A kind of nano lithium titanate composite material and its preparation method, lithium titanate battery

A nano-lithium titanate and composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unclean removal of silicon dioxide, reduced material purity, and reduced cycle performance, and is conducive to absorption and storage. , The effect of improving the rate performance and reducing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

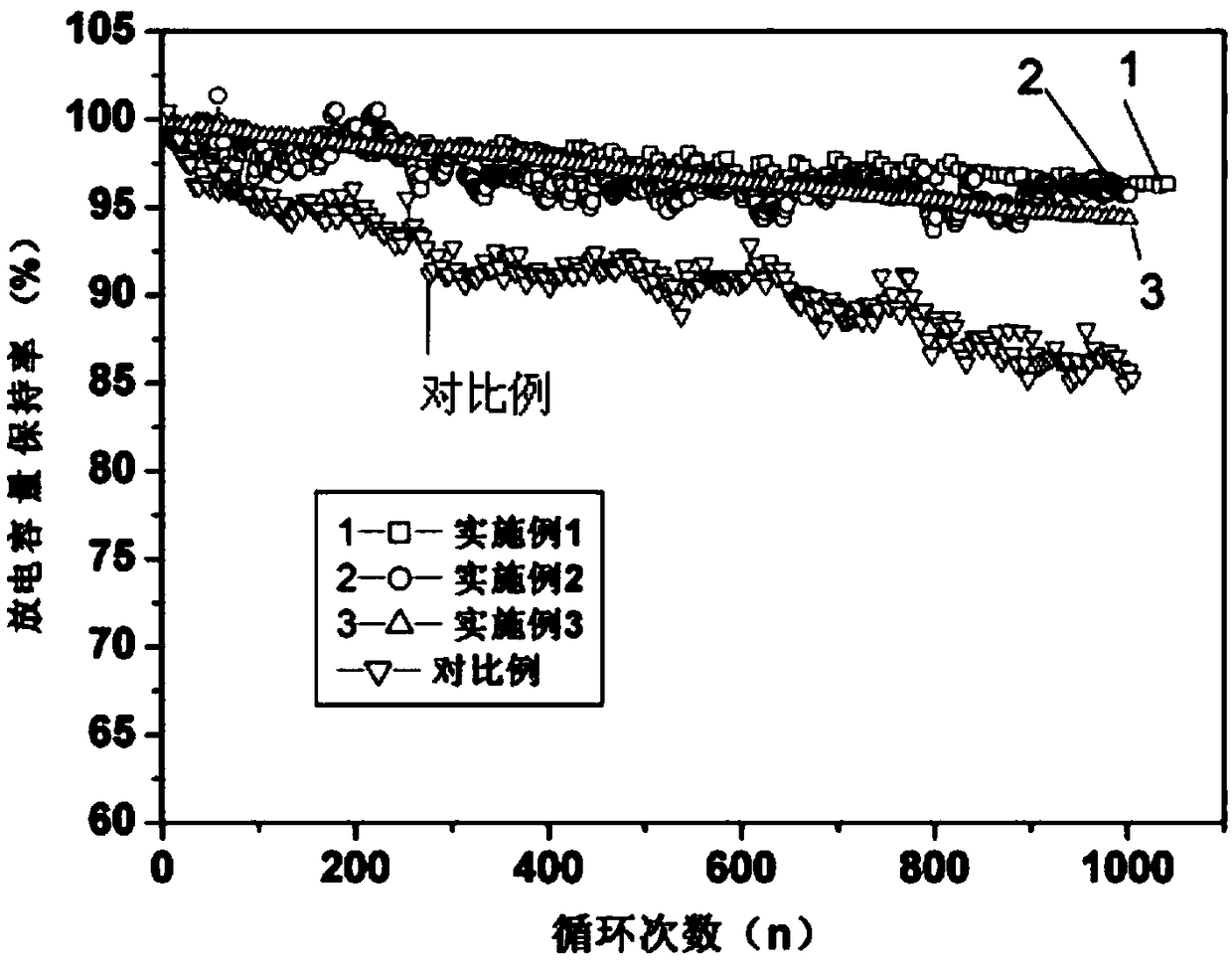

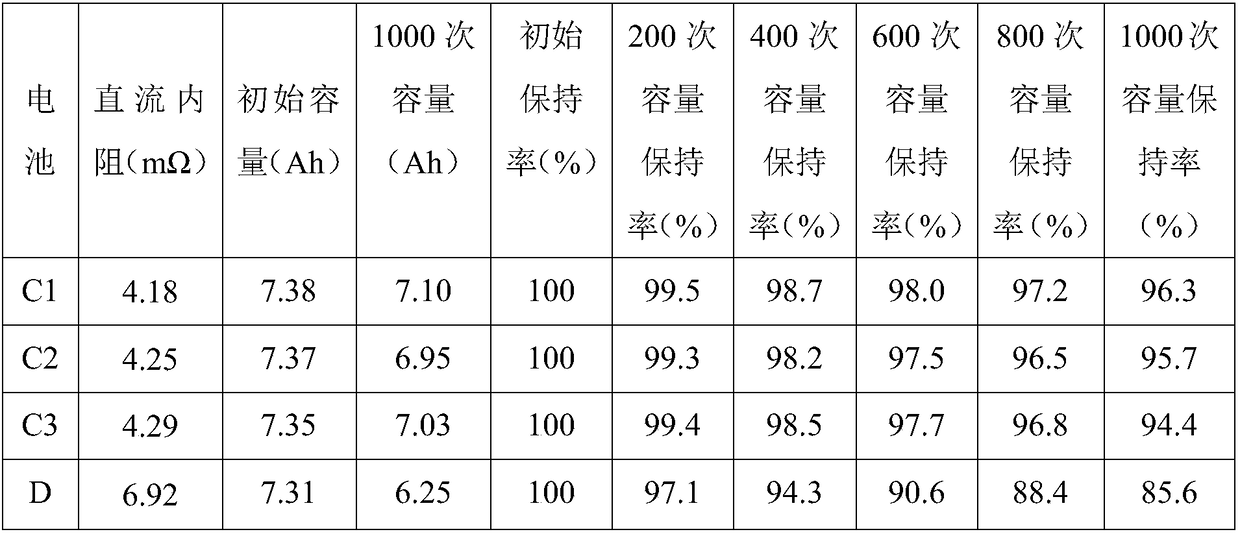

[0028] The nano-lithium titanate composite material of this embodiment has a hollow sphere structure, the inner core is hollow, and the outer shell is lithium titanate and polypropylene microspheres containing aluminum oxide coated on the outer surface of lithium titanate.

[0029] The preparation method of the nano-lithium titanate composite material comprises the following steps:

[0030] 1) Preparation of sulfonated polystyrene microspheres: in a nitrogen atmosphere, first add 20 g of styrene monomer to 200 g of secondary distilled water, heat up to 80 ° C, and after stirring for 30 min, add dropwise 30 g of dissolved 0.8 g of supernatant. The aqueous solution of potassium sulfate was reacted at a temperature of 80 °C for 24 hours, and then the reactant was cooled to room temperature, that is, a polystyrene microsphere emulsion. Take 20g of the emulsion prepared above, centrifuge at 5000r / min for 60min, then wash with water, disperse the obtained solid product into 60g of c...

Embodiment 2

[0035] The nano-lithium titanate composite material of this embodiment has a hollow spherical structure, the inner core is hollow, and the outer shell is lithium titanate and polystyrene microspheres containing aluminum oxide coated on the outer surface of lithium titanate.

