Synthetic method for graphene-based three-dimensional polyaniline array nanocomposite

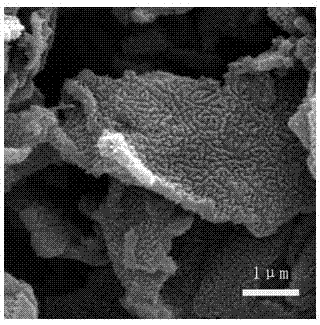

A nanocomposite, graphene-based technology, applied in the field of material chemistry, can solve the problems of limiting the electrochemical performance of materials and irregular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0016] Concrete preparation steps are as follows:

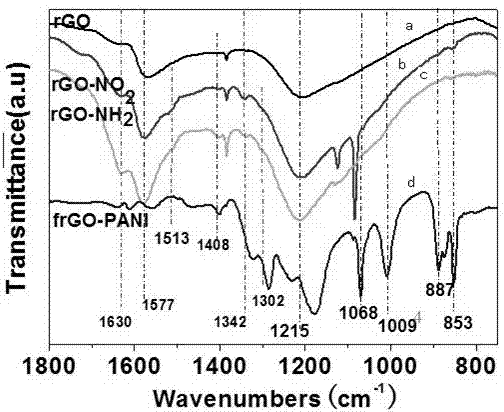

[0017] 1) Disperse 12 mg graphene in 10 mL acetonitrile, add 24 mg tetranitrobenzene tetrafluoroborate diazonium salt as a functional reagent, and 300 mg tetrabutyltetrafluoroborate as a supporting electrolyte, and store in a dark place Stand still for 5 h, centrifuge the product, wash with ethanol, and remove excess diazonium salt and electrolyte;

[0018] 2) Use acetic acid and zinc powder to reduce nitro groups to amine groups: add a certain amount of acetic acid, zinc powder, and ammonium chloride to an ethanol aqueous solution with a volume ratio of 3:2, and the molar ratio of each reactant is nitro compound / Zinc powder=1 / 8; Nitro compound / acetic acid=1 / 0.2; Nitro compound / NH 4 Cl= 1 / 0.12, reacted at 80°C for 3 hours, the product was centrifuged, excess zinc powder was removed with HCl, and the product was vacuum-dried at 60°C for 4 hours;

[0019] 3) Disperse 3 mg of the above product in 1.0 M H 2 SO 4 Add aniline ...

Embodiment 3

[0021] Concrete preparation steps are as follows:

[0022] 1) Disperse 24 mg of graphene in 20 mL of acetonitrile, add 48 mg of tetranitrobenzene tetrafluoroborate diazonium salt as a functional reagent, and 600 mg tetrabutyltetrafluoroborate as a supporting electrolyte, and store in a dark place After standing for 10 h, the product was centrifuged and washed with ethanol to remove excess diazonium salt and electrolyte;

[0023] 2) Use acetic acid and zinc powder to reduce nitro groups to amine groups: add a certain amount of acetic acid, zinc powder, and ammonium chloride to an ethanol aqueous solution with a volume ratio of 3:2, and the molar ratio of each reactant is nitro compound / Zinc powder=1 / 8; Nitro compound / acetic acid=1 / 0.2; Nitro compound / NH 4 Cl= 1 / 0.12, reacted at 80°C for 3 hours, the product was centrifuged, excess zinc powder was removed with HCl, and the product was vacuum-dried at 60°C for 4 hours;

[0024] 3) Disperse 6 mg of the above product in 1.0 M H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com