Metal lithium anode with protective coating, preparation thereof and application of metal lithium anode

A protective coating, metal lithium technology, applied in the field of electrochemistry, can solve the problems of low coulombic efficiency and poor cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

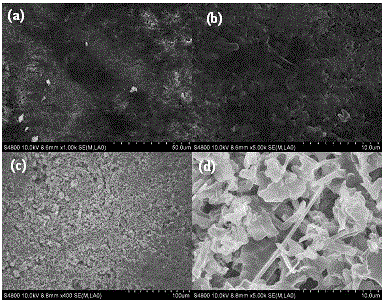

Embodiment 1

[0025] Will 1g n=10-100000, dissolved in 10ml acetone, stirred evenly to dissolve completely to form a homogeneous solution, then formed a film on the surface of metal lithium by spin coating, and then dried in a vacuum oven at room temperature for 8 hours to completely remove acetone. The metal lithium coated with the protective layer was heated at 40° C. for 2 h under an Ar gas atmosphere, so that the polymer chain segments were arranged regularly. Then soak in THF alkaline solution for 6h, dry to remove THF, transfer to the cavity of atomic layer deposition (ALD), use the metal lithium coated with protective layer as the substrate, and use the fast ion conductor Li 7 La3 Zr 2 o 12 As the target material, a fast ion conductor layer is sputtered.

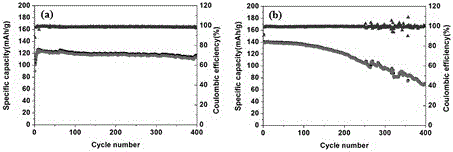

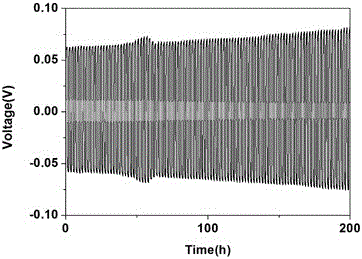

[0026] LiCoO 2 as the positive electrode, with LiPF 6 / EC: DMC (1:1) is the electrolyte, and the lithium metal with a protective coating is used as the negative electrode to assemble the battery. The battery performance is ...

Embodiment 2

[0028] 1.5g n=10-100000, dissolved in 10ml acetone, stirred evenly to dissolve completely to form a homogeneous solution, then formed a film on the surface of metal lithium by spin coating, and then dried in a vacuum oven at room temperature for 8 hours to completely remove acetone. The metal lithium coated with the protective layer was heated at 50° C. for 3 h under an Ar gas atmosphere, so that the polymer chain segments were arranged regularly. Then soak in THF alkaline solution for 6h, dry to remove THF, transfer to the cavity of ALD, use the metal lithium coated with the protective layer as the substrate, and use the fast ion conductor Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 As the target material, a fast ion conductor layer is sputtered.

[0029] LiCoO 2 as the positive electrode, with LiPF 6 / EC: DMC (1:1) is the electrolyte, and the lithium metal with a protective coating is used as the negative electrode to assemble the battery. The battery performance is shown in Ta...

Embodiment 3

[0031] Will 1g n=10-100000, dissolved in 10ml acetone, stirred evenly to dissolve completely to form a homogeneous solution, then formed a film on the surface of metal lithium by spin coating, and then dried in a vacuum oven at room temperature for 8 hours to completely remove acetone. The metal lithium coated with the protective layer was heated at 60° C. for 3 h under an Ar gas atmosphere, so that the polymer chain segments were arranged regularly. Then soak in THF alkaline solution for 6h, then vacuum dry at room temperature to remove THF, transfer to the cavity of ALD, use the metal lithium coated with the protective layer as the substrate, and use TiO 2 As the target material, a fast ion conductor layer is sputtered.

[0032] LiCoO 2 as the positive electrode, with LiPF 6 / EC: DMC (1:1) is the electrolyte, and the lithium metal with a protective coating is used as the negative electrode to assemble the battery. The battery performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com