A method of inhibiting gas generation in battery formation and a lithium ion battery formed by adopting the method

A lithium-ion battery and battery formation technology, which is applied in secondary battery charging/discharging, electrical components, secondary batteries, etc., can solve the problems of battery shell, leakage, fire and explosion, etc., so as to improve the cycle life and reduce the interface Internal resistance, effect of increasing initial capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purpose and effects of the invention, the specific implementation of the invention will now be described in detail with reference to the accompanying drawings.

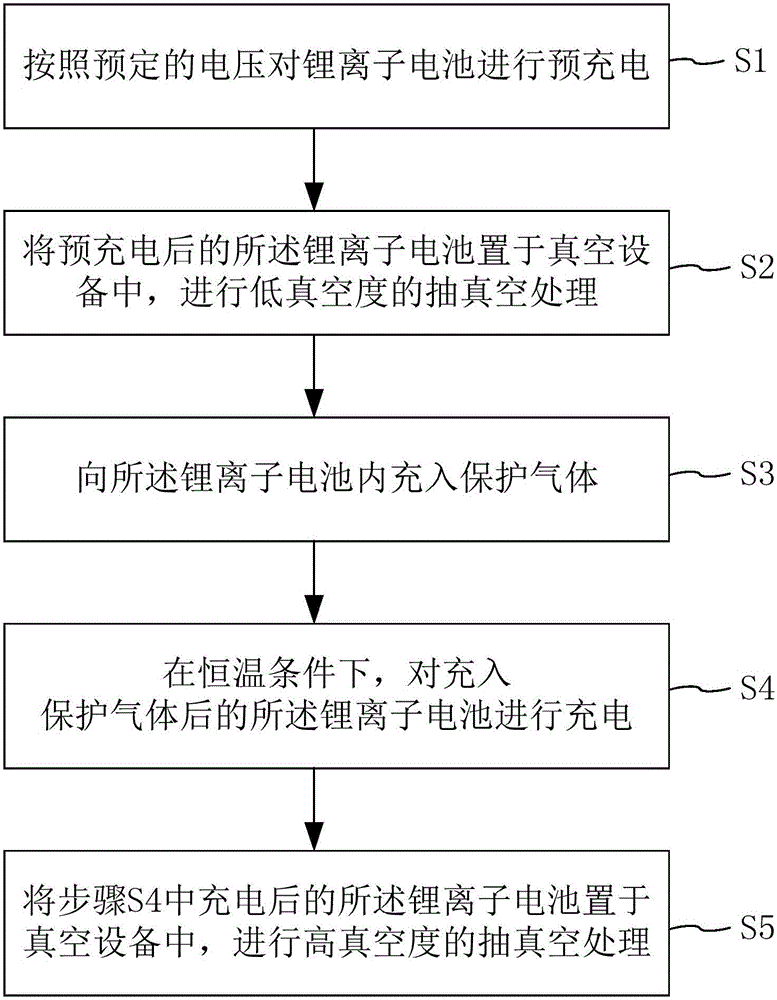

[0028] refer to figure 1 , the invented method of suppressing battery formation and gas production, comprising the following steps:

[0029] S1. Precharge the lithium-ion battery according to a predetermined voltage. The electrolyte of lithium-ion batteries includes vinylene carbonate.

[0030] This pre-charging is carried out on the formation equipment. The predetermined voltage is 2.7V-3.2V. The pre-charge current is 0.05C. The pre-charge time can be 2h.

[0031] The lithium ion battery can be made according to the methods of the prior art. For example, the positive active material is lithium iron phosphate LiFeCOPO 4 , the negative electrode active material is modified graphite, and the separator is a double-sided ceramic separator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com