Patents

Literature

96 results about "Nickel cation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel is classified as a transition metal with nickel(II) having much chemical behaviour in common with iron(II) and cobalt(II). Many salts of nickel(II) are isomorphous with salts of magnesium due to the ionic radii of the cations being almost the same.

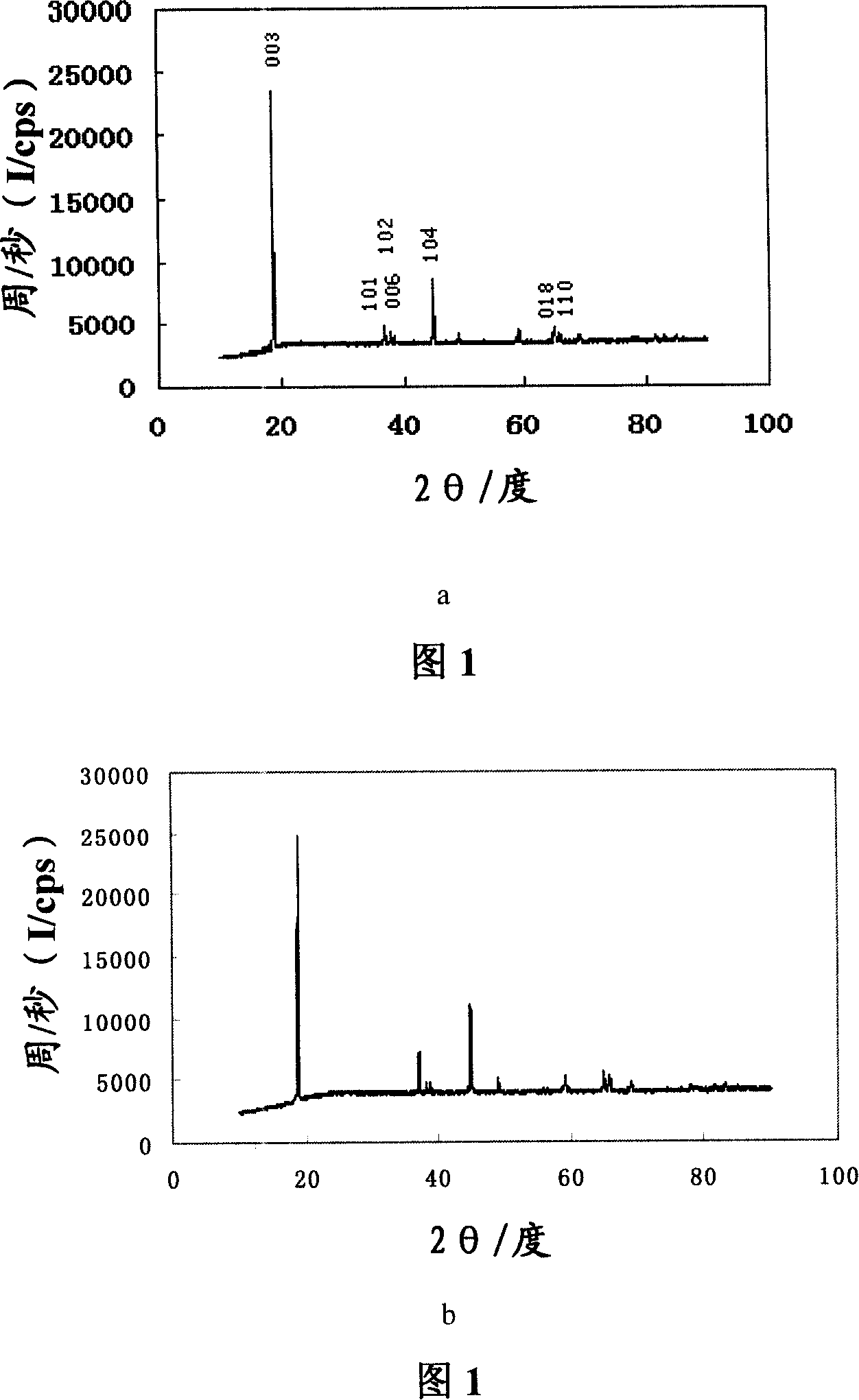

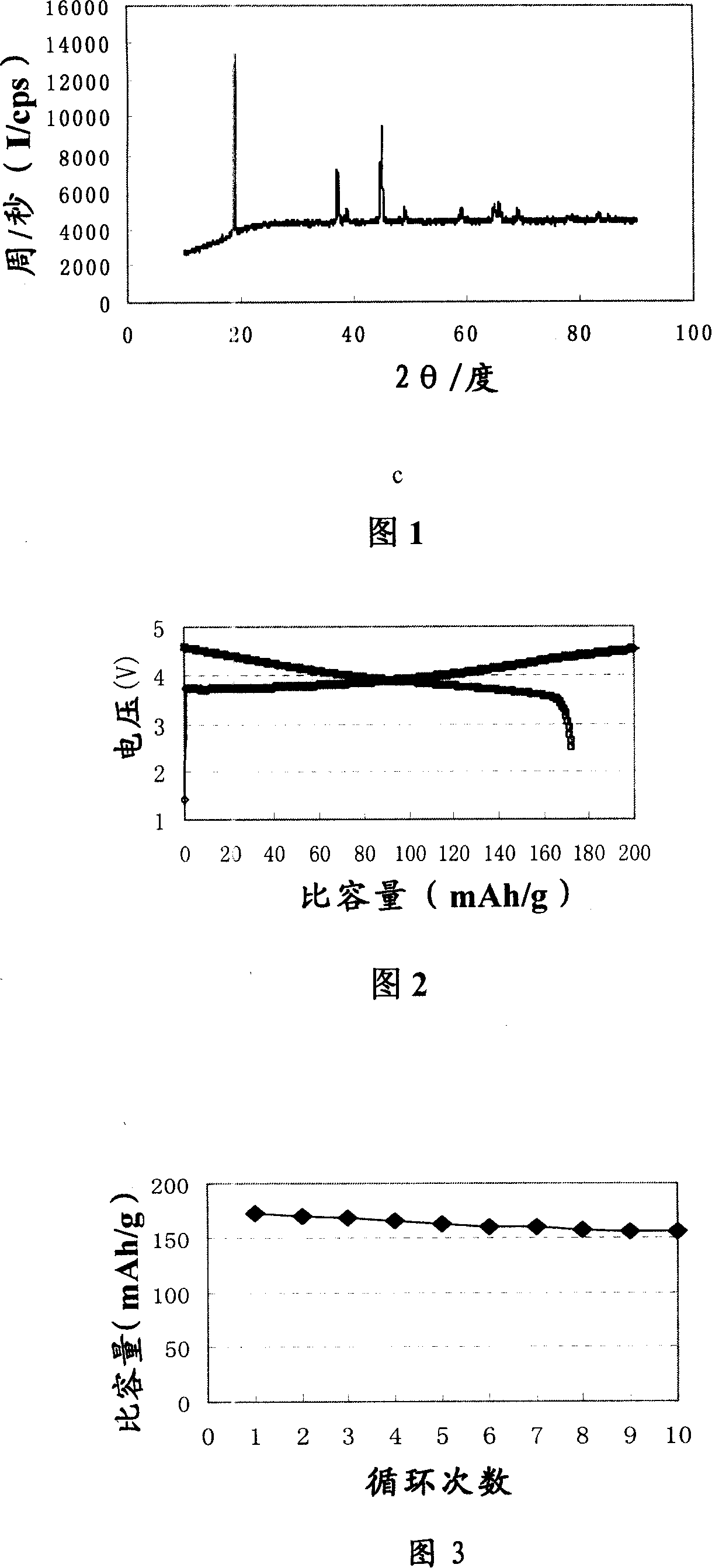

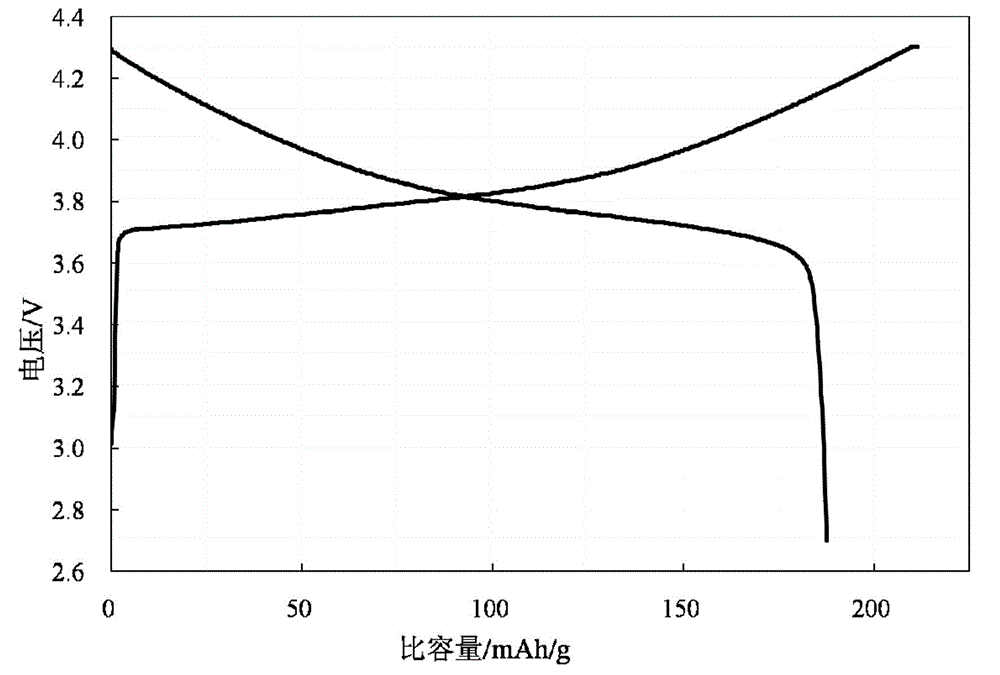

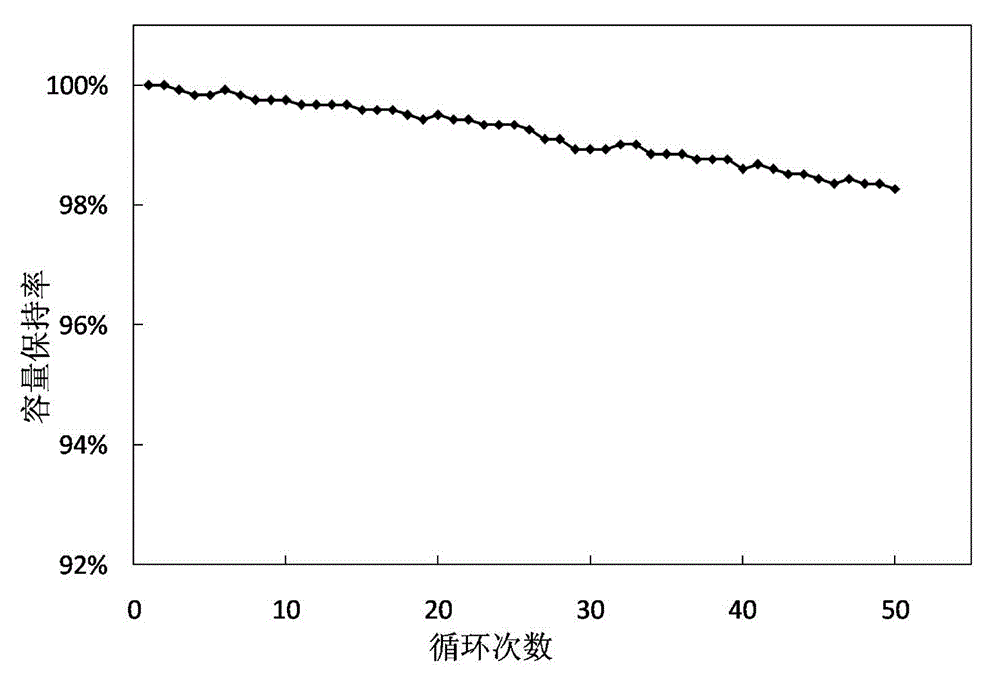

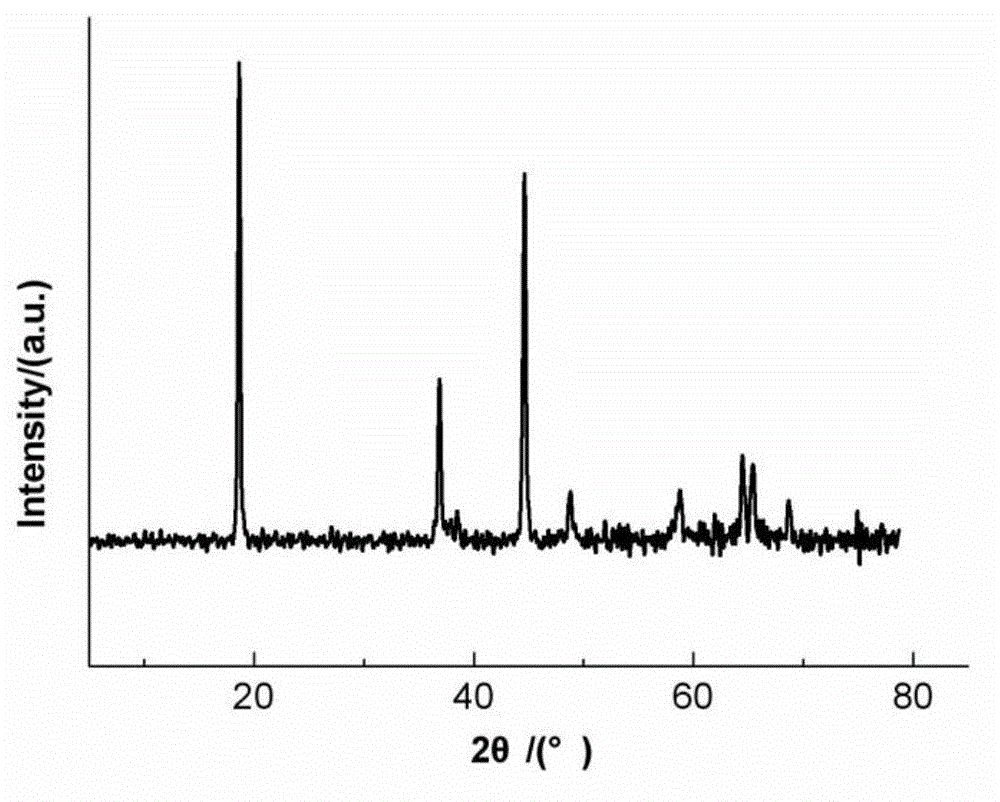

Preparation method of high-capacity layered lithium-rich manganese-based oxide

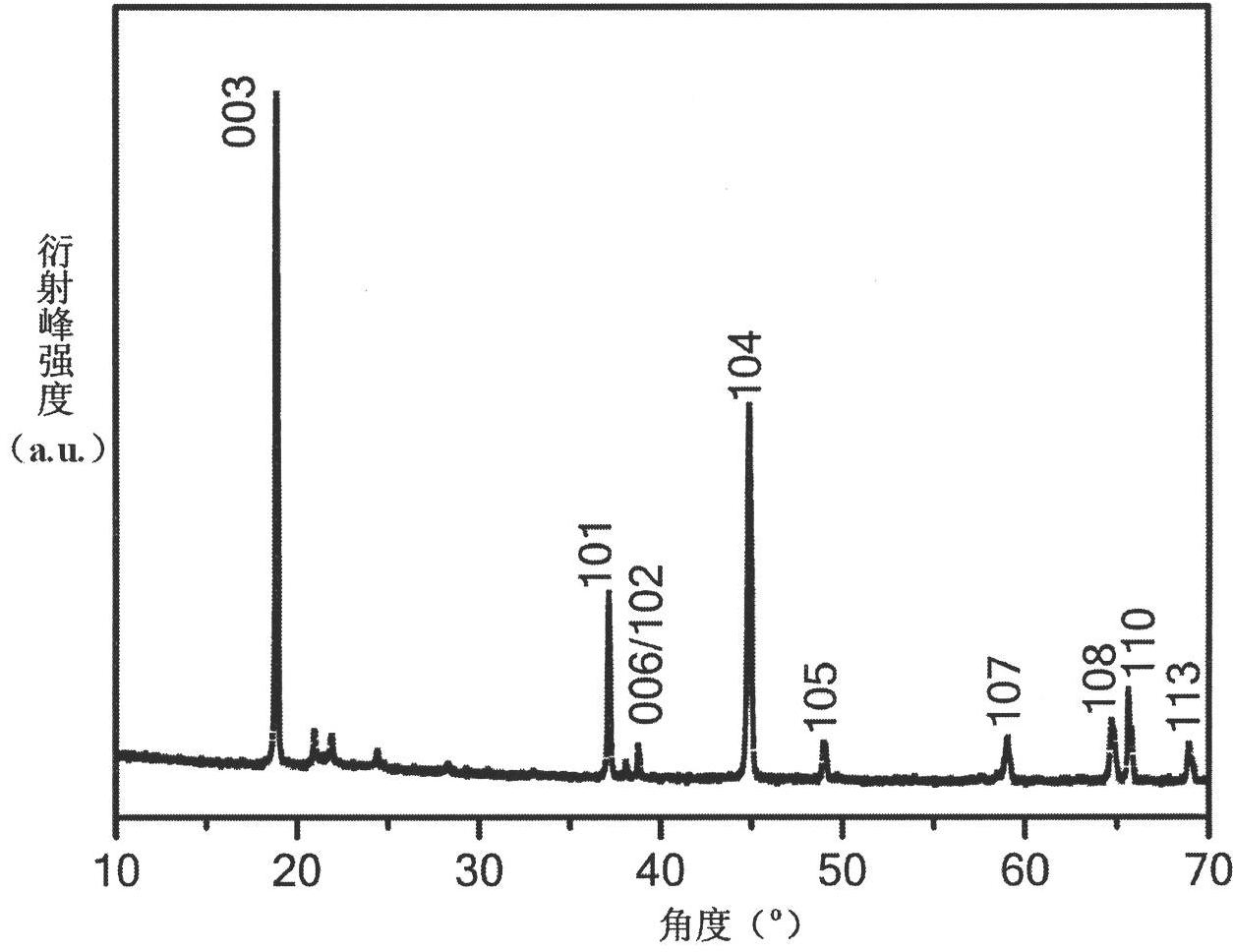

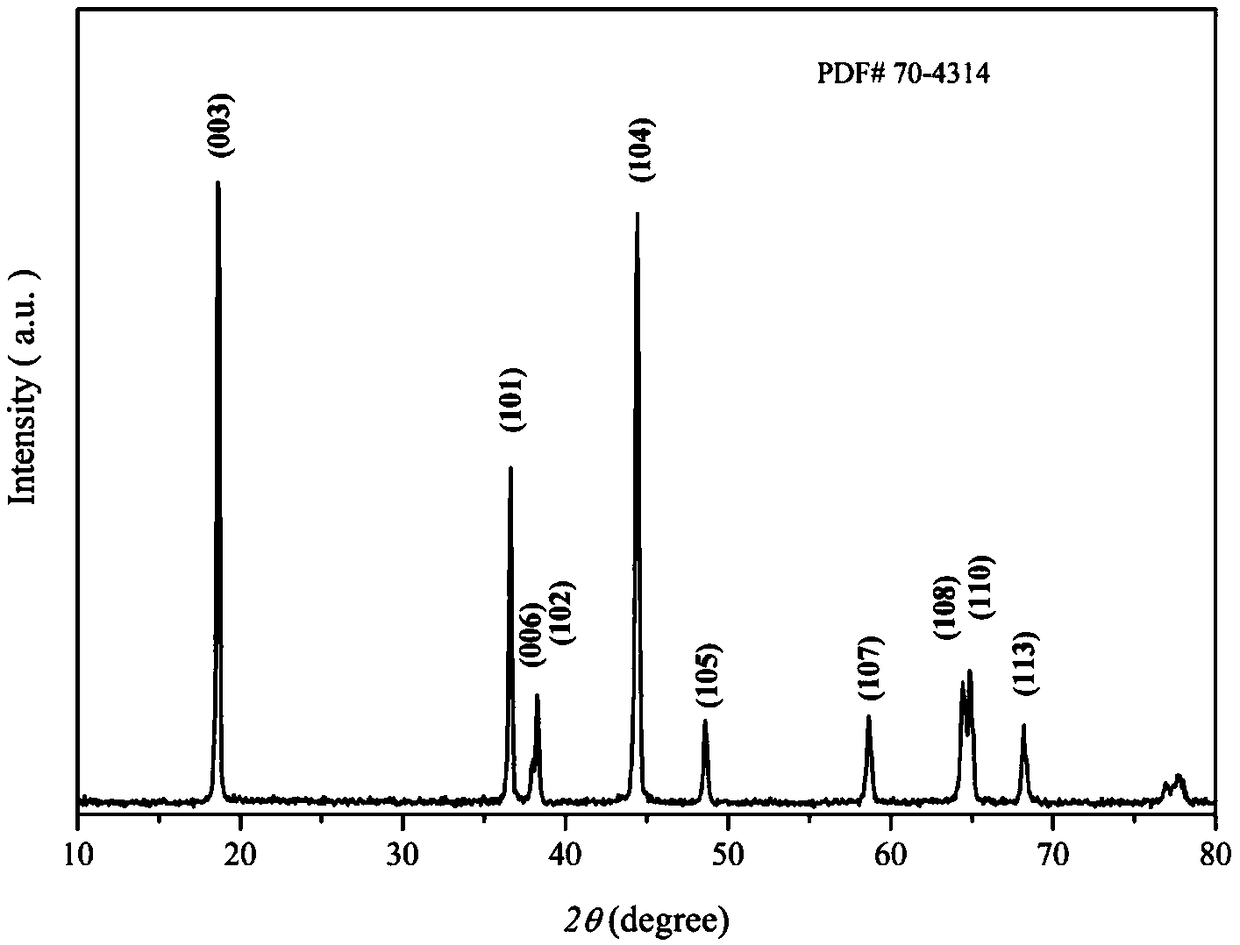

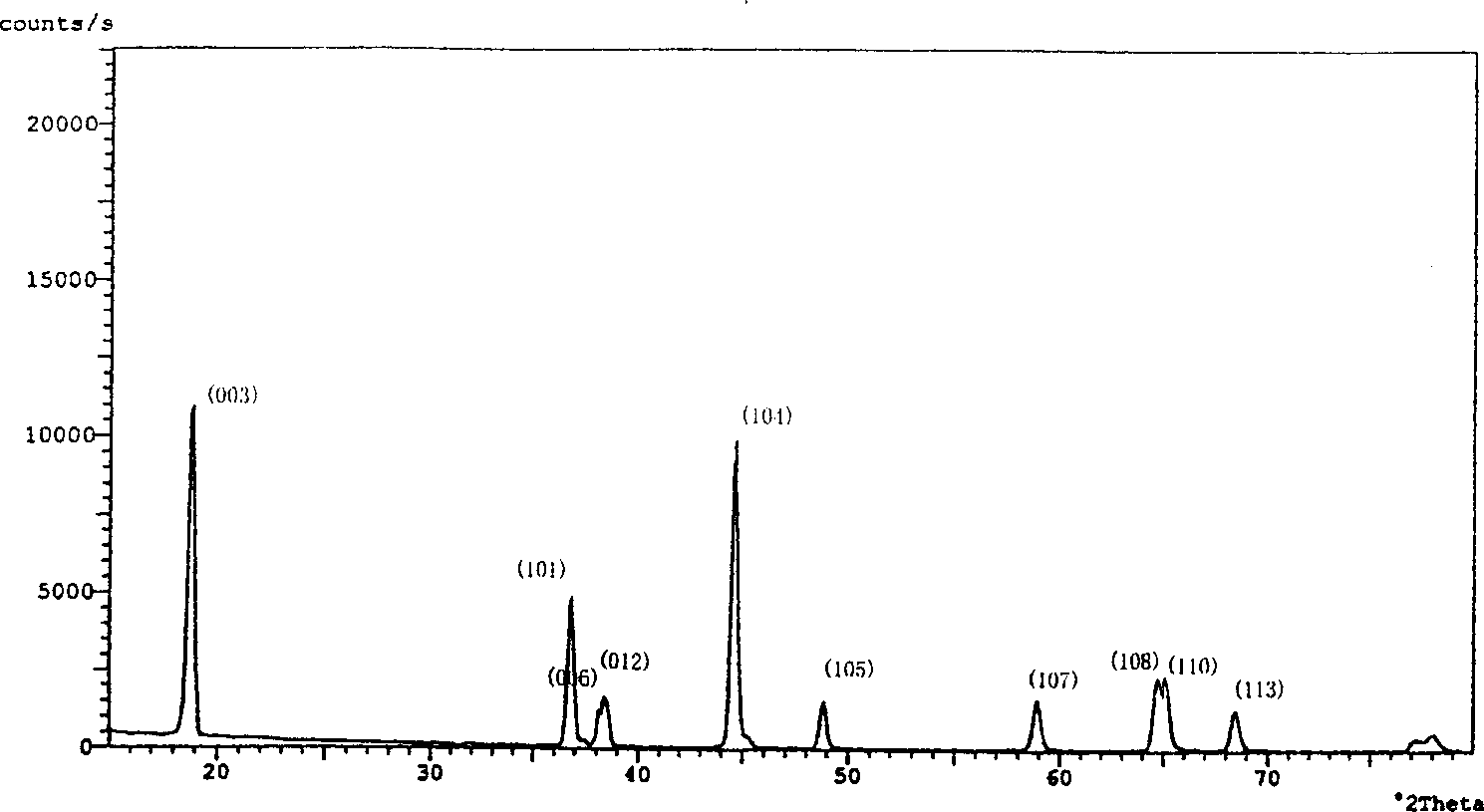

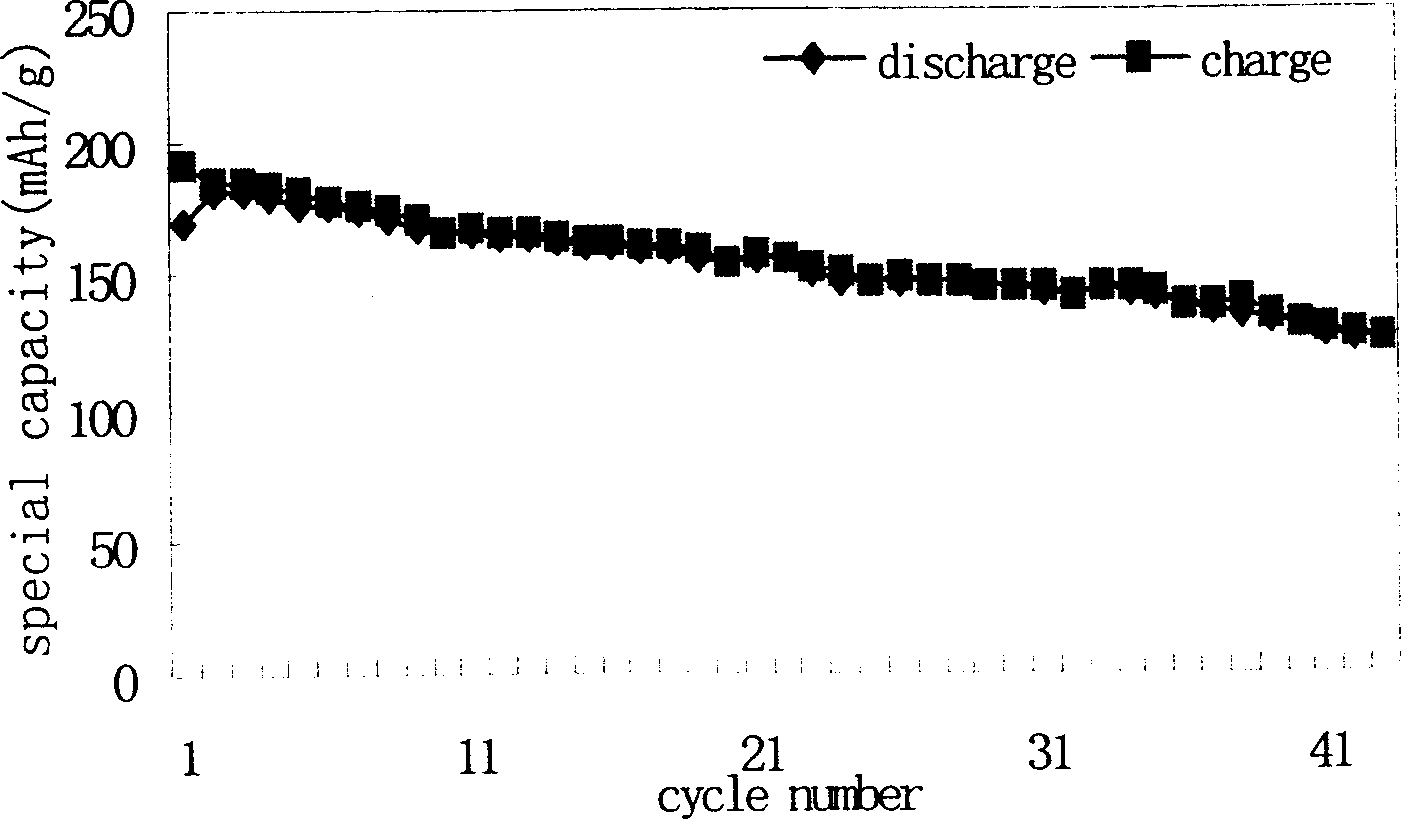

ActiveCN102354741AImprove charge and discharge efficiencyImprove cycle performanceCell electrodesManganeseNickel compounds

The invention relates to a preparation method of a high-capacity layered lithium-rich manganese-based oxide, and the method is characterized by comprising the following steps: a) fully mixing a nickel-containing compound, a manganese-containing compound I and a cobalt-containing compound with a solvent so as to get a solution or suspension; b) adding a precipitator into the solution or suspension obtained in the step a), and filtering to obtain a precipitate; c) drying the precipitate obtained in the step b) so as to get a precursor; d) uniformly mixing the precursor obtained in the step c), a manganese-containing compound II, a doping element M-containing compound and a lithium-containing compound in proportion so as to get mixed powder; and e) performing heat treatment on the