Multistage reaction system, lithium ion multi-element positive electrode material precursor, preparation method of lithium ion multi-element positive electrode material precursor and preparation method of lithium ion multi-element positive electrode material

A multi-stage reaction and reaction system technology, applied in chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of complicated process, poor improvement effect, wide particle size distribution, etc., and achieve controllable particle size. The effect of uniformity, improved structural stability, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

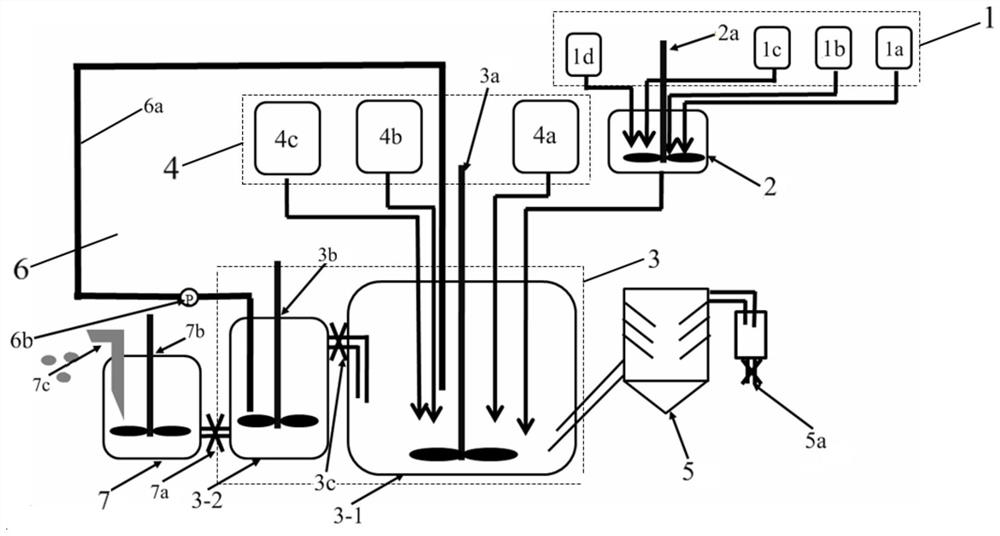

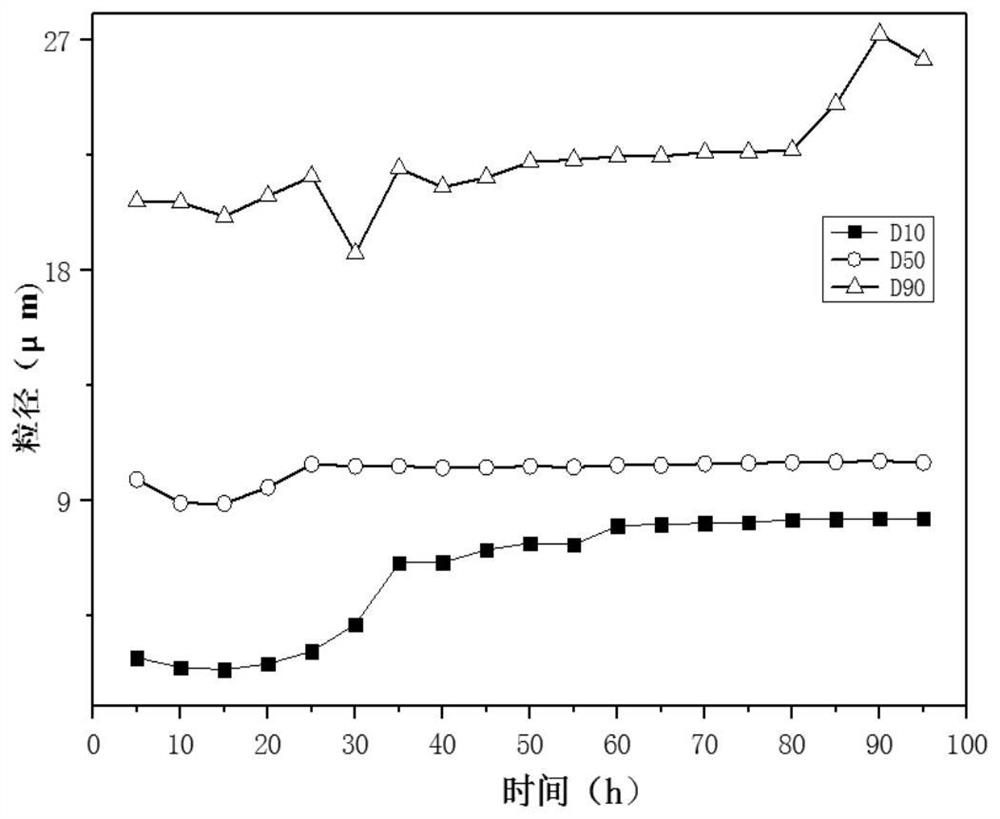

[0117] The present invention provides a preparation method of a lithium ion multi-element cathode material precursor, which is prepared by using the multi-stage reaction system described in the above technical scheme, and specifically includes the following steps:

