Positive electrode material precursor and preparation method thereof, positive electrode material and preparation method thereof

A positive electrode material and precursor technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of reducing material rate performance, reducing material conductivity, affecting the effect of coating modification, etc., to improve structural stability, Effect of reducing interface internal resistance and preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present application also provides a method for preparing a positive electrode material precursor, comprising the following steps:

[0043] Mixing the nickel-containing compound, the cobalt-containing compound, and the manganese-containing compound with water to obtain a mixed solution, the molar ratio of the nickel ions in the nickel-containing compound, the cobalt ions in the cobalt-containing compound to the manganese ions in the manganese-containing compound is x :y: (1-x-y), where, 0≤x≤0.35, 0≤y≤0.35.

[0044] The mixed solution, complexing agent, precipitating agent and metal colloid precursor are mixed, and a positive electrode material precursor is obtained after reaction; the metal colloid precursor forms nano metal colloid in the mixed solution.

[0045] In the process of preparing the positive electrode material precursor, the present application first dissolves the nickel-containing compound, the cobalt-containing compound, and the manganese-containing co...

Embodiment 1

[0064] 1.1 Weigh 0.5mol of nickel sulfate and 1.5mol of manganese sulfate, dissolve them in 1L deionized water to make a mixed solution; weigh 4mol of sodium hydroxide and dissolve them in 1L of deionized water to make a precipitant; weigh 0.1mol Dissolve ammonia water in 1L deionized water to form a complexing agent, weigh 0.001mol aluminum chloride and 0.001mol magnesium chloride to obtain a metal colloid precursor;

[0065] 1.2 Add the mixed solution, precipitating agent, complexing agent and metal colloid precursor to the reaction container at the same time, carry out the coprecipitation reaction, and obtain the coprecipitation product;