mixed powder obtained in the step d) so as to get an ultrahigh-capacity manganese series lithium transition metal compound oxide with an expression of Li(Li0.2Mn0.8-delta-alpha-beta-Ni alpha Co beta M delta)O2. Compared with the prior art, the preparation method provided by the invention has the advantages of high utilization rate of raw materials and low production cost, and the prepared lithium-rich manganese-based oxide has the advantages of excellent charge-discharge performance and excellent cycle performance.

Owner:宁波富理电池材料科技有限公司

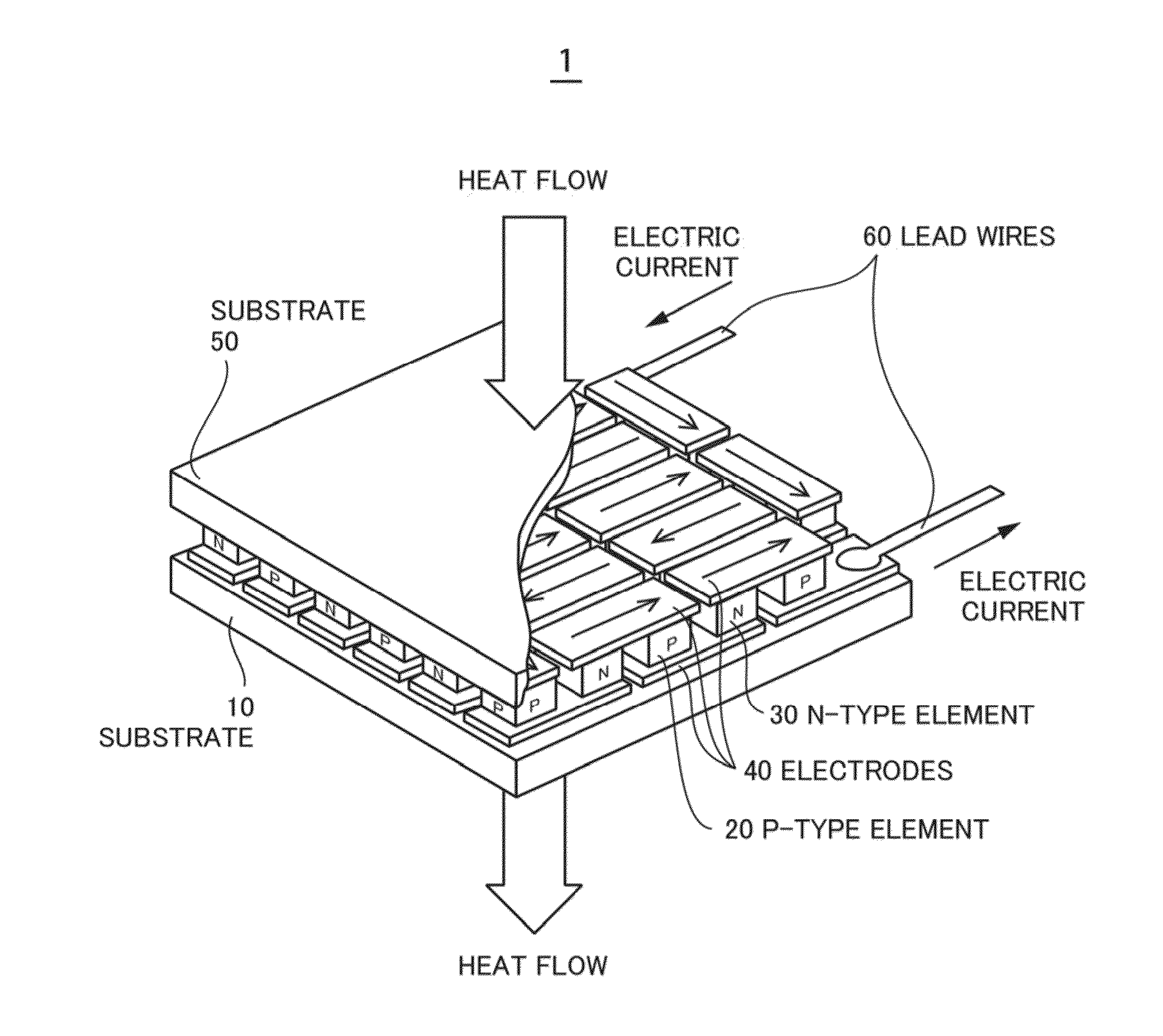

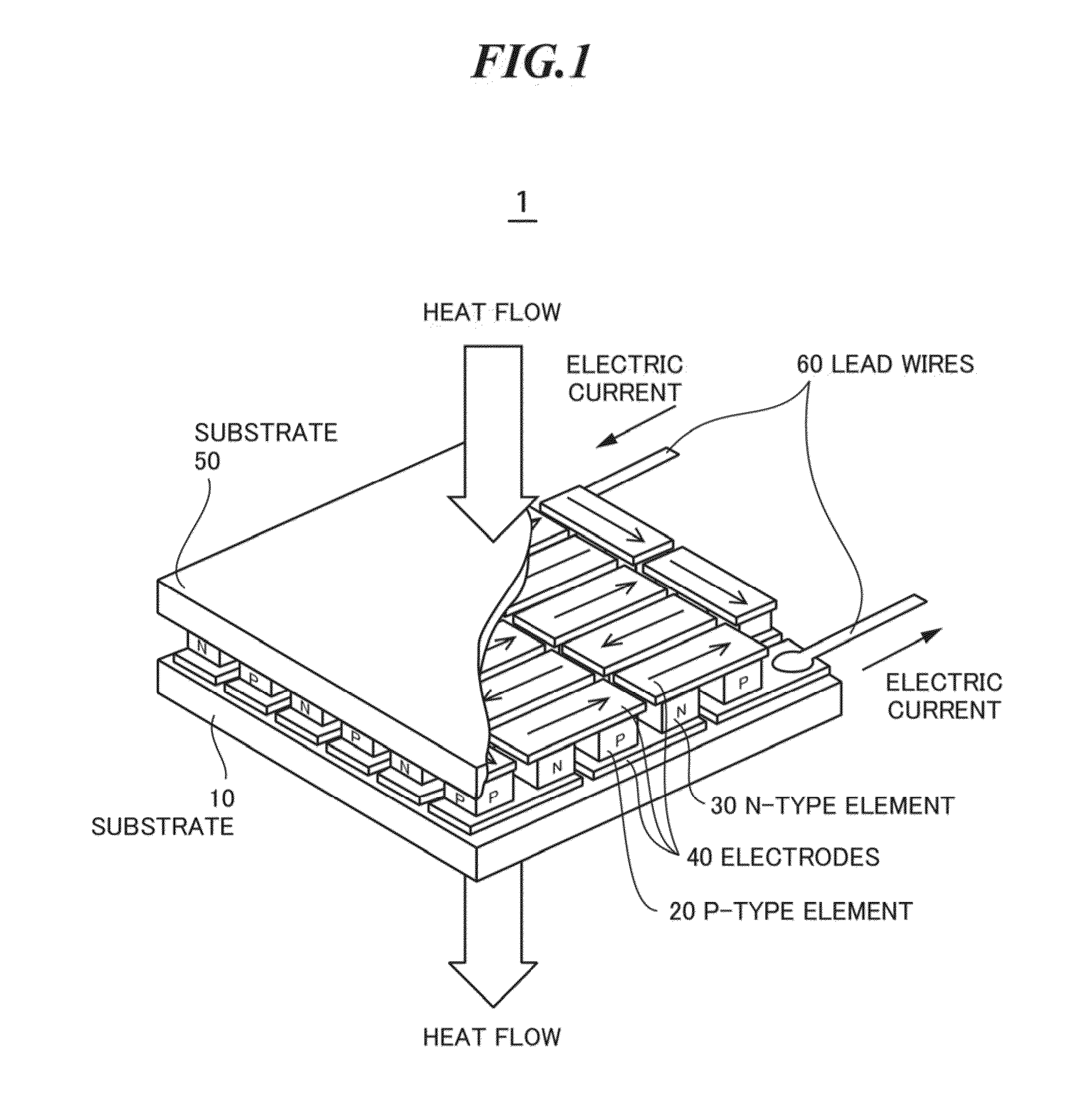

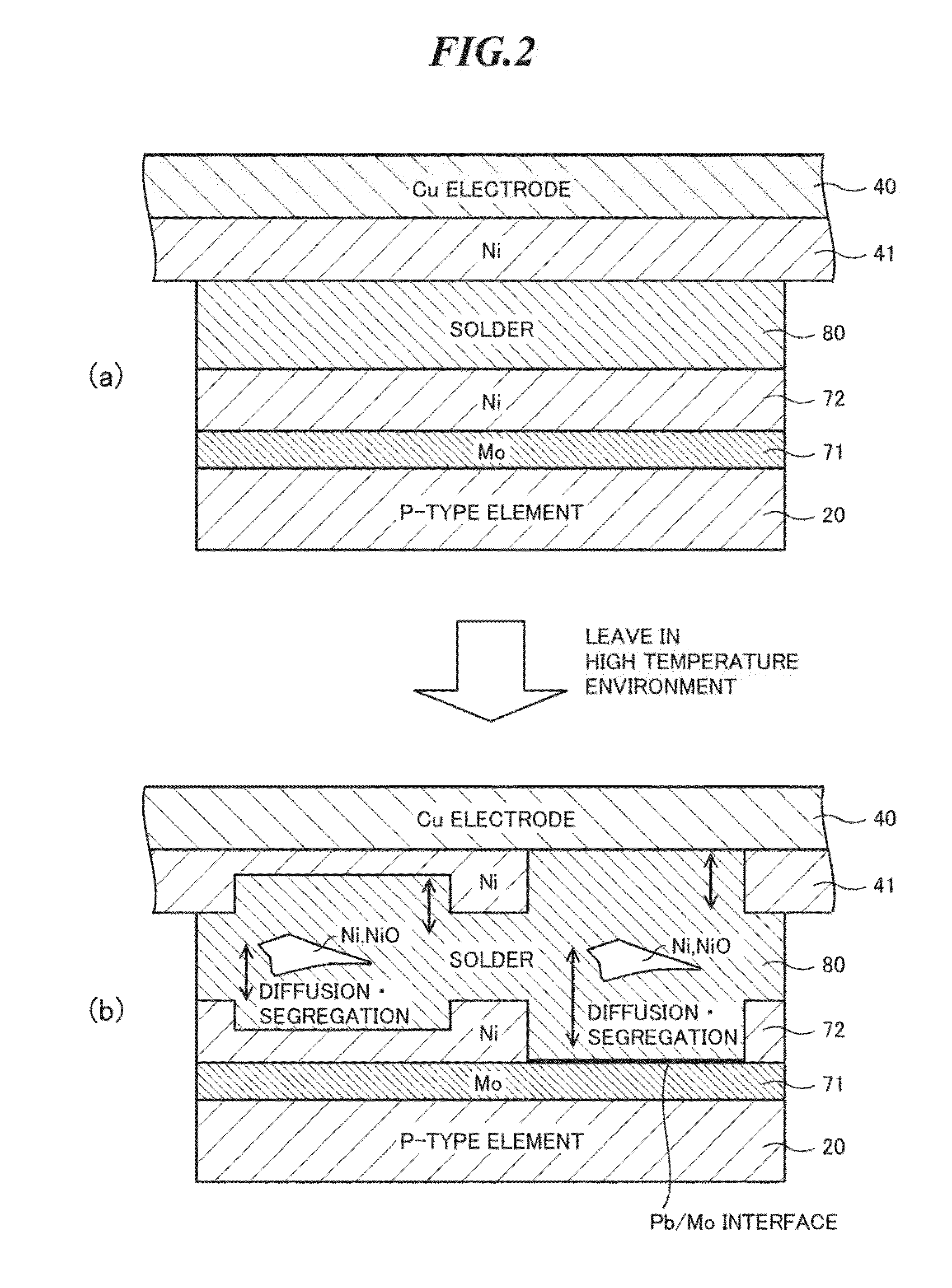

Thermoelectric power module

ActiveUS20130032188A1Suppress DiffuseGood jointThermoelectric device detailsThermodynamicsEngineering

A thermoelectric power module capable of withstanding a long time use in a high temperature environment where a temperature (Th) of a higher temperature portion exceeds 250° C. The thermoelectric power module includes: a thermoelectric power element; a first diffusion prevention layer consisting of molybdenum (Mo) and disposed on a surface of the thermoelectric power element; a second diffusion prevention layer consisting of an intermetallic compound of nickel-tin (Ni—Sn) and disposed on a surface of the first diffusion prevention layer opposite to the thermoelectric power element side; an electrode; a third diffusion prevention layer consisting of an intermetallic compound of nickel-tin (Ni—Sn) and disposed on a surface of the electrode; a solder layer containing lead (Pb) at not less than 85% and configured to join the second diffusion prevention layer and the third diffusion prevention layer to each other.

