Ultrafast laser three-dimensional micro-nanometer texturing method for surfaces of copper foil current collectors on negative poles of lithium ion batteries

A lithium-ion battery, ultrafast laser technology, applied in electrode carriers/current collectors, electrode manufacturing, secondary batteries, etc., can solve problems such as environmental pollution, environmental damage, and singleness, and achieve the effect of improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Combine below figure 1 and figure 2 The present invention is described in further detail.

[0030] (1) Select a piece of smooth copper foil for lithium-ion battery negative electrode and pretreat it, mainly including cutting the smooth copper foil into multiple smooth copper foil current collectors that meet the size requirements, and cutting multiple smooth copper foils After the current collector was ultrasonically cleaned in acetone, it was taken out, rinsed with distilled water, and dried for later use.

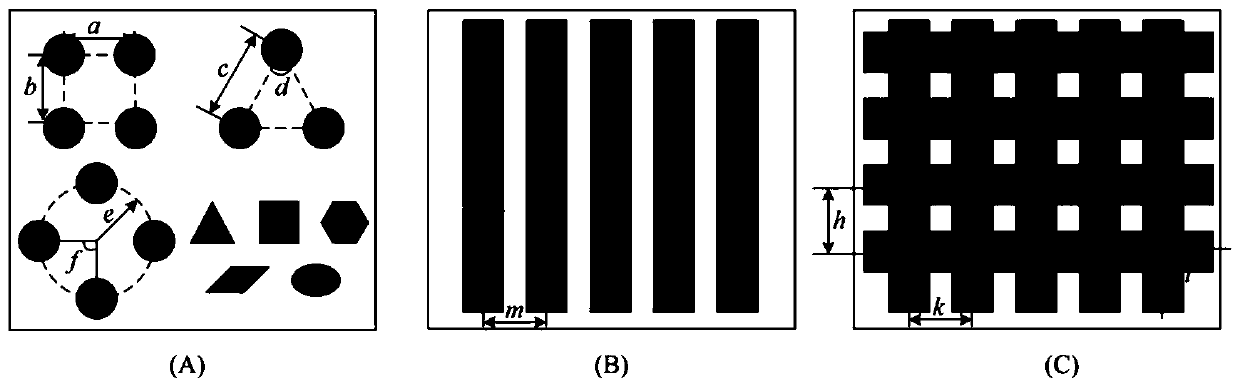

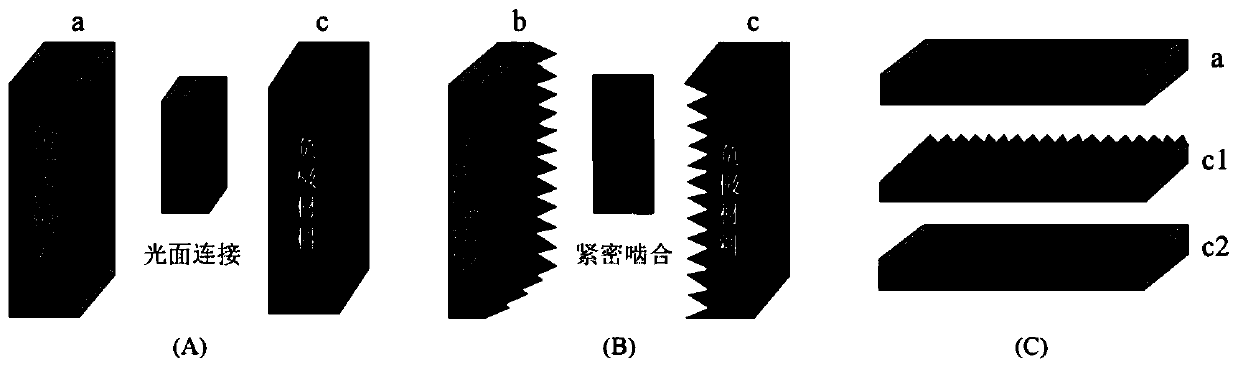

[0031] (2) Using ultrafast lasers to perform characteristic differentiation of three-dimensional micro-nano textures on the surface of multiple smooth copper foil current collectors, such as figure 1 The three-dimensional micro-nano texture of the hole array, the three-dimensional micro-nano texture of the groove array and the three-dimensional micro-nano texture of the orthogonal square column array are shown, and the depth of the three-dimensional micro-nano tex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com