Graphene-modified copper foil electrode used for power battery with silica-based cathode

A graphene modification, power battery technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc. Chemical properties, reducing the decrease in conductivity, preventing the surface from being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

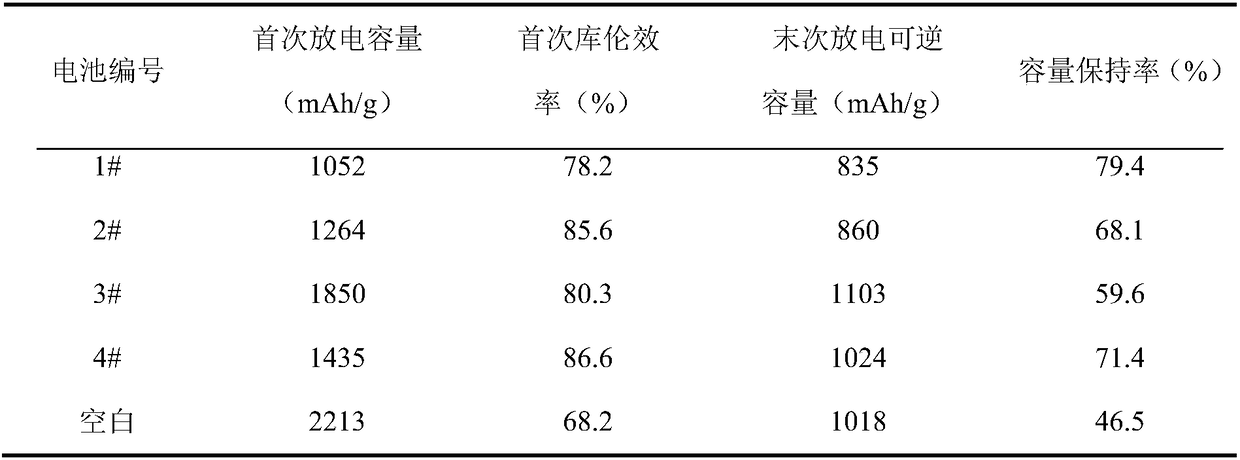

Examples

Embodiment 1

[0025] This embodiment discloses a graphene-modified copper foil electrode for a silicon-based negative power battery, which mainly includes the following steps:

[0026] 1) First, pretreat the copper foil. Put the copper foil in 5% concentration of FeCl in turn 3 and HCl dilute solution for 30 minutes to remove the oxide layer on the surface of copper foil, and then placed in Ar / H 2 Annealing at 1000°C for 30 minutes in a mixed atmosphere to further reduce the surface roughness, stabilize the surface morphology of the copper foil to reduce the number of nucleation points for graphene growth, and eliminate surface structural defects to achieve the growth of single crystal or polycrystalline graphene films;

[0027] 2) Place the copper foil in a quartz tube reactor, use ethylene as the carbon source, and synthesize a continuous few-layer graphene film on the copper foil by CVD. The growth temperature is 750°C, and the flow rate of the ethylene carbon source is 20ml / s ; repass...

Embodiment 2

[0031] This embodiment discloses a graphene-modified copper foil electrode for a silicon-based negative power battery, which mainly includes the following steps:

[0032] 1) First, pretreat the copper foil. Put the copper foil in 5% concentration of FeCl in turn 3 and HCl dilute solution for 10 minutes to remove the oxide layer on the surface of copper foil, and then placed in Ar / H 2 Annealing at 800°C for 30 minutes in a mixed atmosphere to further reduce the surface roughness, stabilize the surface morphology of the copper foil to reduce the number of nucleation points for graphene growth, and eliminate surface structural defects to achieve the growth of single crystal or polycrystalline graphene films;

[0033] 2) Place the copper foil in a quartz tube reaction furnace, use ethylene as the carbon source, and synthesize a continuous few-layer graphene film on the copper foil by CVD. The growth temperature is 900°C, and the flow rate of the ethylene carbon source is 30ml / s ...

Embodiment 3

[0037] This embodiment discloses a graphene-modified copper foil electrode for a silicon-based negative power battery, which mainly includes the following steps:

[0038] 1) First, pretreat the copper foil. Put the copper foil in 5% concentration of FeCl in turn 3 and HCl dilute solution for 30 minutes to remove the oxide layer on the surface of copper foil, and then placed in Ar / H 2 Annealing at 900°C for 20 minutes in a mixed atmosphere to further reduce the surface roughness, stabilize the surface morphology of the copper foil to reduce the number of nucleation points for graphene growth, and eliminate surface structural defects to achieve the growth of single crystal or polycrystalline graphene films;

[0039] 2) Place the copper foil in a quartz tube reaction furnace, use ethylene as the carbon source, and synthesize a continuous few-layer graphene film on the copper foil by CVD. The growth temperature is 800°C, and the flow rate of the ethylene carbon source is 25ml / s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com