Preparation method of composite negative electrode of lithium battery

A lithium battery and negative electrode technology, applied in the field of composite negative electrode preparation, can solve the problem that high flexibility and high conductivity cannot coexist, and achieve the effects of improving mechanical strength and flexibility, high ionic conductivity, and reducing interface ionic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

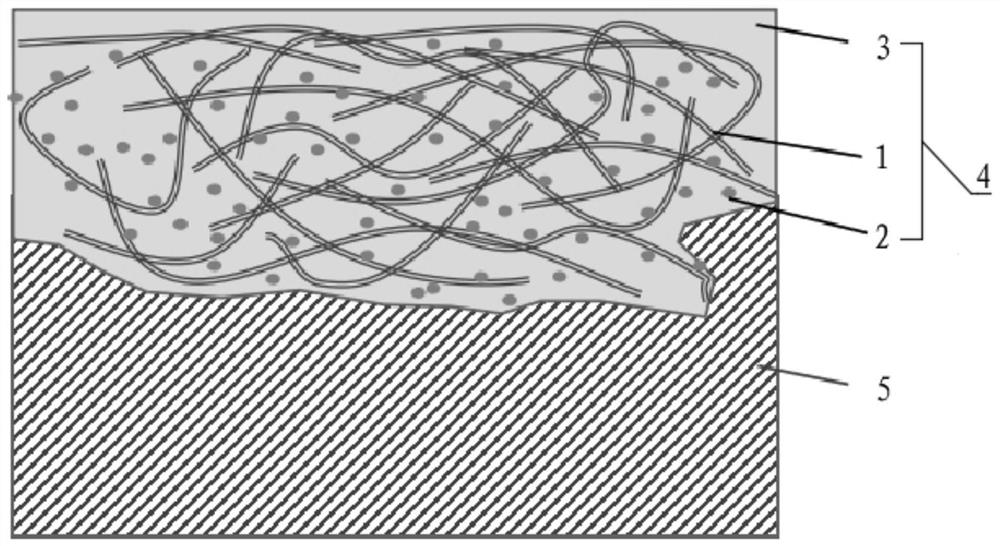

[0016] refer to figure 1 , a preparation method of a composite negative electrode of a lithium battery, comprising the following steps:

[0017] S1: Preparation of inorganic solid electrolytes by electrospinning;

[0018] S2: composite zinc oxide, organic solid electrolyte and lithium salt on the surface of inorganic solid electrolyte by solution casting method to obtain composite solid electrolyte;

[0019] S3: Cast molten metal lithium on one side of the composite solid electrolyte, and cold press to obtain a composite solid electrolyte-metal lithium composite negative electrode.

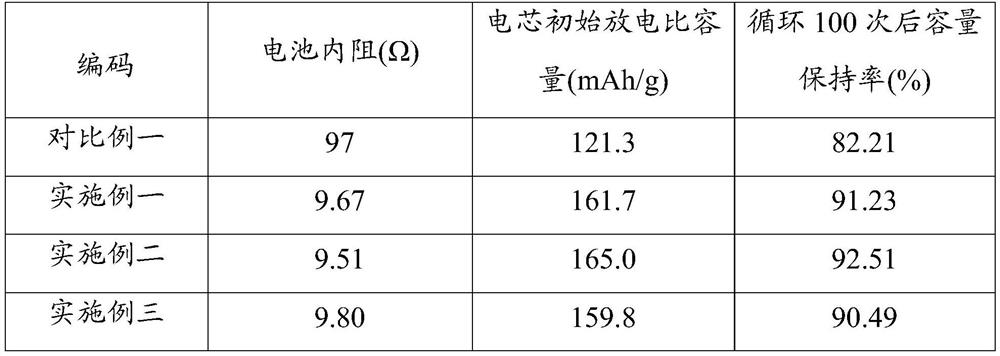

[0020] The working principle of the present invention is to improve the compatibility between the organic-inorganic phases by combining the electrospinning technology, and improve the flexibility of the composite solid electrolyte on the premise of ensuring the high conductivity of lithium ions in the composite solid electrolyte. Zinc oxide is added to the organic solid electrolyte to reduce the...

Embodiment 1

[0040] A method for preparing a composite negative electrode of a lithium battery, comprising the following steps:

[0041] S1: Preparation of inorganic solid electrolyte 1 by electrospinning; specifically, mixing LLTO, polyacrylonitrile and N-methylpyrrolidone at a weight ratio of 10:3:100 to obtain a mixed solution, and the mixed solution was tested at a high voltage of 13kV Electrospinning spraying was carried out to spray the mixed solution onto the aluminum foil. After the solution was sprayed completely, the inorganic solid electrolyte 1 was peeled off from the aluminum foil, transferred to a vacuum drying oven, and vacuum-dried at 60°C for 24 hours before disposal.

[0042]S2: Composite zinc oxide 2, organic solid electrolyte 3 and lithium salt on the surface of inorganic solid electrolyte 1 by solution casting method to obtain composite solid electrolyte 4; specifically, zinc oxide 2, polyethylene oxide, LiSCN, N- Methylpyrrolidone was mixed uniformly at a weight ratio...

Embodiment 2

[0045] A method for preparing a composite negative electrode of a lithium battery, comprising the following steps:

[0046] S1: Preparation of inorganic solid electrolyte 1 by electrospinning; specifically, mixing LGPS, polyvinylidene fluoride and N,N-dimethylformamide at a weight ratio of 20:6:200 to obtain a mixed solution, the mixed solution Electrospinning spraying was carried out at a high voltage of 15kV, so that the mixed solution was sprayed onto the aluminum foil. After the solution was sprayed completely, the inorganic solid electrolyte 1 was peeled off from the aluminum foil, and transferred to a vacuum drying oven for vacuum drying at 70°C. After 32 hours, process it for later use.

[0047] S2: Composite zinc oxide 2, organic solid electrolyte 3 and lithium salt on the surface of inorganic solid electrolyte 1 by solution casting method to obtain composite solid electrolyte 4; specifically, zinc oxide 2, polymethyl methacrylate, LiAsF6 and N , N-dimethylformamide w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com