Solid-state lithium battery and production method thereof

A solid-state lithium and solid-state electrolyte technology, applied in the field of solid-state lithium batteries and their preparation, can solve the problems of liquid electrolyte reducing battery safety performance, battery energy density, etc., to improve safety performance and electrochemical performance, reduce production costs, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

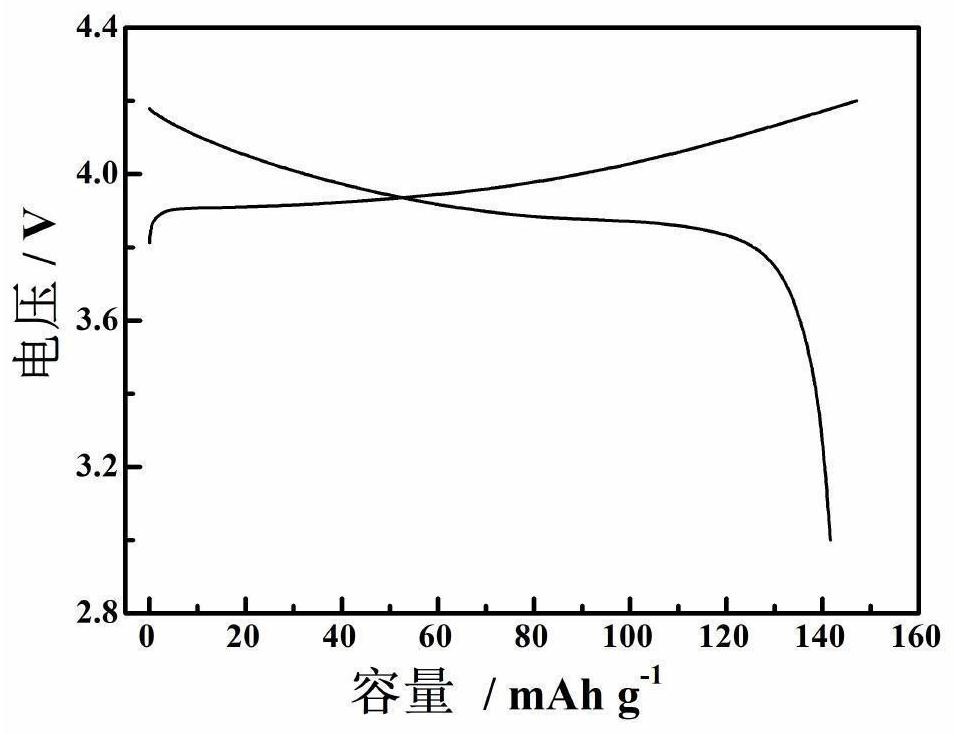

Image

Examples

preparation example Construction

[0047] 2. Preparation method of solid-state lithium battery

[0048] The second aspect of the present application is to provide a method for preparing a solid-state lithium battery, comprising the following steps:

[0049] 1) Mix lithium salt, organic solvent, initiator and acrylate monomer, and stir thoroughly to obtain a polymer gel electrolyte precursor;

[0050] 2) Mixing, mechanical fusion and heat treatment of the positive electrode active particles and NASICON oxide or metal chloride precursor to obtain the positive electrode active material, and coating the positive electrode active material on the positive electrode current collector to obtain the positive electrode sheet;

[0051] 3) mixing the ceramic particles and the binder, fully stirring and evenly coating the surface of the positive electrode or the negative electrode, and then vacuum-drying to obtain the positive electrode-ceramic solid electrolyte composite or the negative electrode-ceramic solid electrolyte ...

Embodiment 1

[0093] This embodiment provides a method for preparing a solid-state lithium battery, comprising the following steps:

[0094] 1) Lithium bistrifluoromethanesulfonylimide / lithium bisoxalate borate (molar ratio 4:1), fluorinated ethylene carbonate / ethyl methyl carbonate (volume ratio 1:1) organic solvent, azobisisobutyl Nitrile initiator (1% of monomer weight) and pentaerythritol triacrylate monomer are mixed, through fully stirring, obtain polymer gel electrolyte precursor, wherein bistrifluoromethanesulfonylimide lithium and bisoxalate lithium borate are relatively When the total molar concentration of fluorinated ethylene carbonate / ethyl methyl carbonate is 1mol / L, the weight ratio of organic solvent to monomer is 3:1;

[0095] 2) Li with a weight ratio of 4:100 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 The ceramic precursor is mixed with lithium cobalt oxide and subjected to mechanical fusion treatment to obtain a surface uniformly coated with Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 The...

Embodiment 2

[0100] This embodiment provides a method for preparing a solid-state lithium battery, comprising the following steps:

[0101] 1) Lithium hexafluorophosphate / lithium bisoxalate borate (molar ratio 5:1), difluoroethylene carbonate / diethyl carbonate (volume ratio 1:1) organic solvent, azobisisobutyronitrile initiator (monomer weight 1%) mixed with pentaerythritol triacrylate monomer, through fully stirring, obtain polymer gel electrolyte precursor, wherein the total molar concentration of lithium hexafluorophosphate and bisoxalate lithium borate relative to difluoroethylene carbonate / diethyl carbonate is 1mol / L, the weight ratio of organic solvent to monomer is 4:1;

[0102] 2) Li with a weight ratio of 3:100 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 Ceramic precursors and LiNi 0.5 co 0.2 mn 0.3 o 2 Mixing, mechanical fusion treatment, the surface is uniformly coated with Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 LiNi 0.5 co 0.2 mn 0.3 o 2 particles, and then heat-treated at 700 °C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com