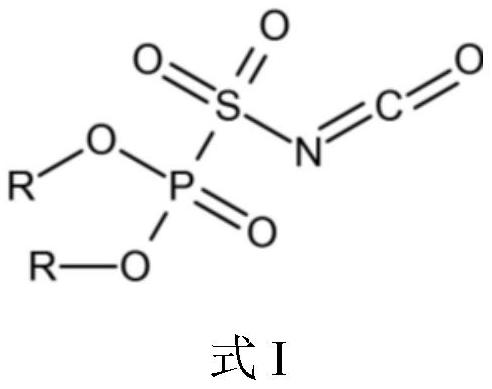

Novel phosphine-containing isocyanate electrolyte additive and application thereof

An electrolyte additive, isocyanic acid technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, circuits, etc., can solve the problems of accelerated battery performance, deterioration and failure, electrolyte decomposition, etc., to reduce reactions, reduce damage, improve effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

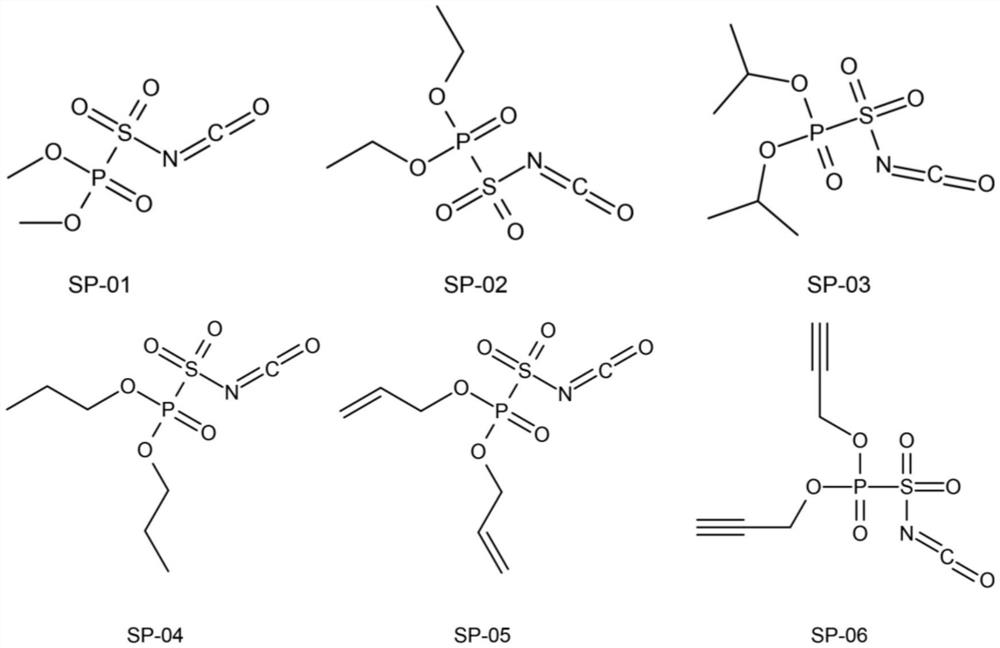

[0035] Preparation of Synthetic Embodiment 1 Compound SP-01

[0036]

[0037] Add 62.0g (0.5mol) trimethyl phosphonite into a 250mL three-necked flask, control the internal temperature -5 ~ 0°C, slowly add 72.2g (0.51mol) sulfonyl chloride isocyanate dropwise, about 1.0hrs dropwise, drop After the addition, keep warm at 0°C for 1 hour, slowly raise the temperature to 105-110°C, stir and react for 6.0 hrs, remove the solvent under reduced pressure until there is no fraction to obtain a dark brown oil, and further rectify under reduced pressure to obtain 34.4 g of a colorless viscous oil Compound SP-01, yield 32.00%.