[0118] a) the material in the raw material tank is sent to the salt preparation kettle, and mixed in the salt preparation kettle to obtain a mixed salt solution;

[0119] b) the mixed salt solution in the salt preparation kettle is sent to the primary reaction kettle, and meanwhile, the ingredients in the batching tank are sent to the primary reaction kettle, and under stirring conditions, the mixed salt solution and the ingredients are in the primary reaction kettle. Carry out coprecipitation reaction in the reactor;

[0120] c) in the process of described co-precipitation reaction, the supernatant liquid in the primary reaction kettle is drawn out by the liquid extraction kettle, and the material in the primary r...

Embodiment 1

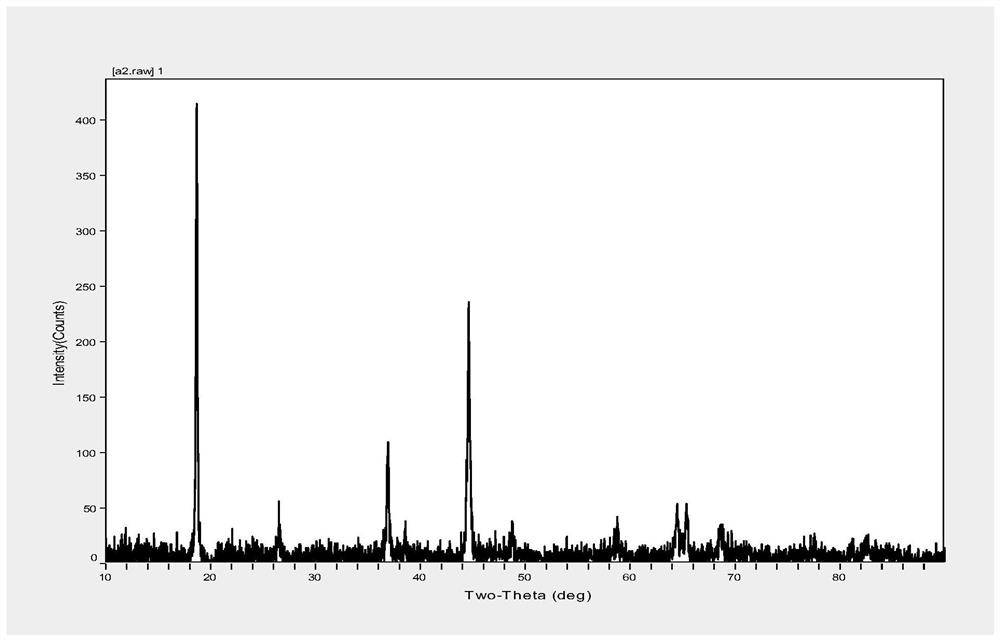

[0167] 1.1 Preparation

[0168] S1, according to the target product Li (Li 0.5 Ni 0.25 co 0.15 mn 0.6 Mg 0.05 )O 2 Molar ratio among, take quantitative nickel sulfate, cobalt sulfate and manganese sulfate respectively, and additive magnesium sulfate, stir respectively and dissolve in deionized water to form nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution and additive solution;

[0169] Add the above-mentioned materials dropwise to the salt mixing kettle 2 through nickel salt solution tank 1a, cobalt salt solution tank 1b, manganese salt solution tank 1c, and additive solution tank 1d respectively, at a rate of 50 mL / min. Stir and mix in the salt mixing kettle 2 to prepare a 2mol / L mixed salt solution.

[0170] S2. Preparation of ingredients:

[0171] Preparation of precipitant solution: Dissolve sodium carbonate in deionized water with stirring to prepare 2mol / L sodium carbonate solution.

[0172] Preparation of complexing agent solution: t...

Embodiment 2

[0186] 1.1 Preparation

[0187] S1, according to the target product Li (Li 0.4 Ni 0.13 Co 0.09 Mn 0.5 Al 0.08 )O 2 In the molar ratio, respectively weigh quantitative nickel sulfate, cobalt sulfate and manganese sulfate, and additive ammonium aluminate, stir and dissolve in deionized water to form nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution and additive solution;

[0188] According to step S1 of Example 1, the transmission material is added dropwise, and the mixture is stirred and mixed in the salt preparation kettle 2 to prepare a 2 mol / L mixed salt solution.

[0189] S2, preparation ingredients:

[0190] Preparation of precipitant solution: Dissolve sodium carbonate in deionized water with stirring to prepare a 2mol / L sodium carbonate solution.

[0191] Preparation of complexing agent solution: take ammonia water with a concentration of 25%, dilute with deionized water, and prepare a complexing agent solution with a concentration of 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com