Aluminum and fluorine dual-modified lithium ion battery cathode material and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electrochemical cycle performance and poor safety performance, and achieve the goals of reducing sensitivity, easy control, and enhanced transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

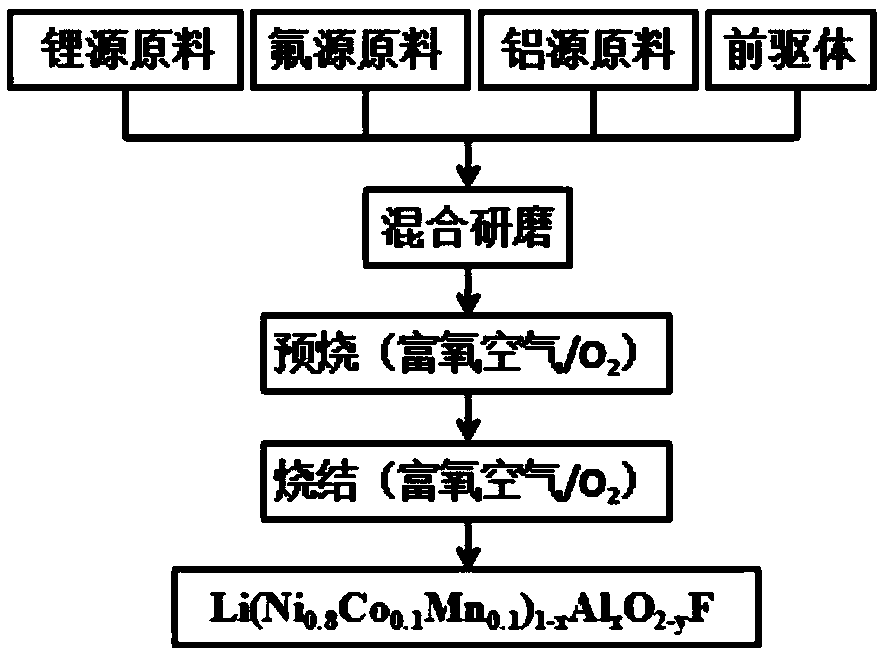

[0045] When the doping amounts of Al and F are 0.02 and 0.01 respectively (that is, x=0.02, y=0.01), 2.2029g LiOH·H 2 O, 4.5704g precursor, 0.3789g Al(NO 3 ) 3 9H 2 O and 0.0132g LiF are mixed, with alcohol as a dispersant, fully ground evenly, then put in oven and dry and grind finely, put it into tube furnace at last under oxygen atmosphere (oxygen flow rate 400ml / min) with Heat up to 470°C at a speed of 3°C / min for 6 hours, then heat up to 780°C at a speed of 2°C / min and bake for 15 hours, then cool down naturally, take out the material and grind it finely to obtain Li(Ni 0.8 co 0.1 mn 0.1 ) 0.98 al 0.02 o 1.99 f 0.01 .

