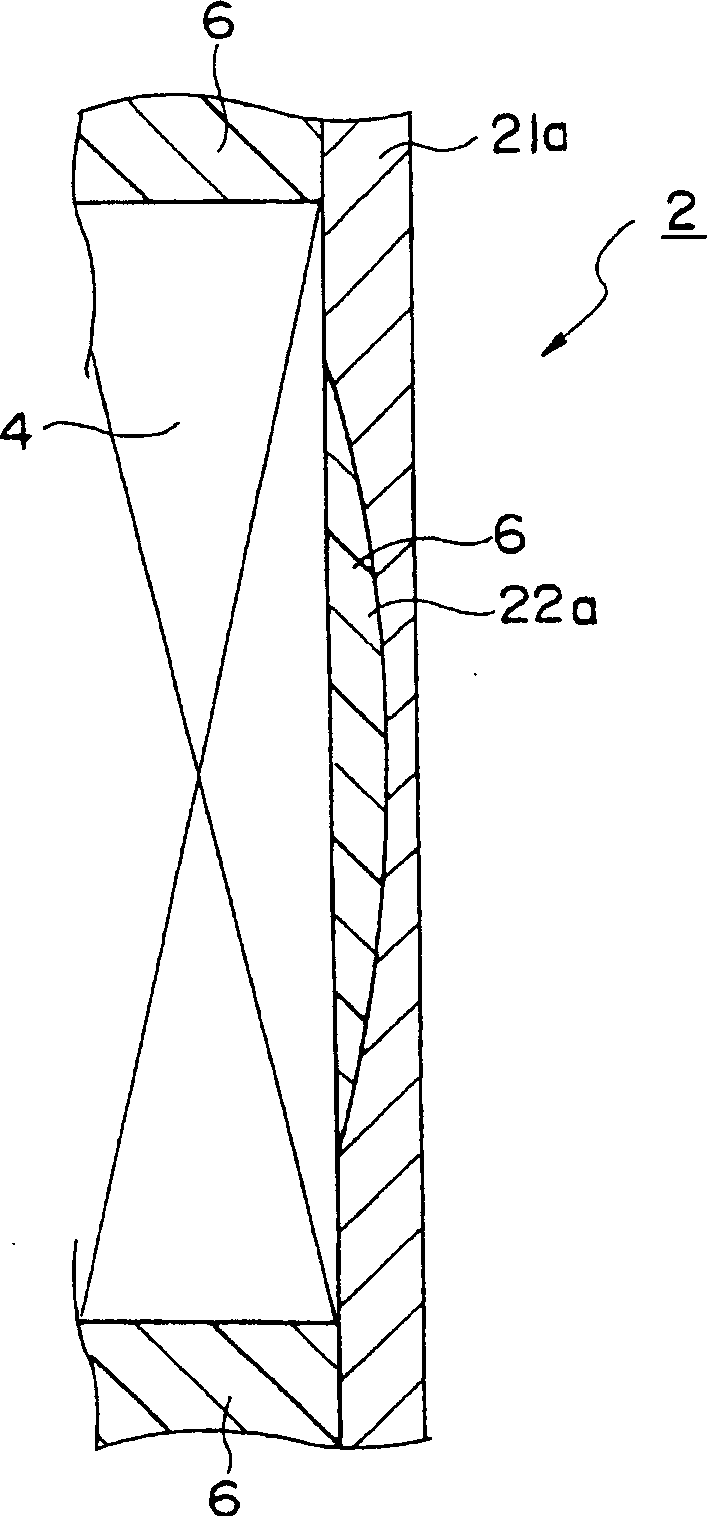

[0023] use below Figure 1 to Figure 6 The structure of the electromagnetic coil of the present invention will be described. figure 1 It is an exploded perspective view illustrating an outline of a bobbin structure forming an electromagnetic coil according to an embodiment of the present invention, figure 2 It is the appearance perspective view of the electromagnetic coil of the embodiment of the present invention, image 3 Is to illustrate the structure of the electromagnetic coil of the present invention figure 1 The enlarged view of the main part of the section along the Fig3-Fig3 section, Figure 4 Is to illustrate the structure of the electromagnetic coil of the present invention figure 1 and figure 2 The longitudinal section along Fig4-Fig4 section, Figure 5 Is to illustrate the structure of the electromagnetic coil of the present invention figure 1 and figure 2 The left longitudinal sectional view along Fig5-Fig5 section, Figure 6 Is to illustrate the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com