Preparation method of integrated all-solid-state lithium ion battery

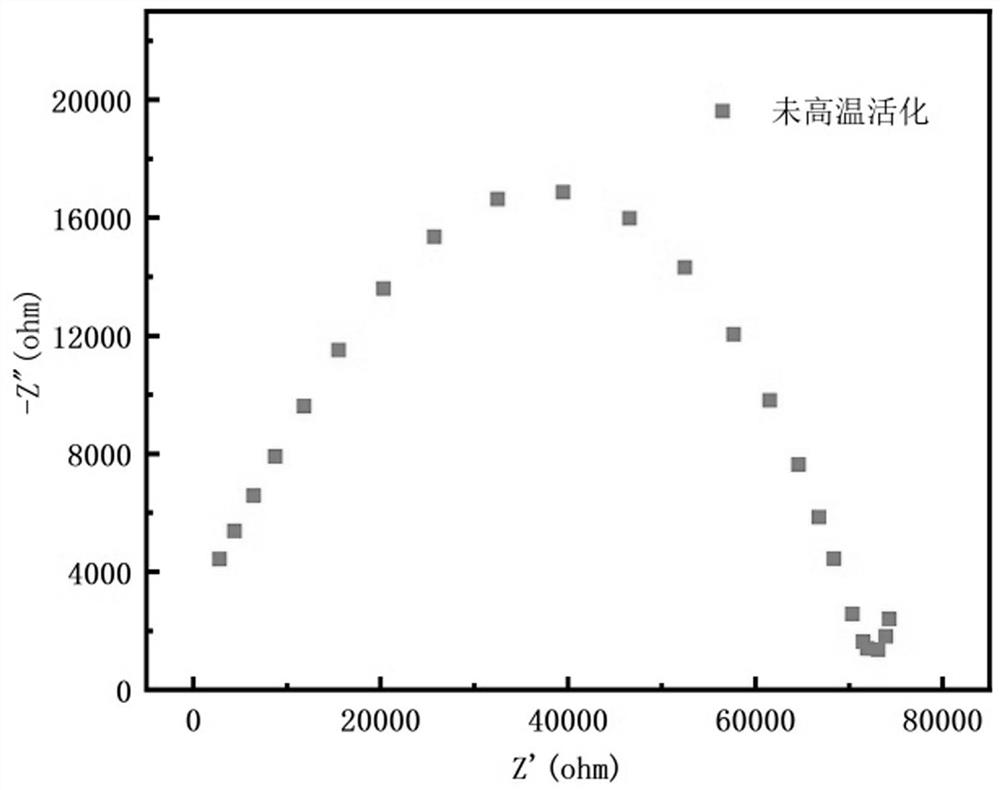

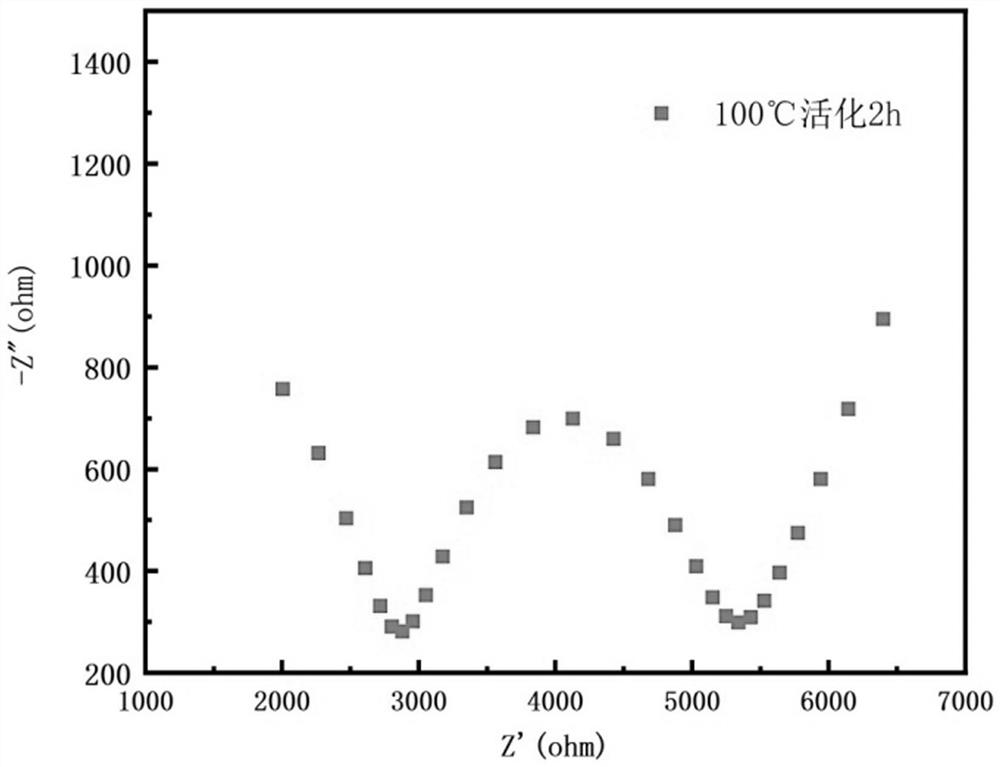

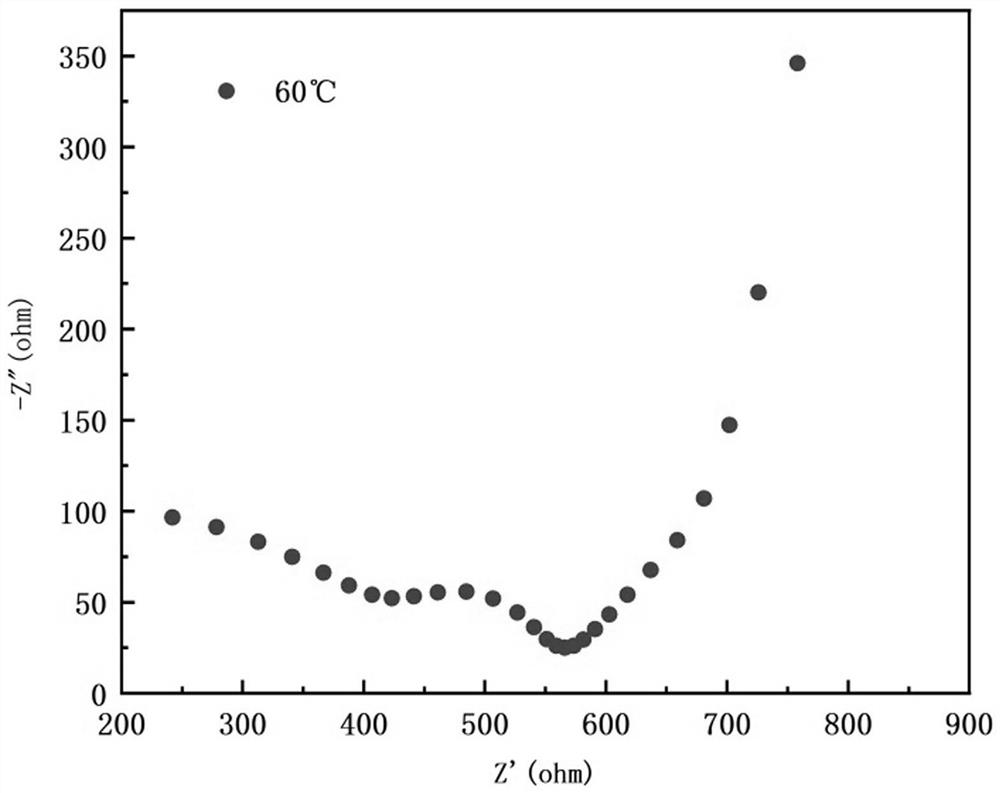

A lithium-ion battery, all-solid-state technology, applied in secondary batteries, electrode manufacturing, solid electrolyte, etc., can solve the problems of unsatisfactory lithium-ion conductivity and high interface impedance between electrodes and electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing an integrated all-solid-state lithium-ion battery, comprising the following steps:

[0029] a. Preparation of solid inorganic electrolyte:

[0030] Lanthanum source La 2 o 3 Pre-sintered at 900 °C for 12 hours, and then the lithium source Li 2 O, lanthanum source La 2 o 3 , zirconium source ZrO 2 , tantalum source Ta 2 o 5 After mixing in a molar ratio of 3.68:1.5:1.4:0.3 and ball milling in an isopropanol solution for 16 hours, the solution was centrifuged and dried in air at 60°C for 12 hours, and the obtained powder was sintered at 900°C for 10 hours. The prepared garnet-type solid oxide Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ;

[0031] b. Preparation of organic-inorganic hybrid electrolyte:

[0032] Dissolve the garnet-type solid oxide LLZTO obtained in step a in acetonitrile and ball mill at a speed of 400r for 12 hours to obtain an acetonitrile suspension of micron-sized oxides, wherein the concentration of the garnet-type solid oxide ...

Embodiment 2

[0036] A method for preparing an integrated all-solid-state lithium-ion battery, comprising the following steps:

[0037] a. Preparation of solid inorganic electrolyte:

[0038] Lanthanum source La 2 o 3 Pre-sintered at 900 °C for 12 hours, and then the lithium source Li 2 O, lanthanum source La 2 o 3 , zirconium source ZrO 2 , tantalum source Ta 2 o 5 After mixing in a molar ratio of 3.68:1.5:1.4:0.3 and ball milling in an isopropanol solution for 16 hours, the solution was centrifuged and dried in air at 60°C for 12 hours, and the obtained powder was sintered at 900°C for 10 hours. The prepared garnet-type solid oxide Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ;

[0039] b. Preparation of organic-inorganic hybrid electrolyte:

[0040] Dissolve the garnet-type solid oxide LLZTO obtained in step a in acetonitrile and ball mill at a speed of 400r for 12 hours to obtain an acetonitrile suspension of micron-sized oxides, wherein the concentration of the garnet-type solid oxide ...

Embodiment 3

[0044] A method for preparing an integrated all-solid-state lithium-ion battery, comprising the following steps:

[0045] a. Preparation of solid inorganic electrolyte:

[0046] Lanthanum source La 2 o 3 Pre-sintered at 900 °C for 12 hours, and then the lithium source Li 2 O, lanthanum source La 2 o 3 , zirconium source ZrO 2 , tantalum source Ta 2 o 5 After mixing in the molar ratio of 3.68:1.5:1.4:0.3 and ball milling in isopropanol solution for 16-24 hours, the solution was centrifuged and dried in air at 60°C for 12 hours, and the obtained powder was sintered at 900°C for 10 -16 hours, the garnet-type solid oxide Li was prepared 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ;

[0047] b. Preparation of organic-inorganic hybrid electrolyte:

[0048] Dissolve the garnet-type solid oxide LLZTO obtained in step a in acetonitrile and ball mill at a speed of 400r for 12 hours to obtain an acetonitrile suspension of micron-sized oxides, wherein the concentration of the garnet-type so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com