[0036] The preparation method of the nano-lithium titanate composite material comprises the following steps:

[0037] 1) Preparation of sulfonated polystyrene microspheres: under nitrogen atmosphere, first add 10g of styrene monomer to 200g of secondary distilled water, heat up to 80°C, stir for 30min, add dropwise 30g dissolved in 0.5g The aqueous solution of potassium sulfate was reacted at a temperature of 80 °C for 24 hours, and then the reactant was cooled to room temperature, that is, a polystyrene microsphere emulsion. Take 20g of the emulsion prepared above, centrifuge at 8000r / min for 45min, then wash with water, disperse the obtained solid product into 60g of concentrated sulfuric acid, react at...

Embodiment 3

[0042] The nano-lithium titanate composite material of this embodiment has a hollow spherical structure, the inner core is hollow, and the outer shell is lithium titanate and polyvinyl chloride microspheres containing aluminum oxide coated on the outer surface of lithium titanate.

[0043] The preparation method of the nano-lithium titanate composite material comprises the following steps:

[0044] 1) Preparation of sulfonated polystyrene microspheres: under nitrogen atmosphere, first add 30g of styrene monomer to 200g of secondary distilled water, heat up to 80°C, stir for 30min, add dropwise 30g dissolved in 1.0g The aqueous solution of potassium sulfate was reacted at a temperature of 80 °C for 24 hours, and then the reactant was cooled to room temperature, that is, a polystyrene microsphere emulsion. Take 20g of the emulsion prepared above, centrifuge at 10000r / min for 10min, then wash with water, disperse the obtained solid product into 60g concentrated sulfuric acid, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com