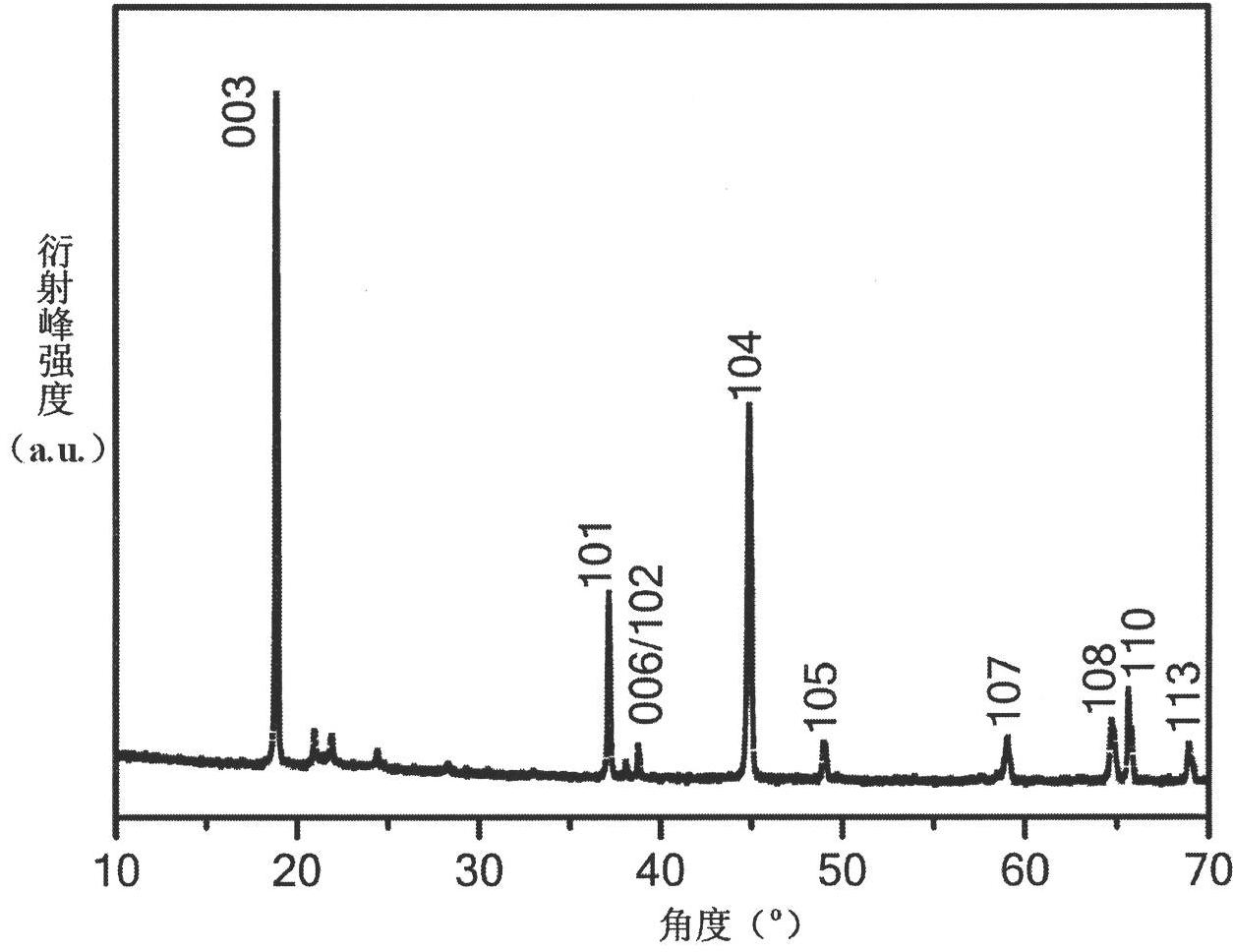

Preparation method of high-capacity layered lithium-rich manganese-based oxide

A lithium-rich manganese-based and oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low use efficiency of precursor raw materials, reduce production costs, etc., achieve superior charge and discharge efficiency and cycle performance, and reduce production costs. cost and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

