Sodium-ion battery diaphragm and preparation method thereof

A technology for sodium-ion batteries and diaphragms, which is applied to battery pack parts, circuits, electrical components, etc. It can solve problems such as difficulty in controlling the uniformity of thickness, application limitations of polyolefin porous membranes, and high price of glass fiber diaphragms. Excellent rated capacity, low interfacial internal resistance, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

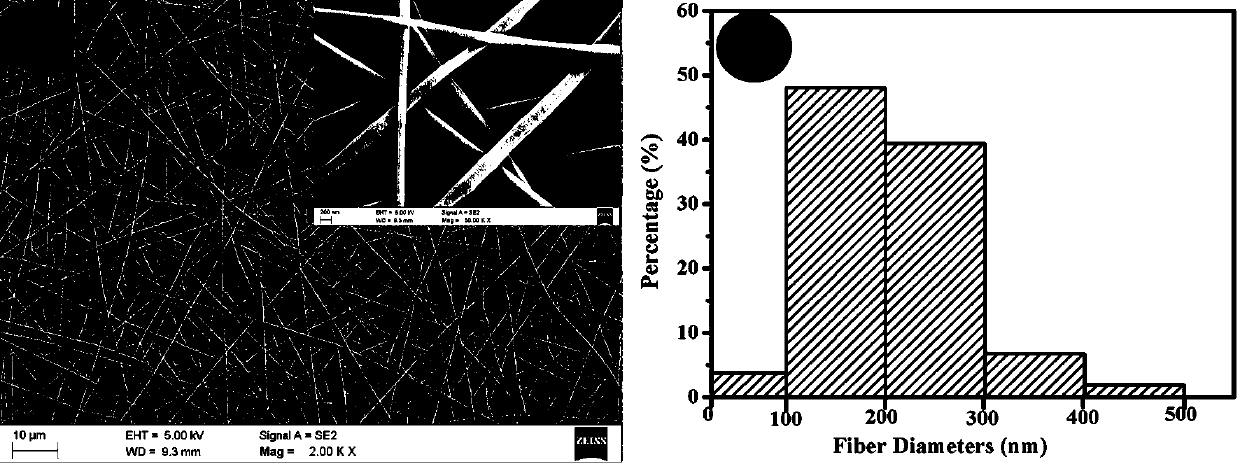

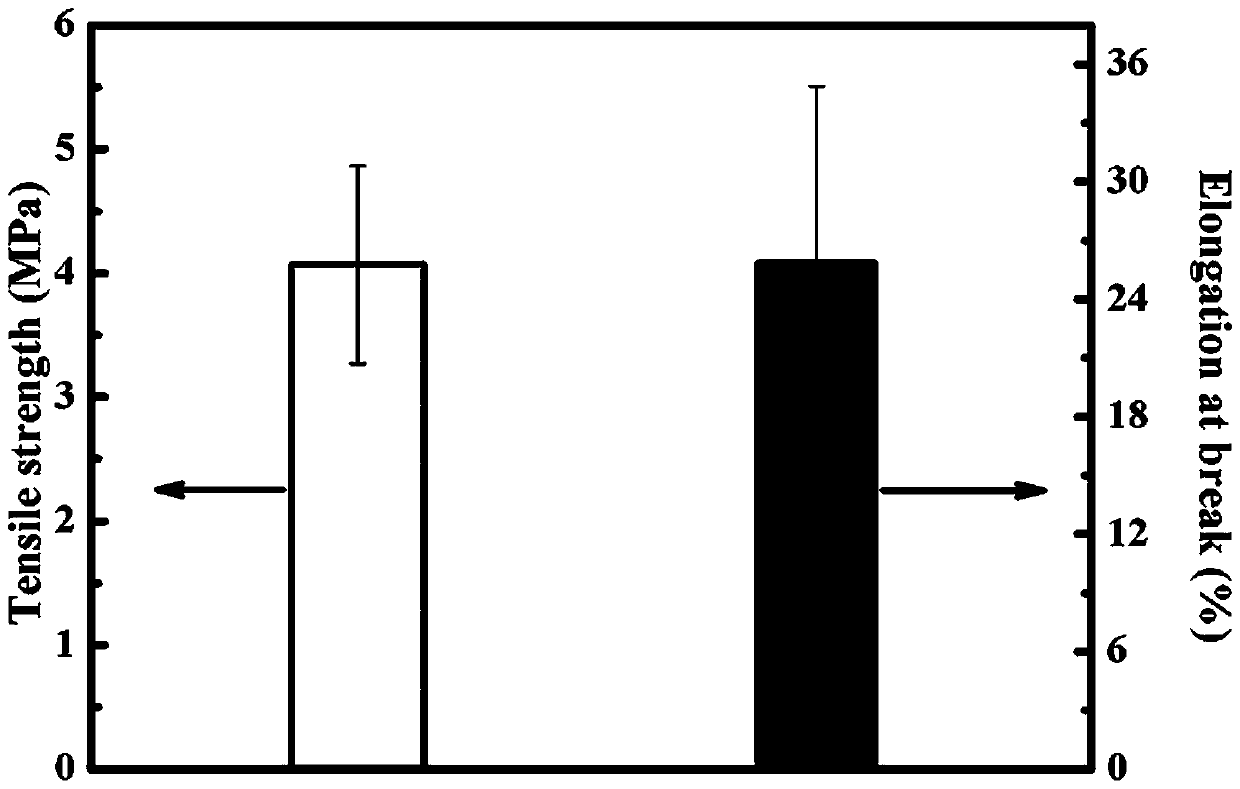

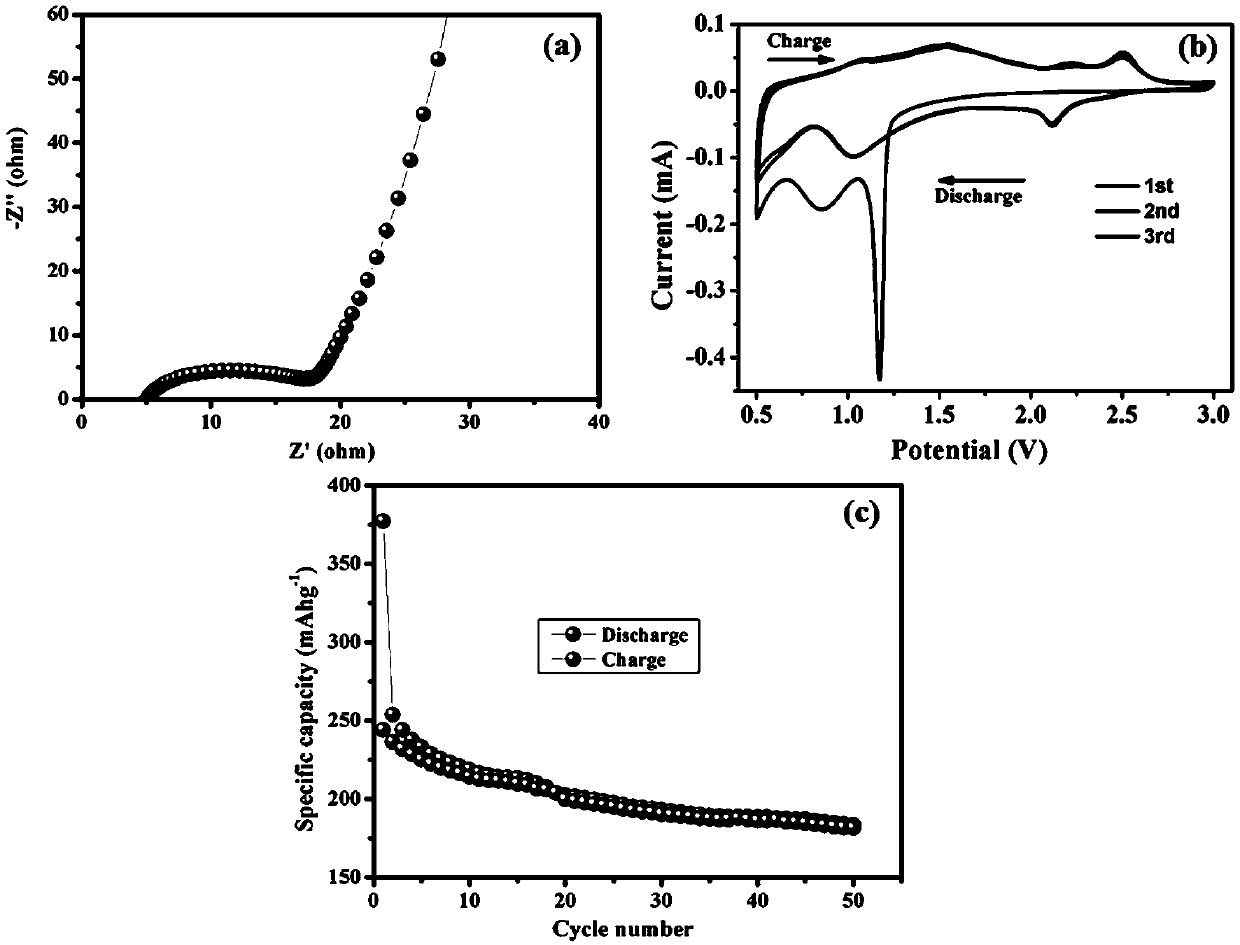

Image

Examples

Embodiment 1

[0027] The preparation method of the sodium ion battery diaphragm of the present embodiment, the steps are as follows:

[0028] (1) Preparation of spinning solution: put commercially available PVDF and PAN powders in 60 o Dry in a vacuum oven at about C for 12 hours, then add the mixed powder of PVDF (0.75 g) and PAN (0.45 g) with a mass ratio of 5:3 to 10 ml of a mixed solvent of DMF and acetone with a volume ratio of 8:2, Put a magnet in the above solution and seal it with plastic wrap, and place it at 60 o Stir on a constant temperature magnetic stirrer in C for 2 h to