Owner:KOMATSU LTD

Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

The present invention relates to a method to prepare cathode material of layered lithium-nickel-cobalt-manganese oxide applied to lithium ion battery. The corresponding materials of metal manganese powers, compounds of lithium, metal cobalt or compounds of cobalt and compounds of nickel are weighted according to the molar ratio expressed and required in the chemical formula LiyNixCo1-2xMnxO2. In the formula, x is more than zero but less than 0.5 and y is more than or equal to 0.9 but less than 1.1; a solvent is added in the materials for wetmilling; and to be dried after wetmilling; then the materials is sintered under high temperature and then to be grinded to acquire the cathode material of layered lithium-nickel-cobalt-manganese oxide. The present invention has the advantages that a wetmilling mixing method is adopted which improves the mixing effect of the materials; a solid phase method is adopted to compound which has the advantages of simple technics process and low cost and is suitable for Industrialized mass production and avoids the complex flows of the body of a wet method before preparation; the metal manganese powers are adopted to replace the traditional manganese compound as materials which greatly improves the tap density of products and can realize higher volume capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Copper foil for printed circuit board and copper clad laminate for printed circuit board

InactiveUS8142905B2High peel strengthEffectively preventing the circuit corrosion phenomenonAnodisationBaby linensCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING & METALS CORP

Method of making NiO and Ni nanostructures

ActiveUS20080019901A1Restore charge neutralityObvious advantagesMaterial nanotechnologyHydrogenFiberGlycol synthesis

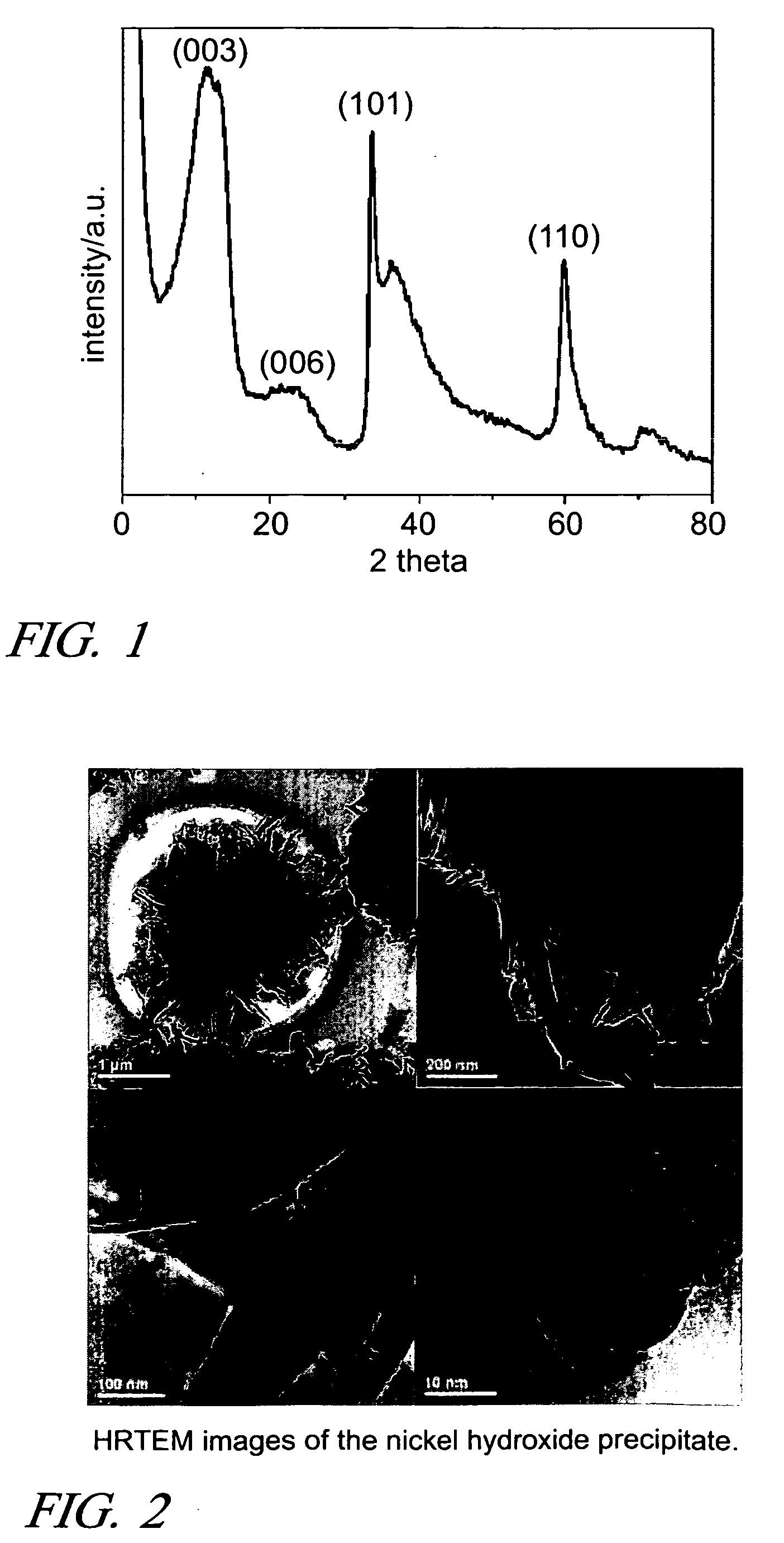

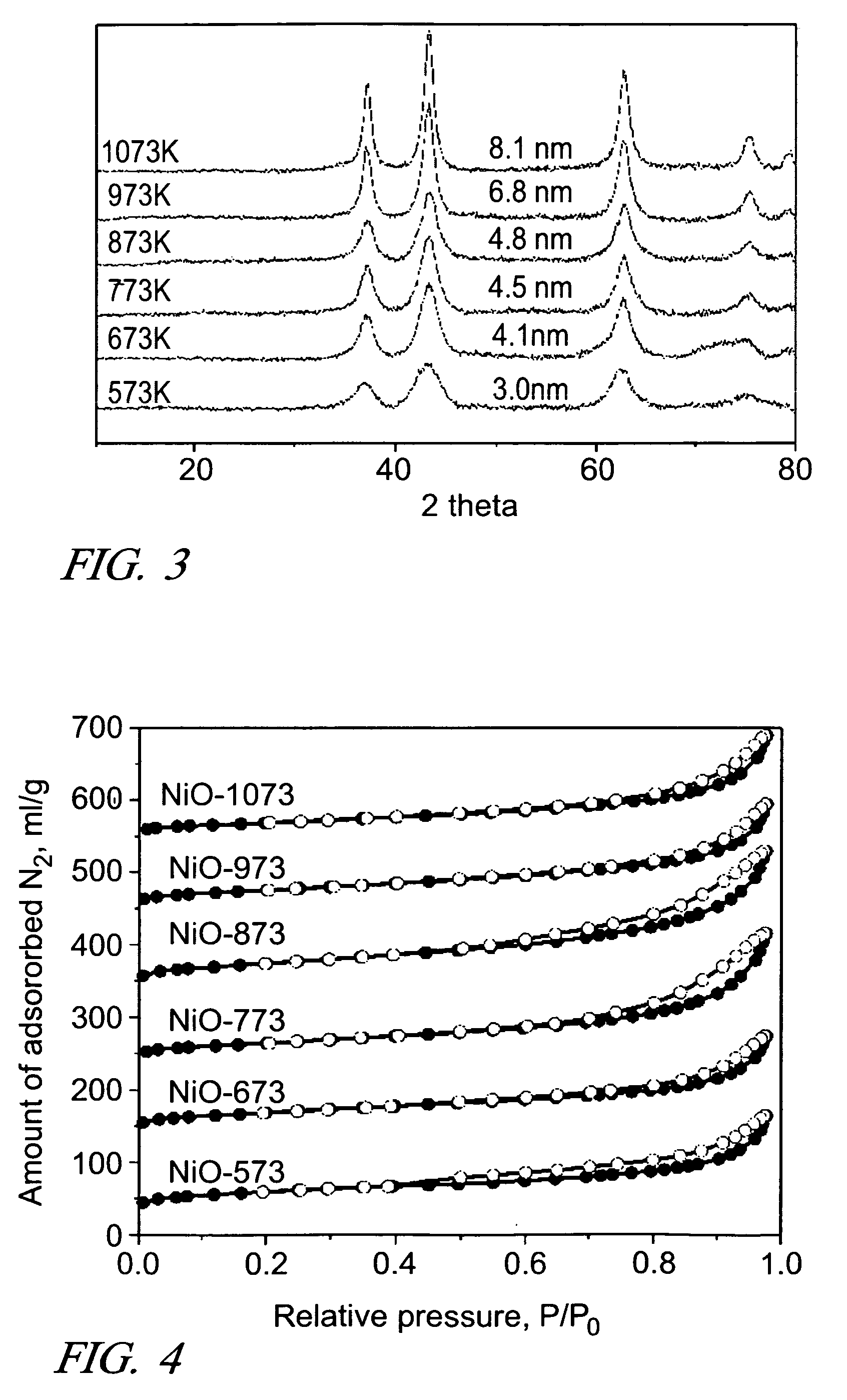

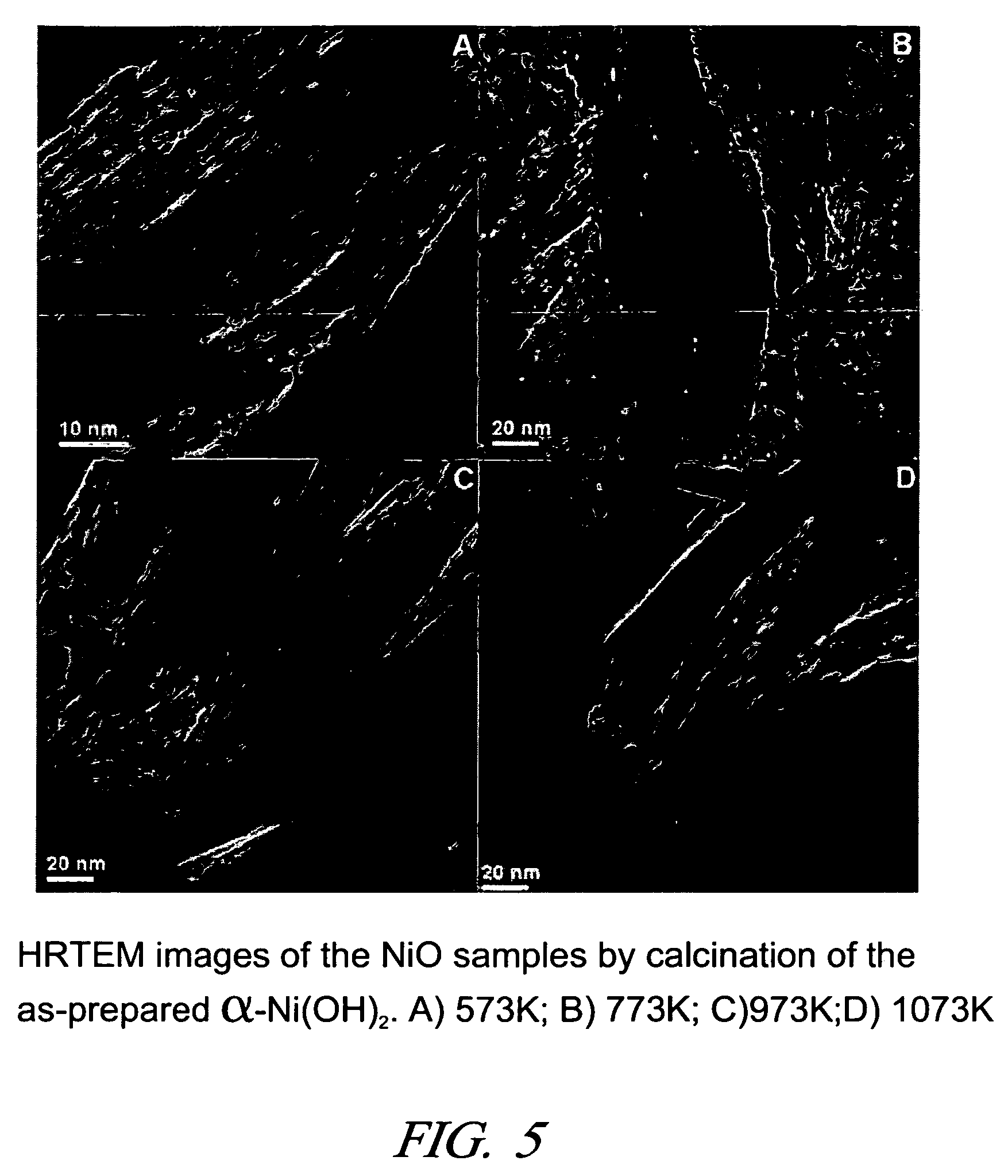

The alpha form of nickel (II) hydroxide is formed by dissolving a compound of nickel (II), such as nickel acetate, in a water miscible dihydric alcohol (diol), such as ethylene glycol, propylene glycol and suitable oligomers, and adding a suitable base such as sodium carbonate. The α-Ni(OH)2 precipitate is separated from the diol-based mother liquor and dried. This stable α-Ni(OH)2 can be calcined at temperatures in the range of about 573K to about 1073K to form nanometer-size particles of NiO having, for example, fibrous shapes. And the small particles of NiO can be reduced with hydrogen to form small, fibrous nickel particles. Both the NiO particles and Ni particles have utility as catalysts and offer utility in applications requiring electronic and / or magnetic properties.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Catalyst for removing oxygen and improving quality of bio-oil and preparation method thereof

InactiveCN102218324AIncrease contentLow oxygenLiquid hydrocarbon mixture productionBio-feedstockCatalytic reformingTO-18

The invention relates to a catalyst for removing oxygen and improving quality of bio-oil and a preparation method thereof. The catalyst comprises active ingredients and a carrier, and is characterized by comprising the following active ingredients and carrier in percentage by weight: 10 to 32 percent of NiO, 5 to 18 percent of MnO3, 5 to 15 percent of CoO and the balance of dolomite carrier. The catalyst has the advantages that: the cheap and readily available dolomite is taken as the carrier, and the active ingredients are compounds of nickel, cobalt and molybdenum, so that the acidity of the bio-oil is weakened and the oxygen content is reduced. The catalyst is easy to prepare, has high strength and catalytic activity, can be regenerated, can be used for preparing high-quality bio-oil from biomass, and also can be applied to preparation of hydrogen through catalytic reforming of the bio-oil.

Owner:ANHUI UNIV OF SCI & TECH

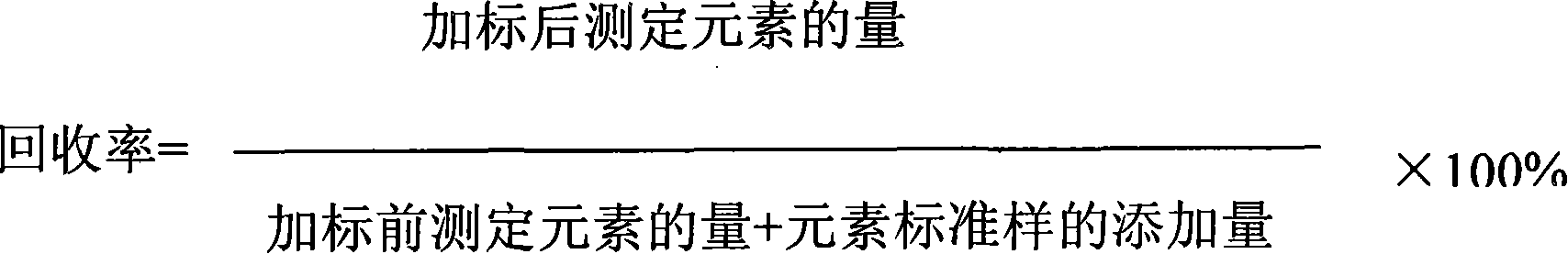

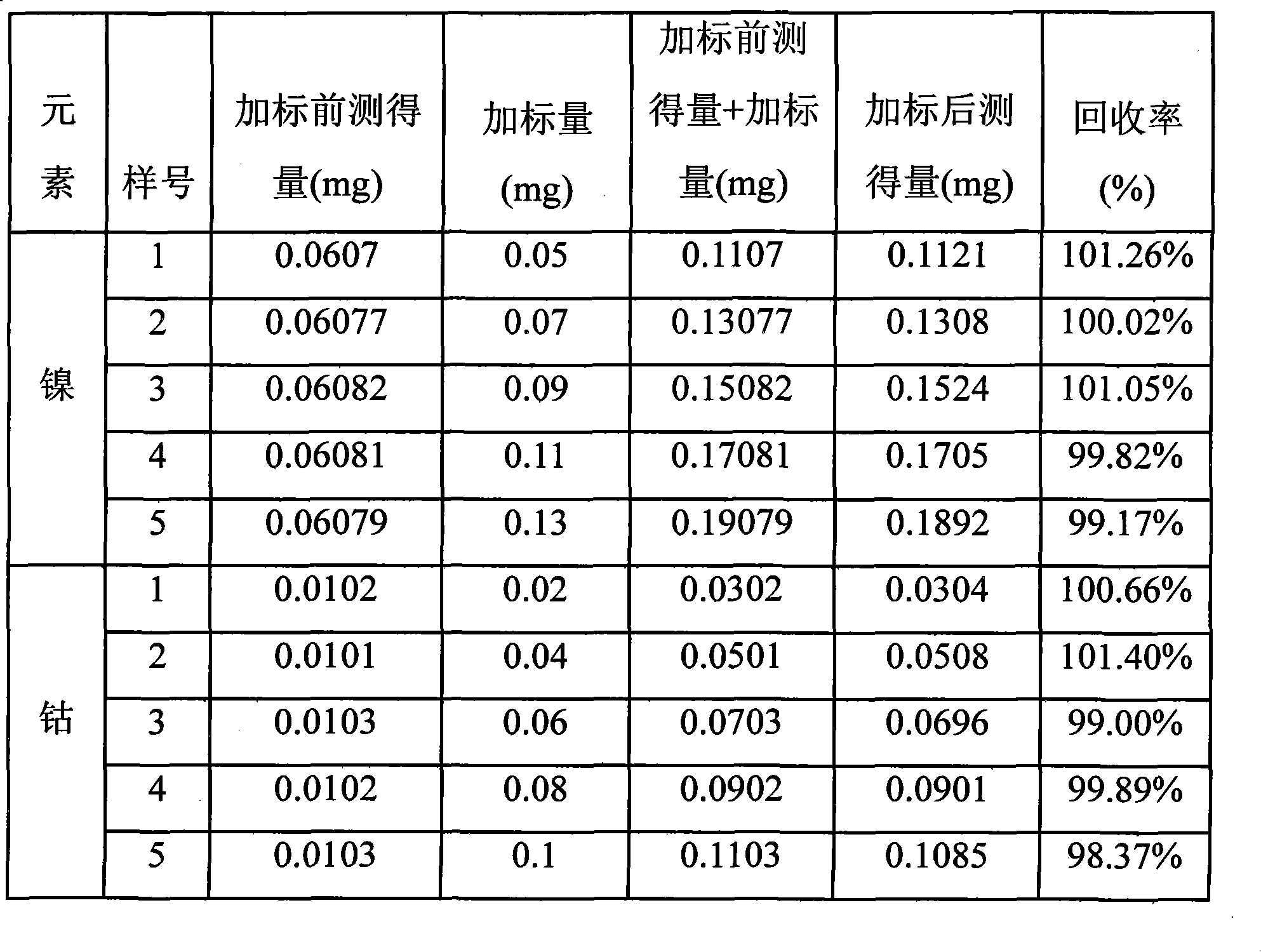

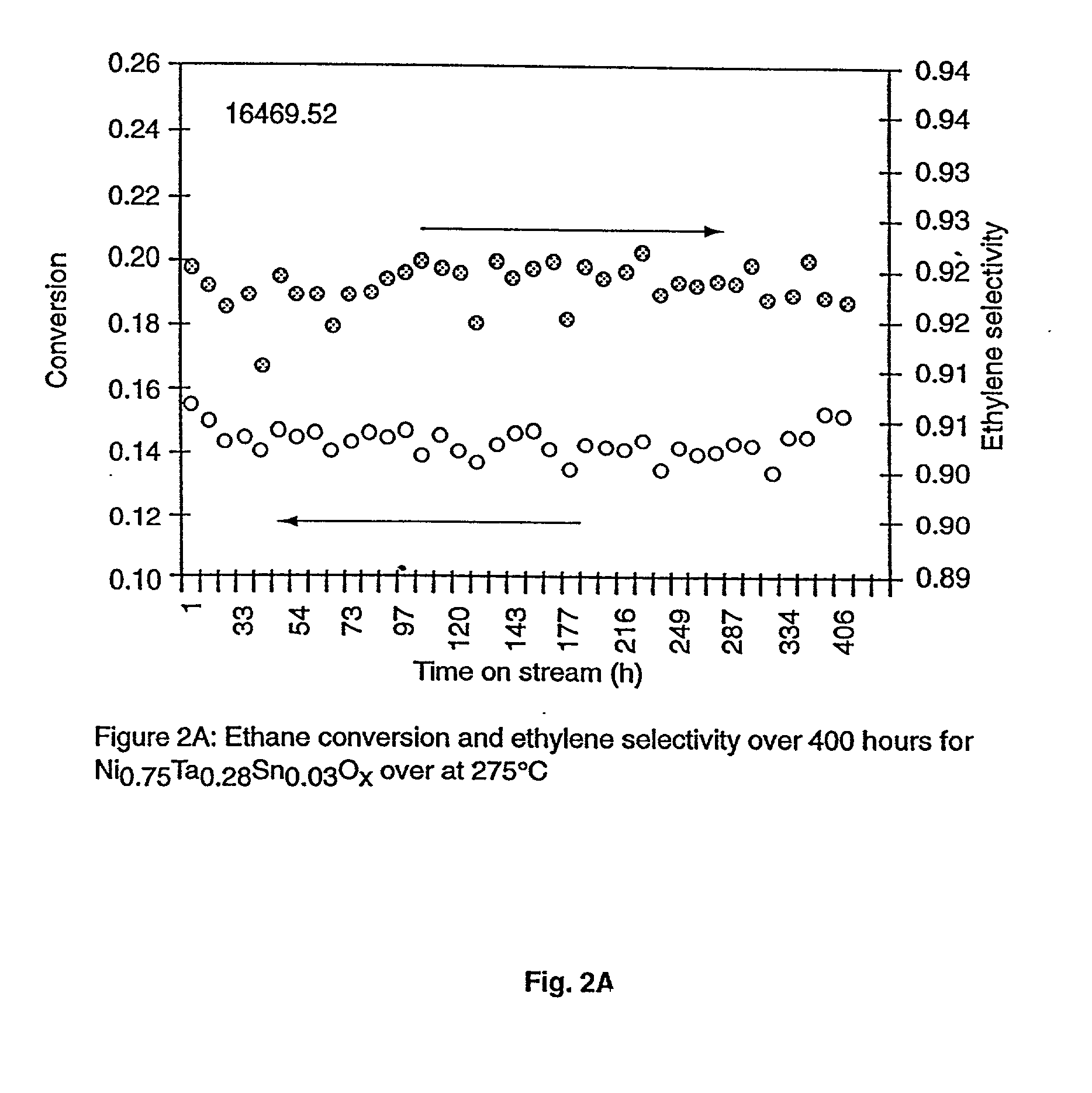

Method for testing nickel and cobalt contents in nickel compound by titration

InactiveCN101609049ALower requirementImprove accuracyMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationCobalt metalNickel compounds

The invention relates to a method for testing nickel and cobalt contents in a nickel compound by a titration, which comprises the following steps of: 1) dissolving the nickel compound to obtain nickel solution; 2) taking the partial nickel solution obtained in step 1), and carrying out complexometric titration on the nickel solution to test the nickel and cobalt metal total content; 3) taking the partial nickel solution obtained in step 1), adding ammonium persulfate, and testing the nickel metal content by using the complexometric titration again; and 4) subtracting the nickel metal content in step 3) from the nickel and cobalt metal total content tested in step 2), and obtaining the cobalt metal content. The nickel and cobalt contents in samples tested by the testing method have the advantages of small relative error and high accuracy. The testing method has the advantages of good repeatability and lower requirements of test conditions at the same time, and is suitable for work and production.

Owner:BYD CO LTD

Copper Foil for Printed Circuit Board and Copper Clad Laminate for Printed Circuit Board

InactiveUS20100261033A1Prevent deterioration in peel strengthImprove heat-resistant peel strengthAnodisationPrinted circuit secondary treatmentCopper foilNickel zinc

Provided is a copper foil for a printed circuit board comprising a layer including nickel, zinc, a compound of nickel and that of zinc (hereinafter referred to a “nickel zinc layer”) on a roughened surface of a copper foil, and a chromate film layer on the nickel zinc layer, wherein the zinc add-on weight per unit area of the nickel zinc layer is 180 μg / dm2 or more and 3500 μg / dm2 or less, and the nickel weight ratio in the nickel zinc layer {nickel add-on weight / (nickel add-on weight+zinc add-on weight)} is 0.38 or more and 0.7 or less. This surface treatment technology of a copper foil is able to effectively prevent the circuit corrosion phenomenon in cases of laminating a copper foil on a resin base material and using a sulfuric acid hydrogen peroxide etching solution to perform soft etching to the circuit.