[0038] GC-MS: 215, 1 H NMR (400MHz): solvent deuterated chloroform, δ (ppm): 3.831 ~ 3.854ppm (d, 6H); 3 1 PNMR (162MHz): solvent deuterated chloroform, δ (ppm): -19.61ppm;

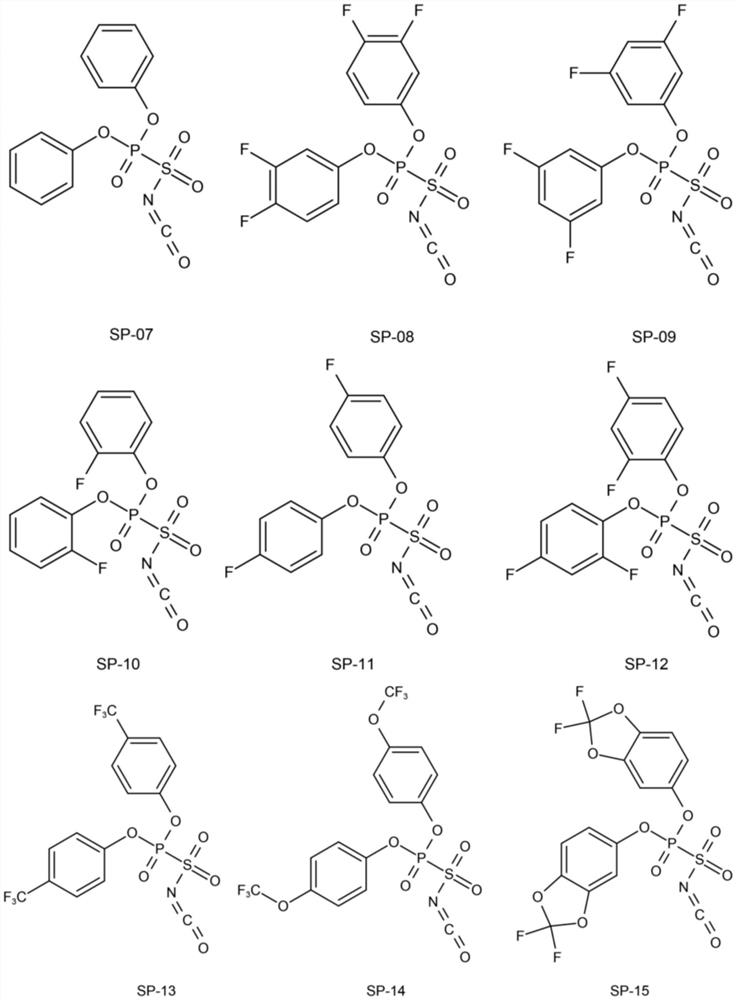

[0039] Preparation of Synthetic Embodiment 2 Compound SP-07

[0040]

[0041]Add 84.9g (0.60mol) of sulfonyl chloride isocyanate into a 250mL three-necked flask, control the interna...

Embodiment 1-10 and comparative example 1~5

[0056] The method that battery embodiment 1-10 and comparative example 1~5 lithium-ion battery non-aqueous electrolytes are used to prepare lithium-ion type button battery is:

[0057] (1) Preparation of positive electrode sheet

[0058] LiCoO 2 Cathode material as an example: the positive electrode LiCoO 2 Powder, carbon black (particle size 1000nm), polyvinylidene fluoride (PVDF) and N, N-dimethylpyrrolidone (NMP) were mixed to make a uniform slurry, and the slurry was uniformly coated on an aluminum foil (15 μm) set fluid, then dried and rolled to obtain LiCoO 2 Cathode material. Bake at 120°C for 12 hours, in the dried pole piece, LiCoO 2 Accounting for 94% of the total coating, the binder accounted for 4%, and carbon black accounted for 2%. Then the obtained pole piece was cut into a disc with a diameter of 8 mm as the positive pole. Other cathode materials LiMn 2 o 4 、LiNi 0.8 co 0.1 mn 0.1 o 2 Prepare in the same way.

[0059] (2) Negative sheet preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com