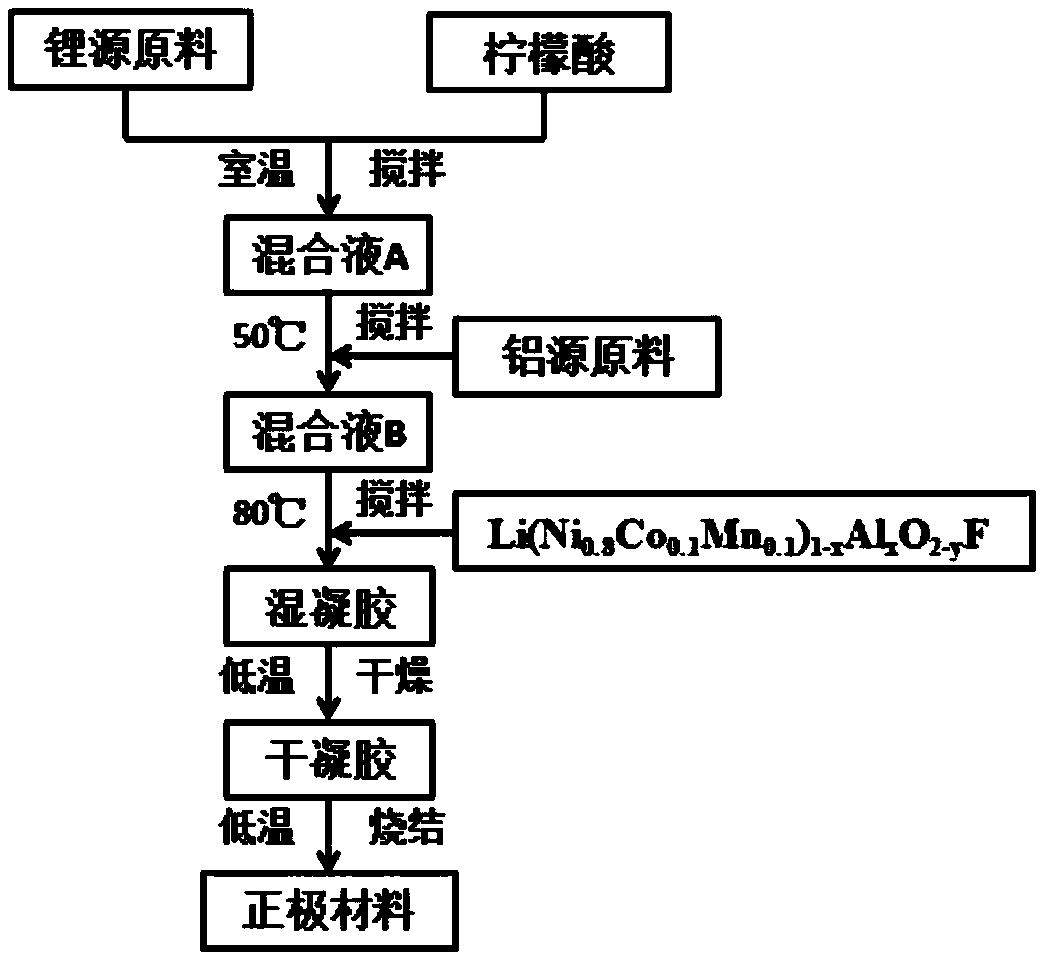

[0046] At the same time, LiAlO 2 When the coating amount is 0.2wt%, weigh 0.0064gLiNO 3 And 0.0193g complexing agent citric acid, be dissolved in appropriate amount of deionized water, stir constantly at room temperature, obtain mixed solution A, weigh 0.0345g Al(NO 3 ) 3 9H 2 O, dissolved in an appropriate amount of deionized water, added dr...

Embodiment 2

[0050] When the doping amounts of Al and F are 0.01 and 0.02 respectively (that is, x=0.01, y=0.02), 2.2029g LiOH·H 2 O, 4.6171g precursor, 0.1895g Al(NO 3 ) 3 9H 2 O and 0.0264g LiF are mixed, with alcohol as a dispersant, fully ground evenly, then put in oven and dry and grind finely, finally it is put into tube furnace under oxygen atmosphere (oxygen flow rate 400ml / min) with Heat up to 470°C at a speed of 3°C / min for 6 hours, then heat up to 780°C at a speed of 2°C / min and bake for 15 hours, then cool down naturally, take out the material and grind it finely to obtain Li(Ni 0.8 co 0.1 mn 0.1 ) 0.99 al 0.01 o 1.98 f 0.02 .

[0051] At the same time, LiAlO 2 When the coating amount is 0.2wt%, weigh 0.0064gLiNO 3 And 0.0193g complexing agent citric acid, be dissolved in appropriate amount of deionized water, stir constantly at room temperature, obtain mixed solution A, weigh 0.0345g Al(NO 3 ) 3 9H 2 O, dissolved in an appropriate amount of deionized water, added...

Embodiment 3

[0055] When the doping amounts of Al and F are 0.02 and 0.02 respectively (that is, x=0.02, y=0.02), 2.2029g LiOH·H 2 O, 4.5704g precursor, 0.3789g Al(NO 3 ) 3 9H 2 O and 0.0264g LiF are mixed, with alcohol as a dispersant, fully ground evenly, then put in oven and dry and grind finely, finally it is put into tube furnace under oxygen atmosphere (oxygen flow rate 400ml / min) with Heat up to 470°C at a speed of 3°C / min for 6 hours, then heat up to 780°C at a speed of 2°C / min and bake for 15 hours, then cool down naturally, take out the material and grind it finely to obtain Li(Ni 0.8 co 0.1 mn 0.1 ) 0.98 al 0.02 o 1.98 f 0.02 .

[0056] At the same time, LiAlO 2 When the coating amount is 0.2wt%, weigh 0.0064gLiNO 3 And 0.0193g complexing agent citric acid, be dissolved in appropriate amount of deionized water, stir constantly at room temperature, obtain mixed solution A, weigh 0.0345g Al(NO 3 ) 3 9H 2 O, dissolved in an appropriate amount of deionized water, added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com