Pump condition monitoring and recovery

a technology of pump condition monitoring and recovery, applied in the field of fluid pumps, can solve the problems of preventing the operation of the vehicle by shutting down the fuel pump, damage to the motor, etc., and achieve the effect of reducing or eliminating the fault condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

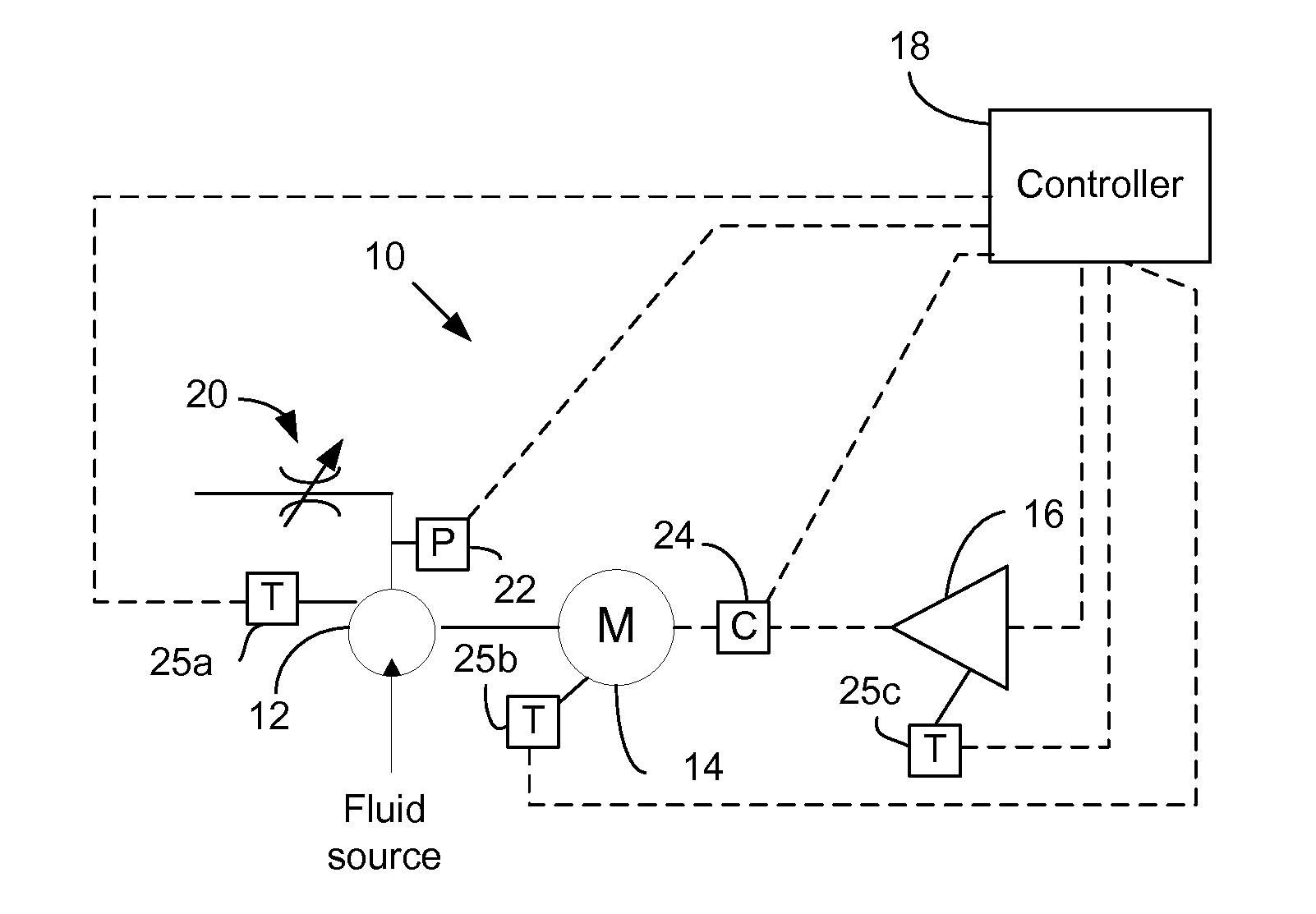

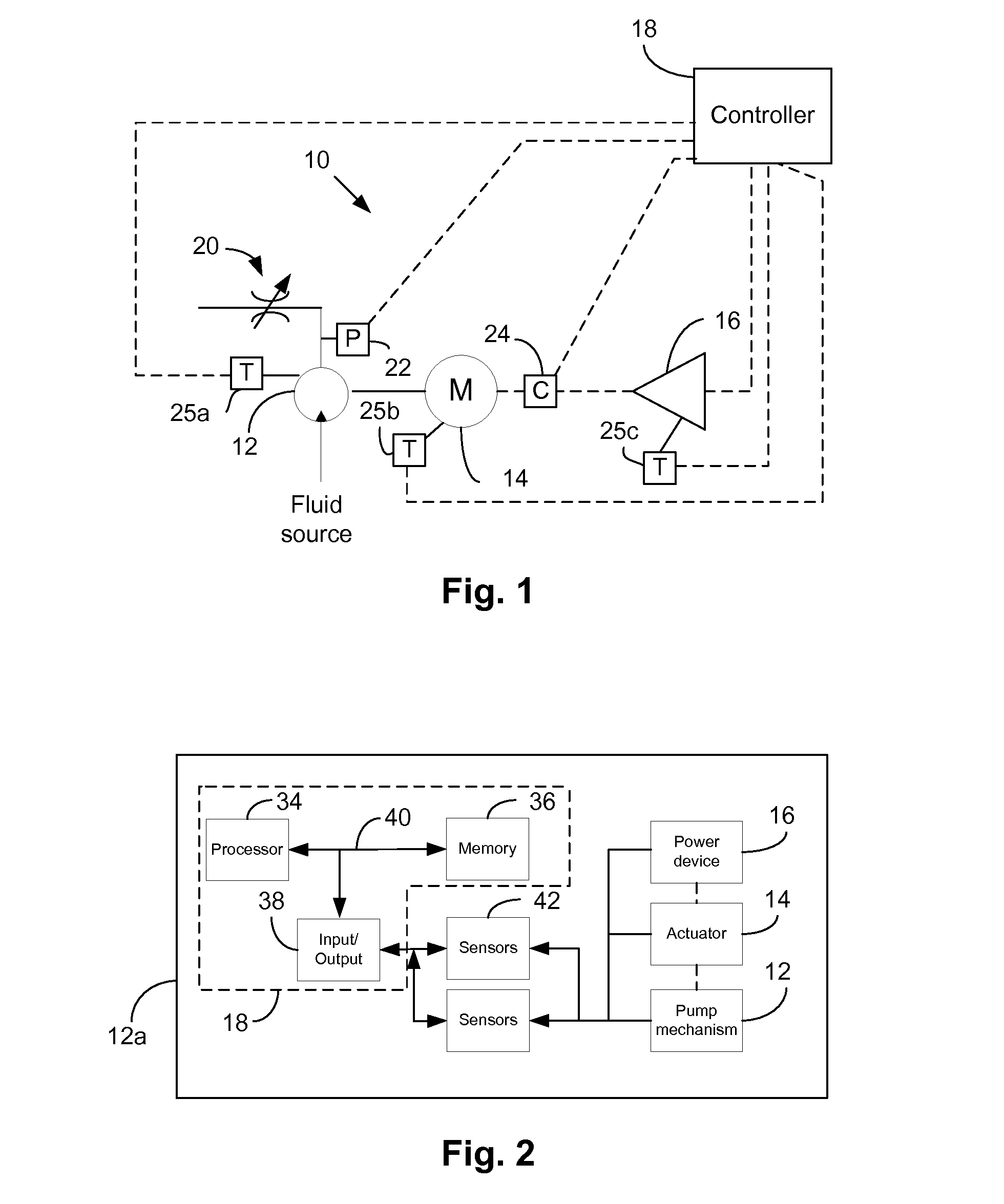

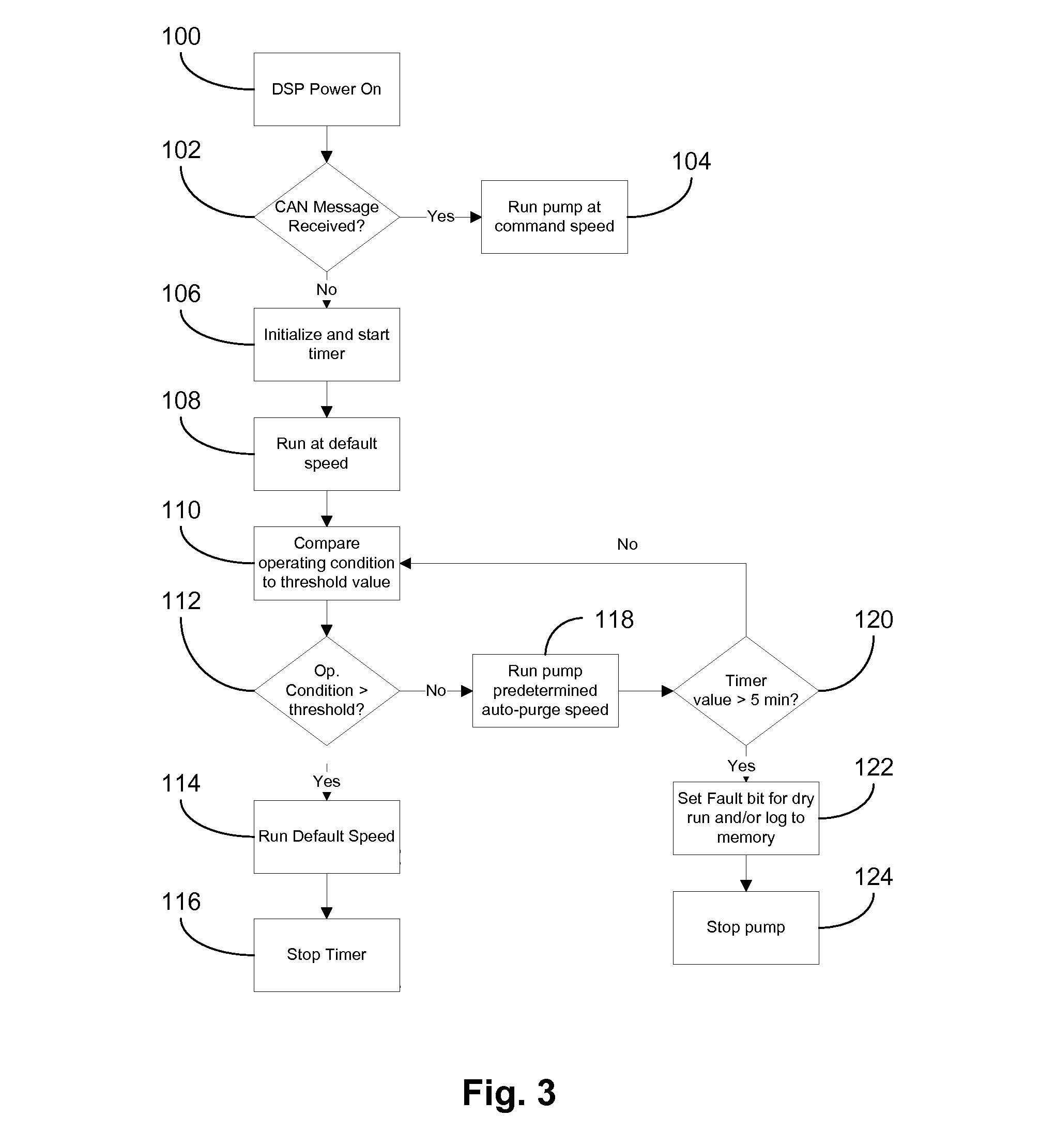

[0038]An apparatus, system and method for controlling a controlled element, such as a fluid pump (e.g., a fuel pump, water pump, oil pump, etc.) and the like, analyzes actual system data to determine the presence of an irregular condition (e.g., a potential fault condition). In the event an irregular condition is detected, certain actions may be taken to prevent occurrence of a fault condition and thus prevent system shutdown, thereby maintaining a level of operation yet minimizing the likelihood of component damage.

[0039]As used herein, the term “fault condition” is defined as an event triggered due to an operating characteristic of the system and / or a component of the system exceeding a prescribed fault threshold level. Continued operation of the system above the fault threshold level may result in system damage.

[0040]As used herein, the term “irregular condition” is defined as an event triggered due to an operating characteristic of the system and / or a component of the system exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com