Inorganic-organic nano composite solid electrolyte membrane and preparation method and application thereof

A solid electrolyte and nanocomposite technology, which is used in solid electrolytes, electrolyte battery manufacturing, non-aqueous electrolytes, etc., to achieve high Coulomb efficiency and cycle life, reduce interface resistance, and inhibit lithium dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

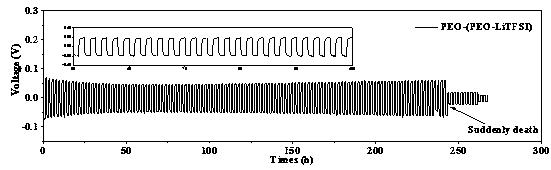

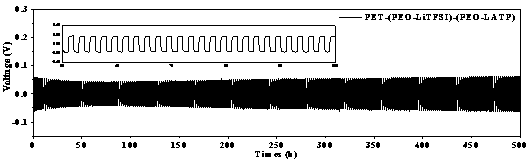

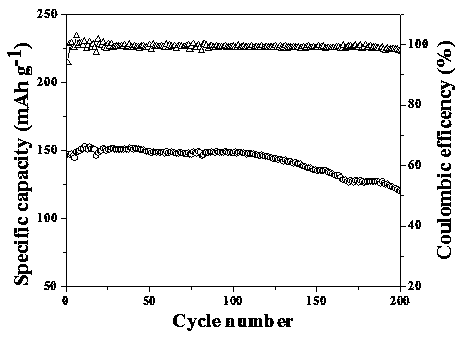

[0035] (1) Preparation of Li by solid-state reaction method 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Inorganic ceramic solid electrolyte powder. Lithium carbonate (Li 2 CO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium monohydrogen phosphate ((NH 4 ) 2 HPO 4 ) and grind to mix. In order to compensate for the loss of lithium salt in the heat treatment process, lithium carbonate is in excess of 10%. After sintering at 900 °C for 2 h, ball milling at 400 rpm for 6 h with acetone as solvent, then calcining at 900 °C for 2 h and ball milling for 6 h to obtain LATP powder. (2) Polyethylene oxide (PEO, molecular weight 400,000) and lithium salt (LiTFSI) were vacuum-dried at 60 °C and 100 °C overnight before use, and then 3 g of PEO and 1 g of LiTFSI were dissolved in 40 mL of acetonitrile (AN) , mechanically stirred at 60°C for 12 h, and then coated on the washed polymer non-woven PET, dried at 60°C and rolled to obtain an interface layer thickness of a...

Embodiment 2

[0037] (1) Preparation of Li by solid-state reaction method 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Inorganic ceramic solid electrolyte powder. Lithium carbonate (Li 2 CO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium monohydrogen phosphate ((NH 4 ) 2 HPO 4 ) and grind to mix. In order to compensate for the loss of lithium salt in the heat treatment process, lithium carbonate is in excess of 10%. After sintering at 900 °C for 2 h, ball milling at 400 rpm for 12 h with acetone as solvent, then calcining at 900 °C for 2 h and ball milling for 12 h to obtain LATP powder. (2) Polyethylene oxide (PEO, molecular weight 400,000) and lithium salt (LiTFSI) were vacuum-dried at 60 °C and 100 °C overnight before use, and then 3 g of PEO and 1 g of LiTFSI were dissolved in 40 mL of acetonitrile (AN) , mechanically stirred at 60 °C for 12 h, and then coated on the washed polymer non-woven PET, dried at 60 °C and then rolled to obtain an interface layer thick...

Embodiment 3

[0039] (1) Preparation of Li by solid-state reaction method 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 (LATP) Inorganic ceramic solid electrolyte powder. Lithium carbonate (Li 2 CO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium monohydrogen phosphate ((NH 4 ) 2 HPO 4 ) and grind to mix. In order to compensate for the loss of lithium salt in the heat treatment process, lithium carbonate is in excess of 10%. After sintering at 900 °C for 2 h, ball milling at 400 rpm for 6 h with acetone as solvent, then calcining at 900 °C for 2 h and ball milling for 6 h to obtain LATP powder. (2) Polyethylene oxide (PEO, molecular weight 400,000) and lithium salt (LiTFSI) were vacuum-dried at 60 °C and 100 °C overnight before use, and then 3 g of PEO and 1 g of LiTFSI were dissolved in 40 mL of acetonitrile (AN) , mechanically stirred at 60 °C for 12 h, and then coated on the washed polymer non-woven PET, dried at 60 °C and then rolled to obtain an interface layer thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com