Low-internal-resistance all-solid-state battery and preparation method thereof

An all-solid-state battery, low internal resistance technology, used in electrolyte battery manufacturing, electrode manufacturing, secondary batteries and other directions, can solve the problem of high internal resistance of all-solid-state batteries, reduce the number of interfaces, have good interface contact, and suppress pole pieces. inflated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

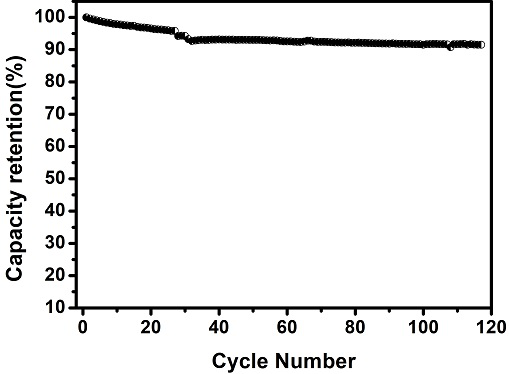

Embodiment 1

[0032] In this example, the positive electrode layer, solid electrolyte layer, negative electrode layer and all-solid-state battery were prepared by the following steps:

[0033] (1) Integrated preparation of the positive electrode layer and the solid state layer: the positive electrode active material nickel cobalt lithium manganese oxide (NCM811), superconducting carbon black, and polyvinylidene fluoride are added to a mixture containing an appropriate amount of NMP according to the mass ratio of 97:1:2. In the solvent double planetary mixer, the wet homogenization process is adopted, the positive electrode active material is added in two batches, and the vacuum is stirred at a high speed. The solid content of the slurry is 70%, and the viscosity of the slurry is 8000mPa.s. Use a coating machine to coat the positive electrode slurry on the aluminum foil in an intermittent coating manner, and the coating surface density is 12.5 mg / cm 2 .

[0034] (2) The polymer polyethylene...

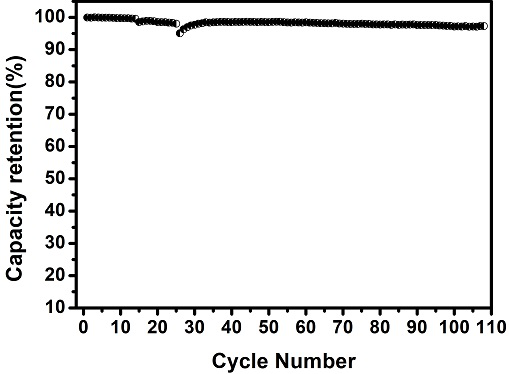

Embodiment 2

[0040] In this example, the positive electrode layer, solid electrolyte layer, negative electrode layer and all-solid-state battery were prepared by the following steps:

[0041] (1) Integrated preparation of the positive electrode layer and the solid state layer: the positive electrode active material lithium cobaltate (LCO), superconducting carbon black, and polyvinylidene fluoride are added to the medium with an appropriate amount of NMP solvent according to the mass ratio of 98:1:1. In the double planetary mixer, the wet homogenization process is adopted, and the positive electrode active material is added in two batches, and the vacuum high-speed stirring is carried out. The solid content of the slurry is 68%, and the viscosity of the slurry is 7000mPa.s. Coat the positive electrode slurry on the aluminum foil by intermittent coating with a coating machine, and the density of the coated surface is 20mg / cm 2 .

[0042] (2) Dissolve the polymer polyvinylidene fluoride and ...

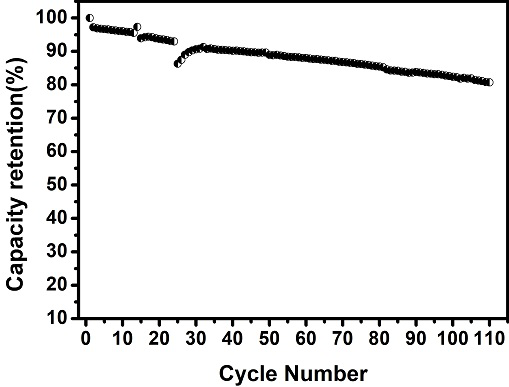

Embodiment 3

[0048] In this example, the positive electrode layer, solid electrolyte layer, negative electrode layer and all-solid-state battery were prepared by the following steps:

[0049] (1) Integrated preparation of the positive electrode layer and the solid layer: the positive active material lithium iron phosphate (LFP), superconducting carbon black, and polyvinylidene fluoride are added to a medium with an appropriate amount of NMP solvent according to the mass ratio of 98:1:1. In the double planetary mixer, the wet homogenization process is adopted, and the positive electrode active material is added in two batches, and the vacuum high-speed stirring is carried out. The solid content of the slurry is 69%, and the viscosity of the slurry is 9000mPa.s. Use a coating machine to coat the positive electrode slurry on the aluminum foil in an intermittent coating manner, and the coating surface density is 18 mg / cm 2 .

[0050] (2) The polymer polyvinyl carbonate and lithium salt LiPF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com