Owner:JX NIPPON MINING& METALS CORP

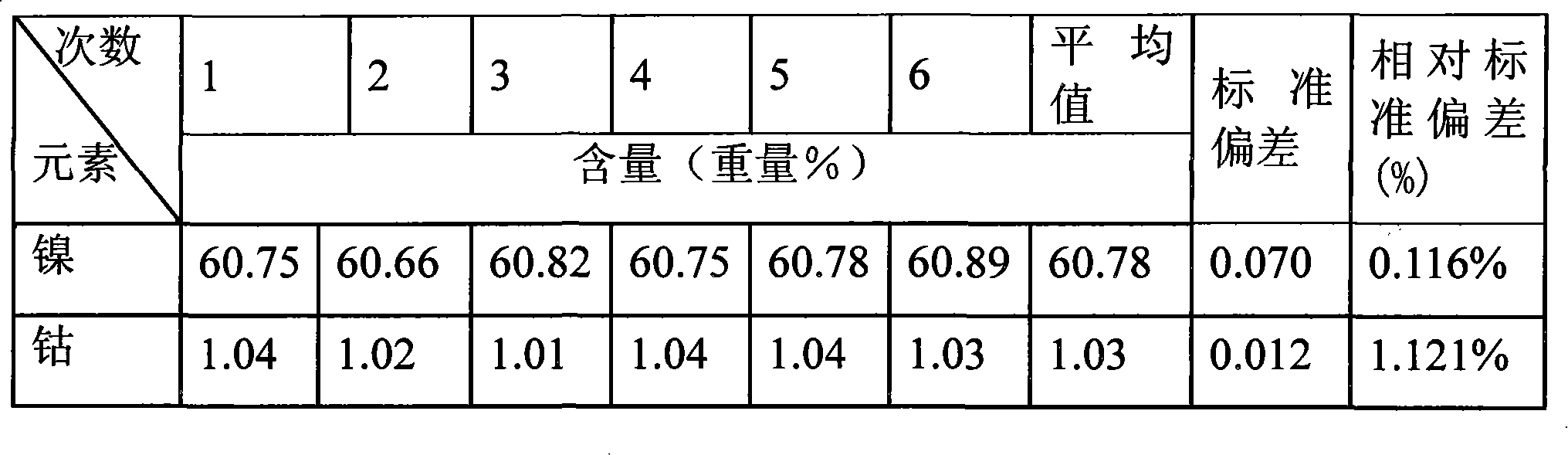

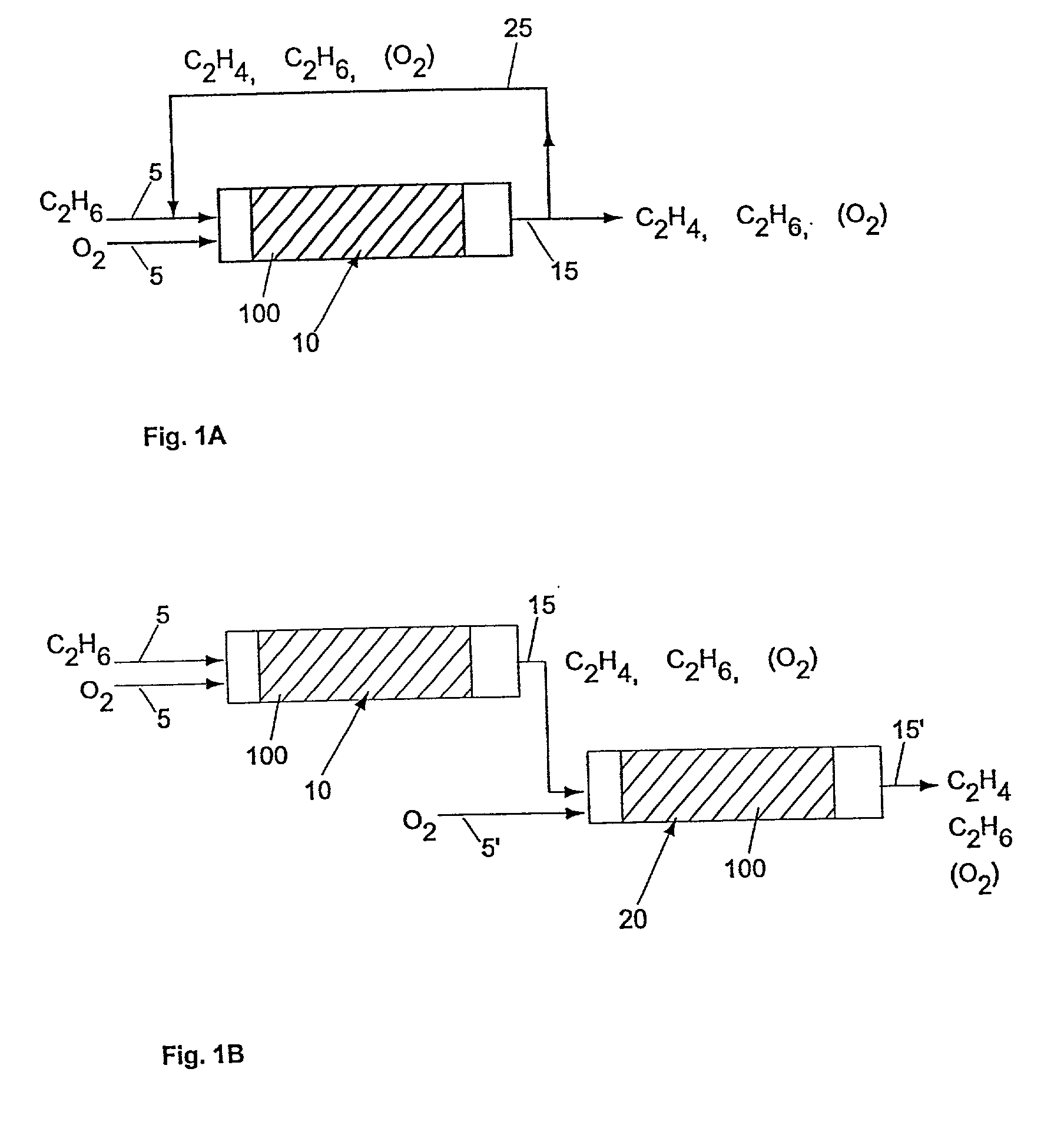

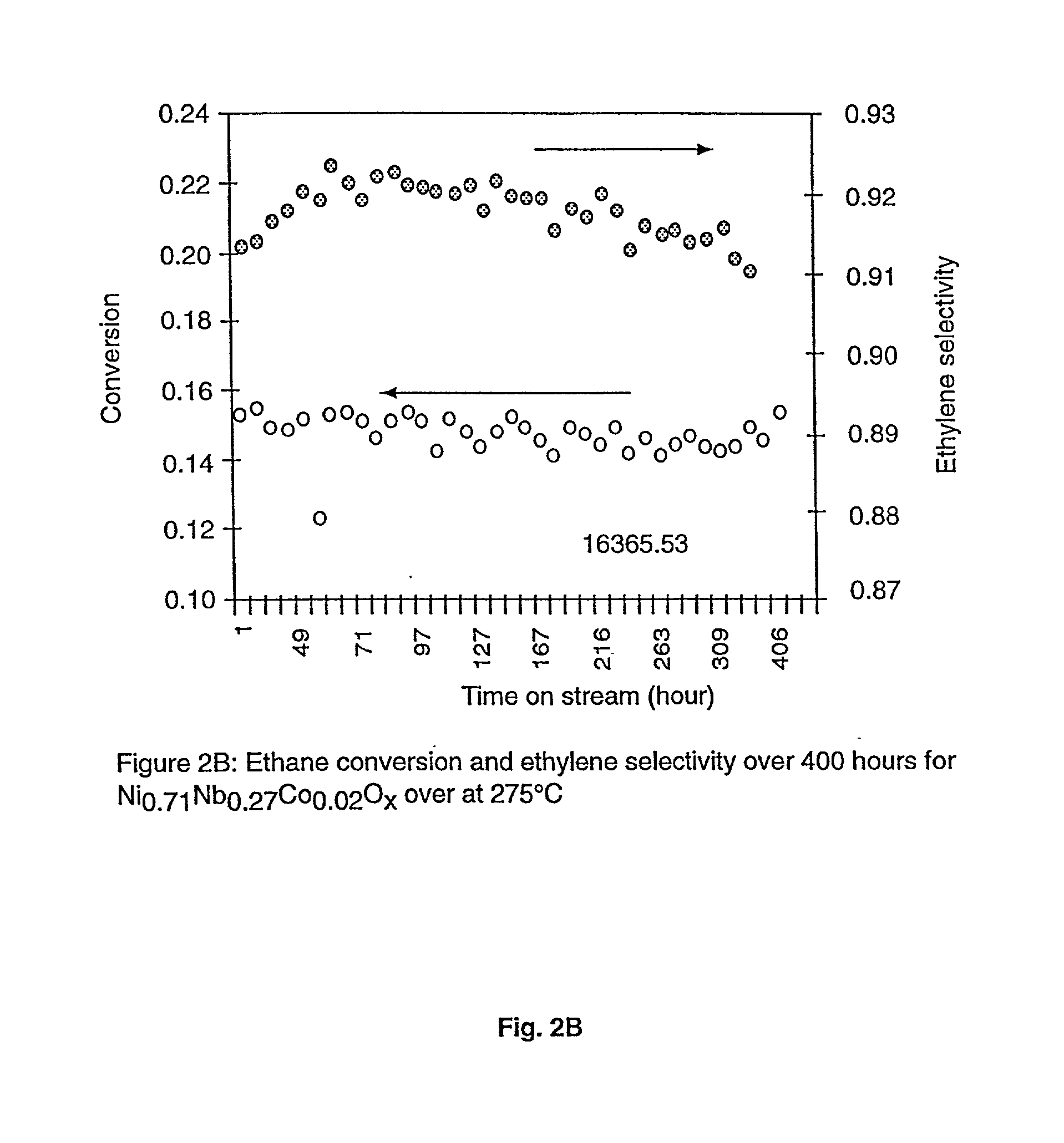

Ni catalysts and methods for alkane dehydrogenation

InactiveUS20020055664A1Favorable and industrially attractive performance characteristicLimited extentOrganic compound preparationCatalystsNiobiumDehydrogenation

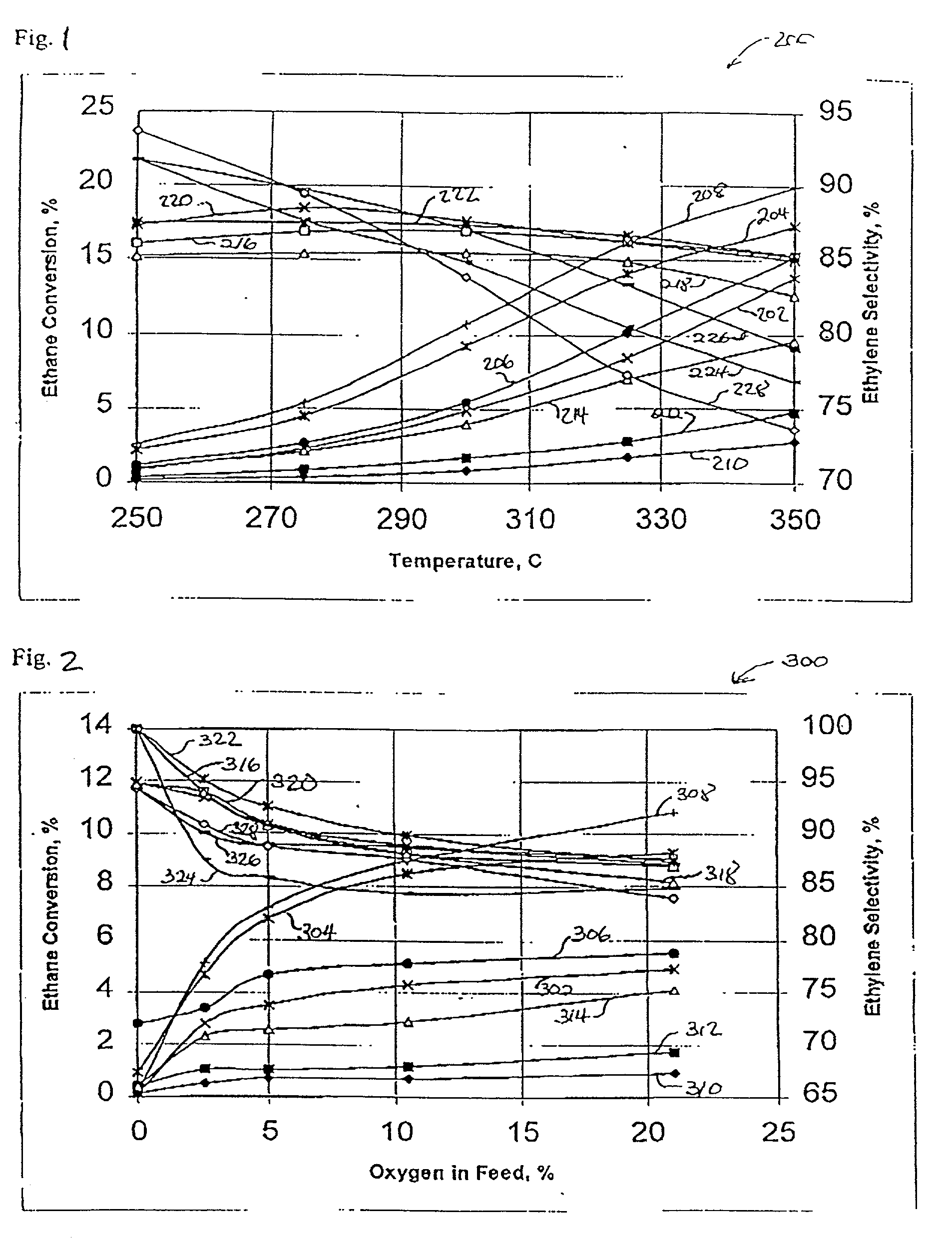

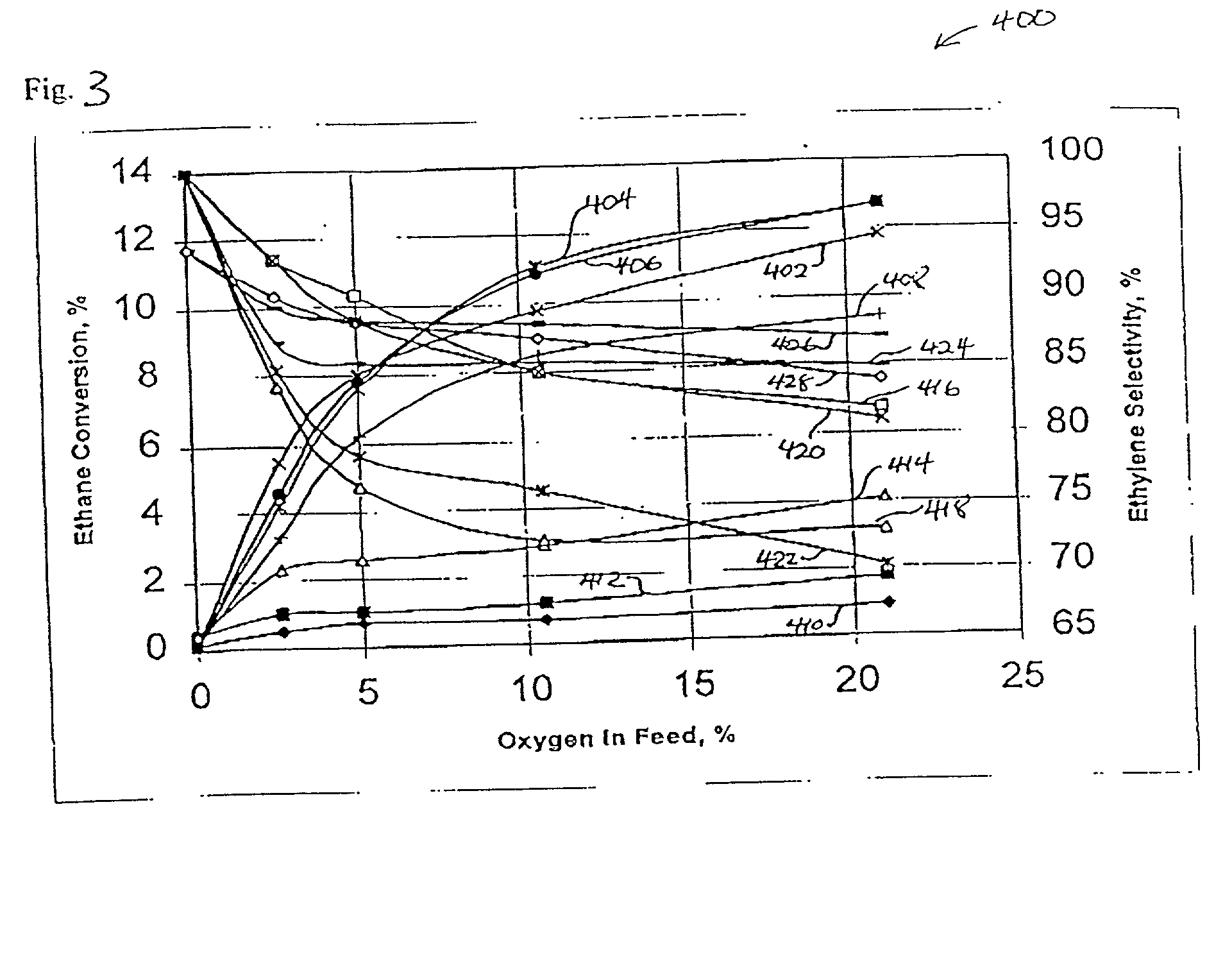

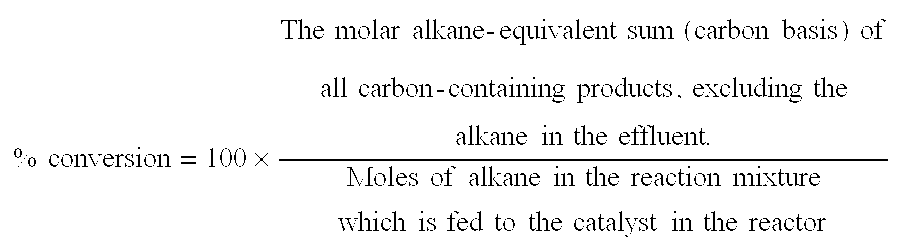

Catalysts and methods for alkane oxydehydrogenation are disclosed. The catalysts of the invention generally comprise (i) nickel or a nickel-containing compound and (ii) at least one or more of titanium (Ti), tantalum (Ta), niobium (Nb), hafnium (Hf), tungsten (W), yttrium (Y), zinc (Zn), zirconium (Zr), or aluminum (Al), or a compound containing one or more of such element(s). In preferred embodiments, the catalyst is a supported catalyst, the alkane is selected from the group consisting of ethane, propane, isobutane, n-butane and ethyl chloride, molecular oxygen is co-fed with the alkane to a reaction zone maintained at a temperature ranging from about 250° C. to about 350° C., and the ethane is oxidatively dehydrogenated to form the corresponding alkene with an alkane conversion of at least about 10% and an alkene selectivity of at least about 70%.

Owner:SYMYX TECHNOLOGIES

Nano grade nickel oxyhydroxide and process for preparing same

InactiveCN1433970ASmall and uniform particle sizeFully dispersed evenly dispersedCell electrodesNickel carbonylsPrimary cellPrimary battery

The present invention relates to the field of cell material, in particular, it relates to a method for preparing positive material nickel oxyhydroxide for zinc-nickel primary cell, zinc-nickel secondary cell and other cells using compound of nickel as active matter, such as cadmium-nickel cell, metal hydride nickel cell and Hawkins cell and nano grade nickel oxyhydroxide prepared by said method. The nano nickel oxyhydroxide is prepared by using nickeous salt as raw material, using sodium hypochlorite as oxidant; adopting precipitation reaction and oxidation reaction simultaneously in alkalineaqueous solution and adopting ultrasonic wave to make oscillation dispersion in the course of reaction. Said invented product is fine and uniform in grain size, large in specific surface area, high in initial discharge specific value, low in self-discharge rate and stable in electric performance.

Owner:SOUTH CHINA UNIV OF TECH

Nickel Titanium Oxide Coated Articles

This disclosure relates to an article comprising at least one substrate and at least one porous coating formed on the at least one substrate. The substrate may be a medical device, for example a Nitinol stent. The porous coating may comprise a nanotubular coating. The nanotubular coating may comprise a compound of nickel, titanium and oxygen. This porous coating may improve re-endothelialization and / or reduce restenosis when it is used in the treatment of cardiovascular diseases.

Owner:RGT UNIV OF CALIFORNIA

Method for detaching impurity copper from solution containing nickel

InactiveCN101250625ACopper removal process is simple and easyHigh copper/nickel mass ratioProcess efficiency improvementSlagSulfur

The invention relates to a method for extracting nickel through hydrometallurgy, which particularly relates to a method for removing copper from nickel containing solution. The method comprises the following steps: utilizing sulfur compound of nickel to be decoppering agent which does a reacton with impurity copper ion in anode liquor to generate copper sulfide sediment, adding thiocarbonic acid nickel in nickel solution, and leading the scope of mole ratio between nickel which contains in thiocarbonic acid nickel and copper which contains in solution to be 1.0-2.0, controlling the scope of solution temperature to be 10-150 DEG C and the scope of pH to be 2-7, wherein copper removing time is 5-300 minutes, filtering, and separating copper which is less than 3mg / l and liquid after removing copper of copper / nickel which is bigger than 15. The decoppering agent of the invention has the advantages of high activity, long activity maintenance time, simple operation and low production cost, harmless ion is not led in the process of removing copper, copper removing slag can directly feed copper to smelt.