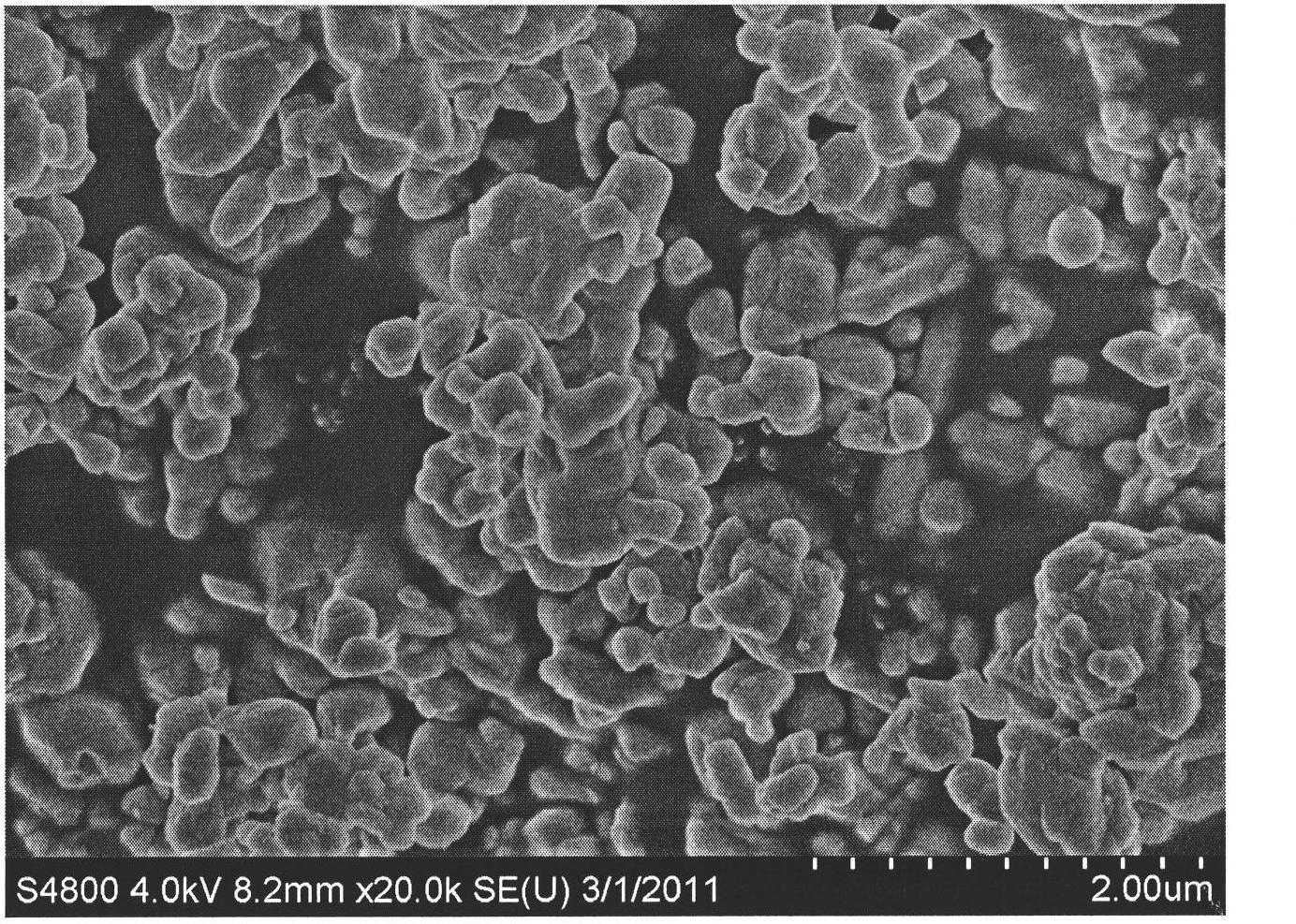

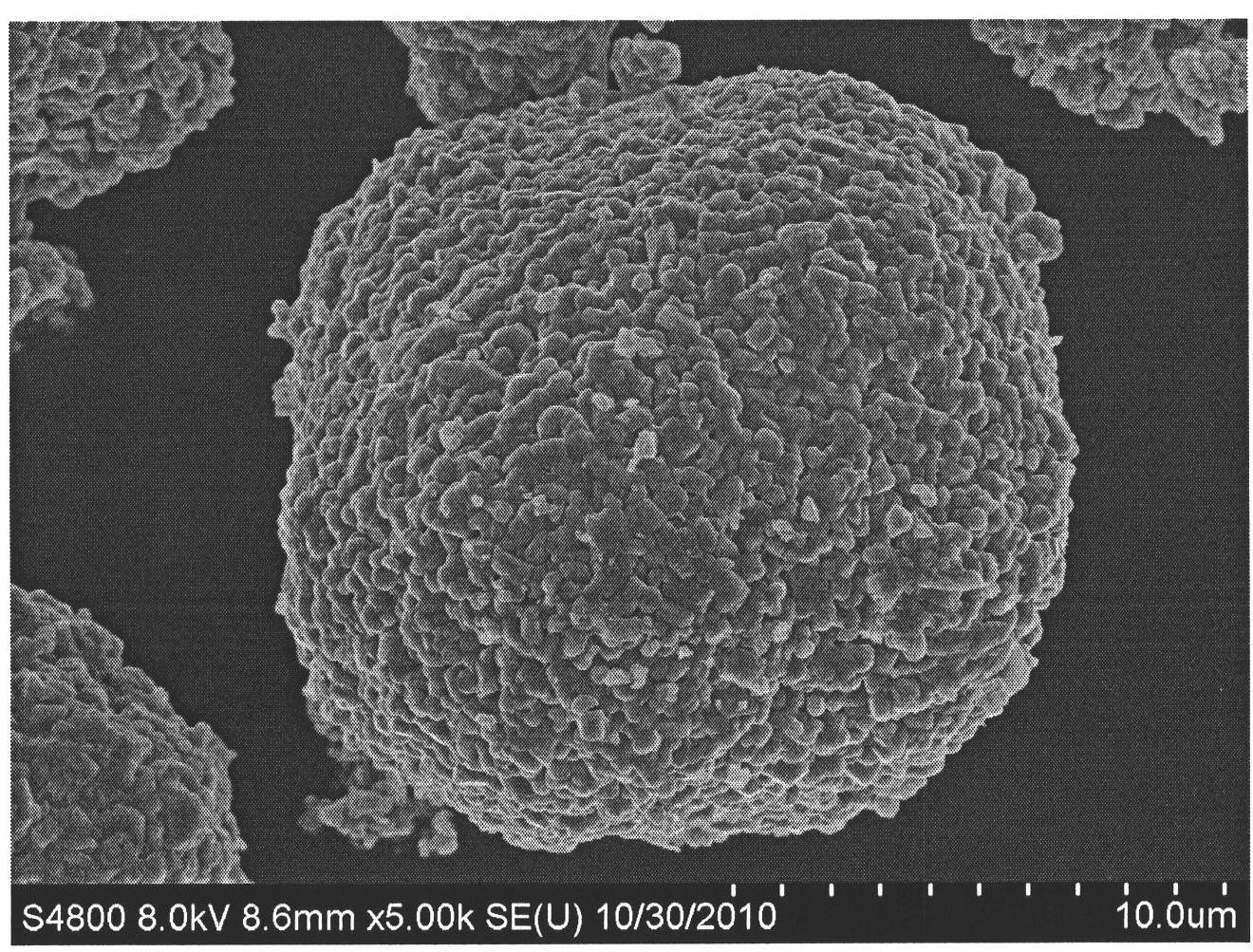

[0034]According to the raw materials, dosage and conditions shown in Table 1, the layered lithium-rich manganese-based oxide was prepared according to the following steps:

[0035] Mix the nickel-containing compound, manganese-containing compound 1, and cobalt-containing compound with the solvent according to the molar ratio Ni:Mn:Co molar ratio of α:x:β to obtain a solution or suspension, and add a precipitant under stirring conditions , controlling the pH value of the obtained mixed solution, and obtaining a mixed precipitate after filtering; drying the mixed precipitate in vacuum at 80° C. for 8 hours to obtain a layered lithium-rich manganese-based oxide precursor.

[0036] Table 1 The recipe and conditions for the preparation of layered lithium-rich manganese-based oxide precursors in Examples 1-10 of the present invention

[0037]

[0038] According to the raw materials, dosage and conditions shown in Table 2, the layered lithium-rich manganese-based oxide was prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com