Ultrahigh molecular weight polyethylene bulletproof plate

An ultra-high molecular weight, polyethylene technology, applied in the direction of layered products, armor plate structure, synthetic resin layered products, etc., can solve the local stress defect of the bulletproof plate, the strength and modulus of the bulletproof plate are reduced, and the bulletproof plate has pores. and bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

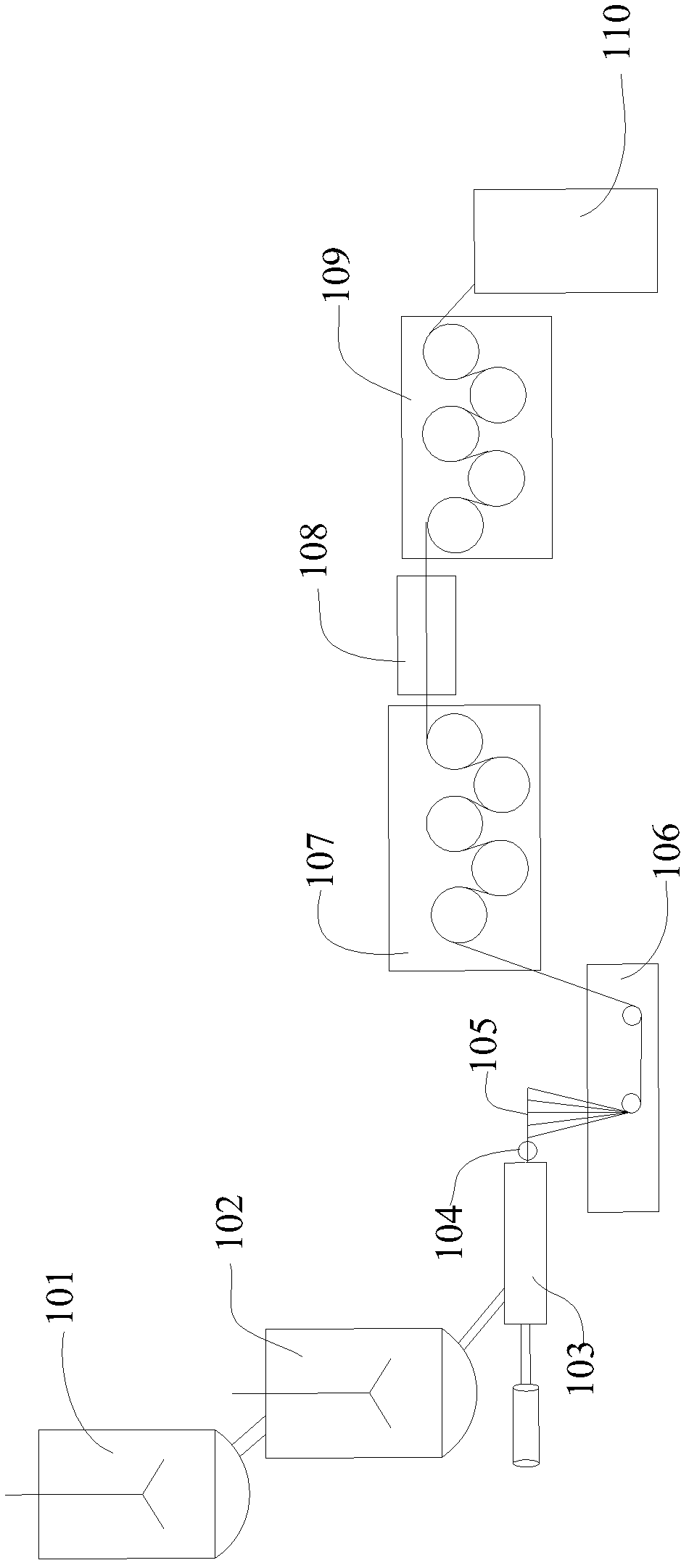

[0065]Preparation of ultra-high molecular weight polyethylene fibers: preheat 230kg of No. 7 solvent oil to 112°C, then put 40,000 kg of ultra-high molecular weight polyethylene and No. 7 solvent oil in the swelling kettle 101 and stir for initial swelling. The initial swelling time is 20 minutes . After the initial swelling, add 690 kg of No. 7 solvent oil at a temperature of 98°C to the swelling kettle for re-swelling to obtain a spinning solution. The re-swelling time is 30 minutes, and the stirring speed remains unchanged. The ambient temperature of the kettle dropped to 98°C.