Owner:CENT SOUTH UNIV

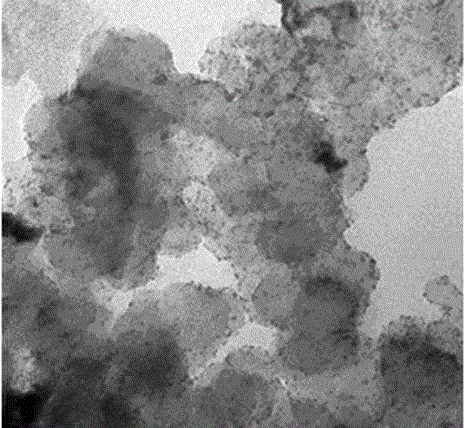

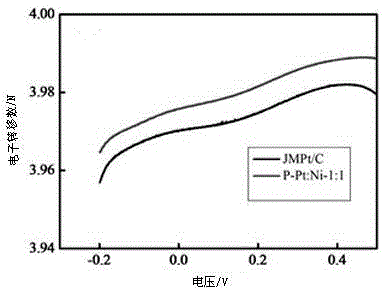

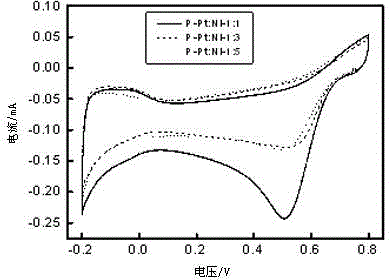

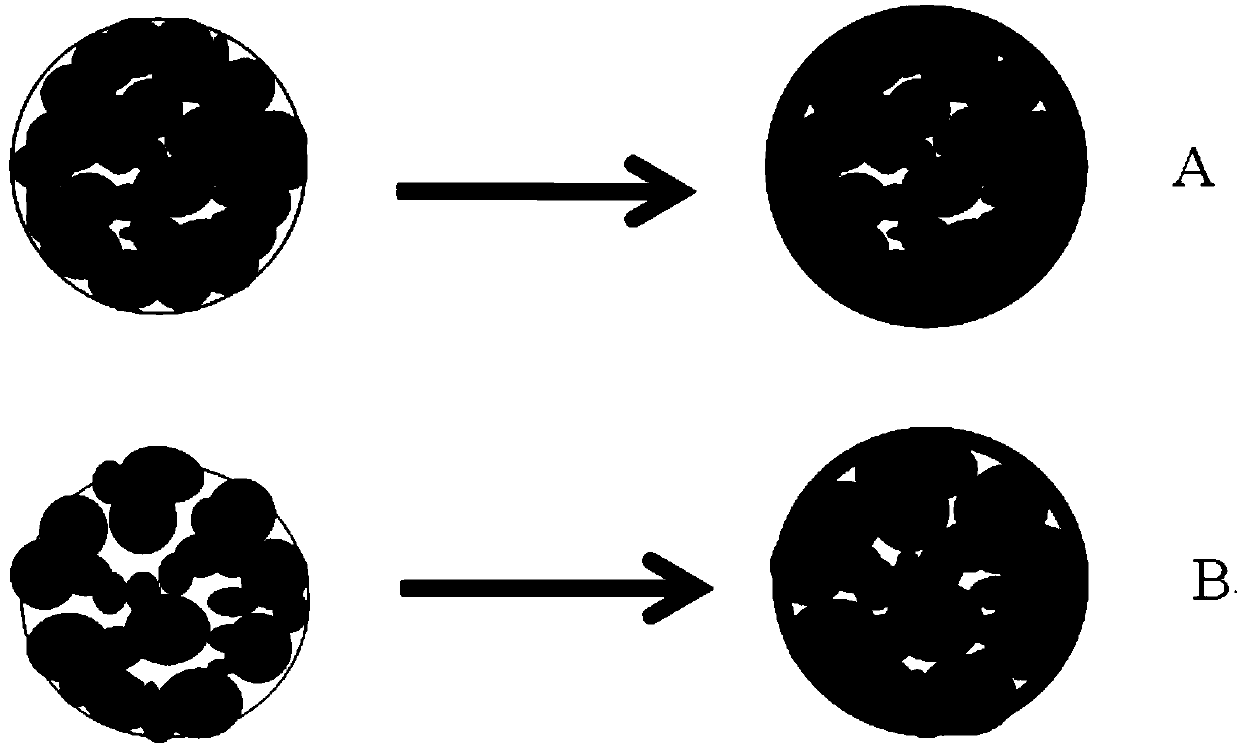

Method for preparing platinum-nickel nucleocapsid structure fuel cell catalyst through microwave reduction

InactiveCN104096575AAvoid uneven loadImprove performanceCell electrodesCatalyst activation/preparationPtru catalystActive agent

A method for preparing a platinum-nickel nucleocapsid structure fuel cell catalyst through microwave reduction comprises the following steps: sequentially adding carbon powder and a surface active agent into an organic solvent and uniformly mixing to obtain a mixture A; adding a compound of nickel into the mixture A and uniformly mixing to obtain a mixture B; performing microwave irradiation on the mixture B, wherein the reaction temperature is 80-800 DEG C and the reaction time is 0.01-120 min, and then performing still standing and cooling to obtain a mixture C; adding a compound of platinum into the mixture C and uniformly mixing to obtain a mixture D; performing microwave irradiation on the mixture D, wherein the reaction temperature is 80-800 DEG C and the reaction time is 0.01-120 min, and performing still standing and cooling to obtain a mixture E; performing washing and drying, and the platinum-nickel nucleocapsid structure fuel cell catalyst is obtained. The platinum-nickel nucleocapsid structure catalyst provided by the invention can be compared with commercial platinum-carbon in catalytic performance, is excellent in performance, and has an electronic transferring number approaching 4.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Positive electrode material precursor, preparation method thereof and positive electrode material

ActiveCN107706364AImprove cycle performanceThe distance between primary particle layers is reducedCell electrodesSecondary cellsManganeseNickel compounds

The invention provides a preparation method of a positive electrode material precursor. The preparation method comprises the following steps of A) mixing a nickel-containing compound, a cobalt-containing compound, a manganese-containing compound and water to obtain a mixed solution; B) mixing the mixed solution, a precipitant and a complexing agent, and performing co-precipitation reaction to obtain a Ni-Co-Mn precursor solution, wherein the Ni-Co-Mn precursor is shown in a general formula (I); and C) mixing an oxidization agent and the Ni-Co-Mn precursor solution during the co-precipitation reaction process, and performing partial oxidization reaction to obtain the positive electrode material precursor, wherein the positive electrode material precursor is a secondary spherical particle composite precursor formed by accumulating primary particles shown in the general formula (I) and a general formula (II), the general formula (I) is Ni<x>Co<y>Mn<1-x-y>CO<3>, the general formula (II) isNi<x>Co<y>Mn<1-x-y>O, 0<x<1, 0<y<1, and (x+y)<1.

Owner:宁波富理电池材料科技有限公司

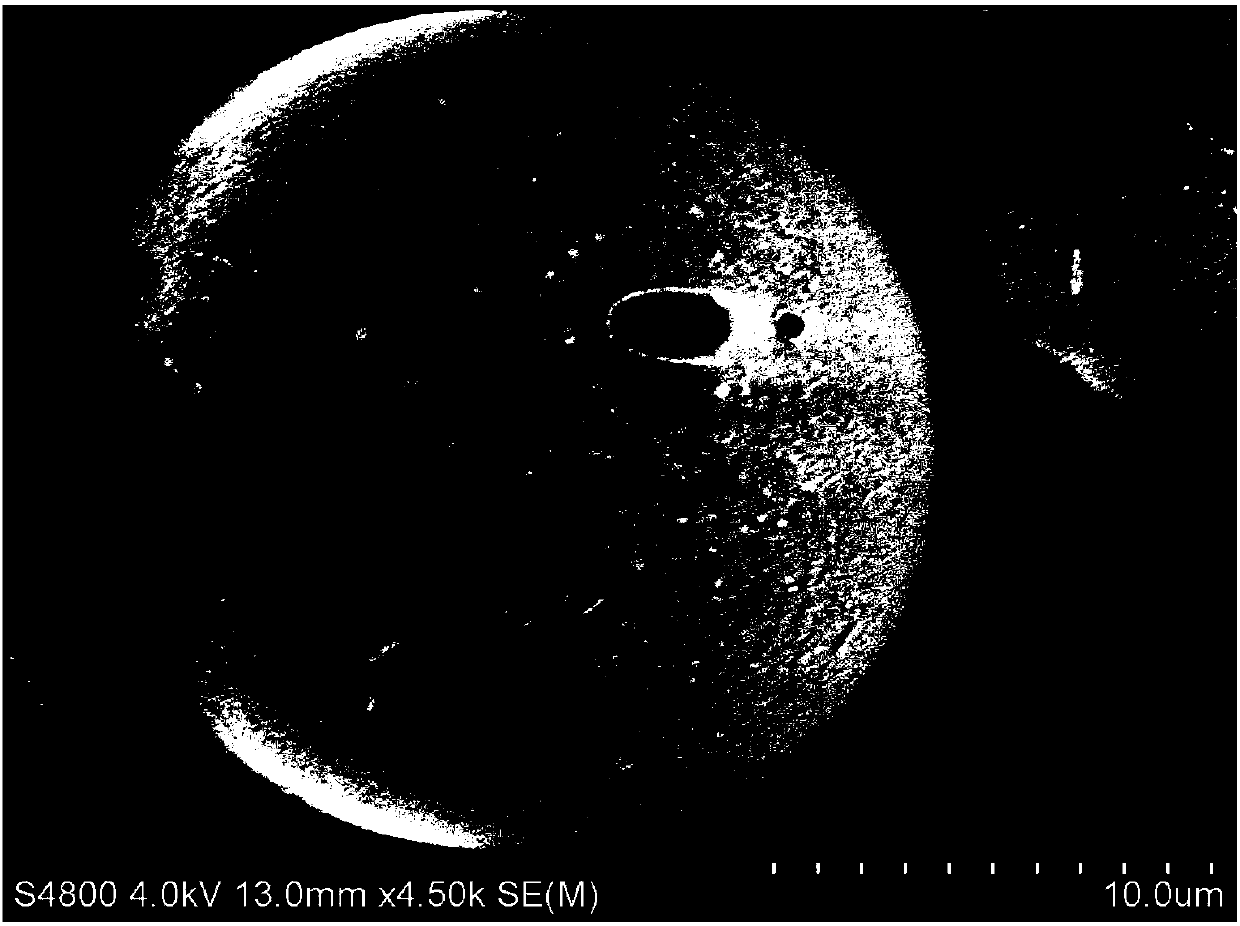

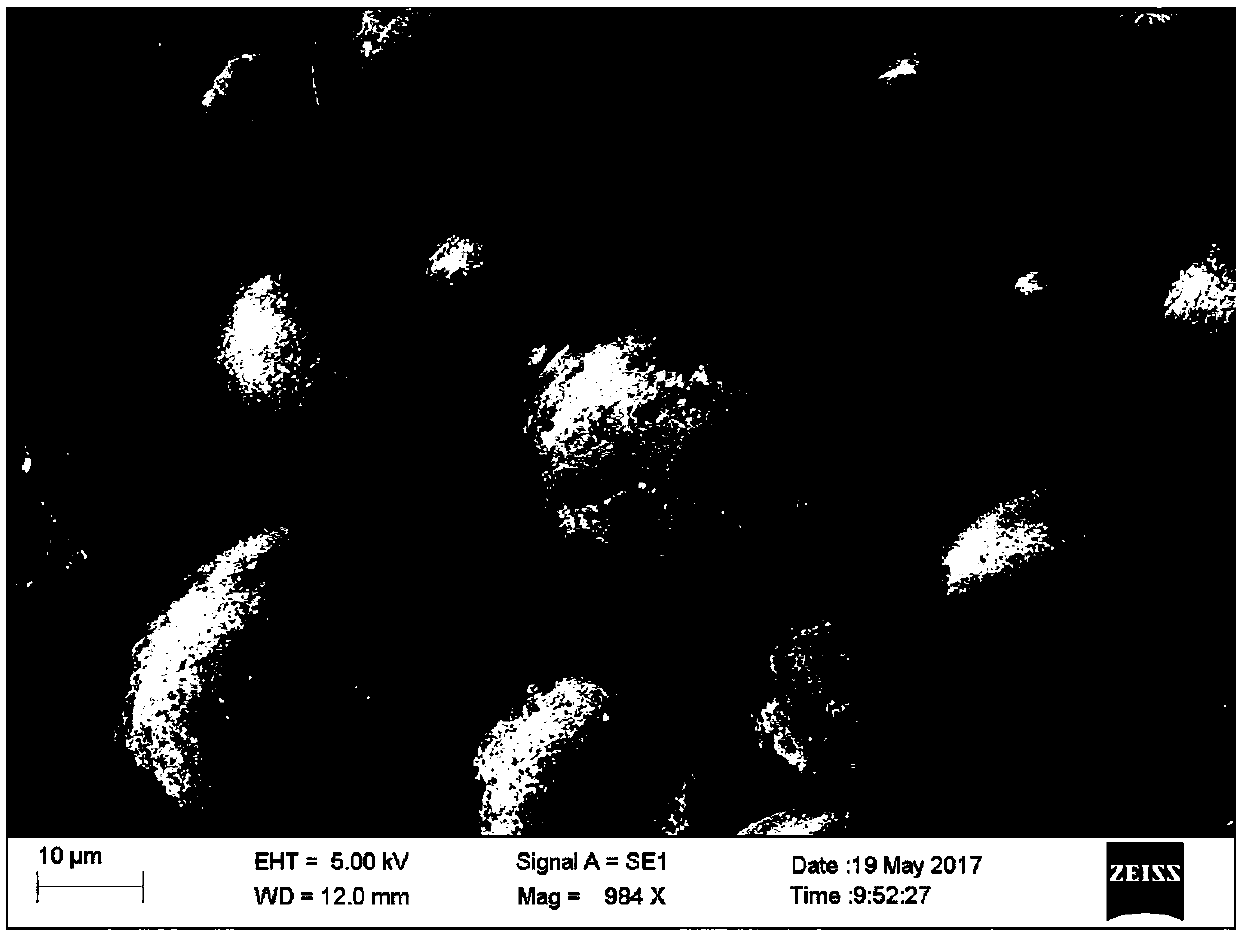

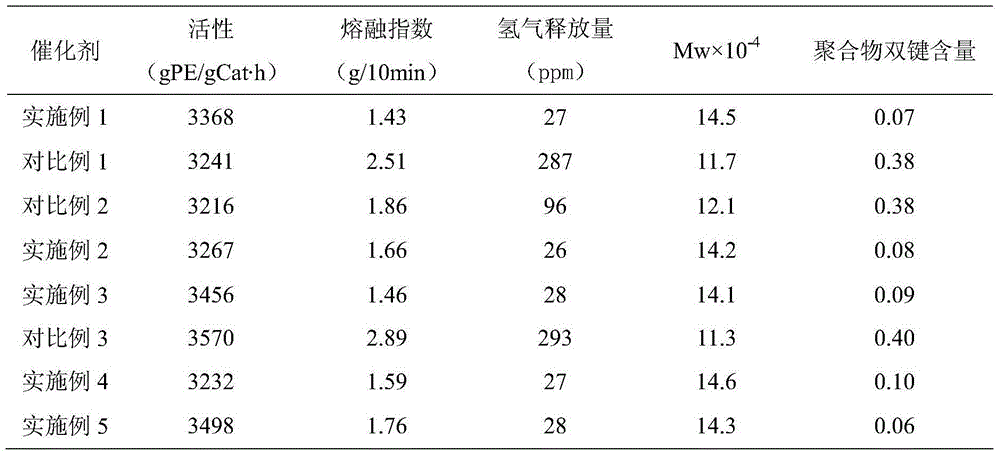

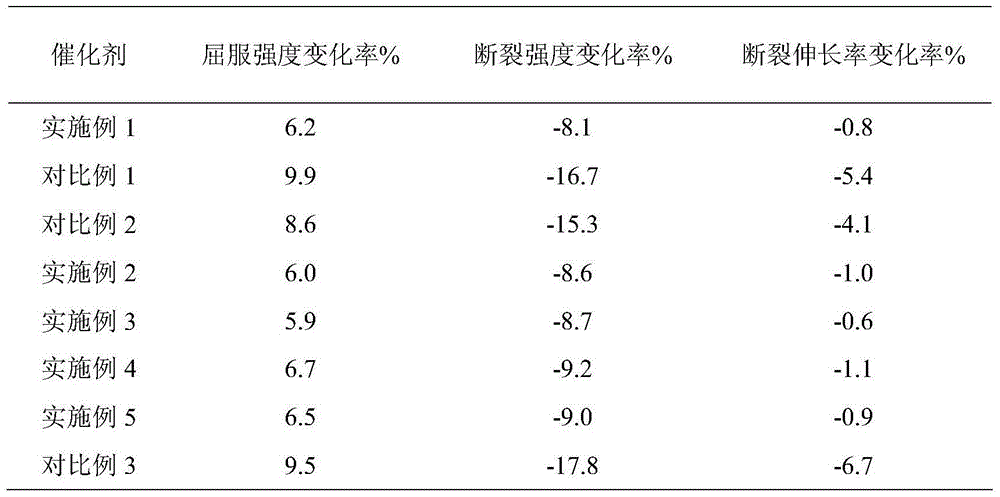

Preparation method of metallocene catalyst

The invention discloses a preparation method of a metallocene catalyst. The method includes preparation of a catalyst mother liquor through reaction of a metallocene compound and a cocatalyst, and carrier loading. The method is characterized in that the carrier before loading is activated by alkyl aluminum and a group VIII metal organic compound, the molar ratio of alkyl aluminum to group VIII metal organic compound n (Al) / n (M1) ranges from 0.1 to 300, M1 represents group VIII metal, the group VIII metal organic compound is preferably at least one acetylacetonate metal compound or naphthenate compound of nickel, palladium, platinum, iron and cobalt. According to the preparation method provided by the invention, the a specific group VIII metal organic compound is introduced into the catalyst to not only reduce the hydrogen produced in the polymerization process but also obviously reduce the number of double bonds in the polymer, so as to obtain a high molecular weight polymer with improved aging resistant performance. The catalyst is applicable to homopolymerization or copolymerization process of various alkenes.

Owner:PETROCHINA CO LTD

Nickel hydroxide active material for use in alkaline storage cell and manufacturing method of the same

InactiveUS6203945B1Alkaline accumulator electrodesNon-aqueous electrolyte accumulator electrodesNickel oxide hydroxideCrystal structure

A nickel hydroxide active material for use in an alkaline storage cell, the active material being essentially composed of nickel hydroxide particles covered with a cobalt compound adhered to their surfaces, wherein the cobalt compound is disordered in a crystal structure and formed in a higher order state containing alkali cation, and wherein the nickel hydroxide is in the form of a higher order nickel compound having an average oxidation value of 2.15 to 2.40.

Owner:FDK CORP

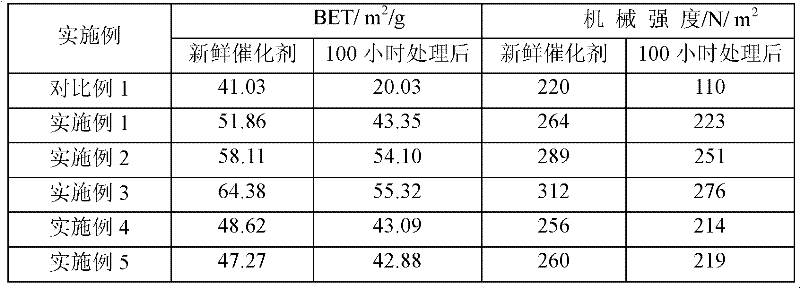

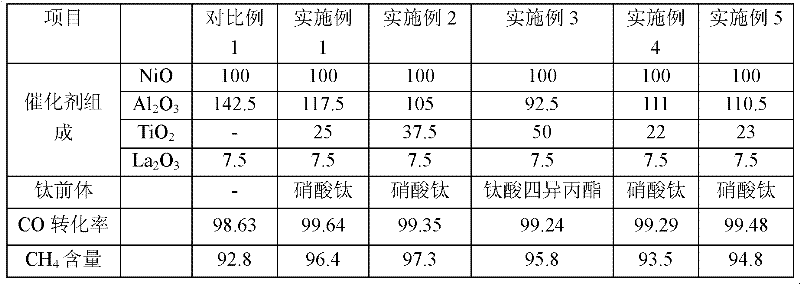

Titanium-containing nickel-based catalyst, as well as preparation method and application thereof

InactiveCN102302936AIncrease surface areaHigh hydrothermal stabilityHydrocarbon from carbon oxidesGaseous fuelsMethanationRare earth

The invention relates to a titanium-containing nickel-based catalyst, as well as a preparation method and application thereof. The titanium-containing nickel-based catalyst comprises NiO (A), vector (B), TiO2 (C) and at least one rare-earth metal oxide RE2O3 (D), wherein the vector comprises Al2O3. The invention also relates to a method for preparing the titanium-containing nickel-based catalyst, which comprises the following steps: (a) nickel cation, rare-earth metal cationic aqueous solution and titanium precursor aqueous solution are provided; (b) the solution in the step (a) is precipitated by using precipitator to obtain suspension or slurry; (c) the suspension or slurry obtained in the step (b) is separated to obtain solid precipitate, and the solid precipitate is mixed with alumina sol, or mixed with Al cationic aqueous solution to form sol; and (d) the sol is granulated and calcined to obtain a high-temperature methanation catalyst. The catalyst contains TiO2 structure auxiliary, so that the carbon deposit phenomenon in the methanation reaction is wakened.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Nickel cobalt lithium aluminate positive material and preparation method thereof

InactiveCN103985856AEliminate the evaporation processEliminate the subsequent crushing processCell electrodesSecondary cellsNickel compoundsEvaporation

The invention relates to a nickel cobalt lithium aluminate positive material and a preparation method thereof. The material has a chemical general formula of LiNi(1-a-b)CoaAlbO2, wherein a is more than 0.1 and less than 0.3, b is more than 0.01 and less than 0.2, and 1-a-b is more than 0 and less than 1. The preparation method comprises the following steps: mixing an insoluble nickel compound, cobalt compound and aluminum compound, performing ball-milling for 4-8 hours, uniformly mixing, performing spray drying, roasting in an oxygen atmosphere at low temperature of 400-600 DEG C for 1-10 hours, mixing with a lithium salt, uniformly ball-milling, performing spray drying, calcining in an oxygen atmosphere at high temperature of 800-1000 DEG C for 6-16 hours, cooling, grinding and screening to prepare the product. Moisture is rapidly evaporated by spray drying, powder with consistent particle size is formed, the evaporation process of an evaporation drying method and a subsequent crushing process are omitted, the process flow is simple, and industrial production is easily realized. Moreover, the material is excellent in electrochemical performance.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