completely dissolve PVDF and PAN, then move the above solution to a six-connected magnetic stirrer at room temperature and stir for 12 h at room temperature to prepare a uniform spinning solution with a concentration of 12%. Finally, the above-mentioned uniform spinning solution is left to stand for a period of time in a vacuum environment, and the air bubbles in the spinning solution are removed;

[0029] ...

Embodiment 2

[0036] The preparation method of the sodium ion battery diaphragm of the present embodiment, the steps are as follows:

[0037] (1) Preparation of spinning solution: put commercially available PVDF and PAN powders in 60 o Dry in a vacuum oven at about C for 12 hours, and then add PVDF (0.9 g) and PAN (0.3 g) mixed powder with a mass ratio of 6:2 to 10 ml of a mixed solvent of DMF and acetone with a volume ratio of 8:2, Put a magnet in the above solution and seal it with plastic wrap, and place it at 60 o Stir on a constant temperature magnetic stirrer in C for 2 h to completely dissolve PVDF and PAN, then move the above solution to a six-connected magnetic stirrer at room temperature and stir for 12 h at room temperature to prepare a uniform spinning solution with a concentration of 12%. Finally, the above-mentioned uniform spinning solution is left to stand for a period of time in a vacuum environment, and the air bubbles in the spinning solution are removed;

[0038] (2) P...

Embodiment 3

[0041] The preparation method of the sodium ion battery diaphragm of the present embodiment, the steps are as follows:

[0042] (1) Preparation of spinning solution: put commercially available PVDF and PAN powders in 60 o Dry in a vacuum oven at about C for 12 hours, then add the mixed powder of PVDF (0.75 g) and PAN (0.45 g) with a mass ratio of 5:3 to 10 ml of a mixed solvent of DMF and acetone with a volume ratio of 8:2, Put a magnet in the above solution and seal it with plastic wrap, and place it at 60 o Stir on a constant temperature magnetic stirrer in C for 2 h to completely dissolve PVDF and PAN, then move the above solution to a six-connected magnetic stirrer at room temperature and stir for 12 h at room temperature to prepare a uniform spinning solution with a concentration of 12%. Finally, the above-mentioned uniform spinning solution is left to stand for a period of time in a vacuum environment, and the air bubbles in the spinning solution are removed;

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com