Positive electrode material precursor and preparation method thereof, positive electrode material and lithium ion battery

A cathode material and precursor technology, applied in batteries, battery electrodes, secondary batteries, etc., can solve the problems of reduced structural stability, unsatisfactory structural stability and cycle performance of ternary NCM materials, and reduce the interface internal resistance. , good structural stability, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

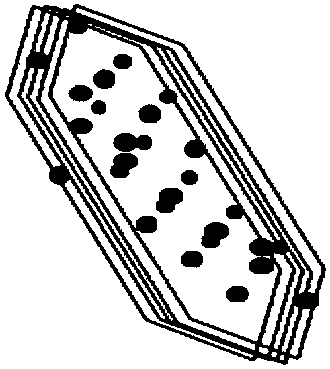

[0075] The present invention provides a kind of preparation method of cathode material precursor, comprises the following steps:

[0076] 1) After mixing nickel salt, manganese salt and / or aluminum salt, cobalt salt and water, a mixed solution is obtained;

[0077] 2) adding the mixed solution, complexing agent and alkali, and reacting to obtain the first mixed solution;

[0078] 3) To the first mixed solution obtained in the above steps, continue to add the mixed solution, complexing agent and alkali, and react again to obtain the second mixed solution;

[0079] 4) Aging the second mixed solution obtained in the above steps to obtain a positive electrode material precursor.

[0080] In the present invention, the selection, ratio, and corresponding optimization principles of materials in the preparation method are preferably consistent with the selection, ratio, and corresponding optimization principles of the materials in the aforementioned positive electrode material precur...

Embodiment 1

[0146] (1) Take nickel sulfate, cobalt sulfate and manganese sulfate respectively to be 21.56kg, 2.8kg and 13.5kg, according to the chemical formula LiNi 0.82 co 0.1 mn 0.08 o 2 The molar ratio concentration in is stirred and dissolved in deionized water, and configured as a 2mol / L mixed salt solution;

[0147] (2) Take by weighing 35.6kg sodium hydroxide, stir and dissolve in deionized water, be configured into a sodium hydroxide solution of 8mol / L, and use as a precipitating agent;

[0148] (3) measure 3400ml of ammonia water, dilute with deionized water, and be configured into 2mol / L ammonia solution, use as complexing agent;

[0149] (4) Heat the water bath in the reactor to 55°C by direct electric heating, slowly add the above three prepared solutions to the reactor respectively, control the pH value of the reactor to 11.3, and react for 35 hours.

[0150] (5) Continue to slowly add the above three prepared solutions to the reaction kettle dropwise, adjust the flow rate...

Embodiment 2

[0162] (1) Take nickel sulfate, cobalt sulfate and manganese sulfate respectively to be 15.77kg, 5.63kg and 3.38kg, according to the chemical molecular formula LiNi 0.6 co 0.2 mn 0.2 o 2 The molar ratio concentration in the solution is stirred and dissolved in deionized water, and configured as a 2mol / L mixed salt solution;

[0163] (2) Take by weighing 17.8kg sodium hydroxide, stir and dissolve in deionized water, configure a 4mol / L sodium hydroxide solution, and use it as a precipitant;

[0164] (3) measure 3400ml of ammonia water, dilute with deionized water, and be configured into 2mol / L ammonia solution, use as complexing agent;

[0165] (4) Heat the water bath in the reactor to 55°C by direct electric heating, slowly add the above three prepared solutions to the reactor respectively, control the pH value of the reactor to 11.25, and react for 30 hours.

[0166] (5) Continue to slowly add the above three configured solutions to the reaction kettle dropwise, adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com