Positive electrode material precursor, preparation method thereof and positive electrode material

A technology of positive electrode materials and precursors, which is applied in the field of positive electrode materials, positive electrode material precursors and their preparation, can solve the problems of low energy density of lithium-ion batteries, and does not consider the influence of the packing density of secondary particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of cathode material precursor, comprises the following steps:

[0038] A) mixing the nickel-containing compound, the cobalt-containing compound and the manganese-containing compound with water to obtain a mixed solution;

[0039] B) mixed solution, precipitation agent and complexing agent are mixed, carry out co-precipitation reaction, obtain nickel-cobalt-manganese precursor solution, described nickel-cobalt-manganese precursor is represented by general formula (I):

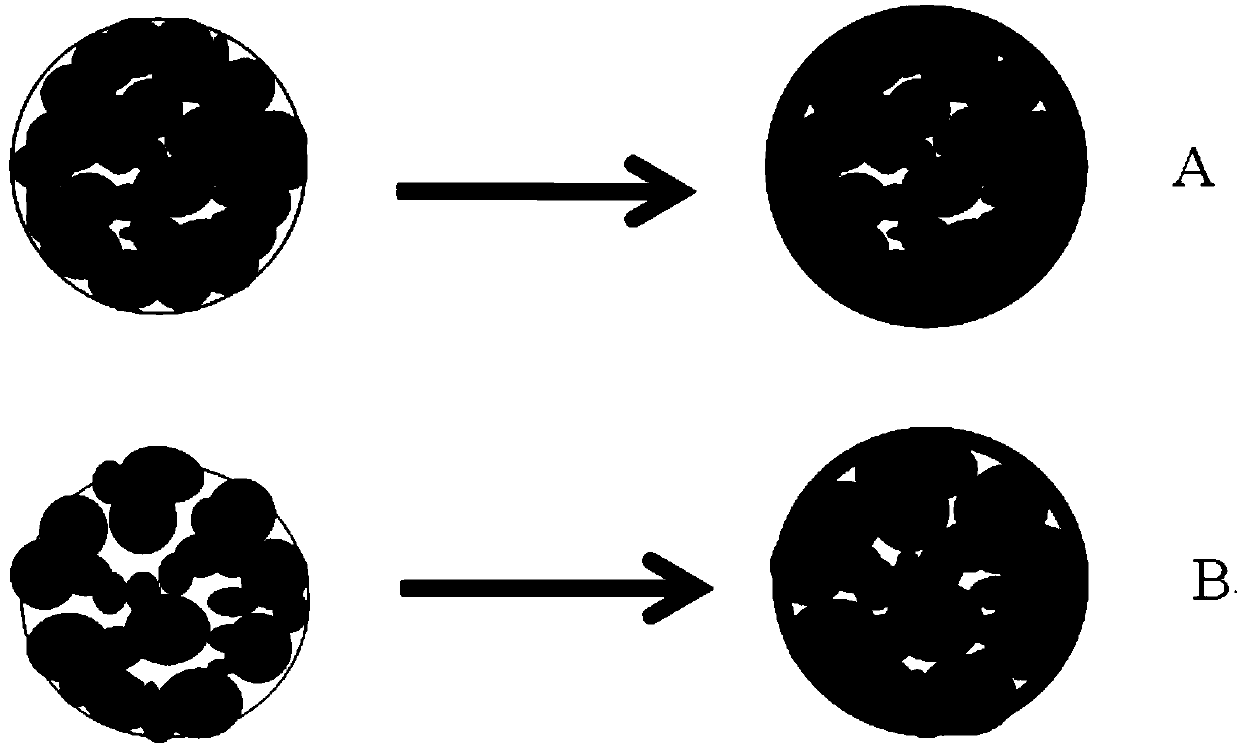

[0040]C) During the coprecipitation reaction process, the oxidizing agent is mixed with the nickel-cobalt-manganese precursor solution, and a partial oxidation reaction is carried out to obtain a positive electrode material precursor, which is composed of general formula (I) and A composite precursor of secondary spherical particles formed by the accumulation of primary particles represented by general formula (II);

[0041] Ni x co y mn 1-x-...

Embodiment 1

[0085] (1) configure the mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate, the mol ratio of described nickel sulfate, cobalt sulfate, manganese sulfate is 1:1:4, the total concentration of nickel sulfate, cobalt sulfate, manganese sulfate in the mixed solution It is 2mol / L.

[0086] (2) Configure a sodium carbonate precipitant solution with a concentration of 4mol / L.

[0087] (3) Configure an ammonia solution with a concentration of 2 mol / L.