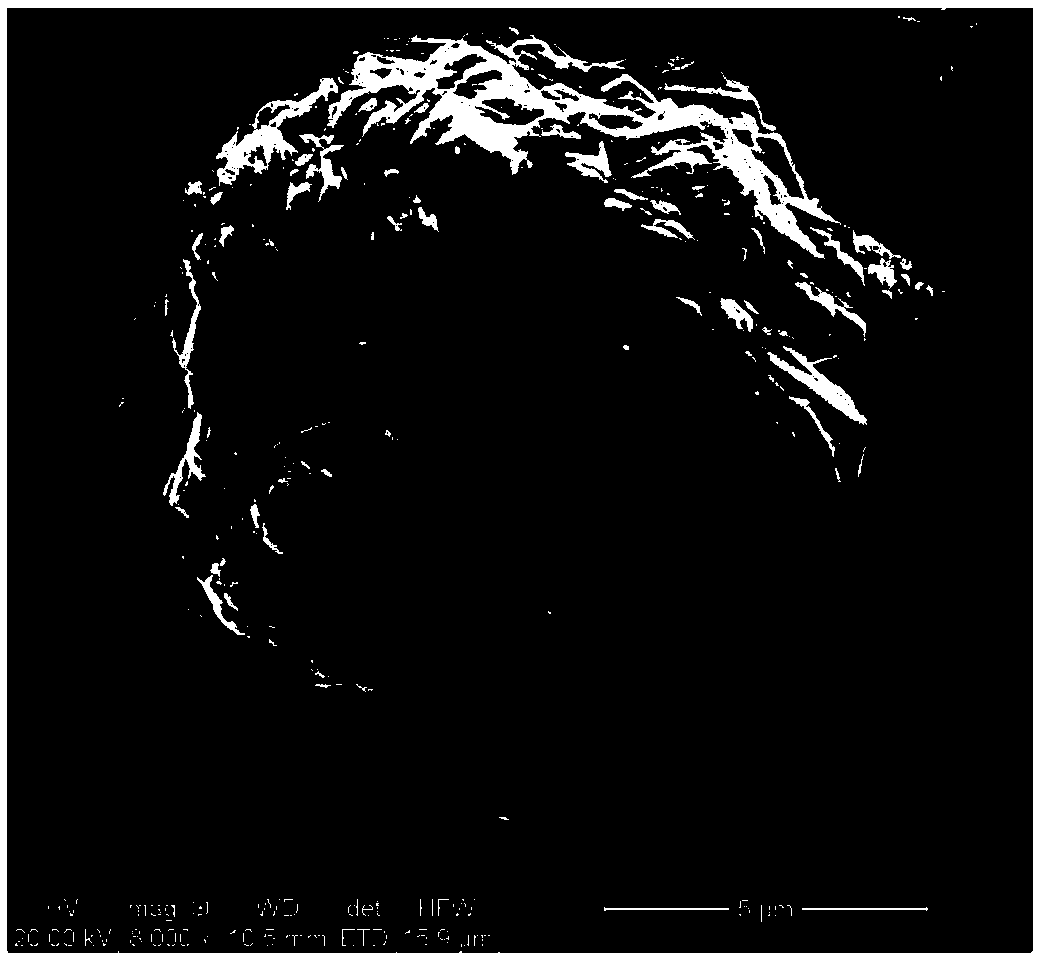

[0066] 1.3 The co-precipitation product is washed and dried to obtain Ni containing nano-Al and nano-Mg sol particles. 0.25 mn 0.75 (OH) 2 Precursor;

[0067] 1.4 After mixing lithium carbonate and the above-mentioned precursor products according to the molar ratio of 0.51:1, heat treatment at 850°C for 16 hours, cool naturally, grind ...

Embodiment 2

[0071] 2.1 Weigh 0.48mol of nickel sulfate, 0.02mol of cobalt chloride, and 1.5mol of manganese sulfate, dissolve them in 1L of deionized water, and make a mixed solution; weigh 5mol of sodium hydroxide, dissolve them in 1L of deionized water, and make Precipitating agent; weigh 0.15mol of ammonia water and dissolve it in 1L of deionized water to form a complexing agent; weigh 0.002mol of aluminum sulfate and 0.001mol of titanic acid to obtain a metal colloid precursor;

[0072] 2.2 Add the mixed solution, precipitating agent, complexing agent and metal colloid precursor to the reaction container at the same time, carry out the co-precipitation reaction, and obtain the co-precipitation product;