Method of making basic aluminum halides

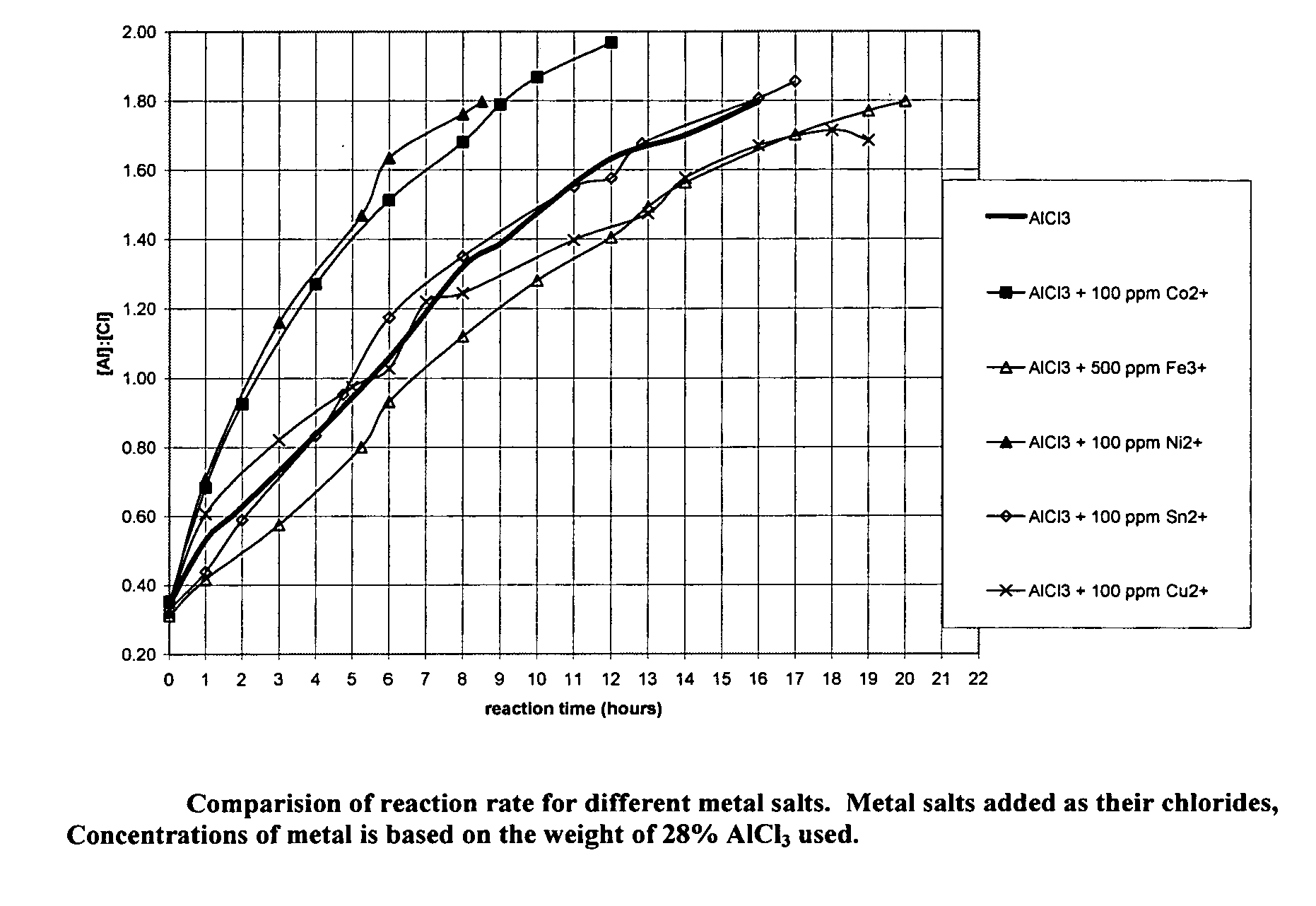

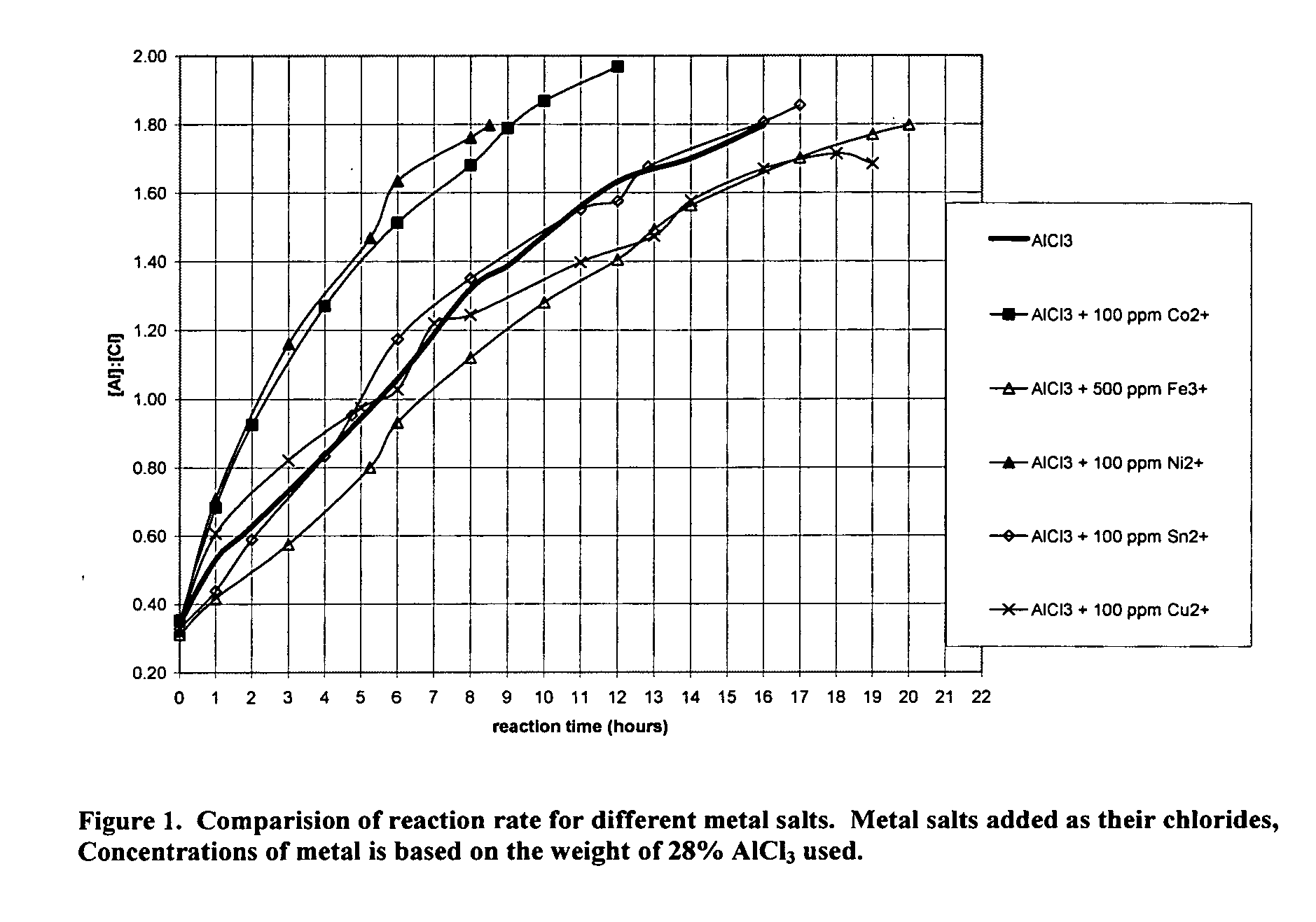

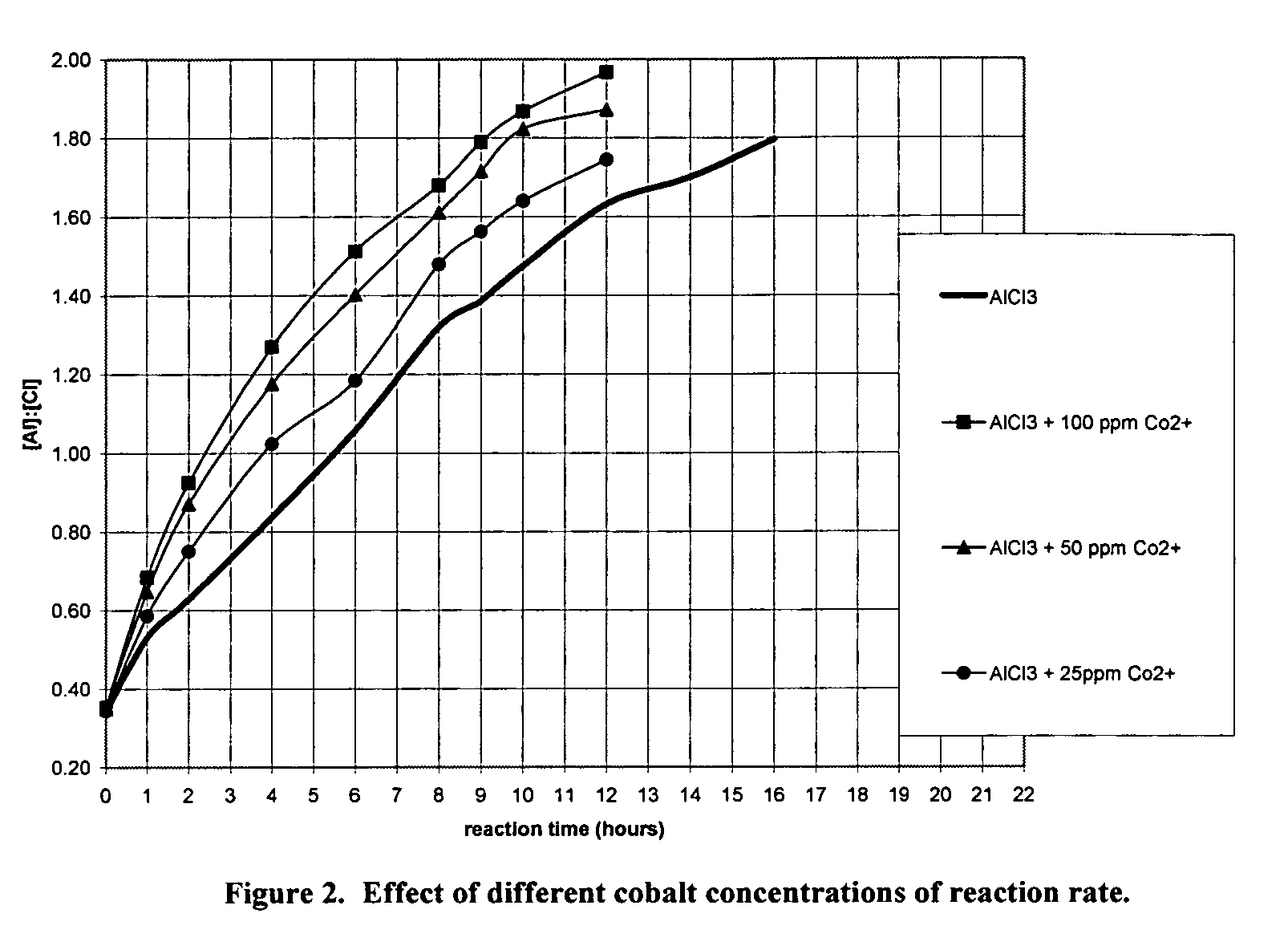

ActiveUS20080181840A1Reduce usageDelayed reaction timePhysical/chemical process catalystsFluoride preparationChlorideCobalt

Owner:SOUTHERN IONICS

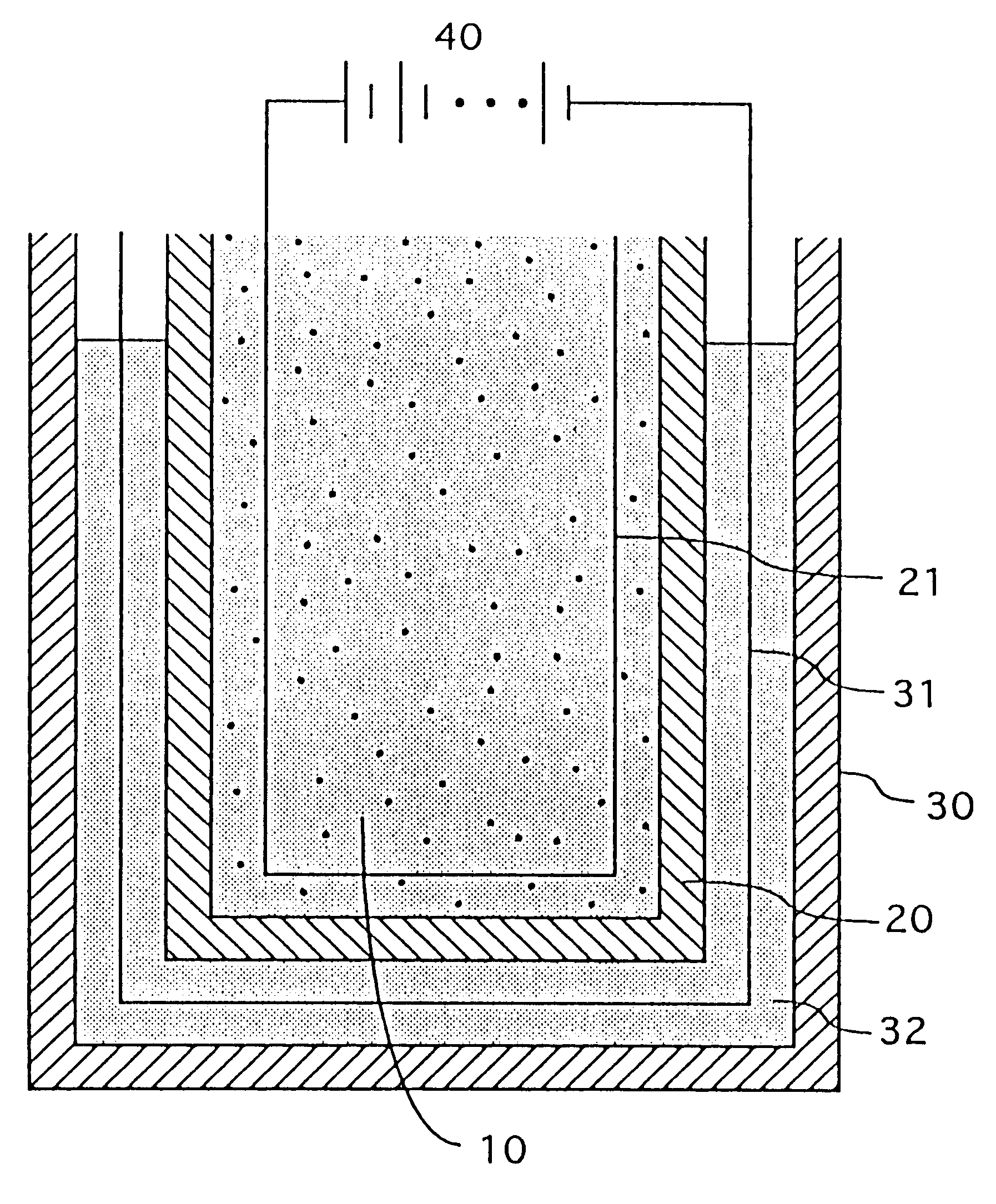

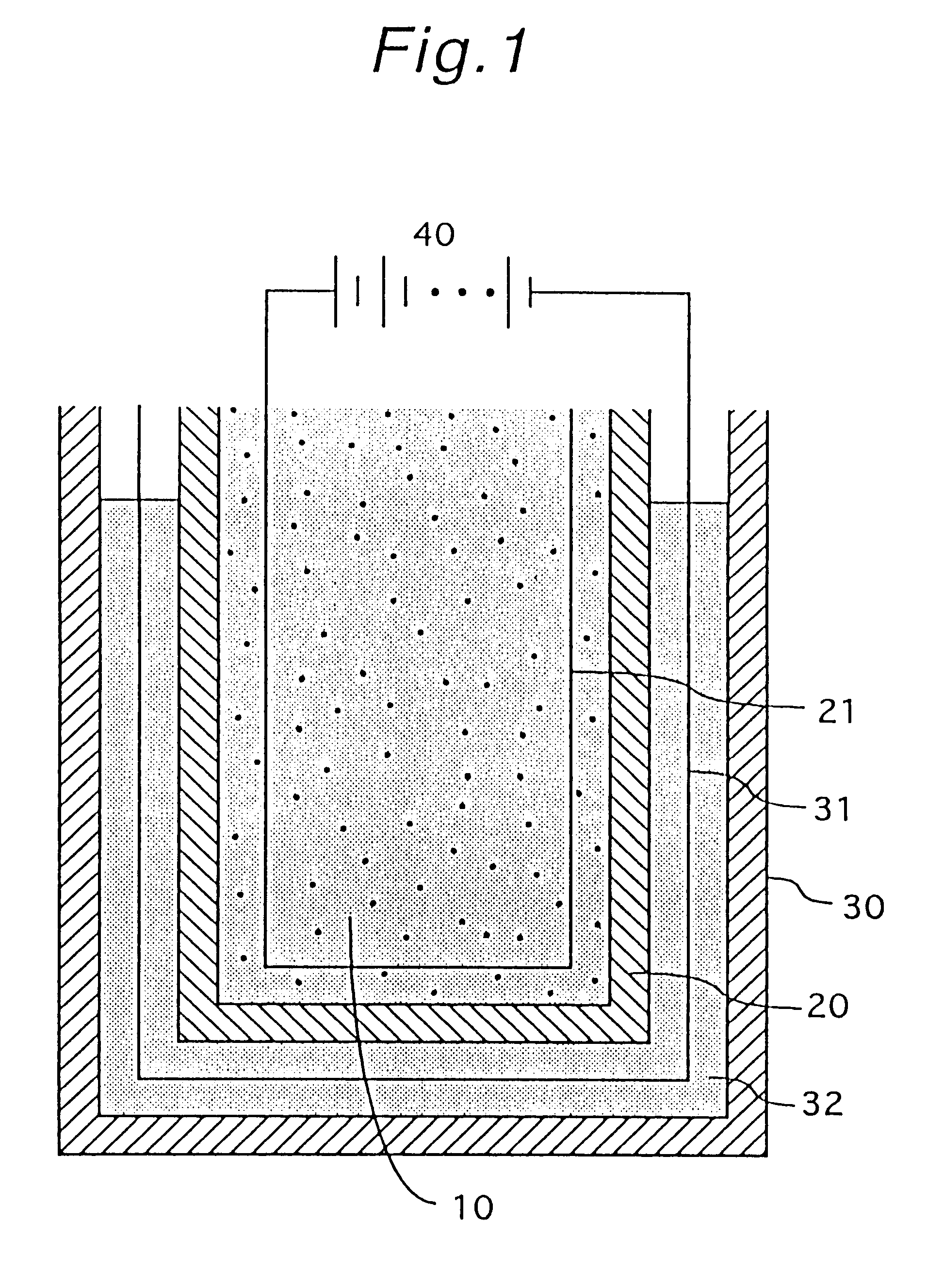

Metal-based anodes for aluminium electrowinning cells

InactiveUS20050194066A1Eliminate pollutionSolution to short lifeSolid state diffusion coatingElectrodesSurface layerNickel compounds

An anode of a cell for the electrowinning of aluminium comprises a nickel-iron alloy substrate having an openly porous nickel metal rich outer portion whose surface is electrochemically active. The outer portion is optionally covered with an external integral nickel-iron oxide containing surface layer which adheres to the nickel metal rich outer portion of the nickel-iron alloy and which in use is pervious to molten electrolyte. During use, the nickel metal rich outer portion contains cavities some or all of which are partly or completely filled with iron and nickel compounds, in particular oxides, fluorides and oxyfluorides.

Owner:DURUZ JEAN JACQUES +2

Polymerization of olefins

Olefins containing selected functional groups such as silyl, ether and alkenyl, and often containing a blocking group, may be copolymerized with unsubstituted olefins such as ethylene and propylene in the presence of certain coordination compounds of nickel or palladium. The resulting polymers are useful as molding resins, elastomers, in adhesives and for films.