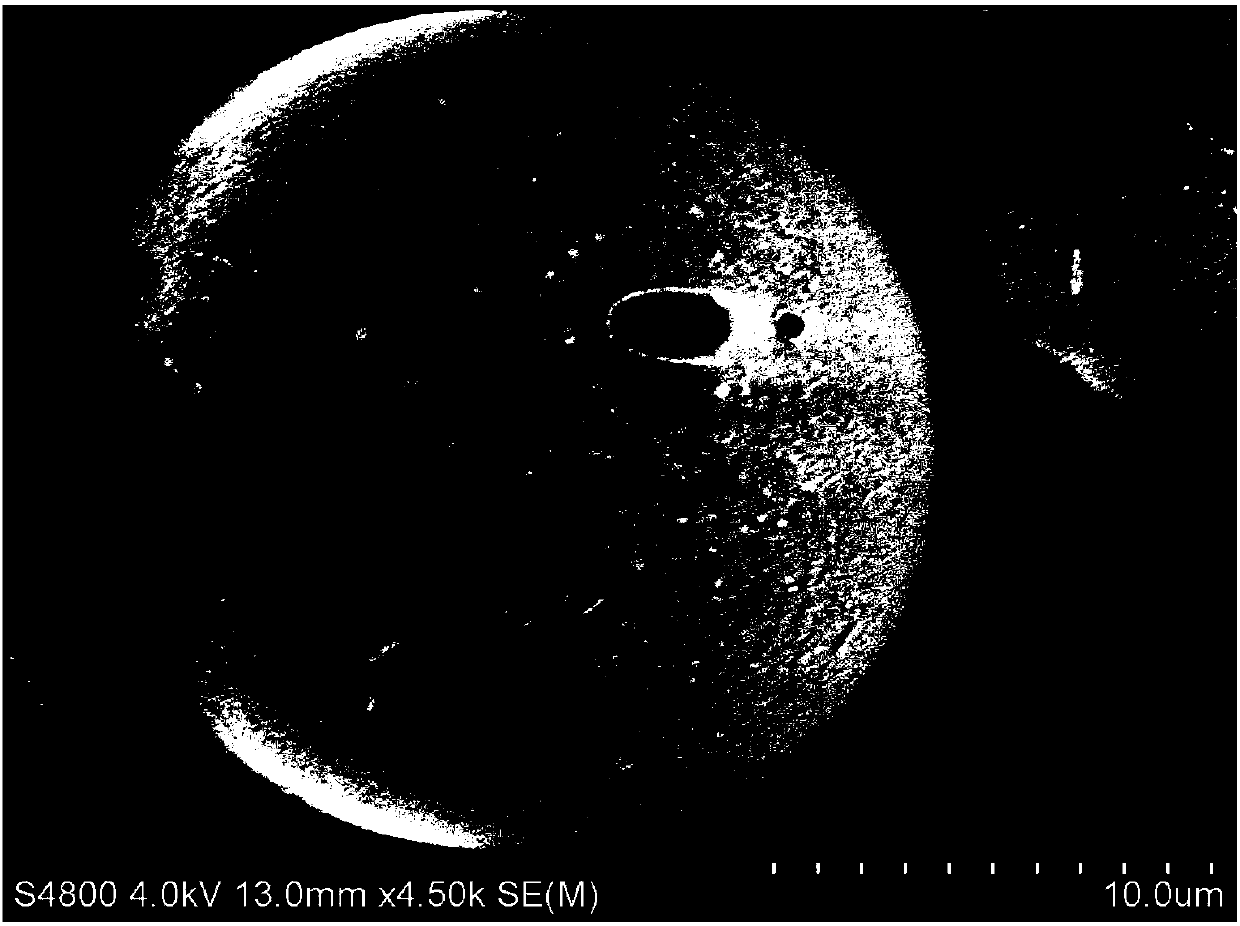

[0088] (4) above-mentioned three kinds of solutions are continuously added in the reactor with stirring, and the ammoniacal liquor add-on of control is (complexing agent: the total molar ratio of nickel cobalt manganese=1:2), regulates the flow rate of sodium carbonate precipitant solution to Control the pH value to 8.1. After 10 hours of reaction, add 0.5 mol / L hydrogen peroxide solution with 5% of the total moles of oxidants every 5 hours. The positive electrode material precursor with high tap density and small pa...

Embodiment 2

[0095] (1) configure the mixed solution of nickel nitrate, cobalt nitrate, manganese nitrate, the mol ratio of described nickel sulfate, cobalt sulfate, manganese sulfate is 1 / 3:1 / 3:1 / 3, nickel sulfate, cobalt sulfate in mixed solution , The total concentration of manganese sulfate is 2mol / L.