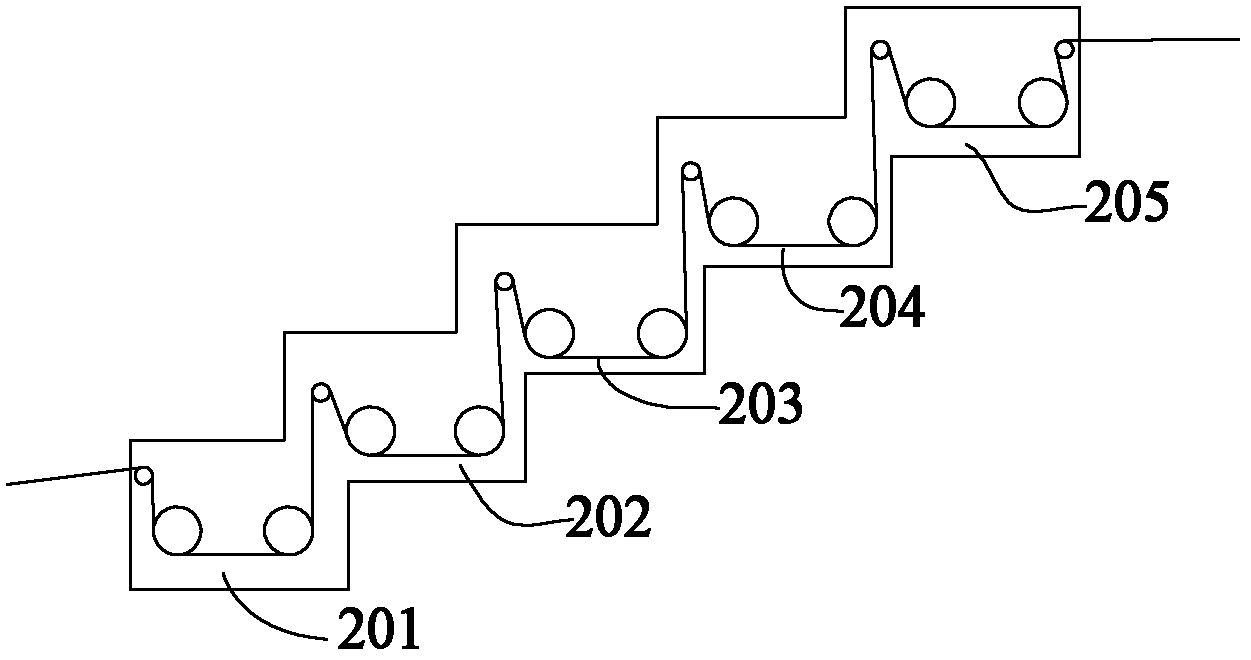

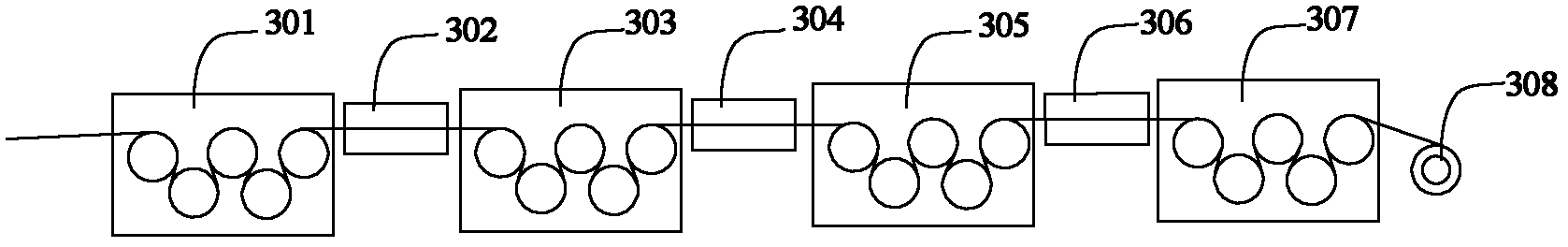

[0066] After re-swelling, a uniform spinning solution is obtained, and the spinning solution is sent into the storage tank 102 to cool to 25° C. and then sent into the twin-screw extruder 103 for extrusion and dissolution. Wherein, the inlet temperature of the twin-screw extruder is 100° C., the intermediate temperature is 185° C., and the outlet temperature is 165° C., the residence time in the t...

Embodiment 2

[0073] After preheating 230kg of No. 7 solvent oil to 112°C, put 40000kg of ultra-high molecular weight polyethylene and No. 7 solvent oil in the swelling kettle 101 and stir for initial swelling. The initial swelling time is 20 minutes. After the initial swelling, add 690 kg of No. 7 solvent oil at a temperature of 98°C to the swelling kettle for re-swelling to obtain a spinning solution. The re-swelling time is 30 minutes, and the stirring speed remains unchanged. The ambient temperature of the kettle dropped to 98°C.

[0074] After re-swelling, a uniform spinning solution is obtained, and the spinning solution is sent into the storage tank 102 to cool to 25° C. and then sent into the twin-screw extruder 103 for extrusion and dissolution. Wherein, the inlet temperature of the twin-screw extruder is 100° C., the intermediate temperature is 185° C., and the outlet temperature is 165° C., the residence time in the twin-screw extruder is 5 minutes, and the twin-screw rotation sp...

Embodiment 3

[0080] The ultrahigh molecular weight polyethylene fibers prepared in Example 1 were used, which were spread on a low density polyethylene film coated with a polystyrene triblock copolymer. Pass the two polymer films bonded with fibers through two rotating press rolls under the action of guide wheels. The temperature of the press rolls is 60° C. and the pressure is 8 MPa to obtain a non-weft fabric with a width of 1.6 m. Owing to what used is the fiber filament of 600D, so the area density of described non-weft cloth is 160g / cm 2 .

[0081] Take 30 layers of the above-mentioned double-layer non-woven fabrics and stack them in the mold, apply a pressure of 8MPa at 85°C for pre-pressing, make the air between the stacks overflow, keep the pressure for 25 minutes, then raise the temperature to 120°C, press Rise to 30MPa, keep the temperature and pressure for 25 minutes to obtain a molded piece, and finally cool the molded piece to room temperature with cooling water, and cut it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com