Synthesis of graphene-based three-dimensional polyaniline array nanocomposites

A nano-composite material, graphene-based technology, applied in the field of material chemistry, can solve the problems of irregular morphology, limited electrochemical performance of materials, etc., to reduce ion diffusion paths, facilitate electron transport, and improve electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0016] Concrete preparation steps are as follows:

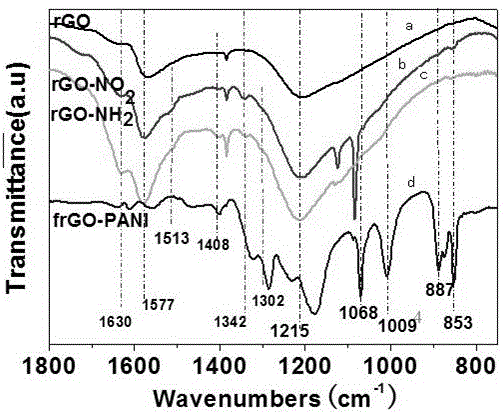

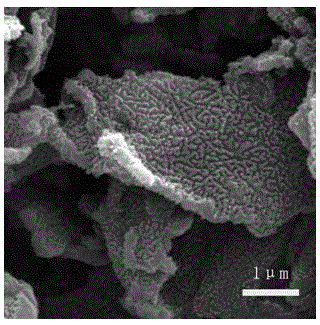

[0017] 1) Disperse 12mg of graphene in 10mL of acetonitrile, add 24mg of tetranitrophenyltetrafluoroborate diazonium salt as a functional reagent, and 300mg of tetrabutyltetrafluoroborate as a supporting electrolyte, and place it in a dark place for 5 hours. The product is centrifuged and washed with ethanol to remove excess diazonium salt and electrolyte;

[0018] 2) Use acetic acid and zinc powder to reduce nitro groups to amine groups: add a certain amount of acetic acid, zinc powder, and ammonium chloride to an ethanol aqueous solution with a volume ratio of 3:2, and the molar ratio of each reactant is nitro compound / Zinc powder=1 / 8; nitro compound / acetic acid=1 / 0.2; nitro compound / NH 4 Cl=1 / 0.12, react at 80°C for 3 hours, centrifuge the product, remove excess zinc powder with HCl, and dry the product in vacuum at 60°C for 4 hours;

[0019] 3) Disperse 3mg of the above product in 1.0MH 2 SO 4 Add aniline and ammoniu...

Embodiment 3

[0021] Concrete preparation steps are as follows:

[0022] 1) Disperse 24mg of graphene in 20mL of acetonitrile, add 48mg of tetranitrophenyltetrafluoroborate diazonium salt as a functional reagent, and 600mg of tetrabutyltetrafluoroborate as a supporting electrolyte, and place it in a dark place for 10 hours. The product is centrifuged and washed with ethanol to remove excess diazonium salt and electrolyte;

[0023] 2) Use acetic acid and zinc powder to reduce nitro groups to amine groups: add a certain amount of acetic acid, zinc powder, and ammonium chloride to an ethanol aqueous solution with a volume ratio of 3:2, and the molar ratio of each reactant is nitro compound / Zinc powder=1 / 8; nitro compound / acetic acid=1 / 0.2; nitro compound / NH 4 Cl=1 / 0.12, react at 80°C for 3 hours, centrifuge the product, remove excess zinc powder with HCl, and dry the product in vacuum at 60°C for 4 hours;

[0024] 3) Disperse 6mg of the above product in 1.0MH 2 SO 4 Add aniline and ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com