[0096] (2) The sodium carbonate precipitating agent solution that configuration concentration is 3mol / L.

[0097] (3) The ammonia water complexing agent solution whose concentration is 1mol / L is configured.

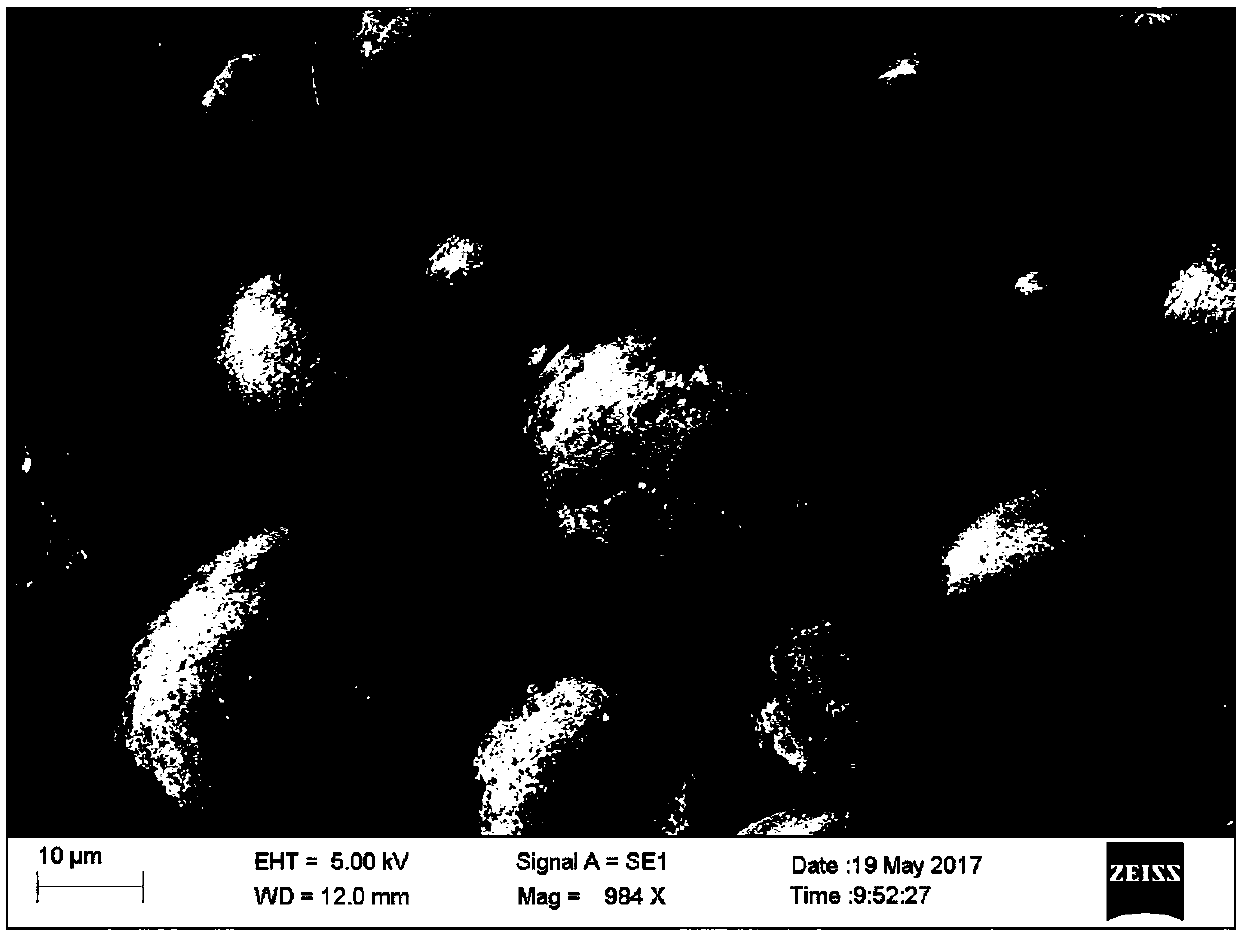

[0098] (4) above-mentioned three kinds of solutions are continuously added in the reactor with stirring, the control complexing agent add-on is (complexing agent: nickel-cobalt-manganese mol ratio=1:2), regulates the flow rate of sodium carbonate precipitant solution to Control the pH value to be 8.3, add the 0.02mol / L peroxyacetic acid solution=of 4% of the total moles of oxidizing agent every 8 hours after the reaction for 15h, add the total moles of the oxidizing agent after 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com