Owner:EI DU PONT DE NEMOURS & CO

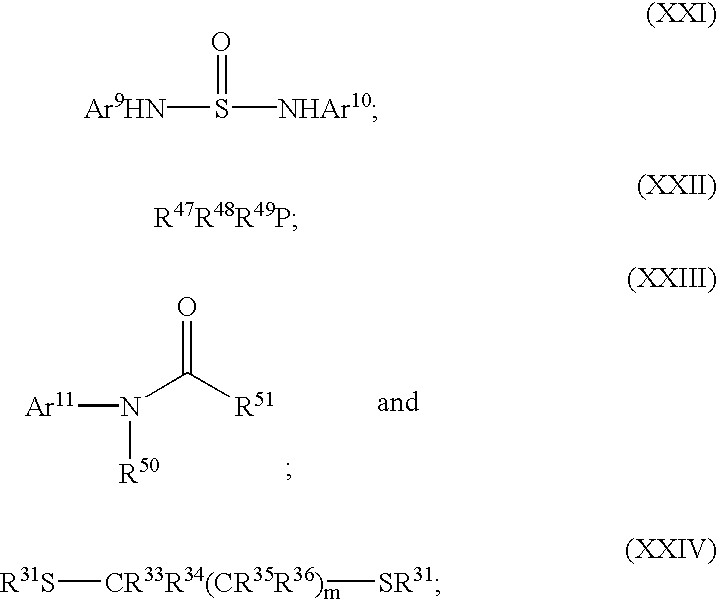

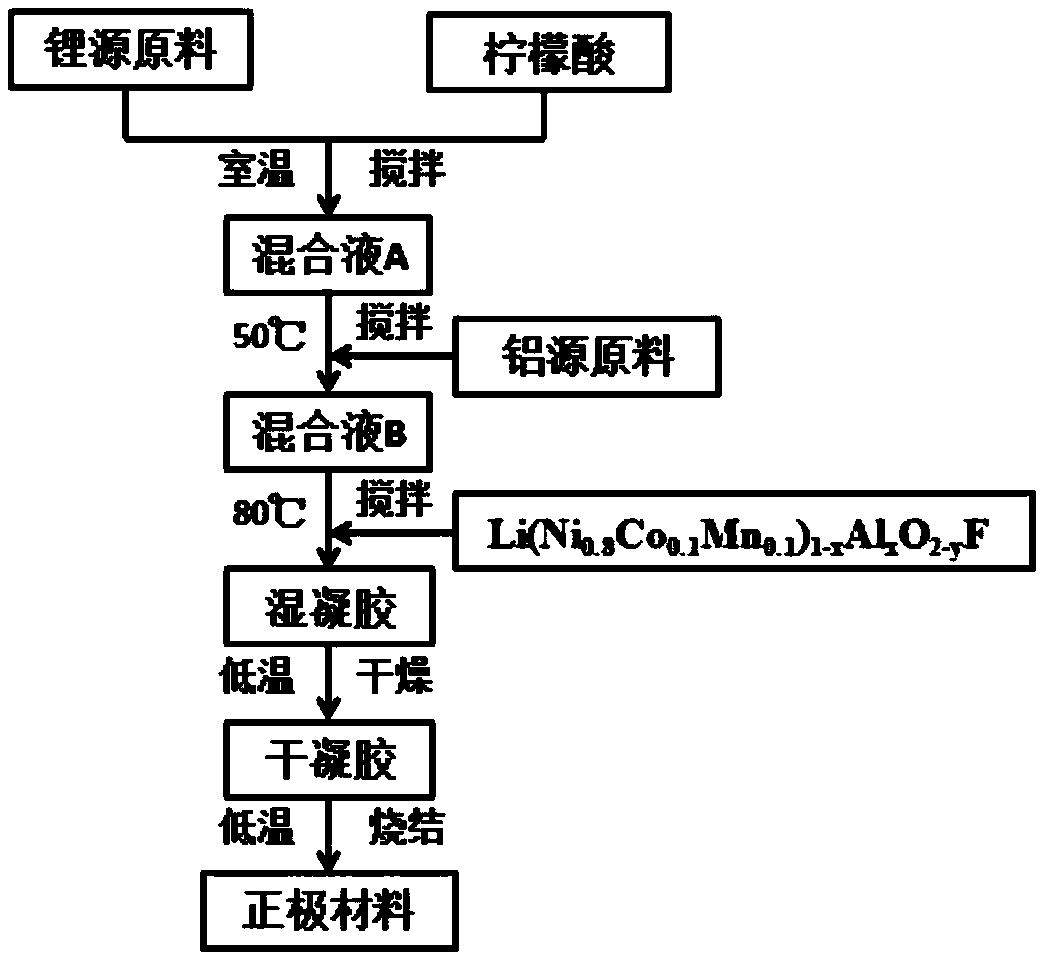

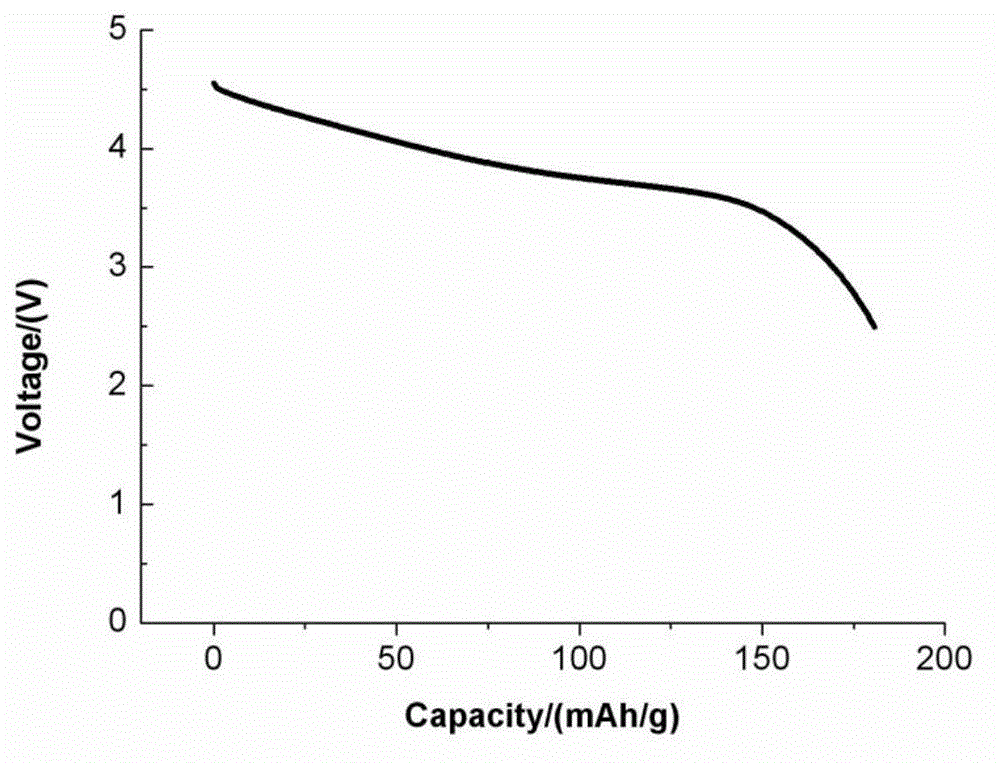

Aluminum and fluorine dual-modified lithium ion battery cathode material and preparation method thereof

InactiveCN108807887AEasy transferStable internal structureCell electrodesSecondary cellsLithium aluminateSide reaction

The invention belongs to the field of lithium ion batteries, and provides a lithium ion battery cathode material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy@LiAlO2 and a preparation method thereof, wherein x is more than 0, and y is less than or equal to 0.05, and the defects of LiNi0.8Mn0.1Co0.1O2 has poor electrochemical cycle performance and poor safety performance are overcome. Aluminum and fluorine are co-doped in a matrix material, and the trivalent aluminum element not only can stabilize the structure of the material, but also can prevent Ni<2+> from substituting Li<+>, so that the mixing of lithium / nickel cations is reduced, and fluorine can inhibit side reaction between the material and electrolyte; at the same time, the surface of a parent material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy is coated with an extremely thin lithium fast ion conductor lithium metaaluminate which can enhance the lithium ion transport and reduce the surface alkalinity; the lithium ion battery cathode material can havehigher discharge specific capacity while improving cycling stability, and has a more stable structure compared with LiNi0.8Co0.1Mn0.1O2, the safety and processing performance of the material are improved, and especially at large magnification and high voltage, the safety performance is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Positive electrode material for lithium ion cell and synthesizing method thereof

InactiveCN1508894AImprove electrochemical stabilityHigh crystallinityElectrode manufacturing processesPositive electrodesLithiumCobalt

In the invention, chemical general expression of positive pole material is: LixNi0.8-y Co0.2MyOp, where M is Cd or Zn, X=0.97-1.2, Y=0-0.1, p=2-2(1+y). The material is synthesized through following steps: (1) grinding, mixing compound of lithium, compound of cobalt, and compound of nickel containing a small quantity of cadmium or zinc, or containing none cadmium and zinc in certain scale evenly; (2) preroasting mixed powers makes it crystallize partially; (3) careful grinding preroasted mixture evenly, then roasting is carried out right along under higher temperature, and obtaining the invented material of positive pole after cooling. The invention possesses advantages of high specific capacity of the material, good performances of charging and discharging cycle, even size of granule, and narrow distribution range as well as simple preparation technique.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Method for preparing lithium-rich solid solution cathode material by virtue of metal reduction process

ActiveCN102881878ALow costWide variety of sourcesHybrid capacitor electrodesCell electrodesManganeseCobalt

The invention relates to a method for preparing lithium-rich solid solution cathode material by virtue of a metal reduction process, and the method comprises the following steps of: respectively weighing compounds of lithium, nickel, manganese and cobalt as well as a metal reducing agent M according to the molar ratio of (1+x):(1-x)* y:(x+z-x*z):(1-x)* k:(1-x)* q among lithium ionic, nickel ionic, manganese ionic, cobalt ionic and the metal reducing agent M; mixing the metal reducing agent M with a wet grinding medium, and then mixing the compounds of nickel, manganese and cobalt into the obtained mixture; performing wet grinding, mixing and adding ammonia water and the compound of lithium to prepare a reaction mixed solution; drying and putting the product at a certain atmosphere; and finally, adopting a two-stage sintering method or two times of multi-step sintering method to prepare the lithium-rich solid solution cathode material with the composition of xLi2MnO3(1-x)Li(Niy Mnz Cok Mq)O2. The prepared electrode material is uniform in composition, has excellent discharge property, and has better discharge cycle performance especially under the condition of large current.

Owner:FUJIAN NORMAL UNIV

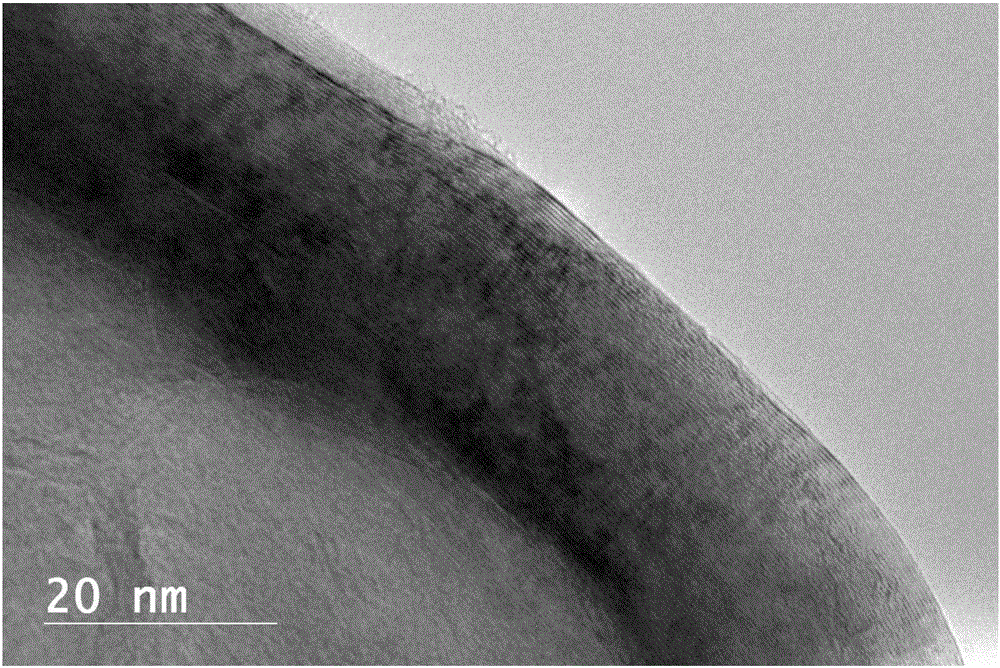

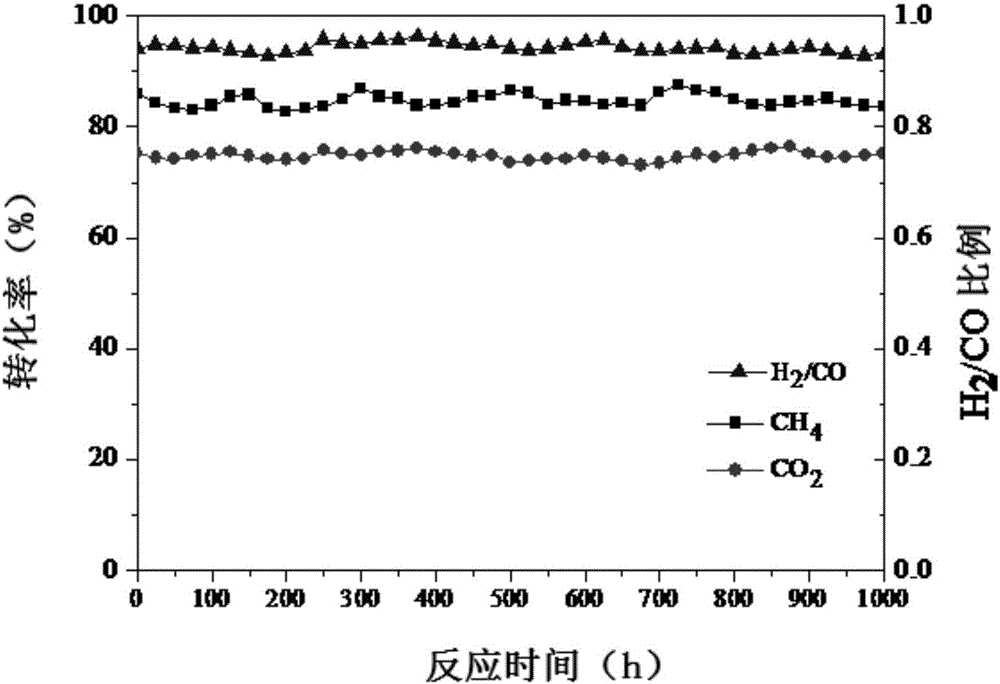

Carbon loaded nickel metal catalyst and preparation method thereof

InactiveCN106824200AHigh catalytic efficiencyImprove stabilityHydrogenCarbon preparation/purificationPhosphoric acidNickel compounds

The invention discloses a carbon loaded nickel metal catalyst and a preparation method thereof. The carbon loaded nickel metal catalyst is prepared by the following steps: mixing a carbon source with a nitric acid, sulfuric acid or phosphoric acid solution with the concentration of 0.1mol / L to 1mol / L according to the ratio of (200g to 350g) : (400mL to 1000mL); reflowing at temperature of 70 DEG C to 85 DEG C for 6h to 12h, and filtering; washing filter dreg with de-ionized water until the pH (Potential of Hydrogen) of a washing solution is equal to 7; drying at 100 DEG C to 110 DEG C for 8h to 12h to obtain a solid A; keeping the heat of the solid A at 150 DEG C to 180 DEG C for 12h to 24h, and washing; drying at 100 DEG C to 110 DEG C for 8h to 12h to obtain a solid B; dissolving a nickel-containing compound into de-ionized water; stirring until the nickel-containing compound is completely dissolved, so as to obtain a solution C; adding the solid B into the solution C with the volume the same as that of the solid B; standing at room temperature for 12h to 24h; drying at 100 DEG to 110 DEG C for 8h to 12h to obtain a solid D; putting the solid D into gas flow without oxygen, heating to 700 DEG C to 1100 DEG C, and keeping the heat for 1h to 5h; then naturally cooling to room temperature. The catalyst prepared by the method has high activity and good stability; pure methane or natural gas is used as a reactant at 850 DEG C, and the reforming reaction is stabilized for at least 1000h.