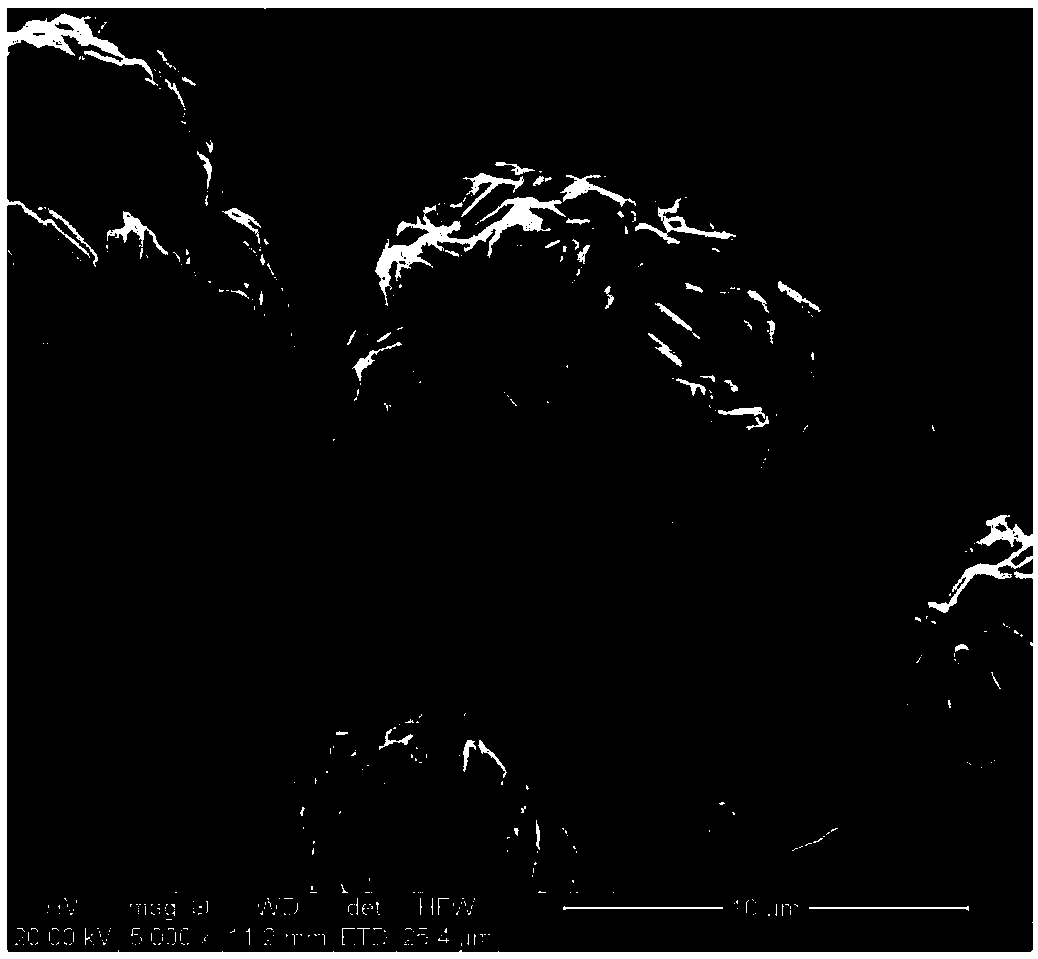

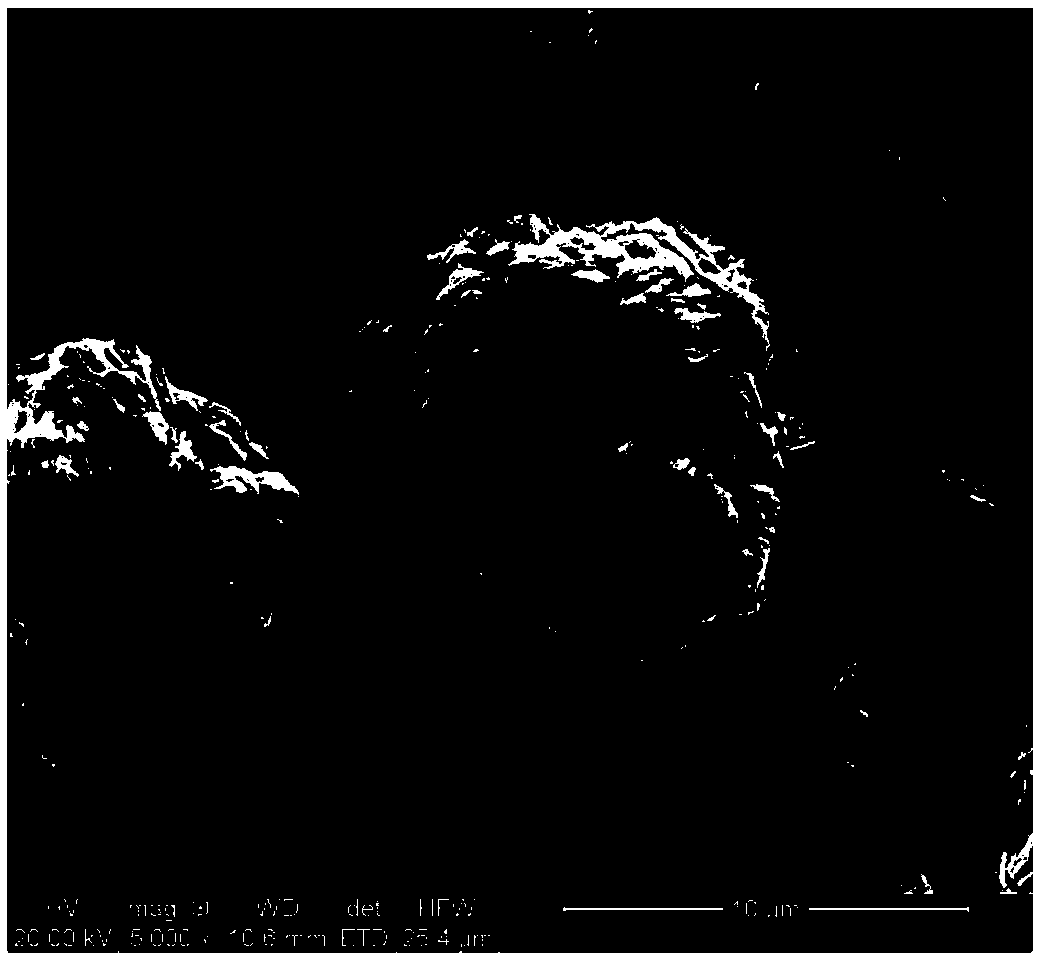

[0073] 2.3 The co-precipitation product is washed and dried to obtain Ni particles containing nano-Al and Ti sol particles. 0.24 co 0.01 mn 0.75 (OH) 2 Precursor;

[0074] 2.4 After mixing lithium carbonate and the above-mentioned precursor products according to the molar ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com