Owner:WUHAN UNIV OF SCI & TECH

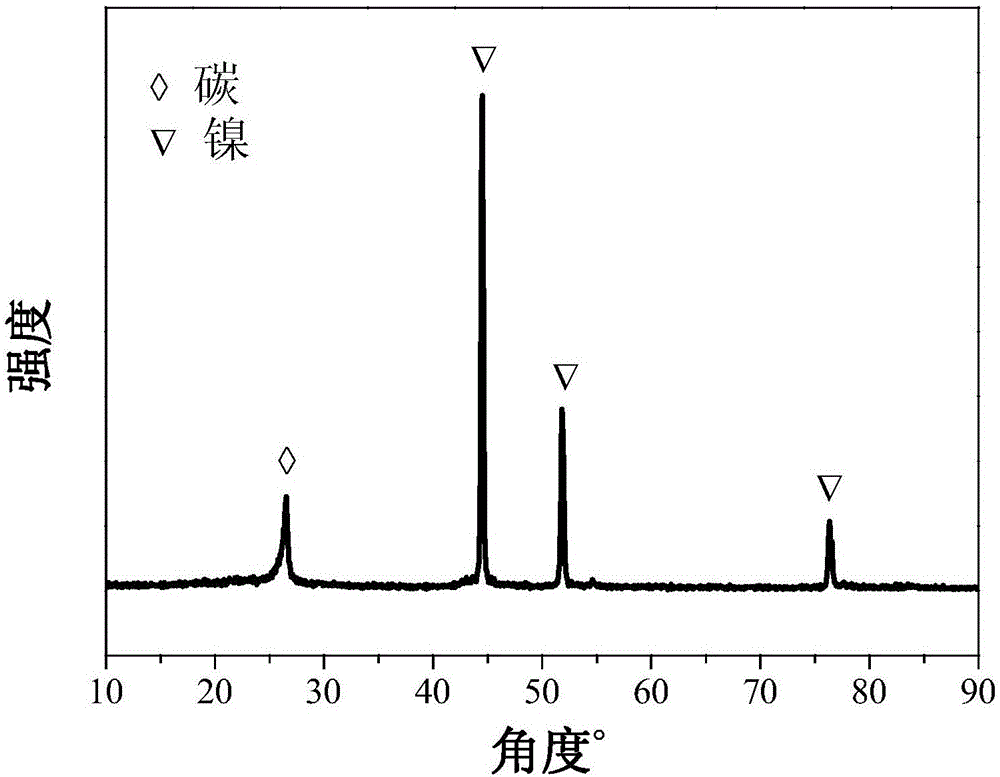

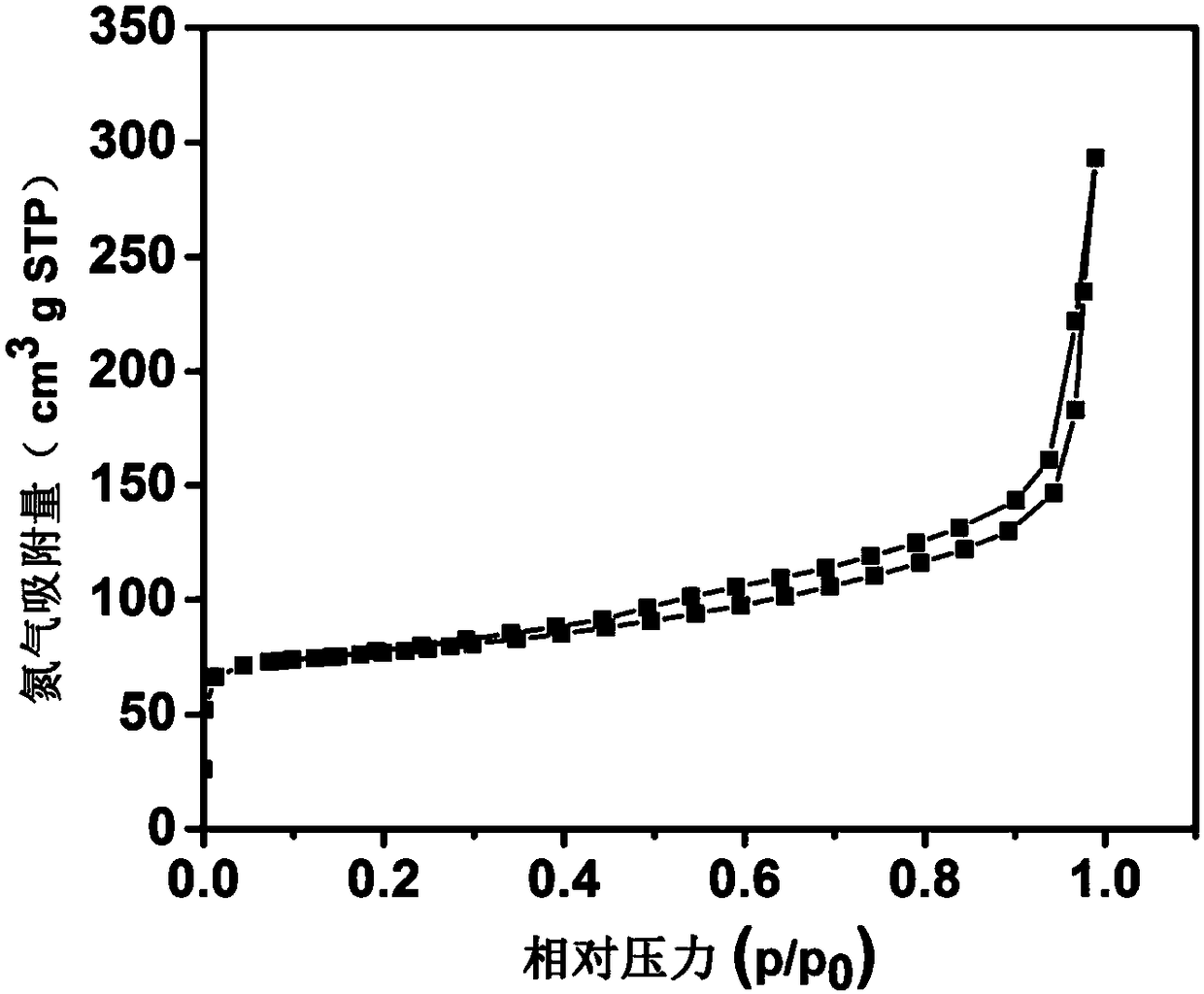

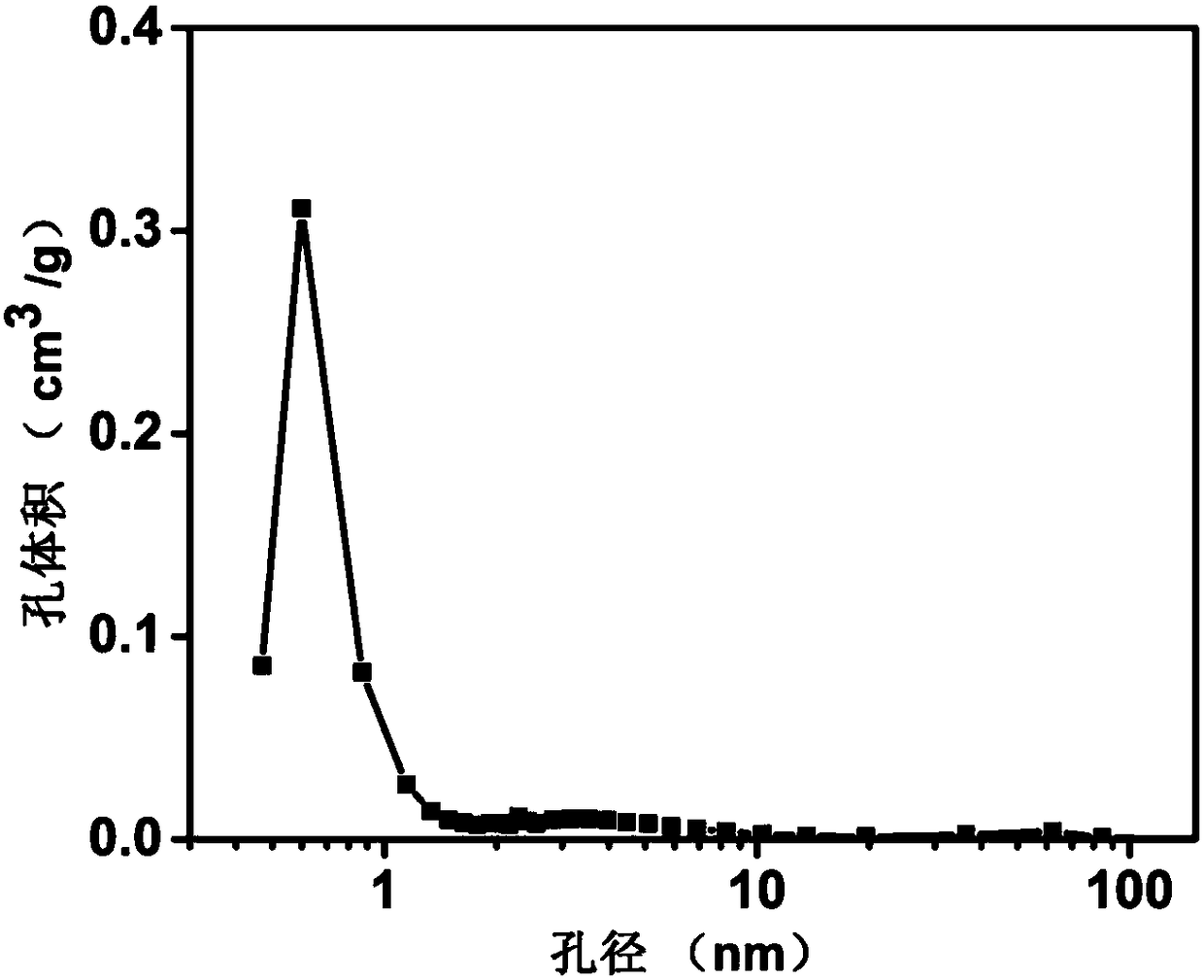

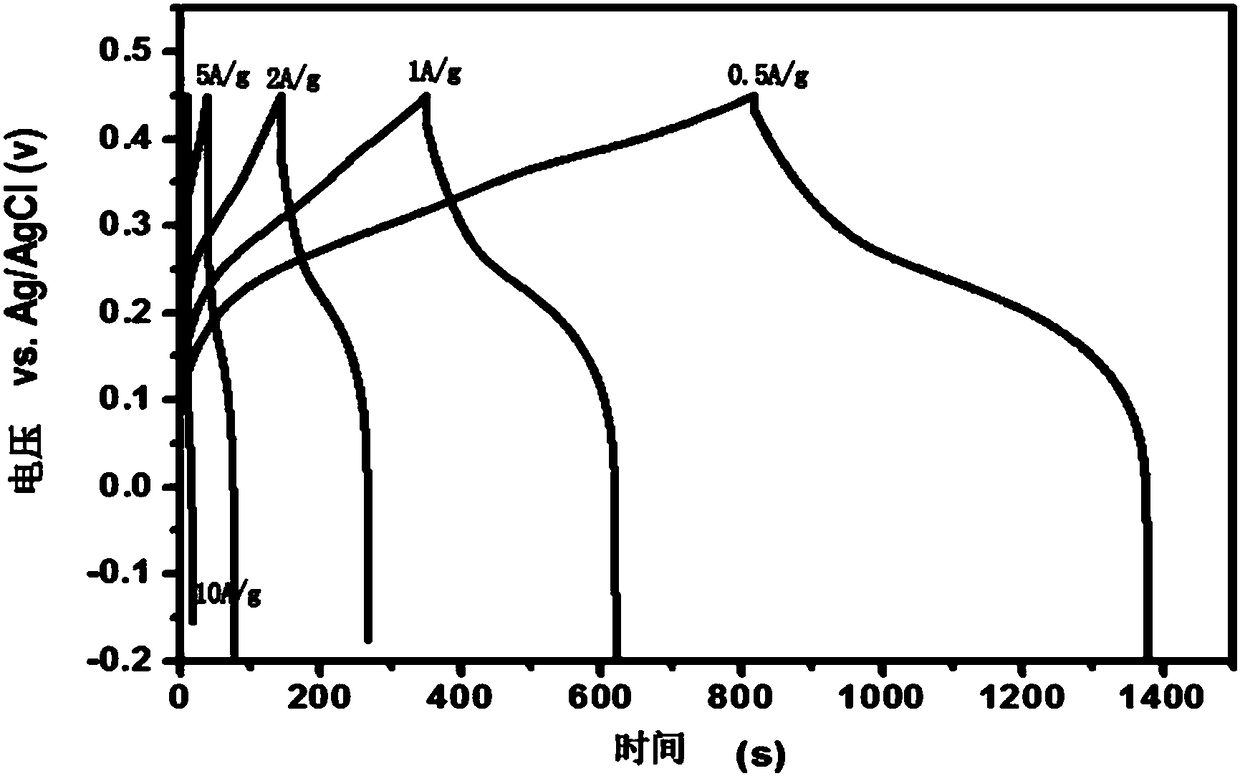

Porous carbon composite material containing cobalt and nickel and preparation method of porous carbon composite material containing cobalt and nickel

InactiveCN108417845ASimple methodLarge specific surface areaHybrid capacitor electrodesCell electrodesCarbon compositesDistillation

The invention discloses a porous carbon composite material containing cobalt and nickel and a preparation method of the porous carbon composite material containing cobalt and nickel. The method includes steps: (1) proportionally dissolving a carbon source, a cobalt-containing compound and a nickel-containing compound into water, stirring, and performing reduced pressure distillation and drying ina vacuum drying oven to obtain a precursor; (2) subjecting the precursor to high-temperature carbonization at 600-900 DEG C in an inert atmosphere; (3) sequentially washing and drying carbonized samples to obtain the porous carbon composite material containing cobalt and nickel. The preparation method is simple, environmentally friendly and convenient for large-scale production. The metal-bearingporous carbon composite material prepared according to the method is appropriate in metal element proportion, high in specific surface area and uniform in pore size distribution and has a promising application prospect in fields of industrial catalysis, electrochemical energy storage and the like.

Owner:SHANGHAI INST OF TECH

Ni catalysts and methods for alkane dehydrogenation

InactiveUS20030097034A1Favorable and industrially attractive performance characteristicLimited extentHeterogenous catalyst chemical elementsCatalystsNiobiumNickel compounds

Catalysts and methods for alkane oxydehydrogenation are disclosed. The catalysts of the invention generally comprise (i) nickel or a nickel-containing compound and (ii) at least one or more of titanium (Ti), tantalum (Ta), niobium (Nb), hafiium (Hf), tungsten (W), yttrium (Y), zinc (Zn), zirconium (Zr), or aluminum (Al), or a compound containing one or more of such element(s). In preferred embodiments, the catalyst is a supported catalyst, the alkane is selected from the group consisting of ethane, propane, isobutane, n-butane and ethyl chloride, molecular oxygen is co-fed with the alkane to a reaction zone maintained at a temperature ranging from about 250 ° C. to about 350 ° C., and the ethane is oxidatively dehydrogenated to form the corresponding alkene with an alkane conversion of at least about 10% and an alkene selectivity of at least about 70%.

Owner:SYMYX SOLUTIONS

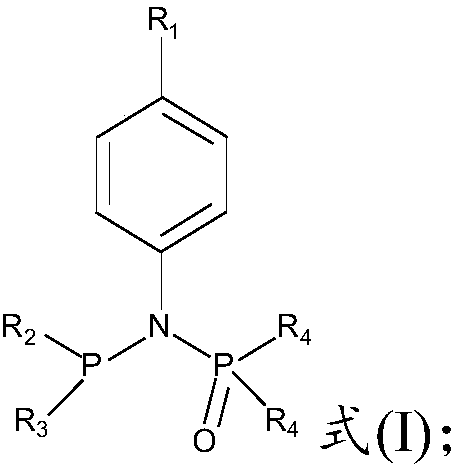

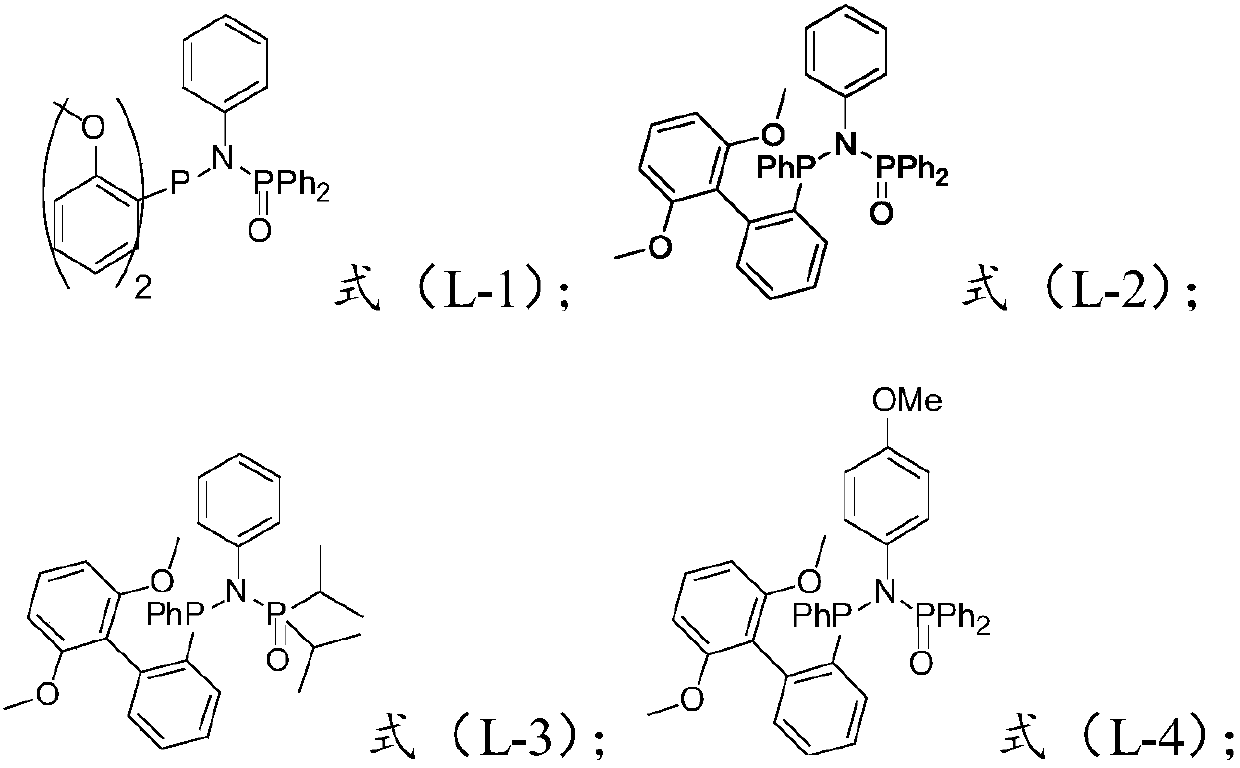

Compound, palladium compound and nickel compound as well as preparation methods thereof

ActiveCN108017670AHigh polymerization activityHigh activityGroup 5/15 element organic compoundsNickel organic compoundsPolyolefinNickel compounds

The invention provides a compound with a structure shown in a formula (I), wherein R1 is selected from one or more of H, C1-C6 alkoxy, substituted C1-C6 alkyl, C1-C6 alkyl, dimethylamino, nitryl and halogen, wherein a substituent group of substituted alkyl is fluorine; R2 and R3 are independently selected from substituted phenyl and substituted biphenylyl; R4 is selected from C1-C6 alkyl and C6-C12 aryl. The electron-withdrawing effect or shared electron effect of a specific R1 group in the structure of the formula (I) has an effect on polymerization activity, besides, in combination with different substituted groups on the phosphine oxide framework, large steric hindrance and other effects of aromatic groups substituted by the substituent group jointly show high polymerization activity, the compound has ethylene homopolymerization molecular weight up to 188,900, wherein the ethylene and MA copolymerization molecular weight is up to 20,700. Therefore, the prepared compound is a polyolefin catalyst with high activity, high molecular weight of copolymer and high insertion ratio.

Owner:UNIV OF SCI & TECH OF CHINA

Ethylene polymerizing titanium-nickel-salicy-alimine composite catalyst and its preparing method

Owner:SUN YAT SEN UNIV

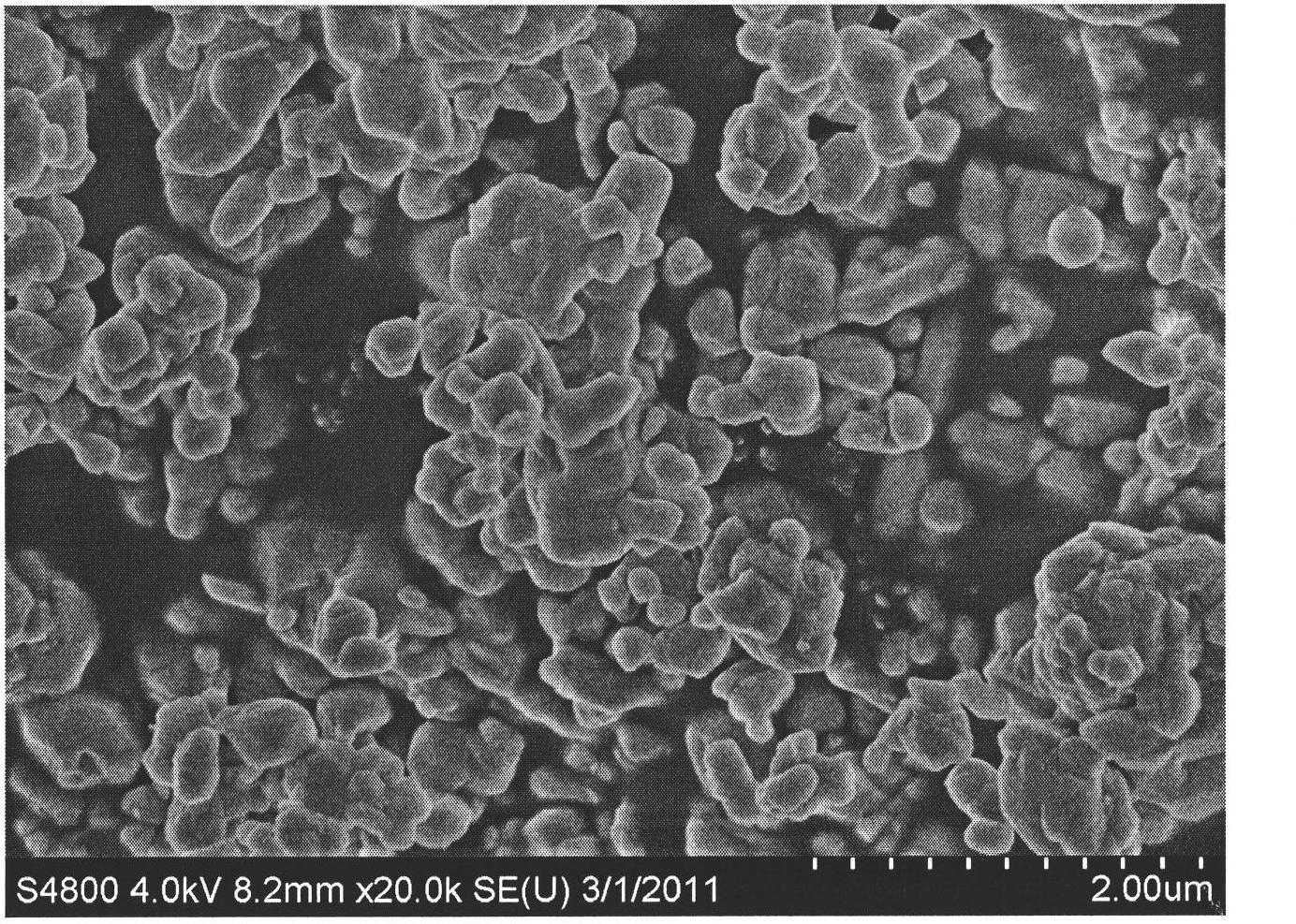

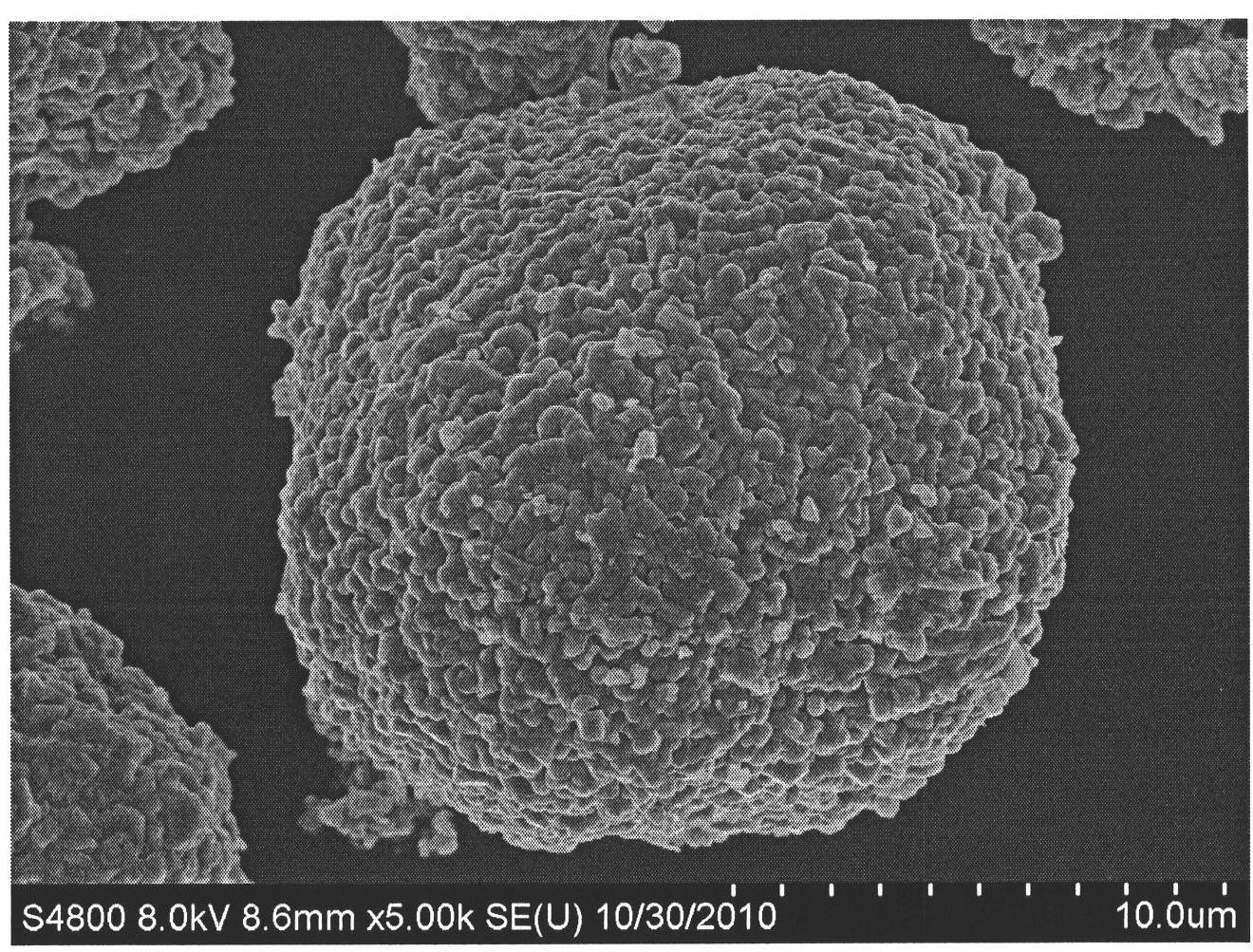

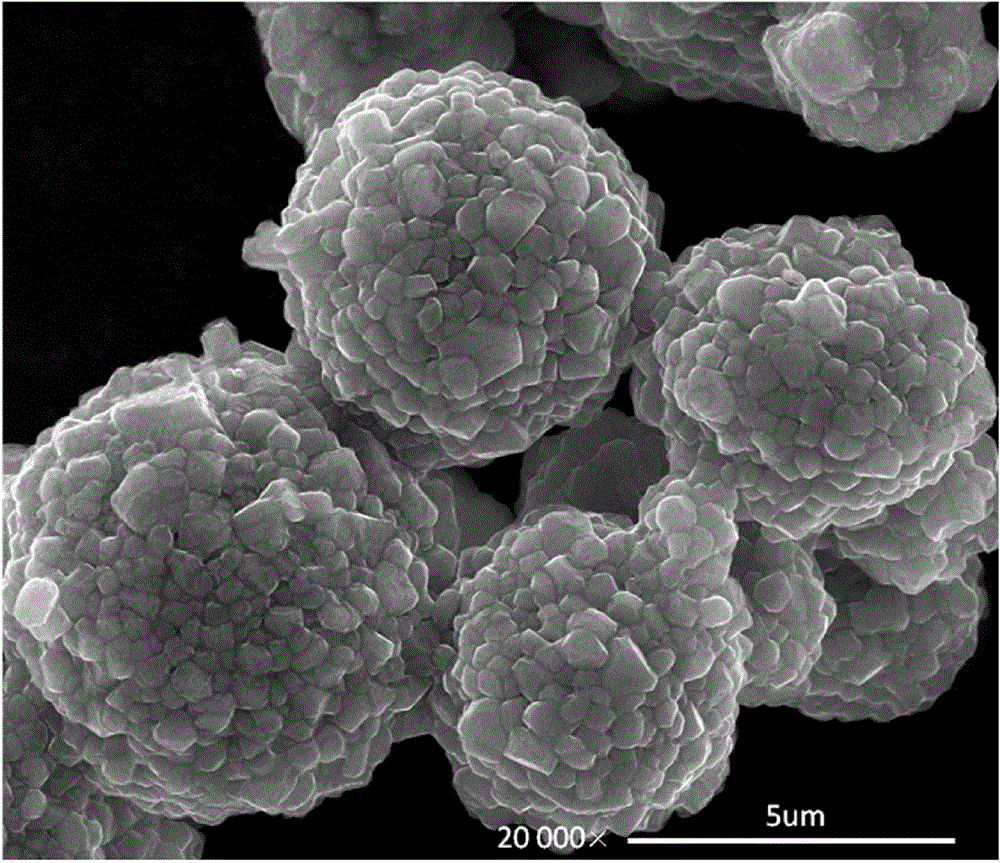

Layered lithium nickel composite oxide powder and process for producing the same

ActiveCN100338801CHigh bulk densityImprove featuresActive material electrodesSecondary cellsLiquid mediumNickel compounds

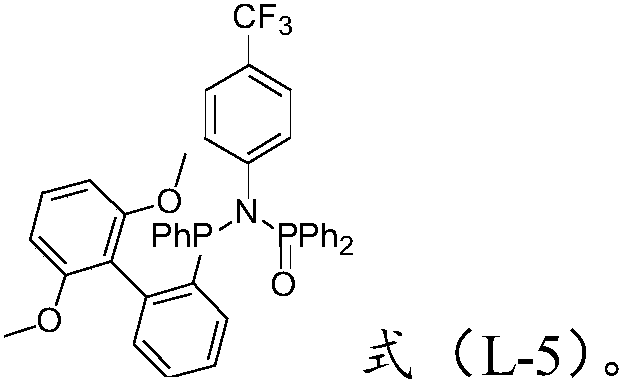

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 mum, the median diameter A of the secondary particles is from 9 to 20 mum, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4<=G / S<=4 and G / S<=0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI RAYON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com